One-step spreading for 2D woven carbon fiber reinforced plastics

-

摘要: 二维编织碳纤维增强树脂复合材料的铺层展开质量对铺覆过程和产品质量有直接且显著的影响。本文针对二维编织碳纤维增强树脂复合材料铺层展开问题进行了研究,建立复合材料材料、随体和全局坐标系,并基于连续介质理论根据坐标系间的转换关系构建了非正交各向异性本构模型;完成了二维编织碳纤维增强树脂复合材料力学性能试验,包括测量复合材料拉伸性能的单向拉伸试验和测量剪切性能的镜框剪切试验;开发了二维编织碳纤维增强树脂复合材料一步法铺层展开算法并基于FORTRAN语言编写了自主可控的一步法铺层展开求解器。计算了口盖零件展开构型,展开构型轮廓线与实验结果分布趋势相同且最大误差仅为5.0 mm,相对误差仅为1.9%;剪切角计算结果与实验分布趋势一致且最大误差仅为4°,验证了一步法铺层展开算法和求解器的有效性。

-

关键词:

- 二维编织碳纤维增强树脂复合材料 /

- 预浸料铺层 /

- 本构模型 /

- 铺层展开 /

- 有限元分析(FEA)

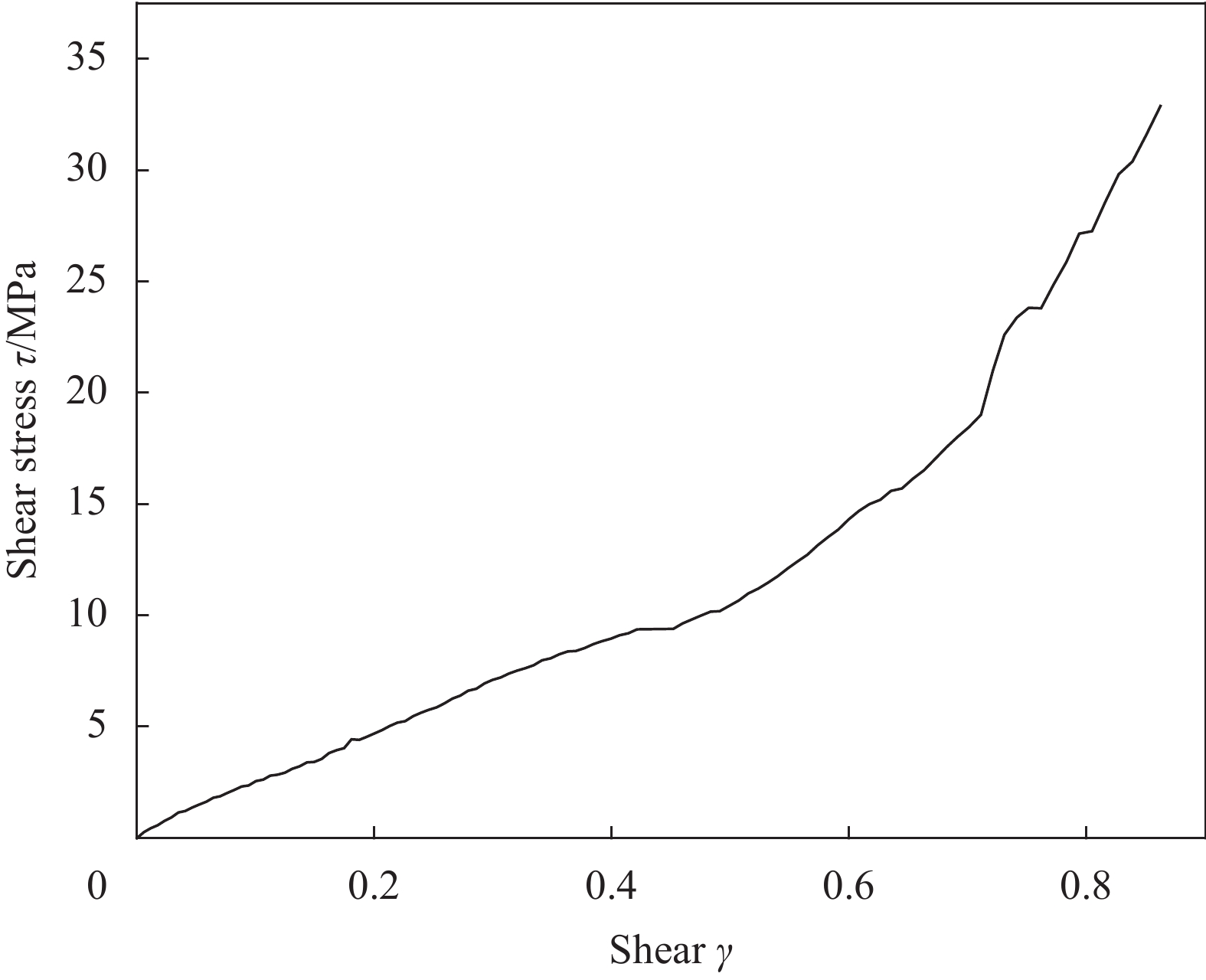

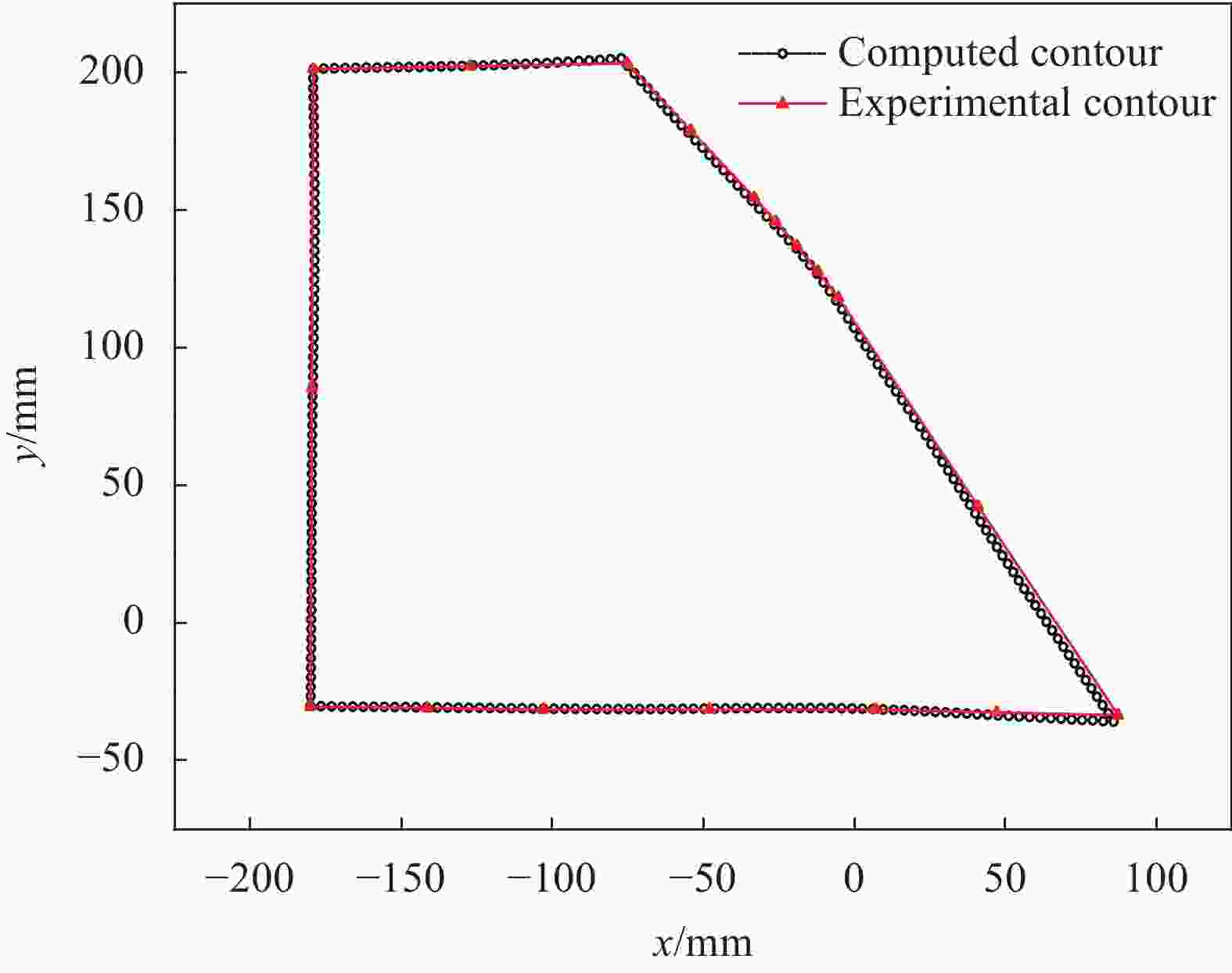

Abstract: Draping for 2D woven carbon fiber reinforced plastics (CFRPs) influences the quality of final composite parts directly and significantly. The problems of laying reinforced carbon fibers in the manufacturing of 2D woven CFRPs were studied. A material coordinate system, a global coordinate system and a body coordinate system were built. A non-orthogonal constitutive model according to coordinate transformation relation was proposed based on continuum theory. Mechanical properties of 2D woven CFRPs were tested by uni-axial tensile tests for measuring the tensile properties and picture-frame tests for measuring the shear properties. A one-step plies spreading algorithm for 2D woven CFRPs was developed and an independent one-step plies spreading solver was developed. A cover part was spread. The result shows great consistency that the maximum error is only 5.0 mm which is a 1.9% margin of error. The carbon fiber shear angle distributions by calculation are consistent with experimental results and the maximum error is only 4°. The one-step spreading algorithm of 2D woven CFRPs was verified by calculations and experiments. -

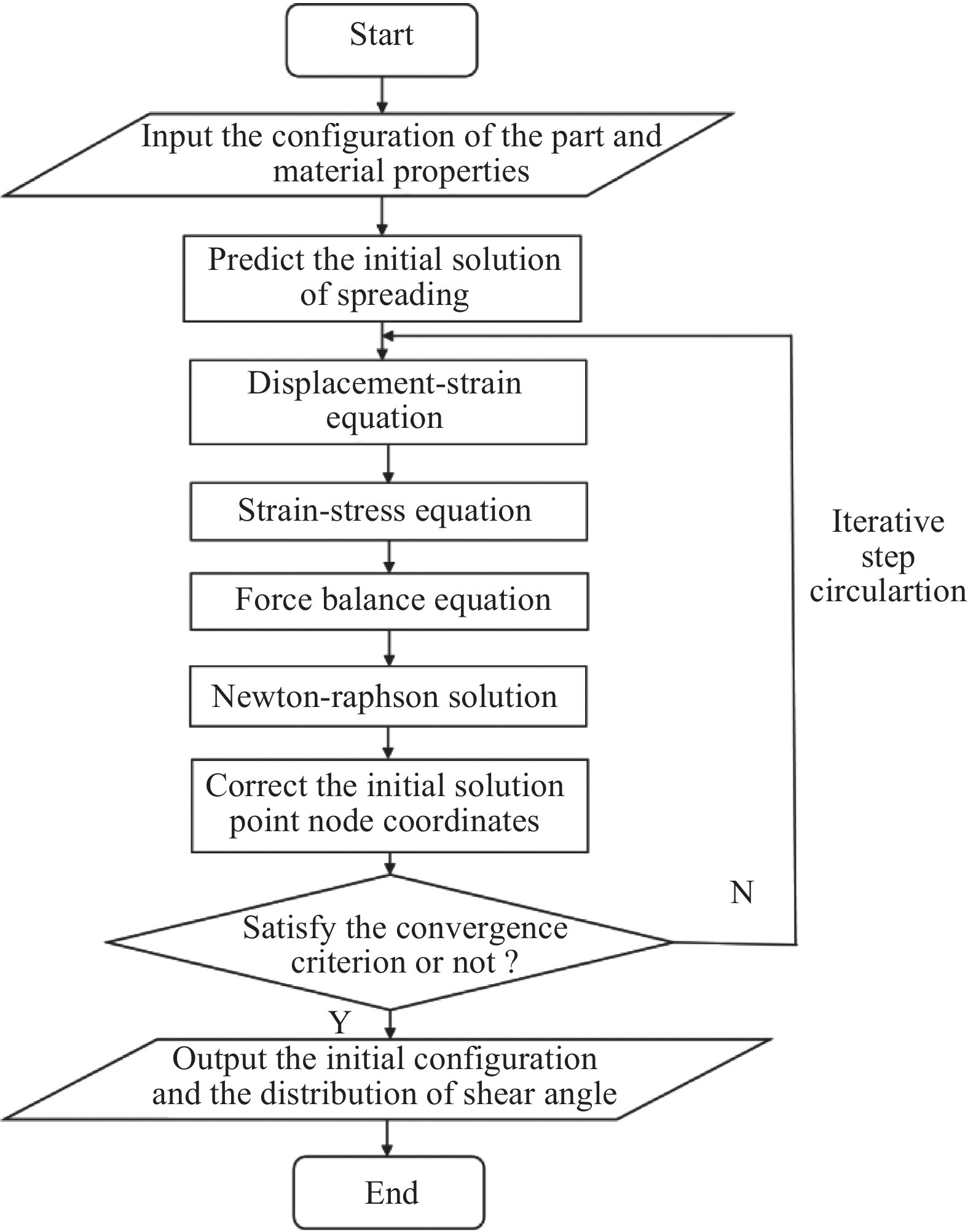

图 2 复合材料一步法铺层展开算法示意图

Figure 2. Schematic diagram of the one-step lay-up algorithm for composites

C0—Initial configuration; C—Part configuration; p0 and q0 points on C0 correspond to the p and q points on C; Xp, Xq. Xp0 and Xq0—Coor-dinate vector of point p, q, p0 and q0; up and uq—Displacement of point p and q; z0 and z—Co-ordinates along thickness direction of point q0 and q; n and n0—Normal of C and C0; h and h0—Thickness of C and C0

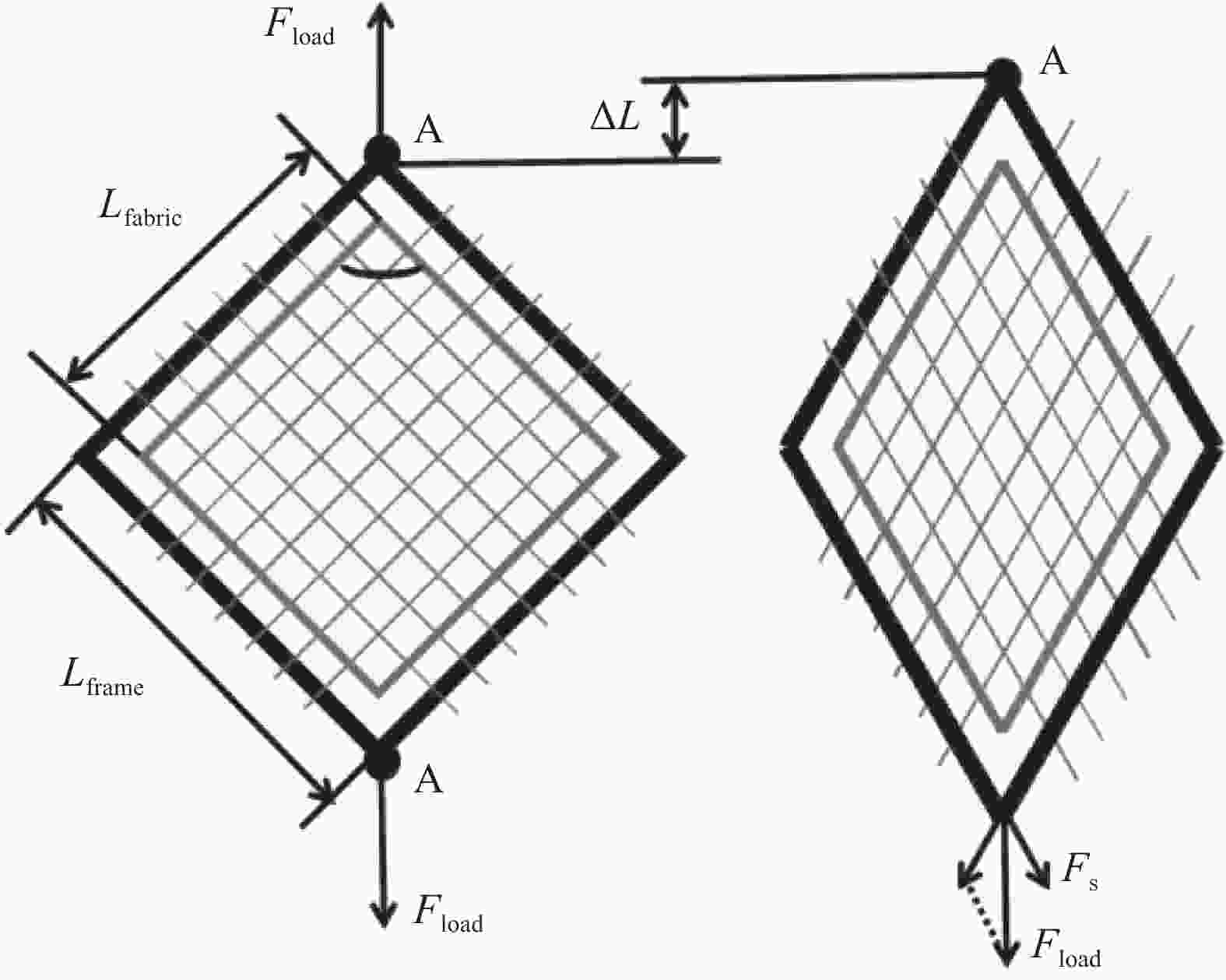

图 8 镜框剪切试验试样变形示意图

Figure 8. Sample deformation diagram of the picture-frame tests

A—Vertex of the picture-frame fixture; Lframe—Length of the fixture; Lfabric—Length of the fiber sample; Fload—Tension of the test; ΔL—Displacement of A; Fs—Partial force of tension acting on the side direction of the picture-frame

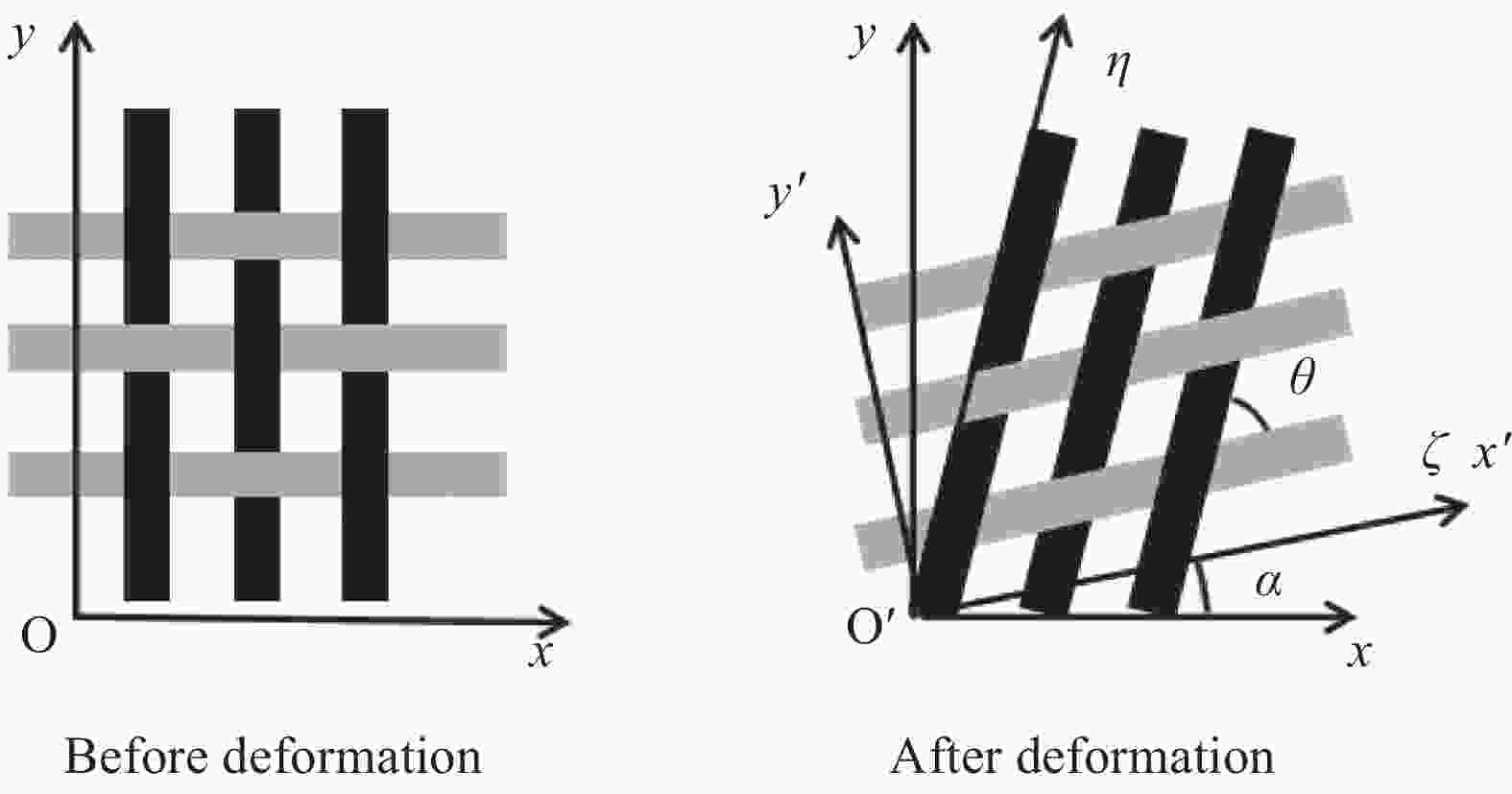

图 11 二维编织碳纤维增强树脂复合材料微元应变分量示意图

Figure 11. Diagram of the strain components of element of 2D woven carbon fiber reinforced plastics

εx’, εy’, εx’y’ and εy’x’—Components of strain under the body coordinate system (x', y'); εζ, εη, εζη and εηζ—Components of strain under the material coordinate system (ζ, η)

图 12 二维编织碳纤维增强树脂复合材料应力分量示意图

Figure 12. Diagram of stress components of 2D woven carbon fiber reinforced plastics

α—Angle between the weft of the material and the x-axis of the global coordinate system; σζ, ση—Components of strain caused by yarn stretch; σm1, σm2—Components of strain caused by yarn rotation; σx, σy—Components of stress along x-axil and y-axil on a macro scale; σxy, σyx—Components of shear stress on a macro scale

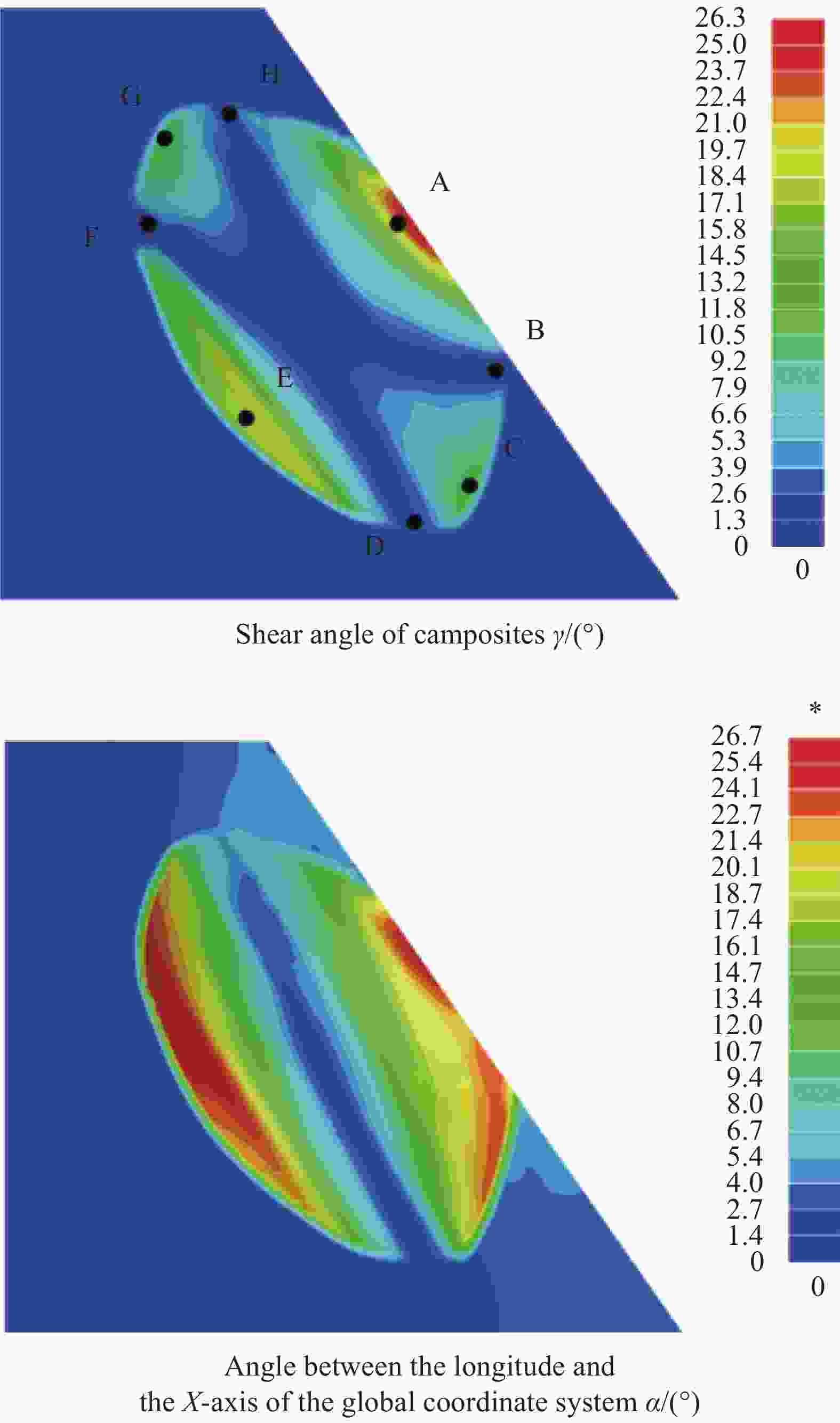

表 1 二维编织碳纤维增强树脂复合材料口盖零件[ 0°/90°]方向铺层剪切角实验值与计算值

Table 1. Experimental and calculated shear angles of the cover part laminated in the direction of [0°/90°] of 2D woven carbon fiber reinforced plastics

Experimental shear

angle/(°)Calculated shear

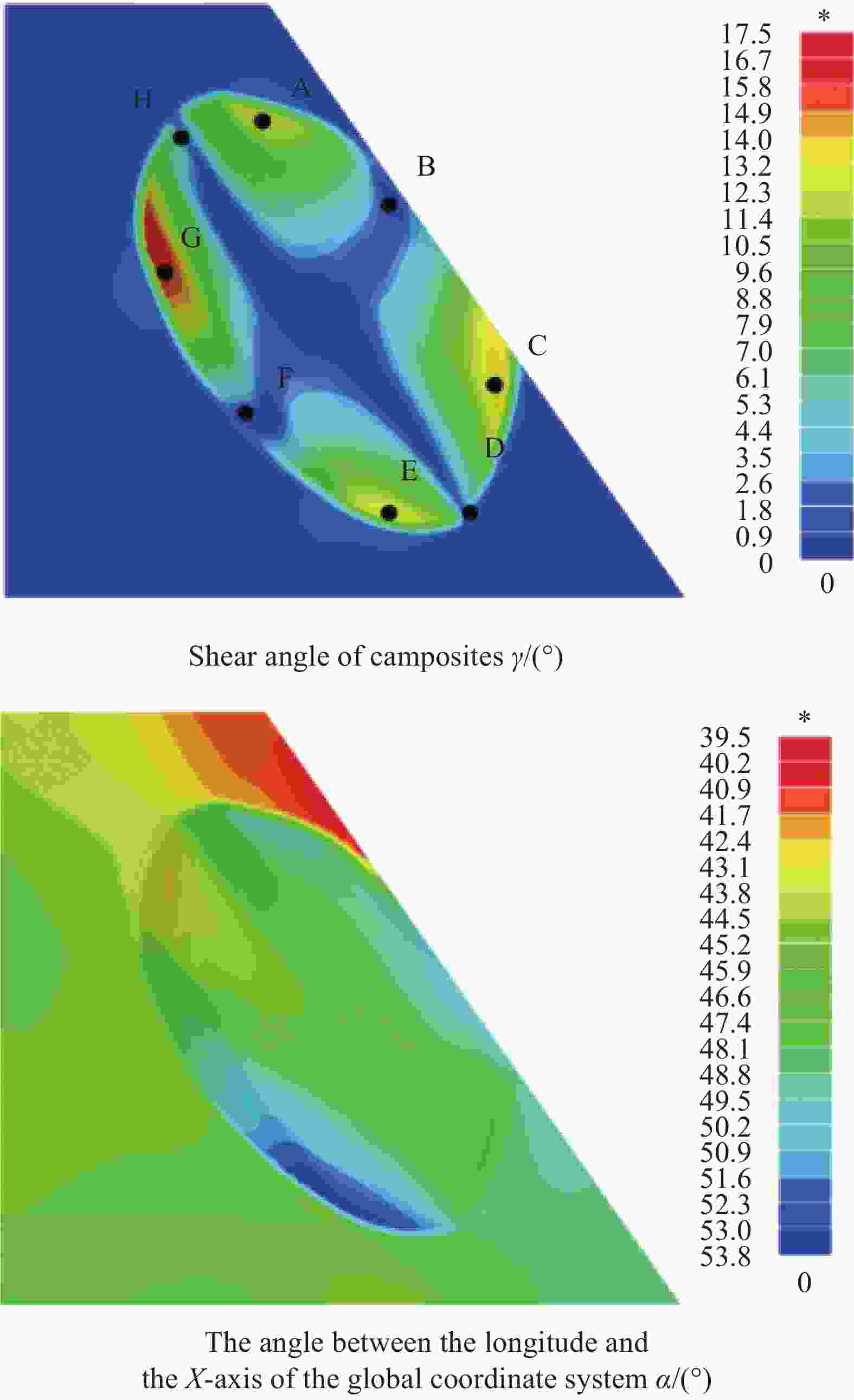

angle/(°)Point A 17.5 22.0 Point B 1.0 0.6 Point C 10.5 11.7 Point D 1.5 1.4 Point E 13.5 17.8 Point F 0.0 0.7 Point G 9.5 11.3 Point H 1.5 2.0 表 2 二维编织碳纤维增强树脂复合材料口盖零件[ 45°/−45°]方向铺层剪切角实验值与计算值

Table 2. Experimental and calculated shear angles of the cover part laminated in the direction of [45°/−45°] of 2D woven carbon fiber reinforced plastics

Experimental shear

angle/(°)Calculated shear

angle/(°)Point A 9.5 13.3 Point B 3.0 0.8 Point C 12.0 13.7 Point D 1.5 2.0 Point E 11.0 13.0 Point F 0.0 0.7 Point G 13.5 16.5 Point H 1.0 1.7 -

[1] MULAY S S, UDHAYARAMAN R. On the constitutive modelling and damage behaviour of plain woven textile composite[J]. International Journal of Solids and Structures,2018,156-157:73-86. [2] DIXIT A, MALI H S. Modeling techniques for predicting the mechanical properties of woven-fabric textile composites: A review[J]. Mechanics of Composite Materials,2013,49(1):1-20. [3] PENG X Q, GUO Z Y, DU T L, YU W R. A simple anisotropic hyperelastic constitutive model for textile fabrics with application to forming simulation[J]. Composites Part B,2013,52:275-281. [4] ZHOU X Y, RUAN X, ZHANG S J, et al. Design optimization for thermal conductivity of plain-woven textile compo-sites[J]. Composite Structures,2021,255:112830. [5] Technavio. New report on global carbon fiber prepreg market[J]. Reinforced Plastics, 2016, 60(4): 193-194. [6] ERCAN S, MALEK B, SIDI B. The bearing strength of pin loaded woven composites manufactured by vacuum assisted resin transfer moulding and hand lay-up techniques[J]. Polymers and Polymer Composites,2012,20(3):153-158. [7] ZHANG Q, GAO Q, CAI J. Experimental and simulation research on thermal stamping of carbon fiber composite sheet[J]. Transactions of Nonferrous Metals Society of China,2014,24(1):217-223. [8] GONG Y K, SONG Z R, NING H M, et al. A comprehensive review of characterization and simulation methods for thermo-stamping of 2D woven fabric reinforced thermoplastics[J]. Composites Part B: Engineering,2020,203:108462. [9] RAMEZANKHANI M, CRAWFORD B, NARAYAN A, et al. Making costly manufacturing smart with transfer learning under limited data: A case study on composites autoclave processing[J]. Journal of Manufacturing Systems,2021,59:345-354. [10] KHAN L A, MEHOOD A H. Cost-effective composites manu-facturing processes for automotive applications[M]//Lightweight Composite Structures in Transport. Cambridge: Woodhead Publishing, 2016: 93-119. [11] 陈中革, 吴建军, 邓良才, 等. 复合材料的铺层展开技术研究[J]. 工具技术, 2014, 48(2):27-30. doi: 10.3969/j.issn.1000-7008.2014.02.007CHEN Zhongge, WU Jianjun, DENG Liangcai, et al. Overlay spread technol-ogy research of composite material[J]. Tool Engineering,2014,48(2):27-30(in Chinese). doi: 10.3969/j.issn.1000-7008.2014.02.007 [12] ROBERTSON R E, HSIUE E S, YEH G S Y. Continuous fiber rearrangements during the molding of fiber composites II:Flat cloth to a rounded cone[J]. Polymer Composites,1984,5(3):191-197. [13] WANG J, PATON R, PAGE J R. The draping of woven fabric preforms and prepregs for production of polymer compo-site components[J]. Composites Part A: Applied Science & Manufacturing,1999,30(6):757-765. [14] ANTHONY K P, GAVIN C, PATRICK D L. Simplified and advanced simulation methods for prediction of fabric draping[J]. Revue Européenne des Éléments Finis,2005,14:677-691. [15] 蔡闻峰, 薛小平, 邓良才. 复合材料曲面铺层的数字化展开技术及发展方向[J]. 航空制造技术, 2012(3):48-51. doi: 10.3969/j.issn.1671-833X.2012.03.006CAI Wenfeng, XUE Xiaoping, DENG Liangcai. Digital curved surface flattening technonogy of composites and its development trend[J]. Aeronautical Manufacturing Technology,2012(3):48-51(in Chinese). doi: 10.3969/j.issn.1671-833X.2012.03.006 [16] 周晔欣, 戴如玥, 黄争鸣. 复合材料结构力学分析CAE软件现状[J]. 应用力学学报, 2020, 37(1):114-122, 475-476.ZHOU Yexin, DAI Ruyue, HUANG Zhengming. Present situation of CAE software for structural mechanics analysis of composite materials[J]. Chinese Journal of Applied Mechanics,2020,37(1):114-122, 475-476(in Chinese). [17] 富威, 王鹏, 李庆芬. 基于Web的复合材料设计专家系统[J]. 哈尔滨工程大学学报, 2004, 25(6):773-776. doi: 10.3969/j.issn.1006-7043.2004.06.019FU Wei, WANG Peng, LI Qingfen. Study on expert system in composite material design based on the Web[J]. Journal of Harbin Engineering University,2004,25(6):773-776(in Chinese). doi: 10.3969/j.issn.1006-7043.2004.06.019 [18] 王涛. 复合材料构件纤维铺覆仿真及特征建模技术研究[D]. 哈尔滨: 哈尔滨工程大学, 2011.WANG Tao. Research on fiber draping and feature modeling of composite material[D]. Harbin: Harbin Engineering University, 2011(in Chinese). [19] 黄小双, 姚远, 彭雄奇, 等. 考虑双拉耦合的复合材料编织物各向异性超弹性本构模型[J]. 复合材料学报, 2016, 33(10):2319-2324.HUANG Xiaoshuang, YAO Yuan, PENG Xiongqi, et al. Anisotropic hyperelastic constitutive model with biaxial tension coupling for woven fabric composite[J]. Acta Materiae Compositae Sinica,2016,33(10):2319-2324(in Chinese). [20] 胡虹玲, 龚友坤, 彭雄奇, 等. 考虑拉剪耦合的二维编织物各向异性超弹性本构模型[J]. 复合材料学报, 2017, 34(6):1388-1393.HU Hongling, GONG Youkun, PENG Xiongqi, et al. An anisotropic hyperelastic constitutive model considering shear-tension coupling for 2-dimensional woven fabrics[J]. Acta Materiae Compositae Sinica,2017,34(6):1388-1393(in Chinese). [21] 张衡, 严飙, 龚友坤, 等. 碳纤维机织物增强热塑性树脂复合材料热冲压叠层模型[J]. 复合材料学报, 2017, 34(12):2741-2746.ZHANG Heng, YAN Biao, GONG Youkun, et al. A lamination model for thermostamping of carbon woven fabric reinforced thermoplastic resin composites[J]. Acta Materiae Compositae Sinica,2017,34(12):2741-2746(in Chinese). [22] 张必超, 彭雄奇, 黄小双. 考虑双拉耦合的复合材料编织物非正交本构模型[J]. 应用数学和力学, 2016, 37(3):227-234.ZHANG Bichao, PENG Xiongqi, HUANG Xiaoshuang. A non-orthogonal constitutive model of composite woven fabric considering shear-tension coupling[J]. Applied Mathematics and Mechanics,2016,37(3):227-234(in Chinese). [23] BIAO L, ZHANG W Z, FENNER J S, et al. Multi-scale modeling of mechanical behavior of cured woven textile compo-sites accounting for the influence of yarn angle variation[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105460. [24] ZHANG W Z, BOSTANABAD L, BIAO L, et al. A numerical Bayesian-calibrated characterization method for multiscale prepreg preforming simulations with tension-shear coupling[J]. Composites Science and Technology,2019,170:15-24. [25] GUO Y Q, BATOZ J L, DETRAUX J M, et al. Finite element procedures for strain estimations of sheet metal forming parts[J]. International Journal for Numerical Methods in Engineering,1990,30(8):1385-1401. doi: 10.1002/nme.1620300804 [26] NGUYEN B N, JOHNSON K I, KHALEEL M A. Analysis of tube free hydroforming using an inverse approach with FLD- based adjustment of process parameters[J]. Journal of Engineering Materials and Technology,2003,125(2):133-140. doi: 10.1115/1.1555651 [27] ZENG D, ZHU X H, ZHANG L, et al. Development of a one-step analysis for preforming of woven carbon fiber compo-sites[C]. 15th International Ls-dyna Users Conference, Detroit, 2018. -

下载:

下载: