Effect of curing and ambient temperature on properties of epoxy resin and bond behavior of near-surface-mounted CFRP-concrete interface

-

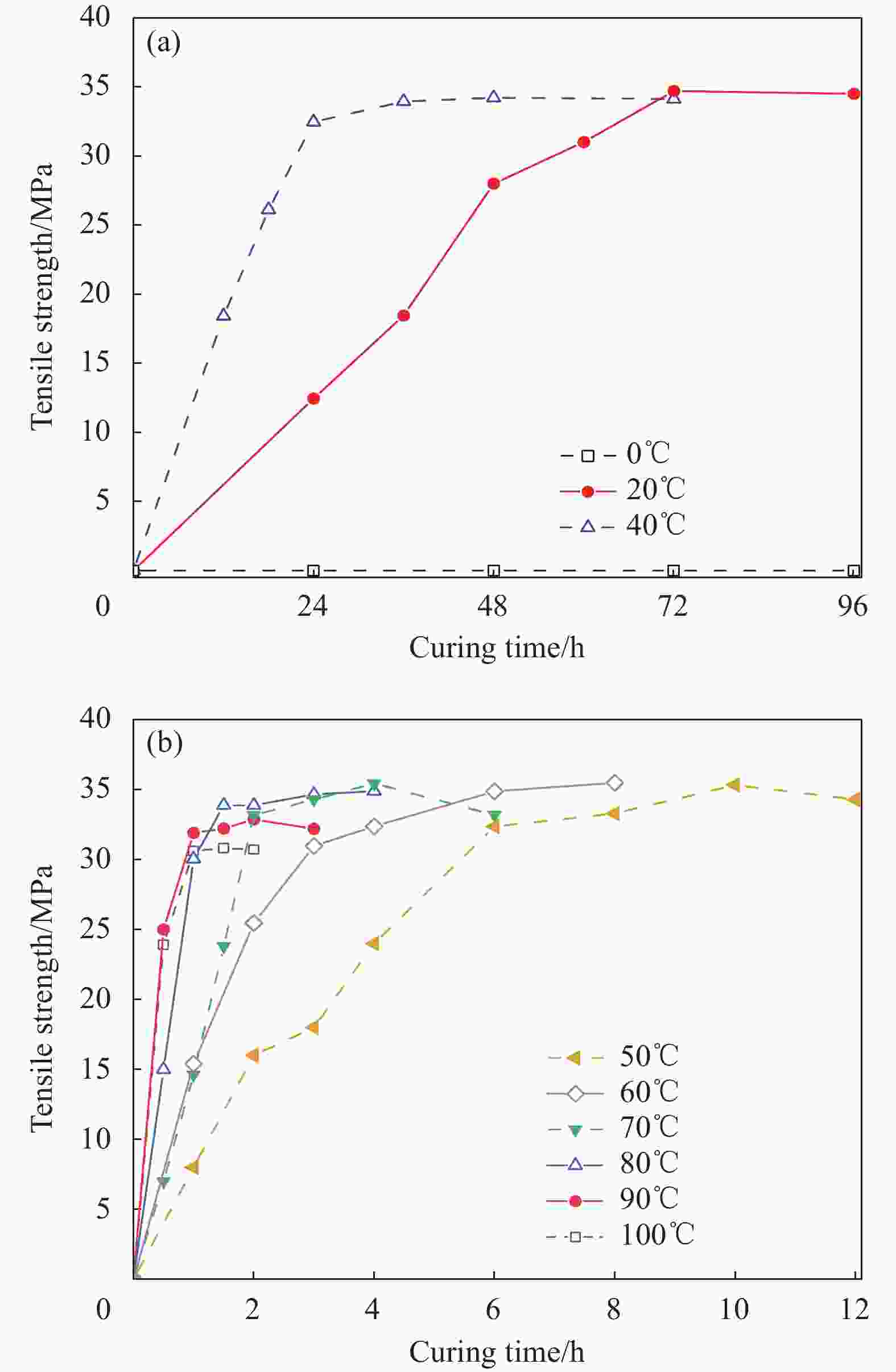

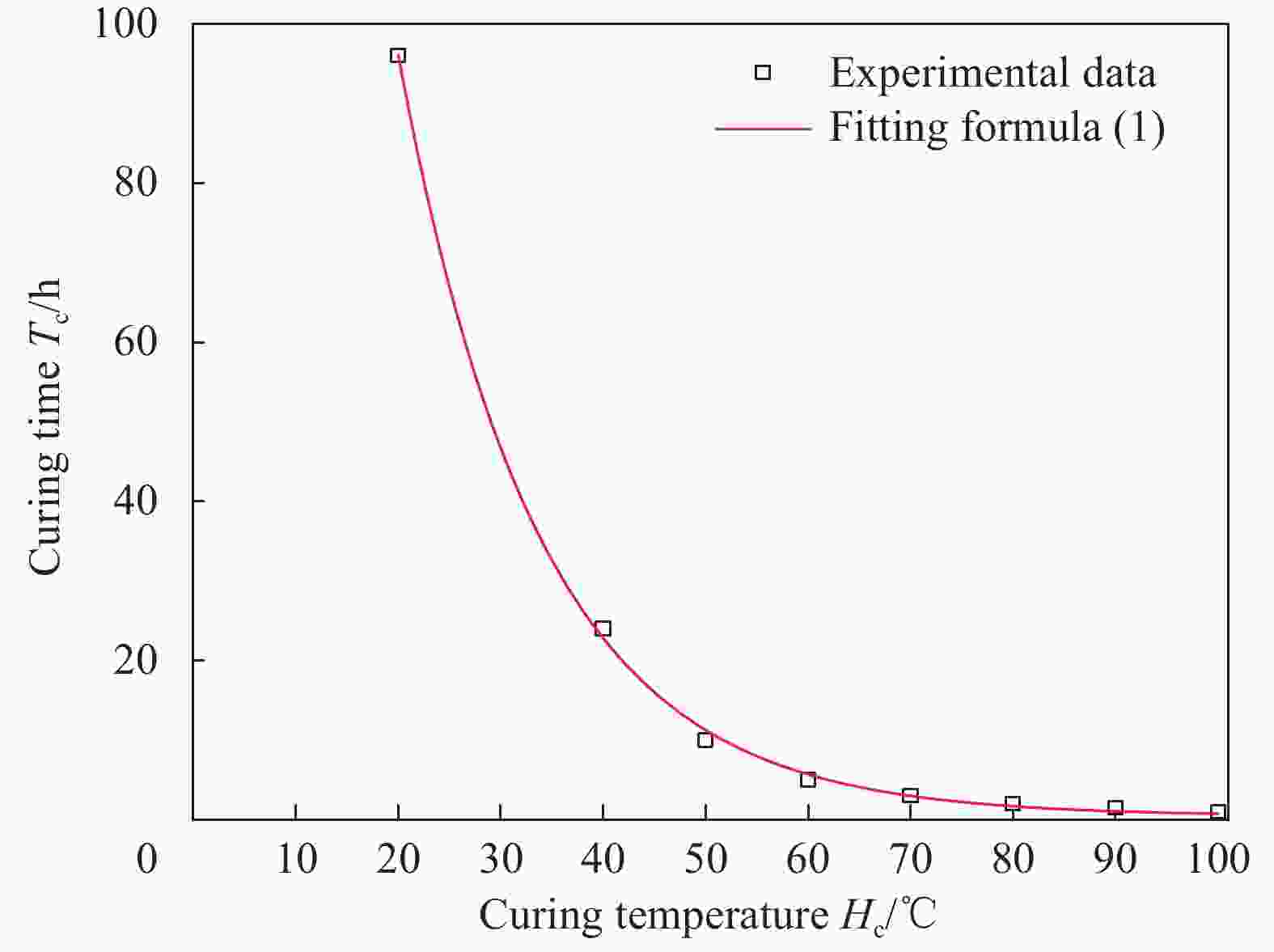

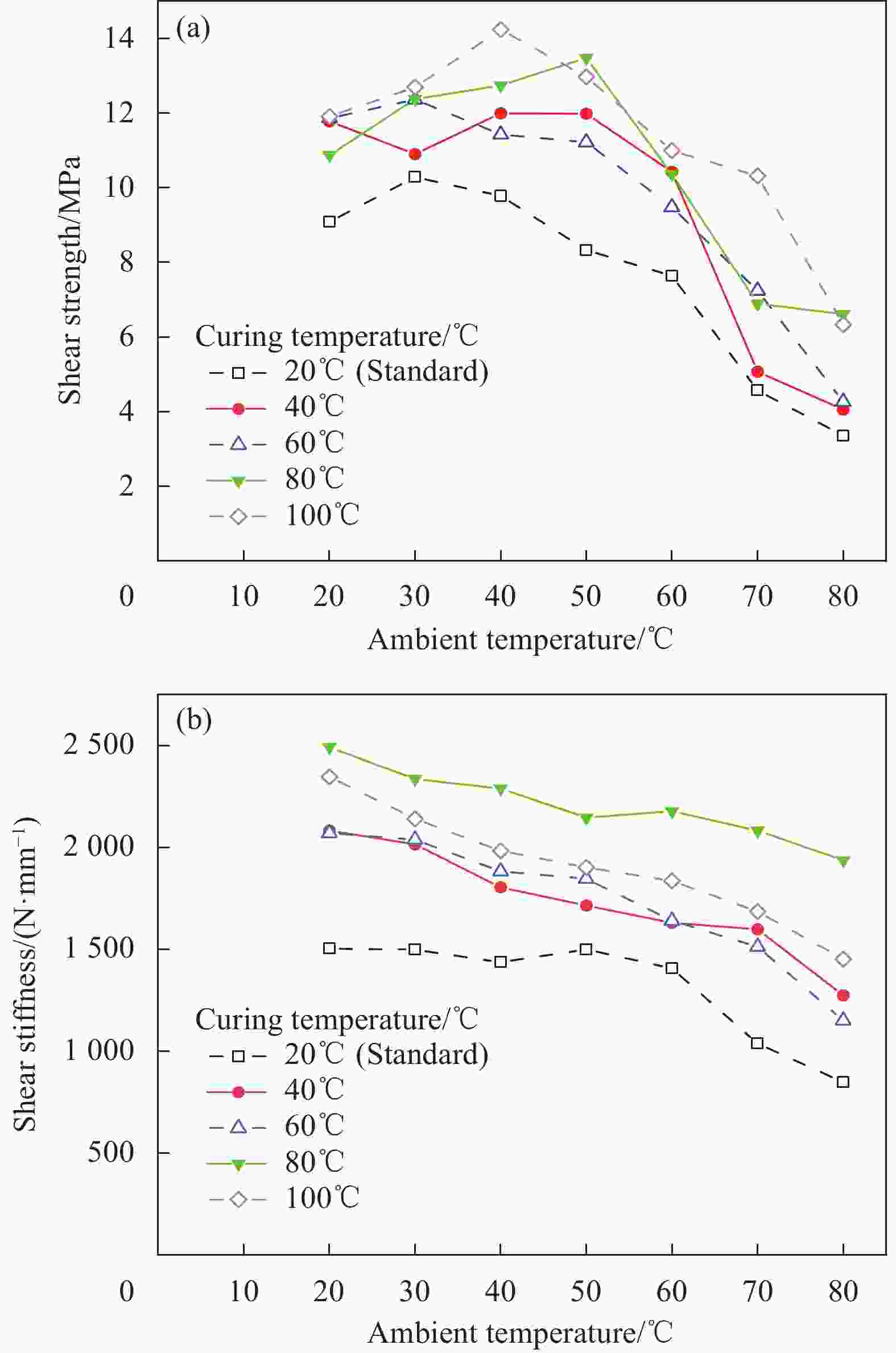

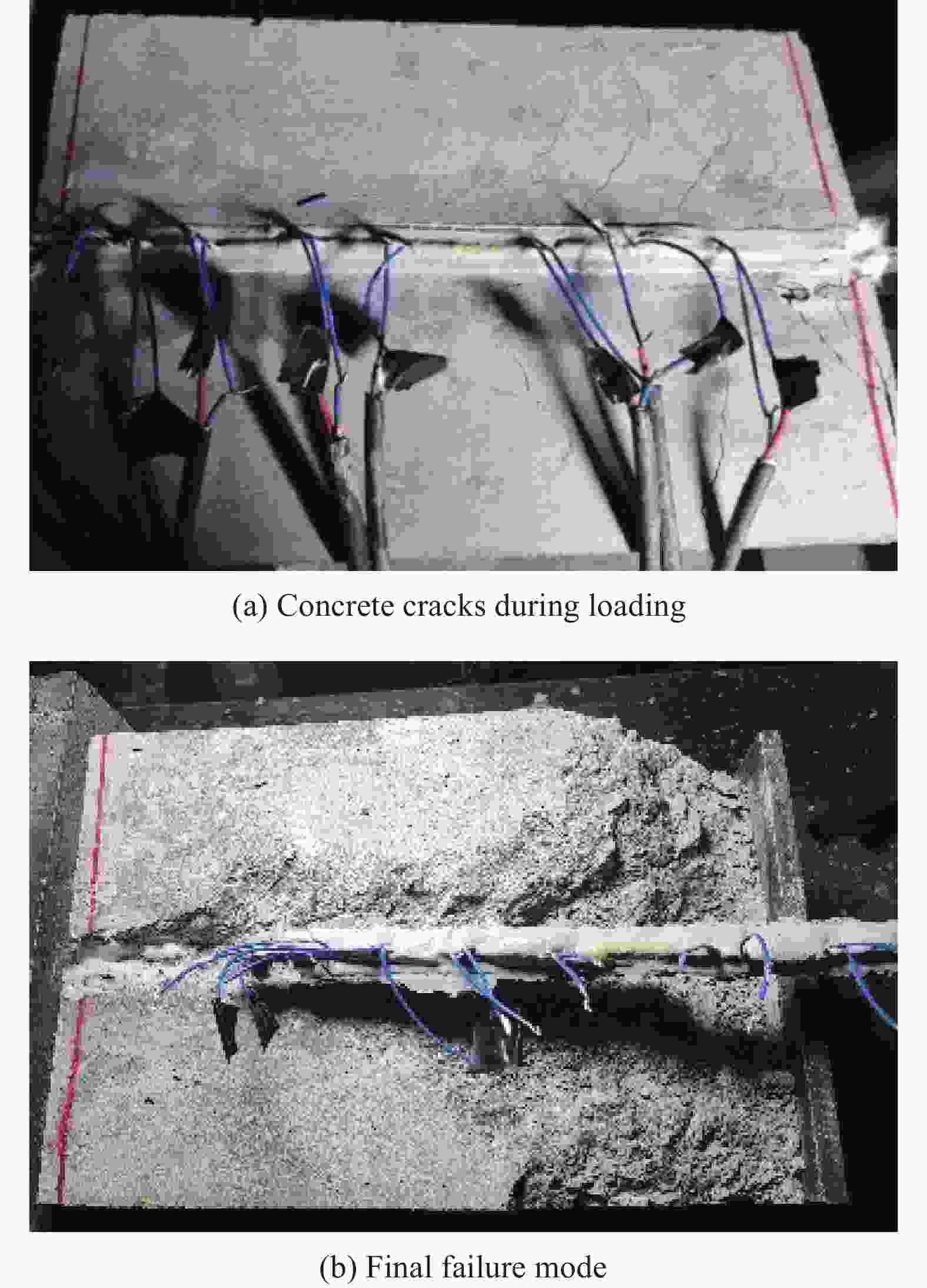

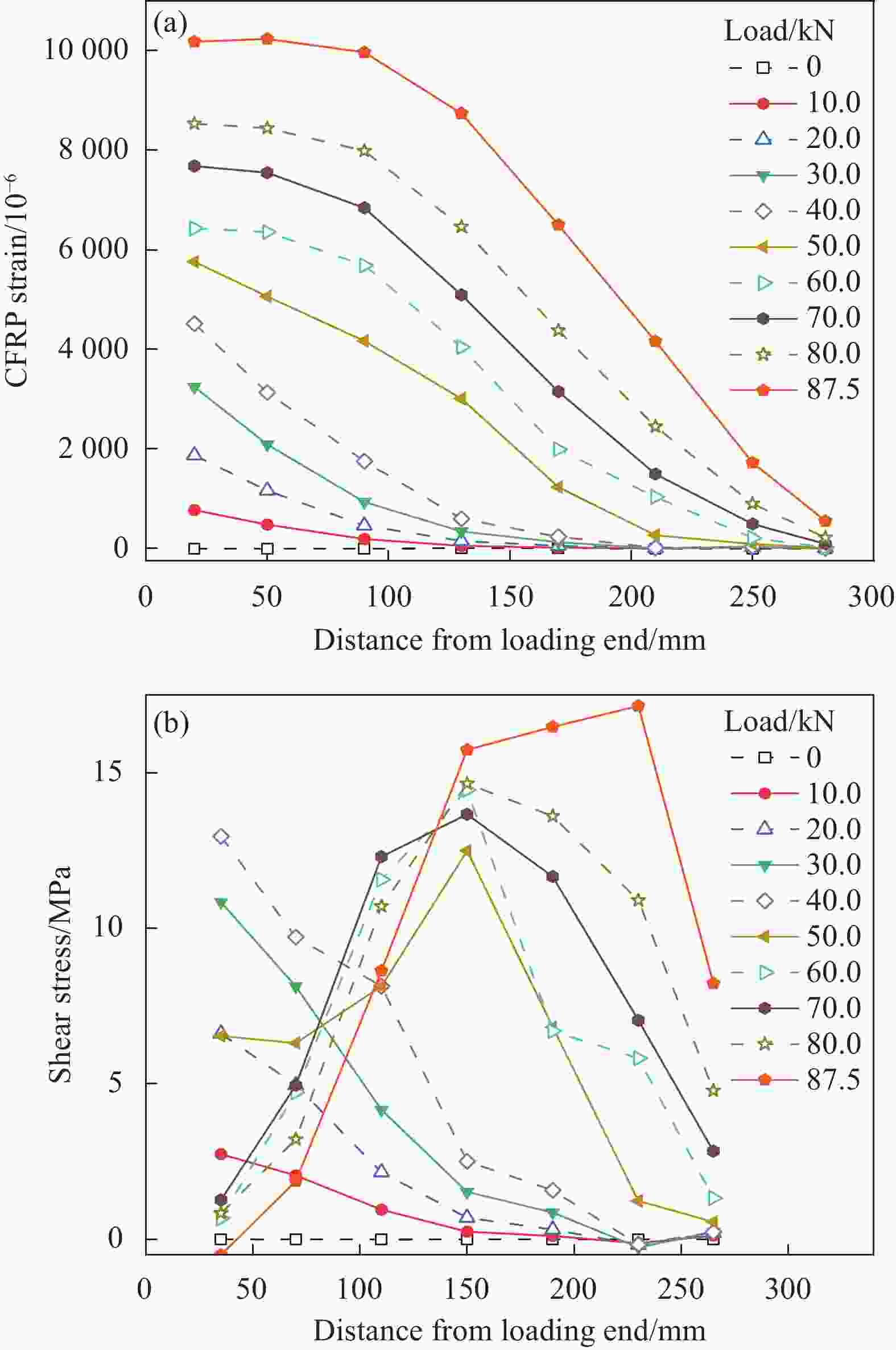

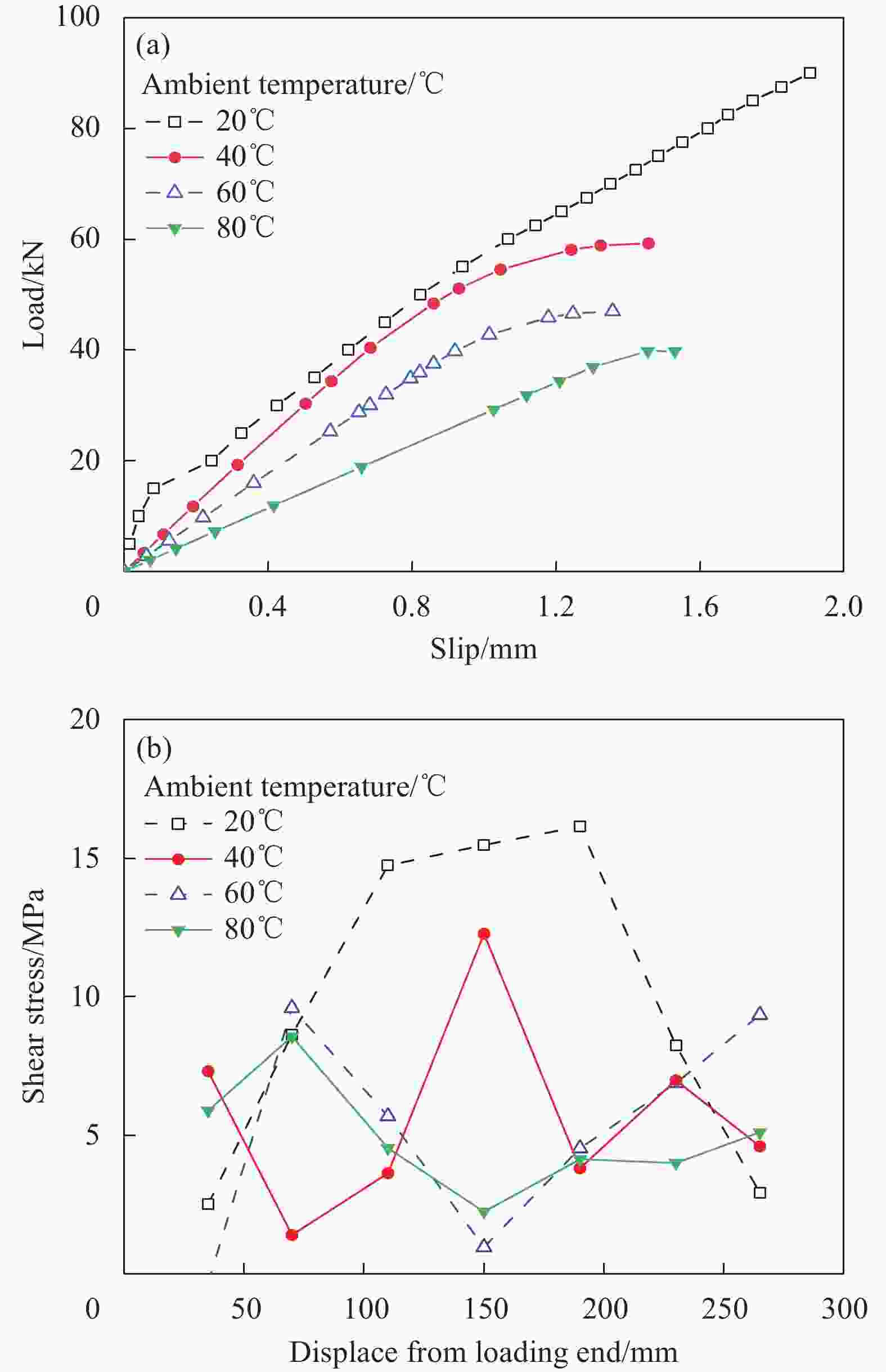

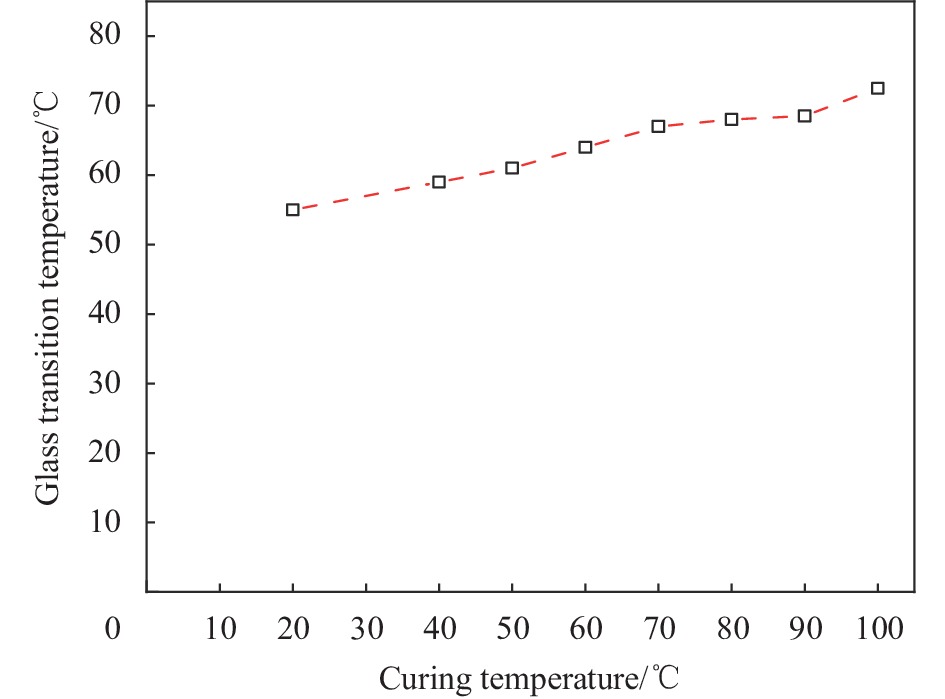

摘要: 表层嵌贴碳纤维增强复合材料(CFRP)加固混凝土结构中的环氧树脂粘结剂具有一定的温度敏感性,试验研究了不同固化温度和试验环境温度下环氧树脂力学性能及其在加固结构中的粘结性能,结果表明:(1) 固化温度的升高大幅缩短了环氧树脂固化时间,对其拉伸强度和剪切强度的影响较小,拉伸强度仅在固化温度超过80℃时小幅下降,降幅在10%以内;试验环境温度的升高会引起环氧树脂软化,导致其拉伸强度和剪切强度显著降低;固化温度更高的环氧树脂在60℃甚至更高试验环境温度下剪切性能更稳定;(2) 固化温度对表层嵌贴CFRP加固构件的界面粘结性能影响较小,但界面粘结性能随着试验环境温度的升高而显著下降,最大降幅约为58.89%,破坏模式也由混凝土内聚破坏转变为环氧树脂-混凝土界面破坏和CFRP-环氧树脂界面破坏;固化温度更高的试件在高试验环境温度下表现出更高的粘结强度。在试验基础上拟合了加固试件界面的粘结-滑移本构曲线,并建立了曲线特征参数与试验环境温度的关系。Abstract: Epoxy resin in near-surface-mounted (NSM) carbon fiber reinforced polymer (CFRP) reinforced concrete structure has a certain temperature sensitivity. The properties of epoxy resin and its bond behavior in the reinforced structure were experimentally studied at different curing temperatures and ambient temperatures. The results show that: (1) The curing time of epoxy resin is greatly shortened with the increase of curing temperature, and has little effect on its tensile strength and shear strength, the tensile strength only decreases slightly by about 10% when curing temperature exceeds 80℃. But the tensile strength and shear strength of epoxy resin decrease obviously with the increase of ambient temperature. Epoxy resins with higher curing temperatures have more stable shear properties at 60℃ or higher ambient temperatures; (2) The effect of curing temperature on the CFRP-concrete interface bond property of NSM CFRP reinforced components is small, but the interfacial bond behavior decreases with the increase of ambient temperature, and the maximum reduction is about 58.89%. The failure mode also changes from concrete cohesive failure to epoxy resin-concrete interface failure and CFRP-epoxy interface failure. The specimen with higher curing temperature shows higher bonding strength at high ambient temperature. In addition, the bond-slip curves of the specimen interface are fitted on the basis of the test, and the relationship between the characteristic parameters of the curve and the ambient temperature is established.

-

Key words:

- epoxy resin /

- near-surface-mounted (NSM) /

- curing temperature /

- ambient temperature /

- bond behavior /

- bond-slip model

-

表 1 材料性能

Table 1. Mechanical performance

Material parameter Epoxy resin CFRP Tensile strength/MPa 40 2564.3 Elasticity modulus/GPa 3.2 140.7 Elongation at break/% 1.5 1.96 Bonding strength/MPa 60 – Compressive strength/MPa 70 – Standard value of tensile shear strength of steel to steel/MPa 14 – Tensile strength of epoxy to

concrete/MPa2.5 – Notes: Epoxy resin was cured at 23℃ for 7 days, and then tested at 23℃; CFRP—Carbon fiber reinforced polymer. 表 2 试验工况

Table 2. Test conditions

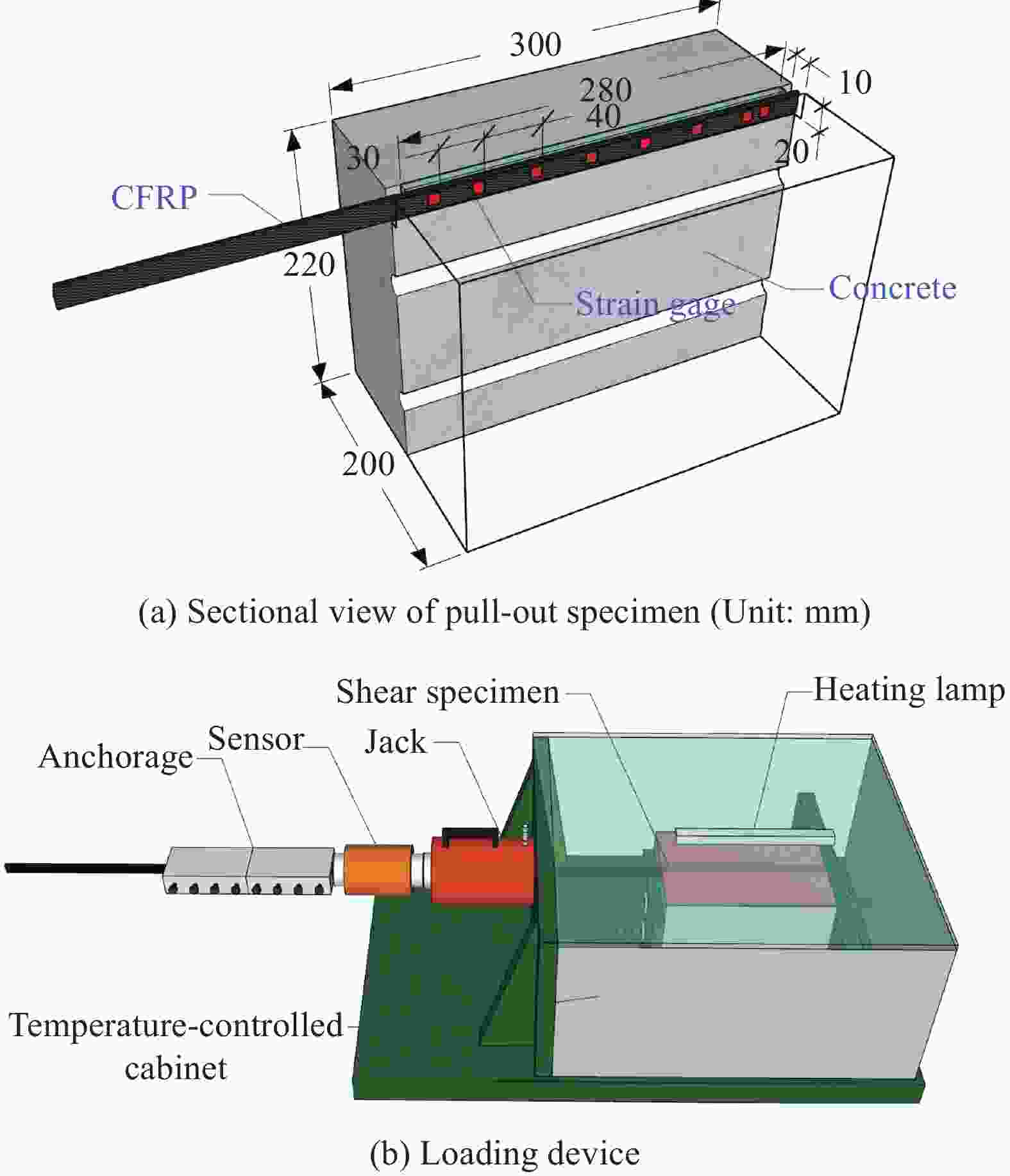

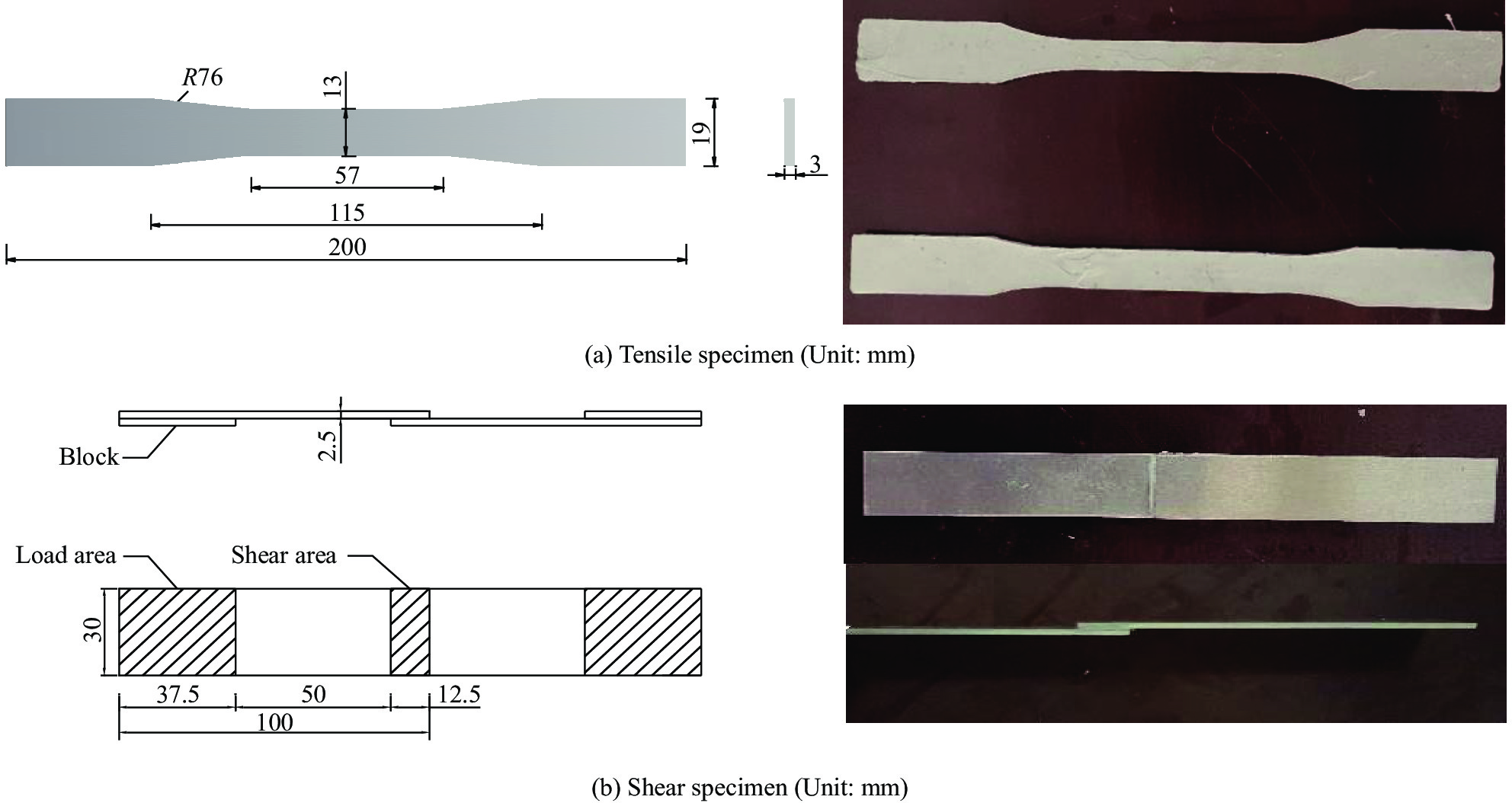

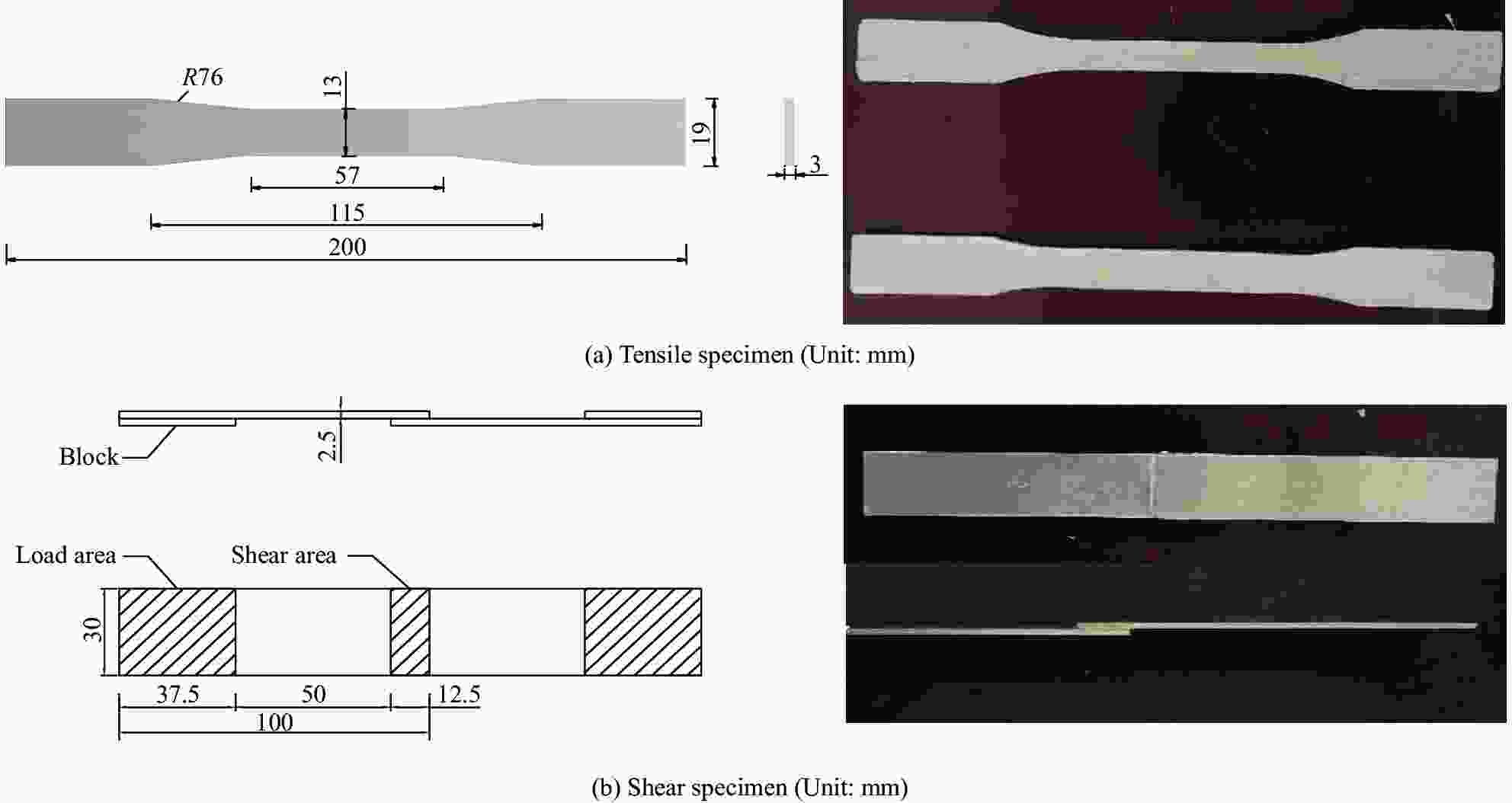

Experiment Curing temperature/℃ Curing time/h Ambient temperature/℃ Purpose Quasi static tensile test (Tensile test) 100 0.5, 1, 1.5, 2 20 The influence of curing temperature on the tensile properties of epoxy resin, and the optimum curing time corresponding to each curing temperature. 90 0.5, 1, 1.5, 2, 3 80 0.5, 1, 1.5, 2, 3, 4 70 0.5, 1, 1.5, 2, 3, 4, 6 60 1, 2, 3, 4, 6, 8, 10 50 1, 2, 3, 4, 6, 8, 10, 12 40 12, 16, 20, 24, 28 20 (Standard) 24, 36, 48, 60, 72, 96 0 24, 48, 72, 96 Quasi static tensile test (Shear test) 100 1.3 20, 30, 40, 50, 60, 70, 80 The effects of curing temperature and ambient temperature on shear properties of epoxy resin. 80 2 60 5 40 24 20 (Standard) 72 Note: Considering the weather condition during the test, the curing condition at room temperature was set at 20℃. 表 3 试验参数设计

Table 3. Design of test parameters

Specimen Curing temperature/℃ Curing time/h Ambient temperature/℃ P-C20-T20 20 96 20 P1-C40-T20 40 24 P1-C60-T20 60 5 P1-C80-T20 80 2 P1-C100-T20 100 1.3 P2-C20-T40 20 96 40 P2-C20-T60 60 P2-C20-T80 80 P3-C80-T40 80 2 40 P3-C80-T60 60 P3-C80-T80 80 Notes: P-C20-T20—Control specimen; P1—Curing temperature group; P2—Ambient temperature group; P3—Heat resistance group; C and T are curing and ambient temperature respectively, followed by the number is the specific value. 表 4 固化温度组表层嵌贴CFRP-混凝土试验结果

Table 4. Test results of near-surface-mounted CFRP-concrete in curing temperature group

Specimen Curing temperature/℃ Curing time/h Failure load/kN Maximum shear stress/MPa Failure mode P-C20-T20 20 96 90.0 16.07 CC+RC P1-C40-T20 40 24 92.5 16.28 CC+RC P1-C60-T20 60 5 87.5 15.55 CC+RC P1-C80-T20 80 2 90.0 15.41 CC+RC P1-C100-T20 100 1.3 87.5 17.15 CC+RC Notes: CC—Cohesive failure of concrete; RC—Interface failure of epoxy resin to concrete. 表 5 试验环境温度组表层嵌贴CFRP-混凝土试验结果

Table 5. Test results of near-surface-mounted CFRP-concrete in ambient temperature group

Specimen Softening degree Failure

load/kNαL/% Maximum shear stress/MPa αS/% Failure mode Decrease P-C20-T20 No 90.0 0.00 16.07 0.00 CC 100.00% P2-C20-T40 Slight 60.0 33.33 12.27 23.65 RC+CC 66.67% P2-C20-T60 Significant 42.5 52.78 9.57 40.45 RC 47.22% P2-C20-T80 Severe 37.0 58.89 8.56 46.73 FR 41.11% Notes: FR—CFRP to epoxy resin interface failure; αL and αS—Decreasing amplitude of the failure load and shear stress of the specimen relative to P-C20-T20. 表 6 耐高温性能组表层嵌贴CFRP-混凝土试验结果

Table 6. Test results of near-surface-mounted CFRP-concrete for heat resistance group

Specimen Curing temperature/℃ Ambient temperature/℃ Failure load/kN αT/% Failure mode P-C20-T20 20 20 90.0 0.00 CC P3-C80-T20 80 90.0 CC P2-C20-T40 20 40 60.0 16.67 RC+CC P3-C80-T40 80 70.0 CC P2-C20-T60 20 60 42.5 11.76 RC P3-C80-T60 80 47.5 RC P2-C20-T80 20 80 37.0 8.11 FR P3-C80-T80 80 40.0 RC Note: αT—Increasing amplitude of specimen cured at 80℃ compared with those cured at 20℃. -

[1] 李荣, 滕锦光, 岳清瑞. FRP材料加固混凝土结构应用的新领域—嵌入式(NSM)加固法[J]. 工业建筑, 2004, 34(4):5-10. doi: 10.3321/j.issn:1000-8993.2004.04.002LI Rong, TENG Jinguang, YUE Qingrui. A new technique for strengthening concrete structure—Near-surface-mounted FRP reinforcement[J]. Industrial Construction,2004,34(4):5-10(in Chinese). doi: 10.3321/j.issn:1000-8993.2004.04.002 [2] 彭晖, 张建仁, 何贤锋, 等. 表层嵌贴预应力CFRP-strip加固钢筋混凝土梁的受力性能研究[J]. 工程力学, 2012, 29(S1):79-85.PENG Hui, ZHANG Jianren, HE Xianfeng, et al. Study of mechanical behavior of reinforced concrete beams with near-surface-mounted prestressed CFRP strips[J]. Engi-neering Mechanics,2012,29(S1):79-85(in Chinese). [3] 滕锦光. 新材料组合结构[J]. 土木工程学报, 2018, 51(12):1-11.TENG Jinguang. New-material hybrid structures[J]. China Civil Engineering Journal,2018,51(12):1-11(in Chinese). [4] 高婧, 范凌云. CFRP筋与海水海砂混凝土粘结性能试验与机制分析[J]. 复合材料学报, 2022, 39(3):1194-1204. doi: 10.13801/j.cnki.fhclxb.20210512.001GAO Jing, FAN Lingyun. Experiment on bond performance between CFRP bar and seawater sea sand concrete and its working mechanism[J]. Acta Materiae Compositae Sinica,2022,39(3):1194-1204(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210512.001 [5] 李游, 李传习, 郑辉, 等. 固化剂混掺对高温下CFRP板-钢板界面黏结性能的影响[J]. 复合材料学报, 2021, 38(12):4073-4089.LI You, LI Chuanxi, ZHENG Hui, et al. Effect of curing agent mixture on interface bond behavior of glued CFRP plate-steel plate at elevated temperature[J]. Acta Materiae Compositae Sinica,2021,38(12):4073-4089(in Chinese). [6] 张靠民, 顾轶卓, 李敏, 等. 快速固化环氧树脂及其碳纤维/环氧复合材料性能[J]. 复合材料学报, 2013, 30(6):21-27. doi: 10.3969/j.issn.1000-3851.2013.06.004ZHANG Kaomin, GU Yizhuo, LI Min, et al. Rapid curing epoxy resin and the properties of carbon fiber/epoxy composite[J]. Acta Materiae Compositae Sinica,2013,30(6):21-27(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.06.004 [7] KOTYNIA R, WALENDZIAK R, STOECKLIN I, et al. RC slabs strengthened with prestressed and gradually anchored CFRP strips under monotonic and cyclic loading[J]. Journal of Composites for Construction,2011,15(2):168-180. doi: 10.1061/(ASCE)CC.1943-5614.0000081 [8] 龚爽, 彭晖, 粟淼, 等. 梯度锚固预应力NSM CFRP加固RC梁静力及疲劳性能研究[J]. 湖南大学学报(自然科学版), 2022, 49(1):113-123.GONG Shuang, PENG Hui, SU Miao, et al. Study on monotonic and fatigue behavior of RC beams strengthened with gradually anchored prestressed NSM CFRP[J]. Journal of Hunan University (Natural Science),2022,49(1):113-123(in Chinese). [9] 龚爽, 张建仁, 林福宽, 等. 梯度锚固预应力NSM CFRP板条加固梁破坏模式与影响因素试验研究[J]. 中国公路学报, 2019, 32(12):156-166.GONG Shuang, ZHANG Jianren, LIN Fukuan, et al. Experimental study on failure modes and influence factors of RC beams strengthened with gradually anchored prestressed NSM CFRP[J]. China Journal of Highway and Transport,2019,32(12):156-166(in Chinese). [10] SILVA M, BISCAIA H. Degradation of bond between FRP and RC beams[J]. Composite Structures,2008,85(2):164-174. doi: 10.1016/j.compstruct.2007.10.014 [11] CARBAS R J C, MARQUES E A S, DA SLIVA L F M, et al. Effect of cure temperature on the glass transition temperature and mechanical properties of epoxy adhe-sives[J]. The Journal of Adhesion,2014,90(1):104-119. doi: 10.1080/00218464.2013.779559 [12] 胡克旭, 董坤, 杨耀武. 结构胶黏剂在温度作用下的剪切性能试验研究[J]. 湖南大学学报(自然科学版), 2016, 43(7):120-125. doi: 10.16339/j.cnki.hdxbzkb.2016.07.016HU Kexu, DONG Kun, YANG Yaowu. Expermental study on shear performances of structural adhesive different temperatures[J]. Journal of Hunan University (Natural Science),2016,43(7):120-125(in Chinese). doi: 10.16339/j.cnki.hdxbzkb.2016.07.016 [13] 彭勃, 余益斌, 单远铭, 等. 环氧建筑结构胶的耐热性能研究[J]. 湖南大学学报(自然科学版), 2013, 40(9):25-29.PENG Bo, YU Yibin, SHAN Yuanming, et al. Study of the heat resistance performance of epoxy structural adhesive[J]. Journal of Hunan University (Natural Science),2013,40(9):25-29(in Chinese). [14] 胡克旭, 董坤, 杨耀武. 温度作用对碳纤维-混凝土界面黏结性能的影响[J]. 同济大学学报(自然科学版), 2016, 44(6):845-852.HU Kexu, DONG Kun, YANG Yaowu. Temperature effect on bond behavior of carbon fiber reinforced polymer to concrete interface[J]. Journal of Tongji University (Natu-ral Science),2016,44(6):845-852(in Chinese). [15] 王飞朋, 苗杰, 牛琪瑛. 固化温度对高架桥梁补修用环氧树脂胶拉伸强度的影响研究[J]. 中国胶粘剂, 2021, 30(7):23-27. doi: 10.13416/j.ca.2021.07.006WANG Feipeng, MIAO Jie, NIU Qiying. Research on influence of curing temperature on tensile strength of epoxy resin adhesive for viaduct repair[J]. China Adhesives,2021,30(7):23-27(in Chinese). doi: 10.13416/j.ca.2021.07.006 [16] CZADERSKI C, MARTINELLI E, MICHELS J, et al. Effect of curing conditions on strength development in an epoxy resin for structural strengthening[J]. Composites Part B: Engineering,2012,43(2):398-410. doi: 10.1016/j.compositesb.2011.07.006 [17] GAMAGE J, WONG M B, AL-MAHAIDI R. Performance of CFRP strengthened concrete members under elevated temperatures[J]. Construction & Building Materials,2005,75(1-4):199-205. [18] 胡克旭, 卢凡, 蔡正华. 高温下碳纤维-混凝土界面受剪性能试验研究[J]. 同济大学学报(自然科学版), 2009, 37(12):1592-1597. doi: 10.3969/j.issn.0253-374x.2009.12.006HU Kexu, LU Fan, CAI Zhenghua. Researches on mechanical property of CFRP-concrete interface at elevated temperatures[J]. Journal of Tongji University (Natural Science),2009,37(12):1592-1597(in Chinese). doi: 10.3969/j.issn.0253-374x.2009.12.006 [19] 胡克旭, 彭东平, 赵传鑫. 温度对CFRP-混凝土界面粘结滑移行为的影响[J]. 防灾减灾工程学报, 2012, 32(S1):45-49. doi: 10.13409/j.cnki.jdpme.2012.s1.023HU Kexu, PENG Dongping, ZHAO Chuanxin. Influence of temperature on the bond-slip behavior of CFRP-concrete Interface[J]. Journal of Disaster Prevention and Mitigation Engineering,2012,32(S1):45-49(in Chinese). doi: 10.13409/j.cnki.jdpme.2012.s1.023 [20] LEONE M, MATTHY S, AIELLO M A. Effect of elevated service temperature on bond between FRP EBR systems and concrete[J]. Composites Part B: Engineering,2009,40(1):85-93. doi: 10.1016/j.compositesb.2008.06.004 [21] 李传习, 曹先慧, 柯璐, 等. 高温对结构加固用环氧黏结剂力学性能的影响[J]. 建筑材料学报, 2020, 23(3):642-649.LI Chuanxi, CAO Xianhui, KE Lu, et al. Effects of high temperatures on mechanical properties of epoxy adhesives for structural strengthening[J]. Journal of Building Materials,2020,23(3):642-649(in Chinese). [22] American Society for Testing Materials. Test method for tensile properties of plastics: ASTM D638-10[S]. West Conshohocken: ASTM International, 2010. [23] 中国国家标准化管理委员会. 胶粘剂拉伸剪切强度的测定(刚性材料对刚性材料): GB/T 7124—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Adhesives—Determination of tensile lap-shear strength of rigid-to-rigid bind assemblies: GB/T 7124—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [24] CUSTODIO J, BROUGHTON J, CRUZ H. Rehabilitation of timber structures—Preparation and environmental service condition effects on the bulk performance of epoxy adhesives[J]. Construction & Building Materials,2011,25(8):3570-3582. doi: 10.1016/j.conbuildmat.2011.03.050 [25] LORENZIS L D, NANNI A. Bond between near-surface mounted fiber-reinforced polymer rods and concrete in structural strengthening[J]. ACI Structural Journal,2002,99(2):123-132. [26] ZHANG S S, TENG J G, YU T. Bond-slip model for CFRP strips near-surface mounted to concrete[J]. Engineering Structures,2013,56:945-953. [27] SU M, ZHONG Q Y, PENG H, et al. Selected machine learning approaches for predicting the interfacial bond strength between FRPs and concrete[J]. Construction and Building Materials, 2020, 270(4): 121456. -

下载:

下载: