Microstructure and mechanical properties of Ni-rich TiNiZr alloy associated with repeated cold-rolling and annealing

-

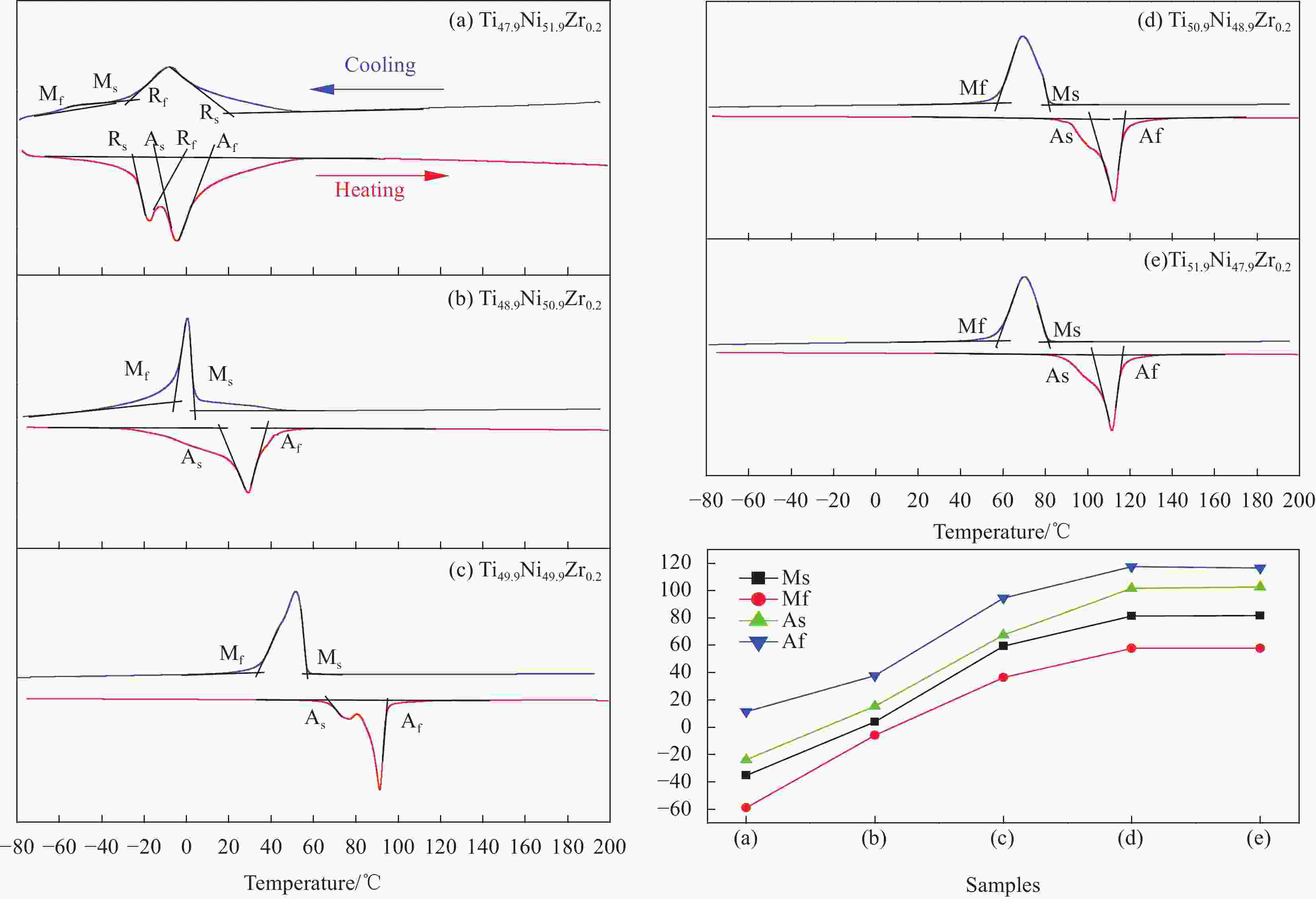

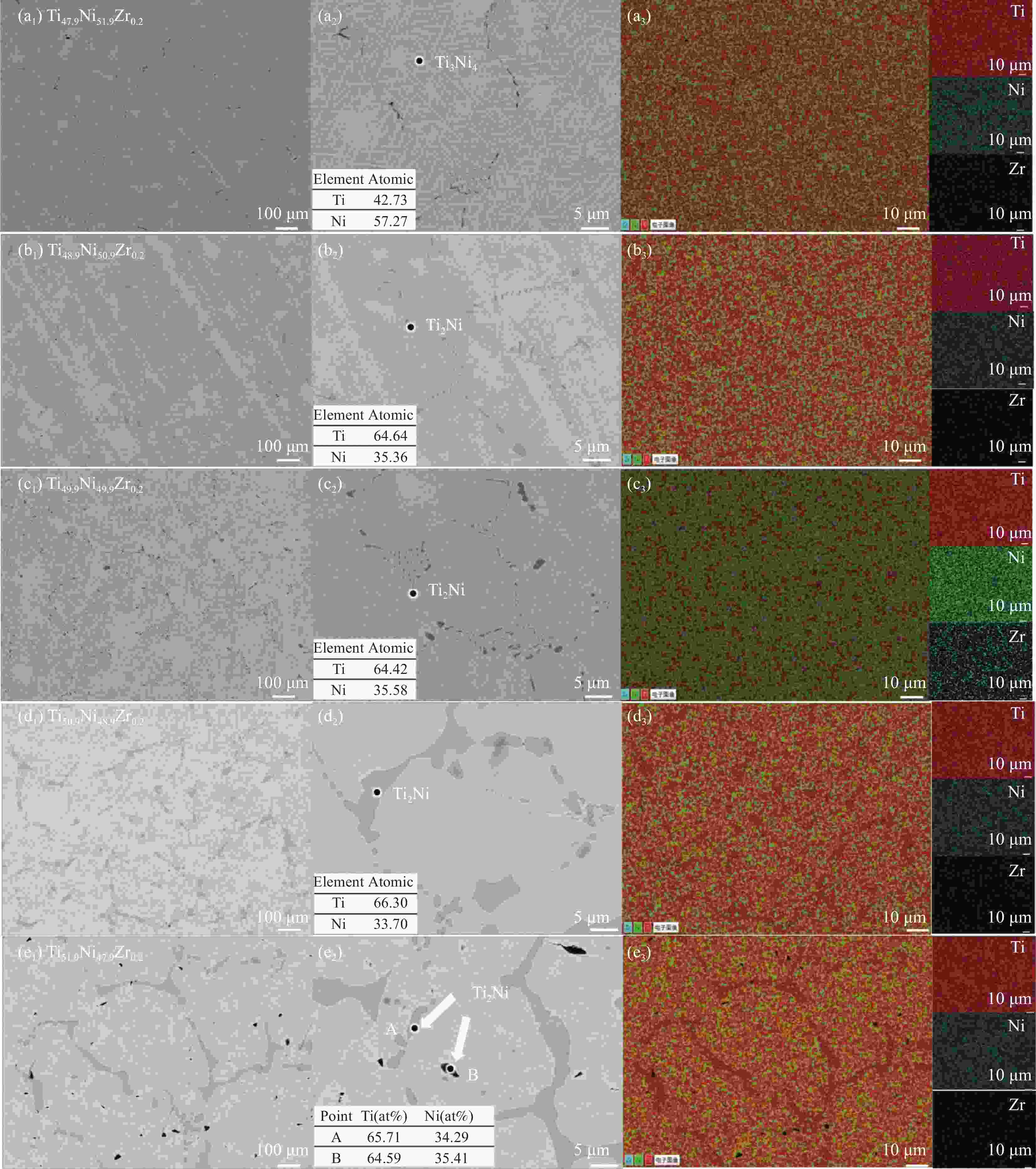

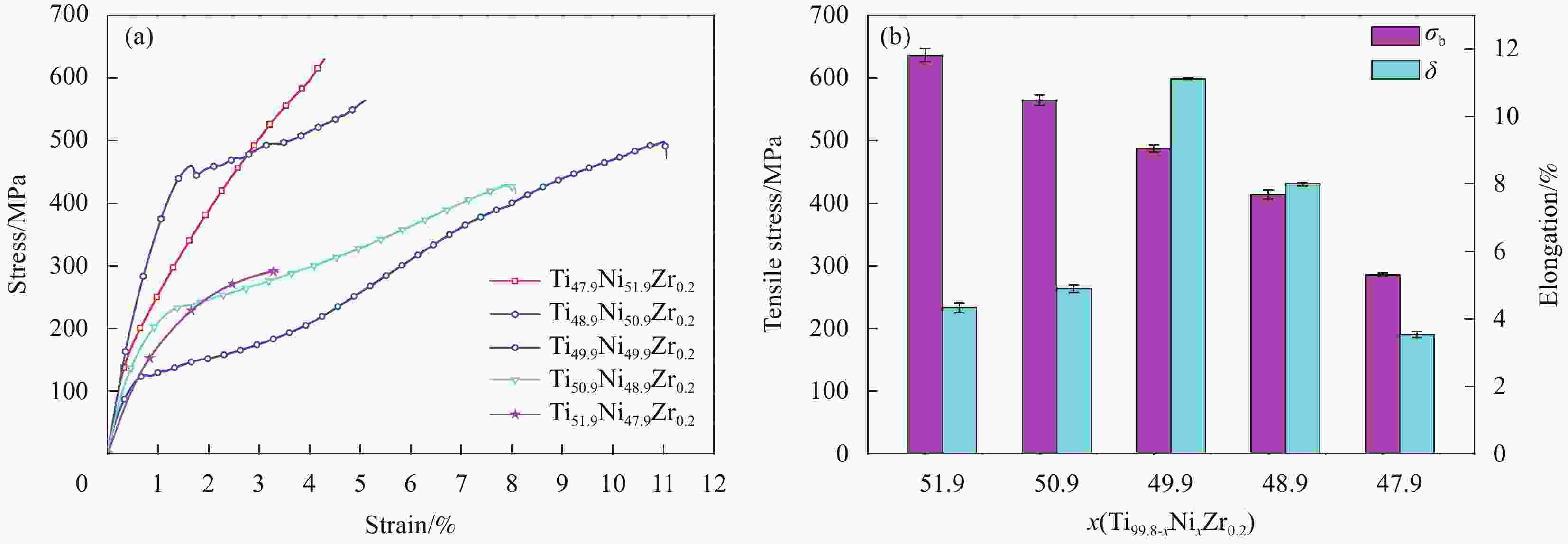

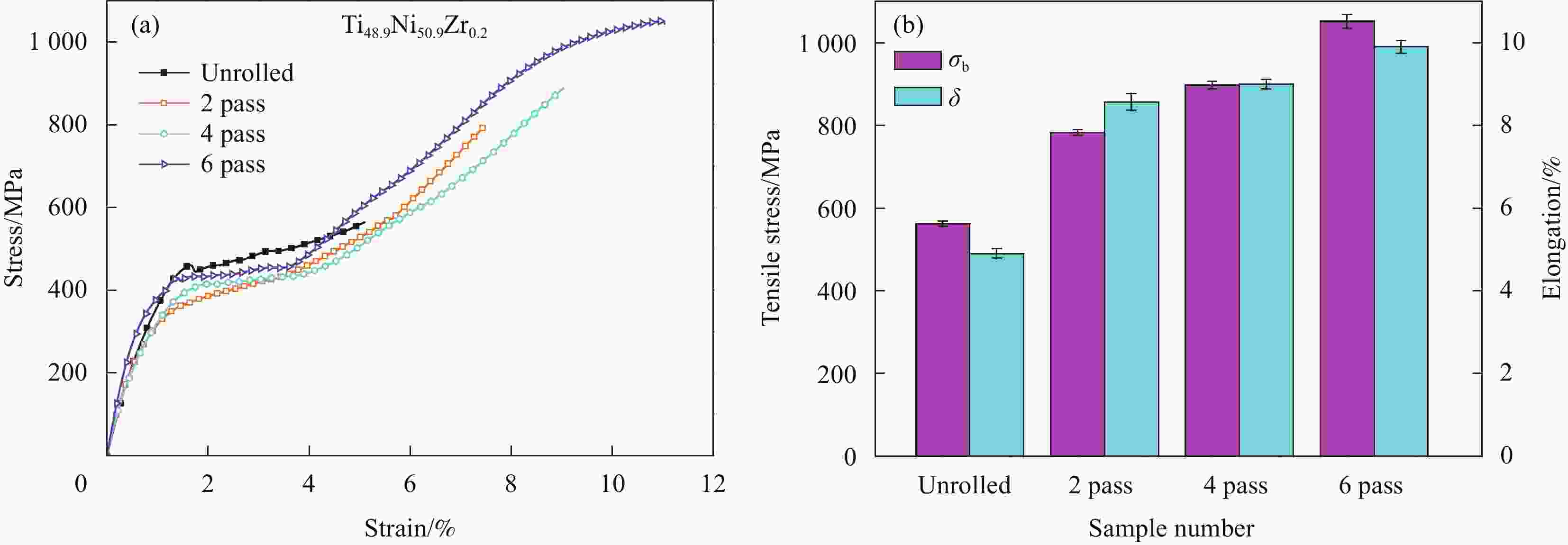

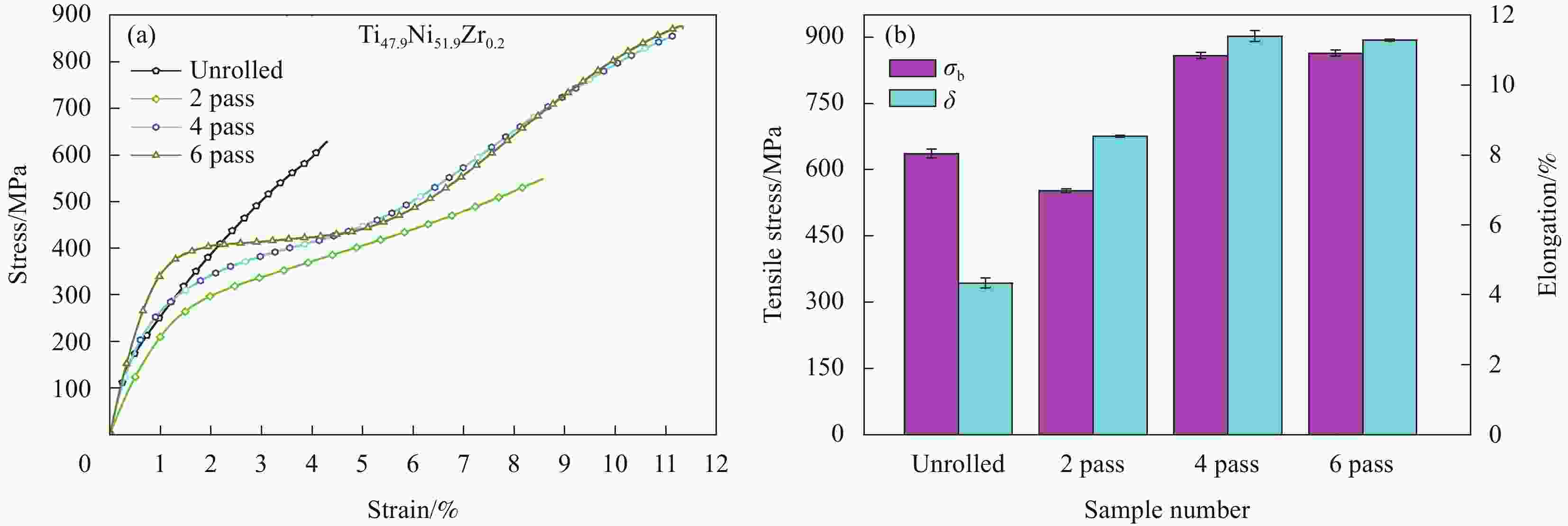

摘要: TiNi形状记忆合金具有优异的功能特性和结构特性,在多种领域有着明确的目标需求。本文聚焦B2结构奥氏体富镍 TiNi合金,拟通过冷轧退火循环调控TiNi合金微观结构,以期提升合金较低的力学强度和塑性形变能力。系统考察了Ti48.9Ni50.9Zr0.2和Ti47.9Ni51.9Zr0.2合金力学性能和微观结构与冷轧形变以及再结晶退火之间的依赖关系。拉伸力学性能测试表明,冷轧退火循环可显著提升合金综合力学性能,其中Ti48.9Ni50.9Zr0.2合金6道次冷轧退火后抗拉强度从未轧制样品的550 MPa提升至1070 MPa,断后伸长率从4.9%增加至10.0%。通过EBSD、SEM和TEM微观结构观察可以发现,合金多道次冷轧退火后,形变组织和再结晶组织交替变化,合金晶粒显著细化,发生了明显的择优取向,合金织构进一步增强。析出相Ti2Ni和Ti3Ni4破碎细化,纳米级Ti3Ni4与基体间有着良好的晶格匹配性。此外,合金中出现了应力诱发的马氏体以及析出相附近大量高密度位错。合金力学性能与材料微观结构密切相关,强度和塑性提升机制可通过细晶强化、位错强化、沉淀强化和织构强化来理解。Abstract: TiNi shape memory alloys have clear target demand in a variety of fields owing to their excellent structural and functional properties. In this paper, focusing on B2 structural austenitic Ni-rich TiNi alloys, it is proposed to modulate the microstructure of the TiNi alloys through repeated cold rolling annealing, with an expectation to enhancing the lower mechanical strength and plastic deformation ability of the alloys. The dependence of the mechanical properties and microstructure of Ti48.9Ni50.9Zr0.2 and Ti47.9Ni51.9Zr0.2 alloys on cold rolling deformation and recrystallization annealing was systematically investigated. The tensile mechanical property tests showed that the repeated cold rolling annealing could significantly enhance the overall mechanical properties of the alloys, in which the tensile strength of Ti48.9Ni50.9Zr0.2 alloy is increased from 550 MPa in the unrolled samples to 1070 MPa after 6 passes of cold rolling annealing, and the elongation after fracture has grown from 4.9% to 10.0%. The EBSD, SEM and TEM microstructural observation reveals that the deformation and recrystallization structures of the alloy change alternately after multi-pass cold rolling and annealing, and the alloy grains are significantly refined and undergo an obvious preferred grain orientation. In addition, the basal texture of the alloy is further enhanced. The Ti2Ni and Ti3Ni4 precipitates were broken and refined during cold deformation, in which the nano-sized Ti3Ni4 precipitate exhibits a favorable matching with matrix. Furthermore, stress-induced martensite as well as a large number of high-density dislocations in the vicinity of the precipitation phases appeared in the alloy. The mechanical properties of alloys are strongly related to the microstructure, and the strengthening mechanisms can be understood by grain refinement strengthening, dislocation strengthening, precipitation strengthening and texture strengthening.

-

Key words:

- TiNi alloy /

- cold-rolled deformation /

- microstructure /

- mechanical properties /

- Ti3Ni4 precipitates

-

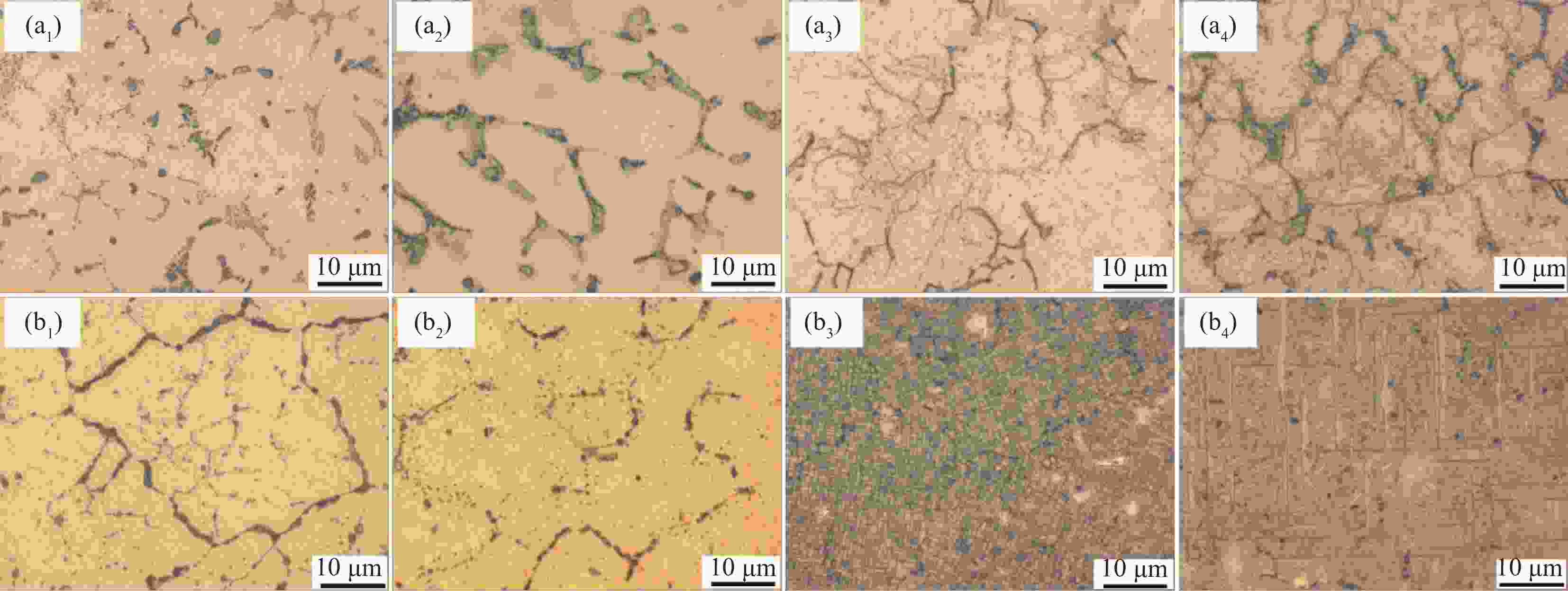

图 6 不同退火时间Ti47.9Ni51.9Zr0.2 (a) 和 Ti48.9Ni50.9Zr0.2 (b)合金金相微观结构:(a1,b1) 0 min; (a2,b2) 60 min; (a3,b3) 150 min; (a4,b4) 600 min.

Figure 6. Metallographic microstructure corresponding to various annealing time of Ti47.9Ni51.9Zr0.2 (a) and Ti48.9Ni50.9Zr0.2 (b): (a1,b1) 0 min; (a2,b2) 60 min; (a3,b3) 150 min; (a4,b4) 600 min

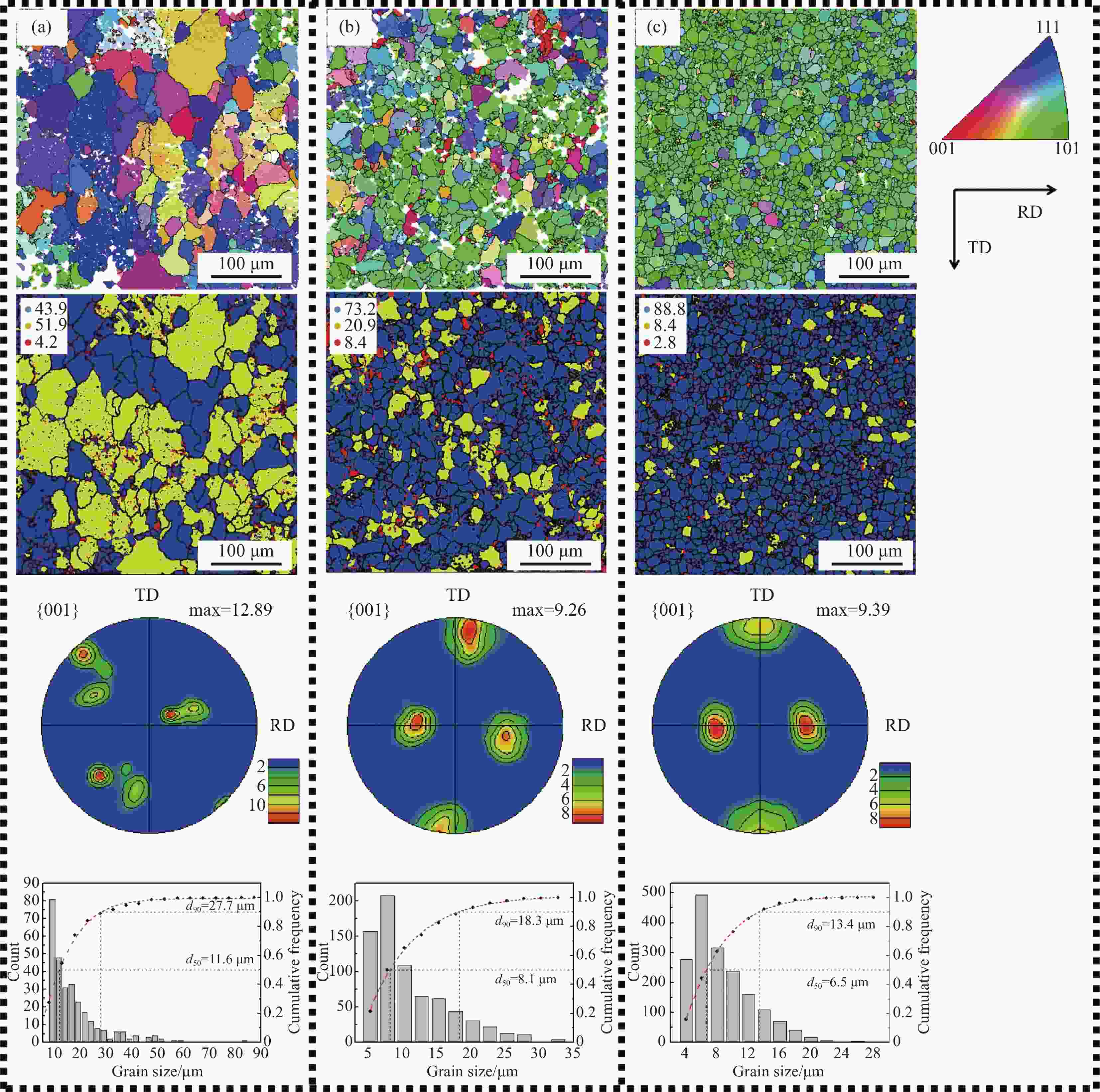

图 11 不同道次冷轧Ti48.9Ni50.9Zr0.2合金反极图(IPF),再结晶体积分数分布图(其中蓝色区域为再结晶晶粒区域、黄色区域为晶粒亚结构区域、红色区域为变形区域,各部分体积分数见图中左上角),{001}面极图和晶粒分布图: (a) 2道次; (b) 4道次;(c) 6道次

Figure 11. Inverse pole figure(IPF) maps, recrystallized fraction component maps (the volume fractions (%) of the recrystallized (blue),substructured (yellow) and deformed (red) regions are given at the top left corners), {001} pole figures and grain size distribution maps of of Ti48.9Ni50.9Zr0.2 alloys subjected to different cold rolling passes: (a) two pass; (b) four pass; (c) six pass

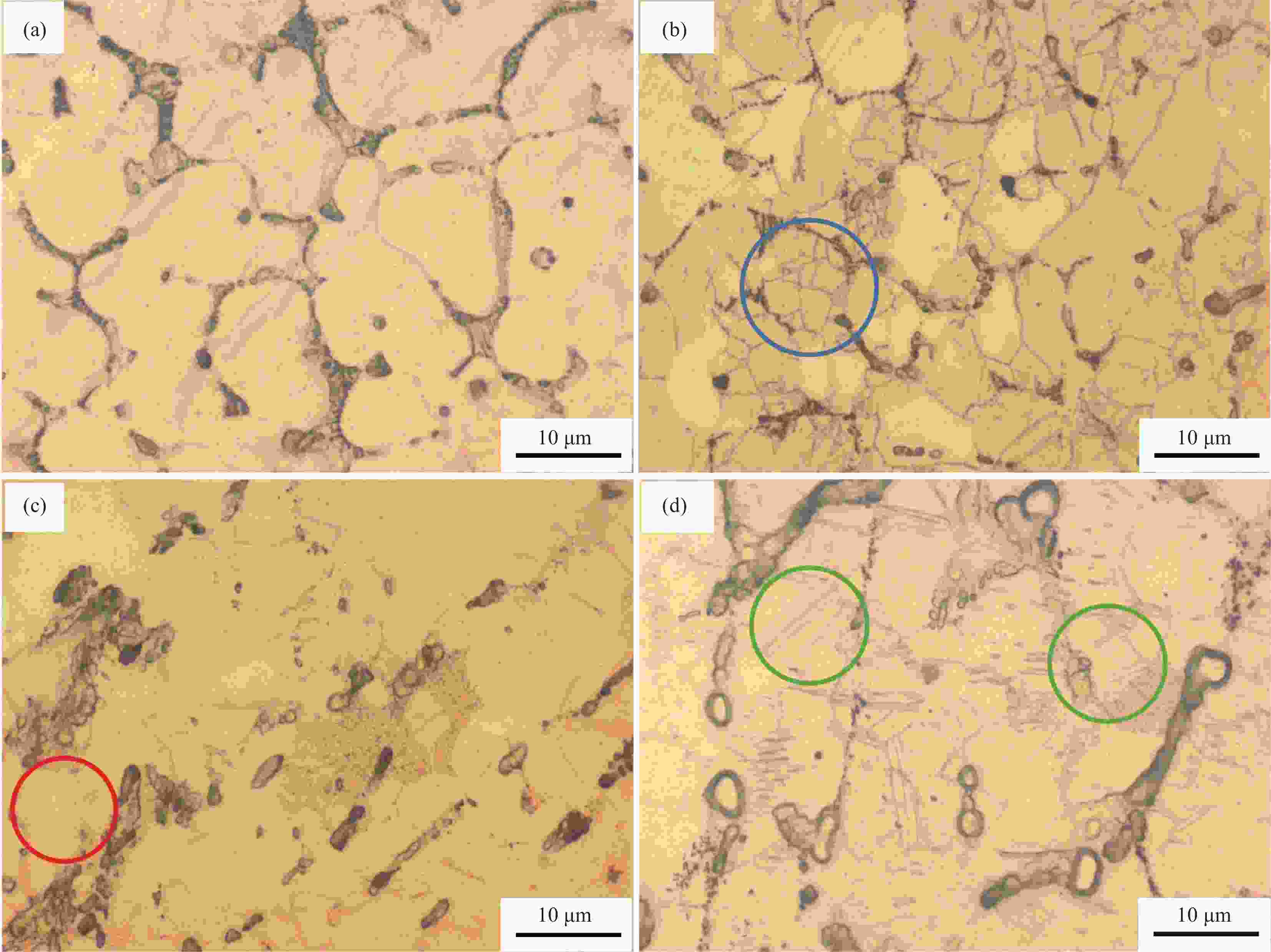

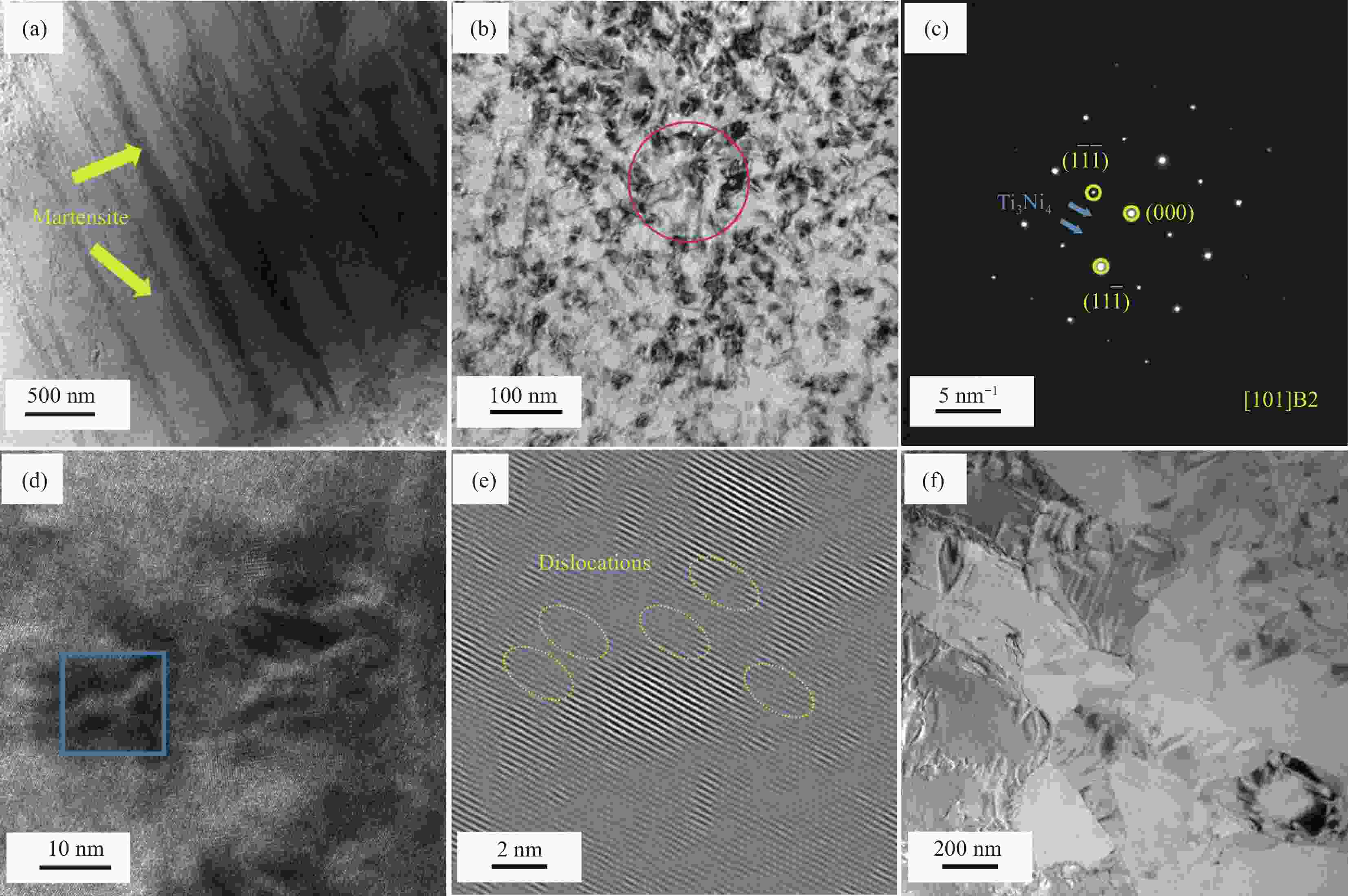

图 12 未冷压 Ti48.9Ni50.9Zr0.2合金TEM微观结构和选区电子衍射(SADP):(a) 低倍率明场图像; (b) 高倍率明场图像; (c) B2基体和Ti2Ni析出相高分辨界面图像; (d) B2基体和Ti3Ni4析出相高分辨界面图像; (e) 图(b)中A区域电子衍射图;(f) 图(b)中B区域电子衍射图

Figure 12. Microstructure of Ti48.9Ni50.9Zr0.2 alloy after solution treating and aging: the bright-field images and corresponding selected area diffraction pattern(SADP): (a) low magnification image; (b) high magnification image of (a);(c)HRTEM images of (b) showing the interface between B2 matrix and Ti2Ni; (d)HRTEM images of (b) showing the interface between B2 matrix and Ti3Ni4; (e) the SADP image of area A in (b);(f) the SADP image of area B in (b)

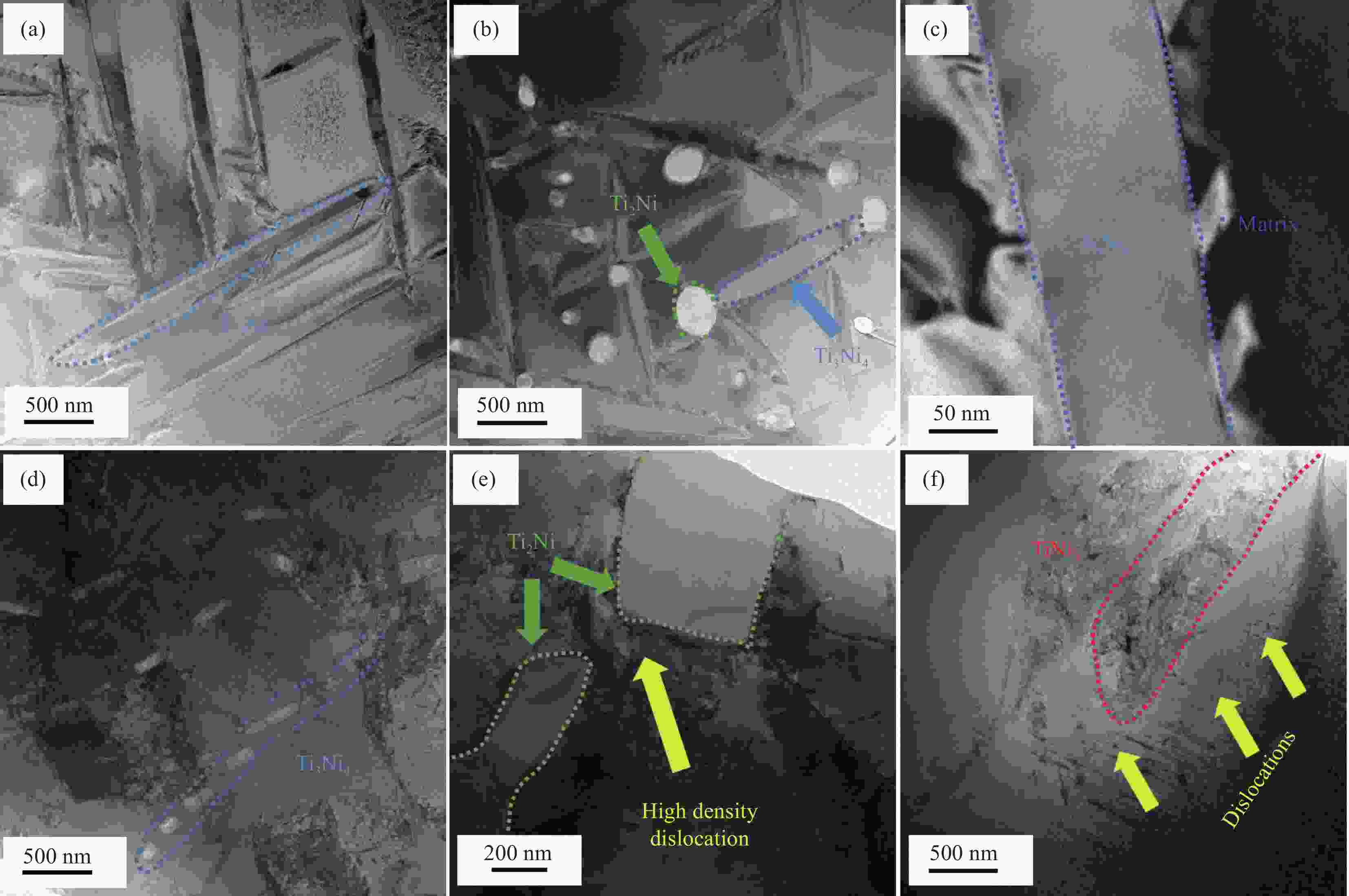

图 13 6道次冷轧后Ti48.9Ni50.9Zr0.2合金断口附近TEM微观结构: (a,b) 微观结构明场像; (c) (b)图中红色圆形区域电子衍射图; (d) (b)图中高分辨图像; (e) (d)图中蓝色区域反傅里叶变换图; (f) 亚微米结构明场像

Figure 13. TEM microstructures near fracture surface of six pass cold-rolled Ti48.9Ni50.9Zr0.2 alloy: (a,b) the bright-field images showing the microstructure of six pass sample; (c)the SADP image of area within red circle (b); (d) HRTEM image of (b); (e) IFFT image of blue area in (d); (f) the bright-field images showing the submicron structure

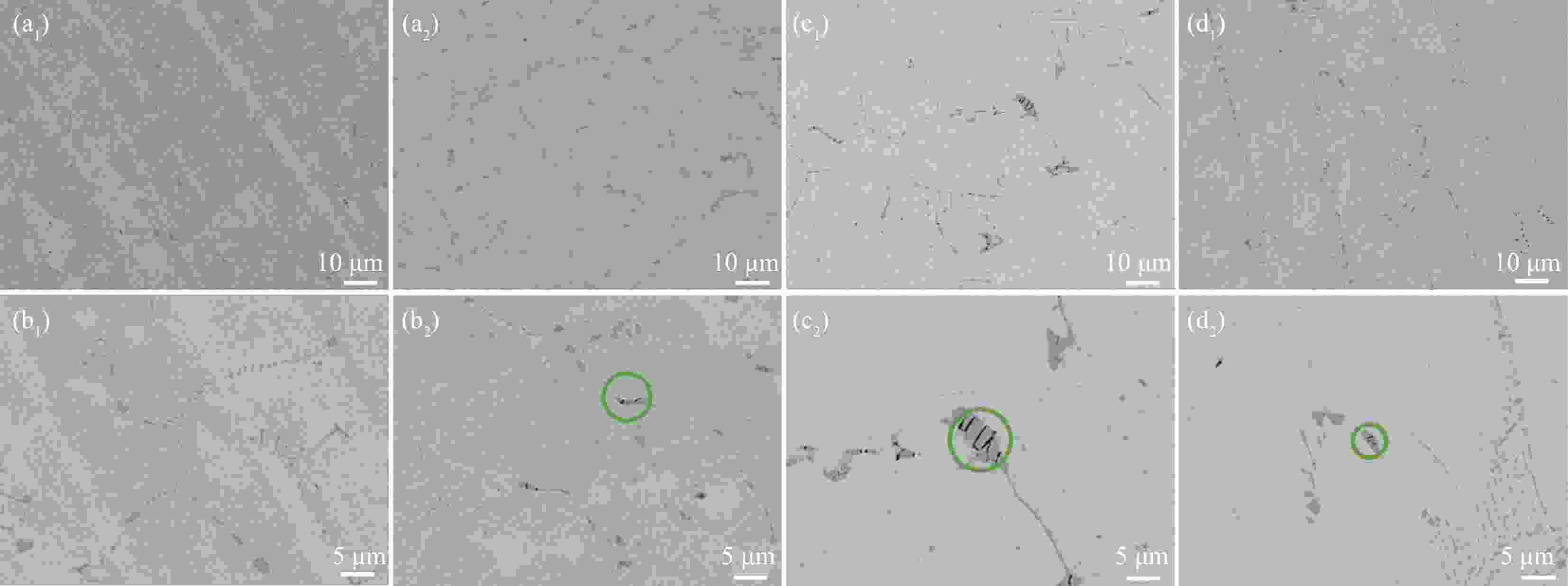

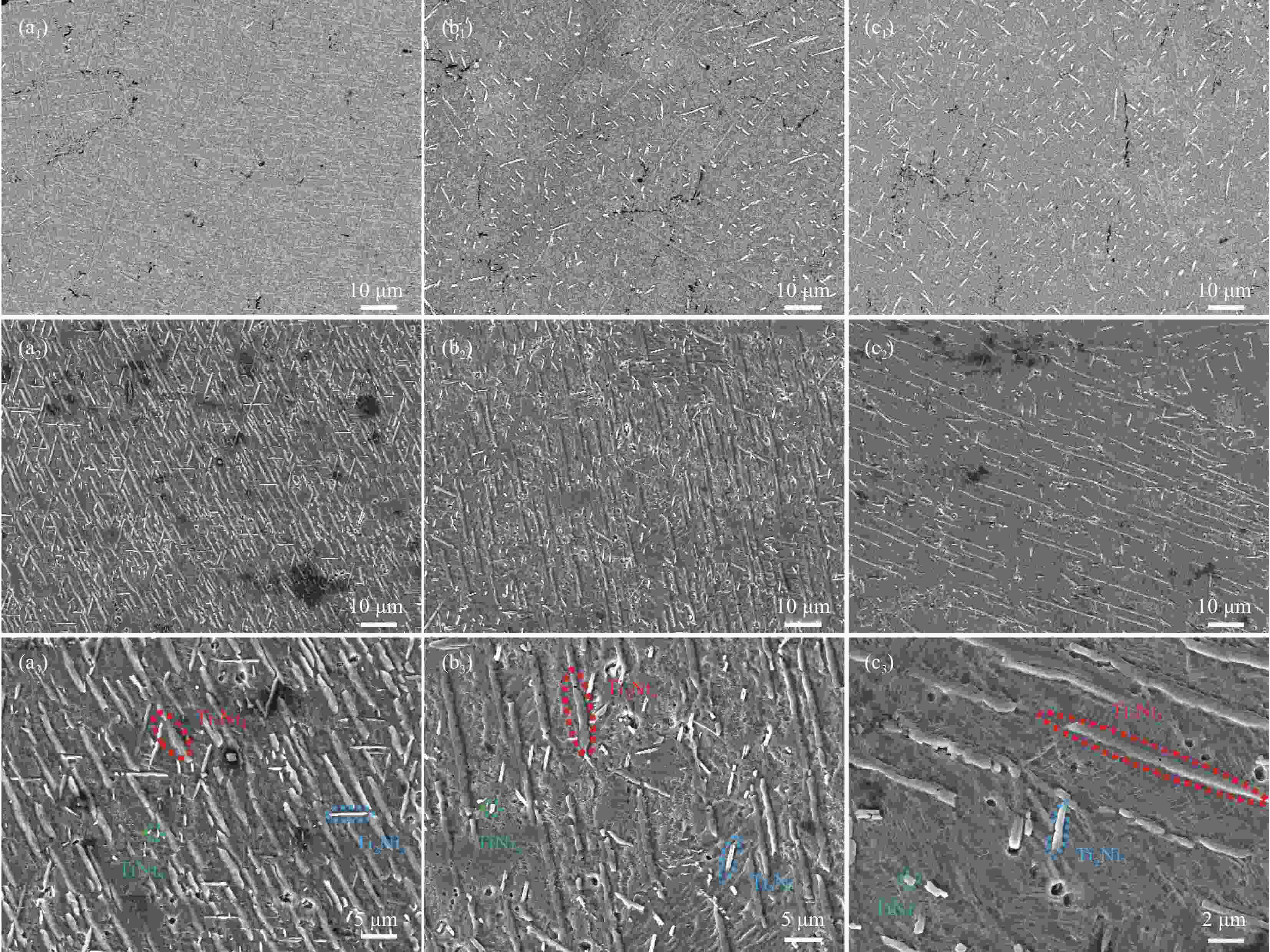

图 14 不同道次冷轧退火后Ti47.9Ni51.9Zr0.2合金SEM微观结构图像:(a) 2道次; (b) 4道次; (c) 6道次,其中(a1-c1)为背散射模式图像,(a2-c2)为二次电子模式图像,(a3-c3)为(a2-c2)的高倍率图像

Figure 14. SEM images of Ti47.9Ni51.9Zr0.2 alloys subjected to different rolling passes and annealing: (a) two pass; (b) four pass; (c) six pass, where (a1-c1) images is in the backscattering pattern; (a2-c2) images is in the secondary electron mode; (a3-c3) is the high magnification images of (a2-c2):

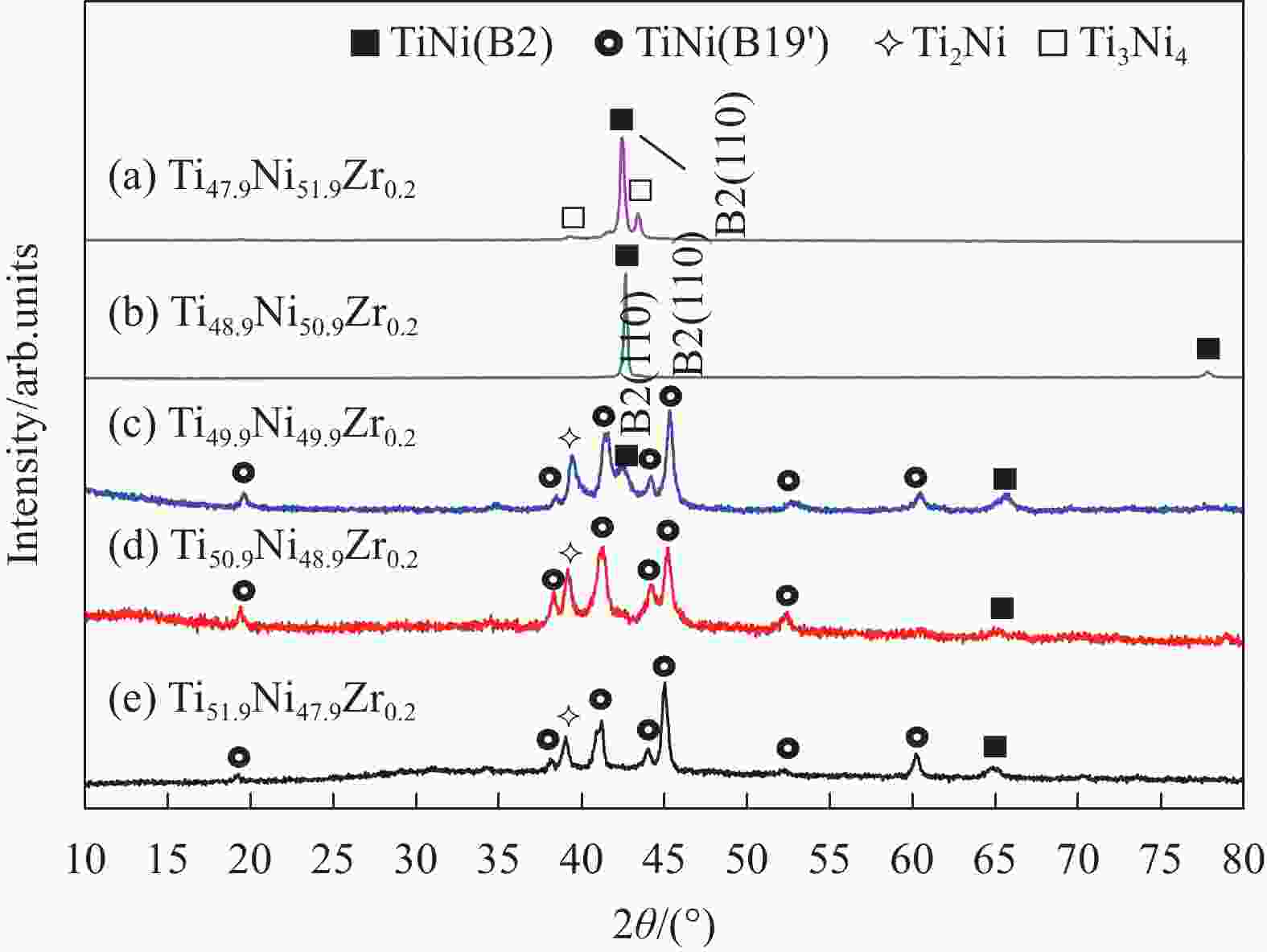

表 1 Ti99.8-xNixZr0.2 (x= 51.9, 50.9, 49.9, 48.9, 47.9)合金EDS 化学组分

Table 1. EDS chemical composition of the Ti99.8-xNixZr0.2 (x= 51.9, 50.9, 49.9, 48.9, 47.9) alloys

Samples Ti(at%) Ni(at%) Zr(at%) Ti47.9Ni51.9Zr0.2 48.10 51.65 0.25 Ti48.9Ni50.9Zr0.2 49.19 50.61 0.20 Ti49.9Ni49.9Zr0.2 49.87 49.94 0.2 Ti50.9Ni48.9Zr0.2 51.09 48.64 0.26 Ti51.9Ni47.9Zr0.2 52.08 47.58 0.35 -

[1] OTSUKA K, REN X. Physical metallurgy of Ti–Ni-based shape memory alloys[J]. Progress in Materials Science, 2005, 50: 511-678. doi: 10.1016/j.pmatsci.2004.10.001 [2] CHENG Y, TING Y Y, CHEN C H. Superelasticity and elastocaloric effect of Ti-rich TiNi shape memory ribbon[J]. Materials Science and Engineering A, 2022, 855: 143945. doi: 10.1016/j.msea.2022.143945 [3] PASTOR F, RODRÍGUEZ J C, BARRERA J M, et al. Effect of Fluoride Content of Mouthwashes on Superelastic Properties of NiTi Orthodontic Archwires[J]. Materials, 2022, 15(19): 6592. doi: 10.3390/ma15196592 [4] LUO S D, QIAN M. Microwave processing of titanium and titanium alloys for structural, biomedical and shape memory applications: Current status and challenges[J]. Materials and Manufacturing Processes, 2018, 33(1): 35-49. doi: 10.1080/10426914.2016.1257800 [5] CHEN Y Y, MOLNÁROVÁ O, TYC O, et al. Recoverability of large strains and deformation twinning in martensite during tensile deformation of NiTi shape memory alloy polycrystals[J]. Acta Materialia, 2019, 180: 243-259. doi: 10.1016/j.actamat.2019.09.012 [6] LU B W, CUI X F, DONG M L, et al. The Influence of Solution Treatments on the Microstructure, Phase Transformation Behavior, and Superelastic Characteristics of Nitinol Synthesized by Plasma Arc Deposition[J]. Journal of Materials Engineering and Performance, 2020, 29(4): 2491-2498. doi: 10.1007/s11665-020-04802-0 [7] GUSEV D E, KOLLEROV M Yu, POPOV A A. Effect of the Volume Fraction of Ti2Ni and Aging on the Structure and Properties of Alloys Based on Titanium Nickelide[J]. Metal Science and Heat Treatment, 2018, 60(1): 72-79. [8] FAN Q C, ZHANG Y H, WANG Y Y, et al. Influences of transformation behavior and precipitates on the deformation behavior of Ni-rich NiTi alloys[J]. Materials Science and Engineering A, 2017, 700: 269-280. doi: 10.1016/j.msea.2017.05.107 [9] QIN Q H, PENG H B, FAN Q C, et al. Effect of second phase precipitation on martensitic transformation and hardness in highly Ni-rich NiTi alloys[J]. Journal of Alloys and Compounds, 2018, 739: 873-881. doi: 10.1016/j.jallcom.2017.12.128 [10] LIU S, LIN Y, WANG G C, et al. Effect of Varisized Ni4Ti3 precipitate on the phase transformation behavior and functional stability of Ti-50.8 at. % Ni alloys[J]. Materials Characterization, 2021, 172: 110832. doi: 10.1016/j.matchar.2020.110832 [11] BHAGYARAJ J, RAMAIAH K V, SAIKRISHNA C N, et al. Behavior and effect of Ti2Ni phase during processing of NiTi shape memory alloy wire from cast ingot[J]. Journal of Alloys and Compounds, 2013, 581: 344-351. doi: 10.1016/j.jallcom.2013.07.046 [12] YI X Y, SUN K S, GAO W H, et al. The precipitation behaviors, martensite transformation and superelasticity in the aged Ni-rich Ti Ni alloy with the assist of super-high stress[J]. Intermetallics, 2019, 104: 8-15. doi: 10.1016/j.intermet.2018.10.015 [13] TIMOFEEVA E E, PANCHENKO E Y, ZHERDEVA M V, et al. Effect of one family of Ti3Ni4 precipitates on shape memory effect, superelasticity and strength properties of the B2 phase in high-nickel [001]-oriented Ti-51.5 at. %Ni single crystals[J]. Materials Science and Engineering A, 2022, 832: 142420. doi: 10.1016/j.msea.2021.142420 [14] KAYA I, KARACA H E, NAGASAKO M, et al. Effects of aging temperature and aging time on the mechanism of martensitic transformation in nickel-rich NiTi shape memory alloys[J]. Materials Characterization, 2020, 159: 110034. doi: 10.1016/j.matchar.2019.110034 [15] ZHANG X N, XIA B Y, SONG J, et al. Effects of equal channel angular extrusion and aging treatment on R phase transformation behaviors and Ti3Ni4 precipitates of Ni-rich TiNi alloys[J]. Journal of Alloys and Compounds, 2011, 509(21): 6296-6301. doi: 10.1016/j.jallcom.2011.03.062 [16] TIMOFEEVA E E, SURIKOV N YU, TAGILTSEV A I, et al. The superelasticity and shape memory effect in Ni-rich Ti-51.5Ni single crystals after one-step and two-step ageing[J]. Materials Science and Engineering A, 2020, 796: 140025. doi: 10.1016/j.msea.2020.140025 [17] CHEN H, XIAO F, LIANG X, et al. Improvement of the stability of superelasticity and elastocaloric effect of a Ni-rich Ti-Ni alloy by precipitation and grain refinement[J]. Scripta Materialia, 2019, 162: 230-234. doi: 10.1016/j.scriptamat.2018.11.024 [18] SERGUEEVA A V, SONG C, VALIEV R Z, et al. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing[J]. Materials Science and Engineering A, 2003, 339(1): 159-165. [19] KARELIN R, KOMAROV V, CHERKASOV V, et al. Structure and Properties of TiNi Shape Memory Alloy after Quasi-Continuous Equal-Channel Angular Pressing in Various Aged States[J]. Metals, 2023, 13(11): 1829. doi: 10.3390/met13111829 [20] YI X Y, GAO W H, WANG H Z, et al. Dependence of aging parameters on precipitation behavior, martensitic transformation and mechanical properties of the aged Ni-Ti alloy under super high pressure[J]. Materials Science and Engineering A, 2018, 736: 354-363. doi: 10.1016/j.msea.2018.09.019 [21] LUO J F, MAO S C, HAN X D, et al. Crystallographic mechanisms of fracture in a textured polycrystalline TiNi shape memory alloy[J]. Journal of Applied Physics, 2007, 102(4): 043526. doi: 10.1063/1.2764215 [22] POLETIKA T M, GIRSOVA S L, LOTKOV A L, et al. Structure and Multistage Martensite Transformation in Nanocrystalline Ti-50.9Ni Alloy[J]. Matals, 2021, 11(8): 1262. [23] KHALIL-ALLAFI J, DLOHUY A, EGGELER G. Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations[J]. Acta Materialia, 2002, 50(17): 4255-4274. doi: 10.1016/S1359-6454(02)00257-4 [24] NAJI H, KHALIL-ALLAFI J, KHALILI V. Microstructural characterization and quantitative phase analysis of Ni-rich NiTi after stress assisted aging for long times using the Rietveld method[J]. Materials Chemistry and Physics, 2020, 241: 122317. doi: 10.1016/j.matchemphys.2019.122317 [25] ZHANG J S, HAP S J, JIANG D Q, et al. In situ synchrotron high-energy X-ray diffraction study of microscopic deformation behavior of a hard-soft dual phase composite containing phase transforming matrix[J]. Acta Materialia, 2017, 130: 297-309. doi: 10.1016/j.actamat.2017.03.052 [26] LI X, YANG P, WANG L-N, et al. Orientational analysis of static recrystallization at compression twins in a magnesium alloy AZ31[J]. Materials Science and Engineering A, 2009, 517: 160-169. doi: 10.1016/j.msea.2009.03.045 [27] MAO S C, HAN X D, ZHANG Z H, et al. Microstructure and texture evolution of ultra-thin TiNi hot-rolled sheets studied by automated EBSD[J]. Materials Letters, 2005, 59: 3567-3571. doi: 10.1016/j.matlet.2005.06.029 [28] RYKLINA E P, POLYAKOVA K A, TABACHKOVA N YU, et al. Effect of B2 austenite grain size and aging time on microstructure and transformation behavior of thermomechanically treated titanium nickelide[J]. Journal of Alloys and Compounds, 2018, 764: 626-638. doi: 10.1016/j.jallcom.2018.06.102 [29] POLETIKA T M, GIRSOVA S L, LOTAOV A I. Ti3Ni4 precipitation features in heat-treated grain/subgrain nanostructure in Ni-rich TiNi alloy[J]. Intermetallics, 2020, 127: 106966. doi: 10.1016/j.intermet.2020.106966 [30] LAURSEN C M, PETER N J, GERSTEIN G, et al. Influence of Ti3Ni4 precipitates on the indentation-induced two-way shape-memory effect in Nickel-Titanium[J]. Materials Science and Engineering A, 2020, 792: 139373. doi: 10.1016/j.msea.2020.139373 [31] FAN Q C, ZHANG Y H, WANG Y Y, et al. Influences of transformation behavior and precipitates on the deformation behavior of Ni-rich NiTi alloys[J]. Materials Science and Engineering A, 2017, 700: 269-280. doi: 10.1016/j.msea.2017.05.107 [32] WU F F, CHEN H M, YANG Z K, et al. Investigation on the electronic structures, elastic and thermodynamic properties of TiNi, Ti2Ni and TiNi3 intermetallic compound[J]. Materials Today Communications, 2023, 34: 105273. doi: 10.1016/j.mtcomm.2022.105273 [33] SURESH S, KIM D-I, BHAUMIK S K, et al. Interrelation of grain boundary microstructure and texture in a hot rolled Ni-rich NiTi alloy[J]. Scripta Materialia, 2012, 66(8): 602-605. doi: 10.1016/j.scriptamat.2012.01.016 [34] SOHRABI M J, MIRZADEH H, SADEGHPOUR S, et al. Grain size dependent mechanical behavior and TRIP effect in a metastable austenitic stainless steel[J]. International Journal of Plasticity, 2023, 160: 103502. doi: 10.1016/j.ijplas.2022.103502 [35] ZHANG X L, YAN J H, LIU T, et al. Microstructural evolution and mechanical behavior of a novel heterogeneous medium Mn cold-rolled steel[J]. Materials Science and Engineering A, 2021, 800: 140344. doi: 10.1016/j.msea.2020.140344 [36] FRENZEL J, WIECZOREK A, OPAHLE I, et al. On the effect of alloy composition on martensite start temperatures and latent heats in Ni-Ti-based shape memory alloys[J]. Acta Materialia, 2015, 90: 213-231. doi: 10.1016/j.actamat.2015.02.029 [37] ZHANG J, CHEN T, LI W, et al. High temperature superelasticity realized in equiatomic Ti-Ni conventional shape memory alloy by severe cold rolling[J]. Materials and Design, 2020, 193: 108875. doi: 10.1016/j.matdes.2020.108875 [38] REN J, ZHANG Y, ZHAO D, et al. Strong yet ductile nanolamellar high-entropy alloys by additive manufacturing[J]. Nature, 2022, 608(7921): 62-68. doi: 10.1038/s41586-022-04914-8 [39] HE C, LI X, LIU Y J, et al. Localized dislocation interactions within slip bands and crack initiation in Mg-10Gd-3Y-0.3Zr alloy[J]. International Journal of Fatigue, 2021, 150: 106302. doi: 10.1016/j.ijfatigue.2021.106302 [40] GAY P B, HIRSCH P B, KELLY A. The estimation of dislocation densities in metals from X- ray data[J]. Acta Metallurgica, 1953, 3: 315-319. [41] HOLEC D, BOJDA O, DLOUHÝ A. Ni4Ti3 precipitate structures in Ni-rich NiTi shape memory alloys[J]. Materials Science and Engineering A, 2008, 481: 462-465. [42] YI X Y, GAO W H, WANG H Z, et al. Dependence of aging parameters on precipitation behavior, martensitic transformation and mechanical properties of the aged Ni-Ti alloy under super high pressure[J]. Materials Science and Engineering A, 2018, 736: 354-363. doi: 10.1016/j.msea.2018.09.019 [43] ADHARAPURAPU R R, JIANG F, VECCHIO K S. Aging effects on hardness and dynamic compressive behavior of Ti–55Ni (at. %) alloy[J]. Materials Science and Engineering A, 2010, 527: 1665-1676. doi: 10.1016/j.msea.2009.10.069 [44] YAN B Y, JIANG S Y, SUN D, et al. Zhang, Martensite twin formation and mechanical properties of B2 austenite NiTi shape memory alloy undergoing severe plastic deformation and subsequent annealing[J]. Materials Characterization, 2021, 178: 111273. doi: 10.1016/j.matchar.2021.111273 [45] LIMA M N D S, LOUREIRO R D C P, BÉREŠ M, et al. Influence of cold deformation on microstructure, crystallographic orientation and tensile properties of an experimental austenitic Fe-26Mn-0.4C steel[J]. Journal of Materials Research and Technology, 2022, 19: 7-19. doi: 10.1016/j.jmrt.2022.05.020 -

点击查看大图

点击查看大图

计量

- 文章访问数: 116

- HTML全文浏览量: 97

- 被引次数: 0

下载:

下载: