-

摘要: 探索具有优异性能的电磁波吸收材料是解决电磁污染的主要手段。然而,如何同时满足材料的高性能和实际应用要求仍然是一个挑战。本文采用溶胶凝胶法、塑炼、混炼及硫化等工艺制备了具有优异力学性能和吸波性能的导电炭黑(CCB)@纳米Fe3O4/天然橡胶(NR)吸波胶片,并通过调节CCB@Fe3O4的添加量来调控胶片的力学和吸波性能。CCB@Fe3O4复合材料的引入极大地改善了胶片的界面损耗和极化损耗,其中CCB可以在提高材料的介电常数和电导率的同时增强力学性能。当CCB@Fe3O4添加量为29wt%时,胶片达到−40.5 dB的最小反射损耗(RL),有效吸收带宽(EAB)为2.4 GHz,厚度为5.0 mm,并展现出最佳的抗拉强度、硬度和磨耗性能。材料优异的吸波性能来源于电-磁损耗协同效应引起的阻抗匹配、强电磁波衰减和高传导损耗。本工作为天然橡胶基吸波胶片的结构设计和实际应用提供了新的思路。Abstract: Exploring electromagnetic wave (EMW) absorbing materials with excellent performance is the main method to solve electromagnetic pollution. However, it remains a challenge to meet the high performance and practical application requirements of materials simultaneously. Conductive carbon black (CCB)@nano Fe3O4/natural rubber (NR) absorbing films with excellent mechanical and EMW absorption properties were prepared by sol-gel method, plasticizing, blending and vulcanization, and the mechanical and EMW absorbing properties of the films were controlled by adjusting the addition amount of CCB@Fe3O4. The introduction of the CCB@Fe3O4 composites greatly ameliorates the interfacial loss and polarization loss of the films, in which the CCB can enhance the mechanical properties while improving the dielectric constant and conductivity of the materials. The film achieves the minimum reflection loss (RL) of -40.5 dB and maximum effective absorption bandwidth (EAB) of 2.4 GHz with the thickness of 5.0 mm when the CCB@Fe3O4 was added at 29wt%, and exhibited the optimal tensile strength, hardness and wear properties. The remarkable EMW absorbing properties of the material originate from impedance matching, strong EMW attenuation and high conduction loss caused by the synergistic effect of dielectric-magnetic loss. This work provides a new mentality for the structure design and practical application of natural rubber-based absorbing films.

-

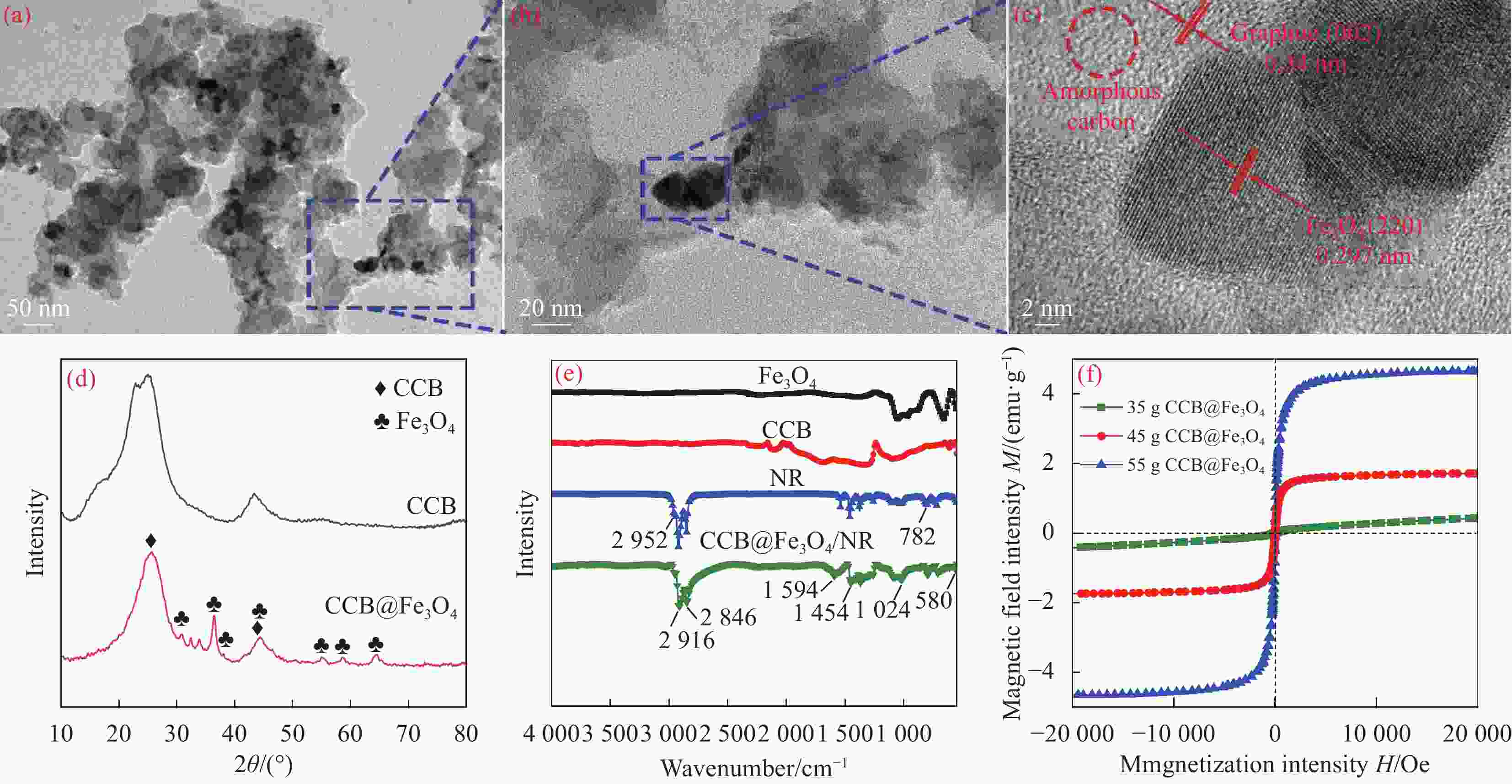

图 2 CCB@Fe3O4复合材料的TEM图像 ((a), (b)) 和HRTEM图像 (c); CCB和CCB@Fe3O4复合材料的XRD图谱 (d); Fe3O4,CCB、NR和CCB@Fe3O4/NR吸波胶片的FTIR图谱 (e); CCB@Fe3O4复合材料的磁滞曲线 (f)

Figure 2. TEM ((a), (b)) and HRTEM (c) images of CCB@Fe3O4 composites; XRD patterns (d) of CCB and CCB@Fe3O4 composites; FTIR sprctra (e) of Fe3O4, CCB, NR and CCB@Fe3O4/NR absorbing films; Hysteresis curves (f) of CCB@Fe3O4 composites

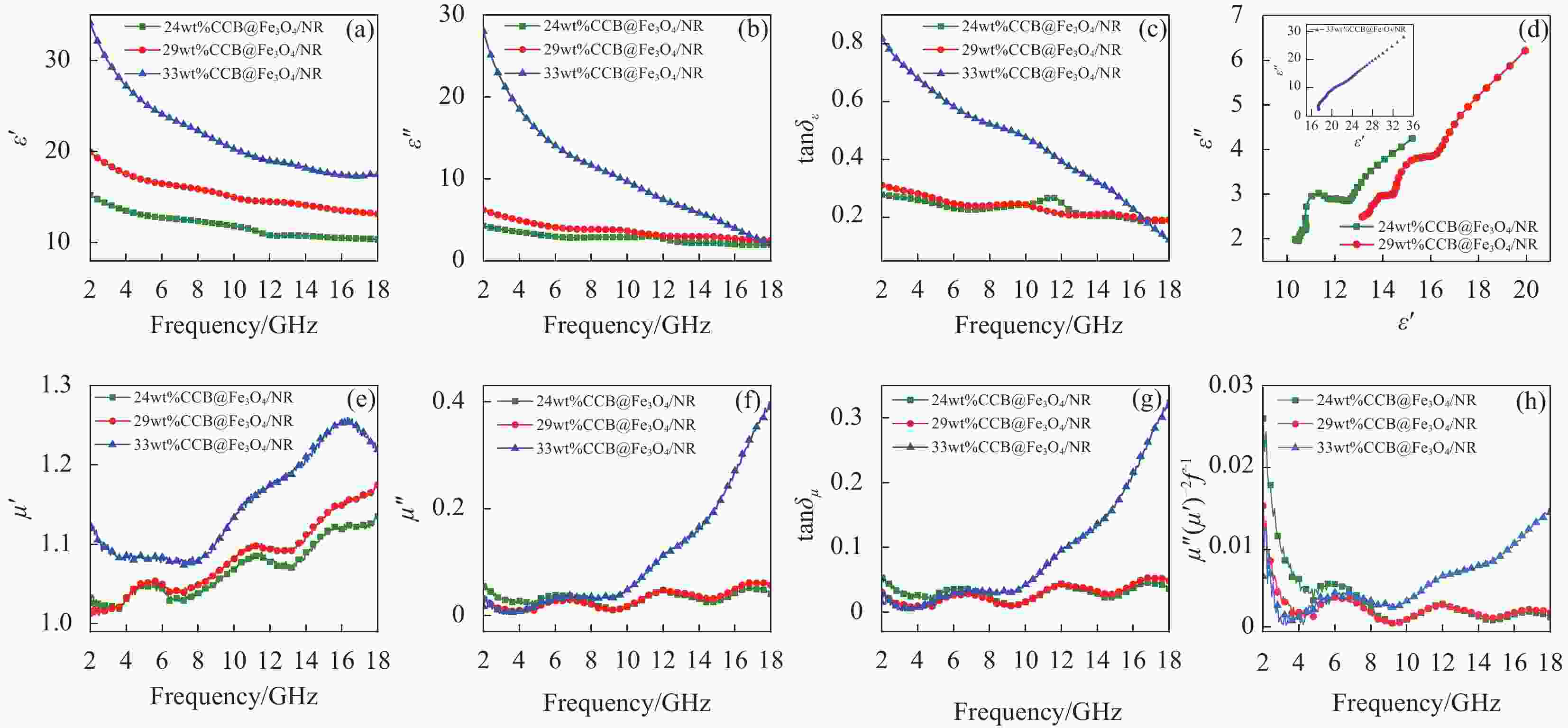

图 4 CCB@Fe3O4/NR吸波胶片的复介电常数的实部ε' (a) 和虚部ε" (b)、复磁导率的实部μ' (e) 和虚部μ" (f)、介电损耗角正切tanδε (c) 和磁损耗角正切tanδμ (g)、Cole-Cole半圆 (d) 和μ″(μ′)−2f −1曲线 (h)

Figure 4. Frequency dependences of the real part ε' (a) and imaginery part ε'' (b) of the complex permittivity, real part μ' (e) and imaginary part μ''(f) part of the complex permeability, dielectric loss tangent (c) and magnetic loss tangent (g), Cole-Cole semicircles (ε′ versus ε″) (d) and frequency dependences of μ″(μ′)−2f −1 (h) for CCB@Fe3O4/NR absorbing films

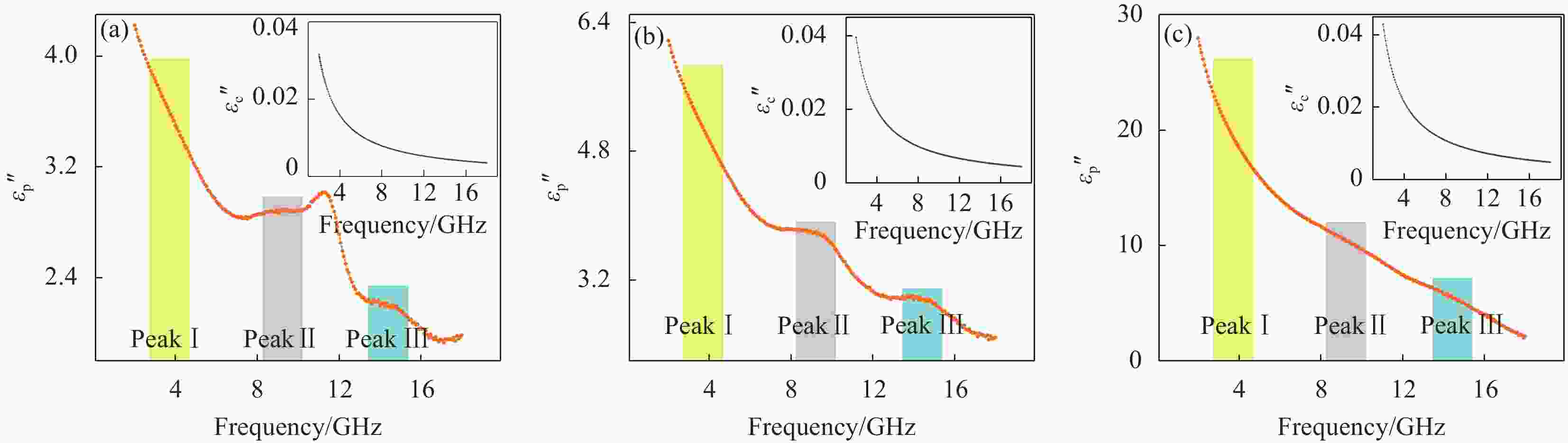

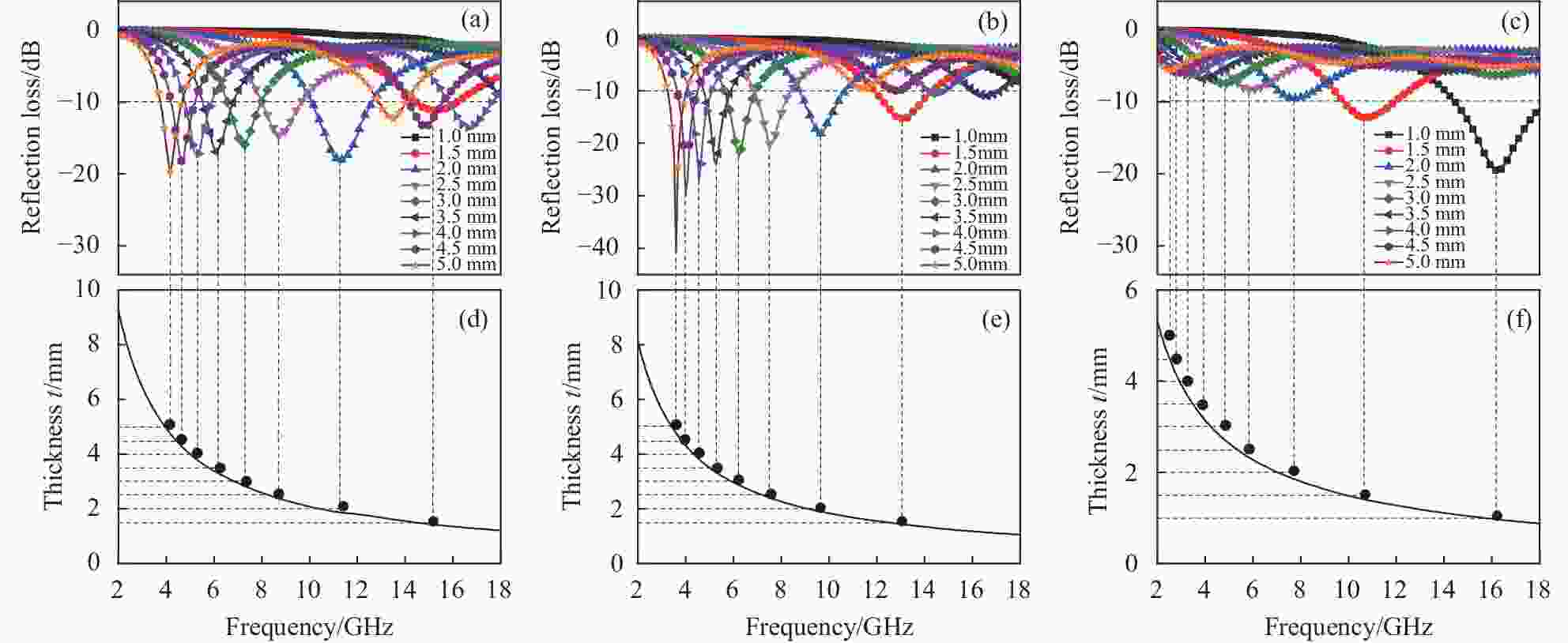

图 7 24wt%CCB@Fe3O4/NR ((a), (d))、29wt%CCB@Fe3O4/NR ((b), (e)) 和33wt%CCB@Fe3O4/NR ((c), (f)) 的3D和2D反射损耗图;24wt%CCB@Fe3O4/NR (g)、29wt%CCB@Fe3O4/NR (h) 和33wt%CCB@Fe3O4/NR (i) 的2D阻抗匹配图

Figure 7. 3D and 2D maps of RL in 2.0-18.0 GHz with a diverse matching thickness (1.0-5.0 mm) for 24wt%CCB@Fe3O4/NR ((a), (d)), 29wt%CCB@Fe3O4/NR ((b), (e)) and 33wt% CCB@Fe3O4/NR ((c), (f)); 2D maps of Z values of 24wt%CCB@Fe3O4/NR (g), 29wt%CCB@Fe3O4/NR (h) and 33wt%CCB@Fe3O4/NR (i)

表 1 导电炭黑(CCB)@纳米Fe3O4/天然橡胶(NR)吸波胶片的填料配方

Table 1. Filler formula of conductive carbon black (CCB)@nano Fe3O4/natural rubber (NR) absorbing films

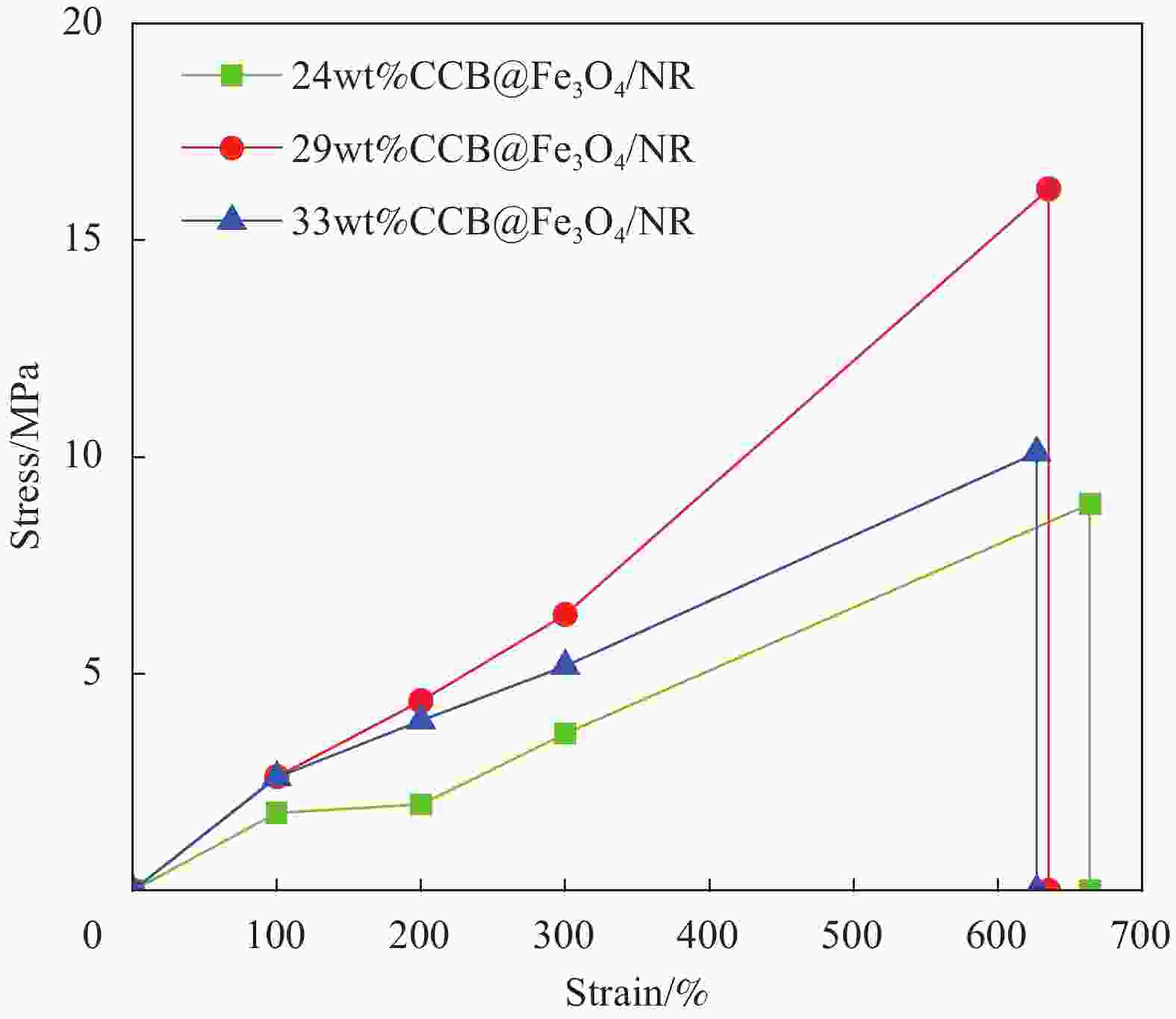

Sample NR/g DMPPD/g C18H36O2/g CZ/g ZnO/nano-ZnO/g CCB@Fe3O4/g S/g 24wt%CCB@Fe3O4/NR 100 1 2 1 5 35 2 29wt%CCB@Fe3O4/NR 100 1 2 1 5 45 2 33wt%CCB@Fe3O4/NR 100 1 2 1 5 55 2 表 2 CCB@Fe3O4/NR吸波胶片的力学性能

Table 2. Mechanical properties of CCB@Fe3O4/NR absorbing films

Sample 100% modulus/MPa 300% modulus/MPa Tensile strength/MPa Break elongation/% Shore hardness 24wt%CCB@Fe3O4/NR 1.79 3.62 8.92 663.88 63 29wt%CCB@Fe3O4/NR 2.63 6.73 16.18 635.28 70 33wt%CCB@Fe3O4/NR 2.61 5.18 10.10 626.88 78 表 3 CCB@Fe3O4/NR吸波胶片与类似工作的电磁波吸收性能对比

Table 3. Comparison of electromagnetic wave absorption performance of CCB@Fe3O4/NR absorbing films with similar work

-

[1] SHEN Y Q, ZHANG F, SONG P F, et al. Design and synthesis of magnetic porous carbon nanofibers with excellent microwave absorption[J]. Journal of Alloys and Compounds,2022,903:163971. doi: 10.1016/j.jallcom.2022.163971 [2] ZHANG Y C, SHEN Y Q, DANG M M, et al. In situ synthesis hydrophobic Co/CoO/C nanofibers with enhanced microwave absorption[J]. Ceramics International,2021,47(7):9178-9187. doi: 10.1016/j.ceramint.2020.12.043 [3] 许占. 一维铁/碳复合材料的制备及其吸波性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.XU Zhan, Pretaration of one-dimensional Fe/C composites and their microwave absorption performance[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [4] 吴梦, 饶磊, 张建峰, 等. MXene及其复合吸波材料的制备与性能研究进展[J]. 复合材料学报, 2022, 39(3):942-955.WU Meng, RAO Lei, ZHANG Jianfeng, et al. Research progress in preparation and performance of MXene and its composite absorbing materials[J]. Acta Materiae Compo-sitae Sinica,2022,39(3):942-955(in Chinese). [5] XU H L, YIN X W, LI M H, et al. Mesoporous carbon hollow microspheres with red blood cell like morphology for efficient microwave absorption at elevated temperature[J]. Carbon,2018,132:343-351. doi: 10.1016/j.carbon.2018.02.040 [6] YANG H, WEN B, WANG L, et al. Carbon nanotubes modified CoZn/C composites with rambutan-like applied to electromagnetic wave absorption[J]. Applied Surface Science,2020,509:145336. doi: 10.1016/j.apsusc.2020.145336 [7] SHEN Y Q, ZHANG F, ZHANG Y C, et al. Space-confined fabrication of hydrophobic magnetic carbon nanofibers for lightweight and enhanced microwave absorption[J]. Carbon,2022,197:544-554. doi: 10.1016/j.carbon.2022.06.001 [8] XU Z, DU Y C, LIU D W, et al. Pea-like Fe/Fe3C nanoparticles embedded in nitrogen-doped carbon nanotubes with tunable dielectric/magnetic loss and efficient electromagnetic absorption[J]. ACS Applied Materials & Interfaces,2019,11(4):4268-4277. [9] SHEN Y Q, ZHANG F, ZHANG Y C, et al. Ni/NiO/SiO2/C nanofibers with strong wideband microwave absorption and robust hydrophobicity[J]. Applied Surface Science,2022,588:152964. doi: 10.1016/j.apsusc.2022.152964 [10] WANG X X, MA T, SHU J C, et al. Confinedly tailoring Fe3O4 clusters-NG to tune electromagnetic parameters and microwave absorption with broadened bandwidth[J]. Che-mical Engineering Journal,2018,332:321-330. doi: 10.1016/j.cej.2017.09.101 [11] DENG B W, LIU Z C, PAN F, et al. Electrostatically self-assembled two-dimensional magnetized MXene/hollow Fe3O4 nanoparticle hybrids with high electromagnetic absorption performance and improved impendence matching[J]. Journal of Materials Chemistry A,2021,9(6):3500-3510. doi: 10.1039/D0TA10551A [12] MA M L, LI W T, Tong Z Y, et al. Facile synthesis of the one-dimensional flower-like yolk-shell Fe3O4@SiO2@NiO nanochains composites for high-performance microwave absorption[J]. Journal of Alloys and Compounds,2020,843:155199. doi: 10.1016/j.jallcom.2020.155199 [13] DU Y C, LIU W W, QIANG R, et al. Shell thickness-dependent microwave absorption of core–shell Fe3O4@C composites[J]. ACS Applied Materials & Interfaces,2014,6(15):12997-13006. [14] VINAYASREE S, SOLOMAN M A, SUNNY V, et al. A microwave absorber based on strontium ferrite-carbon black-nitrile rubber for S and X-band applications[J]. Compo-sites Science and Technology,2013,82:69-75. doi: 10.1016/j.compscitech.2013.04.010 [15] 王萌. 天然橡胶基复合吸波材料的结构设计及吸波性能研究[D]. 大连: 大连理工大学, 2010.WANG Meng. Research on the structural design and the absorbing properties of nature rubber based composite absorbing materials[D]. Dalian: Dalian University of Technology, 2010 (in Chinese). [16] 谢圣武, 白骏烈, 张斌. 柔性橡胶吸波材料的研究进展[J]. 橡胶工业, 2020, 67(7):551-558. doi: 10.12136/j.issn.1000-890X.2020.07.0551XIE Shengwu, BAI Junlie, ZHANG Bin. Research progress of flexible rubber absorbing materials[J]. China Rubber Industry,2020,67(7):551-558(in Chinese). doi: 10.12136/j.issn.1000-890X.2020.07.0551 [17] 耿浩然, 赵鹏飞, 梅俊飞, 等. 二硫化钼/多壁碳纳米管/天然橡胶复合材料制备及吸波性能研究[J]. 功能材料, 2019, 50(12):12210-12215.GENG Haoran, ZHAO Pengfei, MEI Junfei, et al. Preparation and absorbing properties of molybdenum disulfide/multi-walled carbon nanotubes/natural rubber composites[J]. Journal of Functional Materials,2019,50(12):12210-12215(in Chinese). [18] 朱鹏宇. 改性碳纤维/硅橡胶柔性复合材料的力学和吸波性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2021.ZHU Pengyu. Research on mechanical and wave absorbing properties of modified carbon fiber/silicone rubber flexible composite[D]. Harbin: Harbin Institute of Technology, 2021(in Chinese). [19] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People's Republic of China. Determination of tensile stress-strain properties of vulcanized rubber or thermoplastic rubber: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [20] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶压入硬度试验方法 第1部分: 邵氏硬度计法(邵尔硬度): GB/T 531.1—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Vulcanized rubber or thermoplastic rubber indentation hardness test method Part 1: Duromerer method (Shore hardness): GB/T 531.1—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [21] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶体积和/或表面电阻率的测定: GB/T 40719—2021[S]. 北京: 中国标准出版社, 2021.Standardization Administration of the People's Republic of China. Determination of volume and/or surface resistivity of vulcanized rubber or thermoplastic rubber: GB/T 40719—2021[S]. Beijing: China Standards Press, 2021(in Chinese). [22] 中国国家标准化管理委员会. 固体材料微波频段使用波导装置的电磁参数测量方法: GB/T 35679—2017[S]. 北京: 中国标准出版社, 2017.Standardization Administration of the People's Republic of China. Measuring method for electromagnetic parameters of solid materials at microwave frequencies using wave guide: GB/T 35679—2017[S]. Beijing: China Standards Press, 2017(in Chinese). [23] 李乐凡, 赵鹏飞, 吕臻, 等. 共混比对导电炭黑/天然橡胶/环氧化天然橡胶复合材料电磁性能的影响[J]. 材料导报, 2016, 30(5):38-41, 66. doi: 10.11896/j.issn.1005-023X.2016.10.009LI Lefan, ZHAO Pengfei, LU Zhen, et al. Effect of blend ratio on the electromagnetic property of conductive carbon black/natural rubber/epoxidized natural rubber compo-sites[J]. Materials Reports,2016,30(5):38-41, 66(in Chinese). doi: 10.11896/j.issn.1005-023X.2016.10.009 [24] 张学虎, 周卫民, 王坤, 等. Fe3O4/炭黑复合材料的制备及其电化学性能[J]. 炭素技术, 2021, 40(1):31-36.ZHANG Xuehu, ZHOU Weimin, WANG Kun, et al. Preparation and electrochemical properties of Fe3O4/carbon black composites[J]. Carbon techniques,2021,40(1):31-36(in Chinese). [25] LI B, RONG T L, DU X Y, et al. Preparation of Fe3O4 particles with unique structures from nickel slag for enhancing microwave absorption properties[J]. Ceramics International,2021,47(13):18848-18857. doi: 10.1016/j.ceramint.2021.03.224 [26] WU T, LIU Y, ZENG X, et al. Facile hydrothermal synthesis of Fe3O4/C core-shell nanorings for efficient low-frequency microwave absorption[J]. ACS Applied Materials & Interfaces,2016,8(11):7370-7380. [27] 段雯雯, 王建军, 辛振祥, 等. 环氧化天然橡胶改性石墨烯-炭黑/天然橡胶复合材料的制备及性能[J]. 复合材料学报, 2020, 37(7):1667-1674.DUAN Wenwen, WANG Jianjun, XIN Zhenxiang, et al. Preparation and properties of epoxidized natural rubber modified graphene-carbon black/natural rubber compo-sites[J]. Acta Materiae Compositae Sinica,2020,37(7):1667-1674(in Chinese). [28] 庞松, 刘欢欢, 于洋, 等. 高速高载下天然橡胶-反式聚异戊二烯橡胶复合材料的耐磨性[J]. 复合材料学报, 2022, 39(6):2607-2618. doi: 10.13801/j.cnki.fhclxb.20210716.003PANG Song, LIU Huanhuan, YU Yang, et al. Wear resistance of natural rubber-trans-polyisoprene rubber compo-sites under high loads and high speeds[J]. Acta Materiae Compositae Sinica,2022,39(6):2607-2618(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210716.003 [29] ZHANG X, DONG Y, PAN F, et al. Electrostatic self-assembly construction of 2D MoS2 wrapped hollow Fe3O4 nanoflowers@1D carbon tube hybrids for self-cleaning high-performance microwave absorbers[J]. Carbon,2021,177:332-343. doi: 10.1016/j.carbon.2021.02.092 [30] SHEN Y Q, WEI Y P, LI J, et al. Preparation of microwave absorbing Co-C nanofibers with robust superhydrophobic properties by electrospinning[J]. Journal of Materials Science: Materials in Electronics,2019,30(4):3365-3377. doi: 10.1007/s10854-018-00610-4 [31] SHEN Y Q, WEI Y P, MA J Q, et al. Tunable microwave absorption properties of nickel-carbon nanofibers prepared by electrospinning[J]. Ceramics International,2019,45(3):3313-3324. doi: 10.1016/j.ceramint.2018.10.242 [32] YU Y L, WANG M, BAI Y Q, et al. Tuning the inner hollow structure of lightweight amorphous carbon for enhanced microwave absorption[J]. Chemical Engineering Journal,2019,375:121914. doi: 10.1016/j.cej.2019.121914 [33] WANG X Y, ZHU T, CHANG S, et al. 3D nest-like architecture of core-shell CoFe2O4@1T/2H-MoS2 composites with tunable microwave absorption performance[J]. ACS Applied Materials & Interfaces,2020,12(9):11252-11264. [34] JIAN X, WU B, WEI Y, et al. Facile synthesis of Fe3O4/GCs composites and their enhanced microwave absorption properties[J]. ACS Applied Materials & Interfaces,2016,8(9):6101-6109. [35] WANG H C, XIANG L, WEI W, et al. Efficient and lightweight electromagnetic wave absorber derived from metal organic framework-encapsulated cobalt nanoparticles[J]. ACS Applied Materials & Interfaces,2017,9(48):42102-42110. [36] SHEN Y Q, WEI Y P, MA J Q, et al. Self-cleaning functionalized FeNi/NiFe2O4/NiO/C nanofibers with enhanced microwave absorption performance[J]. Ceramics International,2020,46(9):13397-13406. doi: 10.1016/j.ceramint.2020.02.121 [37] YU M A, WANG L R, YANG P G, et al. Preparation and high-performance microwave absorption of hierarchical dendrite-like Co superstructures self-assembly of nanoflakes[J]. Nanotechnology,2017,28(48):485703. doi: 10.1088/1361-6528/aa9045 [38] SONG Z M, LIU X F, SUN X, et al. Alginate-templated synthesis of CoFe/carbon fiber composite and the effect of hierarchically porous structure on electromagnetic wave absorption performance[J]. Carbon,2019,151:36-45. doi: 10.1016/j.carbon.2019.05.025 [39] CAO M S, WANG X X, CAO W Q, et al. Thermally driven transport and relaxation switching self-powered electromagnetic energy conversion[J]. Small,2018,14(29):1800987. doi: 10.1002/smll.201800987 [40] SHU J C, CAO M S, ZHANG M, et al. Molecular patching engineering to drive energy conversion as efficient and environment-friendly cell toward wireless power transmission[J]. Advanced Functional Materials,2020,30(10):1908299. doi: 10.1002/adfm.201908299 [41] LIU W, SHAO Q W, JI G B, et al. Metal-organic-frameworks derived porous carbon-wrapped Ni composites with optimized impedance matching as excellent lightweight electromagnetic wave absorber[J]. Chemical Engineering Journal,2017,313:734-744. doi: 10.1016/j.cej.2016.12.117 [42] SUN F, LIU Q D, XU Y F, et al. Attapulgite modulated thorny nickel nanowires/graphene aerogel with excellent electromagnetic wave absorption performance[J]. Chemical Engineering Journal,2021,415:128976. [43] WANG F Y, SUN Y Q, LI D R, et al. Microwave absorption properties of 3D cross-linked Fe/C porous nanofibers prepared by electrospinning[J]. Carbon,2018,134:264-273. doi: 10.1016/j.carbon.2018.03.081 [44] LI A, ZHANG J P, WANG A Q. Utilization of starch and clay for the preparation of superabsorbent composite[J]. Bioresource Technology,2007,98(2):327-332. doi: 10.1016/j.biortech.2005.12.026 [45] 吕臻, 王中奇, 赵鹏飞, 等. 基体改性对导电炭黑/天然橡胶复合材料电磁性能的影响[J]. 高分子材料科学与工程, 2018, 34(11):69-73. doi: 10.16865/j.cnki.1000-7555.2018.11.012LYU Zhen, WANG Zhongqi, ZHAO Pengfei, et al. Effect of matrix modification on the electromagnetic properties of conductive carbon black/natural rubber composites[J]. Polymer Materials Science and Engineering,2018,34(11):69-73(in Chinese). doi: 10.16865/j.cnki.1000-7555.2018.11.012 [46] 王中奇, 李普旺, 李乐凡, 等. 橡胶分子链接枝对导电炭黑/天然橡胶复合材料电磁性能的影响[J]. 材料导报, 2017, 31:297-300, 308.WANG Zhongqi, LI Puwang, LI Lefan, et al. Effect of polymer graft modification on the electromagnetic properties of conductive carbon black/natural rubber composites[J]. Materials Reports,2017,31:297-300, 308(in Chinese). [47] KONG I, AHMAD S, ABDULLAH M, et al. Magnetic and microwave absorbing properties of magnetite-thermoplastic natural rubber nanocomposites[J]. Journal of Magnetism and Magnetic Materials,2010,322(21):3401-3409. doi: 10.1016/j.jmmm.2010.06.036 -

下载:

下载: