Research progress of plant-derived porous carbon materials in supercapacitors

-

摘要:

超级电容器是一种功率密度高、充放电速率快、使用寿命长、应用范围广的储能装置。影响其性能的主要因素是电极材料,故导电性好、原料易得、成本低、环境友好的电极材料的开发是当今超级电容器的研究重点。植物衍生多孔碳材料因其满足上述要求而受到广泛关注。本文按照前驱体的来源对植物衍生多孔碳材料进行了分类,介绍了近年来国内外植物衍生多孔碳材料用于超级电容器电极材料的研究成果,讨论了植物衍生多孔碳电极材料在超级电容器领域中所面临的挑战,并对植物衍生多孔碳材料的发展前景进行了展望。

Abstract:Supercapacitors represent an energy storage device renowned for its high-power density, rapid charging/discharging rates, long service life, and versatility across diverse applications. The primary factor influencing their performance lies in the electrode materials. Consequently, the development of electrode materials that are conductive, readily available, cost-effective, and environmentally friendly has emerged as a pivotal research focus in the field of supercapacitors. Plant-based porous carbon materials have garnered significant attention due to their adherence to these criteria. This paper categorizes plant-based porous carbons based on their precursor sources, reviews recent research achievements worldwide on their application as electrode materials in supercapacitors, discusses the challenges faced by plant-based porous carbon electrode materials in this domain, and offers an outlook on their promising future.

-

Keywords:

- plant-derived /

- carbon materials /

- supercapacitors /

- electrode materials /

- research progress

-

膜分离技术具有高能效、易操作、环境友好和占地面积小等优点,近年来在气体分离领域受到广泛关注[1-4]。传统气体分离膜多以聚合物膜为主,然而由于聚合物分离膜固有的选择性和渗透性的制约关系(Trade-off效应),使其性能很难再提升[5-6]。研究者发现将多孔材料与聚合物基体共混制成混合基质膜,通过结合两种材料的优点,能够同时提升膜的气体渗透性和选择性,从而突破聚合物膜的Trade-off效应[7-8]。因此,制备混合基质膜是改善膜气体分离性能的一种有效方法。

对于混合基质膜,填料和聚合物基体材料的选择尤为重要。聚酰亚胺由于其优异的热稳定性、良好的力学性能以及可加工性,已经在气体分离膜领域发展多年,是混合基质膜聚合物基体候选材料之一[9-11]。对于填料材料的选择,共价有机框架材料(COFs)是一种由有机单元通过共价键构成的多孔材料,由于其具有优异的稳定性,易功能化、永久空隙率以及高比表面积等优点,在气体分离领域展现出不俗的潜力[12]。由于COFs全有机的性质,使其能够均匀地分散在聚合物基质中,减少了混合基质膜中由于界面缺陷产生的非选择性孔[13-14]。然而,大部分COFs的孔径很难做到2 nm以下,相对于气体分子动力学直径(N2:0.36 nm;O2:0.35 nm;CO2:0.33 nm)还是较大,难以实现对气体的高效分离,从而降低了气体选择性[15-16]。因此,需要对COFs的孔径大小调控或引入一些功能性吸附位点进行改善。研究表明,引入氟原子能够有效改善COFs的孔径大小且能够提供与气体相互作用的吸附位点。Alahakoon等[17]通过使用含氟单体制备出两种氟化COFs,将氟化COFs与未氟化的相比,发现氟化COFs具有更大的比表面积、更小且更明确的孔径。Gao等[18]报道了3种具有—H、—Me和—F取代基的同构三维共价有机骨架,对比不含氟的COFs,氟化COFs具有更高的CO2亲和力,对CO2/N2有着更高的IAST选择性。Yang等[19]制备了一种氟化CTF,通过氟原子的强静电作用以及C—F键与CO2的偶极-四极作用,使其具有优异的CO2吸附能力。

基于上述讨论,本文合成出一种具有较小孔径、高比表面积的氟化共价有机框架材料(TpPa-CF3)。随后,以TpPa-CF3为填料,聚酰亚胺(6FDA-ODA)为基体,制备出不同负载量的TpPa-CF3/6FDA-ODA混合基质膜。表征了其结构和表面、截面的微观形貌,探究了其热性能、力学性能以及疏水性能,最后讨论了混合基质膜的气体渗透性以及在烟道气分离(CO2/N2)和空气分离(O2/N2)上的应用前景。

1. 实验材料及方法

1.1 原材料

4,4-二氨基二苯醚(ODA,98%)、4,4-(六氟异丙烯)二酞酸酐(6FDA,98%+)、2,4,6-三甲酰间苯三酚(Tp,98%)、2-三氟甲基-1,4-苯二胺(Pa-CF3,97%)、1,3,5-三甲基苯(99%+)、1,4-二氧六环(99%)均购自上海阿达玛斯试剂有限公司;乙酸(AR)、N,N-二甲基甲酰胺(DMF,AR)均购自西陇科学股份有限公司;间甲酚(m-Cresol,99%)、异喹啉(97%)均购自上海阿拉丁试剂有限公司;丙酮(Acetone,AR),成都市科隆化学品有限公司;工业酒精(95%),弘昊实验设备有限公司。

1.2 TpPa-CF3的合成

将Tp (63.0 mg,0.30 mmol)、Pa-CF3 (79.0 mg,0.45 mmol)、1,3,5-三甲基苯(1.5 mL)、1,4-二氧六环(1.5 mL)依次加入到Pyrex管(25 mL)中。为使混合物均匀分散,超声处理0.5 h,再加入3 mol/L乙酸溶液(0.5 mL)。随后,用液氮将Pyrex管骤冻抽出空气,再在室温下解冻,此操作循环3次。密闭封管,将Pyrex管在120℃下油浴3天。反应完毕后冷却至室温,过滤收集产物,先用DMF溶液搅拌洗涤3次,再通过索氏提取法进行提纯(提纯溶剂采用丙酮)。随后,收集产物,在真空烘箱中120℃下干燥12 h后,得到橘红色粉末样品TpPa-CF3。

1.3 聚酰亚胺(6FDA-ODA)的合成

在N2氛围下,向装有机械搅拌、冷凝回流的150 mL三口烧瓶内依次加入ODA (2.00 g,9.99 mmol)、间甲酚(28 mL),待ODA完全溶解后再依次加入6FDA (4.44 g,9.99 mmol)、间甲酚(28 mL),随后将温度升到50℃待反应物完全溶解后,滴加5~6滴异喹啉后升温至80℃反应3 h,120℃反应3 h,180℃反应3 h,最后200℃反应12 h。反应结束冷却至室温后,将聚酰亚胺溶液缓慢倒入大量工业酒精中拉丝沉淀,过滤收集产物,在真空烘箱中150℃干燥8 h。随后,使用适量DMF重新溶解并进行二次沉淀以除去聚酰亚胺中残留杂质。

1.4 TpPa-CF3/6FDA-ODA混合基质膜的制备

取一定量的TpPa-CF3粉末分散在DMF (3 mL)中,使用细胞粉碎机,在300 W功率下超声0.5 h后再搅拌6 h,保证TpPa-CF3粉末在DMF溶液中分散均匀。同时,称取0.2 g 6FDA-ODA溶解在DMF (2 mL)中,用针式滤头(0.45 μm,尼龙)过滤除去杂质。随后,将TpPa-CF3的分散液滴加到6FDA-ODA溶液中搅拌12 h,确保TpPa-CF3和6FDA-ODA充分混合。最后,将混合溶液缓慢流延到光滑平整的玻璃板(5 cm×5 cm)上,在80℃下蒸发12 h除去溶剂,待冷却至室温后在温水中脱膜,最后在150℃的真空烘箱中干燥12 h以除去残留的溶剂分子。按以上步骤分别制备含量为0wt%、1wt%、3wt%、5wt%、7wt%的TpPa-CF3/6FDA-ODA混合基质膜。

1.5 表征测试

X射线衍射(XRD):采用荷兰帕纳科公司的X'Pert Pro型X射线衍射仪对制备的TpPa-CF3粉末与薄膜进行晶型及结构表征,扫描范围在3°~40°,扫描速度为2°/min。

傅里叶变换红外光谱(FTIR):采用美国尼高力公司的Nicolette 6700-NXR型傅里叶变换红外光谱仪分析TpPa-CF3和薄膜的化学键组成及官能团。对于粉末样品通过溴化钾压片的方式测试,对于薄膜样品通过制成厚度约为20 μm的薄膜直接测试。扫描范围为400~

4000 cm−1,扫描次数64次以上。固态核磁共振(ssNMR):通过德国布鲁克公司的Avance Neo 400 WB型固体核磁共振波谱仪测试TpPa-CF3的13C NMR,分析其化学键连接方式。所需样品压实后的体积应多于0.5 cm3。

X射线光电子能谱(XPS):采用美国热电公司的Escalab 250 Xi型X射线光电子能谱仪分析TpPa-CF3的化学元素及化学态。采用粉末压片的方式制样。

扫描电子显微镜(SEM):通过日本日立公司的SU 4800型扫描电子显微镜表征TpPa-CF3和薄膜表面、截面的微观形貌。对于粉末样品,用牙签将少量样品涂在导电胶上制样;对于薄膜样品,膜表面直接粘在导电胶上,膜断面通过液氮脆断选取平整截面制样。全部样品在测试前通过喷金处理提高样品导电性。

N2吸附-脱附测试:通过美国康塔公司的Autosorb IQ型比表面及孔隙度分析仪器表征TpPa-CF3的比表面积及孔径分布。采用BET (Brunauer-Emmett-Teller)法计算比表面积,密度泛函理论(DFT)计算孔径分布。

热重分析(TGA):通过德国耐驰公司的STA 449C型综合热分析仪测试TpPa-CF3和薄膜的热稳定性。在N2氛围下测试,升温速率为10℃/min,测试范围在50~800℃。

差示扫描量热分析(DSC):通过德国耐驰公司的DSC 214型差示扫描量热仪测试薄膜的玻璃化转变温度,在N2氛围下以10℃/min的速率升温,测试范围在30~350℃,所有结果均采用消除热历史后的二次升温曲线。

力学性能:通过美国美特斯公司的CMT2103型万能试验机来表征薄膜的力学性能。薄膜样品尺寸为50 mm×10 mm,拉伸载荷为5 kN,拉伸速率为2 mm/min,标距为20 mm。

水接触角测试:通过中国承德优特仪器有限公司JY-PHb型接触角分析仪测定薄膜的亲疏水性能。薄膜样品尺寸为20 mm×20 mm,测试次数至少3次。

气体渗透性测试:通过中国济南兰光公司的VAC-V1型气体渗透仪测试薄膜的气体渗透性能。测试方法为恒体积变压法,测试气体为高纯气体(CO2、O2、N2),测试条件为4 bar,35℃。测试过程如下,将厚度均匀的待测薄膜装入膜腔中,测试前将上下腔气压抽至20 Pa以下,随后下腔关闭,上腔通入待测纯气体形成压差。压差推动气体自上腔(高压侧)向下腔(低压侧)渗透,通过系统计算得到膜的气体渗透系数P。

2. 结果与讨论

2.1 TpPa-CF3的表征

通过粉末X射线衍射(PXRD)对合成的TpPa-CF3的晶体结构进行分析,图1(a)中2θ=4.79°处出现的强峰对应于COF的(100)晶面,其他峰也出现在2θ=7.81°、26.14°处,分别对应于(200)、(001)晶面,其中(001)晶面也是其π-π堆叠峰,通过布拉格方程计算得出其堆叠层间距为0.33 nm。将测试结果与模拟的晶体模型的衍射峰进行对比,结果表明二者衍射峰的位置与强度均匹配良好。TpPa-CF3在Pawley精修后得到的晶胞参数为a=

2.290351 nm,b=2.236760 nm,c=0.423813 nm,α=89.56415 ,β=89.73479 ,γ=120.51471 。实验结果与精修后的PXRD之间的残差值较小,Rwp=1.24%,Rp=0.91%。以上结果初步说明成功合成出了目标晶体结构,且具有良好的结晶性。为进一步说明TpPa-CF3成功合成,通过FTIR对TpPa-CF3以及其构筑单元测试,从图1(b)中可以看到,构筑单元2,4,6-三甲酰间苯三酚(Tp)在

2894 cm−1处醛基的CH=O特征峰和构筑单元2-三氟甲基-1,4-苯二胺(Pa-CF3)在3318 cm−1和3210 cm−1处的—NH2特征峰在产物TpPa-CF3中消失,表明醛胺缩合反应完全。在1282 cm−1处的C—N的特征吸收峰表明烯醇-酮异构的发生。因为框架是以酮的形式存在,结构中有强的分子内氢键及共轭作用,所以在1592 cm−1处的C=C的特征峰和1610 cm−1处的C=O特征峰合并呈肩状[20]。在1128 cm−1处出现了C—F的特征峰。13C固体NMR分析如图1(c)所示,图中显示化学位移在184.2×10−6和108.1×10−6处有两个较明显的信号峰,分别对应于烯醇-酮异构反应所形成的C=O键和C—N键上的C原子,123.6×10−6处归属于C—F上的C原子。其余在119.0×10−6、134.1×10−6和146.5×10−6处的信号峰则归属于芳香单元上的C原子。

FTIR和固体核磁分析结果证实TpPa-CF3的成功合成且以稳定的β-酮胺形式存在。

通过XPS测量TpPa-CF3的全谱和各个元素的光谱,由图2(a)的全谱可知TpPa-CF3是由C、N、O、F 4种元素组成的。图2(b)是C1s的高分辨率XPS光谱,其能够被卷积为4个峰,分别对应于TpPa-CF3中的C=C/C—C(284.8 eV)、C—N(286.2 eV)、C=O(288.9 eV)和C—F(292.9 eV)键,N1s的高分辨率XPS如图2(c)所示,其被卷积为2个峰,分别归属于N—C(400.2 eV)和N—H(403.9 eV)键,F1s的高分辨率XPS如图2(d)所示,其只有一个卷积峰归属于C—F(688.3 eV)。所有以上结果说明TpPa-CF3形成目标结构,由C1s和N1s证明该结构发生了烯醇-酮异构。

通过扫描电镜(SEM)观察TpPa-CF3的微观形貌。如图3(a)所示,TpPa-CF3具有均匀的微观形貌,呈现为“米粒”形颗粒堆积形成的团簇,每一颗“米粒”的尺寸在(100±30) nm。

为了解TpPa-CF3的多孔性,对其进行N2吸附-脱附测试。图3(b)中N2吸脱附曲线呈现出I型曲线特征,TpPa-CF3在相对压力较低的区域(p/p0<0.1),N2的吸附量快速增加,说明材料中存在丰富的微孔结构。通过计算分析得出TpPa-CF3具有较大的比表面积(791.83 m2·g−1),图3(c)显示TpPa-CF3具有较小的孔径(1.18 nm)。这归因于TpPa-CF3中氟原子的高电负性增强了框架中芳香环之间的相互作用力,这种相互作用力有助于COF形成较大的比表面积以及较小的孔径[17]。

通过热重分析TpPa-CF3的热性能。热重曲线如图3(d)所示,从图中看到热损失分为两个阶段,大约在400℃之前的损失可能为残留在孔道里的高沸点溶剂(DMF)的挥发。400℃后出现明显的质量损失,从DTG曲线上可以看到在416℃质量损失的速度最快,这主要归因于TpPa-CF3框架的分解。以上结果可以看出TpPa-CF3具有较好的热稳定性。

2.2 TpPa-CF3/6FDA-ODA混合基质膜的表征

通过XRD对膜结构表征,评价了填料对聚合物链排列的影响。从图4(a)中可以看到所有曲线在2θ=15°左右均出现典型的聚合物宽峰。通过布拉格方程计算,得到膜的分子链间距。纯6FDA-ODA膜的分子链间距为0.574 nm,随着填料TpPa-CF3负载量的增加,链间距呈现先增大后下降的趋势,7%TpPa-CF3/6FDA-ODA膜的链间距最小(0.566 nm)。分子链间距先增大主要是由于小负载量的掺入破坏了分子链的堆积,随着负载量的增大,填料与聚合物基质的相互作用逐渐增强,限制了分子链的迁移率,链间距减小有利于提高气体的选择性。同时,在TpPa-CF3/6FDA-ODA混合基质膜中没有观察到TpPa-CF3粉末的特征峰,这主要是由于在超声搅拌过程中COF填料的部分剥落[21]。

混合基质膜的FTIR图谱如图4(b)所示,所有膜都表现出6FDA-ODA的特征峰,包括C=O的对称(

1783 cm−1)和不对称拉伸(1733 cm−1)、C—N的拉伸振动(1378 cm−1)、C—O—C的拉伸振动(1157 cm−1)、C—F键的吸收峰(1110 cm−1),以及酰亚胺环的弯曲振动(721 cm−1),值得注意的是在1597 cm−1处的特征峰,随着填料的增加而增强,这主要归因于TpPa-CF3和6FDA-ODA中芳香环上的C=C的吸收峰重叠[22]。以上结果说明聚酰亚胺基体和填料之间具有良好的相容性,填料的加入并没有破坏聚酰亚胺的结构。为分析TpPa-CF3的加入对混合基质膜热稳定性的影响,对6FDA-ODA及TpPa-CF3/6FDA-ODA混合基质膜进行了热重测试。如图5(a)所示,混合基质膜的分解分为两个阶段,第一阶段是400℃左右TpPa-CF3框架的分解,第二阶段是500℃左右6FDA-ODA基体膜的分解,填料的加入对膜的热稳定性影响不大。所有混合基质膜都表现出高达500℃的良好热稳定性,远高于工业中膜的操作温度,表明这些膜具有良好的适用性。DSC曲线用于分析膜的玻璃化转变温度(Tg)。如图5(b)所示,6FDA-ODA膜的Tg出现在297.5℃。随着TpPa-CF3负载量的增加,TpPa-CF3/6FDA-ODA膜的Tg从297.5℃逐渐增加到302.1℃,说明TpPa-CF3与6FDA-ODA之间具有良好的界面相互作用,这有利于提升混合基质膜的气体选择性[23]。

膜表面、截面的扫描电镜表征能够反映出填料在膜内的分散情况。如图6(a1)~6(e1)所示,与表面光滑平整的纯膜相比,混合基质膜的表面随着填料负载量的增加逐渐变得粗糙,在负载量达到7wt%时可以看到膜表面出现不平整及大颗粒团聚的现象。图6(a2)~6(e2)为纯膜及其混合基质膜的截面扫描电镜图,纯膜的截面表现出均匀、致密的微观结构,在1wt%~5wt%混合基质膜的截面图中能够观察到随着负载量的增加其截面形貌逐渐变粗糙,同时在膜内能够观察到TpPa-CF3颗粒很好地被聚合物包裹且分散均匀。当填料负载量达到7wt%时膜内出现填料与聚合物基质相分离的现象,说明此时负载量已经达到聚合物基质所能承受的上限,5wt%为其最优负载量。

通过接触角测试仪分析纯膜及其混合基质膜的水接触角(θw)。如图7(a)和表1所示,6FDA-ODA膜的水接触角为79.9°,TpPa-CF3/6FDA-ODA混合基质膜的水接触角为81.4°~89.1°,呈现逐渐增大的趋势。这主要归因于TpPa-CF3框架中含有—CF3疏水基团,因此随着TpPa-CF3含量的增加相应负载量的混合基质膜水接触角也逐渐增加。提升膜的疏水性能有助于阻止水汽进入,提升其气体传输性能。

表 1 不同负载量下TpPa-CF3/6FDA-ODA混合基质膜的力学性能Table 1. Mechanical properties of TpPa-CF3/6FDA-ODA mixed matrix membranes at different loadingsTpPa-CF3 loadings/wt% Tensile strength/MPa Elongation at break/% Young's modulus/GPa θw/(°) 0 74.1 10.1 1.59 79.9 1 79.6 9.7 1.63 81.4 3 82.9 8.6 1.70 83.1 5 93.0 7.8 1.82 84.1 7 84.5 7.3 1.76 89.1 Note: θw—Water contact angle. 对混合基质膜进行拉伸实验以此来检验其力学性能。测试结果如图7(b)和表1所示。从表中可以看出,TpPa-CF3/6FDA-ODA混合基质膜的抗拉强度和杨氏模量随着TpPa-CF3负载量的增加呈现出先增加后下降的趋势,而断裂伸长率呈现逐渐下降的趋势。这主要归因于,在混合基质膜中TpPa-CF3与6FDA-ODA之间较好的相互作用力使得填料与聚合物之间具有良好的界面相容性,增强了膜的刚性。然而,当负载量达到7wt%时,抗拉强度和杨氏模量略微下降,这主要是过量的TpPa-CF3颗粒之间发生团聚,使得界面出现缺陷导致应力集中,降低了膜的力学性能[24]。

利用3种纯气体(CO2、O2、N2)渗透测试来评估不同负载量下TpPa-CF3/6FDA-ODA混合基质膜的渗透性及CO2/N2和O2/N2的理想选择性。结果如表2所示,每一种膜气体渗透系数的大小均与气体分子动力学直径呈反比,即膜的3种气体渗透系数大小排列为P(CO2)>P(O2)>P(N2),3种气体分子动力学直径大小排列为N2(0.36 nm)>O2(0.35 nm)>CO2(0.33 nm)。同6FDA-ODA膜相比所有混合基质膜的气体渗透性都有所提升。由图8(a)中可得,随着TpPa-CF3含量的增加,膜的气体渗透性呈现出先增大后下降的趋势,其中5%TpPa-CF3/6FDA-ODA膜气体渗透性能最佳,P(CO2)提升了149%,P(O2)提升了138%,P(N2)提升了98%。这主要归因于TpPa-CF3的高孔隙率提高了TpPa-CF3/6FDA-ODA膜的比表面积及固有孔隙率,为气体传输提供了快速通道。TpPa-CF3负载量到7wt%时,气体的渗透性明显下降,但仍然比6FDA-ODA膜高。这主要是由于负载量过大,造成TpPa-CF3在膜内团聚堵塞了气体传输的孔道。

表 2 6FDA-ODA及TpPa-CF3/6FDA-ODA混合基质膜的气体渗透系数P和理想选择性Table 2. Gas permeability coefficient P and ideal selectivity of 6FDA-ODA and TpPa-CF3/6FDA-ODA mixed matrix membranesMembrane Permeability/Barrer Ideal selectivity α CO2 O2 N2 α(CO2/N2) α(O2/N2) 6FDA-ODA 12.47 2.55 0.64 19.5 4.0 1%TpPa-CF3/6FDA-ODA 16.91 3.76 0.98 17.2 3.8 3%TpPa-CF3/6FDA-ODA 22.77 4.43 1.03 22.0 4.3 5%TpPa-CF3/6FDA-ODA 31.08 6.08 1.27 24.5 4.8 7%TpPa-CF3/6FDA-ODA 18.62 4.16 1.11 16.8 3.8 Notes: 1 Barrer=10−10 cm3(STP)·cm·cm−2·s−1·cmHg−1; Ideal selectivity α=P(A)/P(B), A and B are two different pure gases. TpPa-CF3/6FDA-ODA膜的气体选择性变化趋势和气体渗透性变化趋势不同,如图8(b)所示,CO2/N2和O2/N2均呈现出先下降后上升再下降的趋势,CO2/N2及O2/N2的理想选择性范围分别在16.8~24.4和3.8~4.8。其中,当TpPa-CF3负载量为5wt%时,混合基质膜的CO2/N2和O2/N2选择性最好,分别是6FDA-ODA膜的125%和119%。理想选择性的提高主要归因于两个方面:一个方面是CO2和O2的分子动力学直径要小于N2的分子动力学直径,从而CO2和O2分子倾向于优先通过。另一个方面,TpPa-CF3中富含大量对CO2具有亲和力的N、O和F等电负性原子,同时框架内还存在能与CO2发生偶极-四极相互作用的强极性C—F键,因此CO2/N2选择性相较于O2/N2的提升更明显[25]。然而,当负载量到7wt%时,混合基质膜的CO2/N2和O2/N2选择性大幅下降,略低于6FDA-ODA膜,这主要归因于当TpPa-CF3的负载量增加一定程度时,其在膜内发生团聚,并和聚合物基质产生部分相分离,产生一些非选择的孔,从而造成CO2/N2和O2/N2理想选择性的大幅下降。

对TpPa-CF3/6FDA-ODA混合基质膜进行72 h的连续气体渗透性测试,以验证膜的稳定性。如图8(c)所示,该膜在72 h的运行试验中P(CO2)下降了18%,CO2/N2的选择性下降了16%,总体表现出了良好的分离稳定性。

为了评估混合基质膜的气体分离性能,图9显示了不同负载量的TpPa-CF3/6FDA-ODA混合基质膜的气体分离性能与Robeson上限的对比。当负载量为5wt%时,其气体分离性能更靠近Robeson上限,气体的渗透性与选择性同步提升。说明适量的引入TpPa-CF3能够改善聚合物膜的气体分离性能。此外,表3显示了文献[26-30]中报道的混合基质膜气体分离性能与本工作的对比,TpPa-CF3/6FDA-ODA混合基质膜显示出适中的气体渗透性以及适中的气体选择性,说明TpPa-CF3/6FDA-ODA混合基质膜还有进一步提升的潜力。

表 3 文献中报道的混合基质膜气体分离性能与本工作的对比Table 3. Comparison of gas separation performance of mixed matrix membranes reported in the literature with the present workMembrane type P(CO2)/Barrer P(O2)/Barrer α(CO2/N2) α(O2/N2) Ref. TpPa-1-nc/Pebax 21 — 72 — [26] COFp-PVAm 270 — 86 — [27] TpBD@PBI-BuI 14.8 — 23 — [28] ZIF-7-I/(BPDA/6FDA-ODA) — 2.9 — 0.19 [29] PBI-PI-based carbon 293.5 93.1 8.3 2.6 [30] 5%TpPa-CF3/6FDA-ODA 31.08 6.08 24.4 4.8 This work Notes: TpPa-1-nc—; COFp—; TpBD—; BPDA—; Pebax—Poly(ether-block-amide); PVAm—Polyvinylamine; PBI-BuI—Tert-butylpolybenzimidazole; ZIF-7-I—Wide-pore ZIF-7; PBI—Polybenzimidazoles; PI—Polyimide. 3. 结 论

(1)采用溶剂热法合成了一种氟化共价有机框架材料(TpPa-CF3),其具有高比表面积(791.83 m2·g−1),较小且均一的孔径(1.18 nm)以及良好的热稳定性。

(2)采用共混法成功制备TpPa-CF3/聚酰亚胺(6FDA-ODA)混合基质膜。通过表征得出,所得膜具有良好的界面相容性以及较高的热稳定性(热分解温度在500℃左右)。水接触角的范围在81.4°~89.1°,且膜具有良好的力学性能,有利于膜在分离过程中的稳定性。

(3) TpPa-CF3的掺入提高了混合基质膜的气体渗透性,随着膜中TpPa-CF3负载量的增加,混合基质膜的气体渗透性呈现先减小后增大再减小的趋势。其中,5%TpPa-CF3/6FDA-ODA膜的气体分离性能最好,其CO2和O2的渗透性能分别提高了149%和138%,CO2/N2和O2/N2的分离性能分别是6FDA-ODA基体膜的125%和119%。

-

表 1 部分植物衍生碳材料的电化学性能

Table 1 Electrochemical properties of some plant-derived carbon materials

Material Activator Specific

Capacitance/(F·g−1)Electrolyte Energy density/

(Wh·kg−1)Power density/

(W·kg−1)Cycling

stabilityReference Shaddock endotheliums KOH 550

(0.2 A·g−1)1 mol·L−1

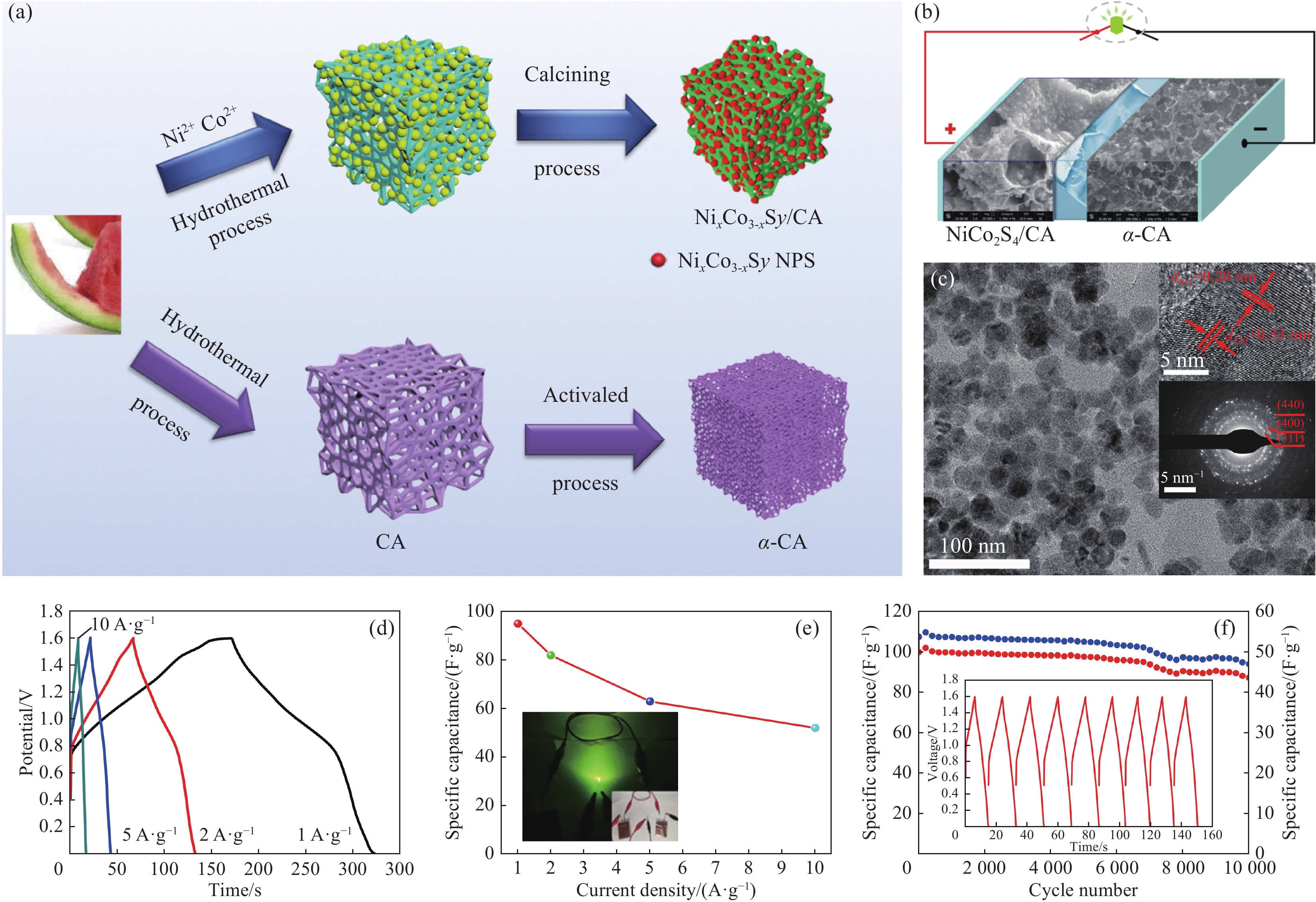

BMIMBF4/AN46.88 300 93.7% 10000 cycles97 Cashew nut husk KOH 305.2

(1 A·g−1)6 mol·L−1

KOH11.2 400 97.1% 4000 cycles98 Zanthoxylum Leaves ZnCl2 196

(0.5 A·g−1)0.5 mol·L−1

Na2SO418.68 225 92% 20000 cycles99 Pine pollen MgCO3 416.9

(1 A·g−1)6 mol·L−1

KOH34.9 181 97.4% 10000 cycles100 Willow catkin KOH 298

(0.5 A·g−1)6 mol·L−1

KOH21.0 180 99.7% 10000 cycles101 Loofah sponge KOH 309.6

(1 A·g−1)6 mol·L−1

KOH16.1 160 81.3% 10000 cycles102 Bamboo fungi [ZnCO3]2·

[Zn(OH)2]3367

(0.5 A·g−1)6 mol·L−1

KOH24.6 400 95.7% 10000 cycles103 Banana CO2 178.9

(1 A·g−1)6 mol·L−1

KOH3.23 50 67% 10000 cycles104 Eucalyptus bark KOH 483.5

(0.5 A·g−1)1 mol·L−1

Na2SO421.7 168.9 83.1% 10000 cycles105 Lacquer wood H3PO4 354

(0.2 A·g−1)1 mol·L−1

H2SO4/ / 95.3% 10000 cycles106 Notes:BMIMBF4/AN is 1-butyl-3-methylimidazolium tetrafluoroborate/acetonitrile -

[1] KUMAR A, BHATTACHARYA T, HASNAIN S M M, et al. Applications of biomass-derived materials for energy production, conversion, and storage[J]. Materials Science for Energy Technologies, 2020, 3: 905-920. DOI: 10.1016/j.mset.2020.10.012

[2] SHARMA S, CHAND P. Supercapacitor and electrochemical techniques: A brief review[J]. Results in Chemistry, 2023, 5: 100885. DOI: 10.1016/j.rechem.2023.100885

[3] SATPATHY S, DAS S, BHATTACHARYYA B K. How and where to use super-capacitors effectively, an integration of review of past and new characterization works on super-capacitors[J]. Journal of Energy Storage, 2020, 27: 101044. DOI: 10.1016/j.est.2019.101044

[4] WANG J, ZHOU J, ZHAO W. Deep reinforcement learning based energy management strategy for fuel cell/battery/supercapacitor powered electric vehicle[J]. Green Energy and Intelligent Transportation, 2022, 1(2): 100028. DOI: 10.1016/j.geits.2022.100028

[5] WINTER M, BRODD R J. What are batteries, fuel cells, and supercapacitors?[J]. Chemical reviews, 2004, 104(10): 4245-4270. DOI: 10.1021/cr020730k

[6] SALLEH N A, KHEAWHOM S, HAMID N A A, et al. Electrode polymer binders for supercapacitor applications: a review[J]. Journal of Materials Research and Technology, 2023, 23: 3470-3491. DOI: 10.1016/j.jmrt.2023.02.013

[7] SUBRAMANIAN B, VEERAPPAN M, RAJAN K, et al. Fabrication of hierarchical indium vanadate materials for supercapacitor application[J]. Global Challenges, 2020, 4(11): 2000002. DOI: 10.1002/gch2.202000002

[8] SENTHIL C, LEE C W. Biomass-derived biochar materials as sustainable energy sources for electrochemical energy storage devices[J]. Renewable and Sustainable Energy Reviews, 2021, 137: 110464. DOI: 10.1016/j.rser.2020.110464

[9] LI Y, GUPTA R, ZHANG Q, et al. Review of biochar production via crop residue pyrolysis: Development and perspectives[J]. Bioresource Technology, 2023, 369: 128423. DOI: 10.1016/j.biortech.2022.128423

[10] “十四五”能源领域科技创新规划[R]. 中国科技奖励, 2022, 09: 23-42. The 14th five-year plan for scientific and technological innovation in the energy sector[R]. China Awards for Science and Technology, 2022, 09: 23-42.

[11] Supercapacitor Market to Generate Revenue of USD24.37 Billion by 2029 Demand, Trends and Growth Industries from 2022 to 2029[J]. M2 Presswire, 2022.

[12] VAITHYANATHAN V K, GOYETTE B, RAJAGOPAL R. A critical review of the transformation of biomass into commodity chemicals: Prominence of pretreatments[J]. Environmental Challenges, 2023, 11: 100700. DOI: 10.1016/j.envc.2023.100700

[13] ANTAR M, LYU D, NAZARI M, et al. Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization[J]. Renewable and Sustainable Energy Reviews, 2021, 139: 110691. DOI: 10.1016/j.rser.2020.110691

[14] KARAM D S, NAGABOVANALLI P, RAJOO K S, et al. An overview on the preparation of rice husk biochar, factors affecting its properties, and its agriculture application[J]. Journal of the Saudi Society of Agricultural Sciences, 2022, 21(3): 149-159. DOI: 10.1016/j.jssas.2021.07.005

[15] 宋晓岚, 段海龙, 王海波, 等. 稻壳基活性炭电极材料制备及其电化学性能研究[J]. 硅酸盐通报, 2017, 36(3): 991-995. SONG Xiaolan, DUAN Hailong, WANG Haibo, et al. Preparation and electrochemical performance of rice husk-based activated carbon electrode[J]. Bulletin of the Chinese Ceramic Society, 017, 36(3): 991-995. (in Chinese)

[16] GAO Y, LI L, JIN Y, et al. Porous carbon made from rice husk as electrode material for electrochemical double layer capacitor[J]. Applied Energy, 2015, 153: 41-47. DOI: 10.1016/j.apenergy.2014.12.070

[17] HE X, LING P, YU M, et al. Rice husk-derived porous carbons with high capacitance by ZnCl2 activation for supercapacitors[J]. Electrochimica Acta, 2013, 105: 635-641. DOI: 10.1016/j.electacta.2013.05.050

[18] LOBATO-PERALTA D R, DUQUE-BRITO E, ORUGBA H O, et al. Sponge-like nanoporous activated carbon from corn husk as a sustainable and highly stable supercapacitor electrode for energy storage[J]. Diamond and Related Materials, 2023, 138: 110176. DOI: 10.1016/j.diamond.2023.110176

[19] 隋光辉, 程岩岩. 以稻壳热解炭制备镧负载多孔炭复合电极材料[J]. 高等学校化学学报, 2024, 45(4): 151-159. SUI Guanhui, CHENG Yanyan. Preparation of lanthanum-loaded porous carbon composite electrode materials from rice husk pyrolytic carbon[J]. Chemical Journal of Chinese Universities, 2024, 45(4): 151-159(in Chinese).

[20] WEI F, GUO Y, WANG S, et al. N, P codoped carbon nanosheets derived from rice husk for supercapacitors with high energy density[J]. Diamond and Related Materials, 2023, 137: 110161. DOI: 10.1016/j.diamond.2023.110161

[21] XIAO S, HUANG J, LIN C, et al. Porous carbon derived from rice husks as sustainable bioresources: Insights into the role of micro/mesoporous hierarchy in Co3O4/C composite for asymmetric supercapacitors[J]. Microporous and Mesoporous Materials, 2020, 291: 109709. DOI: 10.1016/j.micromeso.2019.109709

[22] BARBIERI V, GUALTIERI M L, SILIGARDI C. Wheat husk: A renewable resource for bio-based building materials[J]. Construction and Building Materials, 2020, 251: 118909. DOI: 10.1016/j.conbuildmat.2020.118909

[23] BLEDZKI A K, MAMUN A A, Volk J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites[J]. Composites Part A: Applied Science and Manufacturing, 2010, 41(4): 480-488. DOI: 10.1016/j.compositesa.2009.12.004

[24] CUI J, SUN H, LUO Z, et al. Preparation of low surface area SiO2 microsphere from wheat husk ash with a facile precipitation process[J]. Materials Letters, 2015, 156: 42-45. DOI: 10.1016/j.matlet.2015.04.134

[25] 卓祖优, 宋生南, 黄明堦, 等. 草酸钾-尿素协同活化法制备超大比表面积面粉基多级孔炭及其电化学储能应用[J]. 化工进展, 2023, 42(2): 925-933. ZHUO Zuyou, SONG Shengnan, HUANG Mingjie, et al. Preparation of wheat flour-based hierarchical porous carbon with ultra large specific surface area by synergistic activation of potassium oxalate-urea and its electrochemical energy storage performance[J]. Chemical Industry and Engineering Progress, 2023, 42(2): 925-933(in Chinese).

[26] BAIG M M, GUL I H. Conversion of wheat husk to high surface area activated carbon for energy storage in high-performance supercapacitors[J]. Biomass and Bioenergy, 2021, 144: 105909. DOI: 10.1016/j.biombioe.2020.105909

[27] BAIG M M, GUL I H. Transformation of wheat husk to 3D activated carbon/NiCo2S4 frameworks for high-rate asymmetrical supercapacitors[J]. Journal of Energy Storage, 2021, 37: 102477. DOI: 10.1016/j.est.2021.102477

[28] KONG S, JIN B, QUAN X, et al. MnO2 nanosheets decorated porous active carbon derived from wheat bran for high-performance asymmetric supercapacitor[J]. Journal of Electroanalytical Chemistry, 2019, 850: 113412. DOI: 10.1016/j.jelechem.2019.113412

[29] DU W, ZHANG Z, DU L, et al. Designing synthesis of porous biomass carbon from wheat straw and the functionalizing application in flexible, all-solid-state supercapacitors[J]. Journal of Alloys and Compounds, 2019, 797: 1031-1040. DOI: 10.1016/j.jallcom.2019.05.207

[30] ZHANG R, MA S, LI L, et al. Comprehensive utilization of corn starch processing by-products: A review[J]. Grain & Oil Science and Technology, 2021, 4(3): 89-107.

[31] RATNA A S, GHOSH A, MUKHOPADHYAY S. Advances and prospects of corn husk as a sustainable material in composites and other technical applications[J]. Journal of Cleaner Production, 2022, 371: 133563. DOI: 10.1016/j.jclepro.2022.133563

[32] AHMED M J, DANISH M, ANASTOPOULOS I, et al. Recent progress on corn (Zea mays L. )-based materials as raw, chemically modified, carbonaceous, and composite adsorbents for aquatic pollutants: A review[J]. Journal of Analytical and Applied Pyrolysis, 2023, 172: 106004. DOI: 10.1016/j.jaap.2023.106004

[33] LEITE M, FREITAS A, SILVA A S, et al. Maize (Zea mays L. ) and mycotoxins: A review on optimization and validation of analytical methods by liquid chromatography coupled to mass spectrometry[J]. Trends in Food Science & Technology, 2020, 99: 542-565.

[34] 林彦萍, 任源, 王晓娥, 等. 农业生物质废弃物转化功能材料的研究进展[J]. 环境科学, 2024, 45(7): 4332-4351. LIN Yanping, REN Yuan, WANG Xiaoe, et al. Research progress on functional materials for agricultural biomass waste conversion[J]. Environmental Science, 2024, 45(7): 4332-4351(in Chinese).

[35] 韦会鸽, 李桂星, 雷祥楠, 等. 聚苯胺-玉米苞叶纤维复合材料基柔性自支撑电极的制备及其电化学性能[J]. 复合材料学报, 2022, 39(7): 3462-3468. WEI Huige, LI Guixing, LEI Xiangnan, et al. Polyaniline-corn husk fiber composite based flexible self-standing electrode: Preparation and electrochemical properties[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3462-3468(in Chinese).

[36] ZOU Q. Corn-straw-converted activated carbons with tunable porosity and N/O functionalities as high-performance supercapacitors electrode at commercial-level mass loading[J]. Journal of Energy Storage, 2023, 72: 108673. DOI: 10.1016/j.est.2023.108673

[37] 邢宝林, 陈丽薇, 张传祥, 等. 玉米芯活性炭的制备及其电化学性能研究[J]. 材料导报, 2015, 29(6): 45-48+64. DOI: 10.11896/j.issn.1005-023X.2015.06.010 XING Baolin, CHEN Liwei, ZHANG Chuanxiang, et al. Preparation and electrochemical performance of corncob based activated carbon[J]. Materials Reports, 2015, 29(6): 45-48+64(in Chinese). DOI: 10.11896/j.issn.1005-023X.2015.06.010

[38] YU K, ZHU H, QI H, et al. High surface area carbon materials derived from corn stalk core as electrode for supercapacitor[J]. Diamond and Related Materials, 2018, 88: 18-22. DOI: 10.1016/j.diamond.2018.06.018

[39] RANI M U, NANAJI K, RAO T N, et al. Corn husk derived activated carbon with enhanced electrochemical performance for high-voltage supercapacitors[J]. Journal of Power Sources, 2020, 471: 228387. DOI: 10.1016/j.jpowsour.2020.228387

[40] ZHOU J, YUAN S, LU C, et al. Hierarchical porous carbon microtubes derived from corn silks for supercapacitors electrode materials[J]. Journal of Electroanalytical Chemistry, 2020, 878: 114704. DOI: 10.1016/j.jelechem.2020.114704

[41] SUN K, ZHANG Z, PENG H, et al. Hybrid symmetric supercapacitor assembled by renewable corn silks based porous carbon and redox-active electrolytes[J]. Materials Chemistry and Physics, 2018, 218: 229-238. DOI: 10.1016/j.matchemphys.2018.07.052

[42] TANG J, GUO Z, KONG X, et al. Soybean meal-derived heteroatoms-doped porous carbons for supercapacitor electrodes[J]. Materials Chemistry and Physics, 2022, 284: 126055. DOI: 10.1016/j.matchemphys.2022.126055

[43] WANG A, SUN K, XU R, et al. Cleanly synthesizing rotten potato-based activated carbon for supercapacitor by self-catalytic activation[J]. Journal of Cleaner Production, 2021, 283: 125385. DOI: 10.1016/j.jclepro.2020.125385

[44] ZHANG Q, WANG J, DENG M. Preparation of Porous Carbon from Buckwheat Husk and its Electrochemical Properties[J]. International Journal of Electrochemical Science, 2022, 17(11): 221145. DOI: 10.20964/2022.11.32

[45] HU H, WU G. Porous carbon derived from sweet potato biomass as electrode for zinc-ion hybrid supercapacitors[J]. International Journal of Electrochemical Science, 2021, 16(9): 210937. DOI: 10.20964/2021.09.01

[46] ALBATRNI H, QIBLAWEY H, Al-MARRI M J. Walnut shell based adsorbents: A review study on preparation, mechanism, and application[J]. Journal of Water Process Engineering, 2022, 45: 102527. DOI: 10.1016/j.jwpe.2021.102527

[47] 郭晖, 张记升, 朱天星, 等. 利用核桃壳制备高比表面积活性炭电极材料的研究[J]. 材料导报, 2016, 30(2): 24-27+33. GUO Hui, ZHANG Jisheng, ZHU Tianxing, et al. Preparation of high specific surface area activated carbon electrode materials from walnut shell[J]. Materials Reports, 2016, 30(2): 24-27+33(in Chinese).

[48] FU H, CHEN L, GAO H, et al. Walnut shell-derived hierarchical porous carbon with high performances for electrocatalytic hydrogen evolution and symmetry supercapacitors[J]. International Journal of Hydrogen Energy, 2020, 45(1): 443-451. DOI: 10.1016/j.ijhydene.2019.10.159

[49] 张传涛, 邢宝林, 黄光许, 等. 水热炭化-KOH活化制备核桃壳活性炭电极材料的研究[J]. 材料导报, 2018, 32(7): 1088-1093. ZHANG Chuantao, XING Baolin, HUANG Guangxu, et al. Preparation of walnut shell activated carbons via combination of hydrothermal carbonization and KOH activation[J]. Materials Reports, 2018, 32(7): 1088-1093(in Chinese).

[50] XU X, GAO J, TIAN Q, et al. Walnut shell derived porous carbon for a symmetric all-solid-state supercapacitor[J]. Applied Surface Science, 2017, 411: 170-176. DOI: 10.1016/j.apsusc.2017.03.124

[51] CUI S, MCCLEMENTS D J, XU X, et al. Peanut proteins: extraction, modifications, and applications: a comprehensive review[J]. Grain & Oil Science and Technology, 2023, 6(3): 135-147.

[52] 宋晓琪, 雷西萍, 樊凯, 等. 基于生物质衍生炭在超级电容器中的研究进展[J]. 复合材料学报, 2023, 40(3): 1328-1339. SONG Xiaoqi, LEI Xiping, FAN Kai, et al. Research progress of biomass derived carbon in supercapacitors[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1328-1339(in Chinese).

[53] LIANG K, CHEN Y, WANG S, et al. Peanut shell waste derived porous carbon for high-performance supercapacitors[J]. Journal of Energy Storage, 2023, 70: 107947. DOI: 10.1016/j.est.2023.107947

[54] ZHAN Y, ZHOU H, GUO F, et al. Preparation of highly porous activated carbons from peanut shells as low-cost electrode materials for supercapacitors[J]. Journal of Energy Storage, 2021, 34: 102180. DOI: 10.1016/j.est.2020.102180

[55] NGUYEN N T, LE P A, PHUNG V B T. Biomass-derived carbon hooks on Ni foam with free binder for high performance supercapacitor electrode[J]. Chemical Engineering Science, 2021, 229: 116053. DOI: 10.1016/j.ces.2020.116053

[56] JANNAT N, Al-MUFTI R L, HUSSIEN A, et al. Utilisation of nut shell wastes in brick, mortar and concrete: A review[J]. Construction and Building Materials, 2021, 293: 123546. DOI: 10.1016/j.conbuildmat.2021.123546

[57] BORRES M P, SATO S, EBISAWA M. Recent advances in diagnosing and managing nut allergies with focus on hazelnuts, walnuts, and cashew nuts[J]. World Allergy Organization Journal, 2022, 15(4): 100641. DOI: 10.1016/j.waojou.2022.100641

[58] OZPINAR P, DOGAN C, DEMIRAL H, et al. Activated carbons prepared from hazelnut shell waste by phosphoric acid activation for supercapacitor electrode applications and comprehensive electrochemical analysis[J]. Renewable Energy, 2022, 189: 535-548. DOI: 10.1016/j.renene.2022.02.126

[59] LIU Y, LIU P, LI L, et al. Fabrication of biomass-derived activated carbon with interconnected hierarchical architecture via H3PO4-assisted KOH activation for high-performance symmetrical supercapacitors[J]. Journal of Electroanalytical Chemistry, 2021, 903: 115828. DOI: 10.1016/j.jelechem.2021.115828

[60] FARMA R, TANIA Y, APRIYANI I. Conversion of hazelnut seed shell biomass into porous activated carbon with KOH and CO2 activation for supercapacitors[J]. Materials Today: Proceedings, 2023, 87: 51-56. DOI: 10.1016/j.matpr.2023.02.099

[61] XIE Y, ZHANG D, JATI G N P, et al. Effect of structural and compositional alterations on the specific capacitance of hazelnut shell activated carbon[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 625: 126951. DOI: 10.1016/j.colsurfa.2021.126951

[62] QIN L, HOU Z, LU S, et al. Porous carbon derived from pine nut shell prepared by steam activation for supercapacitor electrode material[J]. International Journal of Electrochemical Science, 2019, 14(9): 8907-8918. DOI: 10.20964/2019.09.20

[63] 王芳平, 马婧, 李小亚, 等. 板栗壳生物炭高性能对称性超级电容器电极材料的制备及性能[J]. 化工进展, 2021, 40(8): 4381. WANG Fangping, MA Jing, LI Xiaoya, et al. Preparation and properties of chestnut shell-based biochar electrode material for high-performance symmetrical supercapacitor[J]. Chemical Industry and Engineering Progress, 2021, 40(8): 4381(in Chinese).

[64] MA C, BAI J, DEMIR M, et al. Water chestnut shell-derived N/S-doped porous carbons and their applications in CO2 adsorption and supercapacitor[J]. Fuel, 2022, 326: 125119. DOI: 10.1016/j.fuel.2022.125119

[65] CAI N, CHENG H, JIN H, et al. Porous carbon derived from cashew nut husk biomass waste for high-performance supercapacitors[J]. Journal of Electroanalytical Chemistry, 2020, 861: 113933. DOI: 10.1016/j.jelechem.2020.113933

[66] HAMID M, AMATURRAHIM S A, DALIMUNTHE I B, et al. Synthesis of magnetic activated carbon-supported cobalt (II) chloride derived from pecan shell (Aleurites moluccana) with co-precipitation method as the electrode in supercapacitors[J]. Materials Science for Energy Technologies, 2023, 6: 429-436. DOI: 10.1016/j.mset.2023.04.004

[67] WU C, ZHANG G, LIU J, et al. A green strategy to prepare nitrogen-oxygen co-doped porous carbons from macadamia nut shells for post-combustion CO2 capture and supercapacitors[J]. Journal of Analytical and Applied Pyrolysis, 2023, 171: 105952. DOI: 10.1016/j.jaap.2023.105952

[68] BHATTACHARJEE C, DUTTA S, SAXENA V K. A review on biosorptive removal of dyes and heavy metals from wastewater using watermelon rind as biosorbent[J]. Environmental Advances, 2020, 2: 100007. DOI: 10.1016/j.envadv.2020.100007

[69] YANG C, LI P, WEI Y, et al. Preparation of nitrogen and phosphorus doped porous carbon from watermelon peel as supercapacitor electrode material[J]. Micromachines, 2023, 14(5): 1003. DOI: 10.3390/mi14051003

[70] OMAR N, ABDULLAH E C, NUMAN A, et al. Facile synthesis of a binary composite from watermelon rind using response surface methodology for supercapacitor electrode material[J]. Journal of Energy Storage, 2022, 49: 104147. DOI: 10.1016/j.est.2022.104147

[71] DONG J, LI S, DING Y. Anchoring nickel-cobalt sulfide nanoparticles on carbon aerogel derived from waste watermelon rind for high-performance asymmetric supercapacitors[J]. Journal of Alloys and Compounds, 2020, 845: 155701. DOI: 10.1016/j.jallcom.2020.155701

[72] ABOAGYE D, BANADDA N, KIGGUNDU N, et al. Assessment of orange peel waste availability in Ghana and potential bio-oil yield using fast pyrolysis[J]. Renewable and Sustainable Energy Reviews, 2017, 70: 814-821. DOI: 10.1016/j.rser.2016.11.262

[73] SIDDIQUI S A, PAHMEYER M J, ASSADPOUR E, et al. Extraction and purification of d-limonene from orange peel wastes: Recent advances[J]. Industrial Crops and Products, 2022, 177: 114484. DOI: 10.1016/j.indcrop.2021.114484

[74] XU C, HU Z, WANG X, et al. Facile preparation of hierarchical porous carbon from orange peels for high-performance supercapacitor[J]. International Journal of Electrochemical Science, 2021, 16(3): 210350. DOI: 10.20964/2021.03.07

[75] DING F, LI J, DU H, et al. Highly porous heteroatom doped-carbon derived from orange peel as electrode materials for high-performance supercapacitors[J]. International Journal of Electrochemical Science, 2020, 15(6): 5632-5649. DOI: 10.20964/2020.06.75

[76] SNOOK G A, KAO P, BEST A S. Conducting-polymer-based supercapacitor devices and electrodes[J]. Journal of Power sources, 2011, 196(1): 1-12. DOI: 10.1016/j.jpowsour.2010.06.084

[77] AJAY K M, DINESH M N, BYATARAYAPPA G, et al. Electrochemical investigations on low cost KOH activated carbon derived from orange-peel and polyaniline for hybrid supercapacitors[J]. Inorganic Chemistry Communications, 2021, 127: 108523. DOI: 10.1016/j.inoche.2021.108523

[78] SUN K, WANG H, PENG H, et al. Manganese oxide nanorods supported on orange peel-based carbon nanosheets for high performance supercapacitors[J]. International Journal of Electrochemical Science, 2015, 10(3): 2000-2013. DOI: 10.1016/S1452-3981(23)04823-X

[79] YUMNAM M, MARAK P R, GUPTA A K, et al. Effect of pomelo peel essential oil on the storage stability of a few selected varieties of freshwater fish[J]. Journal of Agriculture and Food Research, 2023, 11: 100472. DOI: 10.1016/j.jafr.2022.100472

[80] 王芳平, 周凯玲, 马婧, 等. 葡萄柚皮多孔碳高性能对称性超级电容器电极材料的制备及性能[J]. 硅酸盐学报, 2021, 49(3): 495-502. WANG Fangping, ZHOU Kailing, MA Jing, et al. Preparation and properties of porous carbon electrode material of grapefruit peel for high performance symmetrical supercapacitor[J]. Journal of the Chinese Ceramic Society, 2021, 49(3): 495-502(in Chinese).

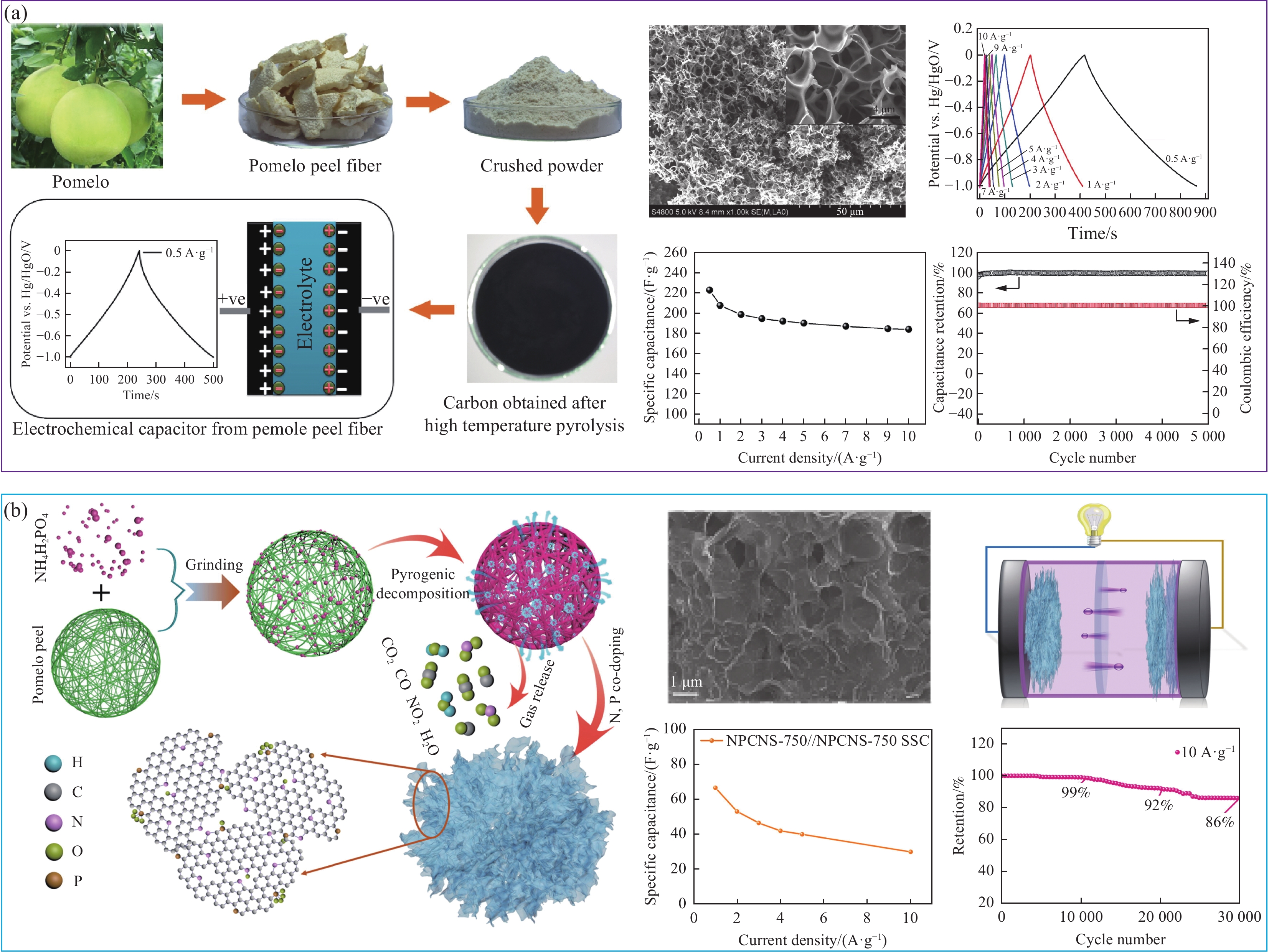

[81] LI J, LIU W, XIAO D, et al. Oxygen-rich hierarchical porous carbon made from pomelo peel fiber as electrode material for supercapacitor[J]. Applied Surface Science, 2017, 416: 918-924. DOI: 10.1016/j.apsusc.2017.04.162

[82] CHEN J, LIN Y, LIU J, et al. Outstanding supercapacitor performance of nitrogen-doped activated carbon derived from shaddock peel[J]. Journal of Energy Storage, 2021, 39: 102640. DOI: 10.1016/j.est.2021.102640

[83] LI G, LI Y, CHEN X, et al. One step synthesis of N, P co-doped hierarchical porous carbon nanosheets derived from pomelo peel for high performance supercapacitors[J]. Journal of Colloid and Interface Science, 2022, 605: 71-81. DOI: 10.1016/j.jcis.2021.07.065

[84] HAN J, PING Y, LI J, et al. One-step nitrogen, boron codoping of porous carbons derived from pomelo peels for supercapacitor electrode materials[J]. Diamond and Related Materials, 2019, 96: 176-181. DOI: 10.1016/j.diamond.2019.05.014

[85] LIU Y, CHANG Z, YAO L, et al. Nitrogen/sulfur dual-doped sponge-like porous carbon materials derived from pomelo peel synthesized at comparatively low temperatures for superior-performance supercapacitors[J]. Journal of Electroanalytical Chemistry, 2019, 847: 113111. DOI: 10.1016/j.jelechem.2019.04.071

[86] SURYA K, MICHAEL M S. Hierarchical porous activated carbon prepared from biowaste of lemon peel for electrochemical double layer capacitors[J]. Biomass and Bioenergy, 2021, 152: 106175. DOI: 10.1016/j.biombioe.2021.106175

[87] KITENGE V N, TARIMO D J, OYEDOTUN K O, et al. Facile and sustainable technique to produce low-cost high surface area mangosteen shell activated carbon for supercapacitors applications[J]. Journal of Energy Storage, 2022, 56: 105876. DOI: 10.1016/j.est.2022.105876

[88] MOHAMMED A A, CHEN C, ZHU Z. Low-cost, high-performance supercapacitor based on activated carbon electrode materials derived from baobab fruit shells[J]. Journal of Colloid and Interface Science, 2019, 538: 308-319. DOI: 10.1016/j.jcis.2018.11.103

[89] 李涛, 何松, 林晓莹, 等. 农林废弃生物质资源精深加工技术进展[J]. 材料导报, 2021, 35(19): 19001-19014. LI Tao, HE Song, LIN Xiaoying, et al. Recent advances on deep processing technologies for resourcing utilization of agricultural and forestry biomass wastes[J]. Materials Reports, 2021, 35(19): 19001-19014(in Chinese).

[90] IWUOZOR K O, ADENIYI A G, EMENIKE E C, et al. Prospects and challenges of utilizing sugarcane bagasse as a bio-coagulant precursor for water treatment[J]. Biotechnology Reports, 2023, 39: e00805. DOI: 10.1016/j.btre.2023.e00805

[91] IWUOZOR K O, EMENIKE E C, IGHALO J O, et al. A review on the thermochemical conversion of sugarcane bagasse into biochar[J]. Cleaner Materials, 2022, 6: 100162. DOI: 10.1016/j.clema.2022.100162

[92] YADAV N, HASHMI S A. High energy density solid-state supercapacitors based on porous carbon electrodes derived from pre-treated bio-waste precursor sugarcane bagasse[J]. Journal of Energy Storage, 2022, 55: 105421. DOI: 10.1016/j.est.2022.105421

[93] CHEN J, QIU J, WANG B, et al. Polyaniline/sugarcane bagasse derived biocarbon composites with superior performance in supercapacitors[J]. Journal of Electroanalytical Chemistry, 2017, 801: 360-367. DOI: 10.1016/j.jelechem.2017.08.014

[94] TU J, QIAO Z, WANG Y, et al. American ginseng biowaste-derived activated carbon for high-performance supercapacitors[J]. International Journal of Electrochemical Science, 2023, 18(2): 16-24. DOI: 10.1016/j.ijoes.2023.01.011

[95] GOPALAKRISHNAN A, RAJU T D, Badhulika S. Green synthesis of nitrogen, sulfur-co-doped worm-like hierarchical porous carbon derived from ginger for outstanding supercapacitor performance[J]. Carbon, 2020, 168: 209-219. DOI: 10.1016/j.carbon.2020.07.017

[96] NGUYEN T B, YOON B, NGUYEN T D, et al. A facile salt-templating synthesis route of bamboo-derived hierarchical porous carbon for supercapacitor applications[J]. Carbon, 2023, 206: 383-391. DOI: 10.1016/j.carbon.2023.02.060

[97] YANG S, WANG S, LIU X, et al. Biomass derived interconnected hierarchical micro-meso-macro-porous carbon with ultrahigh capacitance for supercapacitors[J]. Carbon, 2019, 147: 540-549. DOI: 10.1016/j.carbon.2019.03.023

[98] CAI N, CHENG H, JIN H, et al. Porous carbon derived from cashew nut husk biomass waste for high-performance supercapacitors[J]. Journal of Electroanalytical Chemistry, 2020, 861: 113933. DOI: 10.1016/j.jelechem.2020.113933

[99] XU Y, LEI H, QI S, et al. Three-dimensional zanthoxylum Leaves-Derived nitrogen-Doped porous carbon frameworks for aqueous supercapacitor with high specific energy[J]. Journal of Energy Storage, 2020, 32: 101970. DOI: 10.1016/j.est.2020.101970

[100] WAN L, SONG P, LIU J, et al. Facile synthesis of nitrogen self-doped hierarchical porous carbon derived from pine pollen via MgCO3 activation for high-performance supercapacitors[J]. Journal of Power Sources, 2019, 438: 227013. DOI: 10.1016/j.jpowsour.2019.227013

[101] LI Y, WANG G, WEI T, et al. Nitrogen and sulfur co-doped porous carbon nanosheets derived from willow catkin for supercapacitors[J]. Nano Energy, 2016, 19: 165-175. DOI: 10.1016/j.nanoen.2015.10.038

[102] SU X L, CHEN J R, ZHENG G P, et al. Three-dimensional porous activated carbon derived from loofah sponge biomass for supercapacitor applications[J]. Applied Surface Science, 2018, 436: 327-336. DOI: 10.1016/j.apsusc.2017.11.249

[103] ZHAO Y, CHEN P, TAO S, et al. Nitrogen/oxygen co-doped carbon nanofoam derived from bamboo fungi for high-performance supercapacitors[J]. Journal of Power Sources, 2020, 479: 228835. DOI: 10.1016/j.jpowsour.2020.228835

[104] LEI E, LI W, MA C, et al. CO2-activated porous self-templated N-doped carbon aerogel derived from banana for high-performance supercapacitors[J]. Applied Surface Science, 2018, 457: 477-486. DOI: 10.1016/j.apsusc.2018.07.001

[105] LI K, LIU Z, MA X, et al. A combination of heteroatom doping engineering assisted by molten salt and KOH activation to obtain N and O co-doped biomass porous carbon for high performance supercapacitors[J]. Journal of Alloys and Compounds, 2023, 960: 170785. DOI: 10.1016/j.jallcom.2023.170785

[106] HU S C, CHENG J, WANG W P, et al. Structural changes and electrochemical properties of lacquer wood activated carbon prepared by phosphoric acid-chemical activation for supercapacitor applications[J]. Renewable Energy, 2021, 177: 82-94. DOI: 10.1016/j.renene.2021.05.113

-

其他相关附件

-

本文图文摘要

点击下载

-

-

目的

目前在储能领域,植物衍生多孔碳基超级电容器因其优异的性能而备受研究者的青睐。本文通过综述植物衍生多孔碳材料的制备方法、结构特性及其在超级电容器中的应用效果,深入分析其储能机理、性能优化策略及未来发展方向。这不仅有助于推动超级电容器技术的进一步创新,还为实现绿色、高效的能源存储解决方案提供有力支持。此外,通过探讨当前研究中存在的问题与挑战,提出针对性的改进策略和未来发展方向,为进一步提升超级电容器的性能、推动其产业化应用提供理论依据和实践指导。

方法本文按照前驱体的来源对植物衍生多孔碳材料进行了分类,介绍了近年来国内外植物衍生多孔碳材料用于超级电容器电极材料的研究成果,讨论了植物衍生多孔碳电极材料在超级电容器领域中所面临的挑战,并对植物衍生多孔碳材料的发展前景进行了展望。

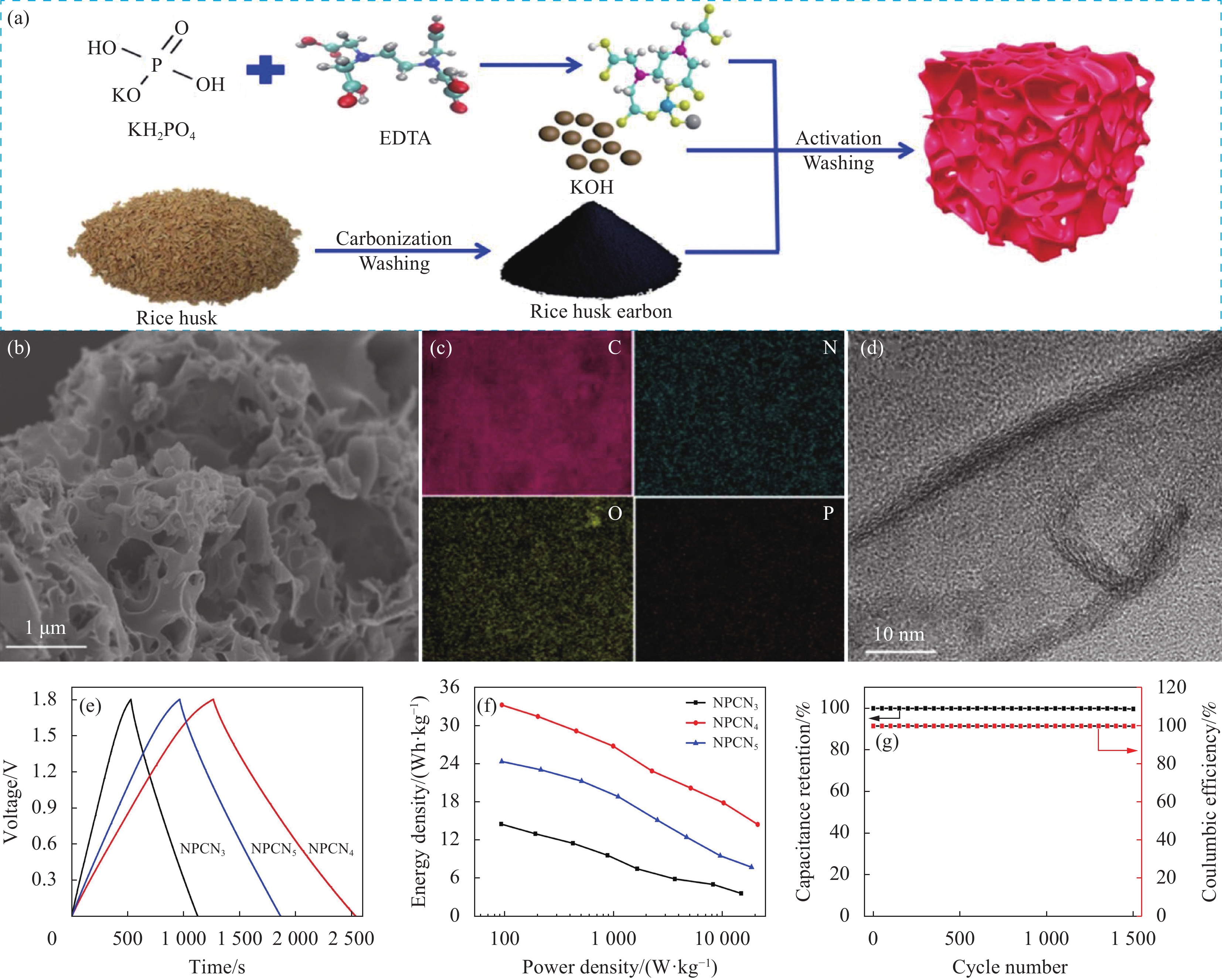

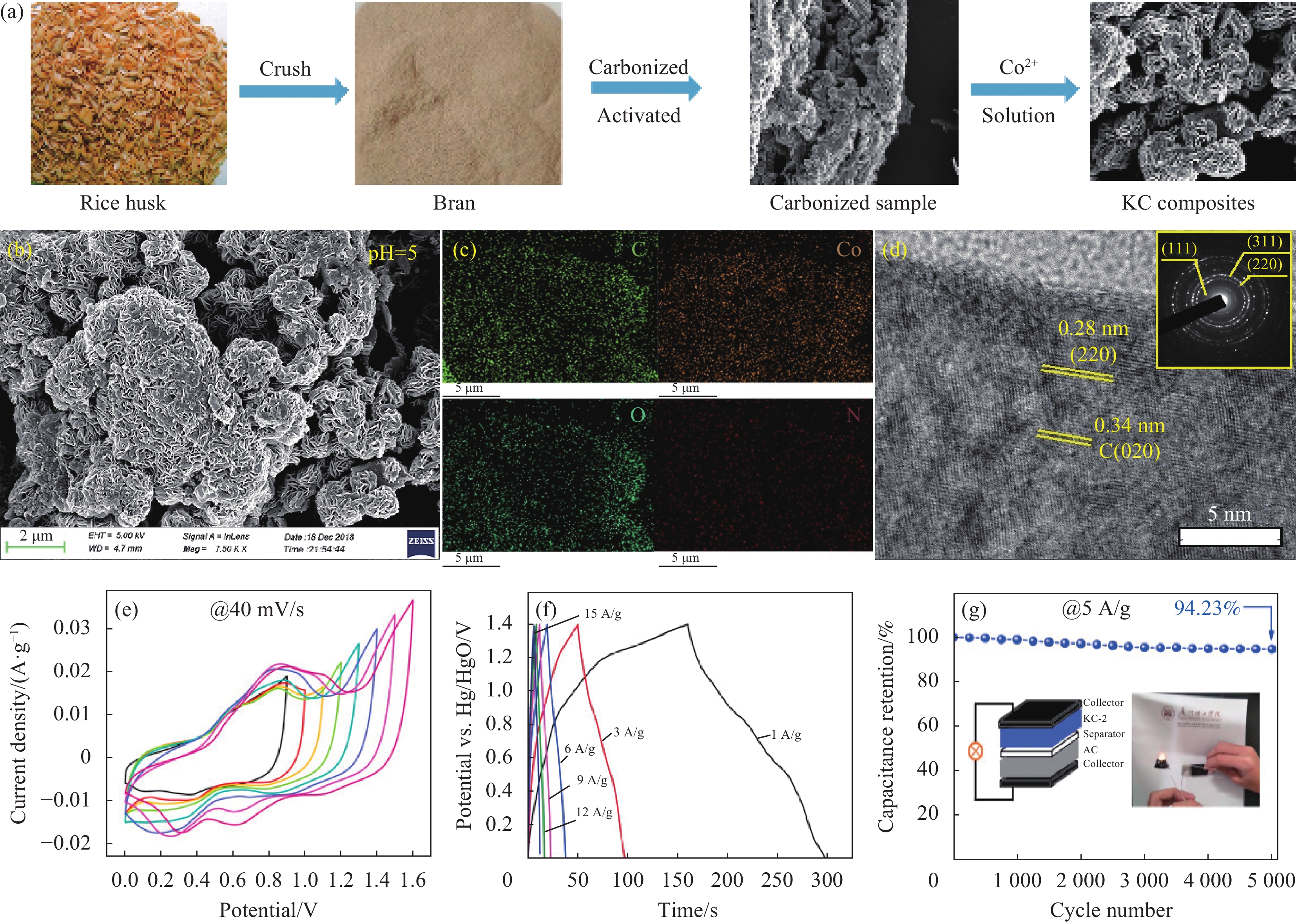

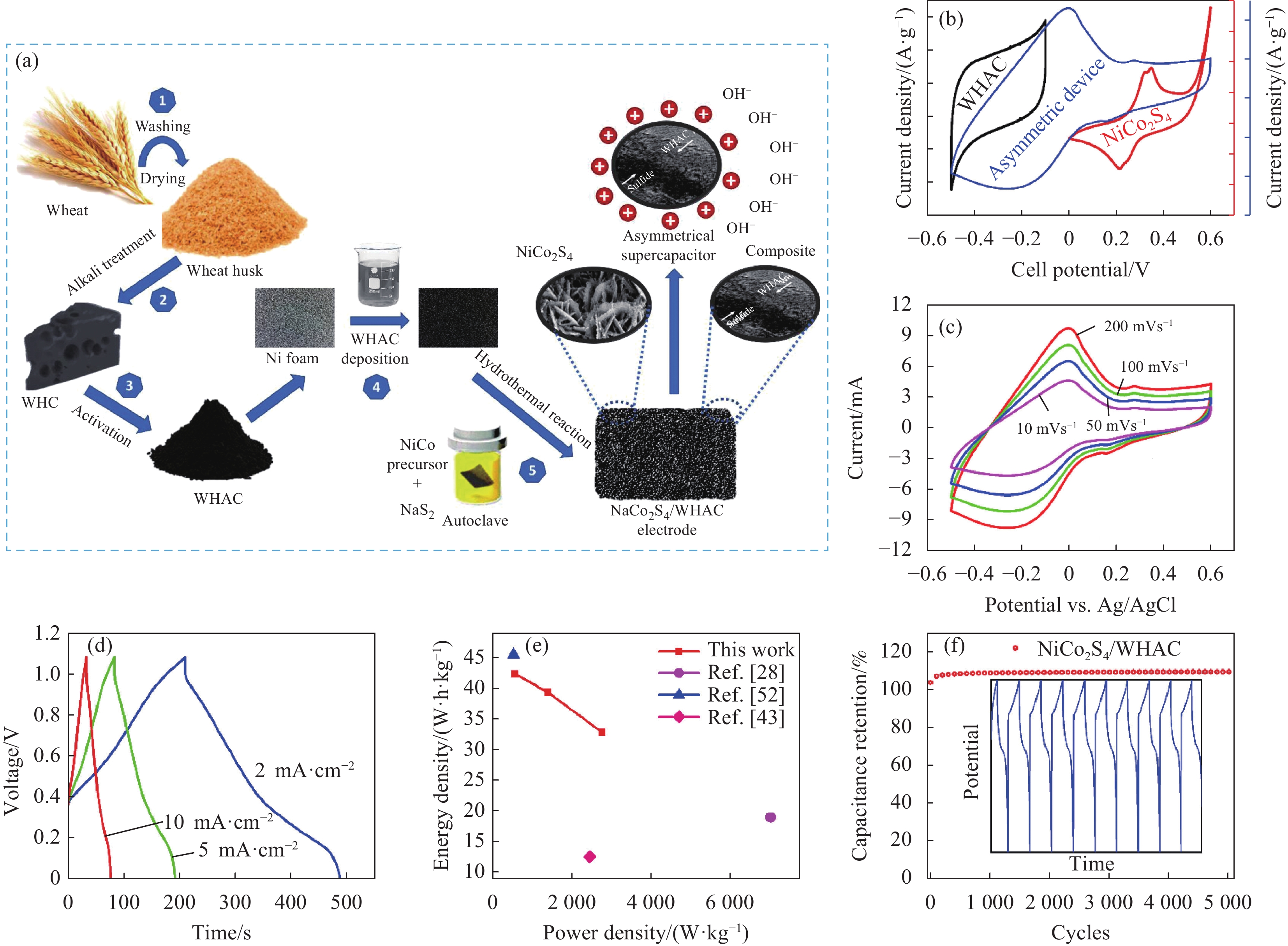

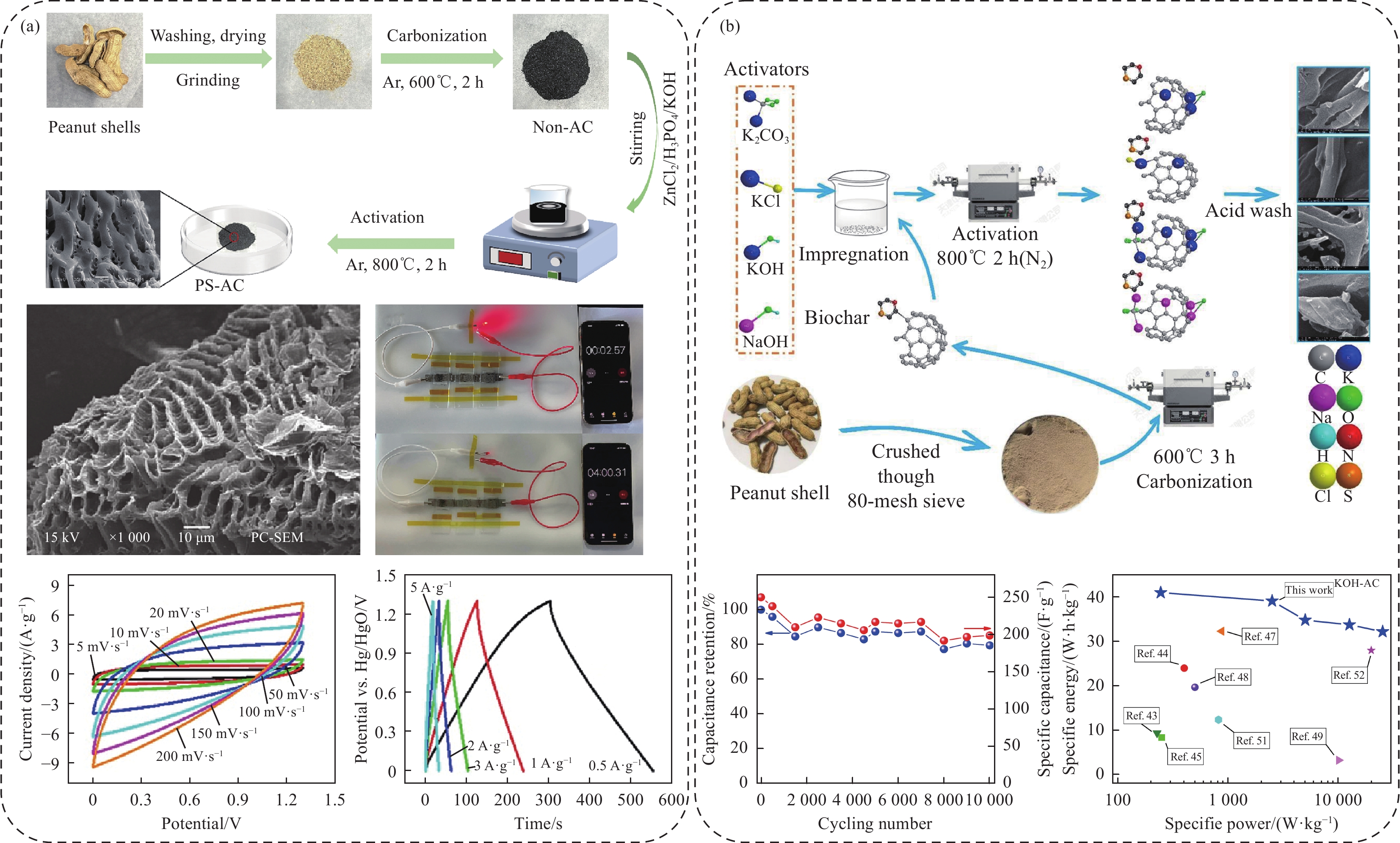

结果1、粮食作物衍生碳材料:粮食作物作为人类主要的食物来源,种类繁多、种植广泛,产量巨大。将其制成超级电容器电极材料不仅有利于离子与电子的传输,还易于实现杂原子掺杂。但由于粮食作物废弃物种类繁杂,材质不均匀,在实际研究和应用中仍存在一些挑战。将生物质与其他材料复合可制备复合电极材料,但复合材料存在成本高,制备条件难调控的缺点,未来还需进一步研究。2、坚果壳衍生碳材料:坚果壳质地坚硬,固定碳含量高,灰分低,且富含醛基、羟基、羧基等活性基团,是一种生产电极材料的优质资源。目前,坚果壳衍生碳材料主要通过高温活化法制得,常用的活化剂主要为碱、酸、盐类,如KOH、HPO、KCl、ZnCl等,单活化剂制备碳材料方法简便,效果良好可行性高。除单活化剂活化法,还存在双活化剂(HPO与KOH、Zn(NO)与KOH)活化法,双活化剂之间的协同作用可以使制备的碳材料具有更丰富的孔隙分布,不同尺寸孔隙之间的协同作用可使得材料表现出良好的电化学性能。3、果皮衍生碳材料:果皮来源广、品种多、产量大,富含纤维素、果胶,是制备碳电极材料的理想材料。果皮衍生碳材料蕴含独特的三维孔道结构且富含不同杂原子(N、O、P、S、B),电化学性能良好。将果皮衍生碳材料与导电聚合物、过渡金属氧化物复合,电容性能更佳,但制备成本,时间较长,同时材料的循环稳定性能会受到一定影响。

结论本文综述了近年来国内外植物衍生多孔碳在超级电容器中的应用及研究进展,归纳总结了不同类别植物衍生多孔碳材料的制备方法、掺杂方法及电化学性能。尽管通过活化和表面性质调控改性,能提高植物衍生多孔碳材料的电化学性能,但还存在以下不足:离子传输内阻大、孔径分布难调控、制备过程较复杂。尽管植物衍生多孔碳材料在超级电容器中的应用前景广阔,但仍面临一些挑战,如提高能量密度、降低内阻、增强电导率以及实现规模化生产等。未来的研究将聚焦于开发新的制备技术、探索新型生物质原料以及改进现有材料的性能。

-

超级电容器是一种高效能、充放电循环稳定的绿色的能源储存器件,因其比传统的蓄电池具有更长的使用寿命、更优的可逆充放电效能以及更低的循环损耗而受到了全世界的极大关注。影响超级电容器的生产成本和性能的关键因素是电极材料。植物衍生多孔碳作为一种常用的高比表面积材料,由于其成本低、性能稳定,在结构和形貌方面得到了广泛的科学研究。生物质碳是一系列具有复杂结构和丰富形态的碳基材料的总和,由于其良好的电导率、稳定的化学循环和优良的电化学特性等特有性质,在能量储存领域包括超级电容器方面展示出了庞大的潜在应用价值。本文综述了近年来国内外植物衍生多孔碳用于超级电容器电极材料的研究进展,归纳总结了不同类别植物衍生多孔碳材料的孔结构、表面官能团对其电化学性能的影响规律,并对植物衍生多孔碳电极材料在超级电容器领域中所面临的挑战与发展前景进行了展望。

各种植物前驱体用作超级电容器的电极材料

下载:

下载: