Three-dimensional hybrid material constructed by cellulose nanofibers/multiwall carbon nanotubes aerogel and foam nickel and its electrochemical capacitance performance

-

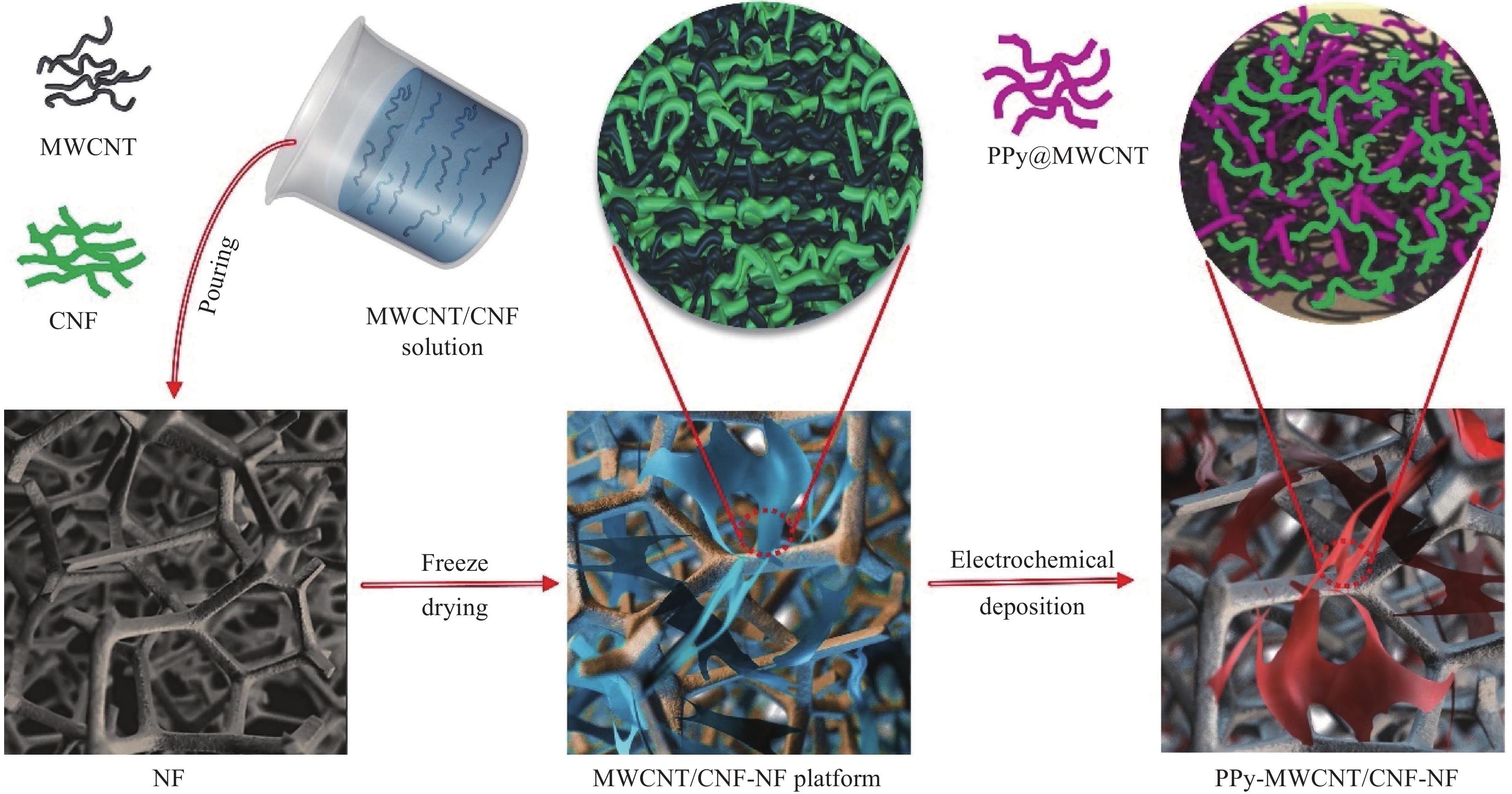

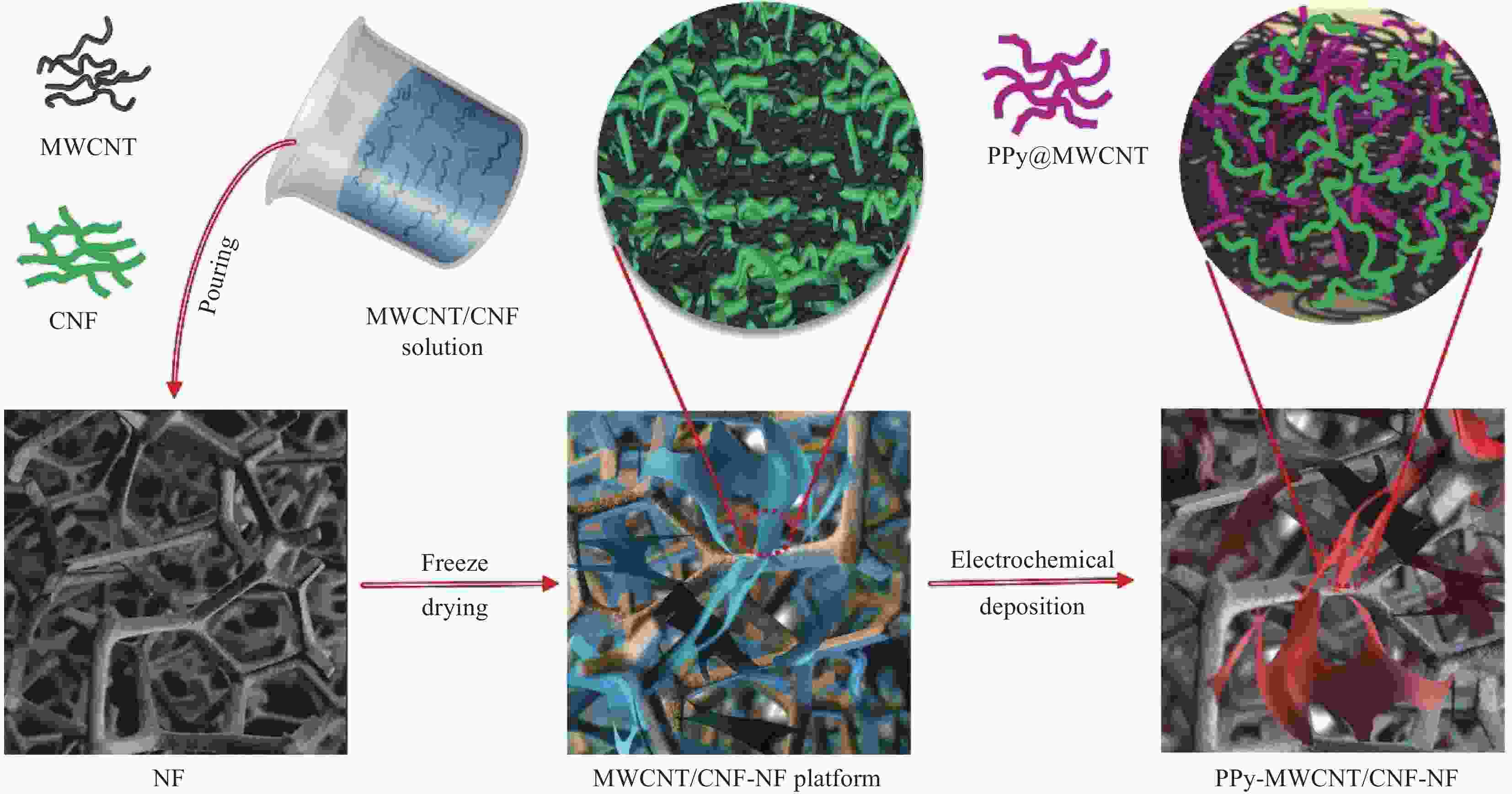

摘要: 三维(3D)电极材料因其独特的结构和优异的电化学性能而被认为是高性能超级电容器的理想候选者。纳米纤维素(CNF)和多壁碳纳米管(MWCNT)被广泛应用于电极材料的开发与设计,但如何利用它们独特的一维纳米结构和固有的物理特性来构筑高性能3D电极材料依然是一个巨大的挑战。采用“自下而上”的策略,以CNF/MWCNT冷冻干燥过程中自聚集形成的气凝胶薄片为填充物,镍泡沫(NF)的3D网状结构为骨架,巧妙构筑了一种具有独特“薄片填充-骨架支撑”结构的MWCNT/CNF-NF三维杂化材料。受益于NF三维骨架优异的导电性和增强作用及MWCNT/CNF气凝胶薄片高的比表面积,以MWCNT/CNF-NF为负载电活性物质聚吡咯(PPy)的平台,通过优化电沉积时间制备的PPy-MWCNT/CNF-NF自支撑电极具有良好的可弯曲性和优异的电化学特性。与预期一样,在5 mA·cm−2的电流密度下该电极的面积比容量高达2217.8 mF·cm−2 (869.9 F·g−1),经过3000次循环后依然具有90.2%的高容量保持率。Abstract: Three-dimensional (3D) electrode materials are ideal candidates for use in fabricating high-performance supercapacitors, owing to their unique network structure and excellent electrochemical properties. Although cellulose nanofibers (CNF) and multiwall carbon nanotubes (MWCNT) are widely used in the development and design of electrode materials, how to use their unique one-dimensional nanostructures and inherent physical properties to build high-performance 3D electrode materials remains a huge challenge. Herein, an aerogel film produced by the freeze-drying self-aggregation of MWCNTs and CNFs was used as the “filling,” and an inter-connected 3D network of nickel foam (NF) as the “framework,” for well-design and fabrication of an MWCNT/CNF-NF hybrid materials. Benefiting from the excellent conductivity and high specific surface area of the MWCNT/CNF-NF, it is exceptionally suitable for use as the electroactive material platform in the fabrication of high-performance electrodes. Therefore, in this work, the high-performance polypyrrole (PPy)-MWCNT/CNF-NF freestanding electrodes were successfully prepared by optimizing the time of the electroactive material polypyrrole. As expected, the electrode exhibits a high areal capacity of 2217.8 mF·cm−2 (869.9 F·g−1) at a current density of 5 mA·cm−2, with good stability even after 3000 charge-discharge cycles.

-

Key words:

- cellulose nanofibers /

- carbon nanotubes /

- electroactive platform /

- polypyrrole /

- freestanding electrode

-

图 3 不同样品的SEM图像:((a), (b)) NF;((c), (d)) MWCNT/CNF-NF平台;((e), (f)) PPy-NF;((g), (h)) PPy-MWCNT/CNF-NF;((i), (j)) MWCNT电沉积PPy后的TEM图像;(k) 大范围制备的MWCNT/CNF-NF照片;(l) 裁成条状的PPy-MWCNT/CNF-NF电极的柔性演示

Figure 3. SEM images of different samples: ((a), (b)) NF; ((c), (d)) MWCNT/CNF-NF platform; ((e), (f)) PPy-NF; ((g), (h)) PPy-MWCNT/CNF-NF; ((i), (j)) TEM images of MWCNT after electrodeposited PPy; (k) Photo of MWCNT/CNF-NF prepared by large scale; (l) Flexibility demonstration of PPy-MWCNT/CNF-NF electrodes

图 4 MWCNT/CNF-NF在5~100 mV·s−1扫描速度下的CV曲线 (a)、1~40 mA·cm−2电流密度下的充放电曲线 (b) 和交流阻抗谱图 (c)

Figure 4. CV curves at 5-100 mV·s−1 scanning speed (a), charge-discharge curves at 1-40 mA·cm−2 current density (b) and Nyquist plots (c) of MWCNT/CNF-NF

Z'—Real impedance; Z''—Imaginary imdepance; Rs—Charge transfer resistance; Rct—Electrolyte resistance; CPE1—Constant phase element

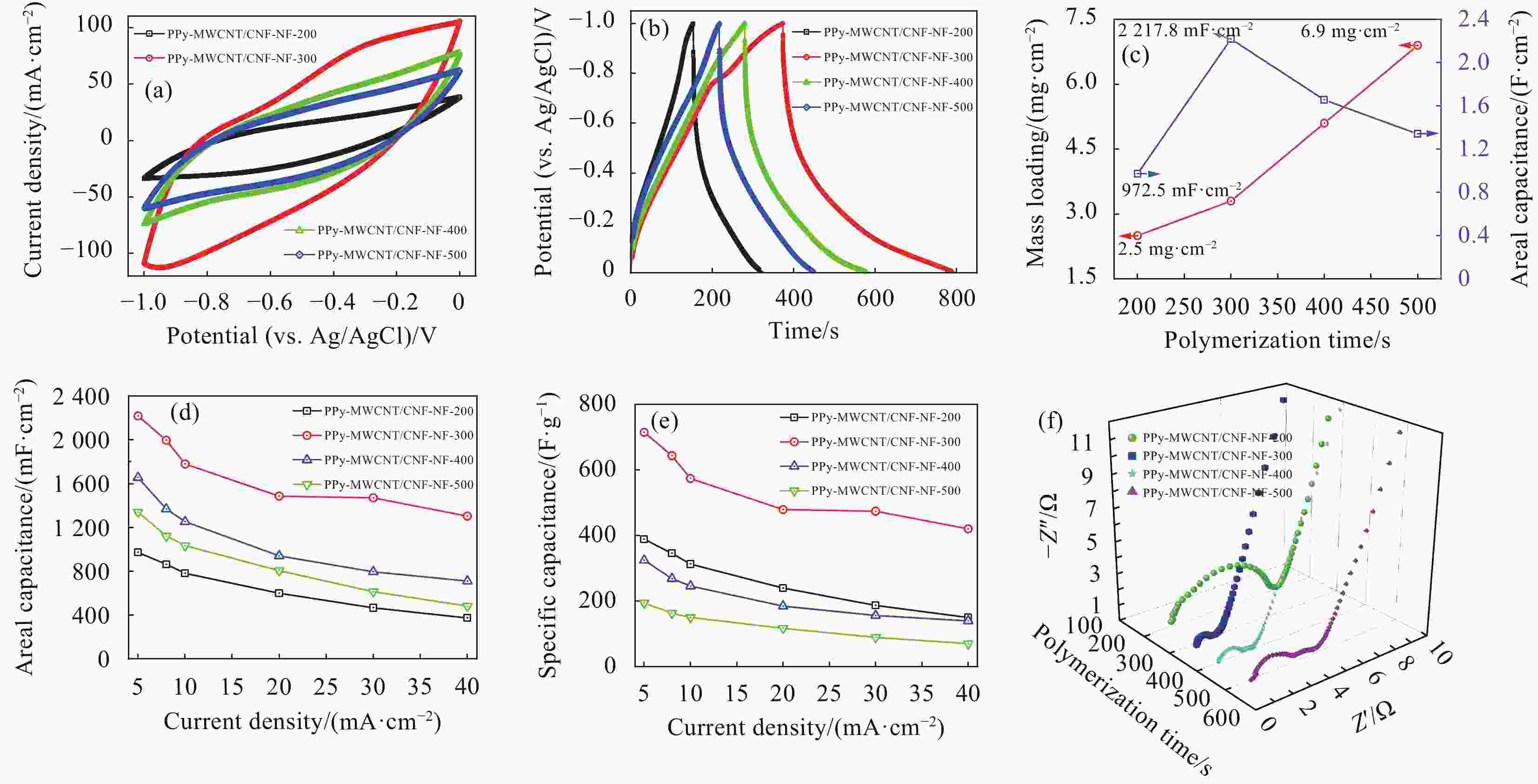

图 5 不同电沉积时间的PPy-MWCNT/CNF-NF电极在100 mV·s−1扫速下收集的CV曲线 (a)、5 mA·cm−2的恒电流充放电CP曲线 (b)、PPy负载量和面积比电容与电沉积时间的函数关系 (c)、面积比容量与电流密度的关系 (d)、质量比容量与电流密度的关系 (e) 和Nyquist阻抗谱图 (f)

Figure 5. CV curves collected at 100 mV·s−1 sweep speed (a), CP curves of 5 mA·cm−2 constant current charge-discharge (b), functional relationship between PPy load and area specific capacitance and electrodeposition time at different electrodeposition time (c), area specific capacity versus current density (d), mass specific capacity versus current density (e) and Nyquist impedance spectrum (f) of PPy-MWCNT/CNF-NF with different electrodeposition times

图 6 不同电极在100 mV·s−1扫速下收集的CV曲线 (a)、5 mA·cm−2的恒电流充放电计时电位分析(CP)曲线 (b)、面积比电容和容量保持率与电流密度的函数关系 (c);(d) PPy-MWCNT/CNF-NF电极在10 mA·cm−2电流密度下的循环稳定性

Figure 6. CV curves collected at 100 mV·s−1 sweep speed (a), Chronopotentiometry (CP) curves of 5 mA·cm−2 constant current charge-discharge (b), functional relationship between area specific capacitance and capacity retention and current density (c) of different electrodes; (d) Cyclic stability of PPy-MWCNT/CNF-NF electrode at 10 mA·cm−2

表 1 不同沉积时间PPy- MWCNT/CNF-NF电极的命名

Table 1. Naming of PPy-MWCNT/CNF-NF electrode with different electrodeposition time

Sample Electrodeposition time/s PPy-MWCNT/CNF-NF-200 200 PPy-MWCNT/CNF-NF-300 300 PPy-MWCNT/CNF-NF-400 400 PPy-MWCNT/CNF-NF-500 500 -

[1] HE J Q, LU C H, JIANG H B. Scalable production of high-performing woven lithium-ion fibre batteries[J]. Nature,2021,597:57-63. doi: 10.1038/s41586-021-03772-0 [2] WANG X N, ZHOU Z Y, SUN Z J, et al. Atomic modulation of 3D conductive frameworks boost performance of MnO2 for coaxial fiber-shaped supercapacitor[J]. Nano-Micro Letters,2021,13(1):4-12. doi: 10.1007/s40820-020-00529-8 [3] LV J, JEERAPAN I, TEHRANI F, et al. Sweat-based wearable energy harvesting-storage hybrid textile devices[J]. Energy Environment Science,2018,11:3431-3442. doi: 10.1039/C8EE02792G [4] 张文枭, 左杏薇, 曲丽君, 等. 基于导电纤维的柔性电子器件研究进展[J]. 复合材料学报, 2022, 40(2):688-709.ZHANG W X, ZUO X W, QU L J, et al. Research progress of flexible electronic devices based on conductive fibers[J]. Acta Materiae Compositae Sinica,2022,40(2):688-709(in Chinese). [5] 聂文琪, 孙江东, 许帅, 等. 纺织基超级电容器研究进展[J]. 复合材料学报, 2022, 39(3):981-992.NIE W Q, SUN J D, XU S, et al. Textile-based for supercapacitors: A review[J]. Acta Materiae Compositae Sinica,2022,39(3):981-992(in Chinese). [6] BALAMURUGAN J, NGUYEN T T, ARAVINDAN V, et al. Flexible solid-state asymmetric supercapacitors based on nitrogen-doped graphene encapsulated ternary metal-nitrides with ultralong cycle life[J]. Advanced Functional Materials,2018,28(44):1804663. doi: 10.1002/adfm.201804663 [7] 刘馨月, 齐晓俊, 管宇鹏, 等. 纤维素纳米纤丝-还原氧化石墨烯/聚苯胺气凝胶柔性电极复合材料的制备与性能[J]. 复合材料学报, 2019, 36(7):1583-1590.LIU X Y, QI X J, GUAN Y P, et al. Preparation and properties of cellulose nanofiber-reduced graphene oxide/polyaniline composite aerogels as flexible electrodes[J]. Acta Materiae Compositae Sinica,2019,36(7):1583-1590(in Chinese). [8] 赵文誉, 王振祥, 郑玉婴, 等. NiS2/三维多孔石墨烯复合材料作为超级电容器电极材料的电化学性能[J]. 复合材料学报, 2020, 37(2):422-431.ZHAO W Y, WANG Z X, ZHENG Y Y, et al. Electrochemical performance of NiS2/3D porous reduce graphene oxide composite as electrode material for supercapacitors[J]. Acta Materiae Compositae Sinica,2020,37(2):422-431(in Chinese). [9] DUBAL D P, CHODANKAR N R, KIM D H, et al. Towards flexible solid-state supercapacitors for smart and wearable electronics[J]. Chemical Society Reviews,2018,47(6):2065-2129. doi: 10.1039/C7CS00505A [10] 韩景泉, 王思伟, 岳一莹, 等. 静电纺定向纳米纤维素-碳纳米管/聚乙烯醇复合纤维导电膜及性能[J]. 复合材料学报, 2018, 35(9):2351-2361.HAN J Q, WANG S W, YUE Y Y, et al. Preparation and characterization of cellulose nanocrystal-carbon nanotube/polyvinyl alcohol composite conductive membranes with oriented fibers by electrospinning[J]. Acta Materiae Compositae Sinica,2018,35(9):2351-2361(in Chinese). [11] LI D L, GONG Y N, WANG M S, et al. Preparation of sandwich-like NiCo2O4/rGO/NiO heterostructure on nickel foam for high-performance supercapacitor electrodes[J]. Nano-Micro Letters,2017,9(2):9-16. [12] 董丽攀, 李政, 王福迎, 等. 细菌纤维素@聚吡咯-单壁碳纳米管导电膜的制备与表征[J]. 复合材料学报, 2019, 36(3):723-729.DONG L P, LI Z, WANG F Y, et al. Preparation and characterization of bacterial cellulose@polypyrrole-single wall carbon nanotube conductive films[J]. Acta Materiae Compositae Sinica,2019,36(3):723-729(in Chinese). [13] 顾升, 王雪, 徐国祺. 基于界面相互作用构建纳米纤维素-羧基化碳纳米管-石墨/聚吡咯柔性电极复合材料[J]. 复合材料学报, 2020, 37(9):2105-2116.GU S, WANG X, XU G Q. Construction of nanocellulose-carboxylated carbon nanotube-graphite/polypyrrole flexible electrode composite based on interface interaction[J]. Acta Materiae Compositae Sinica,2020,37(9):2105-2116(in Chinese). [14] XIA L Y, LI X L, WU Y Q, et al. Electrodes derived from carbon fiber-reinforced cellulose nanofiber/multiwalled carbon nanotube hybrid aerogels for high-energy flexible asymmetric supercapacitors[J]. Chemical Engineering Journal,2020,379:122325-122334. doi: 10.1016/j.cej.2019.122325 [15] CHEN W M, ZHANG D T, YANG K, et al. Mxene (Ti3C2Tx)/cellulose nanofiber/porous carbon film as free-standing electrode for ultrathin and flexible supercapacitors[J]. Chemical Engineering Journal,2021,413:127524. doi: 10.1016/j.cej.2020.127524 [16] ZHANG X Q, HUANG L, QING Y, et al. Fabrication of robust, highly conductive, and elastic hybrid carbon foam platform for high-performance compressible asymmetry supercapacitors[J]. ACS Omega,2021,6:14230-14241. doi: 10.1021/acsomega.1c00952 [17] ZHOU S Y, KONG X Y, ZHENG B, et al. Cellulose nanofiber@conductive metal-organic frameworks for high-performance flexible supercapacitors[J]. ACS Nano,2021,13(8):9578-9586. [18] LIU H Y, XU T, CAI C Y, et al. Multifunctional superelastic, superhydrophilic, and ultralight nanocellulose-based composite carbon aerogels for compressive supercapacitor and strain sensor[J]. Advanced Functional Materials,2022,32(26):2113082. doi: 10.1002/adfm.202113082 [19] TIAN W Q, VAHID M A, REID M S, et al. Multifunctional nanocomposites with high strength and capacitance using 2D MXene and 1D nanocellulose[J]. Advanced Materials,2019,41:1970290. [20] QING Y, SABO R, ZHU J Y, et al. A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches[J]. Carbohydrate Polymers,2013,97:226-234. doi: 10.1016/j.carbpol.2013.04.086 [21] ZHU M, HUANG Y, DENG Q, et al. Highly flexible, freestanding supercapacitor electrode with enhanced perfor-mance obtained by hybridizing polypyrrole chains with MXene[J]. Advanced Energy Materials,2016,6:1600969. doi: 10.1002/aenm.201600969 [22] FARD L A, OJANI R, RAOOF J B, et al. PdCo porous nanostructures decorated on polypyrrole@MWCNTs conduc-tive nanocomposite-modified glassy carbon electrode as a powerful catalyst for ethanol electrooxidation[J]. Applied Surface Science, 2017, 401: 40-48. -

下载:

下载: