Experimental and theoretical investigation on shear performance degradation of GFRP bars in concrete after fire and high temperature

-

摘要: 为研究火灾高温后混凝土内玻璃纤维增强树脂复合材料(GFRP)筋材的剪切性能,选取了100℃、150℃、200℃、300℃、350℃、400℃、500℃、650℃及800℃共9个温度工况,对混凝土内GFRP筋进行了高温作用及水平剪切试验;结合本试验及已有相关试验结果,对高温后混凝土内GFRP筋水平剪切强度预测方法进行了探讨。试验及分析结果表明:300℃高温以内,混凝土内GFRP筋表面温度存在滞后现象,其高温劣化程度明显低于裸筋,剪切强度退化也较缓慢;随着温度超过300℃及混凝土表面裂缝不断发展,内部GFRP筋受高温侵蚀逐步加大,剪切强度出现急剧下降,并出现与裸筋相似的退化规律;在300℃(接近树脂热分解温度)高温下,GFRP筋剪切强度随恒温时间的增加而线性下降,恒温1~3 h时其剪切强度保留率从76.4%降为46.5%。结合双曲正切函数模型,建立了高温后混凝土内GFRP筋水平剪切强度预测模型,其预测值与试验值吻合较好。最后,以剪切强度保留系数0.7为基准,给出了不同保护层厚度下GFRP筋的耐火时间预测值,供工程应用参考。

-

关键词:

- 火灾高温作用 /

- GFRP筋混凝土构件 /

- 水平剪切性能 /

- 预测模型 /

- 变异系数

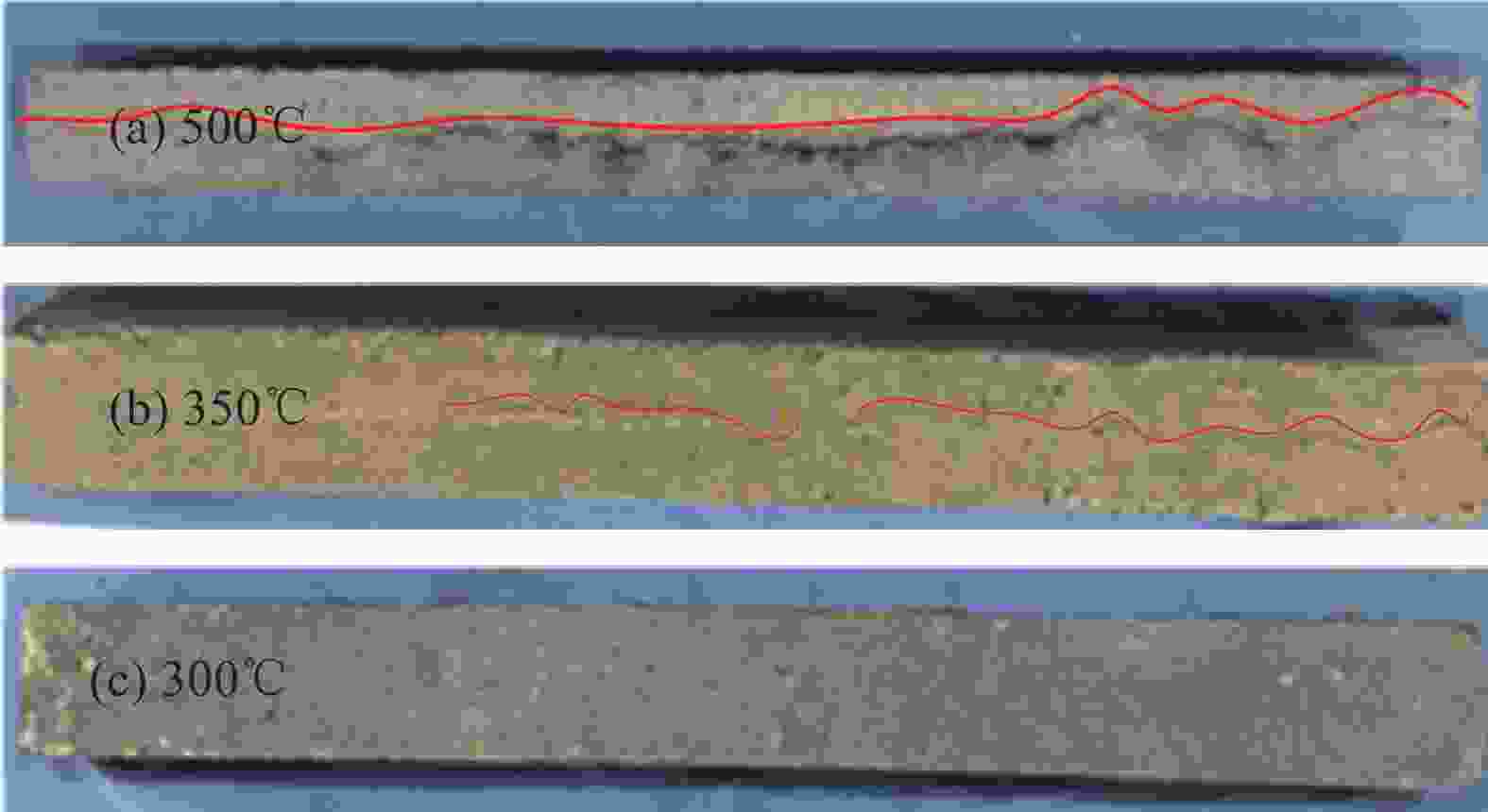

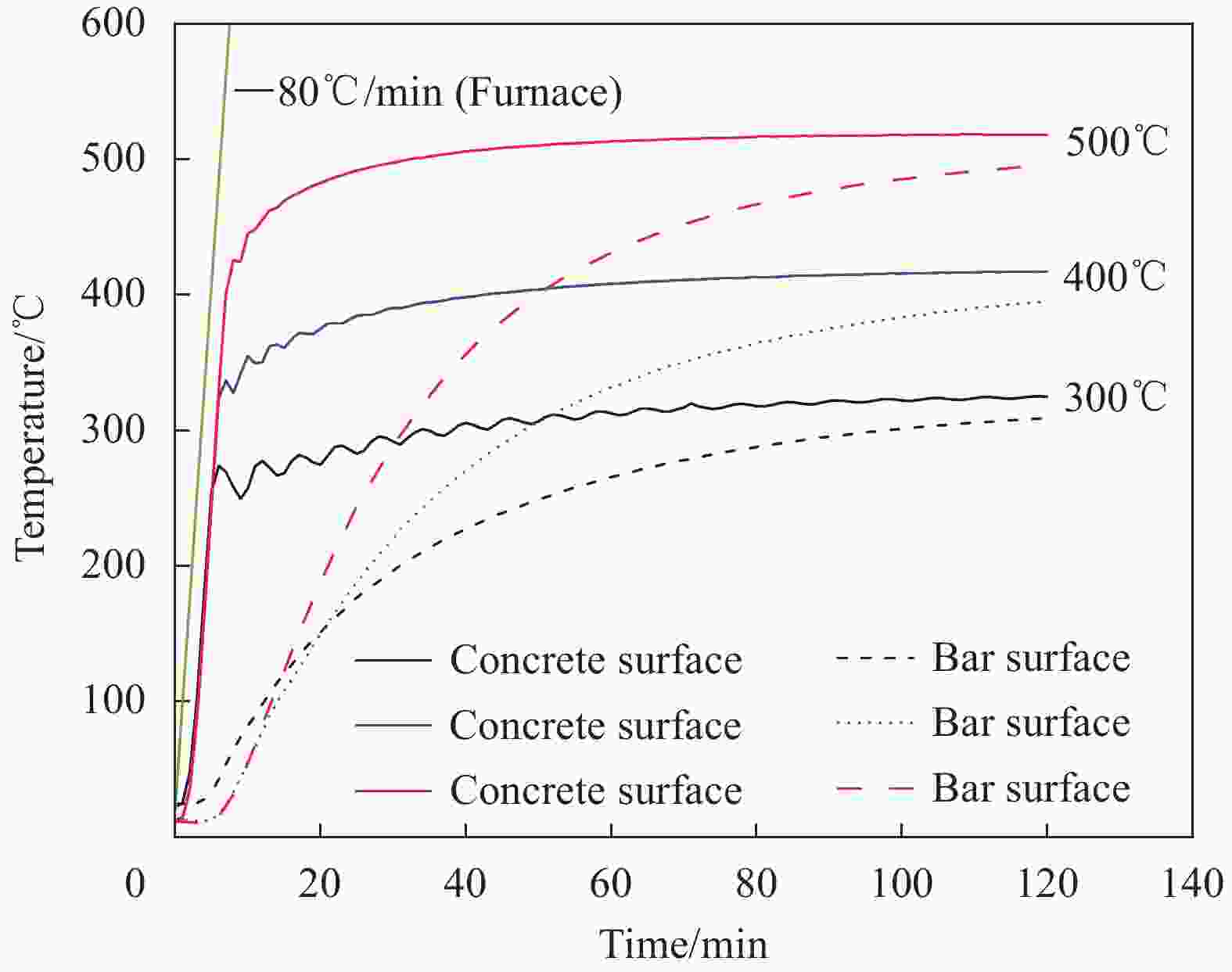

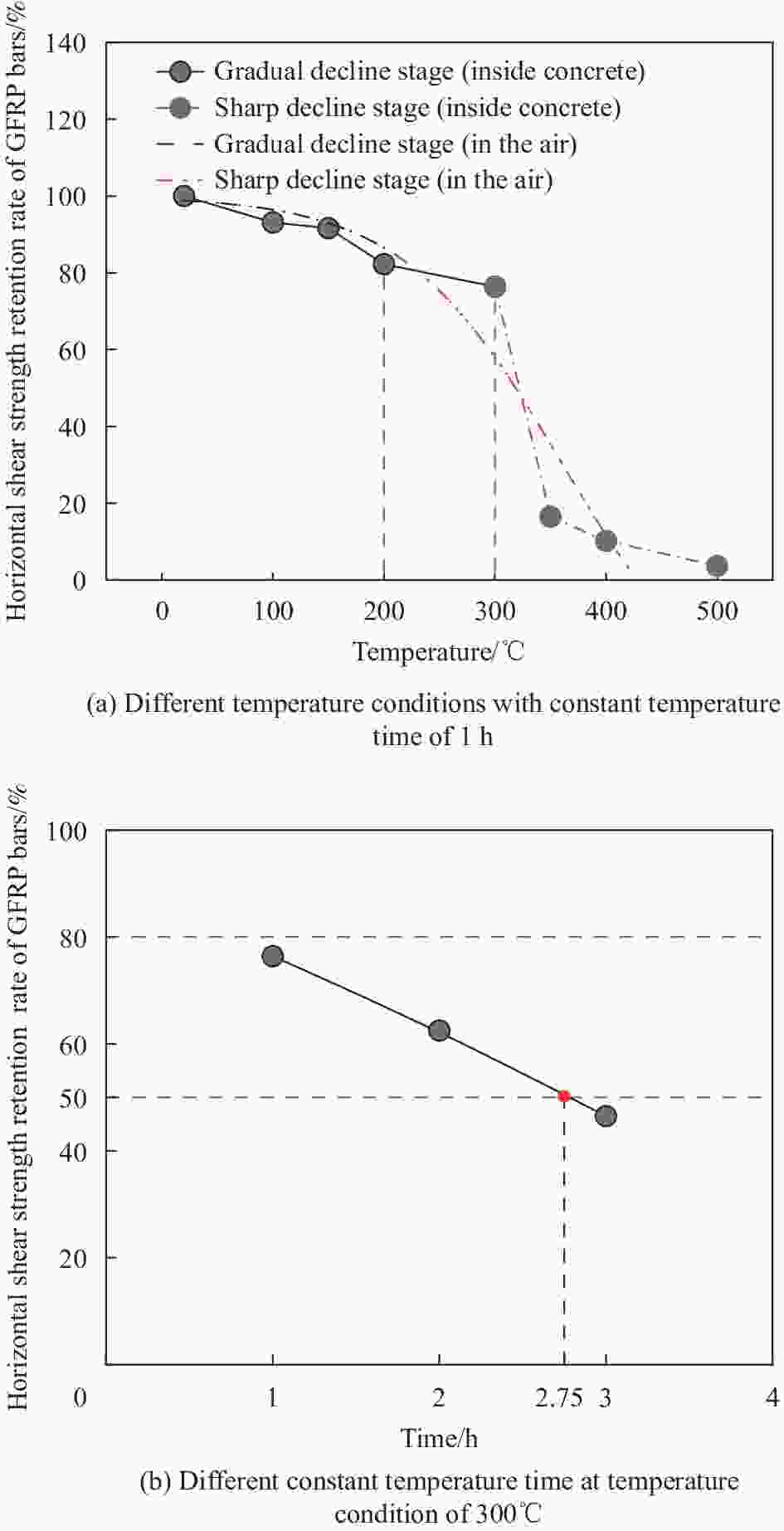

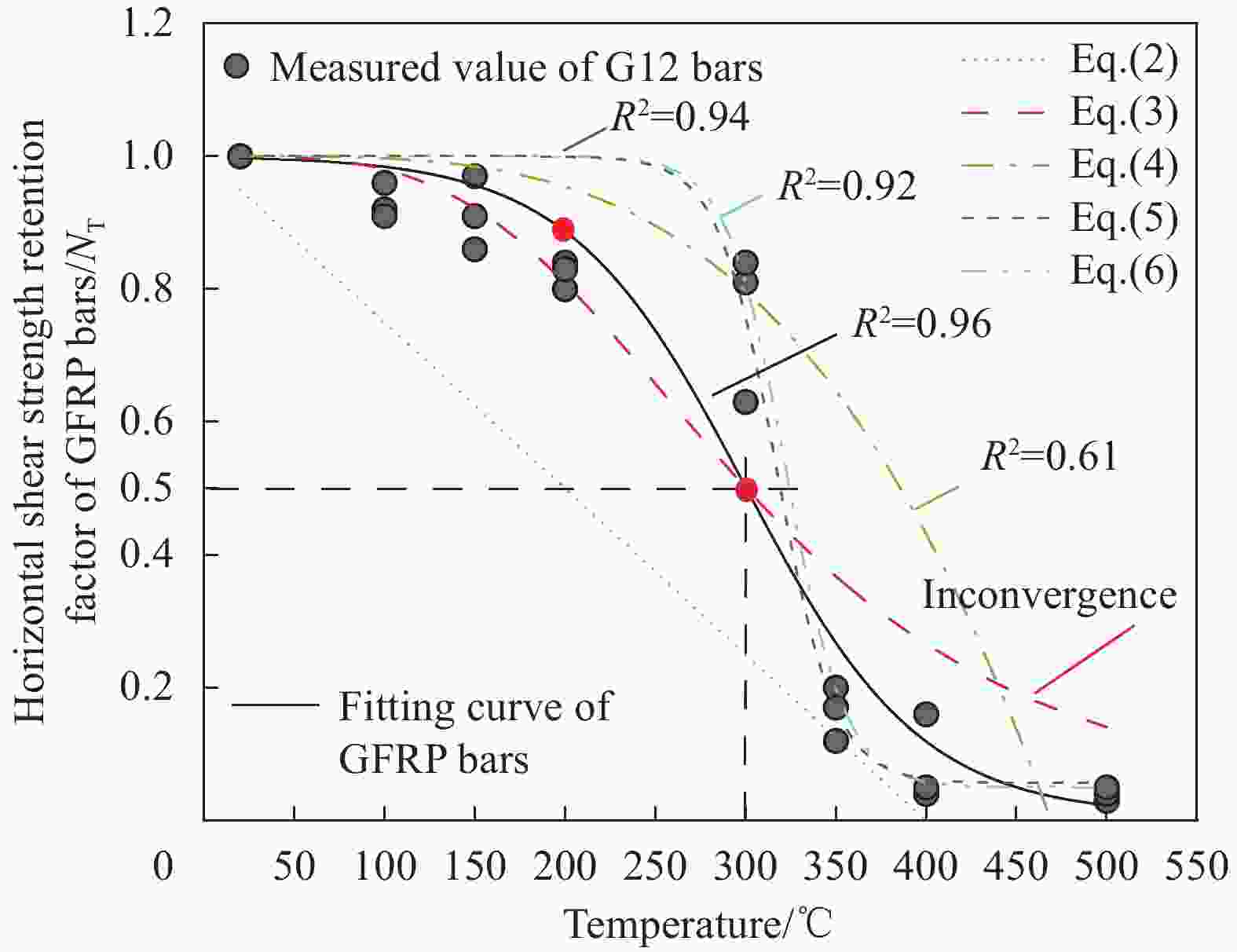

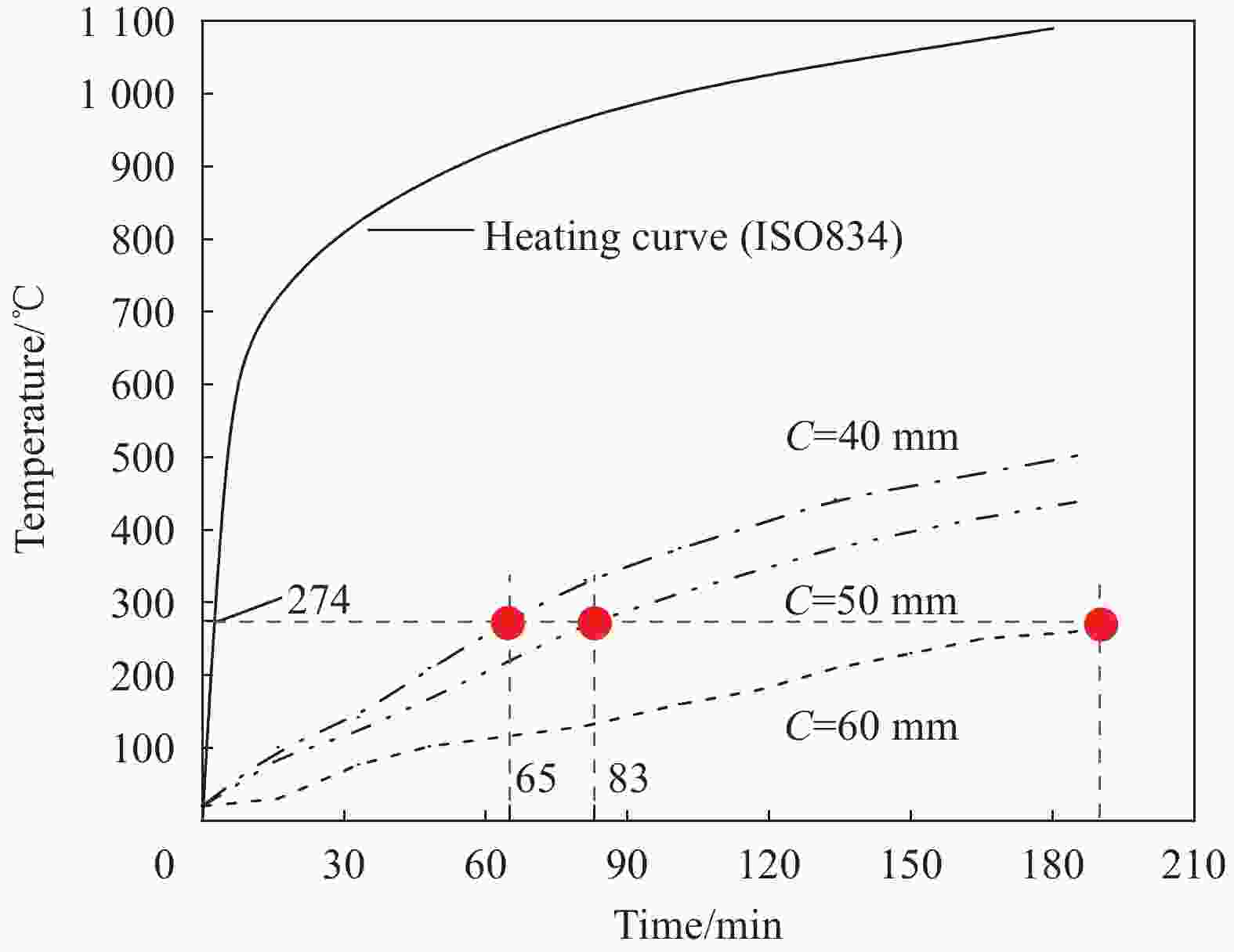

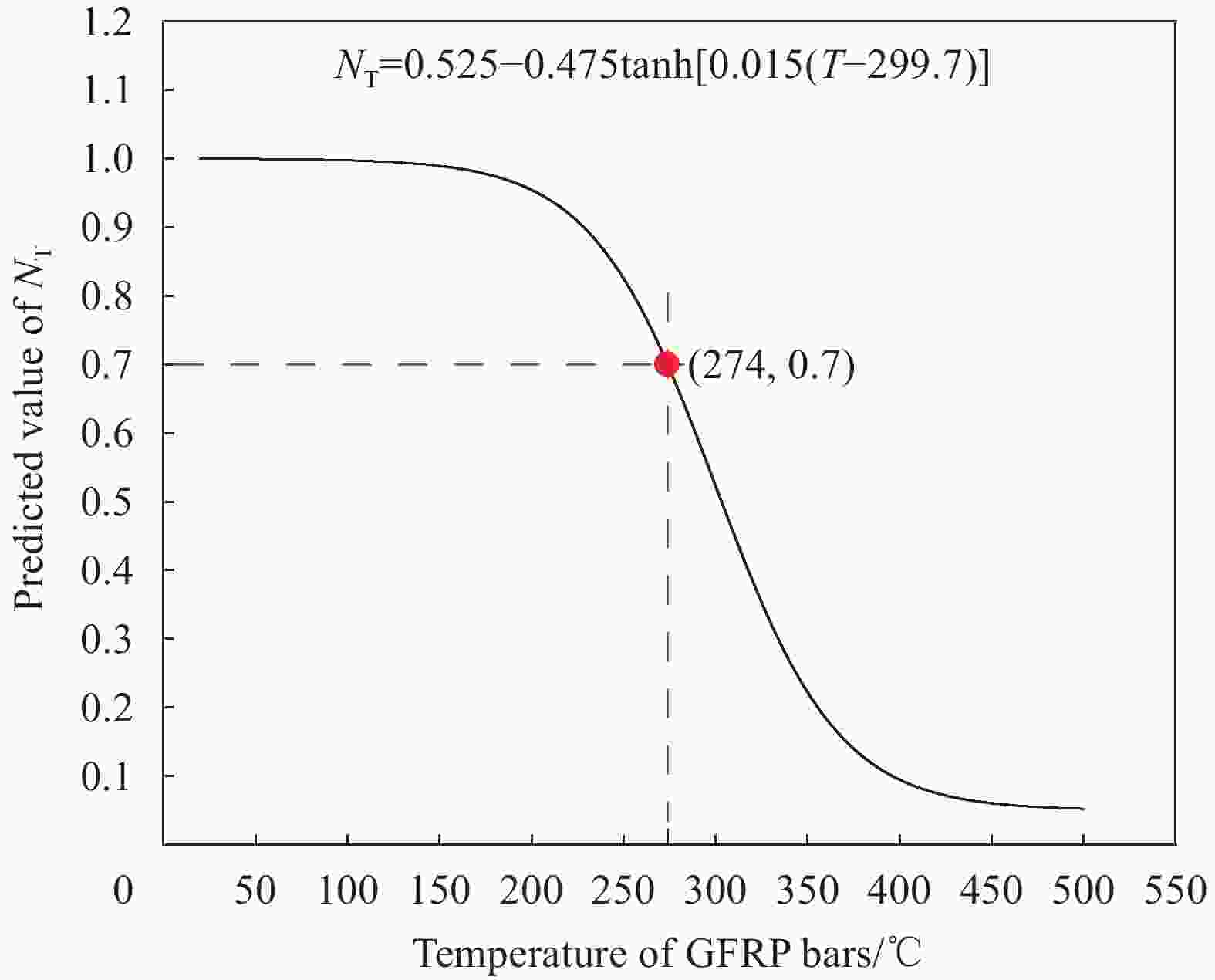

Abstract: To explore the shear performance of glass fiber reinforced polymer (GFRP) bars in concrete after fire and high temperature, nine temperature conditions of 100°C, 150°C, 200°C, 300°C, 350°C, 400°C, 500°C, 650°C and 800°C were selected to treat the GFRP bars placed in concrete, and the horizontal shear tests were carried out on the obtained bar specimens. The method of predicting the horizontal shear strength of GFRP bars in concrete after exposure to high temperature was discussed using the results of this study and some existing tests. Test and analytical results show that within 300°C there is a hysteresis phenomenon in the surface temperature of GFRP bars in concrete. Their high temperature deterioration is significantly lower than that of the bare bars, as well as the shear strength degradation is also relatively slow. As the temperature exceeds 300°C and the concrete surface cracks continue to develop, the deterioration of embedded GFRP bars caused by high temperature gradually enlarges, meanwhile, the shear strength decreases sharply, which shows a similar degradation pattern to that of bare bars. At high temperature of 300°C which is close to the thermal decomposition temperature of resins, the shear strength retention rate of GFRP bars decreases linearly from 76.4% to 46.5% with the constant temperature time increasing from 1 h to 3 h. Based on the hyperbolic tangent function model, a prediction model for the horizontal shear strength of GFRP bars in concrete after high temperature was established and model’s predictions were in good agreement with test values. Finally, considering a shear strength retention factor of 0.7, the predictions of fire resistance time of GFRP bars with different cover thickness were proposed, which can provide some references for engineering application. -

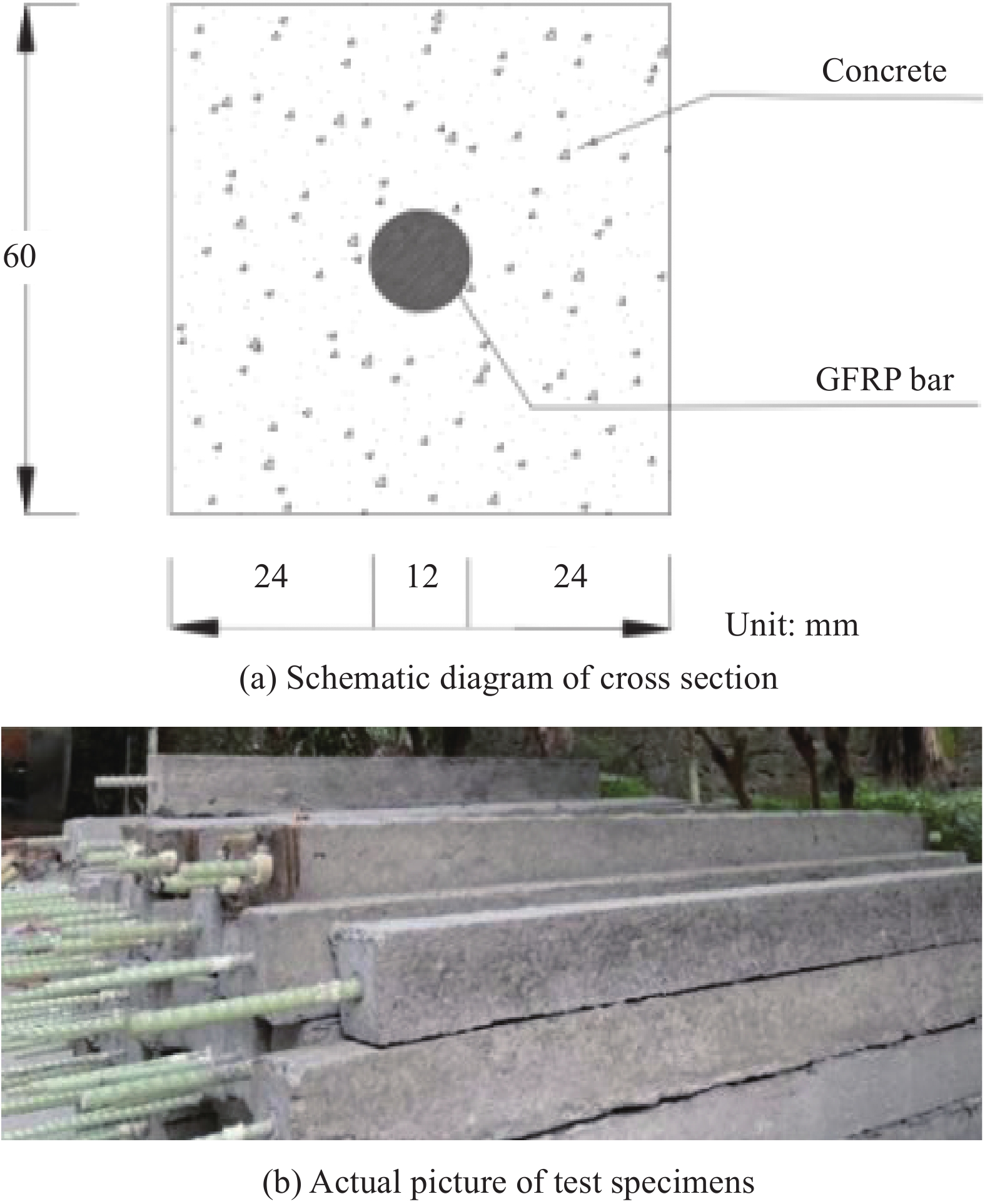

表 1 玻璃纤维增强树脂复合材料(GFRP)筋基本力学性能

Table 1. Basic mechanical properties of glass fiber reinforced polymer (GFRP) bars

Bar type Tensile strength/MPa Tensile elastic modulus/GPa Bending strength/MPa Horizontal shear strength/MPa GFRP 884.6 32.8 875.8 47.7 表 2 混凝土配合比及基本参数

Table 2. Concrete mix ratio and basic parameters

Strength grade of concrete Water binder ratio Material/(kg·m−3) Measured compressive strength/MPa Water Cement Sand Stones C30 0.49 220 449 615 1116 33.8 表 3 不同温度工况下GFRP筋的水平剪切强度及保留率

Table 3. Horizontal shear strength and retention rate of GFRP bars under different temperature conditions

T/℃ F/N S/MPa Statistical characteristics R/% No.1 No.2 No.3 No.1 No.2 No.3 μ/MPa COV 20 7995.3 8607.5 7656.2 47.1 50.8 45.1 47.7 0.06 100.0 100 7791.4 7415.2 7379.4 45.9 43.7 43.5 44.4 0.03 93.1 150 6976.8 7375.1 7878.1 41.1 43.5 46.5 43.7 0.06 91.6 200 6480.6 6766.1 6707.3 38.2 39.9 39.6 39.2 0.02 82.3 300 6564.2 5134.5 6827.3 38.7 30.3 40.3 36.4 0.15 76.4 350 1654.7 1006.1 1335.2 9.8 5.9 7.9 7.9 0.24 16.5 400 315.5 1333.5 – 1.9 7.9 – 4.9 0.87 10.2 500 266.9 326.1 – 1.6 1.9 – 1.7 0.14 3.7 Notes: T—Temperature; F—Maximum load; S—Horizontal shear strength; μ—Average value; COV—Coefficient of variation; R—Retention rate of horizontal shear strength. 表 4 300℃下不同恒温时间t作用后GFRP筋水平剪切强度及保留率

Table 4. Horizontal shear strength and retention rate of GFRP bars after different constant temperature time t at 300℃

t/h F/N S/MPa Statistical characteristics R/% No.1 No.2 No.3 No.1 No.2 No.3 μ/MPa COV 1 6563.3 5134.4 6828.3 38.7 30.3 40.3 36.4 0.15 76.4 2 5784.6 4268.1 5111.3 34.1 25.2 30.1 29.8 0.15 62.5 3 4315.8 3798.1 3232.1 25.5 22.4 19.1 22.3 0.14 46.5 表 5 不同保护层厚度下GFRP筋的耐火时间

Table 5. Fire resistance time for GFRP bars with different cover thickness

Case C/mm tf Case one 40 65 Case two 50 83 Case three 60 190 Note: tf—Fire resistance time. -

[1] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-36. doi: 10.3321/j.issn:1000-131X.2006.03.004YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-36(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [2] 陆春华, 吴小龙, 徐可, 等. 普通/钢纤维混凝土混合配筋梁裂缝和挠度计算分析[J]. 南京工业大学学报(自然科学版), 2022, 44(2):197-206.LU Chunhua, WU Xiaolong, XU Ke, et al. Calculation analysis of the cracking and deflection of ordinary/steel fiber concrete hybrid-reinforced beams[J]. Journal of Nanjing Tech University (Natural Science Edition),2022,44(2):197-206(in Chinese). [3] 王晓璐, 查晓雄. 高温下GFRP筋力学性能的试验研究[J]. 华南理工大学学报(自然科学版), 2011, 39(9):75-81.WANG Xiaolu, CHA Xiaoxiong. Experimental investigation into mechanical behavior of GFRP rebars at elevated temperature[J]. Journal of South China University of Technology (Natural Science Edition),2011,39(9):75-81(in Chinese). [4] 李趁趁, 王英来, 赵军, 等. 高温后FRP筋纵向拉伸性能[J]. 建筑材料学报, 2014, 17(6):1076-1081. doi: 10.3969/j.issn.1007-9629.2014.06.024LI Chenchen, WANG Yinglai, ZHAO Jun, et al. Longitudinal tensile properties of FRP bars after high temperature[J]. Journal of Building Materials,2014,17(6):1076-1081(in Chinese). doi: 10.3969/j.issn.1007-9629.2014.06.024 [5] ASHRAFI H, BAZLI M, NAJAFABADI E P, et al. The effect of mechanical and thermal properties of FRP bars on their tensile performance under elevated temperatures[J]. Construction and Building Materials,2017,157:1001-1010. doi: 10.1016/j.conbuildmat.2017.09.160 [6] 朱德举, 徐旭锋, 郭帅成, 等. 高温后玄武岩和玻璃纤维增强复合材料筋的力学性能[J]. 湖南大学学报(自然科学版), 2021, 48(7):151-159. doi: 10.16339/j.cnki.hdxbzkb.2021.07.018ZHU Deju, XU Xufeng, GUO Shuaicheng, et al. Mechanical properties of basalt and glass fiber reinforced polymer tendons after exposed to elevated temperatures[J]. Journal of Hunan University (Natural Sciences),2021,48(7):151-159(in Chinese). doi: 10.16339/j.cnki.hdxbzkb.2021.07.018 [7] GUO X K, XIONG C S, JIN Z Q, et al. A review on mechanical properties of FRP bars subjected to seawater sea sand concrete environmental effects[J]. Journal of Building Engineering,2022,58(15):105038. [8] AHMAD S M. Shear properties and durability of GFRP reinforcement bar aged in seawater[J]. Polymer Testing,2019,75:312-320. [9] 屈凯. 真实火灾下钢筋混凝土板温度场有限元分析[J]. 硅酸盐通报, 2020, 39(6):1815-1821. doi: 10.16552/j.cnki.issn1001-1625.2020.06.018QU Kai. FFinite element analysis on temperature distribution of reinforced concrete slabs in natural fire[J]. Bulletin of the Chinese Ceramic Society,2020,39(6):1815-1821(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2020.06.018 [10] International Standards Organization (ISO). Fire resistance tests-Elements of building construction—Part 1: General requirements: ISO 834-1[S]. Geneve: International Organization for Standardization, 1999. [11] 中国国家标准化管理委员会. 拉挤玻璃纤维增强塑料杆力学性能试验方法: GB/T 13096—2008[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Test method for mechanical properties of pultruded glass fiber reinforced plastic rods: GB/T 13096—2008[S]. Beijing: China Standards Press, 2009(in Chinese). [12] American Society for Testing and Materials. Standard test method for apparent horizontal shear strength of pultruded reinforced plastic rods by the short-beam method: ASTM D4475-21[S]. West Conshohocken: ASTM, 2021. [13] 金浏, 张仁波, 杜修力, 等. 温度对混凝土结构力学性能影响的研究进展[J]. 土木工程学报, 2021, 54(3):1-18. doi: 10.15951/j.tmgcxb.2021.03.001JIN Liu, ZHANG Renbo, DU Xiuli, et al. Research progress on the influence of temperature on the mechanical performance of concrete structures[J]. China Civil Engineering Journal,2021,54(3):1-18(in Chinese). doi: 10.15951/j.tmgcxb.2021.03.001 [14] 蔡启明, 陆春华, 延永东, 等. BFRP和GFRP筋剪切性能的温度效应[J]. 建筑材料学报, 2022, 25(4):395-400. doi: 10.3969/j.issn.1007-9629.2022.04.010CAI Qiming, LU Chunhua, YAN Yongdong, et al. Tempera-ture effect on shear properties of BFRP and GFRP bar[J]. Journal of Building Materials,2022,25(4):395-400(in Chinese). doi: 10.3969/j.issn.1007-9629.2022.04.010 [15] SAAFI M. Effect of fire on FRP reinforced concrete members[J]. Composite Structures,2002,58(1):11-20. doi: 10.1016/S0263-8223(02)00045-4 [16] NIGRO E, CEFARELLI G, BILOTTA A, et al. Guidelines for flexural resistance of FRP reinforced concrete slabs and beams in fire[J]. Composites Part B: Engineering,2014,58:103-112. doi: 10.1016/j.compositesb.2013.10.007 [17] ZHOU C H, PAN J J, ZHANG Z H, et al. Comparative study on the tensile mechanical behavior of GFRP bars under and after high temperature exposure[J]. Case Studies in Construction Materials, 2022, 16: e00905. [18] MOURITZ A P, GIBSON A G. Fire properties of polymer composite materials[M]. Dordrecht: Springer, 2006. [19] BISBY L A. Fire behaviour of fibre-reinforced polymer (FRP) reinforced or confined concrete[D]. Kingston: Queen's University at Kingston, 2003. [20] 中华人民共和国住房和城乡建设部, 国家质量监督检验检疫总局. 建筑设计防火规范: GB/T 50016—2014(2018)[S]. 北京: 中国计划出版社, 2018.Ministry of Housing and Urban Rural Development of the People's Republic of China, General Administration of Quality Supervision, Inspection and Quarantine. Code for fire protection design of buildings: GB/T 50016—2014(2018)[S]. Beijing: China Planning Press, 2018(in Chinese). [21] 中华人民共和国住房和城乡建设部, 国家质量监督检验检疫总局. 混凝土结构设计规范: GB/T 50010—2010(2015)[S]. 北京: 中国建筑工业出版社, 2015.Ministry of Housing and Urban Rural Development of the People's Republic of China, General Administration of Quality Supervision, Inspection and Quarantine. Code for design of concrete structures: GB/T 50010—2010(2015)[S]. Beijing: China Architecture Press, 2015(in Chinese). [22] HAJILOO H, GERRN M F, NOËL M, et al. Fire tests on full-scale FRP reinforced concrete slabs[J]. Composite Structures,2017,179:705-719. doi: 10.1016/j.compstruct.2017.07.060 [23] American Concrete Institute. Guide for the design and construction of structural concrete reinforced with FRP bars: ACI 440.1 R-15[S]. Farmington Hills: ACI, 2015. -

下载:

下载: