Experimental study and numerical simulation of dynamic fracture behavior of biomimetic spiral structured composite

-

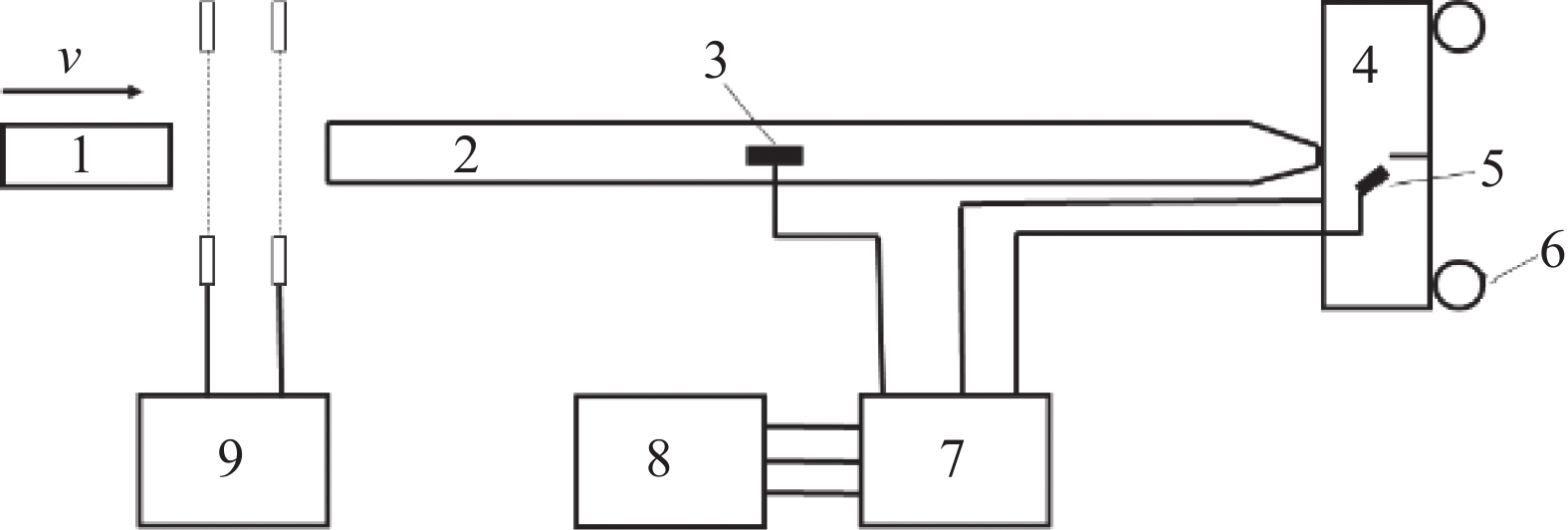

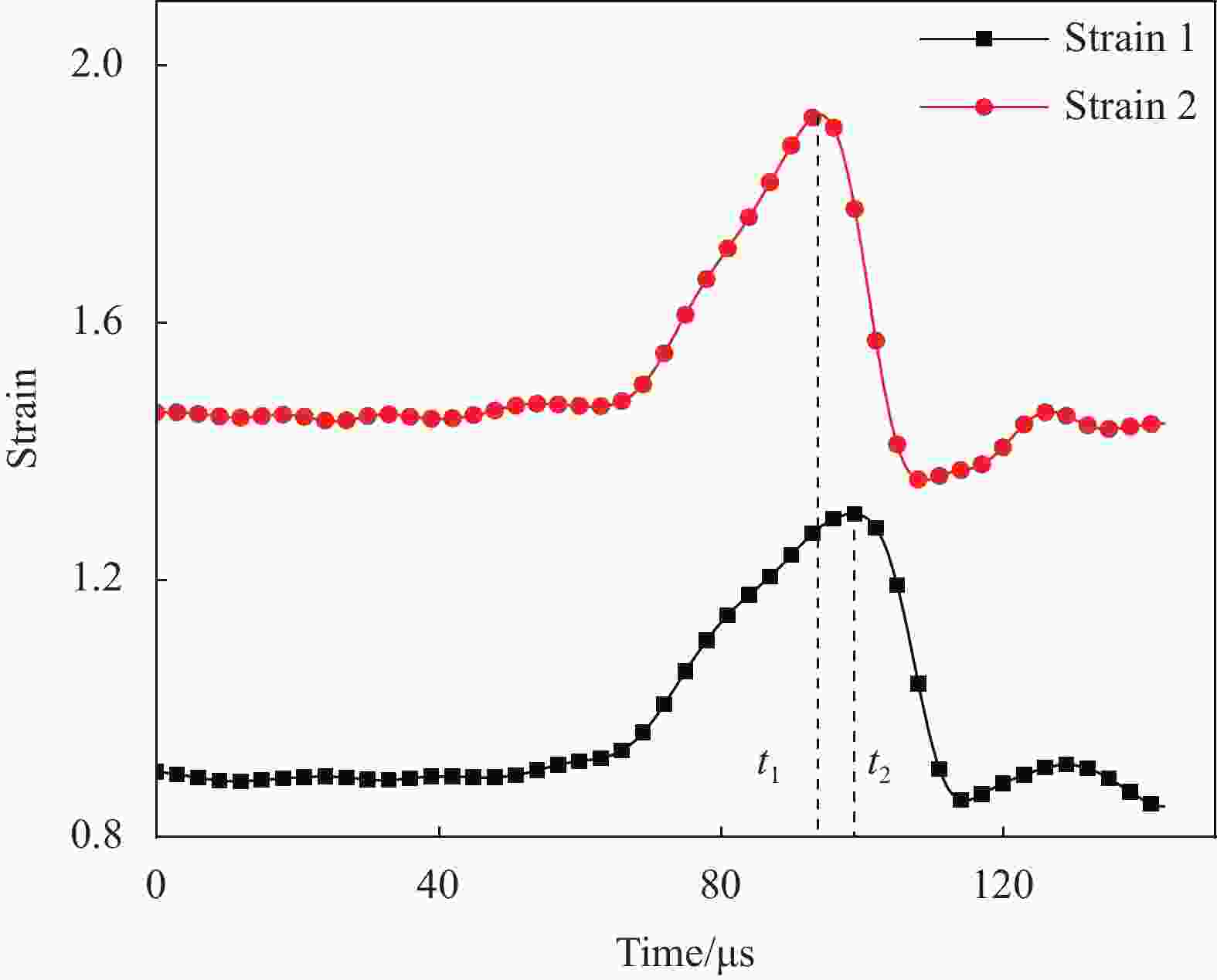

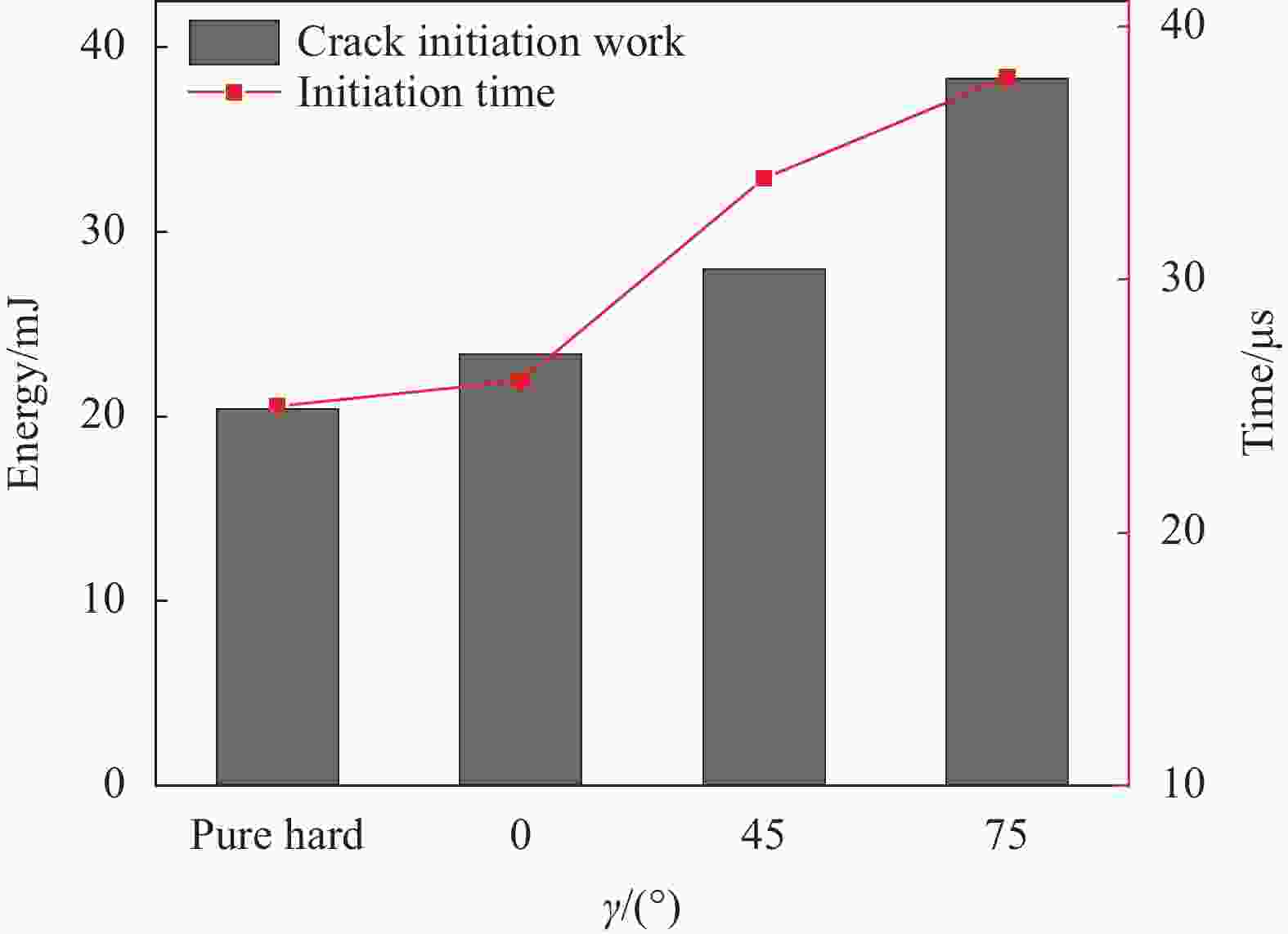

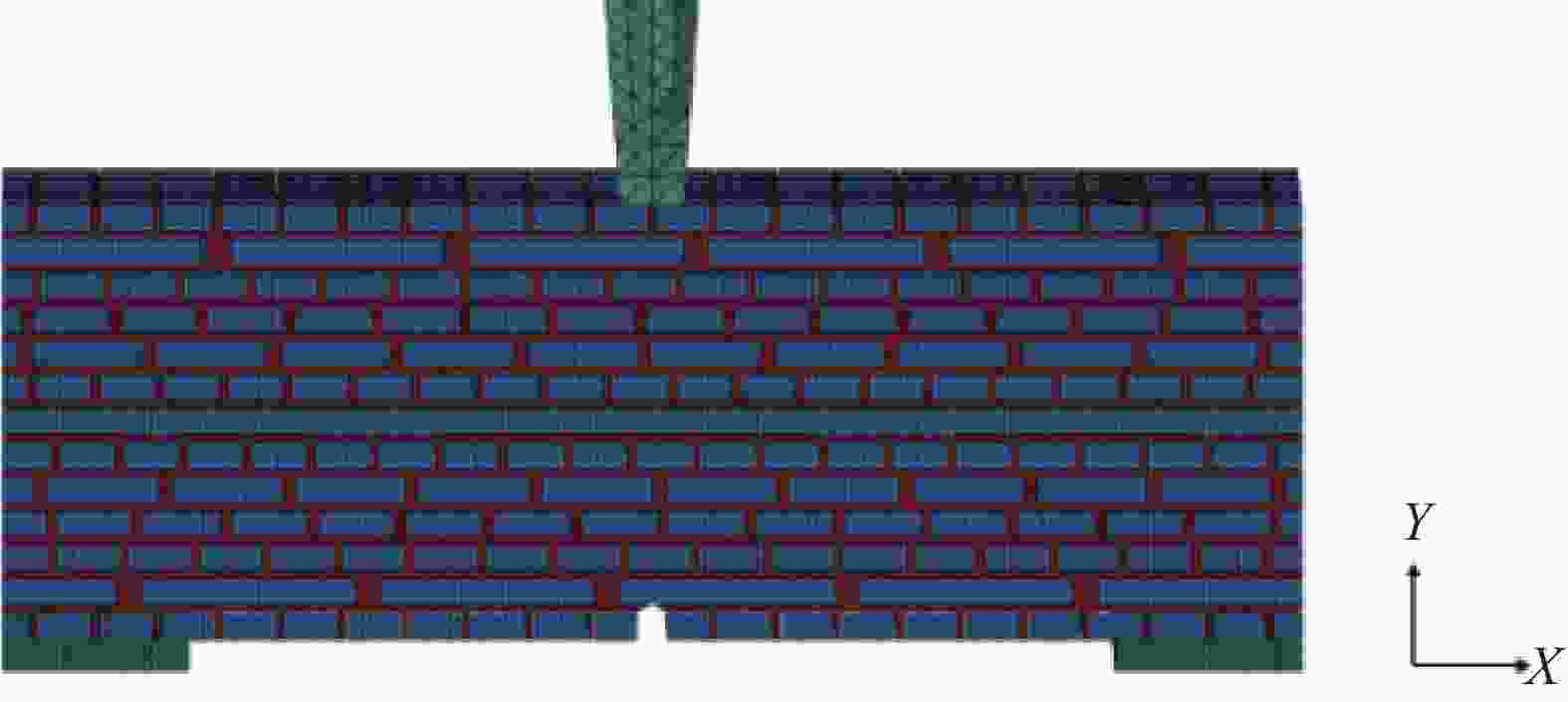

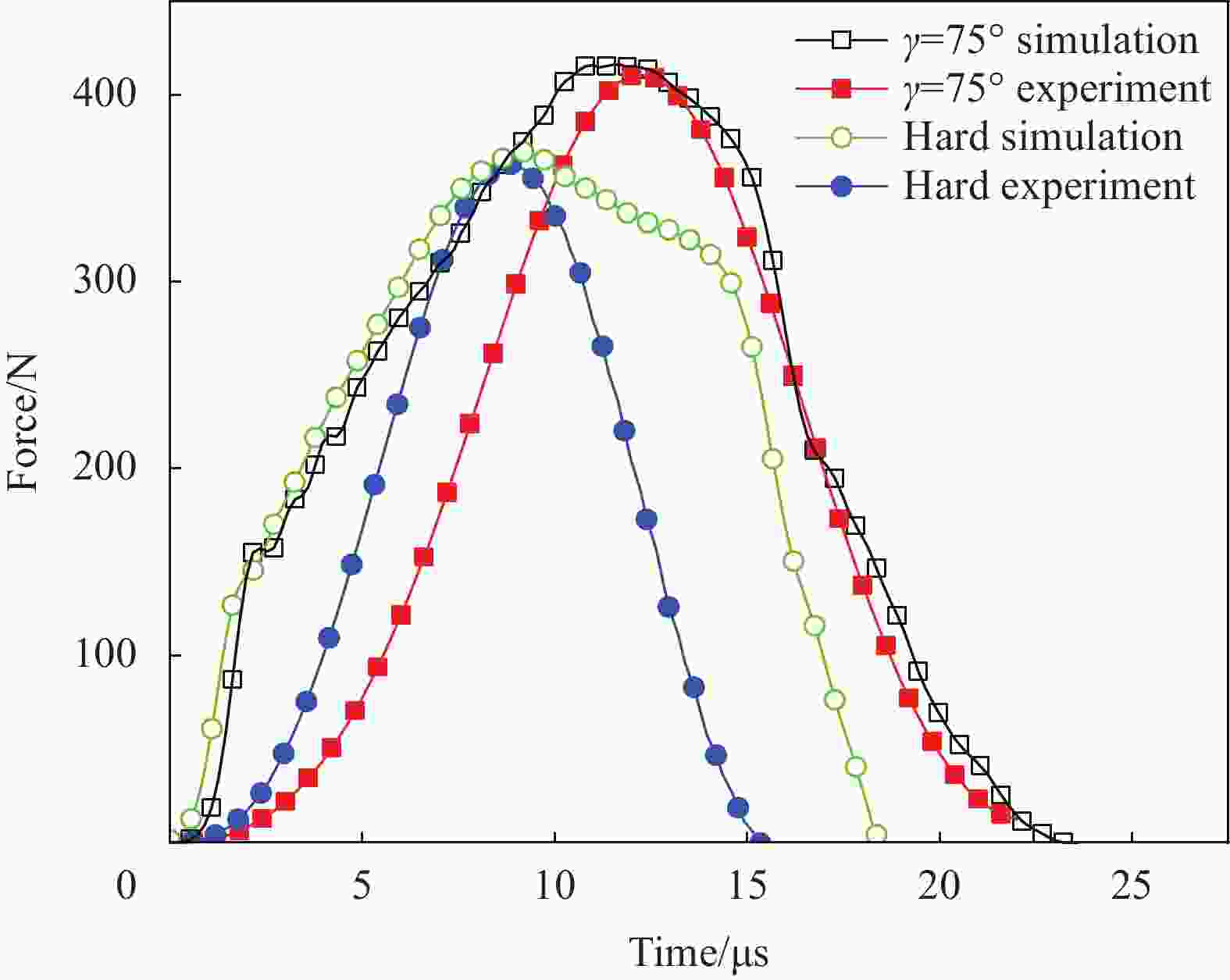

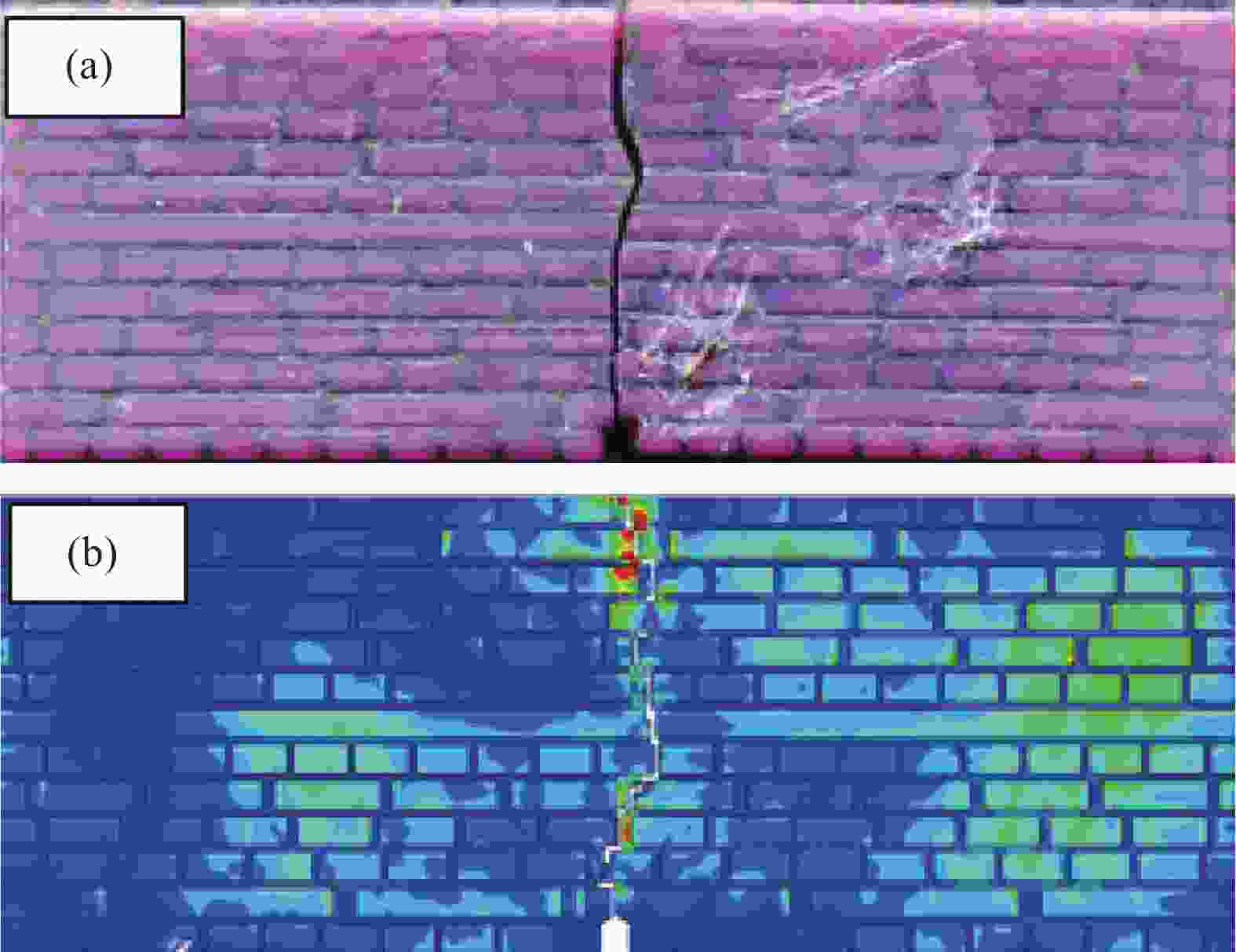

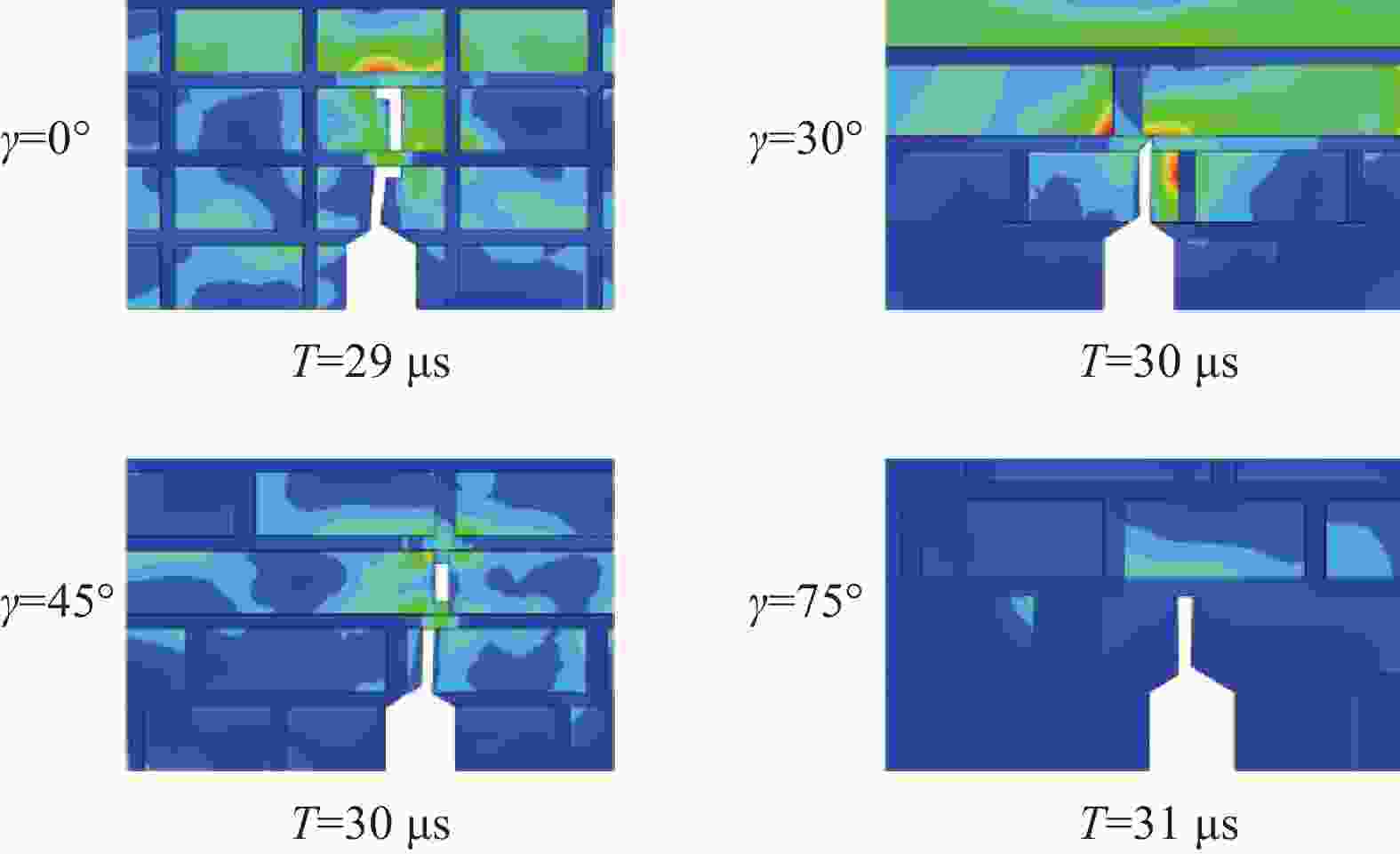

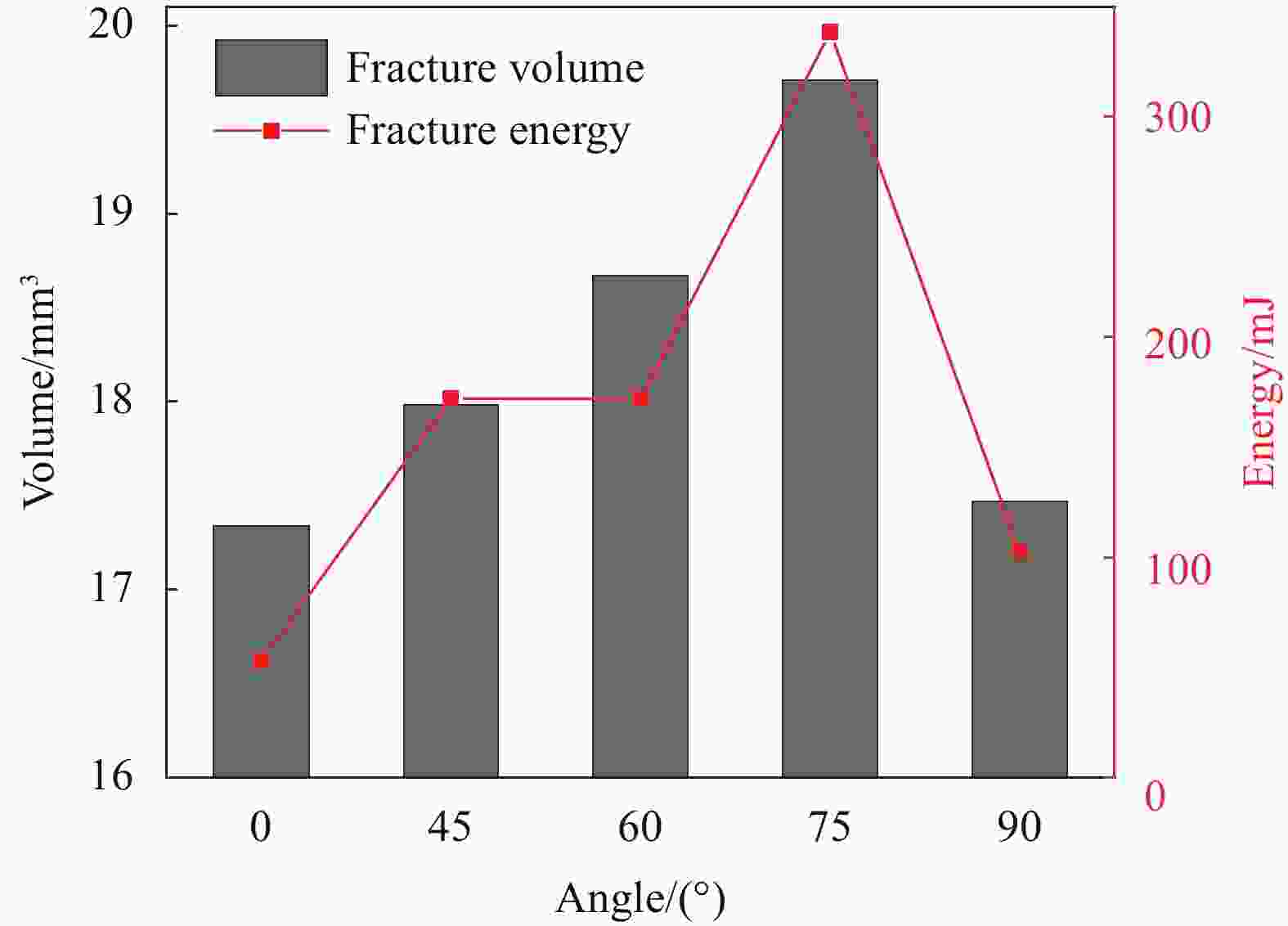

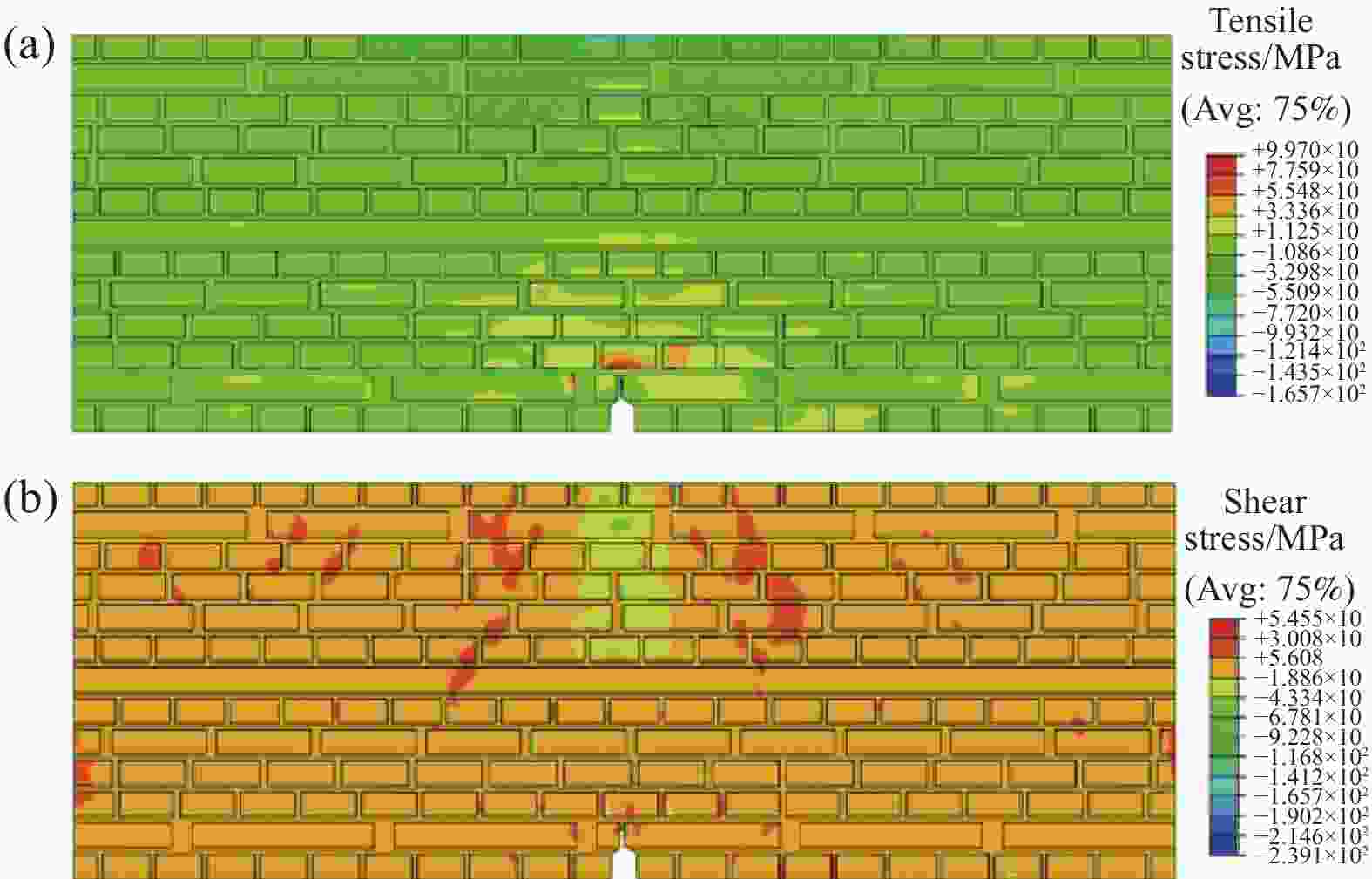

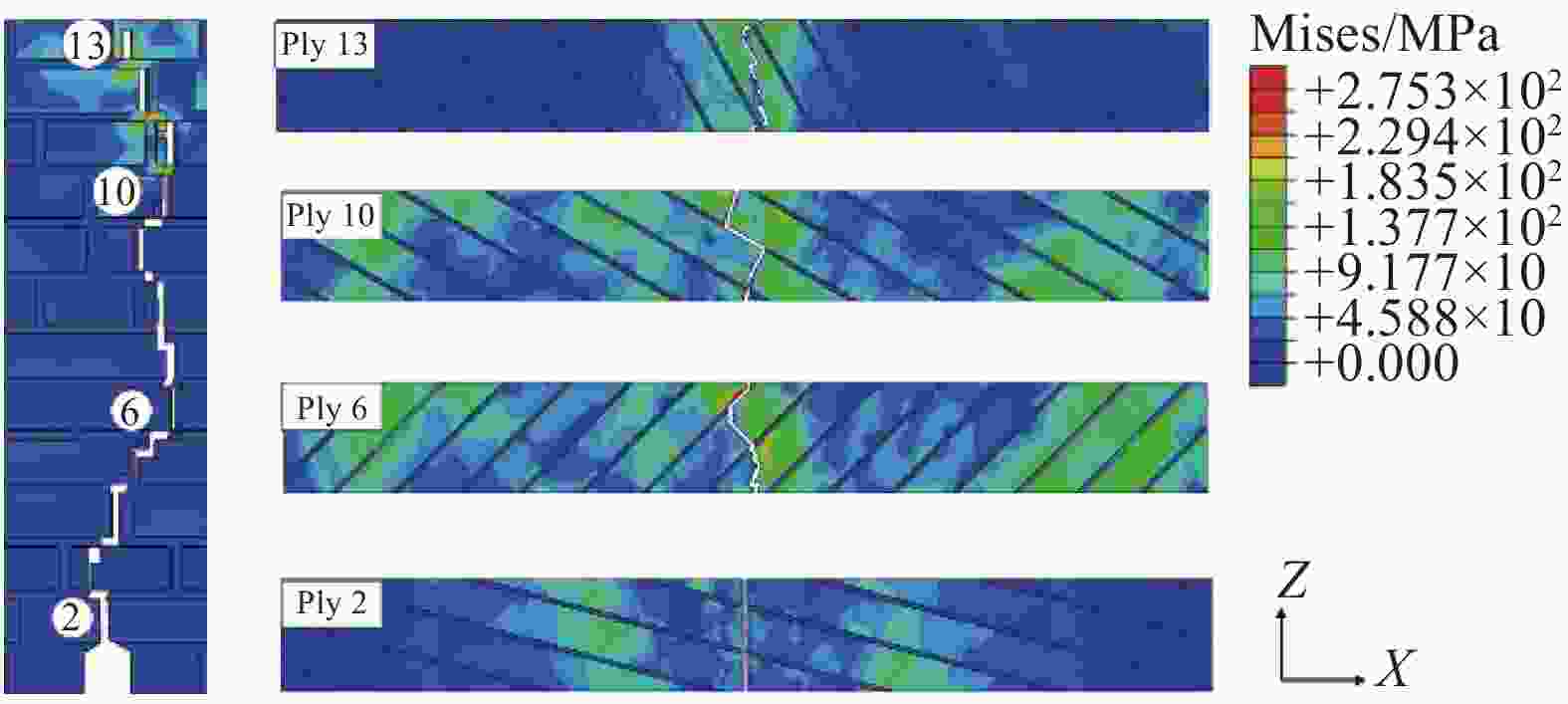

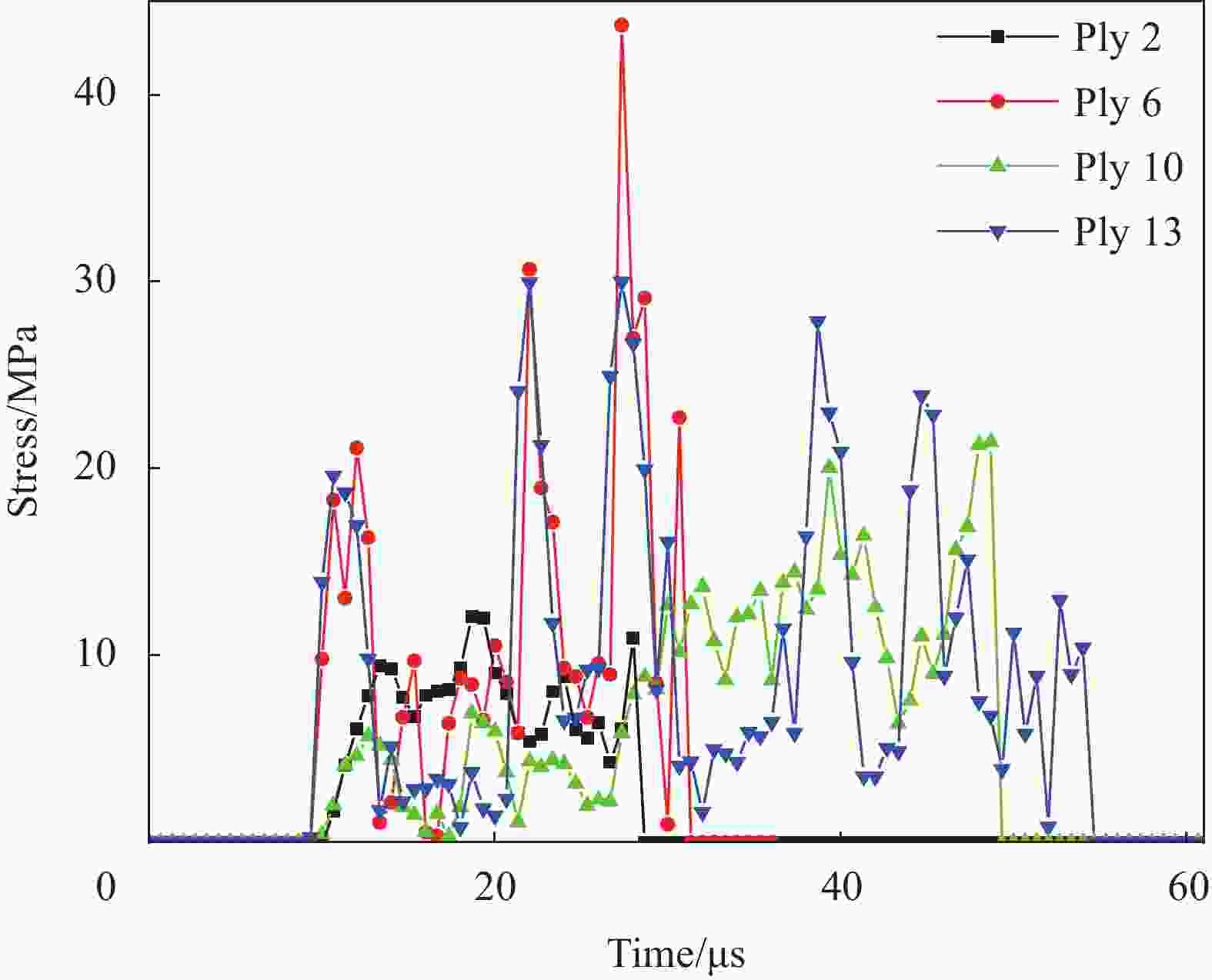

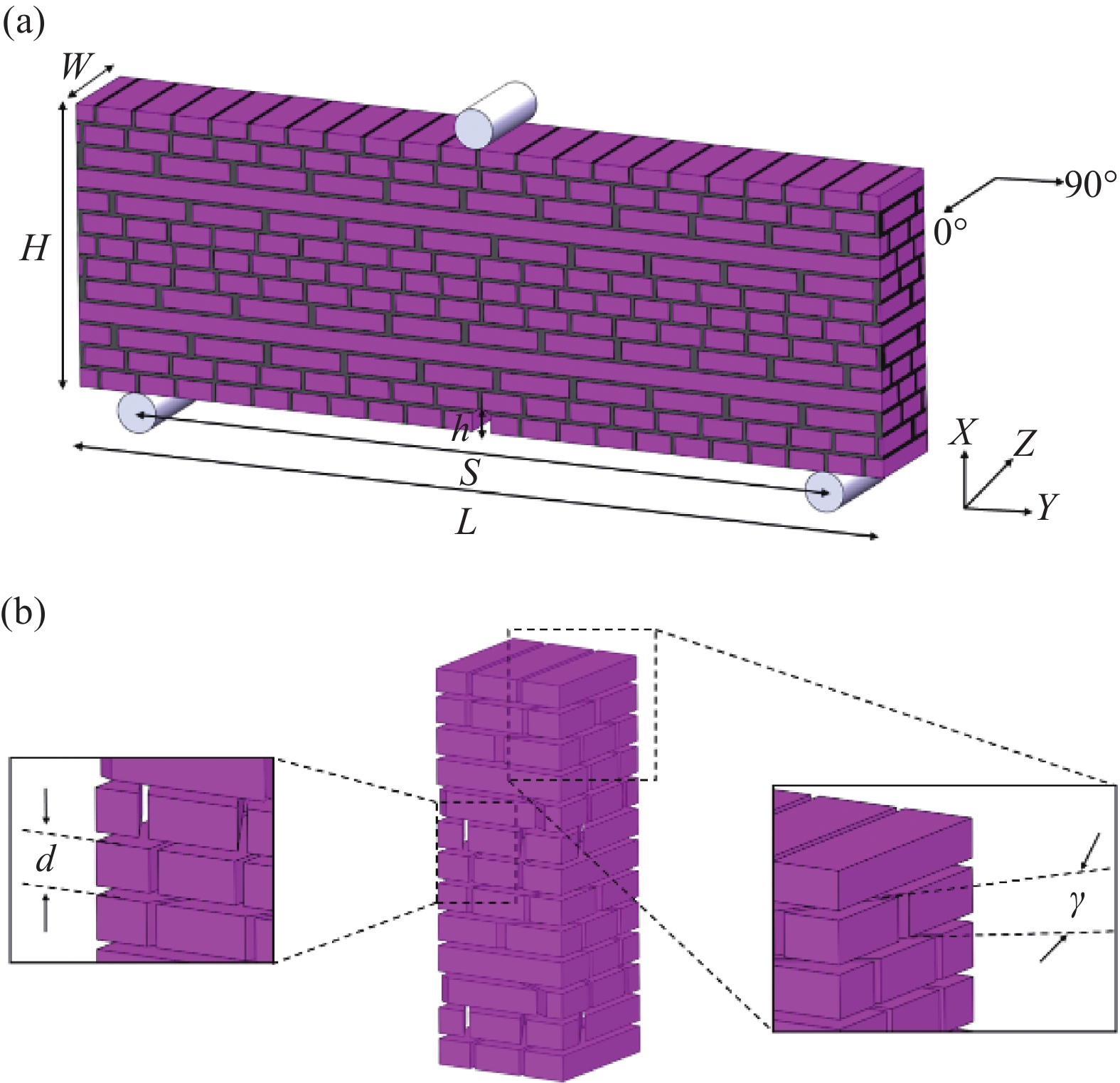

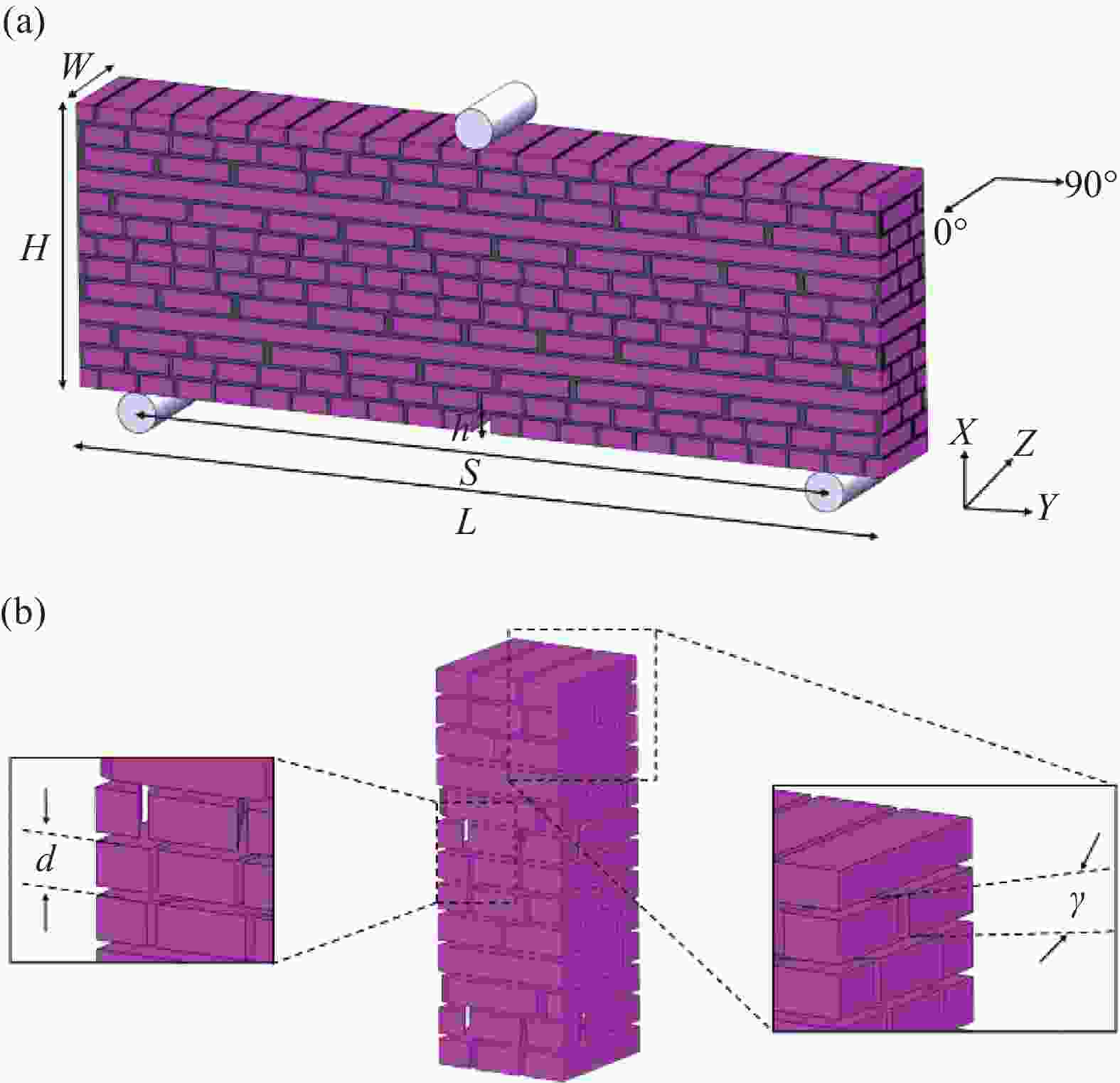

摘要: 通过三点弯动态冲击实验和数值模拟,研究了仿生螺旋结构复合材料的动态断裂韧性,该结构是基于Bouligand结构设计的仿生复合结构。首先使用软硬两种基体通过3D打印技术制备了8组不同角度的试样,使用改进的分离式Hopkinson杆完成了动态三点弯冲击实验,得到了试样的位移-载荷曲线、起裂时间和起裂功,并对试样最终断裂形态进行分析。随后在ABAQUS软件中完成了试样断裂全过程的数值模拟,对裂纹的萌生和扩展过程进行了分析。实验和数值模拟结果都表明螺旋角对试样的断裂韧性有很大的影响,在螺旋角度0°~75°的范围内,随着角度的增加试样的断裂韧性增强,而螺旋角度为90°时试样的断裂韧性急剧下降。实验过程中观察到试样在动态断裂过程中存在裂纹偏转现象。最后考察了裂纹偏转对动态断裂的影响机制,结果显示裂纹偏转改变了复合材料的局部断裂模式,增加了断裂面积,从而提升了材料的断裂韧性。Abstract: The dynamic fracture toughness of the bionic spiral structured composite material was studied through three-point bending dynamic impact experiment and numerical simulation. The structure is a bionic composite structure based on the Bouligand structure design. Firstly, 8 groups of specimens with different angles were prepared by 3D printing technology using two kinds of substrates, soft and stiff, and the dynamic three-point bending impact tests were completed by using an improved split Hopkinson bar. The displacement-load curve, fracture time and fracture energy were obtained, and the final fracture morphology of the sample was analyzed. Then, the numerical simulation of the whole process of specimen fracture was completed in ABAQUS software, and the crack initiation and propagation process were analyzed. Both the experimental and numerical simulation results show that the helix angle has a great influence on the fracture toughness of the specimen, in the range of the helix angle of 0°-75°, the fracture toughness of the specimen increases with the increase of the angle, while when the helix angle is 90°, the fracture toughness of the sample drops sharply. In the process of experiment, it is observed that there is a crack deflection phenomenon during the dynamic fracture process of the sample. Finally, the influence mechanism of the crack deflection on the dynamic fracture was investigated. The results show that the crack deflection changes the local fracture mode of the composite material, increases the fracture area, and therefore improves the fracture toughness of the material.

-

表 1 软质基体Tango Plus和硬质基体VeroWhite Plus材料参数

Table 1. Material parameters of soft Tango Plus and stiff VeroWhite Plus

Material VeroWhite Plus Tango Plus Density/(g·cm−3) 1.18 1.13 Energy dissipation ratio/% 33.4±2.4 99.5±3.7 Flexural stiffness/(kN·mm−1) 1.08±0.11 0.0167±0.0064 Response time/ms 0.48±0.12 ~2000 Maximum force at break/kN 1.76±0.78 0.109±0.059 Maximum displacement/mm 1.57±0.31 27.3±3.1 Maximum velocity without failure/(m·s−1) 3.45 3.40 Maximum energy without failure $ m{V}_{\mathrm{i}\mathrm{n}\mathrm{i}}^{2}/2 $/J 1.99 1.95 Minimum velocity with failure/(m·s−1) 3.50 3.62 Energy absorption with failure $\left(\dfrac{m{V}_{\mathrm{i}\mathrm{n}\mathrm{i} }^{2} }{2}-\dfrac{m{V}_{\mathrm{r}\mathrm{e}\mathrm{s} }^{2} }{2}\right)$/J 1.95 2.19 Notes: Vini—Initial velocity; Vres—Speed of fracture. 表 2 硬质基体和软质基体力学性能

Table 2. Mechanical parameters of stiff matrix and soft matrix

Material Stiff Soft Density/(g·mm3) 1.2 1.1 Young’s modulus/MPa 3000 300 Poisson’s ratio 0.3 0.3 Failure stress/MPa 100 0 Failure strain/MPa 0 1.4 -

[1] BOULIGAND Y. Twisted fibrous arrangements in biological materials and cholesteric mesophases[J]. Tissue Cell,1972,4(2):189-217. doi: 10.1016/S0040-8166(72)80042-9 [2] NALEWAY S E, TAYLOR J R A, PORTER M M, et al. Structure and mechanical properties of selected protective systems in marine organisms[J]. Materials Science and Engineering: C,2016,59:1143-1167. doi: 10.1016/j.msec.2015.10.033 [3] 邵浩彬, 朱军, 周琦, 等. 三角帆蚌贝壳的微结构及尺寸变化特征[J]. 复合材料学报, 2019, 36(10):97-103.SHAO Haobin, ZHU Jun, ZHOU Qi, et al. Characteristics of microstructure and size change of the shell of hyriopsis cumingii[J]. Acta Materiae Compositae Sinica,2019,36(10):97-103(in Chinese). [4] 武晓东, 张海广, 王瑜, 等. 冲击载荷下仿贝壳珍珠层Voronoi结构的动态力学响应[J]. 高压物理学报, 2020, 34(6):61-68.WU Xiaodong, ZHANG Haiguang, WANG Yu, et al. Dynamic mechanical response of voronoi structure of imitated shell nacre under impact load[J]. Chinese Journal of High Pressure Physics,2020,34(6):61-68(in Chinese). [5] NIKOLOV S, PETROV M, LYMPERAKIS L. Revealing the design principles of high-performance biological composites using ab initio and multiscale simulations: The example of lobster cuticle[J]. Advanced Materials (FRG),2010,22(4):519-526. doi: 10.1002/adma.200902019 [6] BOßELMANN F, ROMANO P, FABRITIUS H. The compo-sition of the exoskeleton of two crustacea: The American lobster homarus americanus and the edible crab cancer pagurus[J]. Thermochimica Acta,2008,1(2):65-68. [7] CHEN P Y E A. Structure and mechanical properties of crab exoskeletons (article)[J]. Acta Biomaterialia,2008,4(3):587-596. doi: 10.1016/j.actbio.2007.12.010 [8] YANG R A D, ZAHERI A A B, GAO W A B E, et al. Afm identification of beetle exocuticle: Bouligand structure and nanofiber anisotropic elastic properties[J]. Advanced Functional Materials,2017,27(6):1603993. doi: 10.1002/adfm.201603993 [9] ZIMMERMANN E Z E, GLUDOVATZ B G B, SCHAIBLE E S E, et al. Mechanical adaptability of the bouligand-type structure in natural dermal armour[J]. Nature Communications,2013,4:2634. doi: 10.1038/ncomms3634 [10] WEAVER J C, MILLIRON G W, MISEREZ A, et al. The stomatopod dactyl club: A formidable damage-tolerant biological hammer[J]. Science,2012,336(6086):1275-1280. doi: 10.1126/science.1218764 [11] SHANG J S, NGERN N H H, TAN V B C. Crustacean-inspired helicoidal laminates[J]. Composites Science and Technology,2016,128:222-232. doi: 10.1016/j.compscitech.2016.04.007 [12] 张洪艳, 王海泉, 杨少明. 聚氨酯基螺旋碳纤维复合材料的制备及力学性能研究[J]. 化工新型材料, 2021, 49(3):95-98.ZHANG Hongyan, WANG Haiquan, YANG Shaoming. Preparation and mechanical property of tpu based spiral carbon fiber composite[J]. New Chemical Materials,2021,49(3):95-98(in Chinese). [13] 韩奇钢, 石绍迁, 徐凯强, 等. 仿螳螂虾鳌结构/功能的玄武岩纤维增强复合材料碟簧研究[J]. 塑性工程学报, 2020, 27(10):77-82. doi: 10.3969/j.issn.1007-2012.2020.10.012HAN Qigang, SHI Shaoqian, XU Kaiqiang, et al. Study on basalt fiber reinforced composite disc spring of bionic structure/function of dactyl club of mantis shrimp[J]. Journal of Plasticity Engineering,2020,27(10):77-82(in Chinese). doi: 10.3969/j.issn.1007-2012.2020.10.012 [14] 陈昊宇, 殷莎, 胡建星, 等. 航天器冲击防护用热塑性仿生复合材料的弯曲性能研究[J]. 航天器环境工程, 2019, 36(2):151-155. doi: 10.12126/see.2019.02.008CHEN Haoyu, YIN Sha, HU Jianxing, et al. Bending properties of thermoplastic bioinspired helicoidal laminated composites used in impact protection of spacecraft[J]. Spacecraft Environment Engineering,2019,36(2):151-155(in Chinese). doi: 10.12126/see.2019.02.008 [15] ZHANG X, LUAN Y, LI Y, et al. Bioinspired design of lightweight laminated structural materials and the intralayer/interlayer strengthening and toughening mechanisms induced by the helical structure[J]. Composite Structures,2021,276:114575. doi: 10.1016/j.compstruct.2021.114575 [16] AMORIM L, SANTOS A, NUNES J P, et al. Quasi static mechanical study of vacuum bag infused bouligand inspired composites[J]. Polymer Testing,2021,100:107261. doi: 10.1016/j.polymertesting.2021.107261 [17] 戎志丹, 王亚利, 孟亚奎. 超高性能水泥基复合材料抗多次冲击性能[J]. 东南大学学报(自然科学版), 2020, 50(2):320-326. doi: 10.3969/j.issn.1001-0505.2020.02.016RONG Zhidan, WANG Yali, MENG Yakui. Multiple impact resistance of ultra-high performance cement-based composites[J]. Journal of Southeast University (Natural Science Edition),2020,50(2):320-326(in Chinese). doi: 10.3969/j.issn.1001-0505.2020.02.016 [18] 宁子轩, 王琳, 程兴旺, 等. 分离式霍普金森压杆加载下不同组织Ti-6321钛合金的动态响应行为[J]. 兵工学报, 2021, 42(4):862-870. doi: 10.3969/j.issn.1000-1093.2021.04.020NING Zixuan, WANG Lin, CHENG Xingwang, et al. Dynamic response behaviors of Ti-6321 titanium alloys with different microstructures under split hopkinson pressure bar loading[J]. Acta Armamentarii,2021,42(4):862-870(in Chinese). doi: 10.3969/j.issn.1000-1093.2021.04.020 [19] 胡年明, 朱锡, 侯海量, 等. 基于霍普金森压杆气凝胶及其复合材料抗冲击性能试验研究[J]. 海军工程大学学报, 2017, 29(5):43-47.HU Nianming, ZHU Xi, HOU Hailiang, et al. An experimental research on anti-impact ability of aerogel and its composite based on hopkinson bar[J]. Journal of Naval University of Engineering,2017,29(5):43-47(in Chinese). [20] SUKSANGPANYA N, YARAGHI N A, PIPES R B, et al. Crack twisting and toughening strategies in bouligand architectures[J]. International Journal of Solids and Structures,2018,150:83-106. doi: 10.1016/j.ijsolstr.2018.06.004 [21] YANG R, ZAHERI A, GAO W, et al. AFM identification of beetle exocuticle: Bouligand structure and nanofiber anisotropic elastic properties[J]. Advanced Functional Materials,2017,27(6):1603993. [22] KÖRBELIN J, GORALSKI P, KÖTTER B, et al. Damage tolerance and notch sensitivity of bio-inspired thin-ply bouligand structures[J]. Composites Part C: Open Access,2021,5:100146. doi: 10.1016/j.jcomc.2021.100146 [23] TOMASZ Ł, ALEXIS R. Constitutive relations under impact loadings[M]. Vienna: Springer, 2014. [24] WU X, MENG X, ZHANG H. An experimental investigation of the dynamic fracture behavior of 3D printed nacre-like composites[J]. Journal of the Mechanical Behavior of Biomedical Materials,2020,112:104068. doi: 10.1016/j.jmbbm.2020.104068 [25] 孟祥生, 武晓东, 张海广. 3D打印浆砌层合结构复合材料层间断裂韧性的数值模拟[J]. 高压物理学报, 2020, 34(4):136-144.MENG Xiangsheng, WU Xiaodong, ZHANG Haiguang. Numerical simulation on interlaminar fracture toughness of 3D printed mortar laminated composites[J]. Chinese Journal of High Pressure Physics,2020,34(4):136-144(in Chinese). [26] GU G X, TAKAFFOLI M, BUEHLER M J. Hierarchically enhanced impact resistance of bioinspired composites[J]. Advanced Materials,2017,29(28):1700060. doi: 10.1002/adma.201700060 -

下载:

下载: