Effect of shear key arrangement on the bonding properties of prefabricated UHPC-NC interface

-

摘要: 为了研究预制超高性能混凝土UHPC与普通混凝土(NC)界面的黏结滑移性能,以预制UHPC表面剪力钉的密度和分布间距为试验参数,完成了12组UHPC-NC复合试件的双面剪切试验。结果表明,设置剪力钉构造措施的试件其破坏形态主要有3种,分别为(a) UHPC-NC黏结面与UHPC剪力钉均发生剪切破坏;(b) UHPC-NC黏结面剪切破坏、UHPC剪力钉同时发生剪切和剥离破坏;(c) UHPC-NC黏结面剪切破坏、NC基体轴压破坏。剪力钉密度与分布间距对UHPC-NC试件的黏结面抗剪强度有显著影响;尤其是剪力钉密度,黏结面抗剪强度随着剪力钉密度呈抛物线增长关系。在相同剪力钉密度下,剪力钉分布间距较大试件的黏结面抗剪强度比间距较小试件提高了19.04%~41.74%。基于现有模型及试验结果,建立了考虑黏结面破坏形态及抗剪试验方法的预制UHPC-NC黏结面抗剪强度的计算公式,其计算值与试验值吻合度较高,可为UHPC-NC复合试件的界面设计提供参考。

-

关键词:

- UHPC-NC复合试件 /

- 抗剪强度 /

- 破坏形态 /

- 剪力钉密度 /

- 分布间距

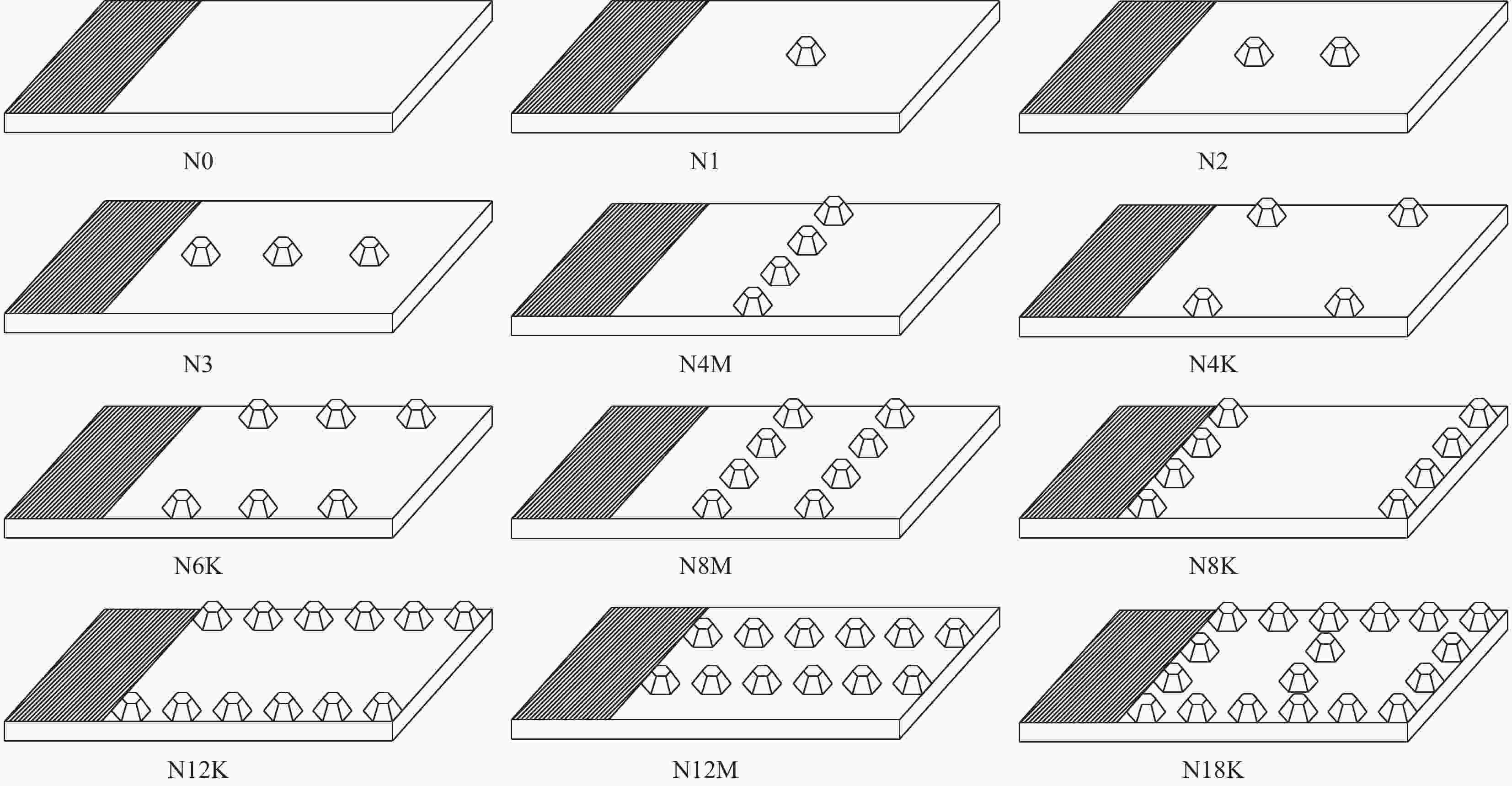

Abstract: In order to study the bond-slip behavior of the interface between prefabricated ultra-high performance concrete (UHPC) and normal concrete (NC), 12 sets of UHPC-NC bond specimens were tested using double-sided shear tests with the density and spacing of shear studs on the prefabricated UHPC surface as the experimental parameters. The results show that, after the shear studs being installed on the formwork, there are three main failure modes of the specimens, namely (a) shear failure of UHPC-NC bond surface and UHPC shear studs; (b) shear failure of UHPC-NC bond surface and simultaneous shear and peeling failure of UHPC shear studs; and (c) shear failure of UHPC-NC bond surface and axial compression failure of NC matrix. The density and distribution interval of shear studs have a significant impact on the shear strength of UHPC-NC bond surface, especially the shear stud density. The shear strength on the bond surface increases parabolically with the density of shear studs. Under the same density of shear stud, the specimens with larger distribution interval of shear stud have a 19.04%-41.74% increase in shear strength on the bond surface, compared to the specimens with smaller distribution interval. On the basis of existing models and experimental results, a calculation formula for the shear strength of prefabricated UHPC-NC bond surface is established. It considers the failure modes of bond surface and the shear testing methods. The calculated results are in good agreement with the experimental values. This can provide a reference for the interface design of UHPC-NC composite specimens. -

表 1 UHPC-NC试件设计

Table 1. UHPC-NC Specimen design

Specimen number Perimeter diameter of

the shear nail/mmShear nail

height/mmNumber of shear

nails/ pieceShear nail

densityN0 0 0 0 0 N1 50 30 1 0.533 N2 50 30 2 1.067 N3 50 30 3 1.6 N4K 50 30 4 2.133 N6K 50 30 6 3.2 N8K 50 30 8 4.267 N12K 50 30 12 6.4 N18H 50 30 18 9.6 N4M 50 30 4 2.133 N4K 50 30 4 2.133 N8M 50 30 8 4.267 N8M 50 30 8 4.267 N12M 50 30 12 6.4 Note: In N1, N represents shear nails, and 1 represents the number of shear nails; K represents a large distribution interval of shear nails; M represents a small spacing between shear nails. 表 2 试验结果

Table 2. Experimental results

Specimen number Ultimate load Pu/kN Shear stress/MPa Failure mode N0 100.2 1.67 Shear failure of the adhesive surface N1 130.2 2.17 A N2 149.4 2.49 A N3 185.8 3.10 A N4K 205.99 3.43 B N6K 273.2 4.55 B N8K 288 4.8 B N12K 356.53 5.94 C N18K 393.6 6.56 C N4M 145.1 2.42 B N8M 206 3.43 B N12M 299.6 4.99 B 表 3 单个剪力钉的黏结抗剪强度

Table 3. Shear strength of a single shear bond

Specimen number Shear nail density Shear stress/MPa Shear stress after deduction/MPa Shear strength of a single nail/MPa N0 0 1.67 1.67 - N1 0.53 2.17 0.55 0.55 N2 1.07 2.49 0.93 0.47 N3 1.6 3.10 1.59 0.53 N4K 2.13 3.43 1.98 0.50 N6K 3.20 4.55 3.21 0.54 N8K 4.27 4.8 3.57 0.45 N12K 6.40 5.94 4.93 0.41 N18K 9.60 6.56 5.87 0.33 表 4 试验结果

Table 4. Experimental results

Specimen number Test values

τu/MPaEurocode 2

τ1/MPaACI 318M-05

τ2/MPaAASHTO LRFD

τ3/MPaGB 50010-2010

τ4/MPaτu/τ1 τu/τ2 τu/τ3 τu/τ4 N0 1.67 0.822 0.55 0.7 0.4 2.032 3.306 2.385 4.175 N1 2.17 1.057 0.55 0.7 0.4 2.053 3.945 3.1 5.425 N2 2.49 1.057 0.55 0.7 0.4 2.356 4.527 3.557 6.225 N3 3.10 1.057 0.55 0.7 0.4 2.933 5.636 4.429 7.75 N4K 3.43 1.057 0.55 0.7 0.4 3.245 6.236 4.9 8.575 N6K 4.55 1.057 0.55 0.7 0.4 4.305 8.273 6.5 11.375 N8K 4.8 1.057 0.55 0.7 0.4 4.541 8.727 6.857 12 N12K 5.94 1.057 0.55 0.7 0.4 5.620 10.8 8.486 14.85 N18K 6.56 1.057 0.55 0.7 0.4 6.206 11.927 9.371 16.4 N4M 2.42 1.057 0.55 0.7 0.4 2.289 4.4 3.457 6.05 N8M 3.43 1.057 0.55 0.7 0.4 3.245 6.236 4.9 8.575 N12M 4.99 1.057 0.55 0.7 0.4 4.721 9.073 7.129 12.475 Notes: τu is the test value of this article; τ1 is the value according to the formula in the Eurocode 2 specification; τ2 is the value according to the formula in ACI 318M-05 specification; τ3 is the value according to the formula in AASHTO LRFD specification; τ4 is the value according to the formula in GB 50010-2010 specification. 表 5 UHPC-NC试件黏结面抗剪强度修正模型计算值与试验值(MPa)

Table 5. Calculated values of corrected model and experimental values for shear strength of UHPC-NC specimens (MPa)

Specimen number Calculated value/MPa

(Test value/Calculated value)Literature [11]

specimen numberCalculated value/MPa

(Test value/Calculated value)Literature [21]

specimen numberCalculated value/MPa

(Test value/Calculated value)N0 1.589(1.051) SB3 2.822(0.456) ZJ-Z-1-1 2.622(0.793) N1 2.111(1.028) SB4 3.355(0.554) ZJ-Z-1-2 3.645(0.850) N2 2.606(0.955) SB5 3.693(0.553) ZJ-Z-1-3 4.467(0.698) N3 3.070(1.010) SC3 3.892(0.789) ZJ-Z-2-2 3.645(0.859) N4K 3.505(0.979) SC4 4.626(0.618) ZJ-Z-2-3 4.467(0.960) N6K 4.289(1.061) SC5 5.094(0.601) — — N8K 4.956(0.969) SD3 4.772(0.642) — — N12K 5.940(1.000) SD4 5.673(0.627) — — N18K 6.544(1.002) SD5 6.246(0.603) — — 表 6 引入参数后UHPC-NC试件黏结面抗剪强度修正模型计算值与试验值(MPa)

Table 6. Calculated and experimental values of the modified model of shear strength of bonded surface of UHPC-NC specimens after the introduction of parameters (MPa)

Specimen number of this document Calculated value/MPa

(Test value/Calculated value)Literature [11]

specimen numberCalculated value/MPa

(Test value/Calculated value)Literature [21]

specimen numberCalculated value/MPa

(Test value/Calculated value)N0 1.589(1.051) SB3 1.648(0.781) ZJ-Z-1-1 2.181(0.954) N1 2.111(1.028) SB4 1.959(0.948) ZJ-Z-1-2 3.033(1.022) N2 2.606(0.955) SB5 2.157(0.946) ZJ-Z-1-3 3.717(0.839) N3 3.070(1.010) SC3 2.273(1.068) ZJ-Z-2-2 3.033(1.032) N4K 3.505(0.979) SC4 2.702(1.058) ZJ-Z-2-3 3.717(1.154) N6K 4.289(1.061) SC5 2.975(1.028) - - N8K 4.956(0.969) SD3 2.787(1.100) - - N12K 5.940(1.000) SD4 3.313(1.074) - - N18K 6.544(1.002) SD5 3.648(1.033) - - -

[1] 王鹏刚, 赵明海, 田砾, 等. 预制键槽式UHPC与后浇混凝土界面粘结抗剪性能[J]. 复合材料学报, 2024, 41(5): 2633-2644.WANG Peng-gang, ZHAO Ming-hai, LI Tian, et al. Shear performance of interface bonding between prefabricated keyway UHPC and post-cast concrete [J/OL][J]. Journal of Composite Materials, 2024, 41(5): 2633-2644 (in Chinese). [2] 邵旭东, 邱明红, 晏班夫, 等. 超高性能混凝土在国内外桥梁工程中的研究与应用进展[J]. 材料导报, 2017, 31(23): 33-43. doi: 10.11896/j.issn.1005-023X.2017.023.004SHAO Xu-dong, QIU Ming-hong, YAN Ban-fu, et al. A Review on the Research and Application of Ultra-high Performance Concrete in Bridge Engineering A Around the World[J]. Materials Reports, 2017, 31(23): 33-43(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.023.004 [3] 李庆华, 徐世烺. 超高韧性水泥基复合材料基本性能和结构应用研究进展[J]. 工程力学, 2009, 26(增刊2): 23-67.LI Qing-hua, XU Shi-lang. Performance and application of ultra high toughness cementitious composite[J]. Engineering Mechanics, 2009, 26(Suppl.2): 23-67(in Chinese). [4] 邓明科, 卜新星, 潘姣姣, 等. 型钢高延性混凝土短 柱抗震性能试验研究[J]. 工程力学, 2017, 34(1): 163-170. doi: 10.6052/j.issn.1000-4750.2015.06.0484DENG Ming-ke, BU Xin-xing, PAN Jiao-jiao, et al. Experimental study on seismic behavior of steel reinforced high ductile concrete short columns[J]. Engineering Mechanics, 2017, 34(1): 163-170(in Chinese). doi: 10.6052/j.issn.1000-4750.2015.06.0484 [5] 邓明科, 姚昕, 张阳玺, 等. 基于梁式试验的UHPC-高强钢筋搭接黏结性能[J/OL]. 复合材料学报: 1-14.DENG Ming-ke, YAO Xin, ZHANG Yang-xi et al. Lap bonding properties of UHPC-high-strength steel bars based on beam test [J/OL]. Journal of Composite Materials: 1-14 [2024-03-20] (in Chinese). [6] MUÑOZ M A C, DEVIN A M A, THERESA P M A, et al. Bond performance between ultrahigh-performance concrete and normal-strength concrete[J]. Journal of Materials in Civil Engineering, 2014, 26(8): 04014031. doi: 10.1061/(ASCE)MT.1943-5533.0000890 [7] BASSAM A T, ABU B H B, MEGAT M A, et al. Microstructural analysis of the adhesion mechanism between old concrete substrate and UHPFC[J]. Journal of Adhesion Science and Technology, 2014, 28(18): 1846-1864. doi: 10.1080/01694243.2014.925386 [8] 王兴旺. UHPC与普通钢筋混凝土结构界面抗剪性能研究[D]. 长沙: 湖南大学, 2016.WANG Xing-wang. Study on interfacial shear resistance between UHPC and ordinary reinforced concrete structures [D]. Changsha: Hunan University, 2016(in Chinese). [9] HUSAM H H, KENNETH K W, SHAD M S, et al. Interfacial properties of ultrahigh-performance concrete and high-strength concrete bridge connections[J]. Journal of Materials in Civil Engineering, 2016, 28(5): 04015208. doi: 10.1061/(ASCE)MT.1943-5533.0001456 [10] 张锐, 胡棚, 李晰, 等. U形UHPC永久模板RC无腹筋组合梁抗剪性能试验[J]. 中国公路学报, 2021, 34(8): 145-156. doi: 10.3969/j.issn.1001-7372.2021.08.013ZHANG Rui, HU Peng, LI Xi, et al. Shear behavior of reinforced concrete composite beams without stirrups using U-shaped UHPC permanent formwork[J]. China Journal of Highway and Transport, 2021, 34(8): 145-156(in Chinese). doi: 10.3969/j.issn.1001-7372.2021.08.013 [11] 王德弘, 沈彤, 鞠彦忠, 等. 后浇普通混凝土与预制UHPC的黏结受剪性能研究[J]. 建筑结构学报, 2020, 41(S2): 411-419.WANG De-hong, SHEN Tong, Ju Yan-zhong, et al. Study on bonding shear properties of post-poured ordinary concrete and prefabricated UHPC[J]. Journal of Building Structures, 2020, 41(S2): 411-419(in Chinese). [12] 杨俊, 周建庭, 张中亚, 等. UHPC-NC键槽界面抗剪性能研究[J]. 中国公路学报, 2021, 34(8): 132-144. doi: 10.3969/j.issn.1001-7372.2021.08.012Yang Jun, Zhou Jianting, Zhang Zhongya et al. Study on interfacial shear performance of UHPC-NC keyway[J]. China Journal of Highway and Transport, 2021, 34(8): 132-144(in Chinese). doi: 10.3969/j.issn.1001-7372.2021.08.012 [13] 柴敏, 罗素蓉. 自密实混凝土与老混凝土黏结抗剪性能试验研究[J]. 福州大学学报(自然科学版), 2013, 41(5): 922-927.CHAI Min, LUO Su rong. Experimental study on shear performance of self-compacting concrete and old concrete[J]. Journal of Fuzhou University (Natural Science Edition), 2013, 41(5): 922-927(in Chinese). [14] 李平先, 赵国藩, 张雷顺. 环氧砂改善新老混凝土黏结强度试验研究[J]. 大连理工大学学报, 2005, (2): 255-259. doi: 10.3321/j.issn:1000-8608.2005.02.021LI Ping-xian, ZHAO Guo-fan, ZHANG Lei-shun. Experimental study on epoxy sand to improve the bond strength of new and old concrete[J]. Journal of Dalian University of Technology, 2005, (2): 255-259(in Chinese). doi: 10.3321/j.issn:1000-8608.2005.02.021 [15] 刘传奇. 新旧混凝土界面黏贴机理试验研究[D]. 西安: 长安大学, 2014: 45-47.LIU Chuan-qi Experimental study of old and new concrete interface mechanism of paste [D]. Xi'an: Changan University, 2014: 45-47(in Chinese). [16] 混凝土结构设计规范: GB60010-2010 [S] 北京: 中国建筑工业出版社, 2010.Code for design of concrete structures: GB 50010-2010 [S]. Beijing: China Architecture & Building Press, 2010(in Chinese). [17] British Standards Institution. Eurocode 2: design of concrete structures: part 1: general rules and rules for buildings: BS EN 1992-1-1 [S] London: British Standards Institution, 2004. [18] ACI 318 Committee. Building code requirements for structural concrete and commentary: ACI 318M-05 [S]. Farmington Hills, MI: American Concrete Institute, 2005. [19] American Association of State Highway and Transportation Officials. AASHTO LRFD bridge design specification [S]. Washington DC: American Association of State Highway and Transportation Officials, 2005. [20] 东南大学. 混凝土结构, 上册, 混凝土结构设计原理[M] 北京: 中国建筑工业出版社2015 .Southeast University. Concrete structure, the first volume, Design theory for concrete structure [M]. Beijing: China Architecture & Building Press, 2015(in Chinese). [21] 周建庭, 胡天祥, 杨俊, 等. 键槽构造UHPC-NC界面黏结性能试验研究[J]. 材料导报, 2021, 35(16): 16050-16057. doi: 10.11896/cldb.20070033ZHOU Jianting, HU Tianxiang, YANG Jun, et al. Experimental study on adhesion properties of UHPC-NC interface of keyway structure[J]. Materials Reports, 2021, 35(16): 16050-16057(in Chinese). doi: 10.11896/cldb.20070033 [22] 杨冠宇. 不同试验条件下锚索剪切力学行为及失效特征研究[D]. 中国矿业大学, 2018: 58-63.YANG Guanyu. Study on the behaviors and failure characteristics of cable bolt under various shearing loading experimental environment [D]. China University of Mining and Technology, 2018: 58-63(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 47

- HTML全文浏览量: 22

- 被引次数: 0

下载:

下载: