In-plane shear behavior characterization of unidirectional thermoset prepreg and its viscoelastic constitutive modeling

-

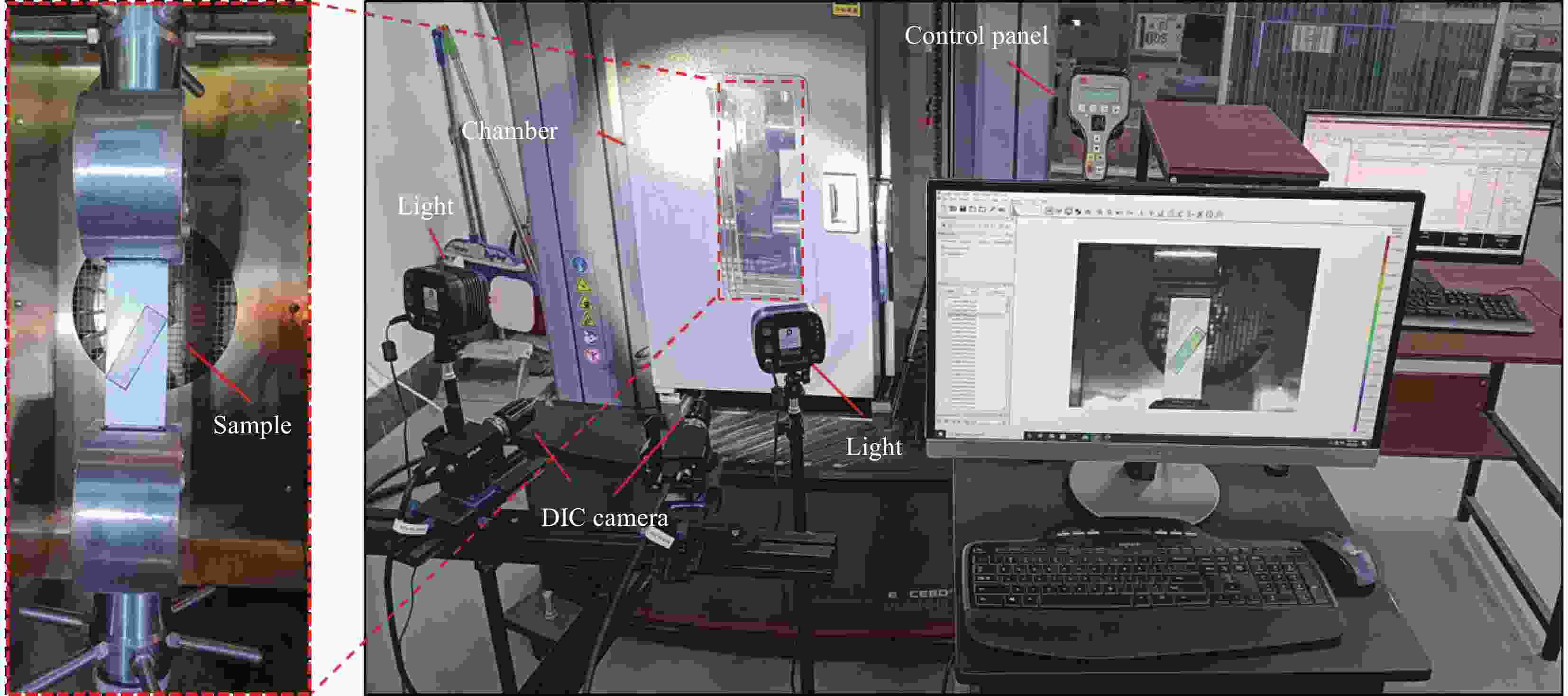

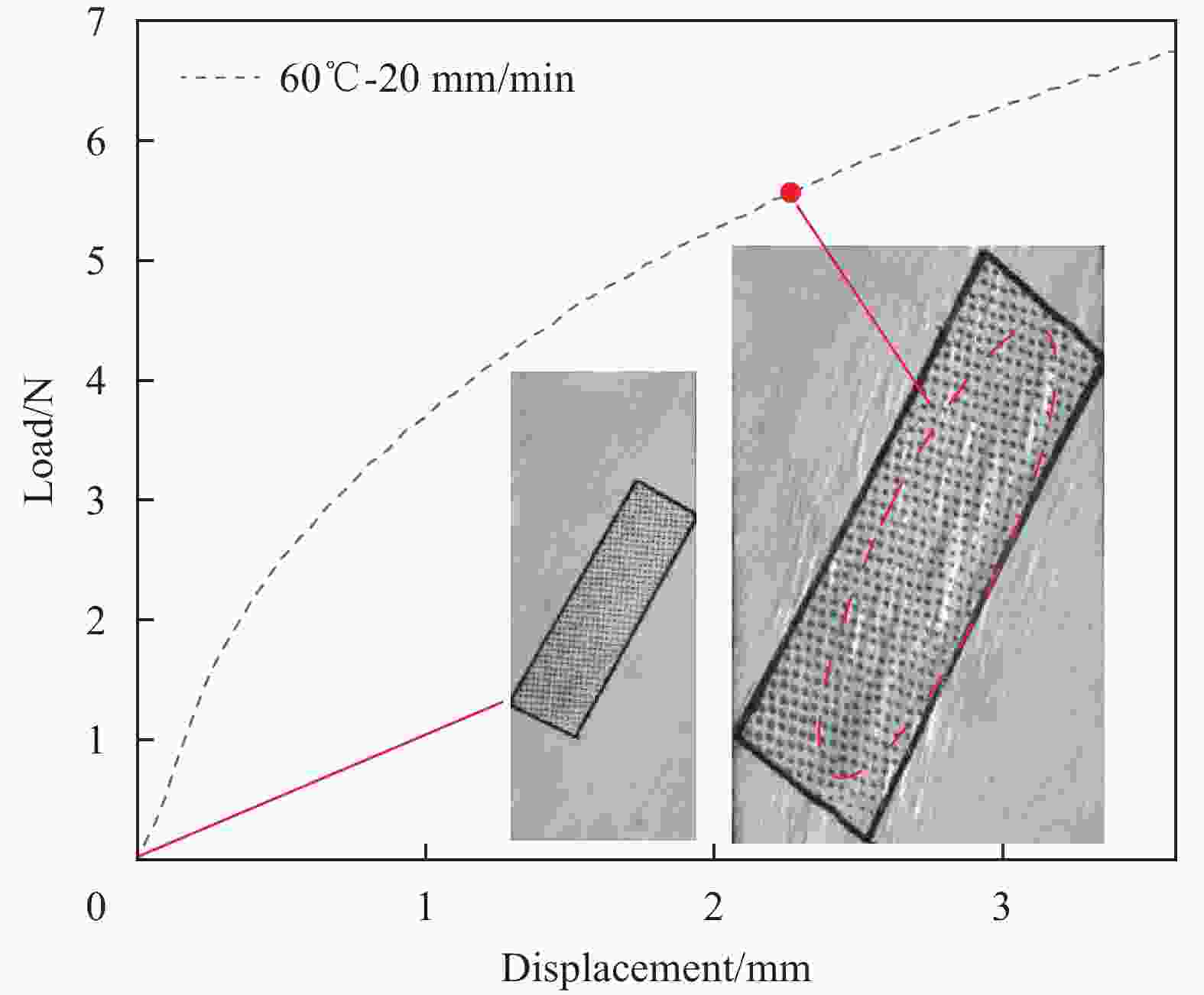

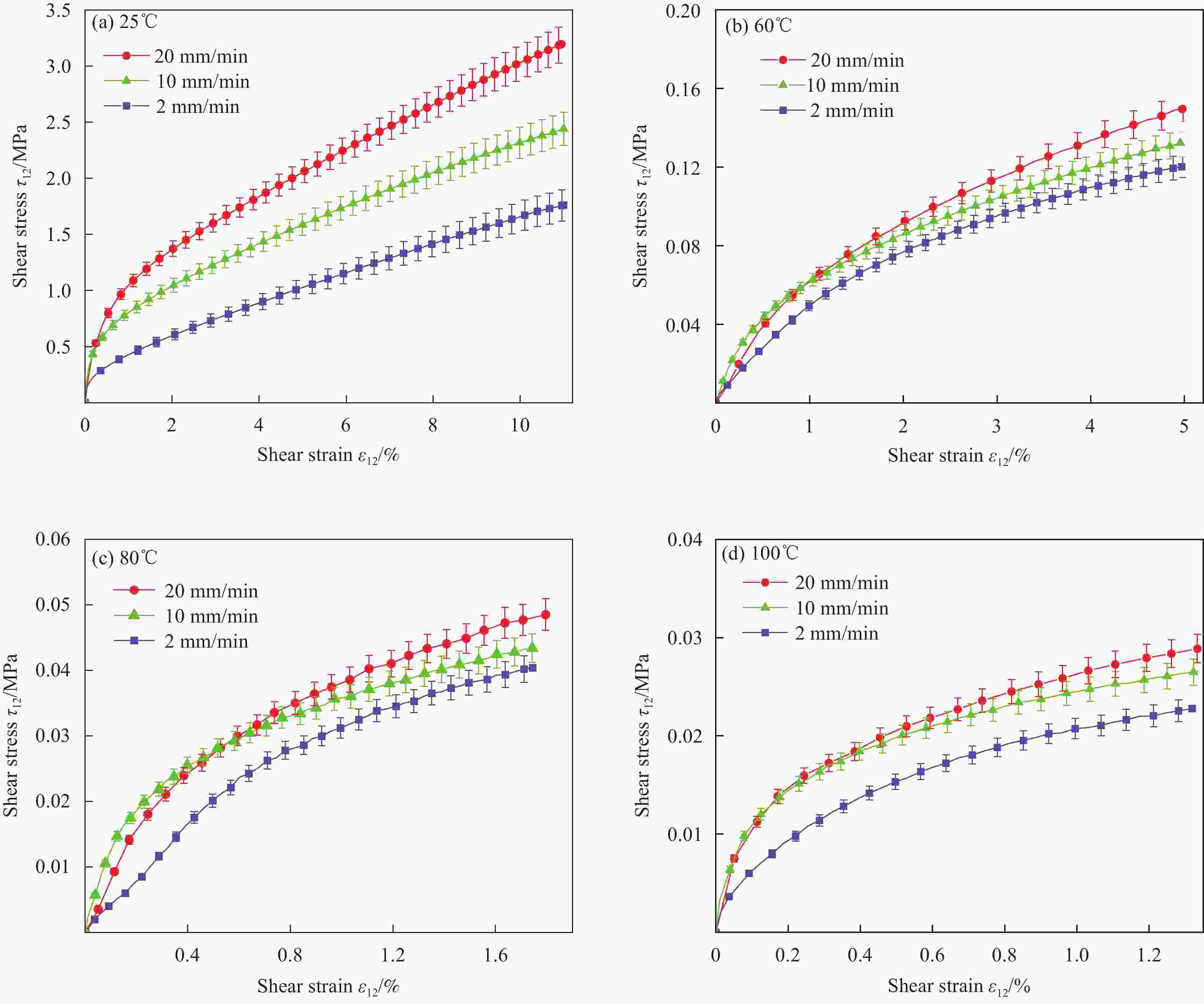

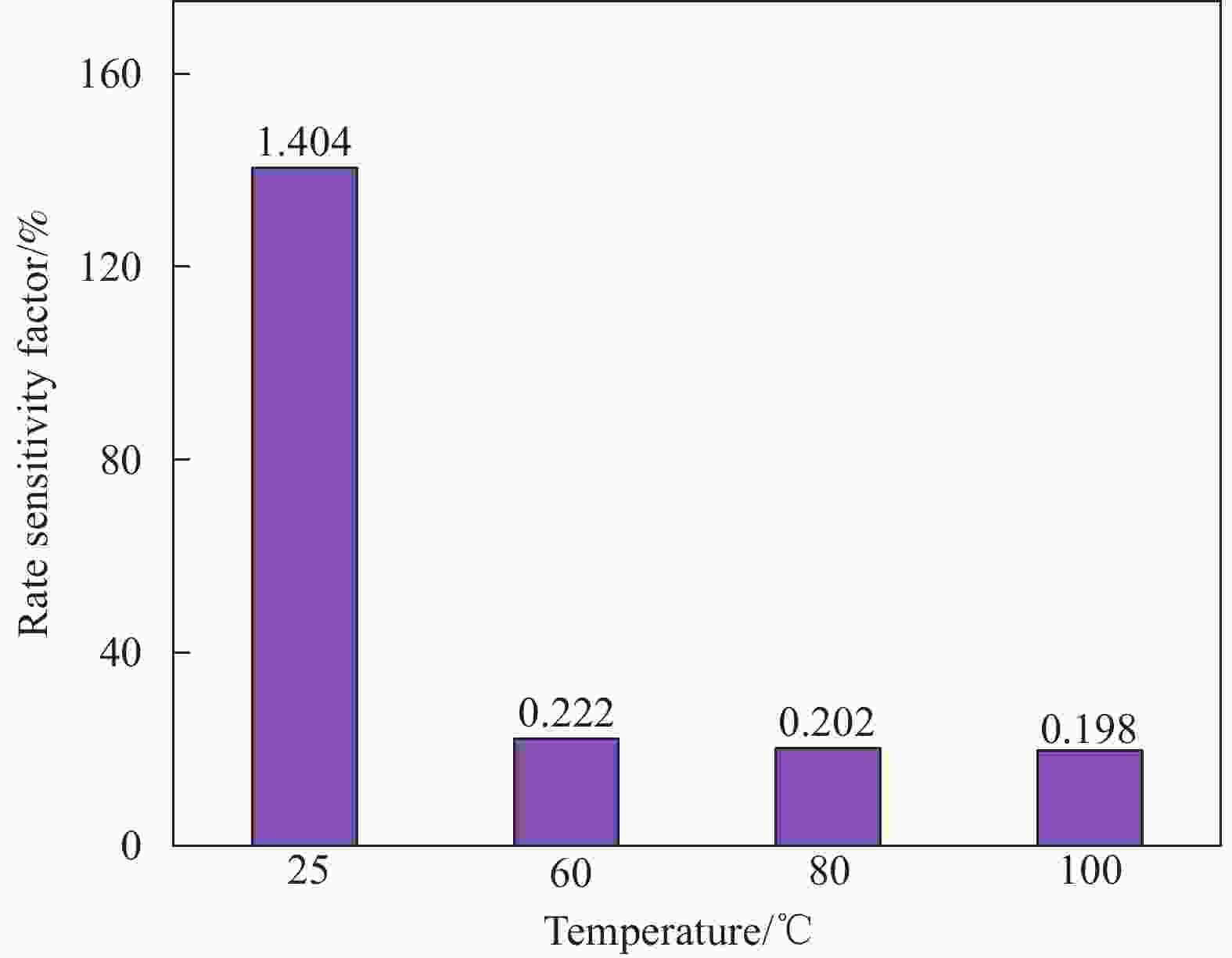

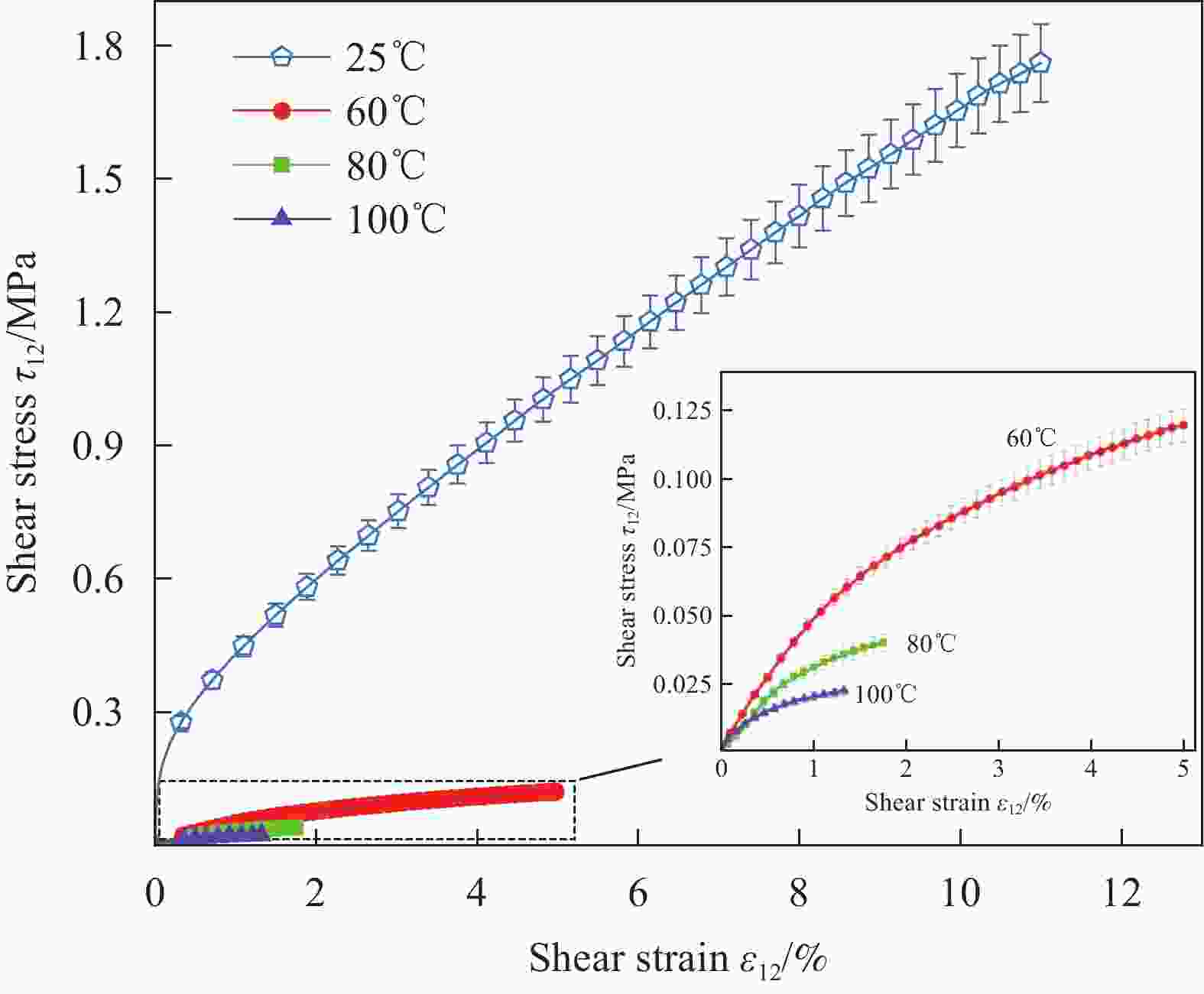

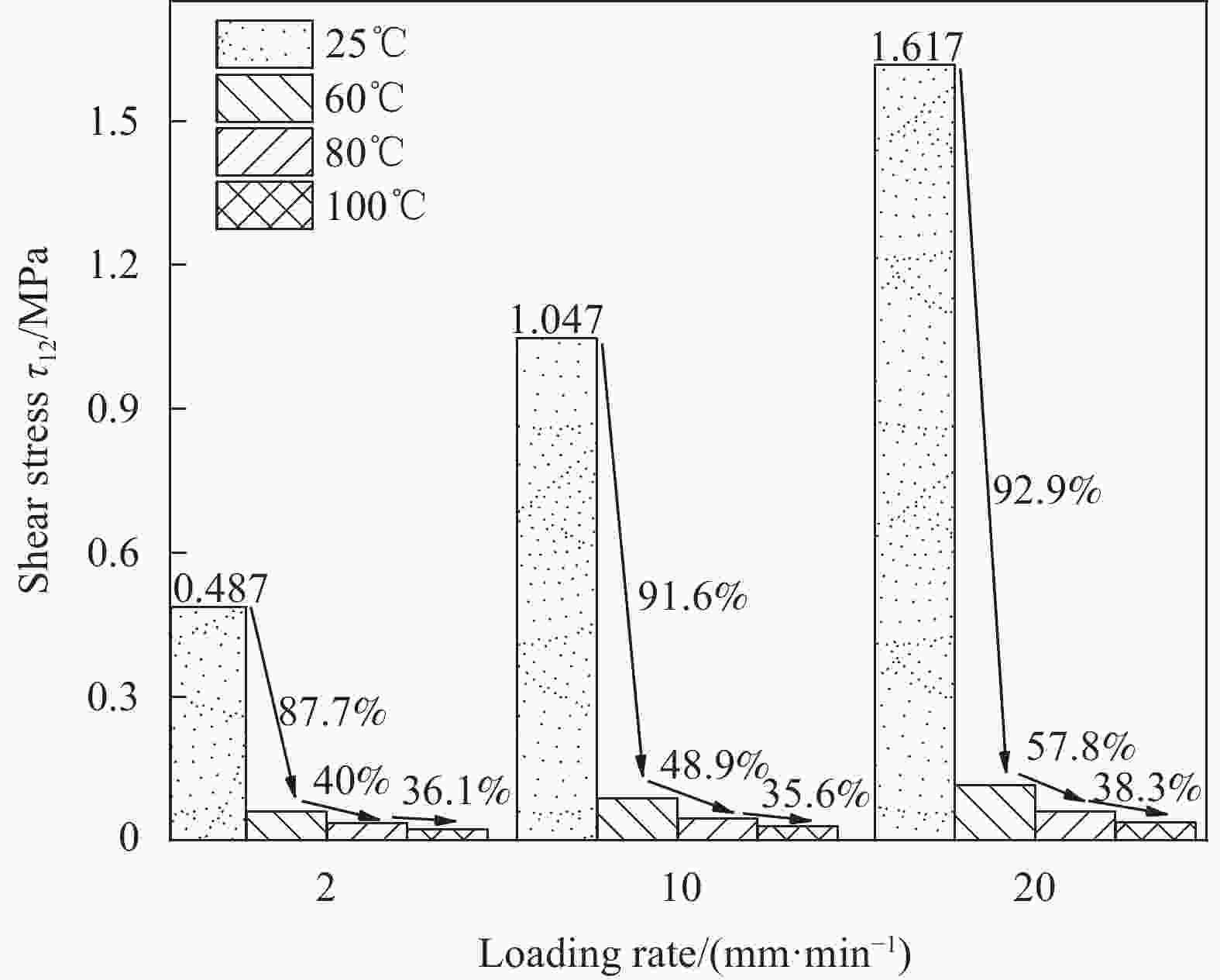

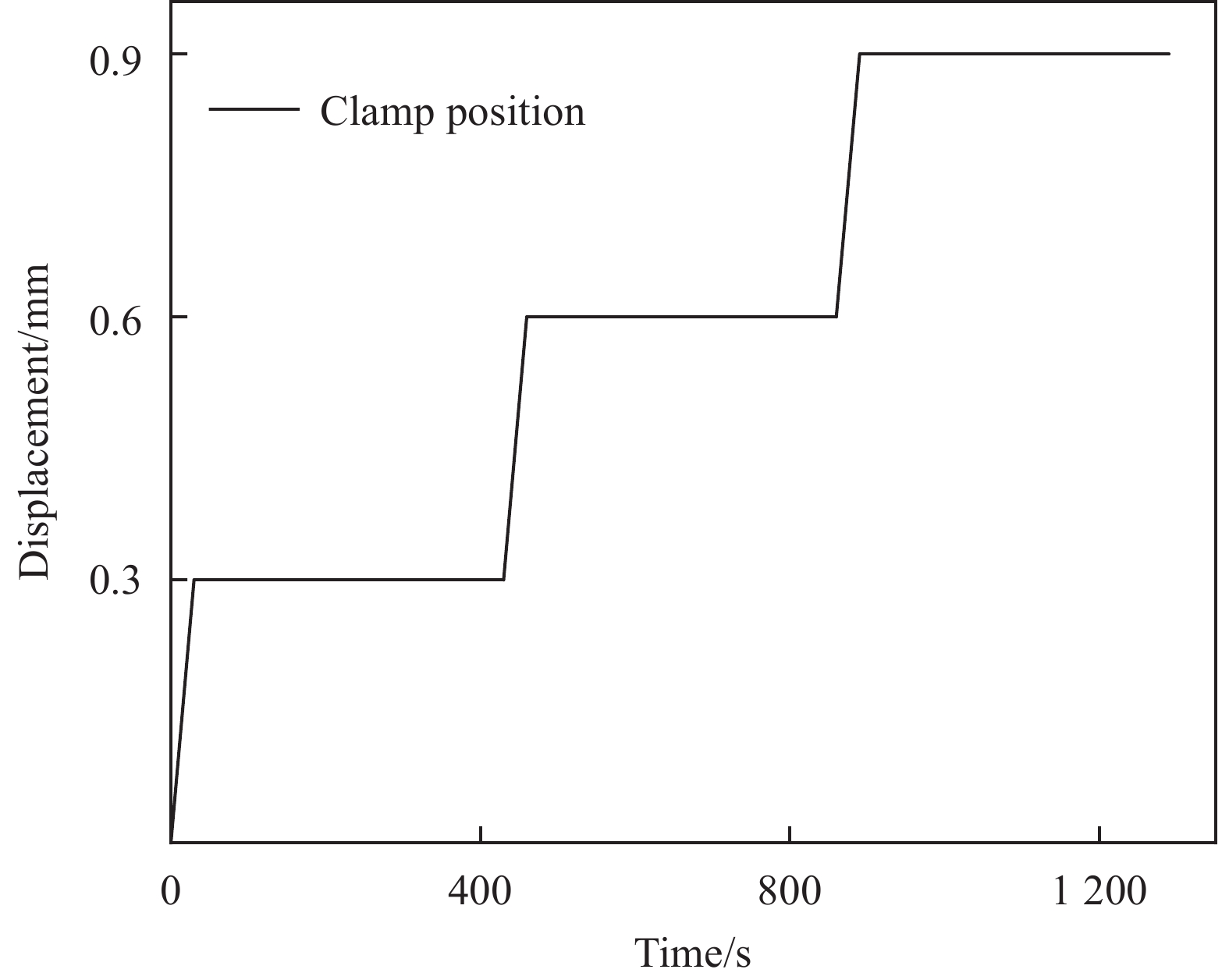

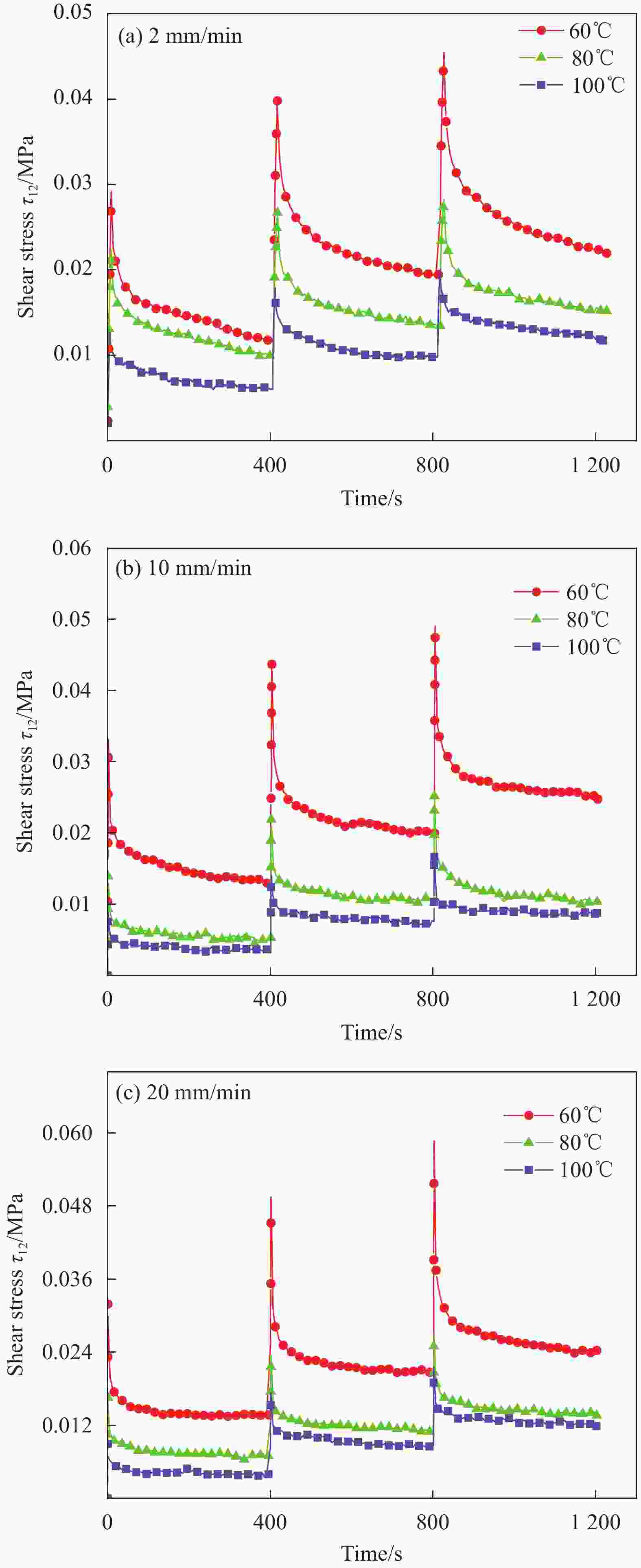

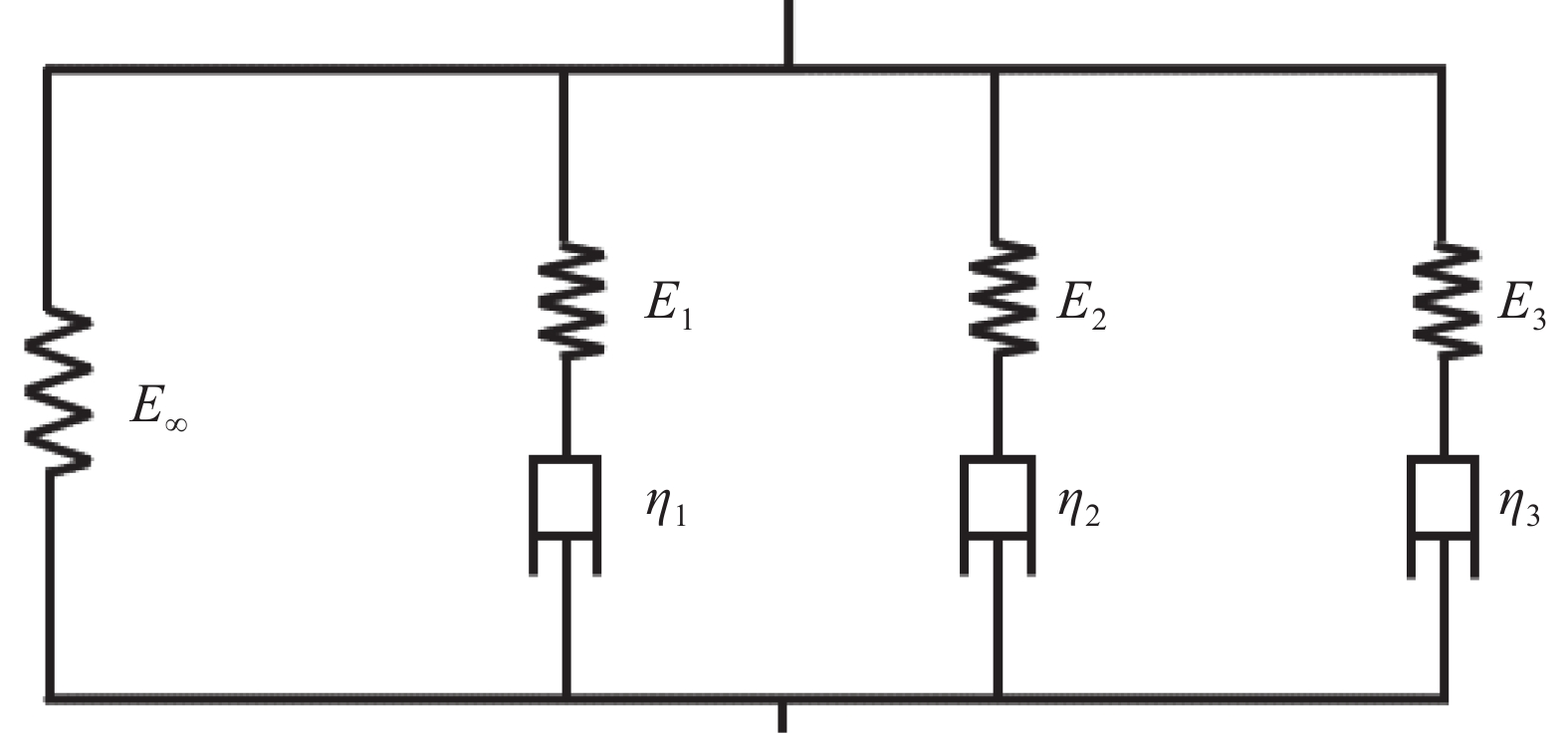

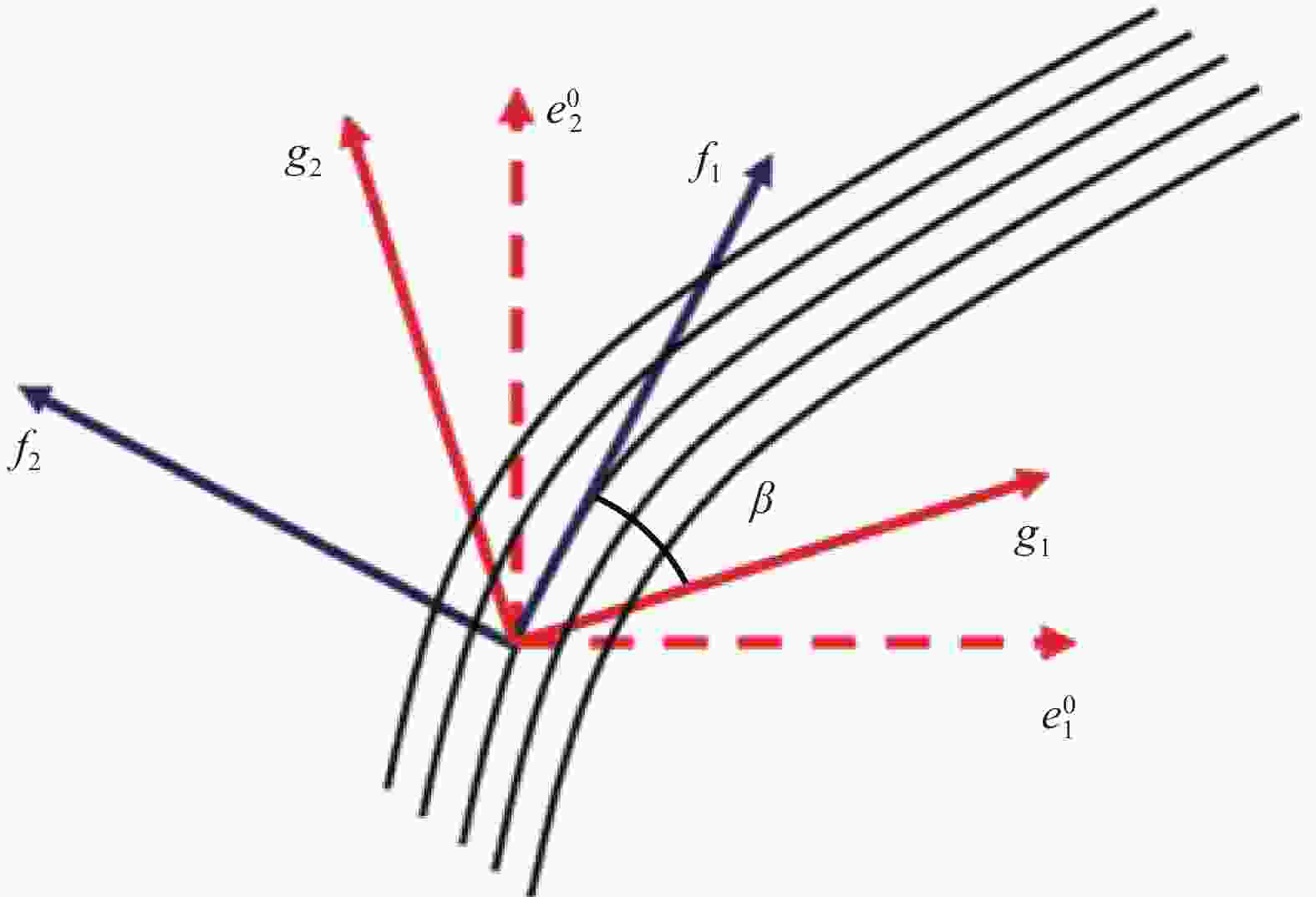

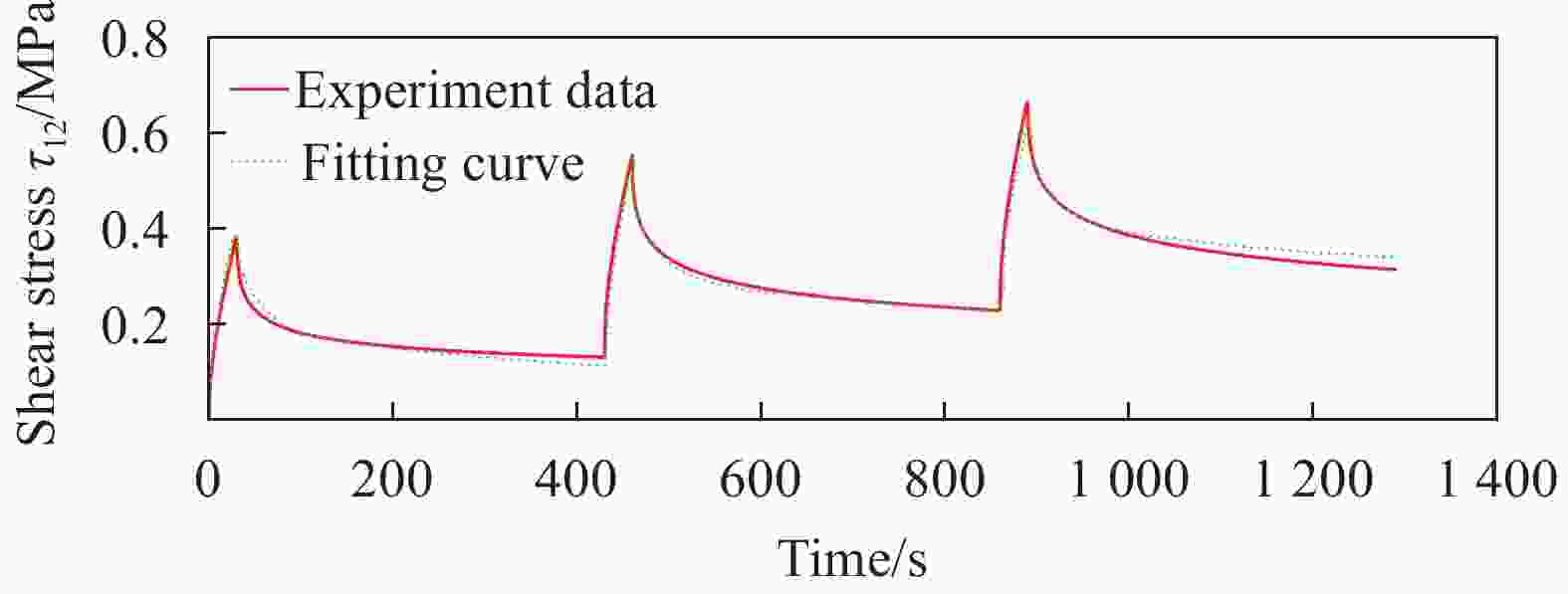

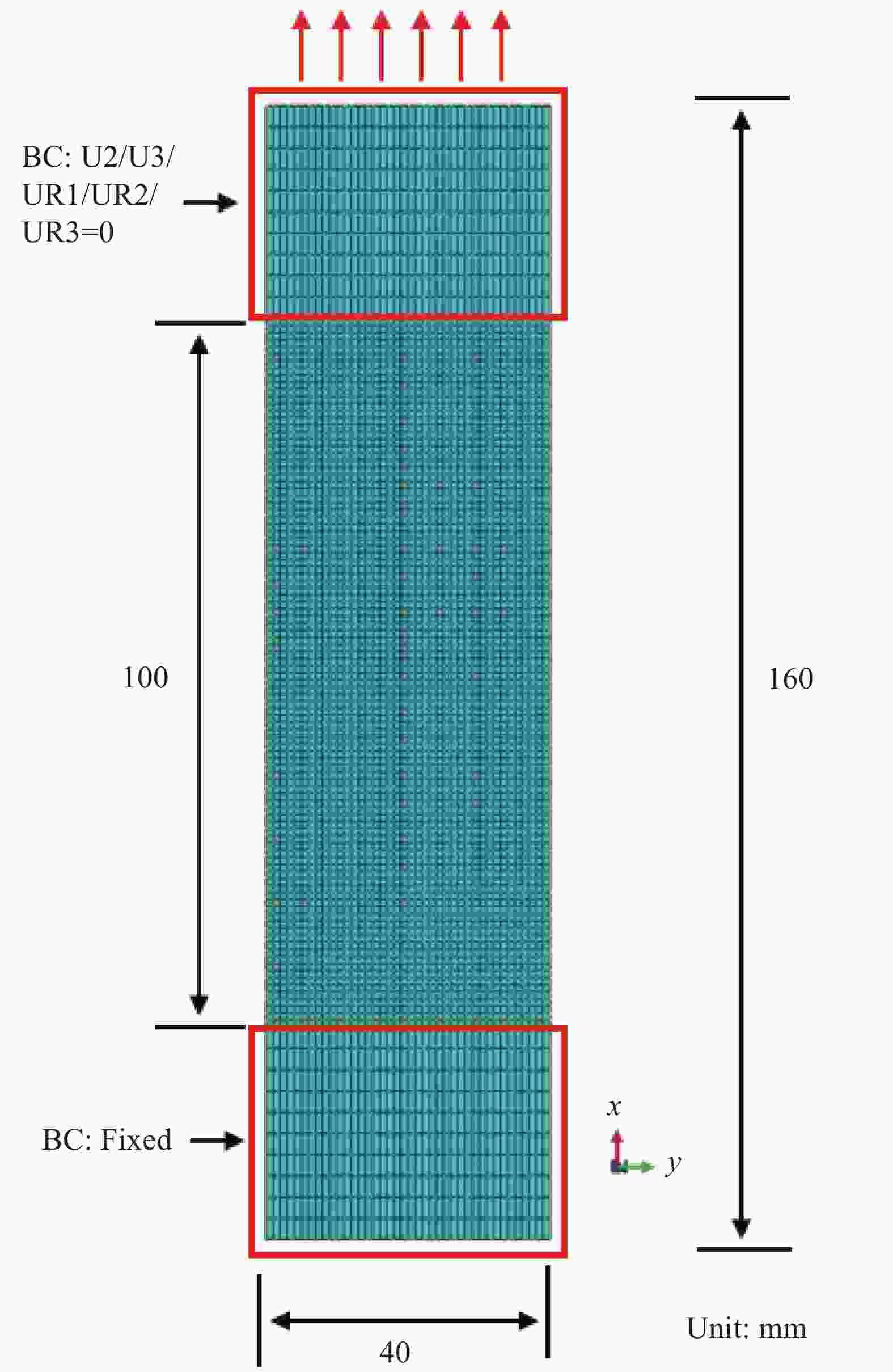

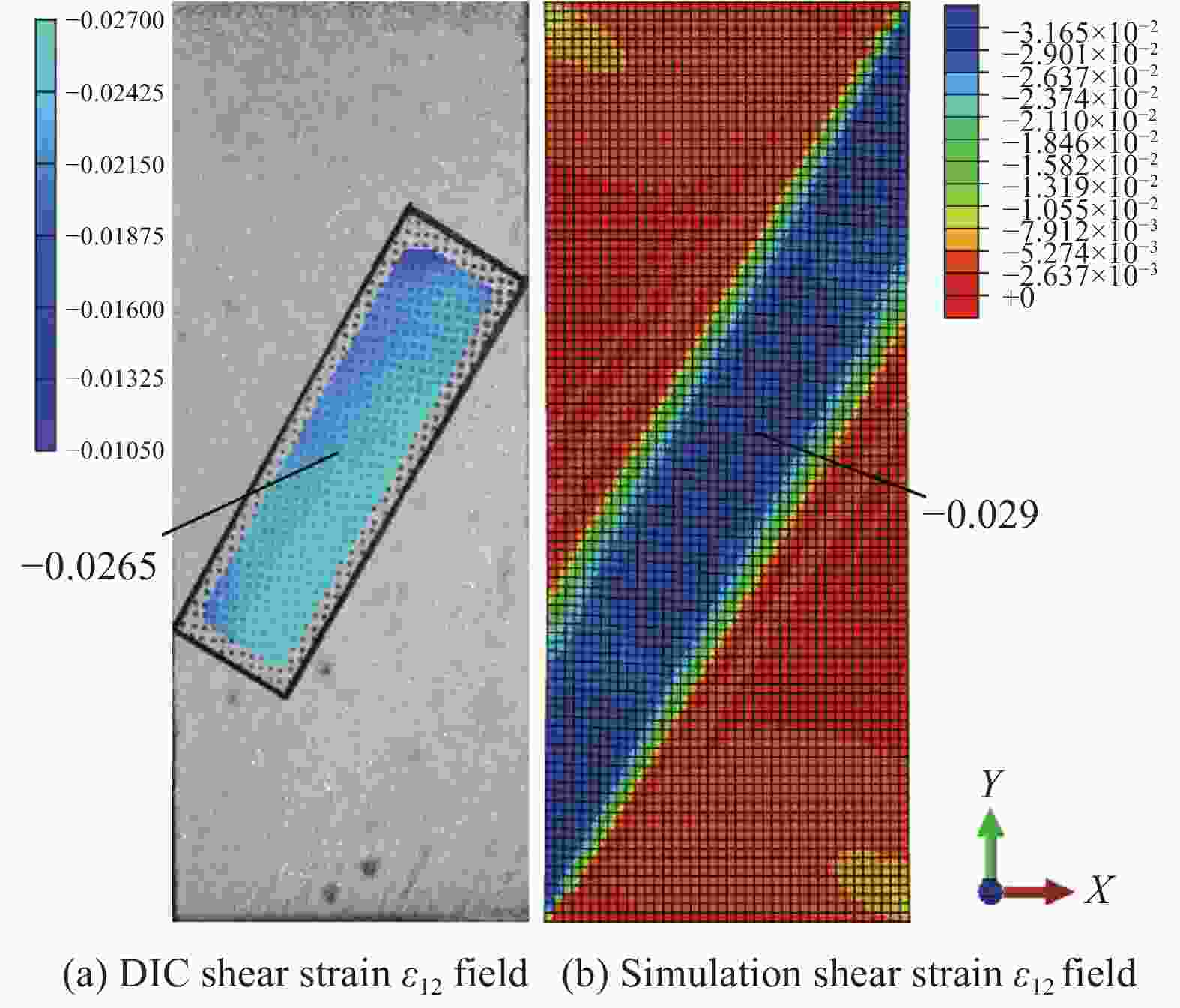

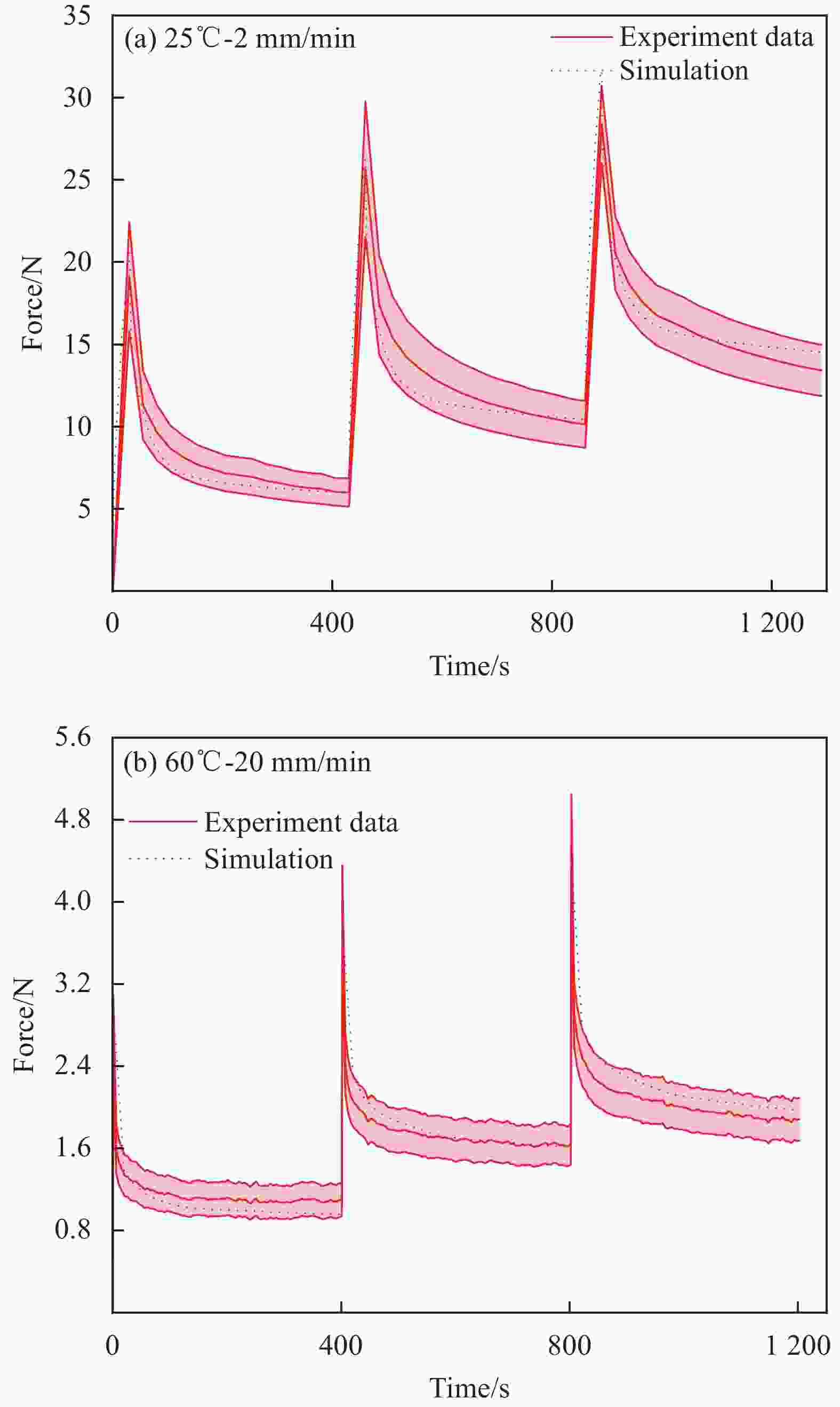

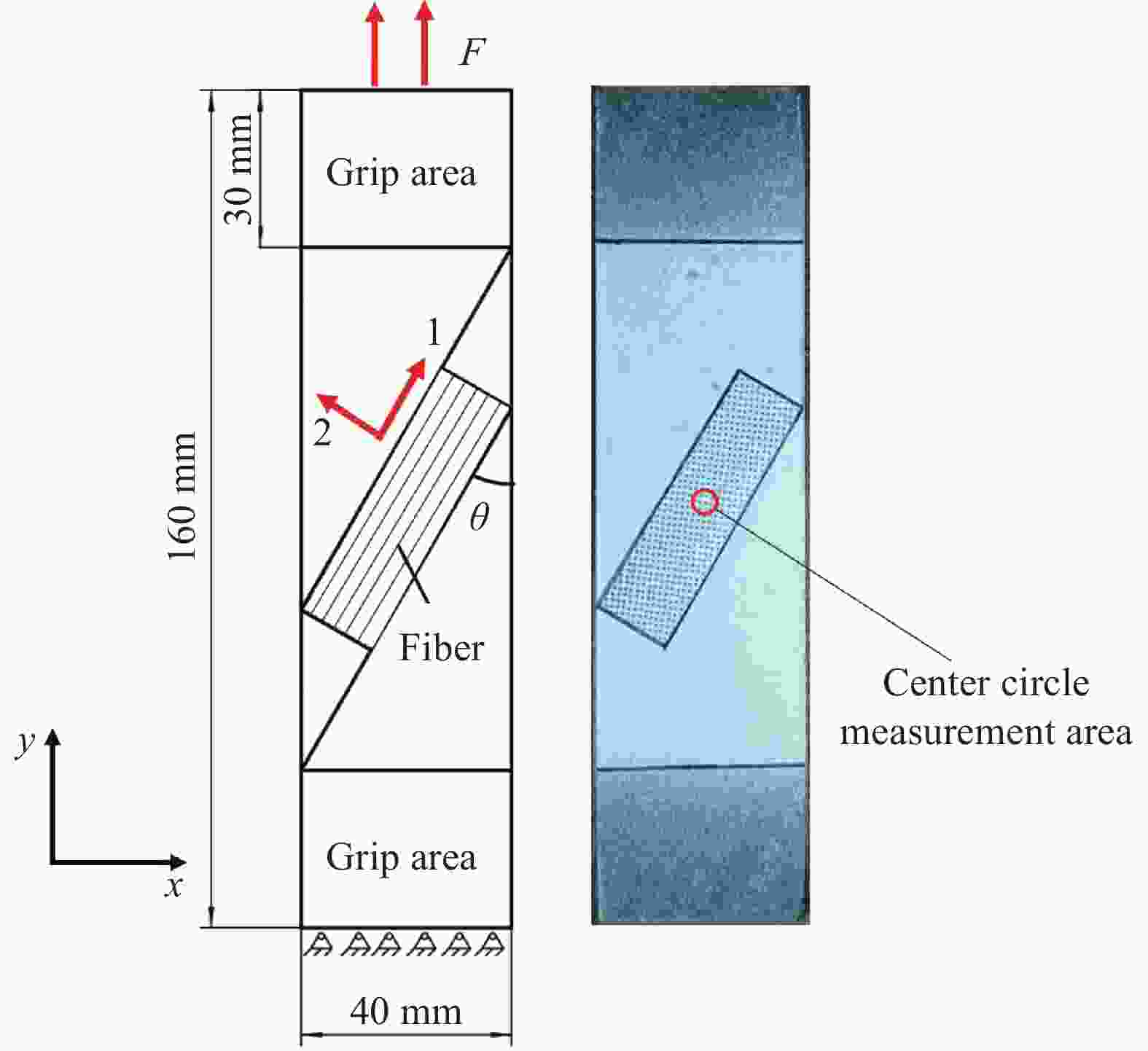

摘要: 单向热固性预浸料的面内剪切变形对最终复合材料构件的成型质量和力学性能有着显著影响。对此,本文研究了单向热固性预浸料在不同成型温度和加载速率下的面内剪切及应力松弛行为。结果表明:单向热固性预浸料呈现出与温度和加载速率强相关的非线性面内剪切变形行为,剪切变形对加载速率的敏感性随着温度的升高而降低,应力松弛速度随着温度的升高而加快,温度越高将会越快处于应力松弛稳定状态。基于单向热固性预浸料的面内剪切及应力松弛行为,构建了精准追踪纤维方向变化的广义Maxwell粘弹性本构模型,并编写VUMAT用户材料子程序,对单向热固性预浸料的偏轴拉伸阶梯加载应力松弛进行模拟,与试验结果表现出较好的一致性,证明了该本构模型的有效性和正确性。Abstract: The in-plane shear deformation behavior of unidirectional thermoset prepreg has significant effect on the forming quality and mechanical properties of composite parts after hot diaphragm forming. In this paper, the in-plane shear and stress relaxation behavior of unidirectional thermoset prepreg at different forming temperatures and loading rates were investigated. The test results show that the unidirectional thermoset prepreg exhibits a nonlinear in-plane shear deformation behavior strongly related to temperature and loading rate, and the sensitivity of shear deformation to loading rate decreases with the increasing of temperature. The relaxation rate of unidirectional thermoset prepreg accelerates with the increasing of temperature, and the sooner it is in a stable state. Based on the in-plane shear stress relaxation behavior of unidirectional thermoset prepreg, a generalized Maxwell viscoelastic constitutive model was constructed, which could accurately track fiber orientation change. The viscoelastic constitutive model was implemented in the user material subroutine VUMAT in Abaqus. The off-axis tensile stress relaxations were simulated. It is in good agreement with the experimental results, indicating the effectiveness of the viscoelastic constitutive model.

-

表 1 单向热固性预浸料CCF800 H/AC531的材料参数

Table 1. Material parameters of unidirectional thermoset prepreg CCF800 H/AC531

Parameter Value Thickness/mm 0.18 Fiber surface density/(g·mm−2) 145 Resin content/% 35 表 2 单向热固性预浸料CCF800 H/AC531粘弹性参数

Table 2. Viscoelastic parameters of unidirectional thermoset prepreg CCF800 H/AC531

Parameter Loading rate ${E_\infty }$ ${E_1}$ ${E_2}$ ${E_3}$ ${\tau _1}$ ${\tau _2}$ ${\tau _3}$ 25℃ 2 mm/min 1.40 114.76 9.50 8.41 1.39 30.33 537.27 60℃ 0.0100 7.60 1.56 2.97 1.52 14.38 475.91 80℃ 0.0035 7.87 0.49 2.36 0.92 11.66 330.74 100℃ 0.0012 22.79 0.83 2.55 0.25 8.07 498.22 25℃ 10 mm/min 5.74 161.48 19.40 14.90 1.68 14.77 133.56 60℃ 0.0171 31.29 0.91 3.32 0.15 13.23 559.08 80℃ 0.0165 16.42 0.99 2.27 0.15 17.93 637.27 100℃ 0.0160 10.64 0.51 1.49 0.15 13.28 877.01 25℃ 20 mm/min 6.30 203.95 28.79 17.48 1.62 15.07 187.06 60℃ 0.0183 57.86 2.23 5.09 0.09 11.68 624.43 80℃ 0.0288 9.86 0.31 1.34 0.12 13.15 641.18 100℃ 0.0278 7.81 0.45 1.44 0.10 12.29 999.98 -

[1] TOWSYFYAN H, BIGURI A, BOARDMAN R, et al. Successes and challenges in non-destructive testing of aircraft composite structures[J]. Chinese Journal of Aeronautics, 2019, 33(3): 771-791. [2] YANG Y, CHENG H, LIANG B, et al. A novel virtual material layer model for predicting natural frequencies of composite bolted joints[J]. Chinese Journal of Aeronautics, 2021, 34(8): 101-111. doi: 10.1016/j.cja.2020.05.028 [3] 蒋诗才, 安学锋, 闫丽, 等. 国产T800级高韧性环氧树脂基复合材料C梁热隔膜预成型工艺研究[J]. 复合材料科学与工程, 2020, 37(12): 109-114. doi: 10.3969/j.issn.1003-0999.2020.12.018JIANG Shicai, AN Xuefeng, YAN Li, et al. Study on preform technology of C-beam hot diaphragm of domestic T800 high toughness epoxy resin matrix composite[J]. Composites Science and Engineering, 2020, 37(12): 109-114(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.12.018 [4] 李伟, 张晨乾, 叶宏军, 等. 固化工艺参数对国产T800增强高韧性复合材料性能的影响[J]. 复合材料科学与工程, 2020(6): 98-104. doi: 10.3969/j.issn.1003-0999.2020.06.017LI Wei, ZHANG Chenqian, YE Hongjun, et al. Effect of curing process parameters on the properties of high toughness composites reinforced by domestic T800 carbon fiber[J]. Composites Science and Engineering, 2020(6): 98-104(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.06.017 [5] 孙立帅, 刘闯, 李玉军, 等. 变厚度复合材料U型零件固化变形仿真预测与结构影响因素[J]. 复合材料学报, 2023, 40(1): 553-566.SUN Lishuai, LIU Chuang, LI Yujun, et al. Prediction and analysis of cure-induced deformation of composite U-shaped parts with variable thickness[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 553-566(in Chinese). [6] 王显峰, 段少华, 唐珊珊, 等. 复合材料自动铺放技术在航空航天领域的研究进展[J]. 航空制造技术, 2022, 65(16): 64-77.WANG Xianfeng, DUAN Shaohua, TANG Shanshan, et al. Progress of composite automated placement technology in aviation field[J]. Aeronautical Manufacturing Technology, 2022, 65(16): 64-77(in Chinese). [7] 张小辉, 朱玉祥, 张少秋, 等. 先进复合材料自动铺丝技术研究进展[J]. 航空制造技术, 2018, 61(7): 54-61.ZHANG Xiaohui, ZHU Yuxiang, ZHANG Shaoqiu, et al. Research progress on automated fiber placement technology[J]. Aeronautical Manufacturing Technology, 2018, 61(7): 54-61(in Chinese). [8] ZHANG L, WANG X, PEI J, et al. Review of automated fibre placement and its prospects for advanced composites[J]. Journal of Materials Science, 2020, 55(3): 7121-7155. [9] 张建宝, 肖军, 文立伟, 等. 自动铺带技术研究进展[J]. 材料工程, 2010(7): 87-91. doi: 10.3969/j.issn.1001-4381.2010.07.019ZHANG Jianbao, XIAO Jun, WEN Liwei, et al. Research progress of automated tape-laying technology[J]. Journal of Materials Engineering, 2010(7): 87-91(in Chinese). doi: 10.3969/j.issn.1001-4381.2010.07.019 [10] AIR A, SHAMSUDDOHA M, PRUSTY B G. A review of type V composite pressure vessels and automated fibre placement based manufacturing[J]. Composites Part B: Engineering, 2023, 253: 110573. doi: 10.1016/j.compositesb.2023.110573 [11] LIN H, WANG J, LONG A C, et al. Predictive modelling for optimization of textile composite forming[J]. Composites Science and Technology, 2007, 67(15-16): 3242-3252. doi: 10.1016/j.compscitech.2007.03.040 [12] THIJE R H W T, AKKERMAN R. Solutions to intra-ply shear locking in finite element analyses of fiber reinforced materials[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(7): 1167-1176. doi: 10.1016/j.compositesa.2008.03.014 [13] BOISSE P, HAMILA N, VIDAL-SALLE E, et al. Simulation of wrinkling during textile composite reinforcement forming: Influence of tensile, in-plane shear and bending stiffnesses[J]. Composites Science and Technology, 2011, 71(5): 683-692. doi: 10.1016/j.compscitech.2011.01.011 [14] LARBERY Y, ÅKERMO M. In-plane deformation of multilayered unidirectional thermoset prepreg: Modelling and experimental verification[J]. Composites Part A:Applied Science and Manufacturing, 2014, 56: 203-212. doi: 10.1016/j.compositesa.2013.10.005 [15] 吕柄熠, 王时玉, 校金友, 等. 基于非正交本构模型的热塑性机织物预浸料宽温域赋形褶皱缺陷仿真方法[J]. 复合材料学报, 2023, 40(4): 2355-2364.LYU Bingyi, WANG Shiyu, XIAO Jinyou, et al. A simulation method of forming wrinkle defects in thermoplastic woven fabric prepregs in a wide temperature range based on non-orthogonal constitutive model[J]. Acta Materiae Compositae Sinica, 2023, 40(4): 2355-2364(in Chinese). [16] HARRISON P, CLIFFORD M J, LONG A C. Shear characterization of viscous woven textile composites: A comparison between picture frame and bias extension experiments[J]. Composites Science and Technology, 2004, 64(10-11): 1453-1465. doi: 10.1016/j.compscitech.2003.10.015 [17] BOISSE P, HAMILA N, GUZMAN-MALDONADO E, et al. The biasextension test for the analysis of in-plane shear properties of textile composite reinforcements and prepregs: A review[J]. International Journal of Material Forming, 2017, 10: 473-492. doi: 10.1007/s12289-016-1294-7 [18] HARRISON P, ABDIWI F, GUO Z, et al. Characterising the shear-tension coupling and wrinkling behaviour of woven engineering fabrics[J]. Composites Part A: Applied Science and Manufacturing, 2012, 43: 903-914. doi: 10.1016/j.compositesa.2012.01.024 [19] MARGOSSIAN A, BEL S, HINTERHOELZL R. On the characterisation of transverse tensile properties of molten unidirectional thermoplastic composite tapes for thermoforming simulations[J]. Composites Part A: Applied Science and Manufacturing, 2016, 88: 48-58. doi: 10.1016/j.compositesa.2016.05.019 [20] 陈萍, 赵月青, 陈菲, 等. 单向碳纤维/环氧树脂预浸料叠层的面内变形行为[J]. 复合材料学报, 2020, 37(5): 1049-1055.CHEN Ping, ZHAO Yueqing, CHEN Fei, et al. In-plane deformation behavior of unidirectional carbon fiber/epoxy prepreg layups[J]. Acta Materiae Compositae Sinica, 2020, 37(5): 1049-1055(in Chinese). [21] ZHANG B, KIM B C. Experimental characterisation of large in-plane shear behaviour of unidirectional carbon fibre/epoxy prepreg tapes for continuous tow shearing (CTS) process[J]. Composites Part A: Applied Science and Manufacturing, 2022, 162. [22] ZHAO Y, GU Y, ZHANG T, et al. Characterization of intra-ply shear behaviors of unidirectional prepregs during hot diaphragm forming process[J]. Polymer Composites, 2020, 42(2): 1008-1020. [23] BRANDS D, WIJSKAMP S, GROUVE W J B, et al. In-plane shear characterization of unidirectional fiber reinforced thermoplastic tape using the bias extension method[J]. Frontiers in Materials, 2022, 9: 863952. doi: 10.3389/fmats.2022.863952 [24] WANG Y, CHEA M K, BELNOUE J P H, et al. Experimental characterisation of the in-plane shear behaviour of UD thermoset prepregs under processing conditions[J]. Composites Part A: Applied Science and Manufacturing, 2020, 133: 105865. doi: 10.1016/j.compositesa.2020.105865 [25] POTTER K. In-plane and out-of-plane deformation properties of unidirectional preimpregnated reinforcement[J]. Composites Part A: Applied Science and Manufacturing, 2002, 33: 1469-1477. doi: 10.1016/S1359-835X(02)00138-0 [26] ZHAO Z, ZHANG K, CHENG H, et al. Experimental characterization and numerical modelling of bending behavior of carbon fiber unidirectional thermoset prepregs[J]. Journal of Reinforced Plastics and Composites, 2023. [27] WANG Y, BELNOUE J P H, IVANOV D S, et al. Hypo-viscoelastic modelling of inplane shear in UD thermoset prepregs[J]. Composites Part A: Applied Science and Manufacturing, 2021, 146: 106400. doi: 10.1016/j.compositesa.2021.106400 [28] 佘彩凤. 金属变形滞后回弹的本构模型UMAT二次开发及有限元分析[D]. 北京: 北京理工大学, 2015.SHE Caifeng . Secondary development and finite element analysis of the constitutive model UMAT for delayed rebound of metal deformation[D]. Beijing: Beijing Institute of Technology University, 2015(in Chinese). -

下载:

下载: