Preparation of carbon nanotubes/diatomite based porous ceramic composites and its photothermal evaporation performance

-

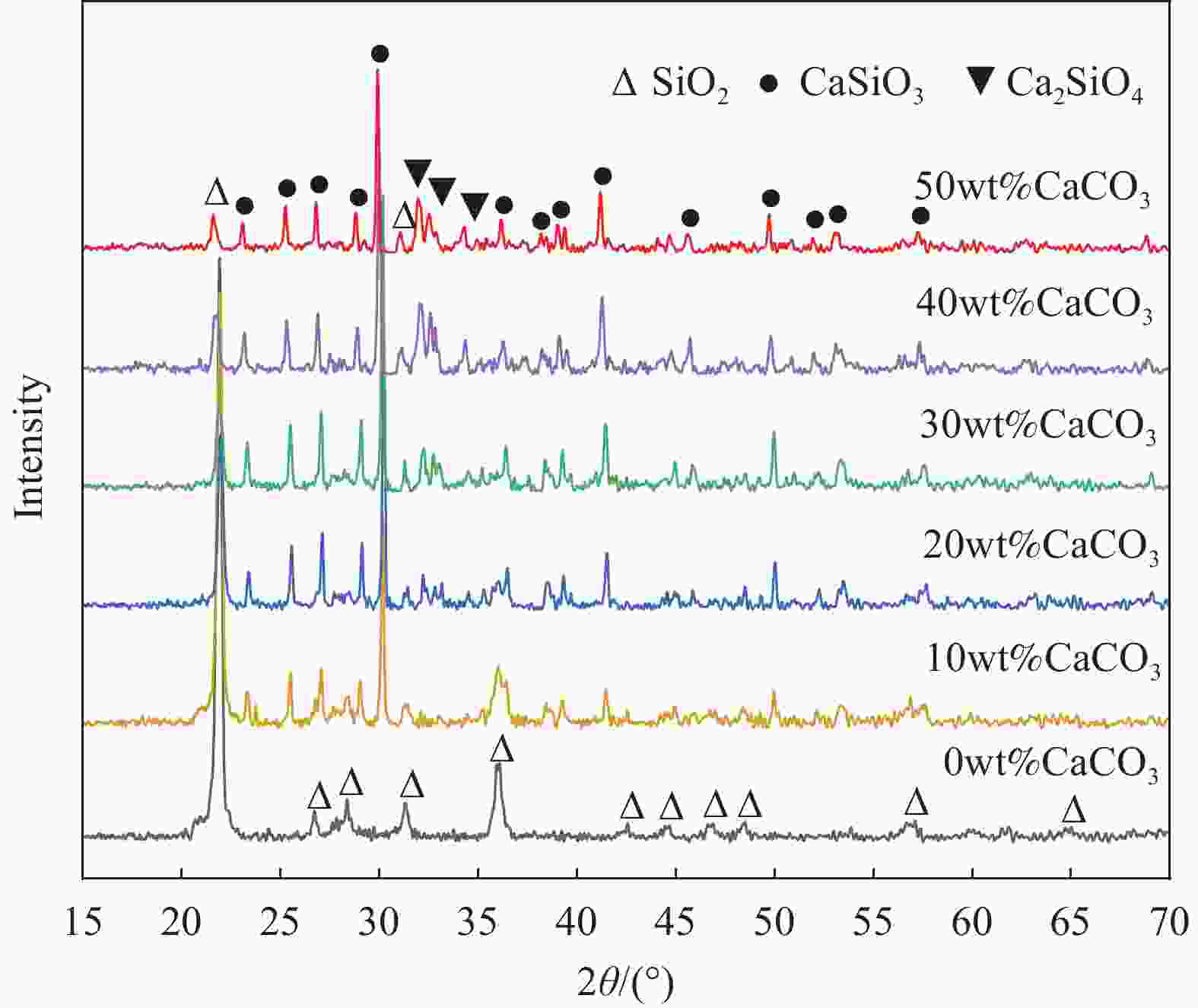

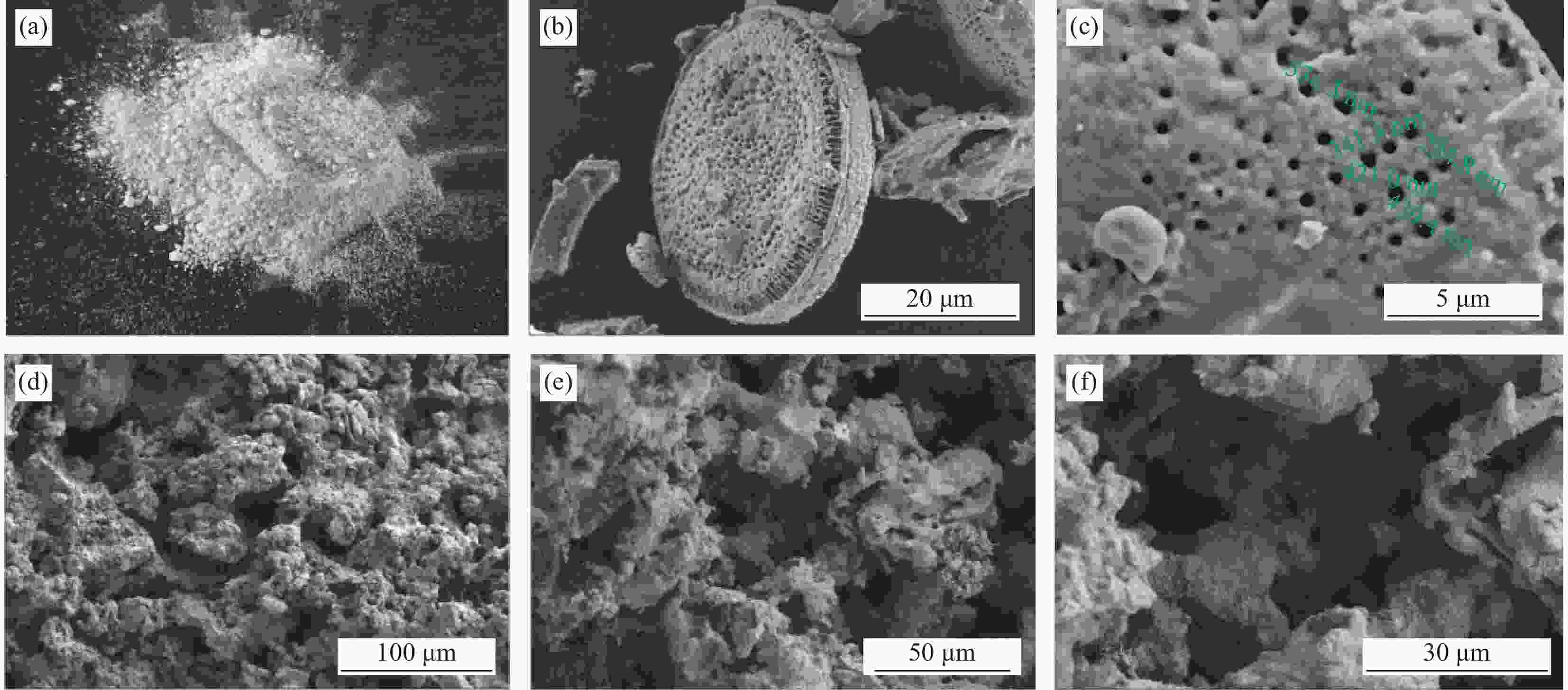

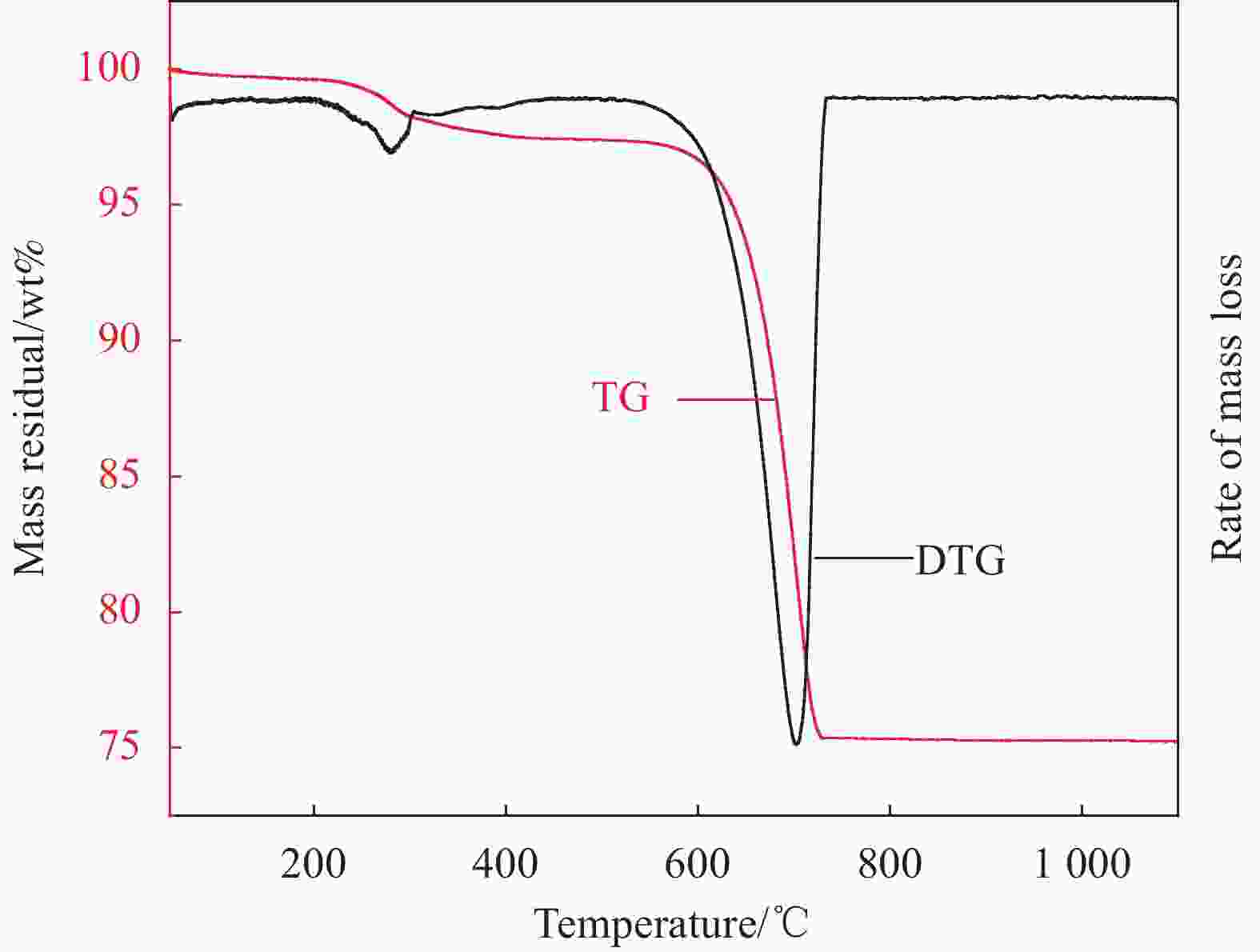

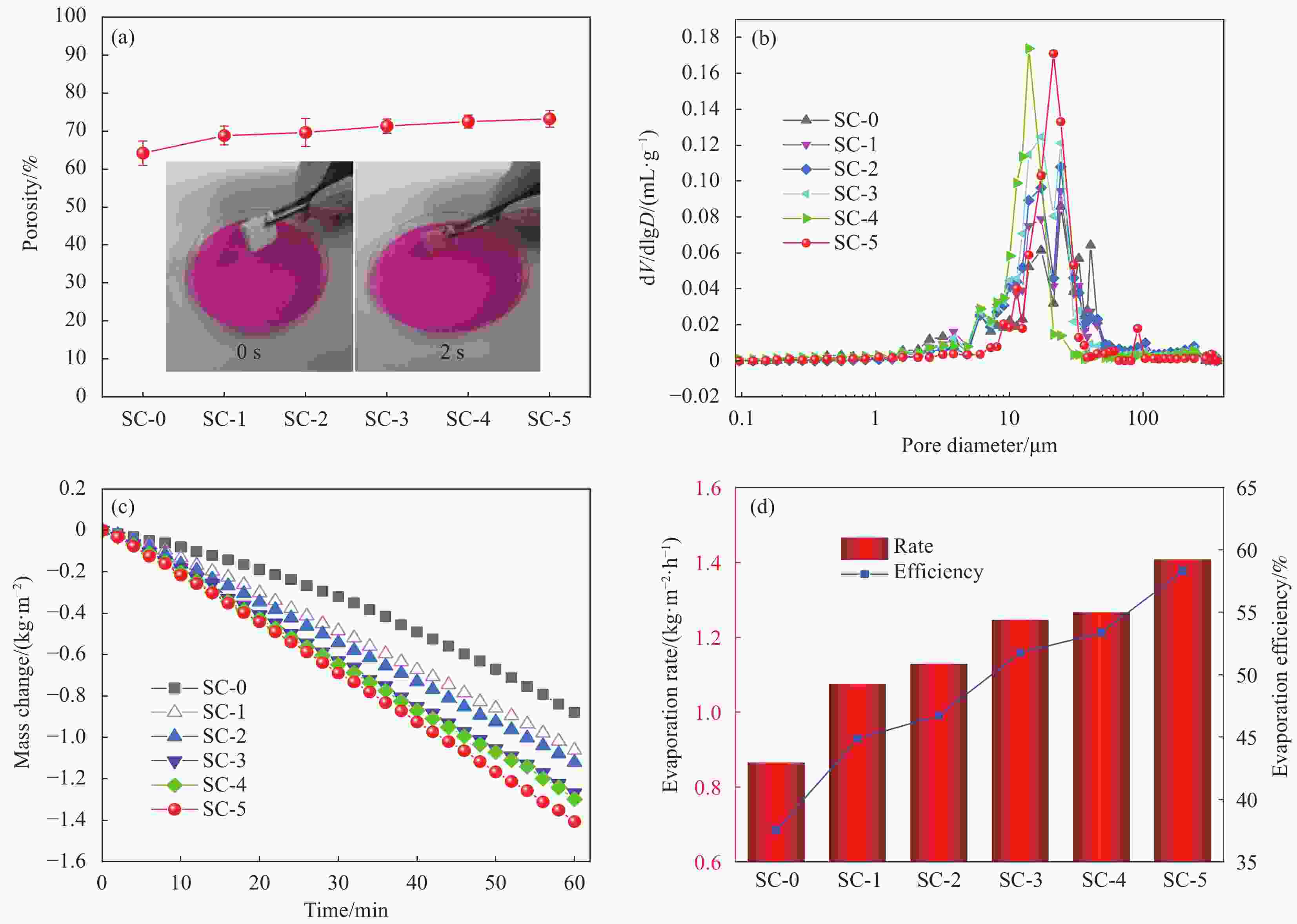

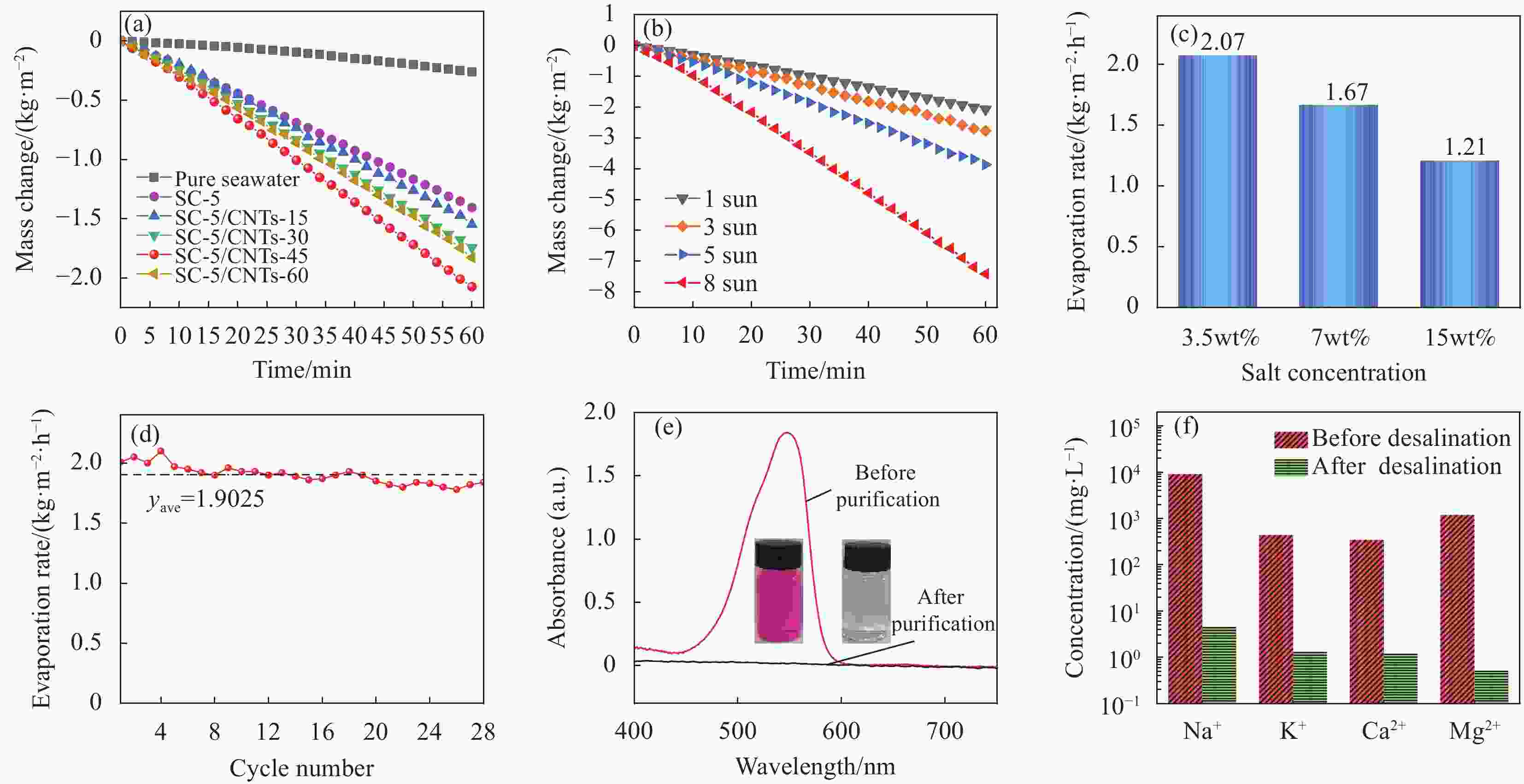

摘要: 界面型光蒸汽转化技术为从海水和废水中提取淡水提供了一种高效、可持续的策略,以有效应对水资源短缺危机。本文以天然硅藻土为主要原料、CaCO3为造孔剂,采用注浆成型工艺,制备硅藻土基多孔陶瓷,并将多壁碳纳米管与海藻酸钠混合凝胶涂覆到陶瓷表面,制备出碳纳米管/硅藻土基多孔陶瓷复合材料。结果表明:硅藻土基多孔陶瓷具有三维连通的多孔结构,孔径主要分布在10~30 µm。当CaCO3质量分数为50wt%时,孔隙率可达73.2%。得益于多孔结构的多重散射效应及亲水性、碳纳米管优异的光热转换能力,一个太阳光强下,蒸发器蒸发速率和能量转化效率最高可达2.07 kg·m−2·h−1和95.6%,对于海水和废水可实现接近100%的离子截留率,并具有良好的循环稳定性,在海水淡化领域具有广阔的应用潜力。Abstract: Interface solar steam generation technology provides an efficient and sustainable strategy for extracting fresh water from seawater and wastewater, which can effectively solve the current water crisis. In present work, diatomite based porous ceramics were prepared by grouting molding process by using natural diatomite as the main raw material and CaCO3 as the pore forming agent. Then, carbon nanotube/diatomite based porous ceramic composites were prepared successfully by surface modification of the diatomite based porous ceramics coating with the multi walled carbon nanotubes and sodium alginate mixed gel. Characterizations confirm that the diatomite based porous ceramics have a three-dimensional connected porous structure, and the pore size is mainly 10-30 µm. When the mass fraction of CaCO3 is 50wt%, the porosity can reach 73.2%. Owing to the multiple scattering effect and hydrophilicity of the porous structure and the excellent photothermal conversion ability of carbon nanotubes, the evaporator show excellent properties. Under one solar intensity, the evaporation rate and energy conversion efficiency of the evaporator are up to 2.07 kg·m−2·h−1 and 95.6%, respectively and maintains good cycle stability. Additionally, the ion rejection rate of seawater and wastewater for the evaporator can achieve nearly 100%. It shows broad application potential in the field of seawater desalination.

-

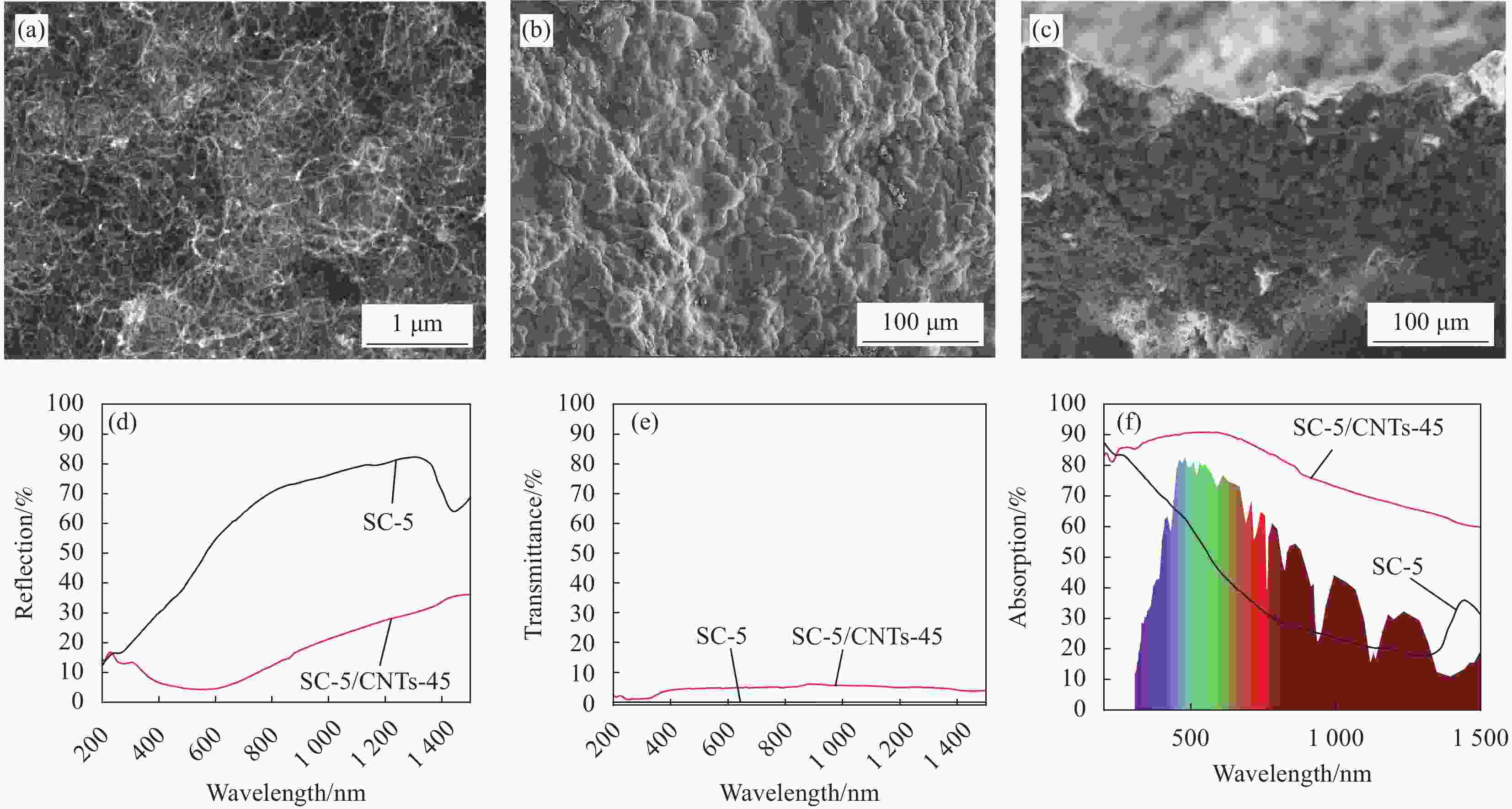

图 8 (a)不同比例复合材料的质量损失曲线;SC-5/CNTs-45水蒸发性能:(b)不同光强的质量损失曲线;(c)不同海水浓度速率图;(d)循环测试图;(e)淡化前后海水主要离子浓度;(f)净化罗丹明b前后紫外-可见吸收光谱

yave—Average evaporation rate of cyclic evaporation experiment

Figure 8. (a) Mass change curves of composites with different proportions; Evaporation performance of SC-5/CNTs-45: (b) Mass change curves under different solar intensities; (c) Evaporation rates under different salinity concentrations; (d) Cyclic curve; (e) Seawater concentration of main ions before and after purification; (f) UV-Vis absorption spectra before and after purification of Rhodamine B

表 1 硅藻土基多孔陶瓷的原料用量

Table 1. Raw material amount of diatomite based porous ceramics

Sample Diatomite/g CMC/g Isobam-104/g Deionized water/mL CaCO3/g SC-0 8.4 0.02 0.24 12 0 SC-1 8.4 0.02 0.24 12 2.07 SC-2 8.4 0.02 0.24 12 4.14 SC-3 8.4 0.02 0.24 12 6.21 SC-4 8.4 0.02 0.24 12 8.28 SC-5 8.4 0.02 0.24 12 10.35 Note: CMC—Sodium carboxymethylcellulose. 表 2 碳纳米管(CNTs)/硅藻土基多孔陶瓷复合材料的用量

Table 2. Amount of carbon nanotubes (CNTs)/diatomite based porous ceramics

Sample Diatomite/g CMC/g Isobam-104/g Deionized water/mL CaCO3/g CNTs/mg SC-5/CNTs-15 8.4 0.02 0.24 12 0 15 SC-5/CNTs-30 8.4 0.02 0.24 12 2.07 30 SC-5/CNTs-45 8.4 0.02 0.24 12 4.14 45 SC-5/CNTs-60 8.4 0.02 0.24 12 6.21 60 表 3 本工作与相关研究在一个光强下性能对比

Table 3. Comparison the performance of this work with related studies under one solar intensity

Sample Evaporation rate/(kg·m−2·h−1) Evaporation efficiency/% Ref. Our work 2.07 95.9 — Cotton-CNT fabric 1.59 89.6 [7] Graphene oxide/CNTs 1.58 87.5 [8] All-carbon nanotube hybrid films 1.37 87.4 [34] Cellulose/carbon nanotubes membrane 1.60 89 [35] CNT@dialdehyde microcrystalline cellulose membrane 1.58 90.86 [36] Porous Ni mesh/CNTs 2.13 94.3 [37] Hydroxyapatite nanowires/CNT photothermal paper 1.31 83.2 [38] -

[1] 王笑影, 褚文娣, 葛梦妮, 等. 巯基接枝氧化石墨烯/聚酰胺复合膜制备及反渗透脱盐性能[J]. 复合材料学报, 2021, 38(8):2479-2488. doi: 10.13801/j.cnki.fhclxb.20201030.008WANG Xiaoying, CHU Wendi, GE Mengni, et al. Fabrication of sulfhydryl grafted graphene oxide/polyamide composite membranes for reverse osmosis desalination[J]. Acta Materiae Compositae Sinica,2021,38(8):2479-2488(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201030.008 [2] BAE K, KU B J, KIM Y, et al. Black diatom colloids toward efficient photothermal converters for solar-to-steam generation[J]. ACS Applied Materials & Interfaces,2019,11(4):4531-4540. [3] XU R Q, WEI N, LI Z K, et al. Construction of hierarchical 2D/2D Ti3C2/MoS2 nanocomposites for high-efficiency solar steam generation[J]. Journal of Colloid and Interface Science,2021,584(2):125-133. [4] SHARON H, REDDY K S. A review of solar energy driven desalination technologies[J]. Renewable and Sustainable Energy Reviews,2015,41(1):1080-1118. [5] XU W C, HU X Z, ZHUANG S D, et al. Flexible and salt resistant Janus absorbers by electrospinning for stable and efficient solar desalination[J]. Advanced Energy Materials,2018,8(14):1702884. doi: 10.1002/aenm.201702884 [6] ZHOU L, LI X Q, NI G W, et al. The revival of thermal utilization from the sun: Interfacial solar vapor generation[J]. National Science Review,2019,6(3):562-578. doi: 10.1093/nsr/nwz030 [7] KOU H, LIU Z X, ZHU B, et al. Recyclable CNT-coupled cotton fabrics for low-cost and efficient desalination of seawater under sunlight[J]. Desalination,2019,462(7):29-38. [8] LI L, ZANG L L, ZHANG S C, et al. GO/CNT-silica Janus nanofibrous membrane for solar-driven interfacial steam generation and desalination[J]. Journal of the Taiwan Institute of Chemical Engineers,2020,111(6):191-197. [9] ZHANG P P, LIAO Q H, YAO H Z, et al. Three-dimensional water evaporation on a macroporous vertically aligned graphene pillar array under one sun[J]. Journal of Materials Chemistry A,2018,6(31):15303-15309. doi: 10.1039/C8TA05412F [10] YANG J L, PANG Y S, HUANG W X, et al. Functionalized graphene enables highly efficient solar thermal steam generation[J]. ACS Nano,2017,11(6):5510-5518. doi: 10.1021/acsnano.7b00367 [11] CHEN L, WANG H Y, KURAVI S, et al. Low-cost and reusable carbon black based solar evaporator for effective water desalination[J]. Desalination,2020,483(6):114412. [12] JIAO S P, LIU M, LI Y, et al. Emerging hydrovoltaic technology based on carbon black and porous carbon materials: A mini review[J]. Carbon,2022,193(6):339-355. [13] MU S L, NAN J J, SHI C Y, et al. A flexible polymer nanofiber-gold nanoparticle composite film for solar-thermal seawater desalination[J]. Macromolecular Rapid Communications,2020,41(24):2000390. doi: 10.1002/marc.202000390 [14] ZHANG Y, WANG Y, YU B, et al. Hierarchically structured black gold film with ultrahigh porosity for solar steam generation[J]. Advanced Materials,2022,34(4):2200108. [15] LIU F, LIANG W D, HE J X, et al. Fabrication of Ag nanoparticles doped hypercrosslinked polymers monoliths for solar desalination[J]. Polymer,2021,231(9):124115. [16] XIAO S N, ZHAO X W, LIU S Y, et al. rGO-CuOx composites reduced by solid-phase microwave thermal shock for high-efficient seawater desalination and purification[J]. Advanced Sustainable Systems,2022,6(5):2100500. [17] TAO F J, ZHANG Y L, YIN K, et al. Copper sulfide-based plasmonic photothermal membrane for high-efficiency solar vapor generation[J]. ACS Applied Materials & Interfaces,2018,10(41):35154-35163. [18] GUO Z Z, WANG G, MING X, et al. PEGylated self-growth MoS2 on a cotton cloth substrate for high-efficiency solar energy utilization[J]. ACS Applied Materials & Interfaces,2018,10(29):24583-24589. [19] 魏天琪, 李秀强, 李金磊, 等. 界面光蒸汽转化研究进展[J]. 科学通报, 2018, 63(14):1405-1416.WEI Tianqi, LI Xiuqiang, LI Jinlei, et al. Interfacial solar vapor generation[J]. Chinese Science Bulletin,2018,63(14):1405-1416(in Chinese). [20] WANG Y C, ZHANG L B, WANG P. Self-floating carbon nano-tube membrane on macroporous silica substrate for highly efficient solar-driven interfacial water evaporation[J]. ACS Sustainable Chemistry & Engineering,2016,4(3):1223-1230. [21] HAN L, LI F L, DENG X G, et al. Foam-gelcasting preparation, microstructure and thermal insulation performance of porous diatomite ceramics with hierarchical pore structures[J]. Journal of the European Ceramic Society,2017,37(7):2717-2725. doi: 10.1016/j.jeurceramsoc.2017.02.032 [22] 侯雪艳, 文华, 赵海涛, 等. 表面疏水修饰增强改性硅藻土调湿性能及其对聚氨酯膜透湿性的影响[J]. 复合材料学报, 2023, 40(2):929-939. doi: 10.13801/j.cnki.fhclxb.20220414.001HOU Xueyan, WEN Hua, ZHAO Haitao, et al. Modified diatomite with enhanced moisture-regulating by surface hydrophobicity and its effect on water vapor permeability of polyurethane film[J]. Acta Materiae Compositae Sinica,2023,40(2):929-939(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220414.001 [23] HAO L P, GAO W Y, YAN S, et al. Preparation and characterization of porous ceramics with low-grade diatomite and oyster shell[J]. Materials Chemistry and Physics,2019,235(9):121741. [24] 王卿, 鲍崇高, 李世佳, 等. 硅藻土光固化成型浆料和多孔陶瓷的制备[J]. 硅酸盐通报, 2022, 41(4):1416-1422. doi: 10.3969/j.issn.1001-1625.2022.4.gsytb202204036WANG Qing, BAO Chonggao, LI Shijia, et al. Fabrication of diatomite slurries and diatomite porous ceramics based on stereo lithography apparatus[J]. Bulletin of the Chinese Ceramic Society,2022,41(4):1416-1422(in Chinese). doi: 10.3969/j.issn.1001-1625.2022.4.gsytb202204036 [25] BI Y B, ZHANG H J, WANG H F, et al. Facile preparation of reduced GO modified porous ceramics with hierarchical pore structure as a highly efficient and durable sorbent material[J]. Journal of the European Ceramic Society,2020,40(5):2106-2112. doi: 10.1016/j.jeurceramsoc.2020.01.008 [26] DENG L L, DU P X, YU W B, et al. Novel hierarchically porous allophane/diatomite nanocomposite for benzene adsorption[J]. Applied Clay Science,2019,168(2):155-163. [27] 杨勤桃, 农接亮, 解庆林, 等. 改性硅藻土在污水处理中的应用研究进展[J]. 化工新型材料, 2022, 50(1):298-302. doi: 10.19817/j.cnki.issn1006-3536.2022.01.060YANG Qintao, NONG Jieliang, XIE Qinglin, et al. Research progress on application of modified diatomite in wastewater treatment[J]. New Chemical Materials,2022,50(1):298-302(in Chinese). doi: 10.19817/j.cnki.issn1006-3536.2022.01.060 [28] HU Z B, ZHENG S L, JIA M Z, et al. Preparation and characterization of novel diatomite/ground calcium carbonate composite humidity control material[J]. Advanced Powder Technology,2017,28(5):1372-1381. doi: 10.1016/j.apt.2017.03.005 [29] JIANG F, ZHANG L L, JIANG Z, et al. Diatomite-based porous ceramics with high apparent porosity: Pore structure modification using calcium carbonate[J]. Ceramics International,2019,45(5):6085-6092. doi: 10.1016/j.ceramint.2018.12.082 [30] ZHENG R J, REN Z J, GAO H M, et al. Effects of calcination on silica phase transition in diatomite[J]. Journal of Alloys and Compounds,2018,757:364-371. doi: 10.1016/j.jallcom.2018.05.010 [31] 卢尚青, 吴素芳. 碳酸钙热分解进展[J]. 化工学报, 2015, 66(8):2895-2902. doi: 10.11949/j.issn.0438-1157.20150670LU Shangqing, WU Sufang. Advances in calcium carbonate thermal decomposition[J]. Journal of Chemical Industry and Engineering (China),2015,66(8):2895-2902(in Chinese). doi: 10.11949/j.issn.0438-1157.20150670 [32] XIAO J X, GUO Y, LUO W Q, et al. A scalable, cost-effective and salt-rejecting MoS2/SA@melamine foam for continuous solar steam generation[J]. Nano Energy,2021,87(9):106213. [33] HU W J H, XIE L, ZENG H B. Novel sodium alginate-assisted MXene nanosheets for ultrahigh rejection of multiple cations and dyes[J]. Journal of Colloid and Interface Science,2020,568(5):36-45. [34] YU Y L, CHEN S, JIA Y, et al. Ultra-black and self-cleaning all carbon nanotube hybrid films for efficient water desalination and purification[J]. Carbon,2020,169:134-141. doi: 10.1016/j.carbon.2020.06.089 [35] YANG Z Y, ZANG L L, DOU T W, et al. Asymmetric cellulose/carbon nanotubes membrane with interconnected pores fabricated by droplet method for solar-driven interfacial evaporation and desalination[J]. Membranes,2022,12(4):369. doi: 10.3390/membranes12040369 [36] ZHU R F, WANG D, LIU Y M, et al. Bifunctional superwetting carbon nanotubes/cellulose composite membrane for solar desalination and oily seawater purification[J]. Chemical Engineering Journal,2022,433:133510. doi: 10.1016/j.cej.2021.133510 [37] LI Q, ZHANG S Q, WEI N, et al. Porous Ni/CNTs composite membrane as solar absorber for highly efficient solar steam generation[J]. Solar Energy Materials and Solar Cells,2022,243:111815. doi: 10.1016/j.solmat.2022.111815 [38] XIONG Z C, ZHU Y J, QIN D D, et al. Flexible fire-resistant photothermal paper comprising ultralong hydroxyapatite nanowires and carbon nanotubes for solar energy-driven water purification[J]. Small,2018,14(50):1803387. doi: 10.1002/smll.201803387 [39] GLEN A D. Methods for calculating brine evaporation rates during salt production[J]. Journal of Archaeological Science,2008,35(6):1453-1462. doi: 10.1016/j.jas.2007.10.013 [40] WEI N, LI Z K, LI Q, et al. Scalable and low-cost fabrication of hydrophobic PVDF/WS2 porous membrane for highly efficient solar steam generation[J]. Journal of Colloid and Interface Science,2021,588(4):369-377. -

下载:

下载: