Research on the induced crystallization behavior of high-performance thermoplastics resin-based composites

-

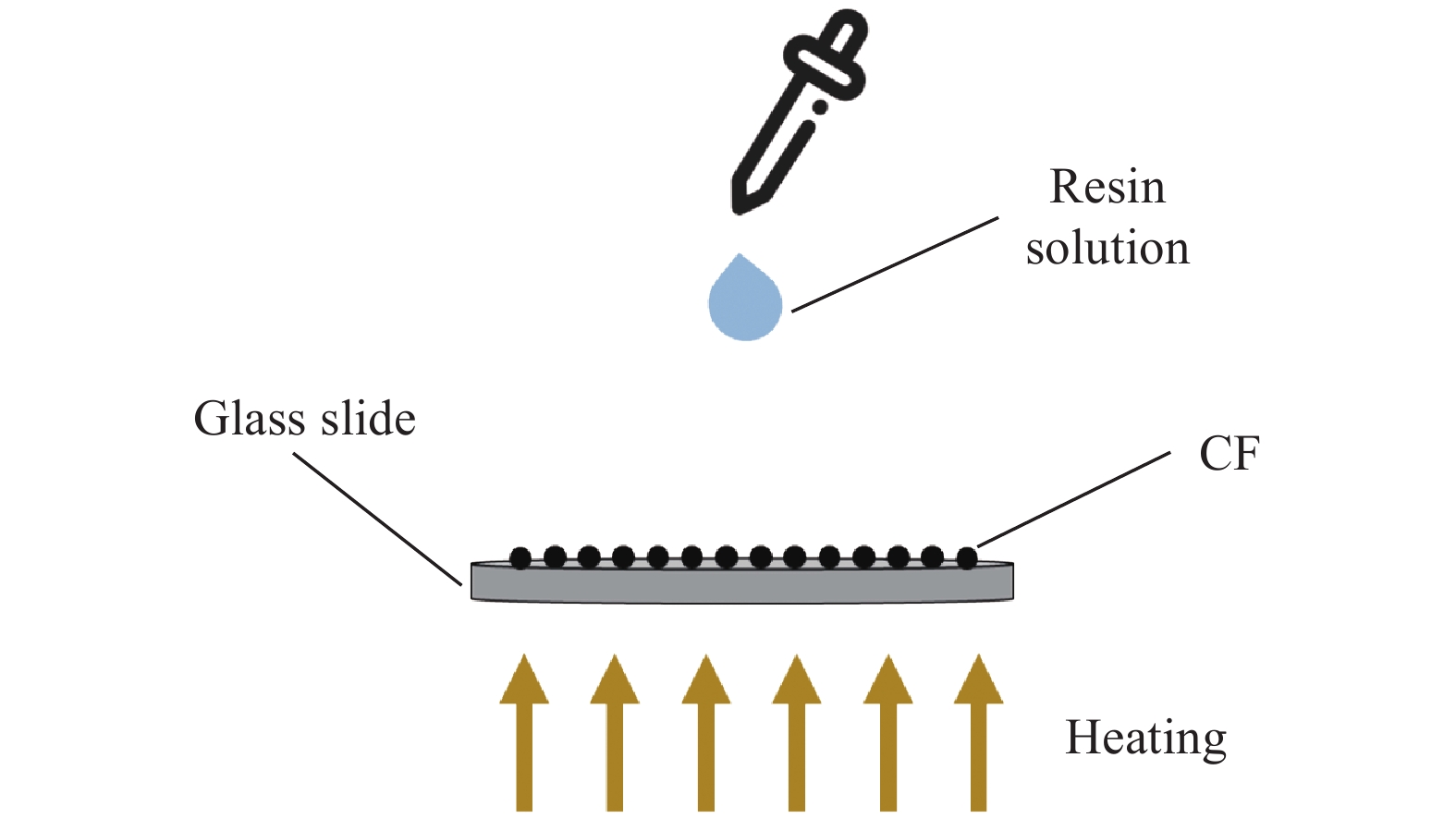

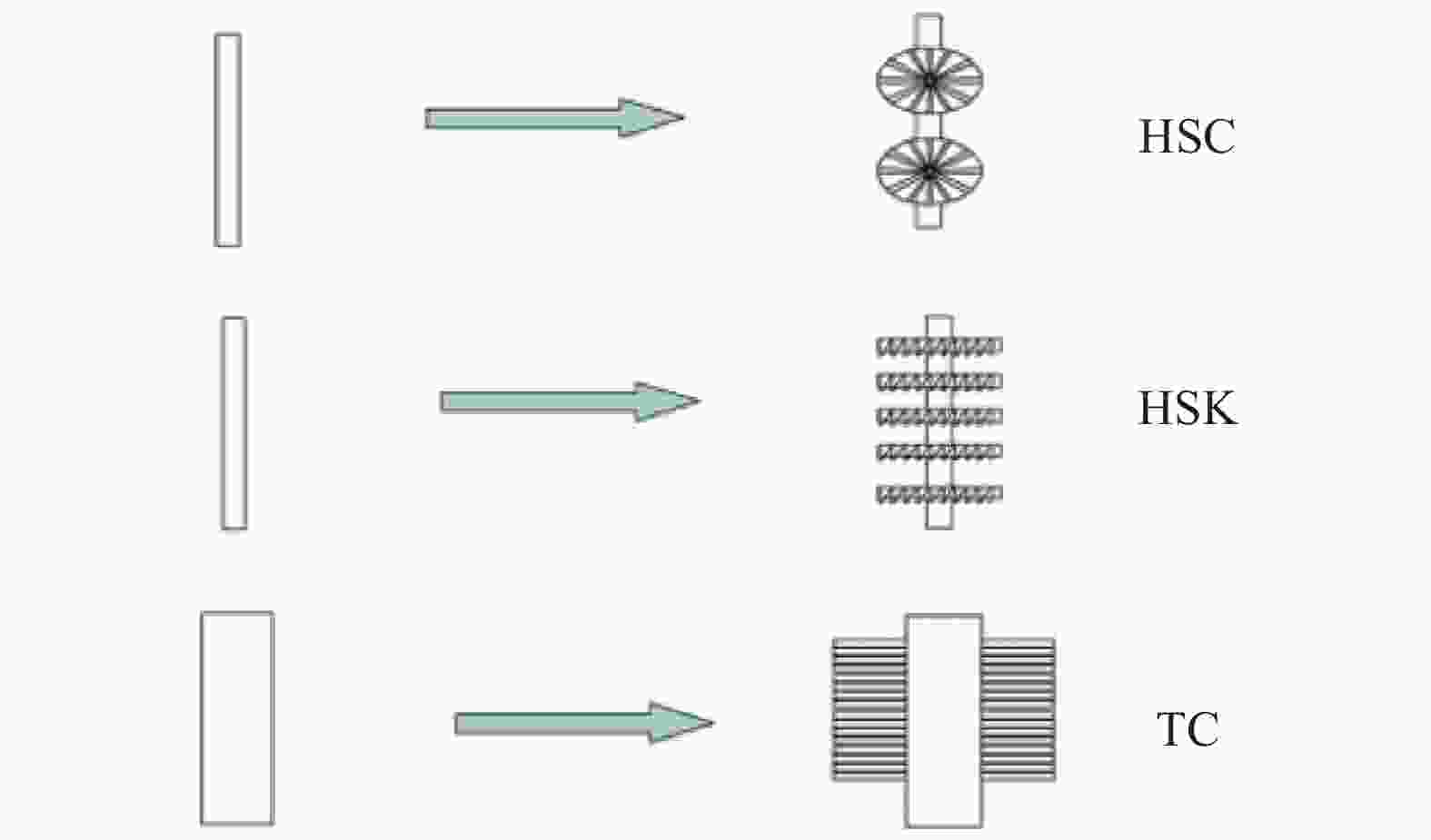

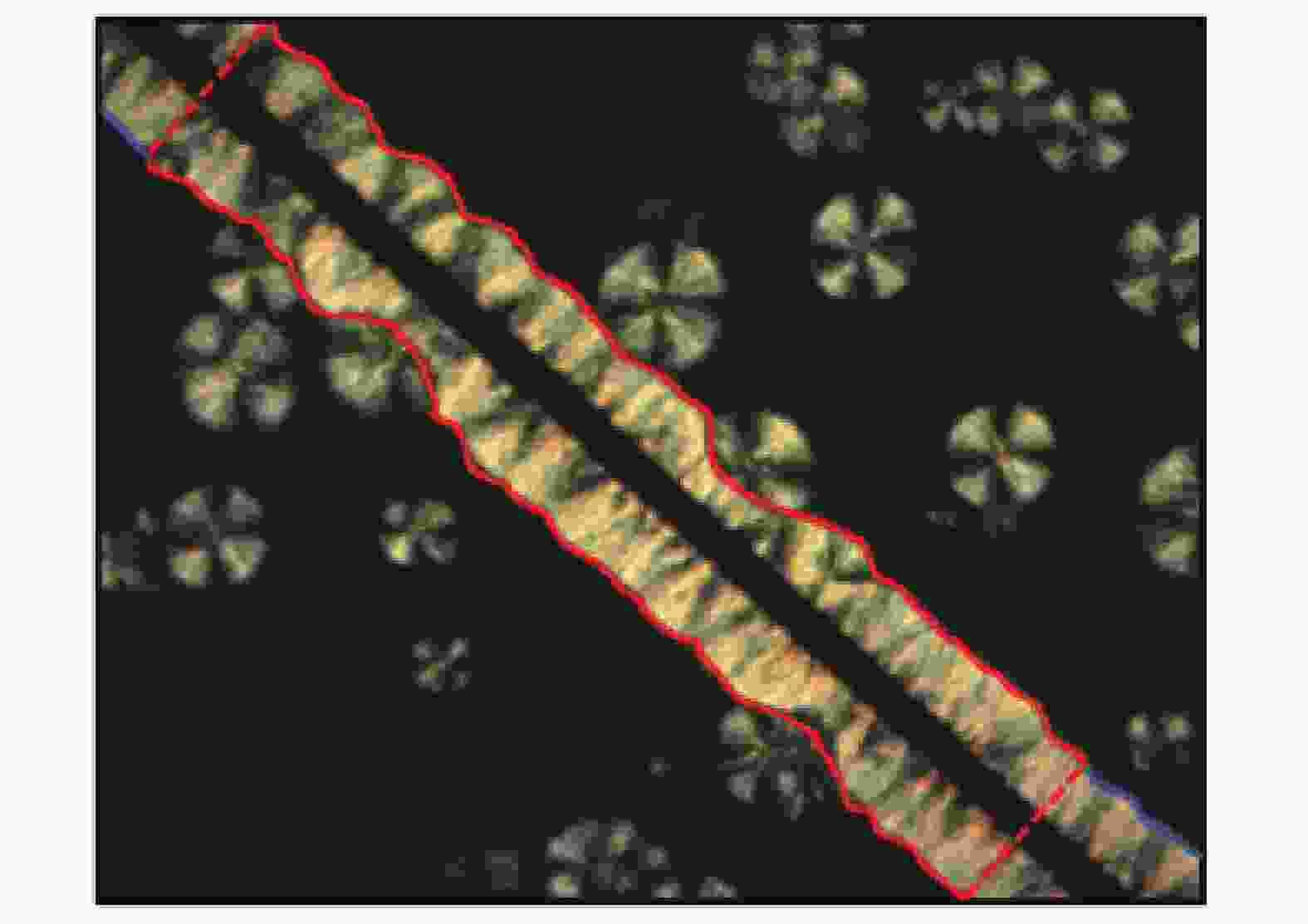

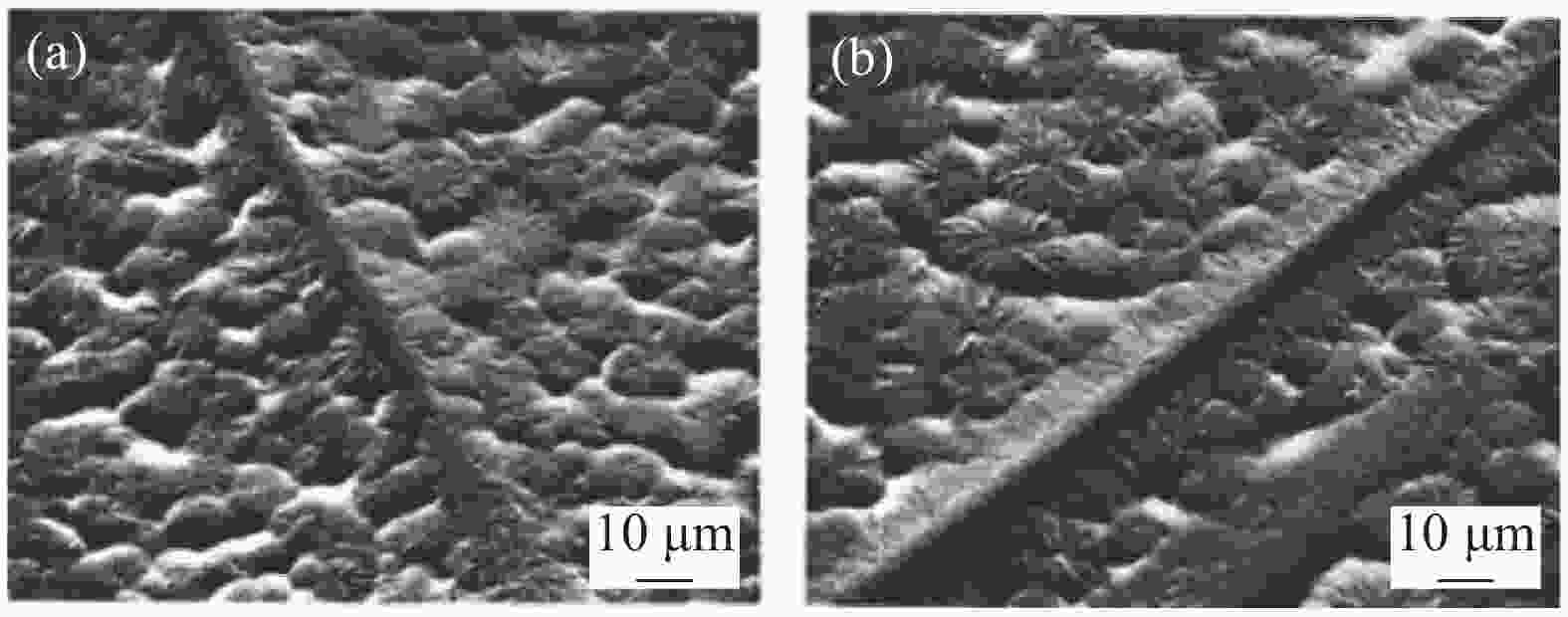

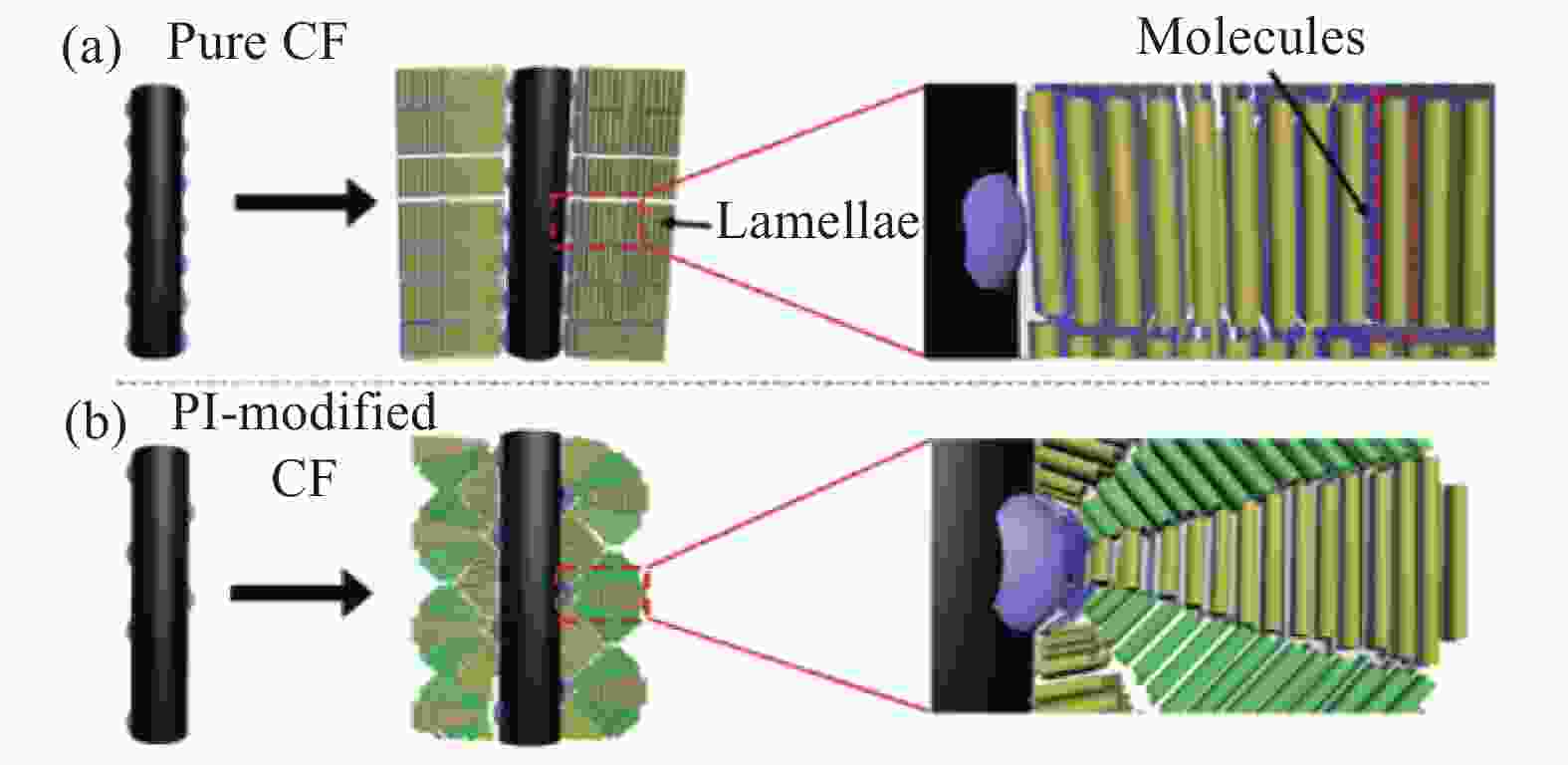

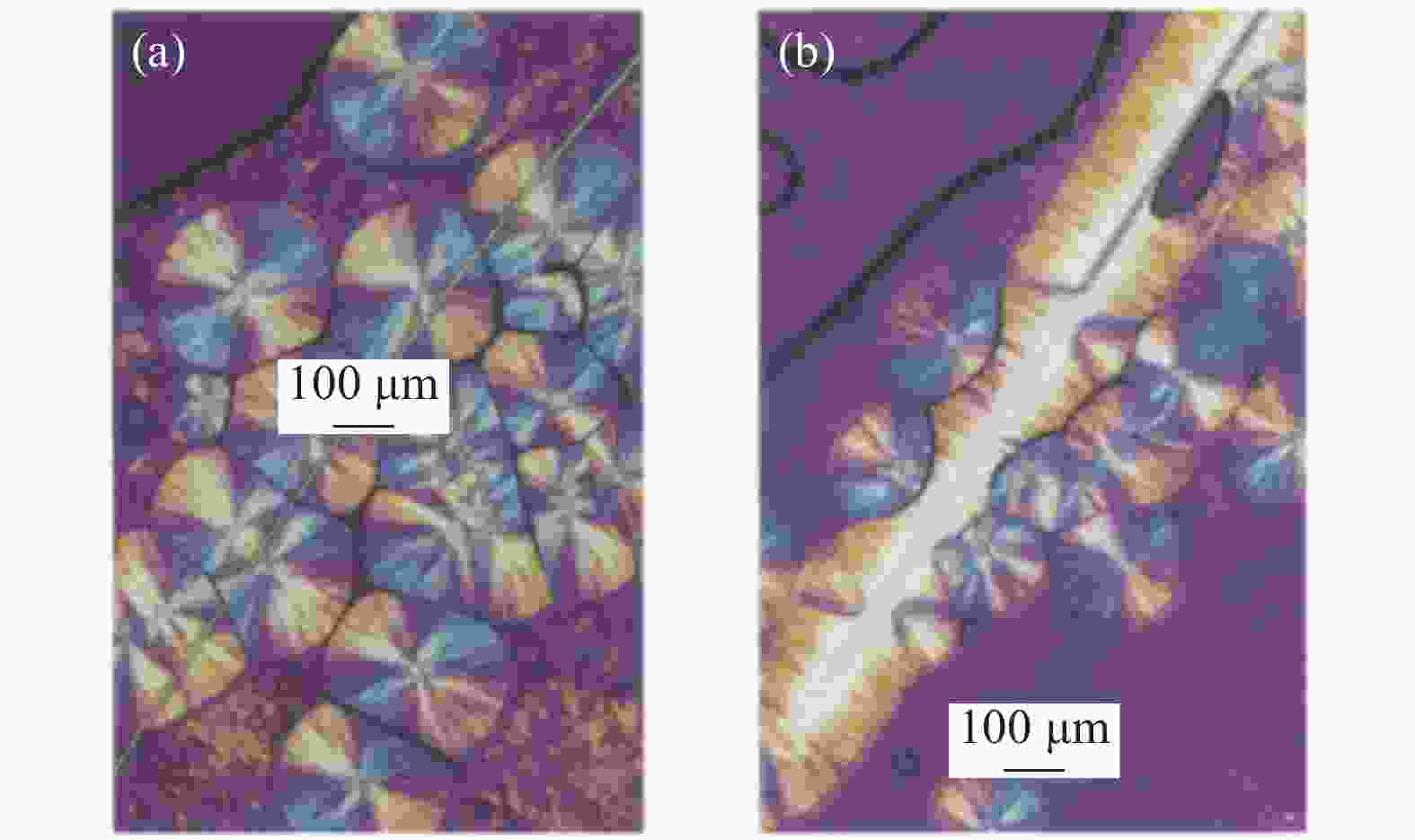

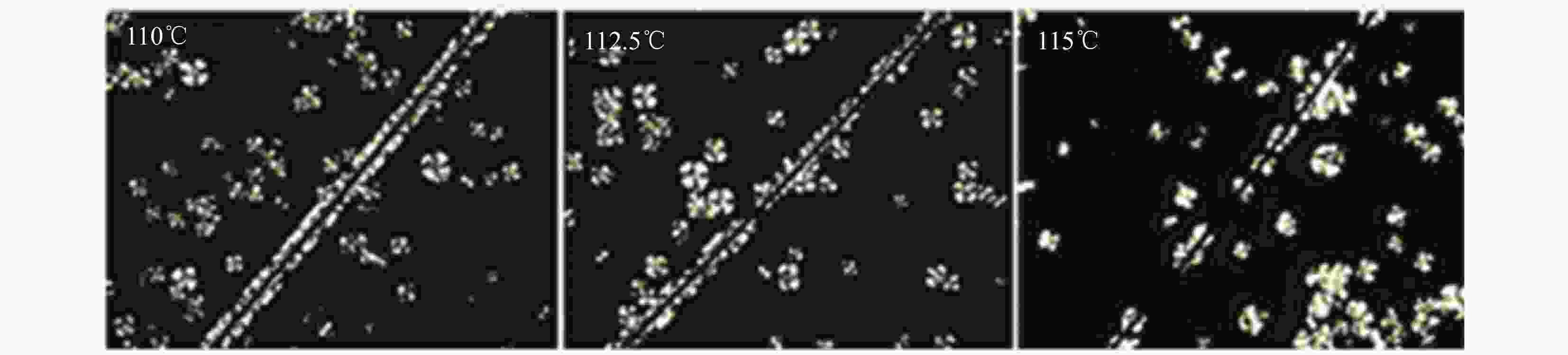

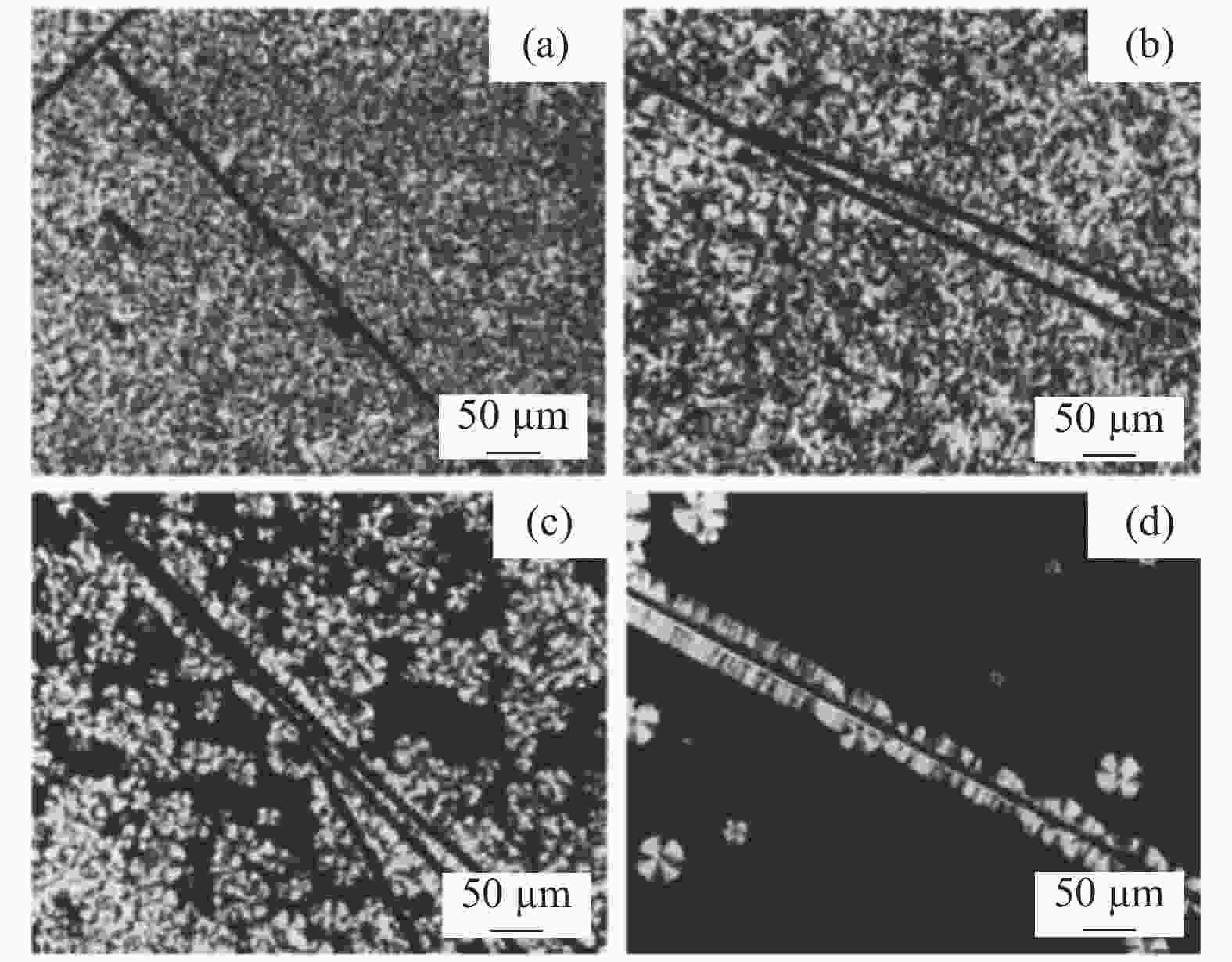

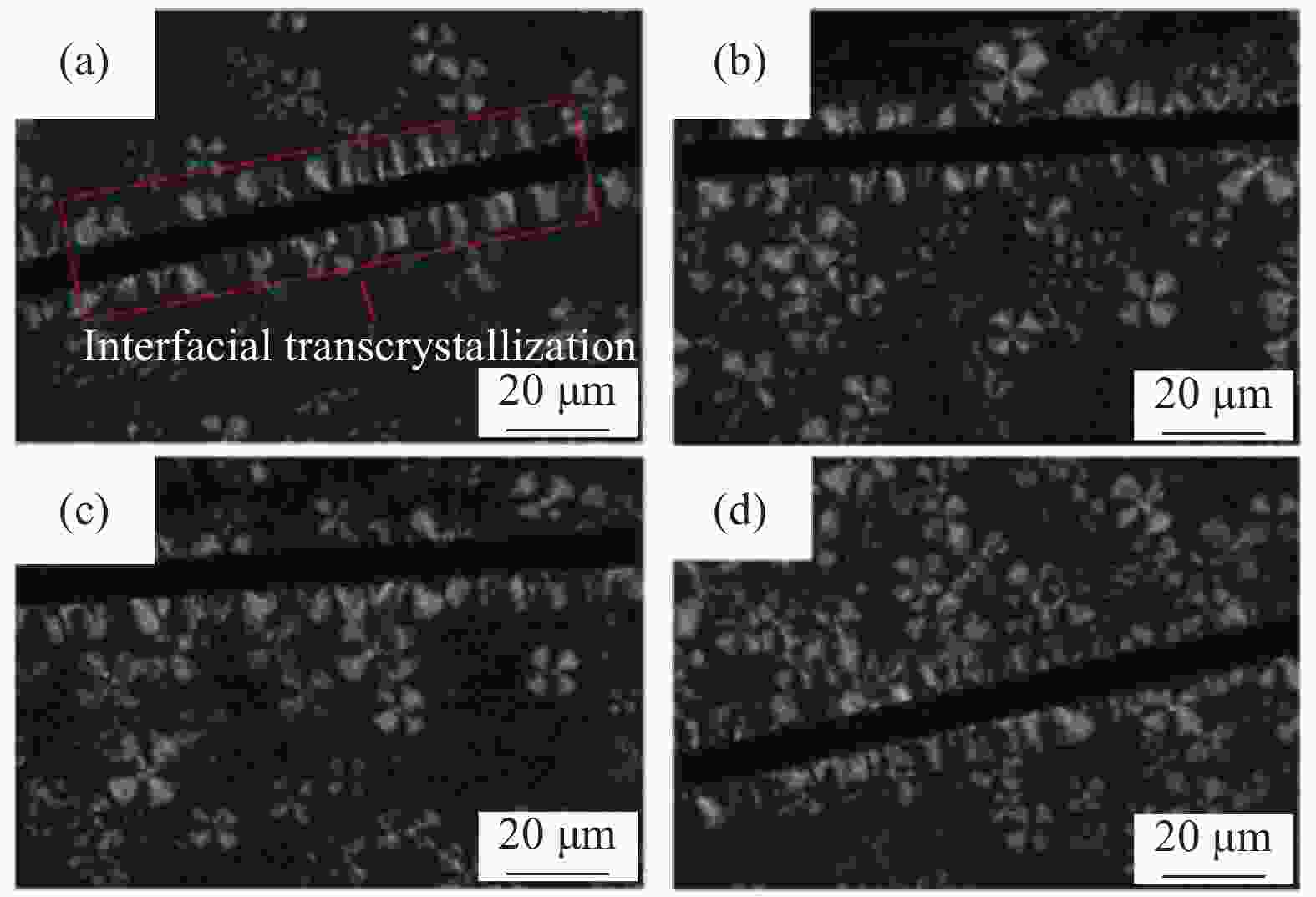

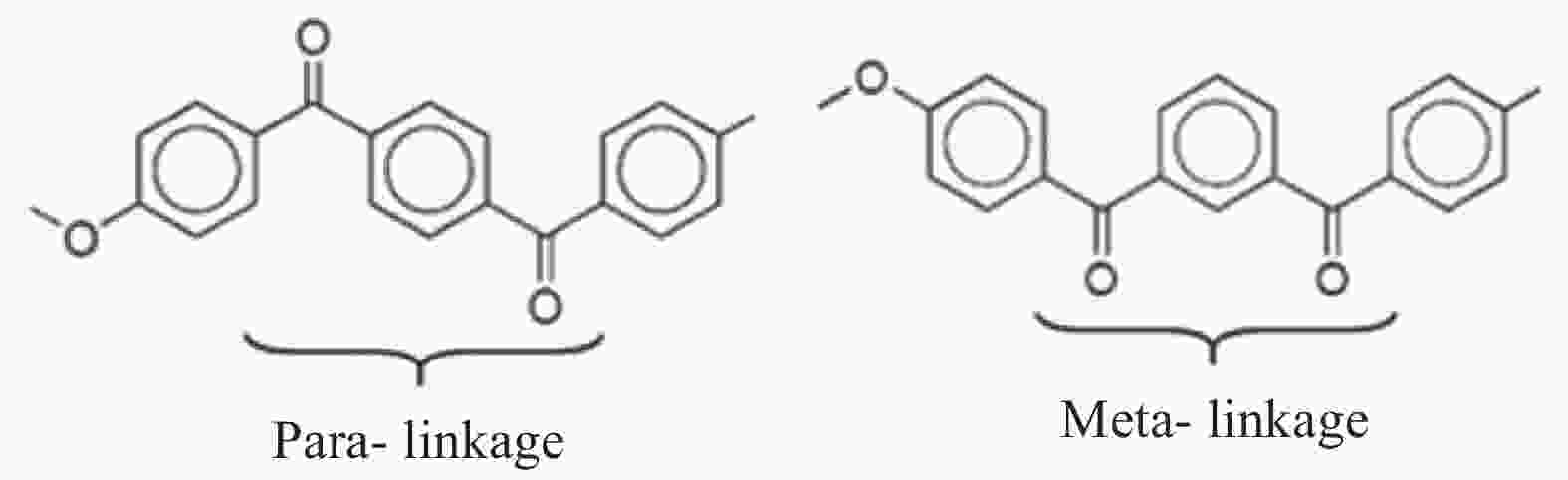

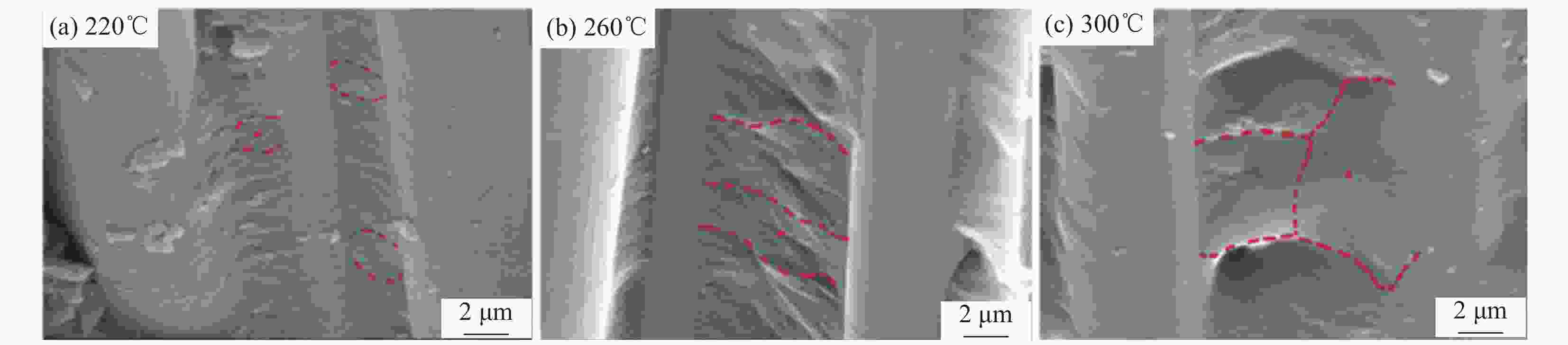

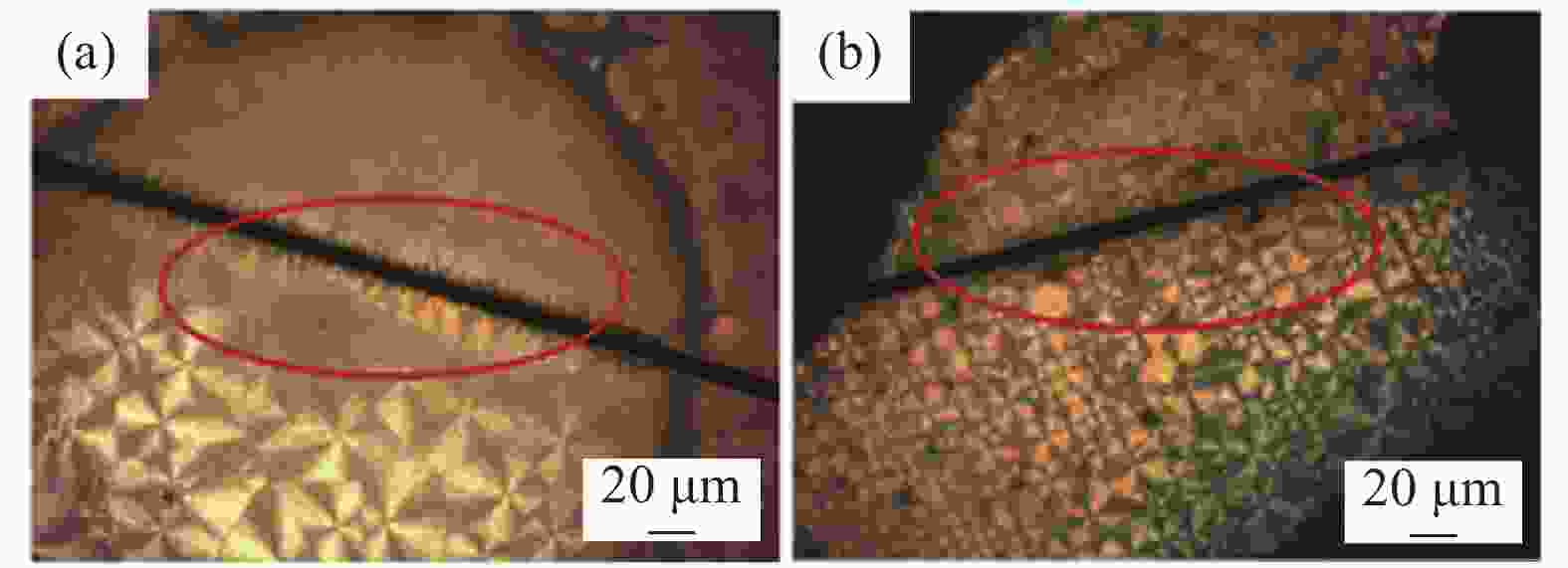

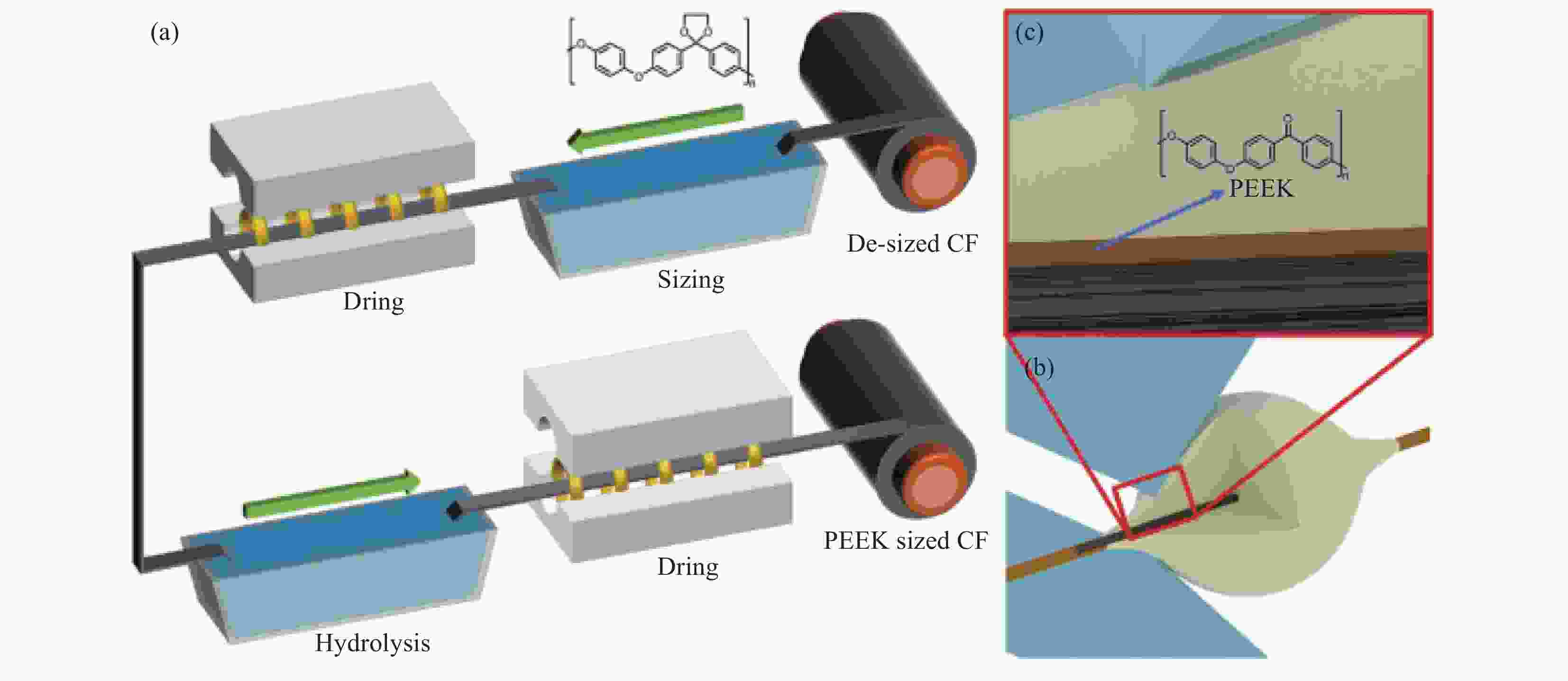

摘要: 在热塑性树脂基复合材料中,优化界面性能对于提升复合材料的整体性能表现具有非常重要的作用。当碳纤维(CF)作为增强体与半结晶型的高性能热塑性树脂基体,如聚醚醚酮(PEEK)、聚芳醚酮(PAEK)或聚苯硫醚(PPS)等复合时,纤维与树脂界面上发生的诱导结晶现象,会对复合材料的界面性能产生显著影响。本文以高性能热塑性树脂基复合材料研究中诱导结晶问题为切入点,综述了该领域的研究进展。文章涵盖了从诱导结晶样品的制备方法到其最终性能变化的全过程,并分析了诱导结晶的类型及其影响因素,同时描述了高性能热塑性树脂中几种典型的横晶(TC)形态。此外,本文还着重探讨了TC结构对高性能热塑性树脂基复合材料界面性能的具体影响,并提出了当前该领域仍然存在的问题和面临的挑战。Abstract: In thermoplastic resin-based composites, optimizing interfacial properties is crucial for enhancing the overall characteristics of the composites. When carbon fibers (CFs) are employed as the reinforcement, combined with semi-crystalline high-performance thermoplastic resins such as polyetheretherketone (PEEK), polyaryletherketone (PAEK), or polyphenylene sulfide (PPS) as the matrix, the induced crystallization phenomenon at the fiber/resin interface significantly impacts the interfacial properties of the composite. Taking the issue of induced crystallization in the study of high-performance thermoplastic resin-based composites as the starting point, this article comprehensively reviews the research progress in this area. The article covers the entire process from the preparation methods of induced crystallization samples to their final performance changes, analyzes the classification and influencing factors of induced crystallization, and describes several typical transcrystallinity (TC) morphologies in high-performance thermoplastic resins. Additionally, this article focuses on discussing the specific impact of TC on the interfacial properties of high-performance thermoplastic resin-based composites, and proposes the existing problems and challenges in this field.

-

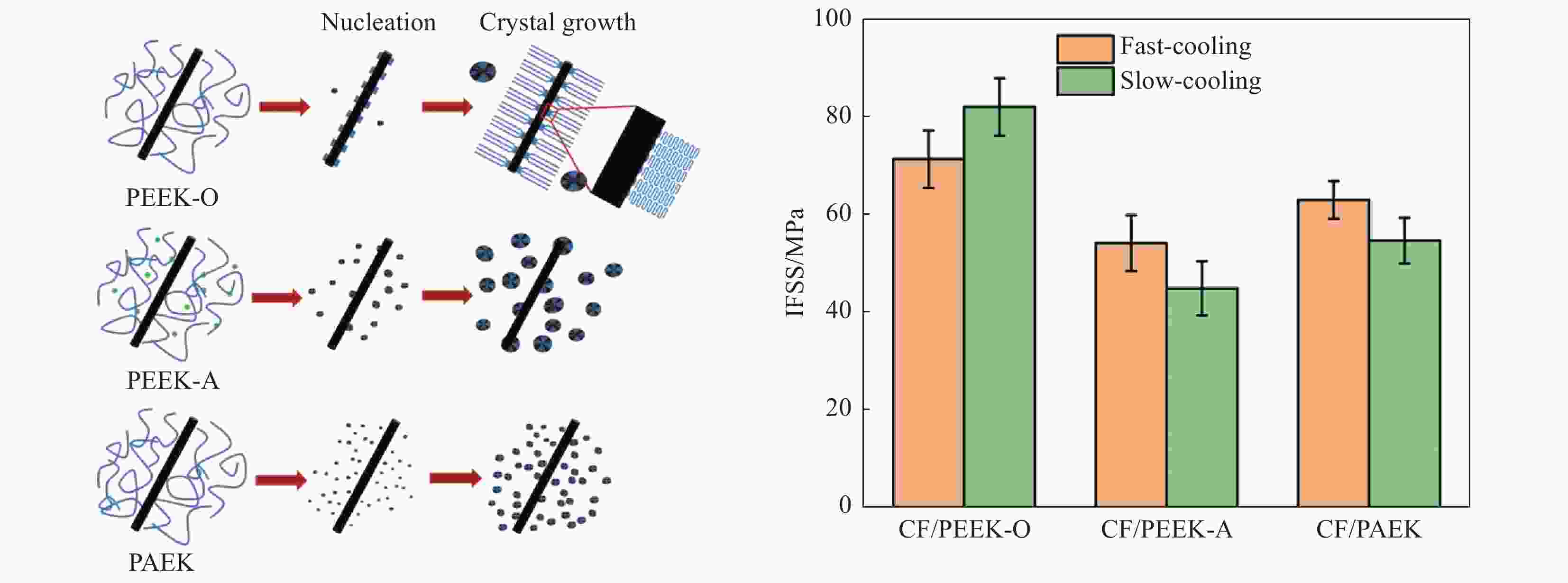

表 1 CF/聚合物界面处的剪切强度(MPa)[91]

Table 1. Shear strength at the carbon fiber/polymer interface (MPa) [91]

Resin type Fast-cooling Slow-cooling Annealing Polycarbonate (PC) 52 75 - Polyphenylene sulfide (PPS) 36 61 71 Polyetheretherketone (PEEK) 74 97 112 Composites type Crystallinity Modulus Strength Strain failure % GPa MPa % LS 36 3.9 111 4.8 LF 42 4.3 106 4.4 SF 42 3.9 63 1.9 SS 45 4.0 60 1.7 Note: The first letter L stands for long melt holding time -Long, S stands for short melt holding time -Short. The second letter S stands for slow cooling rate - Slow and F stands for fast cooling rate - Fast. -

[1] LIU L, HU J, ZHAO L, et al. Construction of solvent-resistant interphase of CF/PEEK composites via introducing water-based crosslinkable polyaryl ether sizing agent[J]. Composites Science and Technology, 2022, 225: 109530. doi: 10.1016/j.compscitech.2022.109530 [2] HASSAN E A M, GE D, YANG L, et al. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF[J]. Composites Part A: Applied Science and Manufacturing, 2018, 112: 155-160. doi: 10.1016/j.compositesa.2018.05.029 [3] ZHANG Z, ZENG H. Investigation on the spherulitic morphology of poly(ether-ether-ketone)[J]. Die Makromolekulare Chemie, 1992, 193(7): 1745-1752. doi: 10.1002/macp.1992.021930718 [4] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, (3): 24-36. doi: 10.3321/j.issn:1000-131X.2006.03.004Ye Leping, Feng Peng. Application and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal, 2006, (3): 24-36(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [5] XU Z, LI J, WU X, et al. Effect of kidney-type and circular cross sections on carbon fiber surface and composite interface[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(2): 301-307. doi: 10.1016/j.compositesa.2007.10.015 [6] GAO S-L, KIM J-K. Cooling rate influences in carbon fibre/PEEK composites. Part III: impact damage performance[J]. Composites Part A: Applied Science and Manufacturing, 2001, 32(6): 775-785. doi: 10.1016/S1359-835X(00)00189-5 [7] YAN F, YAN T, WANG G, et al. A novel thermoplastic water-soluble sizing agent for the interfacial enhancement of carbon fiber/polyether ether ketone composites[J]. Composites Part B: Engineering, 2024, 272: 111205. doi: 10.1016/j.compositesb.2024.111205 [8] HU J, YAN F, LIU H, et al. Water-based PEKC-COOH sizing agent for enhancing the interfacial adhesion of carbon fiber/polyether-ether-ketone composites[J]. Composites Part B: Engineering, 2021, 225: 109279. doi: 10.1016/j.compositesb.2021.109279 [9] UEMATSU H, YOSHIDA K, YAMAGUCHI A, et al. Enhancement of interfacial shear strength due to cooperative π-π interaction between polyphenylene sulfide and carbon fiber and molecular orientation of polyphenylene sulfide via the π-π interaction[J]. Composites Part A: Applied Science and Manufacturing, 2023, 165: 107355. doi: 10.1016/j.compositesa.2022.107355 [10] TARDIF X, PIGNON B, BOYARD N, et al. Experimental study of crystallization of PolyEtherEtherKetone (PEEK) over a large temperature range using a nano-calorimeter[J]. Polymer Testing, 2014, 36: 10-19. doi: 10.1016/j.polymertesting.2014.03.013 [11] KUO M C, KUO J S, YANG M H, et al. On the crystallization behavior of the nano-silica filled PEEK composites[J]. Materials Chemistry and Physics, 2010, 123(2-3): 471-480. doi: 10.1016/j.matchemphys.2010.04.043 [12] 权慧, 李忠明, 杨鸣波, 等. 半晶聚合物复合材料中的横晶[J]. 高分子通报, 2005, (3): 9-20. doi: 10.3969/j.issn.1003-3726.2005.03.002QUAN Hui, LI Zhongming, YANG Mingbo, et al. Advance in the study of transcrystallinity in semi-crystalline polymer composites[J]. Polymer Bulletin, 2005, (3): 9-20(in Chinese). doi: 10.3969/j.issn.1003-3726.2005.03.002 [13] THOMASON J L, VAN ROOYEN A A. Transcrystallized interphase in thermoplastic composites[J]. Journal of Materials Science, 1992, 27(4): 897-907. doi: 10.1007/BF01197639 [14] LI X, ZHAO Y, WANG K. Interfacial crystallization behavior of poly (ether-ether-ketone) on polyimide-modified CCF300 carbon fibers[J]. Polymer Composites, 2020, 41(6): 2433-2445. doi: 10.1002/pc.25547 [15] 张志毅, 曾汉民. 纤维诱发聚醚醚酮界面结晶效应的研究[J]. 中山大学学报(自然科学版), 1990, (3): 86-88.ZHANG Zhiyi, ZENG Hanmin. Investigations on interfacial crystallization effects of PEEK nucleated by fibers[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni, 1990, (3): 86-88(in Chinese). [16] QUAN H, LI Z-M, YANG M-B, et al. On transcrystallinity in semi-crystalline polymer composites[J]. Composites Science and Technology, 2005, 65(7-8): 999-1021. doi: 10.1016/j.compscitech.2004.11.015 [17] 孙伟东, 陆波, 权亚博, 等. 半晶聚合物基复合材料的界面结晶行为[J]. 上海塑料, 2013, (3): 1-6. doi: 10.3969/j.issn.1009-5993.2013.03.001SUN Weidong, LU Bo, QUAN Yabo, et al. Interfacial crystallization behavior of semi-crystalline polymer-based composites[J]. Shanghai Plastics, 2013, (3): 1-6(in Chinese). doi: 10.3969/j.issn.1009-5993.2013.03.001 [18] LIU Q, SUN X, LI H, et al. Orientation-induced crystallization of isotactic polypropylene[J]. Polymer, 2013, 54(17): 4404-4421. doi: 10.1016/j.polymer.2013.04.066 [19] GAO S-L, KIM J-K. EFFECT OF COOLING RATE ON INTERPHASE PROPERTIES OF CARBON FIBRE/PEEK COMPOSITES[J]. Journal of the Society of Materials Science, Japan, 1999, 48(9Appendix): 157-162. doi: 10.2472/jsms.48.9Appendix_157 [20] THOMASON J L, VAN ROOYEN A A. Transcrystallized interphase in thermoplastic composites[J]. Journal of Materials Science, 1992, 27(4): 889-896. doi: 10.1007/BF01197638 [21] ZHANG J, LIU G, AN P, et al. The effect of cooling rates on crystallization and low-velocity impact behaviour of carbon fibre reinforced poly(aryl ether ketone) composites[J]. Composites Part B: Engineering, 2023, 254: 110569. doi: 10.1016/j.compositesb.2023.110569 [22] WANG B, WEN T, ZHANG X, et al. Nucleation of Poly (lactide) on the Surface of Different Fibers[J]. Macromolecules, 2019, 52(16): 6274-6284. doi: 10.1021/acs.macromol.9b01078 [23] NARDIN M, ASLOUN E M, MULLER F, et al. Study of the carbon fiber–Poly(Ether–Ether–Ketone) (PEEK) interfaces, 3: influence and properties of interphases[J]. Polymers for Advanced Technologies, 1991, 2(4): 161-169. doi: 10.1002/pat.1991.220020401 [24] MERETZ S, AUERSCH W, MAROTZKE C, et al. Investigation of morphology-dependent fracture behaviour with the single-fibre pull-out test[J]. Composites Science and Technology, 1993, 48(1): 285-290. [25] PERON B, LOWE A, BAILLIE C. The effect of transcrystallinity on the interfacial characteristics of polypropylene/alumina single fibre composites[J]. Composites Part A: Applied Science and Manufacturing, 1996, 27(9): 839-845. doi: 10.1016/1359-835X(96)00007-3 [26] GAO S-L, KIM J-K. Cooling rate influences in carbon fibre/PEEK composites. Part 1. Crystallinity and interface adhesion[J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(6): 517-530. doi: 10.1016/S1359-835X(00)00009-9 [27] GAO S-L, KIM J-K. Cooling rate influences in carbon fibre/PEEK composites. Part II: interlaminar fracture toughness[J]. Composites Part A: Applied Science and Manufacturing, 2001, 32(6): 763-774. doi: 10.1016/S1359-835X(00)00188-3 [28] LIU J, LI H, DUAN Y, et al. Morphologies of iPP induced by its partially carbon-coated homogeneity fibers[J]. Polymer, 2003, 44(18): 5423-5428. doi: 10.1016/S0032-3861(03)00587-1 [29] CHEN J, YANG D. Phase Behavior and Rhythmically Grown Ring-Banded Spherulites in Blends of Liquid Crystalline Poly(aryl ether ketone) and Poly(aryl ether ether ketone)[J]. Macromolecules, 2005, 38(8): 3371-3379. doi: 10.1021/ma047904f [30] HU S, YANG F, CAO Y, et al. Influence of chain entanglements and melt memory effect on the crystallization behavior of polyphenylene sulfide[J]. Polymer, 2023, 285: 126390. doi: 10.1016/j.polymer.2023.126390 [31] 张志毅, 曾汉民. 聚醚醚酮球晶结构的形态特征研究[J]. 高分子学报, 1991, (4): 409-414.ZHANG Zhiyi, ZENG Hanmin. Investigation on the morphology characteristics of PEEK spherulites strycture[J]. Acta Polymerica Sinica, 1991, (4): 409-414(in Chinese). [32] WANG S, YANG Y, MU Y, et al. Synergy of electrochemical grafting and crosslinkable crystalline sizing agent to enhance the interfacial strength of carbon fiber/PEEK composites[J]. Composites Science and Technology, 2021, 203: 108562. doi: 10.1016/j.compscitech.2020.108562 [33] WANG S D, ZHANG S W, YANG Y C, et al. Direct electrochemical grafting of crystalline PAEK macromolecule on carbon fiber to enhance the interfacial properties of PEEK/CF composites[J]. Composites Science and Technology, 2022, 220: 109262. doi: 10.1016/j.compscitech.2022.109262 [34] MOON C-K. The effect of interfacial microstructure on the interfacial strength of glass fiber/polypropylene resin composites[J]. Journal of Applied Polymer Science, 1994, 54(1): 73-82. doi: 10.1002/app.1994.070540108 [35] JENCKEL E, TEEGE E, HINRICHS W. Transkristallisation in hochmolekularen Stoffen[J]. Kolloid-Zeitschrift, 1952, 129(1): 19-24. doi: 10.1007/BF01802755 [36] CAI Y, PETERMANN J, WITTICH H. Transcrystallization in fiber-reinforced isotactic polypropylene composites in a temperature gradient[J]. Journal of Applied Polymer Science, 1997, 65(1): 67-75. doi: 10.1002/(SICI)1097-4628(19970705)65:1<67::AID-APP9>3.0.CO;2-O [37] WANG H, WANG S, WANG X, et al. Regulation of polymorphic behavior of poly(butylenes adipate) by nylon 6 fiber[J]. Polymer Bulletin, 2017, 74(10): 4195-4207. doi: 10.1007/s00289-017-1940-3 [38] WU C-M, CHEN M, KARGER-KOCSIS J. Transcrystallization in syndiotactic polypropylene induced by high-modulus carbon fibers[J]. Polymer Bulletin, 1998, 41(2): 239-245. doi: 10.1007/s002890050357 [39] YAO L, LI M, WU Q, et al. Comparison of sizing effect of T700 grade carbon fiber on interfacial properties of fiber/BMI and fiber/epoxy[J]. Applied Surface Science, 2012, 263: 326-333. doi: 10.1016/j.apsusc.2012.09.054 [40] SORENSEN L, GMüR T, BOTSIS J. Residual strain development in an AS4/PPS thermoplastic composite measured using fibre Bragg grating sensors[J]. Composites Part A: Applied Science and Manufacturing, 2006, 37(2): 270-281. doi: 10.1016/j.compositesa.2005.02.016 [41] NING N, FU S, ZHANG W, et al. Realizing the enhancement of interfacial interaction in semicrystalline polymer/filler composites via interfacial crystallization[J]. Progress in Polymer Science, 2012, 37(10): 1425-1455. doi: 10.1016/j.progpolymsci.2011.12.005 [42] CHEN E J H, HSIAO B S. The effects of transcrystalline interphase in advanced polymer composites[J]. Polymer Engineering & Science, 1992, 32(4): 280-286. [43] LUSTIGER A. Morphological aspects of the interface in the PEEK-carbon fiber system[J]. Polymer Composites, 1992, 13(5): 408-412. doi: 10.1002/pc.750130511 [44] XU H, XIE L, JIANG X, et al. Toward stronger transcrystalline layers in poly(L-lactic acid)/natural fiber biocomposites with the aid of an accelerator of chain mobility[J]. Journal of Physical Chemistry B, 2014, 118(3): 812-823. doi: 10.1021/jp409021q [45] ZENG H, ZHANG Z, ZHANG M, et al. Young's modulus of transcrystallinities in semicrystalline thermoplastic composites[J]. Journal of Applied Polymer Science, 1994, 54(5): 541-551. doi: 10.1002/app.1994.070540504 [46] CHATTERJEE A M, PRICE F P, NEWMAN S. Heterogeneous nucleation of crystallization of high polymers from the melt. III. Nucleation kinetics and interfacial energies[J]. Journal of Polymer Science: Polymer Physics Edition, 1975, 13(12): 2391-2400. doi: 10.1002/pol.1975.180131213 [47] LEE Y, PORTER R S. Crystallization of poly(etheretherketone) (PEEK) in carbon fiber composites[J]. Polymer Engineering & Science, 1986, 26(9): 633-639. [48] WADDON A J, HILL M J, KELLER A, et al. On the crystal texture of linear polyaryls (PEEK, PEK and PPS)[J]. Journal of Materials Science, 1987, 22(5): 1773-1784. doi: 10.1007/BF01132406 [49] DAVIES P, CANTWELL W J. Fracture of glass/polypropylene laminates: influence of cooling rate after moulding[J]. Composites, 1994, 25(9): 869-877. doi: 10.1016/0010-4361(94)90028-0 [50] DOUMENG M, BERTHET F, DELBé K, et al. Effect of size, concentration, and nature of fillers on crystallinity, thermal, and mechanical properties of polyetheretherketone composites[J]. Journal of Applied Polymer Science, 2021, 139(5). [51] ZHU K, TAN H, WANG Y, et al. Crystallization and Mechanical Properties of Continuous Carbon Fiber Reinforced Polyether-ether-ketone Composites[J]. Fibers and Polymers, 2019, 20(4): 839-846. doi: 10.1007/s12221-019-8791-5 [52] ABDOU J P, REYNOLDS K J, PFAU M R, et al. Interfacial crystallization of isotactic polypropylene surrounding macroscopic carbon nanotube and graphene fibers[J]. Polymer, 2016, 91: 136-145. doi: 10.1016/j.polymer.2016.03.055 [53] LUO B, LI H, ZHOU C, et al. Mechanistic Insights into the Shear-Inducedβ-Form Crystal Formation of iPP[J]. Macromolecular Chemistry and Physics, 2016, 217(12): 1354-1360. doi: 10.1002/macp.201500542 [54] WANG C, LIU C R. Transcrystallization of polypropylene composites: nucleating ability of fibres[J]. Polymer, 1999, 40(2): 289-298. doi: 10.1016/S0032-3861(98)00240-7 [55] ZHOU M, XU S M, LI Y H, et al. Transcrystalline formation and properties of polypropylene on the surface of ramie fiber as induced by shear or dopamine modification[J]. Polymer, 2014, 55(13): 3045-3053. doi: 10.1016/j.polymer.2014.05.013 [56] SU Y A, LIU P P, JING D Q, et al. Improved interfacial adhesion in carbon fiber/poly (ether ether ketone) composites with the sulfonated poly (ether ether ketone) sizing treatment[J]. Journal of Applied Polymer Science, 2021, 138(45): 51326. doi: 10.1002/app.51326 [57] MARTIN A, ADDIEGO F, MERTZ G, et al. Pitch-Based Carbon Fibre-Reinforced PEEK Composites: Optimization ofInterphase Properties by Water-Based Treatments and Self-Assembly[J]. Journal of Materials Science and Engineering, 2016, 6: 1-9. [58] FU Y, LI H, CAO W. Enhancing the interfacial properties of high-modulus carbon fiber reinforced polymer matrix composites via electrochemical surface oxidation and grafting[J]. Composites Part A: Applied Science and Manufacturing, 2020, 130: 105719. doi: 10.1016/j.compositesa.2019.105719 [59] ZHOU M, LI Y, HE C, et al. Interfacial crystallization enhanced interfacial interaction of Poly (butylene succinate)/ramie fiber biocomposites using dopamine as a modifier[J]. Composites Science and Technology, 2014, 91: 22-29. doi: 10.1016/j.compscitech.2013.11.019 [60] SUN B, QIN Y, XU Y, et al. Study of shear-induced interfacial crystallization in polymer-based composite through in situ monitoring interfacial shear stress[J]. Journal of Materials Science, 2013, 48(15): 5354-5360. doi: 10.1007/s10853-013-7330-9 [61] LI T Q, ZHANG M Q, ZHANG K, et al. Long-range effects of carbon fiber on crystallization of semicrystalline thermoplastics[J]. Polymer, 2000, 41(1): 161-168. doi: 10.1016/S0032-3861(99)00140-8 [62] WANG W, QI Z, JERONIMIDIS G. Studies on interface structure and crystal texture of poly(ether-ether-ketone)-carbon fibre composite[J]. Journal of Materials Science, 1991, 26(21): 5915-5920. doi: 10.1007/BF01130134 [63] ZHANG M, XU J, ZHANG Z, et al. Effect of transcrystallinity on tensile behaviour of discontinuous carbon fibre reinforced semicrystalline thermoplastic composites[J]. Polymer, 1996, 37(23): 5151-5158. doi: 10.1016/0032-3861(96)00341-2 [64] 李博澜, 张凤, 焦梦晓, 等. PEEK/CF复合材料中PEEK结晶行为研究进展[J]. 合成树脂及塑料, 2024, 41(1): 68-74.LI Bolan, ZHANG Feng, JIAO Mengxiao, et al. Research progress of crystallization behavior of PEEK in PEEK/CF composites[J]. China Synthetic Resins and Plastics, 2024, 41(1): 68-74(in Chinese). [65] ZHANG Z, ZENG H. Nucleation and crystal growth of PEEK on carbon fiber[J]. Journal of Applied Polymer Science, 1993, 48(11): 1987-1995. doi: 10.1002/app.1993.070481112 [66] ZHANG Z, ZENG H. Interfacial crystallization of Peek/Pes-C blends on carbon fibre[J]. European Polymer Journal, 1993, 29(12): 1647-1650. doi: 10.1016/0014-3057(93)90260-M [67] JAR P Y, CANTWELL W J, KAUSCH H H. Study of the crystal morphology and the deformation behaviour of carbon fibre reinforced PEEK (APC-2)[J]. Composites Science and Technology, 1992, 43(3): 299-306. doi: 10.1016/0266-3538(92)90100-H [68] 曾汉民, 张志毅. 结晶性高聚物基体复合材料的界面结晶效应[J]. 材料工程, 1992, (1): 6-10.ZENG Hanmin, ZHANG Zhiuyi. The Interface crystal effect of crystalline polymer matrix composites[J]. Journal of Materials Engineering, 1992, (1): 6-10(in Chinese). [69] LI N, CHEN J, LIU H, et al. Effect of preheat treatment on carbon fiber surface properties and fiber/PEEK interfacial behavior[J]. Polymer Composites, 2018, 40(S2): E1407-E1415. [70] 陈平, 于祺, 孙明, 等. 高性能热塑性树脂基复合材料的研究进展[J]. 纤维复合材料, 2005, (2): 52-57. doi: 10.3969/j.issn.1003-6423.2005.02.016CHEN Ping, YU Qi, SUN Ming, et al. Advances in High Perfor mance FRTP Composites[J]. Fiber Composites, 2005, (2): 52-57(in Chinese). doi: 10.3969/j.issn.1003-6423.2005.02.016 [71] QUIROGA CORTéS L, CAUSSé N, DANTRAS E, et al. Morphology and dynamical mechanical properties of poly ether ketone ketone (PEKK) with meta phenyl links[J]. Journal of Applied Polymer Science, 2016, 133(19). [72] 孙永周. 开展我国聚醚酮酮研究的建议[J]. 塑料工业, 1990, (2): 25-31.SUN Yongzhou. Suggestions for development of polyetherketoneketones in China[J]. China Plastics Industry, 1990, (2): 25-31(in Chinese). [73] PéREZ-MARTíN H, MACKENZIE P, BAIDAK A, et al. Crystallinity studies of PEKK and carbon fibre/PEKK composites: A review[J]. Composites Part B: Engineering, 2021, 223: 109127. doi: 10.1016/j.compositesb.2021.109127 [74] PéREZ-MARTíN H, MACKENZIE P, BAIDAK A, et al. Crystallisation behaviour and morphological studies of PEKK and carbon fibre/PEKK composites[J]. Composites Part A: Applied Science and Manufacturing, 2022, 159: 106992. doi: 10.1016/j.compositesa.2022.106992 [75] CHELAGHMA S, PASSIEUX J-C, DE ALMEIDA O, et al. Modélisation Pixel Coloring de la cristallisation du PEKK [C]; Comptes Rendus JNC 21 - Bordx INP 2019: 9. [76] 崔永丽, 应鹏展, 王晓虹. 特种工程塑料聚芳醚酮[J]. 塑料工业, 2006, (S1): 295-298. doi: 10.3321/j.issn:1005-5770.2006.z1.087CUI Yongli, YING Pengzhan, WANG Xiaohong. Special engineering plastics of polyaryletherketone[J]. China Plastics Industry, 2006, (S1): 295-298(in Chinese). doi: 10.3321/j.issn:1005-5770.2006.z1.087 [77] 徐利敏, 赵剑锋, 雷玉平, 等. 特种工程塑料PAEK的性能及应用[J]. 塑料科技, 2006, (5): 66-68. doi: 10.3969/j.issn.1005-3360.2006.05.011XU Limin, ZHAO Jianfeng, LEI Yuping, et al. Application and Properties of Special Engineering Plastic PAEK[J]. Plastics Science and Technology, 2006, (5): 66-68(in Chinese). doi: 10.3969/j.issn.1005-3360.2006.05.011 [78] 赵晓刚, 冀克俭, 邓卫华, 等. 高性能聚芳醚酮的发展及应用[J]. 工程塑料应用, 2009, 37(3): 80-83. doi: 10.3969/j.issn.1001-3539.2009.03.022ZHAO Xiaogang, JI Kejian, DENG Weihua, et al. Development and application of high performance polyaryletherketones[J]. Engineering Plastics Applications, 2009, 37(3): 80-83(in Chinese). doi: 10.3969/j.issn.1001-3539.2009.03.022 [79] 倪志春. 国内外聚醚醚酮开发应用进展[J]. 国外塑料, 2013, 31(10): 32-36. doi: 10.3969/j.issn.1002-5219.2013.10.010NI Zhichun. Development and application of domestic and foreign PEEK[J]. World Plastics, 2013, 31(10): 32-36(in Chinese). doi: 10.3969/j.issn.1002-5219.2013.10.010 [80] YE L, SCHEURING T, FRIEDRICH K. Matrix morphology and fibre pull-out strength of T700/PPS and T700/PET thermoplastic composites[J]. Journal of Materials Science, 1995, 30(19): 4761-4769. doi: 10.1007/BF01154482 [81] YU L, WANG K, SUN M, et al. Hydrothermal aging behavior and effects on carbon fabric/polyphenylene sulfide composite[J]. Polymer Composites, 2024, 45(1): 836-846. doi: 10.1002/pc.27819 [82] REN Y, YU M, LI Z, et al. Exploring the self-nucleation effect: Transforming crystalline morphology for improved mechanical performance of carbon fiber reinforced polyphenylene sulfide composites[J]. Composites Part B: Engineering, 2024, 272: 111231. doi: 10.1016/j.compositesb.2024.111231 [83] WANG S, WANG T, ZHANG S, et al. Enhancing fiber-matrix interface in carbon fiber/poly ether ether ketone (CF/PEEK) composites by carbon nanotube reinforcement of crystalline PEEK sizing[J]. Composites Part B: Engineering, 2023, 251: 110470. doi: 10.1016/j.compositesb.2022.110470 [84] ZENG L, LIU X, CHEN X, et al. π - π interaction between carbon fibre and epoxy resin for interface improvement in composites[J]. Composites Part B: Engineering, 2021, 220: 108983. doi: 10.1016/j.compositesb.2021.108983 [85] SCHULZ E, KALINKA G, AUERSCH W. Effect of transcrystallization in carbon fiber reinforced poly(p-phenylene sulfide) composites on the interfacial shear strength investigated with the single fiber pull-out test[J]. Journal of Macromolecular Science, Part B Physics, 1996, 35: 527-546. doi: 10.1080/00222349608220393 [86] 张立峰, 王盛, 乔伟林, 等. 单向碳纤维复合材料界面力学性能测试研究[J]. 机械科学与技术, 2019, 38(8): 1296-1300.ZHANG Lifeng, WANG Sheng, QIAO Weilin, et al. Experimental Study on Interface Mechanical Propertiesof Unidirectional Carbon Fiber Composites[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(8): 1296-1300(in Chinese). [87] 顾洋洋, 姚佳楠, 王力风, 等. 聚芳醚酮树脂基体特性对复合材料界面性能和层间性能的影响[J]. 复合材料学报, 2023, 40(08): 4481-90.GU Yangyang, YAO Jianan, WANG Lifeng, et al. Influence of poly aryl ether ketone resin matrix properties on interfacial properties and interlayer properties of composites[J]. Acta Materiae Compositae Sinica, 2023, 40(08): 4481-4490(in Chinese). [88] 嵇醒, 戴瑛. 复合材料界面剪切强度试验方法评定[C]. 中国力学学会, 重庆力学学会. 重庆大学, 四川大学. 2009年度海峡两岸工程力学研讨会论文集. 2009: 167-173.JI Sheng, DAI Ying. Evaluation of test methods for interfacial shear strength of composites[C]. Chinese Society of Mechanics, Chongqing Society of Mechanics. Chongqing University, Sichuan University. 2009 Proceedings of Cross-Strait Engineering Mechanics. 2009: 167-173(in Chinese). [89] GAO Y, XIE M, LIU L, et al. Effect of supra-molecular microstructures on the adhesion of SWCNT fiber/iPP interface[J]. Polymer, 2013, 54(1): 456-463. doi: 10.1016/j.polymer.2012.11.043 [90] 戴瑛, 嵇醒. 单纤维段裂试验评述[J]. 力学进展, 2006, 36(2): 211-221. doi: 10.3321/j.issn:1000-0992.2006.02.005DAI Ying, JI Sheng. Review of single fiber fragmentation test[J]. Advances in Mechanics, 2006, 36(2): 211-221(in Chinese). doi: 10.3321/j.issn:1000-0992.2006.02.005 [91] KOBAYASHI H, HAYAKAWA E, KIKUTANI T, et al. Effect of quenching and annealing on fiber pull-out from crystalline polymer matrices[J]. Advanced Composite Materials, 1991, 1(2): 155-168. doi: 10.1163/156855191X00252 [92] YANG Y, WANG T, WANG S, et al. Strong Interface Construction of Carbon Fiber–reinforced PEEK Composites: An Efficient Method for Modifying Carbon Fiber with Crystalline PEEK[J]. Macromolecular Rapid Communications, 2020, 41(24): 2000001. doi: 10.1002/marc.202000001 [93] JENG C-C, CHEN M. Flexural failure mechanisms in injection-moulded carbon fibre/PEEK composites[J]. Composites Science and Technology, 2000, 60(9): 1863-1872. doi: 10.1016/S0266-3538(00)00076-2 [94] YU K, ZHANG J, LIU G, et al. Inverse effects of cooling rates on the interfacial shear strength of carbon Fiber/PEEK composites with and without presence of transcrystal layers[J]. Polymer, 2024, 302: 127067. doi: 10.1016/j.polymer.2024.127067 -

点击查看大图

点击查看大图

计量

- 文章访问数: 52

- HTML全文浏览量: 37

- 被引次数: 0

下载:

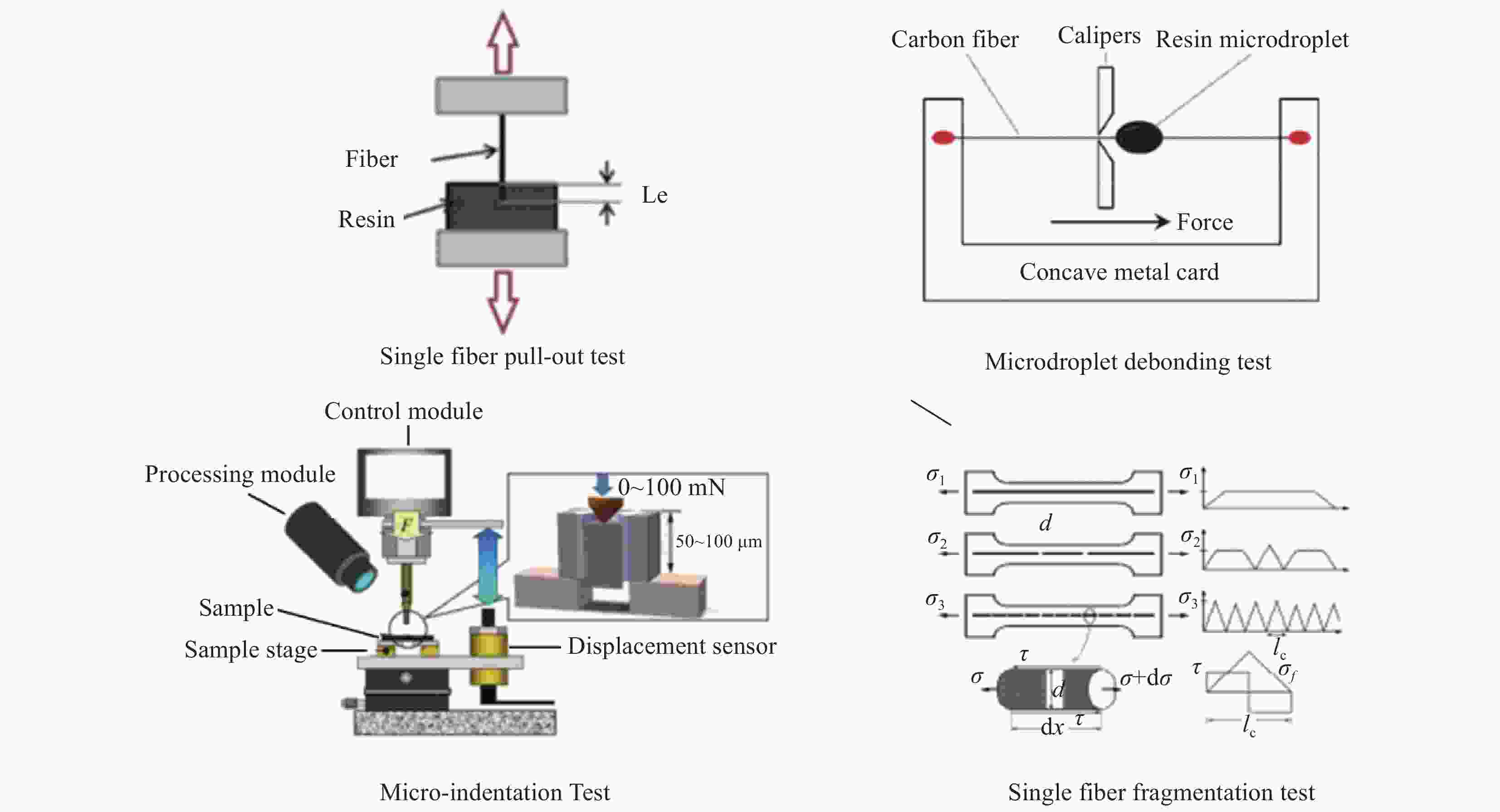

下载: