Preparation of colored carbon fiber and its color responsiveness

-

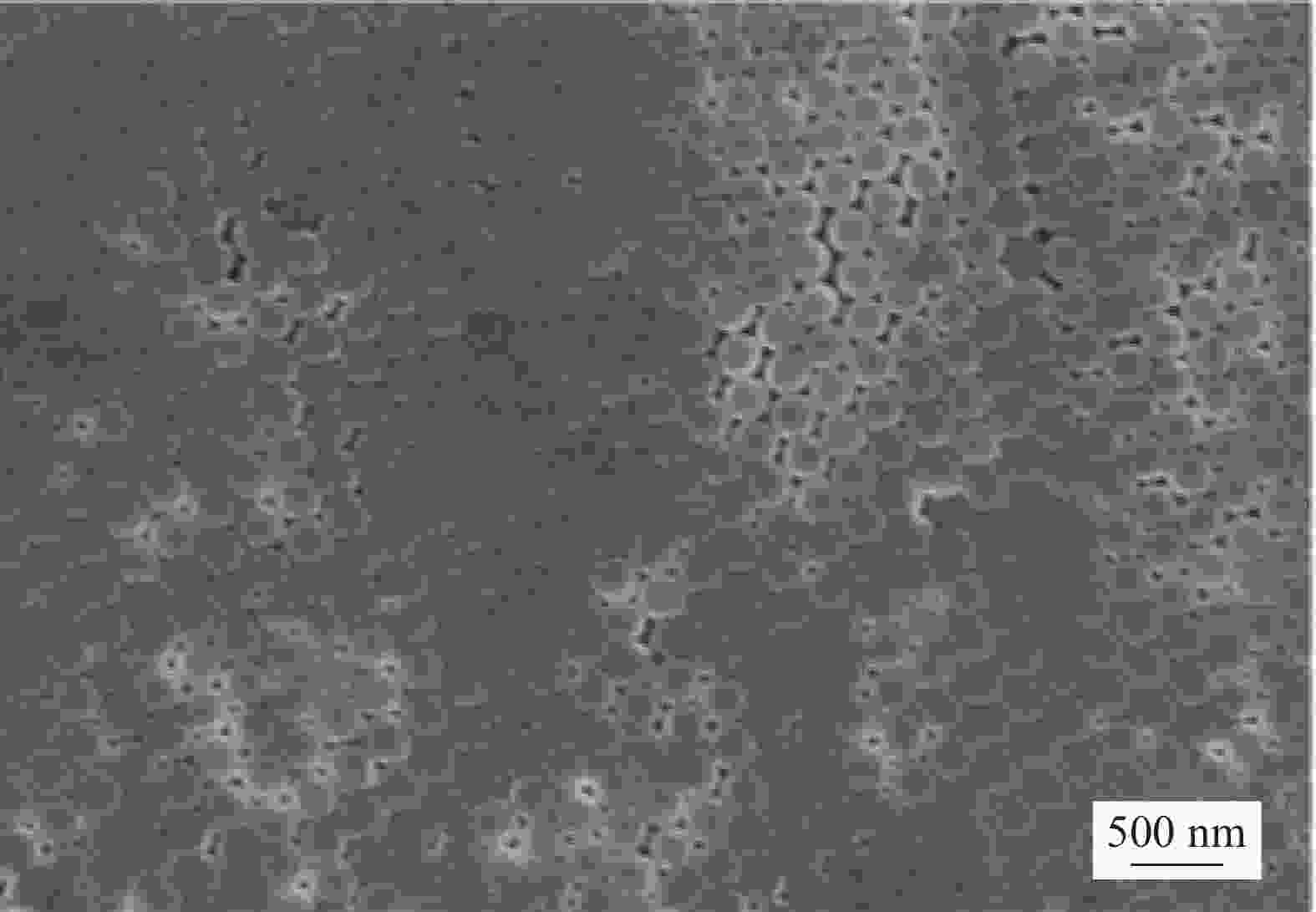

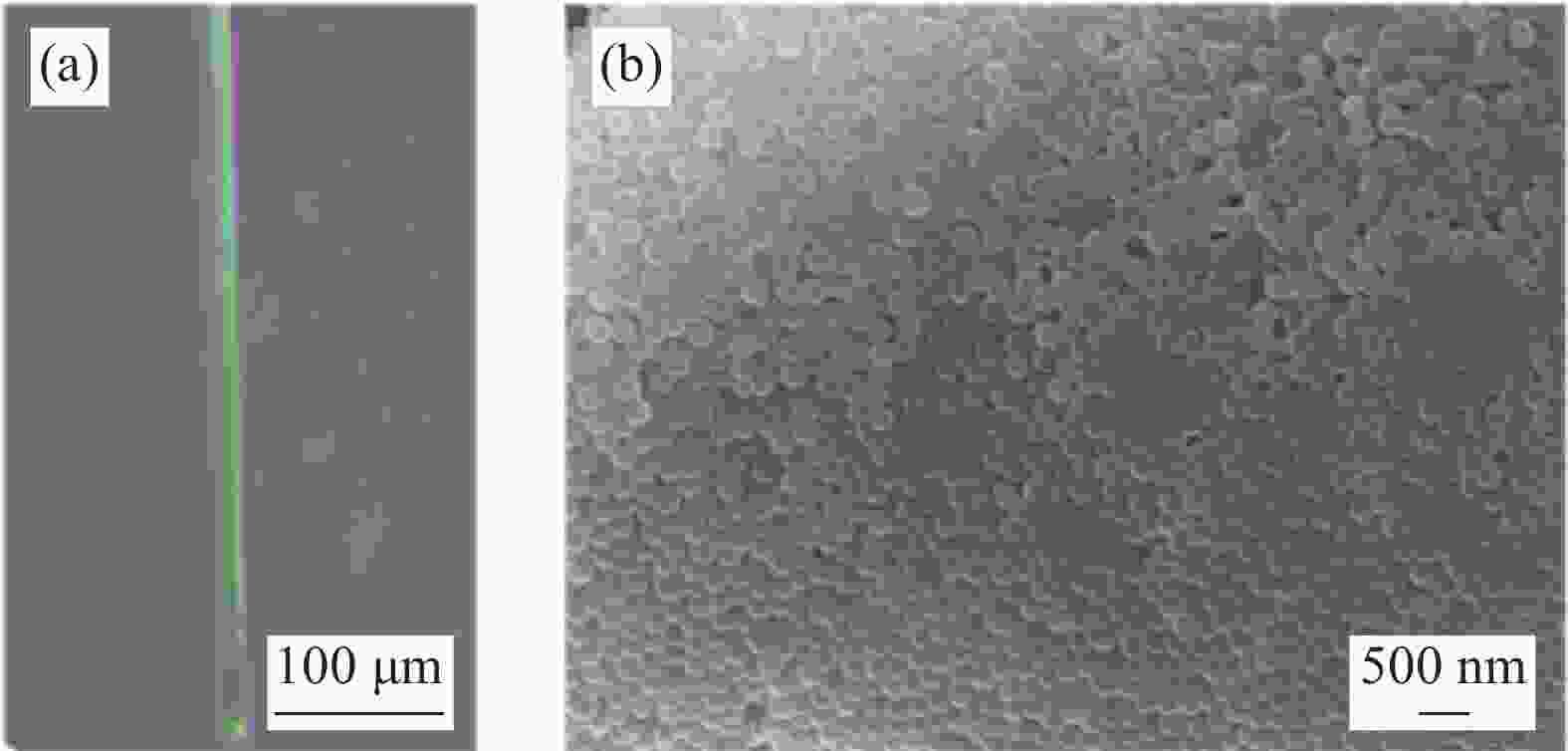

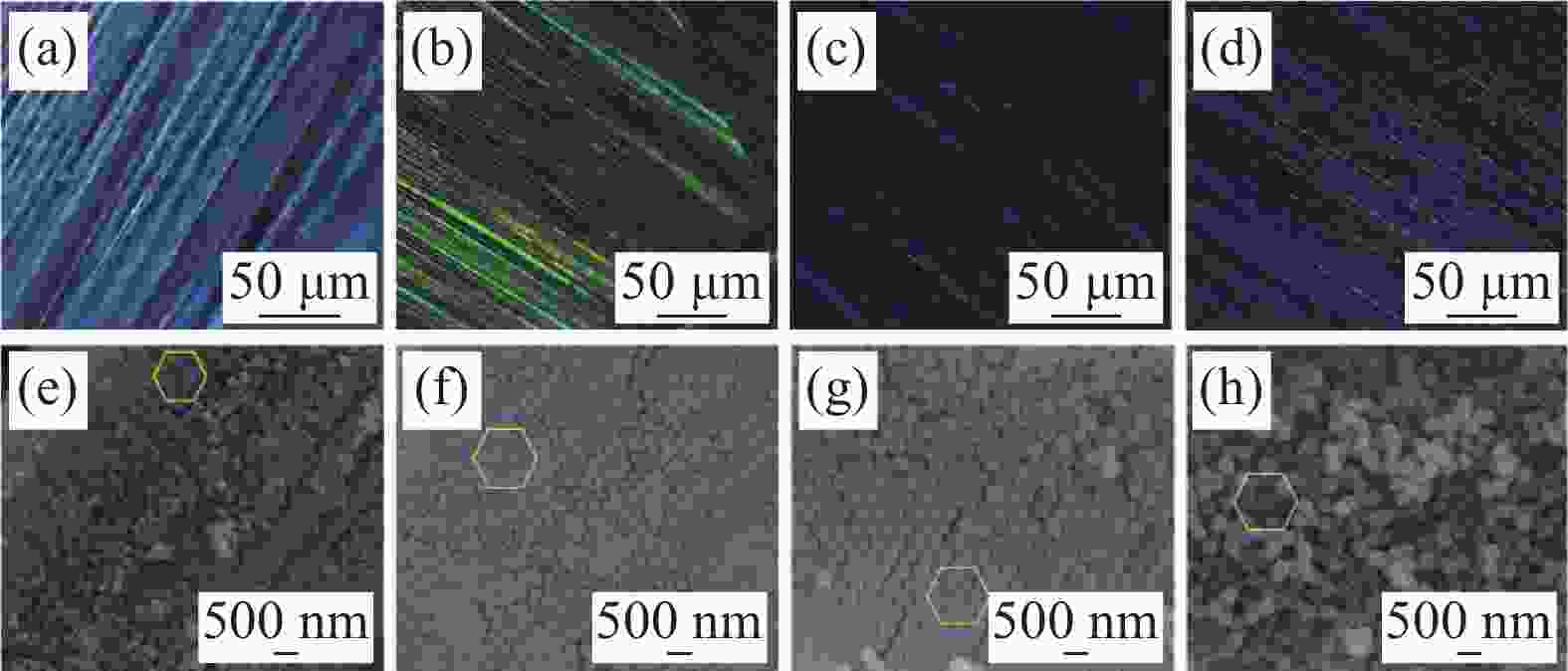

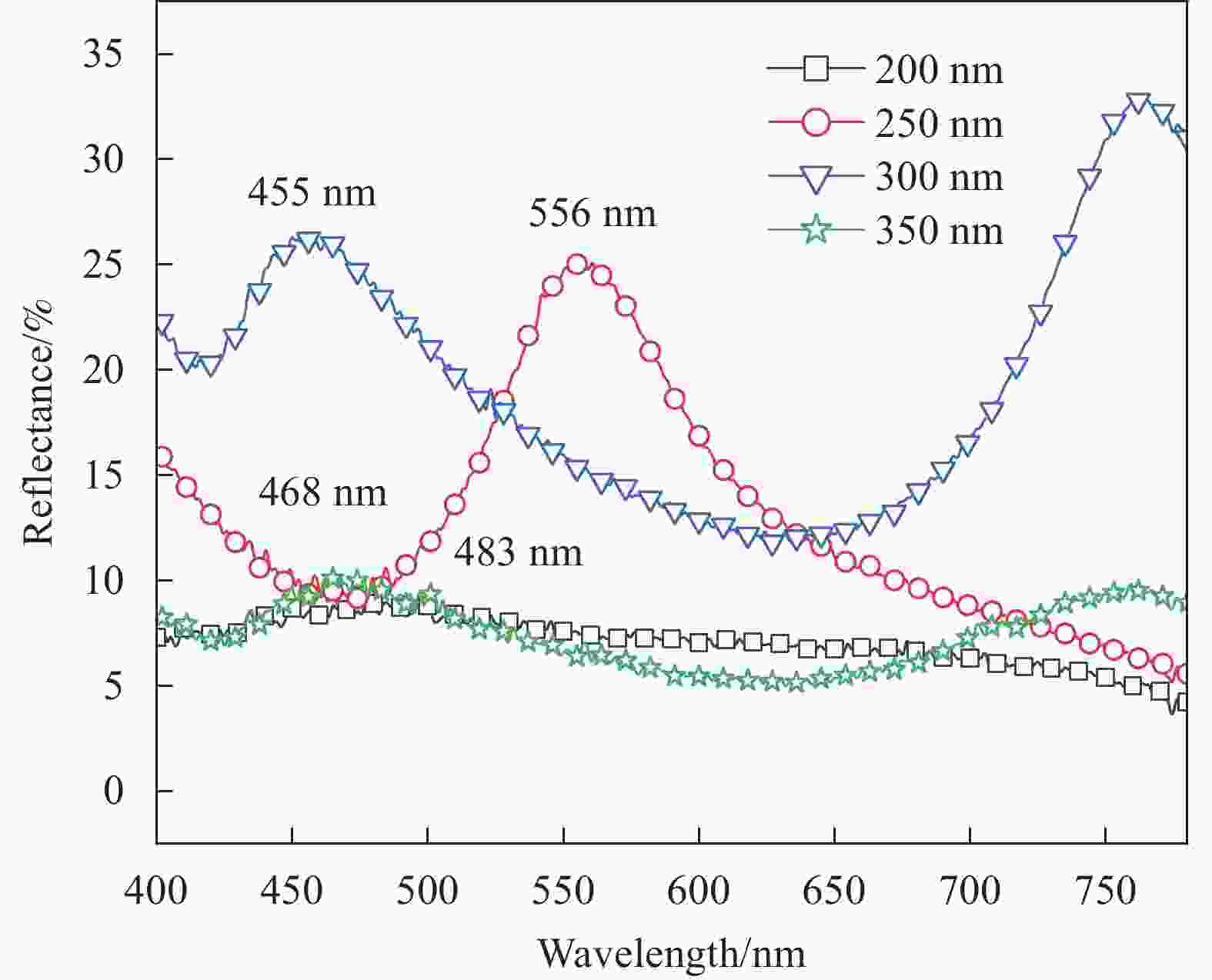

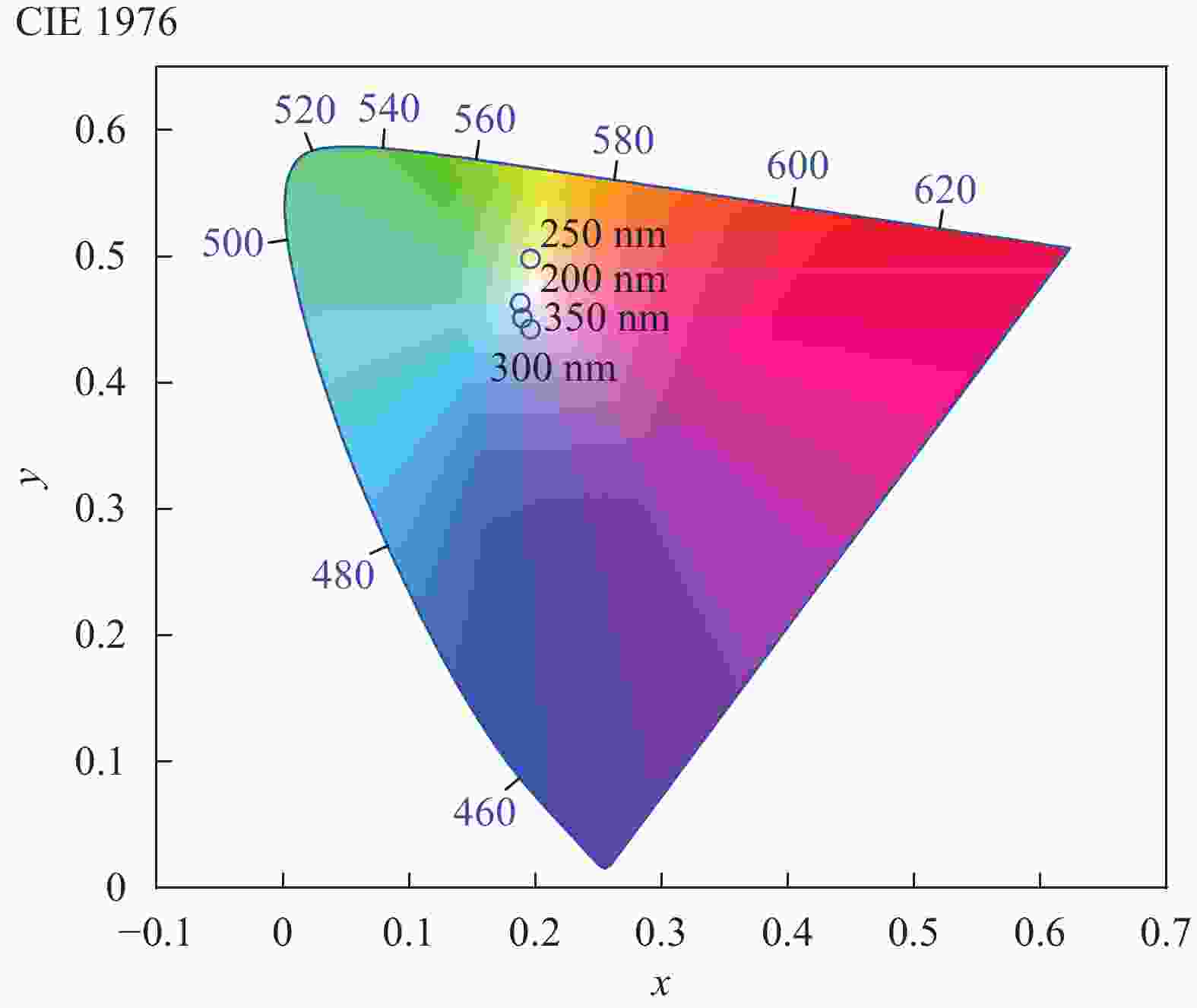

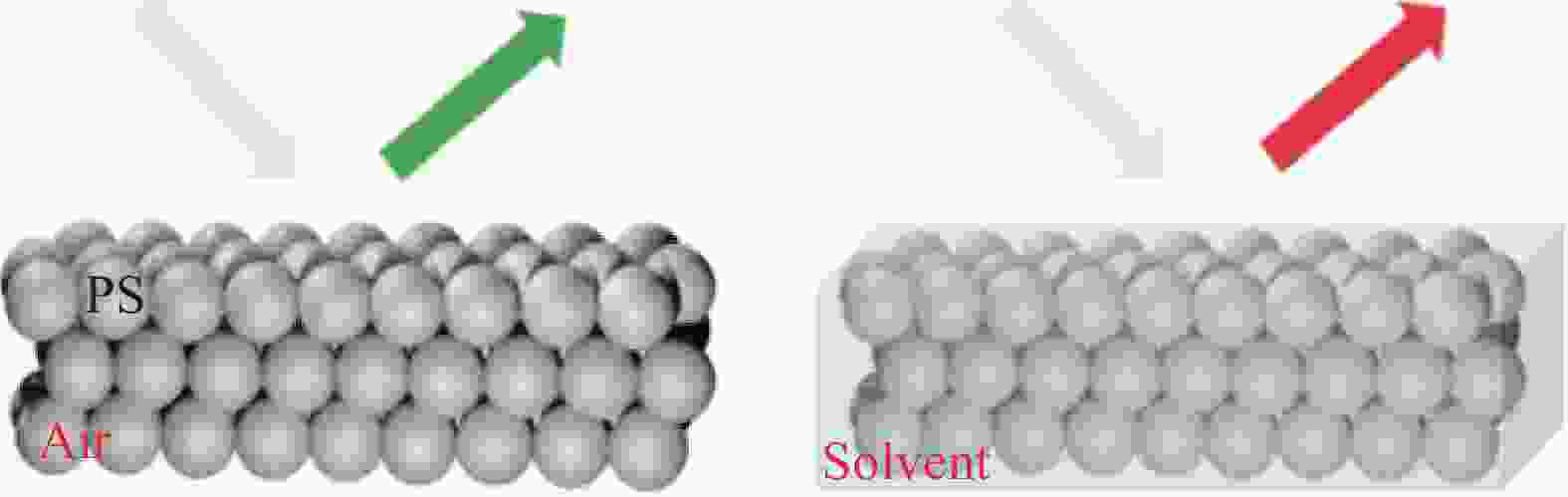

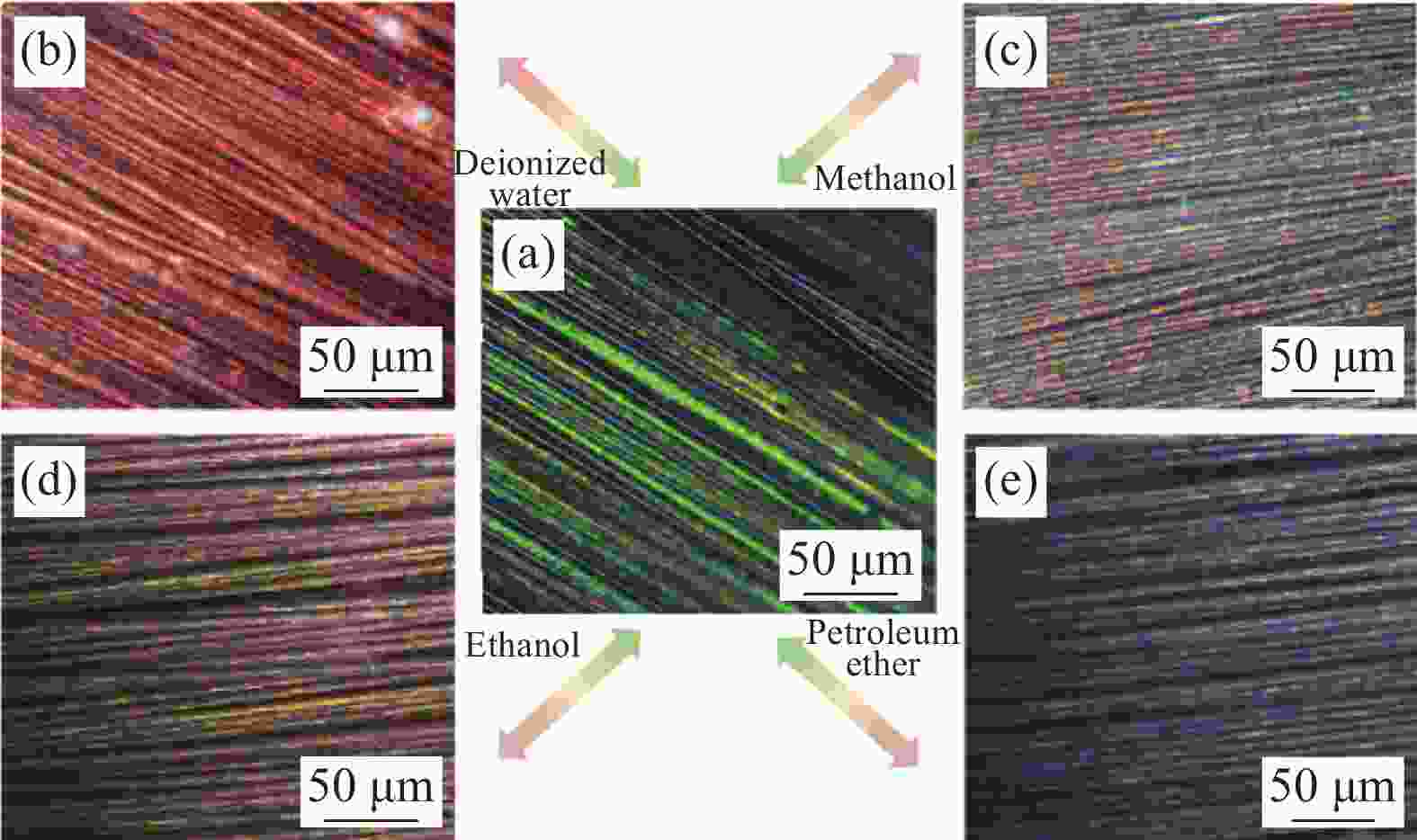

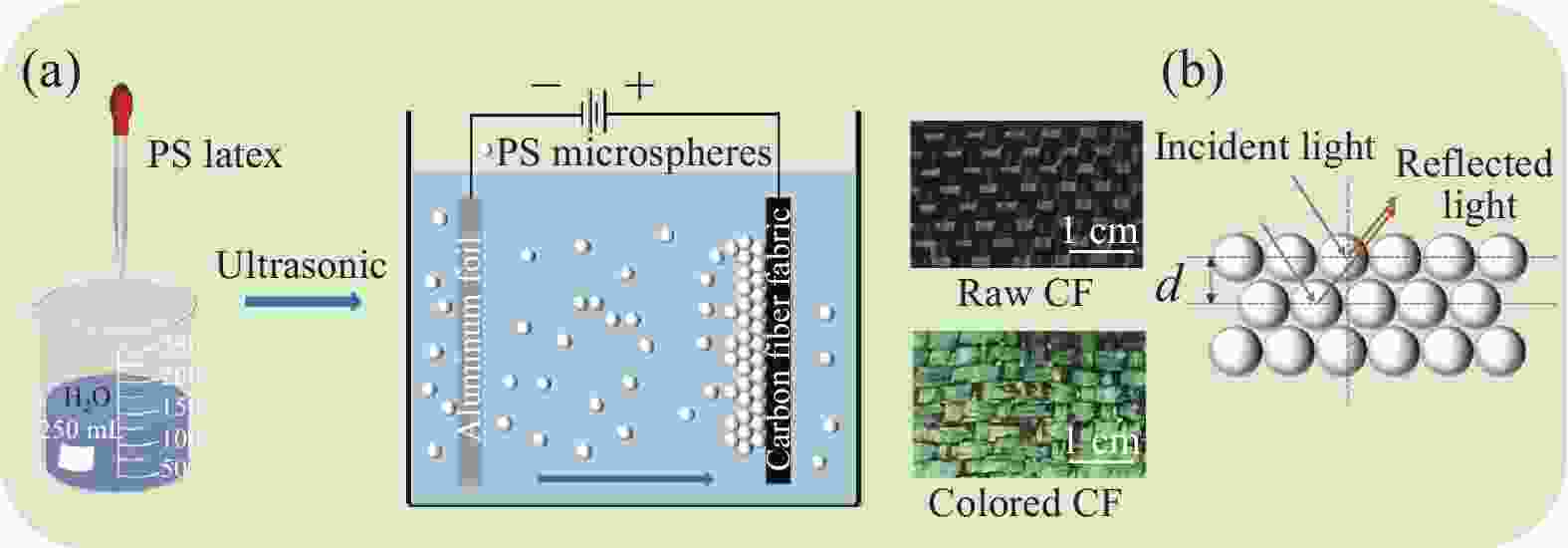

摘要: 碳纤维(CF)具有极为优异的力学性能、耐热性、良好的导电性,在航空航天、军事和体育等领域被广泛应用。然而,由于CF自身类石墨结构缺乏极性基团,导致其表面呈现出化学惰性,传统染料难以对CF上色,限制了CF在光学领域的彩色响应以及传感领域的深入研究。采用工艺简单快捷的电泳沉积法(EPD)分别在碳纤维单丝和织物表面沉积不同粒径的聚苯乙烯(PS)微球,构造不同的光子晶体结构色。利用光子晶体带隙可调的性质调控反射波长,从而在碳纤维表面实现结构色响应变化。研究发现:在外加电场作用下,PS微球组装成有序堆积的光子晶体结构。随粒径的差异可呈现出不同的结构色:如蓝色、绿色、紫色、海军蓝等。其中,采用粒径为250 nm微球排布的碳布获得了较高的色彩饱和度。通过改变微球间隙中的填充溶剂,还能够使其内部折射率发生变化,从而呈现出可逆的色彩响应性变化。Abstract: Carbon fiber (CF) exhibits exceptional mechanical properties, thermal resistance, and electrical conductivity, making it widely utilized in aerospace, military, and sports applications. However, due to the absence of polar groups in the graphite-like structure of CF itself, the surface of CF is chemically inert, and it is difficult to color CF with traditional dyes, which limits the color response of CF in the field of optics and in-depth research in the field of sensing. Polystyrene (PS) microspheres of different sizes were deposited on the surface of carbon fiber monofilaments and fabrics by electrophoretic deposition (EPD), which is a simple and fast process. The wavelength of reflection is regulated by the adjustable photonic crystal band gap so that the structural color response can be changed on the surface of carbon fiber. It is found that PS microspheres can be assembled into ordered stacked photonic crystal structures under the action of the applied electric field. The difference in particle size can show different structural colors: such as blue, green, purple, navy blue, and so on. Among them, carbon cloth with 250 nm microspheres was used to obtain higher color saturation. By changing the filling solvent in the microsphere gap, the internal refractive index can also be changed, thus showing a reversible change in color response.

-

表 1 不同粒径的聚苯乙烯微球Zeta电位

Table 1. Zeta potential of polystyrene microspheres with different particle sizes

category Particle size /nm Zeta potential /mv PS-h 250 −32 PS-c 200 −42 PS-c 250 −35 PS-c 300 −35 PS-c 350 −37 Note: Homemade microspheres are abbreviated as PS-h and commercially purchased microspheres are labeled as PS-c. -

[1] BHANUPRAKASH L, PARASURAM S, VARGHESE S. Experimental investigation on graphene oxides coated carbon fibre/epoxy hybrid composites: Mechanical and electrical properties[J]. Composites Science and Technology, Elsevier, 2019, 179: 134-144. doi: 10.1016/j.compscitech.2019.04.034 [2] LIN Z, JIA X, Yang J, et al. High structural stability of colored carbon fiber cloths modified by FeOOH[J]. Applied Surface Science, 2021, 545: 148994. doi: 10.1016/j.apsusc.2021.148994 [3] ZHANG W, DENG X, SUI G, et al. Improving interfacial and mechanical properties of carbon nanotube-sized carbon fiber/epoxy composites[J]. Carbon, Pergamon, 2019, 145: 629-639. doi: 10.1016/j.carbon.2019.01.063 [4] QIN J, WANG C, WANG Y, et al. Synthesis and growth mechanism of carbon nanotubes growing on carbon fiber surfaces with improved tensile strength[J]. Nanotechnology, 2018, 29(39): 395602. doi: 10.1088/1361-6528/aad10c [5] YU J, LEE C H, KAN C-W, et al. Fabrication of Structural-Coloured Carbon Fabrics by Thermal Assisted Gravity Sedimentation Method[J]. Nanomaterials, 2020, 10(6): 1133. doi: 10.3390/nano10061133 [6] XU H, ZHU Y, GUO Y, et al. Bio-inspired structural coloration of carbon fiber based on thin film interference: Synergistically enhancing thermal durability, tensile strength and interface properties of colored fiber[J]. Reactive and Functional Polymers, 2024, 194: 105789. doi: 10.1016/j.reactfunctpolym.2023.105789 [7] LIU H, ZHANG Y, JIN M, et al. Preparation of carbon fiber substrates with structural colors based on photonic crystals[J]. Dyes and Pigments, 2022, 203: 110338. doi: 10.1016/j.dyepig.2022.110338 [8] ZHAO K, CHENG J, SUN N, et al. Photonic Janus Carbon Fibers with Structural Color Gradient for Multicolored, Wirelessly Wearable Thermal Management Devices[J]. Advanced Materials Technologies, 2022, 7(5): 2101057. doi: 10.1002/admt.202101057 [9] 张子璐 , 刘云燕 , 谢新媛 , 邓民威, 李风煜. 多彩结构色-柔性光子晶体材料与应用[J]. 包装工程, 2022, 43(19): 40–48.ZHANG Zi-Lu, LIU Yun-Yan, XIE Xin-Yuan, DENG Min-Wei, LI Feng-Yu. Versatile Structure Color-Flexible Photonic Crystal Material and Its Application[J]. Packaging Engineering, 2022, 43(19): 40-48(in Chinese). [10] ZHOU S, ZHANG C, FU Z, et al. Color construction of multi-colored carbon fibers using glucose[J]. Nature Communications, Nature Publishing Group, 2024, 15(1): 1979. [11] WEI B, ZHANG Z, YANG D, et al. Lattice Transformation-Induced Retroreflective Structural Colors[J]. ACS Applied Materials & Interfaces, American Chemical Society, 2023, 15(40): 47350–47358. [12] XIE X, ZHANG Z, JIANG Q, et al. A Rainbow Structural Color by Stretchable Photonic Crystal for Saccharide Identification[J]. ACS Nano, American Chemical Society, 2022, 16(12): 20094-20099. [13] HU Y, WEI B, YANG D, et al. Chameleon-Inspired Brilliant and Sensitive Mechano-Chromic Photonic Skins for Self-Reporting the Strains of Earthworms[J]. ACS Applied Materials & Interfaces, 2022, 14(9): 11672-11680. [14] LAI X, PENG J, CHENG Q, et al. Bioinspired Color Switchable Photonic Crystal Silicone Elastomer Kirigami[J]. Angewandte Chemie International Edition, 2021, 60(26): 14307-14312. doi: 10.1002/anie.202103045 [15] ZHANG Z, WEI B, HU Y, et al. Extraordinary sensitive mechanochromic hydrogels for visually detecting ultrasmall pressure[J]. Cell Reports Physical Science, 2023, 4(5): 101387. doi: 10.1016/j.xcrp.2023.101387 [16] SUN L, CHEN Z, XU D, et al. Electroconductive and Anisotropic Structural Color Hydrogels for Visual Heart-on-a-Chip Construction[J]. Advanced Science, 2022, 9(16): 2105777. doi: 10.1002/advs.202105777 [17] WANG X, WANG Y, LU C, et al. Chameleon-inspired flexible photonic crystal lens-shaped dynamic pressure sensor based on structural color shift[J]. Cell Reports Physical Science, 2023, 4(7): 101490. doi: 10.1016/j.xcrp.2023.101490 [18] LIU G, HAN P, CHAI L, et al. Fabrication of cotton fabrics with both bright structural colors and strong hydrophobicity[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 600: 124991. doi: 10.1016/j.colsurfa.2020.124991 [19] WEI L, SHANG S, ZHENG Y, et al. Iridescent structural colors printing on cellulose fabrics with robust structural coloration[J]. Dyes and Pigments, 2024, 221: 111824. doi: 10.1016/j.dyepig.2023.111824 [20] NIU W, ZHANG L, WANG Y, et al. Multicolored Photonic Crystal Carbon Fiber Yarns and Fabrics with Mechanical Robustness for Thermal Management[J]. ACS Applied Materials & Interfaces, 2019, 11(35): 32261-32268. [21] XU P, HOU J, CHENG J, et al. Color carbon fiber and its discoloration response[J]. Carbon, 2022, 199: 42-50. doi: 10.1016/j.carbon.2022.07.039 [22] VUKUSIC P, SAMBLES J R, LAWRENCE C R. Colour mixing in wing scales of a butterfly[J]. Nature, Nature Publishing Group, 2000, 404(6777): 457-457. [23] CHEN F, YANG H, LI K, et al. Facile and Effective Coloration of Dye-Inert Carbon Fiber Fabrics with Tunable Colors and Excellent Laundering Durability[J]. ACS Nano, 2017, 11(10): 10330-10336. doi: 10.1021/acsnano.7b05139 [24] ZHOU C, QI Y, ZHANG S, et al. Rapid fabrication of vivid noniridescent structural colors on fabrics with robust structural stability by screen printing[J]. Dyes and Pigments, 2020, 176: 108226. doi: 10.1016/j.dyepig.2020.108226 [25] LI K, LI C, LI H, et al. Designable structural coloration by colloidal particle assembly: from nature to artificial manufacturing[J]. iScience, 2021, 24(2): 102121. doi: 10.1016/j.isci.2021.102121 [26] HUANG N N, GAO J, SHENG S Z, et al. Structural Design of Intelligent Reversible Two-Way Structural Color Films[J]. Nano Letters, American Chemical Society, 2023, 23(16): 7389-7396. -

点击查看大图

点击查看大图

计量

- 文章访问数: 41

- HTML全文浏览量: 23

- 被引次数: 0

下载:

下载: