Research on the induced crystallization behavior of high-performance thermoplastics resin-based composites

-

摘要:

在热塑性树脂基复合材料中,优化界面性能对于提升复合材料的整体性能表现具有非常重要的作用。当碳纤维(CF)作为增强体与半结晶型的高性能热塑性树脂基体,如聚醚醚酮(PEEK)、聚芳醚酮(PAEK)或聚苯硫醚(PPS)等复合时,纤维与树脂界面上发生的诱导结晶现象,会对复合材料的界面性能产生显著影响。本文以高性能热塑性树脂基复合材料研究中诱导结晶问题为切入点,综述了该领域的研究进展。本文涵盖了从诱导结晶样品的制备方法到其最终性能变化的全过程,并分析了诱导结晶的类型及其影响因素,同时描述了高性能热塑性树脂中几种典型的横晶(TC)形态。此外,本文还着重探讨了TC结构对高性能热塑性树脂基复合材料界面性能的具体影响,并提出了当前该领域仍然存在的问题和面临的挑战。

Abstract:In thermoplastic resin-based composites, optimizing interfacial properties is crucial for enhancing the overall characteristics of the composites. When carbon fibers (CF) are employed as the reinforcement, combined with semi-crystalline high-performance thermoplastic resins such as polyetheretherketone (PEEK), polyaryletherketone (PAEK), or polyphenylene sulfide (PPS) as the matrix, the induced crystallization phenomenon at the fiber/resin interface significantly impacts the interfacial properties of the composite. Taking the issue of induced crystallization in the study of high-performance thermoplastic resin-based composites as the starting point, this article comprehensively reviews the research progress in this area. The article covers the entire process from the preparation methods of induced crystallization samples to their final performance changes, analyzes the classification and influencing factors of induced crystallization, and describes several typical transcrystallinity (TC) morphologies in high-performance thermoplastic resins. Additionally, this article focuses on discussing the specific impact of TC on the interfacial properties of high-performance thermoplastic resin-based composites, and proposes the existing problems and challenges in this field.

-

强韧、轻质复合多级结构材料在能源储存转化、环境治理、生物医学及航天等战略领域的应用越来越受关注[1-4],其中二维多级层状结构材料独特的电子限域效应赋予这类材料独特的物理、化学性质及丰富的科学内涵,在众多的领域都有重要的应用前景,特别是电子器件、光电器件等方面[5-6]。但人工合成材料不能像天然材料(贝壳、骨骼等)一样通过大量的相互作用对结构基元进行精准的调控,以致各结构基元在受力时应力不能有效传递导致材料断裂,影响力学性质、进而限制材料的应用[7-10]。

受自然界启发,研究工作者发展了大量具有强韧力学性能的二维层状结构材料,通常采取的方案是将高强度的无机纳米片与高柔性的有机聚合物通过层-层(LBL)组装、真空抽滤组装、空气诱导组装、冰模板等方法复合,得到类贝壳珍珠层的“砖-泥”结构[11-13]。如Shin等[14]将还原石墨烯氧化物(RGOF)与碳纳米管(SWNT)复合,用RGOF-SWNT复合体填充聚乙烯醇(PVA),获得了具有强韧性的RGOF-SWNT-PVA复合膜材料。Cao等[15]鉴于电磁屏蔽材料对厚度与力学性能的需要,选择Ti3C2Tx (MXene)与纤维素纳米纤维(CNF)为功能基元通过真空抽滤自组装的方法得到了高电磁屏蔽效率的复合膜材料,同时保证了材料的强度和韧性。Yoo等[16]通过静电组装氮化硼(BNNS)与明胶获得机械强度媲美人体骨密质的复合膜,且表现出优异的生物相容性,有望应用于组织工程与骨内植入领域。Woo等[17]利用交联剂(CA) 将片层氧化石墨烯(GO)通过化学键相连,形成仿贝壳结构的GO/CA层状复合薄膜,由于GO之间强大的共价键网络,复合薄膜表现出优异的力学性能,在航空航天、电子保护器、渗透膜等领域有潜在应用。过去研究者们采用纳米填充质增强聚合物薄膜的工作在拉伸强度上都有明显的提升,但断裂伸长率却变化不大甚至有所降低,导致复合薄膜的韧性提升被限制。究其原因在于结构基元之间可作为牺牲性成键的相互作用力较少,也将其归结为应力传递效率较低。综上所述,发展一种普适性的复合膜增强增韧方法仍然具有一定的挑战性[18-20]。

利用聚乙烯亚胺(PEI)修饰过后的纤维素纳米晶(PCNC)与蒙脱土纳米片(MMT)静电自组装得到MMT-PCNC组装体,将其分散到PVA水溶液中并搅拌均匀,随后倒入培养皿中利用溶剂蒸发法成膜。得到的MMT-PCNC/PVA复合膜拉伸强度与断裂伸长率同步增加,性能平衡。此法提高了材料的应力传递效率,有效增加了复合膜的拉伸强度;同时利用多重弱相互作用实现了断裂强度、断裂伸长率以及韧性的同步提升。

1. 实验材料及方法

1.1 原材料

蒙脱土粉末购买于浙江丰虹新材料有限公司,棉浆浆板购买于河北中国纸业公司,浓硫酸(98%)购买于北京化学试剂厂,聚乙烯醇(PVA,醇解度为87%~89%,AR)在阿拉丁上海有限公司购买,聚乙烯亚胺(PEI,Mw=10000,AR)购买于阿达玛斯试剂有限公司。实验过程中所用到的试剂都未经任何处理。

1.2 PCNC的制备

晶态纳米纤维素(Cellulose nanocrystals, CNC)悬浮液制备方法参考文献[21]制得,PEI修饰的CNC具体制备过程如下:取10 mL PEI水溶液(3.0wt%)加入到5 mL CNC悬浮液(3.0wt%)中,室温下连续搅拌1 h,随后用浓盐酸将混合溶液pH调到1.3以增强CNC与PEI之间的离子相互作用。继续搅拌十分钟后,将混合溶液高速离心20 min(13000 r/min),弃去上层清液,将沉淀用超纯水(18.2 MΩ·cm,Mill-Q Corp)洗涤三次,去掉未发生相互作用的游离PEI聚合物。最后再将沉淀加入水中,超声30 min重新分散,8000 r/min低速离心8 min,去掉CNC聚集体,收集上层清液得到单分散的CNC悬浮液,浓度为1.0wt%,命名为PCNC。

1.3 MMT悬浮液的制备

将2 g MMT粉末加入到500 mL超纯水中,连续溶解搅拌一周后静置72 h,收集上层清液得到剥离充分的MMT纳米片备用,浓度为0.2wt%。

1.4 MMT-PCNC组装体的制备

将MMT (0.2wt%)悬浮溶液逐滴加入到PCNC (1.0wt%)悬浮溶液中,持续搅拌24 h,得到MMT-PCNC组装体悬浮液,控制MMT与PCNC的质量比分别为1∶1、1∶2、1∶4。得到不同MMT、PCNC质量比的组装体,分别命名为1MMT-1PCNC、1MMT-2PCNC、1MMT-4PCNC,具体组成见表1。

1.5 MMT-PCNC/PVA复合膜的制备

将上述组装体悬浮液加入到PVA水溶液中,搅拌过夜,使组装体分散均匀,组装体含量控制为PVA质量的20%。将混合液置于直径为60 mm的聚乙烯塑料培养皿中室温干燥2天,得到柔性MMT-PCNC/PVA复合膜。

表 1 蒙脱土-纤维素纳米晶(MMT-PCNC)组装体的组成Table 1. Compositions of the montmorillonite-cellulose nanocrystal (MMT-PCNC) assembliesSample 1MMT-1PCNC 1MMT-2PCNC 1MMT-4PCNC Composition Mass fraction Mass ratio Mass ratio Mass ratio MMT 0.2% 1 1 1 PCNC 1.0% 1 2 4 1.6 样品性能及表征

SEM结果在JSM-6510A上获得,样品用导电胶粘贴于样品台表面,喷金60 s,电压设置为20 kV,电流设置为86 μA[22]。TEM结果在FEI Tecnai G2S-Twin上获得,样品滴于200 mm铜网上,室温晾干,加速电压为200 kV。溶液的Zeta电势常温下在Malvern Zetasizer Nano-ZS90上获得,样品浓度为0.1wt%[23]。傅立叶红外光谱(FTIR)测试在Bruker IFS 66v/S红外光谱仪上进行,扫描范围为 400~4000 cm−1,扫描速度为4 cm−1,制样过程参考文献[24],样品采用KBr压片,测试前置于60℃烘箱干燥1 h。力学性能测试在万能材料测试机(Instron 5944, UK)上进行,所用传感器为2000 N,拉伸速率为5 mm·min−1,夹距为10 mm。所有的样品测试均在常温下进行,样品长度约为50 mm、宽度约为5 mm、厚度约为0.3 mm,每组样品重复测量3次。

2. 结果与讨论

2.1 MMT-PCNC组装体的形成过程

图1(a)~1(c)分别为CNC、PCNC、MMT悬浮溶液置于室温下一个月之后的光学照片,从图中可以看到溶液基本都呈乳白色,无沉淀产生,说明所有的溶液均非常稳定。CNC由硫酸水解制得,表面含有磺酸基,带负电,Zeta电势分析得到CNC的电势值为−21.3 mV。加入PEI对其进行修饰后,在其表面引入了氨基,带正电,Zeta电势分析显示,PEI修饰过后的CNC (PCNC)电势值由−21.3 mV增加到35.4 mV。对MMT进行Zeta电势表征得到,其电势值为−31.3 mV,与PCNC所带电荷相反,数值匹配,为静电相互作用驱动形成MMT-PCNC组装体提供了必要的条件(图1(d))。

对修饰前后的CNC进行TEM表征,可以看到PCNC仍为棒状结构,长度与直径相比较CNC有明显的增加(图2)。经过统计,平均长度由164 nm增加到206 nm,平均直径由22 nm增加到26 nm (图3),说明PEI聚电解质已成功包覆于CNC的表面,形成PCNC。

将不同质量比的PCNC与MMT悬浮液混合,得到不同质量比的MMT-PCNC组装体悬浮液(1MMT-2PCNC、1MMT-1PCNC、1MMT-4PCNC),组装后发现三组不同配比的溶液均不同程度的发生聚沉,出现明显颗粒感,说明两种结构基元发生相互作用,且组装以后尺寸变大。以1MMT-2PCNC组装体为例,分别对组装前后的结构基元(MMT纳米片、PCNC纳米棒和1MMT-2PCNC组装体)进行TEM表征(图4)。如图4(a)所示,MMT呈分散、不规则片层结构,横向尺寸大约有100~1000 nm。在1MMT-2PCNC组装体的TEM图像中可以看到PCNC纳米棒附着于MMT纳米片的表面及边缘上,取向各异,在MMT表面上形成一层稠密的PCNC层(图4(c)及插图)。组装体的尺寸取决于原始MMT与PCNC的尺寸。

2.2 MMT-PCNC/PVA复合膜的形貌

图5为不同MMT-PCNC/PVA复合膜的SEM图像。如图所示,纯PVA薄膜截面致密,无有序结构。而由不同MMT、PCNC质量比的组装体所构成的复合膜均具有明显层状结构,为干燥成膜过程中MMT纳米片组装而成,由图5(c)、5(d)可见,层间具有明显PCNC附着(图中箭头所指),表明由于较强的静电相互作用,使MMT-PCNC组装体在成膜过程中得以有效保存,但由于层间还存在PVA分子,使得PCNC被部分覆盖,电镜下只观察到棒状尖端。图5(b)中,由于PCNC含量相对较少,未在截面处观察到明显PCNC结构。

2.3 MMT-PCNC/PVA复合膜的力学性能

对复合膜及纯PVA膜进行力学性能的测试(图6),测试结果总结于表2中。如图6所示,相比较纯PVA膜,MMT-PCNC作为增强质对复合膜的力学性能产生正影响,拉伸强度、断裂伸长率、韧性都不同程度的增加,杨氏模量均略有下降;其中,1MMT-1PCNC/PVA复合膜拉伸强度增长最为明显,为196%;1MMT-2PCNC/PVA复合膜的断裂伸长率、韧性增加最为明显(图6插图),分别为175%和900%。这些均得益于复合膜内部的弱相互作用[25-26]:MMT与PCNC之间通过静电组装,使组装体内部存在大量静电相互作用;MMT-PCNC组装体表面携带羟基和氨基,易与PVA分子侧基羟基形成氢键,增加了组装体与基体的界面相互作用[27]。这些弱相互作用在复合膜受到拉伸时首先断裂,充当牺牲性成键,使复合膜内部的MMT、PCNC产生滑移,断裂伸长率提高,进而提升韧性[28-29];其次,附着于MMT表面的PCNC通过静电与氢键相互作用将MMT与PVA连接,形成具有砖-泥结构的片层复合膜,当应力作用于膜上时,可在这些刚性结构基元之间有效传递,从而增加复合膜的强度。二者协同作用使材料单位应变时所需的应力减小,即刚性减小。

表 2 MMT-PCNC/PVA复合膜的力学性能Table 2. Mechanical properties of the MMT-PCNC/PVA hybrid filmsHybrid films of filler/PVA Elongation-at-break

/%Tensile strength

/MPaYoung’s modulus

/MPaToughness

/(MJ·m−3)PVA 28±3 26±3 101±13 3±1 1MMT-1PCNC/PVA 50±4 77±7 97±6 27±6 1MMT-2PCNC/PVA 77±4 63±8 100±3 30±9 1MMT-4PCNC/PVA 42±2 54±9 92±7 13±2 为了证实氢键的存在,对1MMT-2PCNC/PVA复合膜、纯PVA膜以及冷冻干燥的纯CNC进行了红外分析。如图7所示,在3000~3500 cm−1区域内出现的透过峰归属于PVA羟基伸缩振动,对比几个样品—OH的透过峰峰位可以发现,1MMT-2PCNC/PVA复合膜的峰位较纯CNC和PVA向低波数方向移动。过去研究表明[30-33],氢键的形成是导致羟基峰位发生偏移的主要原因。PEI修饰的CNC表面存在大量的氨基,MMT表面也有一定量的羟基,因此组装体1MMT-2PCNC与PVA之间势必会形成氢键,导致羟基峰发生移动。在1025 cm−1、1733 cm−1以及2945 cm−1波数处出现的峰分别归属于PVA的C—OH、C=O以及脂肪质C—H的伸缩振动[34],在1256 cm−1、1370 cm−1以及1446 cm−1处出现的峰分别归属于PVA的C—H、O—H的弯曲振动以及C—H非平面摇摆振动[35-37]。CNC在3382 cm−1、2915 cm−1、1649 cm−1及1055 cm−1处分别出现明显的透过峰,其中3382 cm−1、2915 cm−1归属于CNC的O—H与C—H的伸缩振动,1649 cm−1归属于CNC吡喃糖环的伸缩振动,而1055 cm−1归属于CNC中吸附了水分子的羟基伸缩振动[38]。

为了进一步研究自组装体改善聚合物薄膜力学性能的强韧化机制,人为破坏薄膜表面造成裂纹进行SEM测试。如图8(a)所示,裂纹均非直线传播,而是随着主裂纹的扩展出现了明显的微裂纹偏转(图8(a)中白色折线),说明MMT、PCNC、PVA之间存在强烈的相互作用,与之前分析一致。存在于片层之间的PCNC通过静电以及氢键作用将PVA和MMT相互连接,当应力施加时充当桥连剂,阻止裂纹扩展,随着应力增大,裂纹将沿着纳米纤维发生偏转,直至最终断裂,这一过程将导致裂纹路径增大,消耗更多的能量,实现复合材料的强韧化[26, 39]。

![]() 图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model

图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model通过观察组装体中MMT与PCNC的不同比例组装体对薄膜力学性能的影响发现,随着组装体中PCNC含量的增加,拉伸强度逐渐减弱,当MMT与PCNC比例为1∶4时,断裂伸长率也明显下降(图6),原因可能是随着PCNC含量的增加,组装体质量加重,更易发生聚沉,且当其分布于聚合物基体中时,不易分散均匀,导致复合膜力学性能下降[40-41]。

3. 结 论

(1) 组装体1MMT(蒙脱土)-1PCNC(纤维素纳米晶)和1MMT-2PCNC对PVA(聚乙烯醇)力学性能增强较为明显,拉伸强度分别增加196%、142%;断裂伸长率增幅分别为79%、175%;韧性增幅分别为800%、900%;复合膜杨氏模量略有下降。

(2) MMT-PCNC/PVA复合膜中存在多种弱相互作用(静电相互作用、氢键),给应力的传递提供了有效的途径,同时引起裂纹偏转,达到消耗能量的目的,使其在拉伸强度提高的同时断裂伸长率也得到提升。本文提出了一种新的合理设计构筑先进复合纳米材料的思路,即用自组装的方法制备组装体,并利用组装体中存在的大量弱相互作用提升聚合物薄膜的力学性质,从而拓展其应用。

-

Resin type Fast-cooling Slow-cooling Annealing Polycarbonate (PC) 52 75 – Polyphenylene sulfide (PPS) 36 61 71 Polyetheretherketone (PEEK) 74 97 112 Composite

typeCrystallinity/

%Modulus/

GPaStrength/

MPaStrain

failure/%LS 36 3.9 111 4.8 LF 42 4.3 106 4.4 SF 42 3.9 63 1.9 SS 45 4.0 60 1.7 Notes: The first letter L stands for long melt holding time -Long, S stands for short melt holding time -Short; The second letter S stands for slow cooling rate - Slow and F stands for fast cooling rate - Fast. -

[1] LIU L, HU J, ZHAO L, et al. Construction of solvent-resistant interphase of CF/PEEK composites via introducing water-based crosslinkable polyaryl ether sizing agent[J]. Composites Science and Technology, 2022, 225: 109530. DOI: 10.1016/j.compscitech.2022.109530

[2] HASSAN E A M, GE D, YANG L, et al. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF[J]. Composites Part A: Applied Science and Manufacturing, 2018, 112: 155-160. DOI: 10.1016/j.compositesa.2018.05.029

[3] ZHANG Z, ZENG H. Investigation on the spherulitic morphology of poly(ether-ether-ketone)[J]. Die Makromolekulare Chemie, 1992, 193(7): 1745-1752. DOI: 10.1002/macp.1992.021930718

[4] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006(3): 24-36. DOI: 10.3321/j.issn:1000-131X.2006.03.004 YE Lieping, FENG Peng. Application and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal, 2006(3): 24-36(in Chinese). DOI: 10.3321/j.issn:1000-131X.2006.03.004

[5] XU Z, LI J, WU X, et al. Effect of kidney-type and circular cross sections on carbon fiber surface and composite interface[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(2): 301-307. DOI: 10.1016/j.compositesa.2007.10.015

[6] GAO S L, KIM J K. Cooling rate influences in carbon fibre/PEEK composites. Part III: Impact damage performance[J]. Composites Part A: Applied Science and Manufacturing, 2001, 32(6): 775-785. DOI: 10.1016/S1359-835X(00)00189-5

[7] YAN F, YAN T, WANG G, et al. A novel thermoplastic water-soluble sizing agent for the interfacial enhancement of carbon fiber/polyether ether ketone composites[J]. Composites Part B: Engineering, 2024, 272: 111205. DOI: 10.1016/j.compositesb.2024.111205

[8] HU J, YAN F, LIU H, et al. Water-based PEKC-COOH sizing agent for enhancing the interfacial adhesion of carbon fiber/polyether-ether-ketone composites[J]. Composites Part B: Engineering, 2021, 225: 109279. DOI: 10.1016/j.compositesb.2021.109279

[9] UEMATSU H, YOSHIDA K, YAMAGUCHI A, et al. Enhancement of interfacial shear strength due to cooperative π-π interaction between polyphenylene sulfide and carbon fiber and molecular orientation of polyphenylene sulfide via the π-π interaction[J]. Composites Part A: Applied Science and Manufacturing, 2023, 165: 107355. DOI: 10.1016/j.compositesa.2022.107355

[10] TARDIF X, PIGNON B, BOYARD N, et al. Experimental study of crystallization of polyetheretherketone (PEEK) over a large temperature range using a nano-calorimeter[J]. Polymer Testing, 2014, 36: 10-19. DOI: 10.1016/j.polymertesting.2014.03.013

[11] KUO M C, KUO J S, YANG M H, et al. On the crystallization behavior of the nano-silica filled PEEK composites[J]. Materials Chemistry and Physics, 2010, 123(2-3): 471-480. DOI: 10.1016/j.matchemphys.2010.04.043

[12] 权慧, 李忠明, 杨鸣波, 等. 半晶聚合物复合材料中的横晶[J]. 高分子通报, 2005(3): 9-20. DOI: 10.3969/j.issn.1003-3726.2005.03.002 QUAN Hui, LI Zhongming, YANG Mingbo, et al. Advance in the study of transcrystallinity in semi-crystalline polymer composites[J]. Polymer Bulletin, 2005(3): 9-20(in Chinese). DOI: 10.3969/j.issn.1003-3726.2005.03.002

[13] THOMASON J L, VAN ROOYEN A A. Transcrystallized interphase in thermoplastic composites[J]. Journal of Materials Science, 1992, 27(4): 897-907. DOI: 10.1007/BF01197639

[14] LI X, ZHAO Y, WANG K. Interfacial crystallization behavior of poly (ether-ether-ketone) on polyimide-modified CCF300 carbon fibers[J]. Polymer Composites, 2020, 41(6): 2433-2445. DOI: 10.1002/pc.25547

[15] 张志毅, 曾汉民. 纤维诱发聚醚醚酮界面结晶效应的研究[J]. 中山大学学报(自然科学版), 1990(3): 86-88. ZHANG Zhiyi, ZENG Hanmin. Investigations on interfacial crystallization effects of PEEK nucleated by fibers[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni, 1990(3): 86-88(in Chinese).

[16] QUAN H, LI Z M, YANG M B, et al. On transcrystallinity in semi-crystalline polymer composites[J]. Composites Science and Technology, 2005, 65(7-8): 999-1021. DOI: 10.1016/j.compscitech.2004.11.015

[17] 孙伟东, 陆波, 权亚博, 等. 半晶聚合物基复合材料的界面结晶行为[J]. 上海塑料, 2013(3): 1-6. DOI: 10.3969/j.issn.1009-5993.2013.03.001 SUN Weidong, LU Bo, QUAN Yabo, et al. Interfacial crystallization behavior of semi-crystalline polymer-based composites[J]. Shanghai Plastics, 2013(3): 1-6(in Chinese). DOI: 10.3969/j.issn.1009-5993.2013.03.001

[18] LIU Q, SUN X, LI H, et al. Orientation-induced crystallization of isotactic polypropylene[J]. Polymer, 2013, 54(17): 4404-4421. DOI: 10.1016/j.polymer.2013.04.066

[19] GAO S L, KIM J K. Effect of cooling rate on interphase properties of carbon fibre/PEEK composites[J]. Journal of the Society of Materials Science, Japan, 1999, 48(9): 157-162. DOI: 10.2472/jsms.48.9Appendix_157

[20] THOMASON J L, VAN ROOYEN A A. Transcrystallized interphase in thermoplastic composites[J]. Journal of Materials Science, 1992, 27(4): 889-896. DOI: 10.1007/BF01197638

[21] ZHANG J, LIU G, AN P, et al. The effect of cooling rates on crystallization and low-velocity impact behaviour of carbon fibre reinforced poly(aryl ether ketone) composites[J]. Composites Part B: Engineering, 2023, 254: 110569. DOI: 10.1016/j.compositesb.2023.110569

[22] WANG B, WEN T, ZHANG X, et al. Nucleation of poly (lactide) on the surface of different fibers[J]. Macromolecules, 2019, 52(16): 6274-6284. DOI: 10.1021/acs.macromol.9b01078

[23] NARDIN M, ASLOUN E M, MULLER F, et al. Study of the carbon fiber-poly(ether-ether-ketone) (PEEK) interfaces, 3: Influence and properties of interphases[J]. Polymers for Advanced Technologies, 1991, 2(4): 161-169. DOI: 10.1002/pat.1991.220020401

[24] MERETZ S, AUERSCH W, MAROTZKE C, et al. Investigation of morphology-dependent fracture behaviour with the single-fibre pull-out test[J]. Composites Science and Technology, 1993, 48(1): 285-290.

[25] PERON B, LOWE A, BAILLIE C. The effect of transcrystallinity on the interfacial characteristics of polypropylene/alumina single fibre composites[J]. Composites Part A: Applied Science and Manufacturing, 1996, 27(9): 839-845. DOI: 10.1016/1359-835X(96)00007-3

[26] GAO S L, KIM J K. Cooling rate influences in carbon fibre/PEEK composites. Part 1. Crystallinity and interface adhesion[J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(6): 517-530. DOI: 10.1016/S1359-835X(00)00009-9

[27] GAO S L, KIM J K. Cooling rate influences in carbon fibre/PEEK composites. Part II: Interlaminar fracture toughness[J]. Composites Part A: Applied Science and Manufacturing, 2001, 32(6): 763-774. DOI: 10.1016/S1359-835X(00)00188-3

[28] LIU J, LI H, DUAN Y, et al. Morphologies of iPP induced by its partially carbon-coated homogeneity fibers[J]. Polymer, 2003, 44(18): 5423-5428. DOI: 10.1016/S0032-3861(03)00587-1

[29] CHEN J, YANG D. Phase behavior and rhythmically grown ring-banded spherulites in blends of liquid crystalline poly(aryl ether ketone) and poly(aryl ether ether ketone)[J]. Macromolecules, 2005, 38(8): 3371-3379. DOI: 10.1021/ma047904f

[30] HU S, YANG F, CAO Y, et al. Influence of chain entanglements and melt memory effect on the crystallization behavior of polyphenylene sulfide[J]. Polymer, 2023, 285: 126390. DOI: 10.1016/j.polymer.2023.126390

[31] 张志毅, 曾汉民. 聚醚醚酮球晶结构的形态特征研究[J]. 高分子学报, 1991(4): 409-414. ZHANG Zhiyi, ZENG Hanmin. Investigation on the morphology characteristics of PEEK spherulites strycture[J]. Acta Polymerica Sinica, 1991(4): 409-414(in Chinese).

[32] WANG S, YANG Y, MU Y, et al. Synergy of electrochemical grafting and crosslinkable crystalline sizing agent to enhance the interfacial strength of carbon fiber/PEEK composites[J]. Composites Science and Technology, 2021, 203: 108562. DOI: 10.1016/j.compscitech.2020.108562

[33] WANG S D, ZHANG S W, YANG Y C, et al. Direct electrochemical grafting of crystalline PAEK macromolecule on carbon fiber to enhance the interfacial properties of PEEK/CF composites[J]. Composites Science and Technology, 2022, 220: 109262. DOI: 10.1016/j.compscitech.2022.109262

[34] MOON C K. The effect of interfacial microstructure on the interfacial strength of glass fiber/polypropylene resin composites[J]. Journal of Applied Polymer Science, 1994, 54(1): 73-82. DOI: 10.1002/app.1994.070540108

[35] JENCKEL E, TEEGE E, HINRICHS W. Transkristallisation in hochmolekularen Stoffen[J]. Kolloid-Zeitschrift, 1952, 129(1): 19-24. DOI: 10.1007/BF01802755

[36] CAI Y, PETERMANN J, WITTICH H. Transcrystallization in fiber-reinforced isotactic polypropylene composites in a temperature gradient[J]. Journal of Applied Polymer Science, 1997, 65(1): 67-75. DOI: 10.1002/(SICI)1097-4628(19970705)65:1<67::AID-APP9>3.0.CO;2-O

[37] WANG H, WANG S, WANG X, et al. Regulation of polymorphic behavior of poly(butylenes adipate) by nylon 6 fiber[J]. Polymer Bulletin, 2017, 74(10): 4195-4207. DOI: 10.1007/s00289-017-1940-3

[38] WU C M, CHEN M, KARGER-KOCSIS J. Transcrystallization in syndiotactic polypropylene induced by high-modulus carbon fibers[J]. Polymer Bulletin, 1998, 41(2): 239-245. DOI: 10.1007/s002890050357

[39] YAO L, LI M, WU Q, et al. Comparison of sizing effect of T700 grade carbon fiber on interfacial properties of fiber/BMI and fiber/epoxy[J]. Applied Surface Science, 2012, 263: 326-333. DOI: 10.1016/j.apsusc.2012.09.054

[40] SORENSEN L, GMÜR T, BOTSIS J. Residual strain development in an AS4/PPS thermoplastic composite measured using fibre Bragg grating sensors[J]. Composites Part A: Applied Science and Manufacturing, 2006, 37(2): 270-281. DOI: 10.1016/j.compositesa.2005.02.016

[41] NING N, FU S, ZHANG W, et al. Realizing the enhancement of interfacial interaction in semicrystalline polymer/filler composites via interfacial crystallization[J]. Progress in Polymer Science, 2012, 37(10): 1425-1455. DOI: 10.1016/j.progpolymsci.2011.12.005

[42] CHEN E J H, HSIAO B S. The effects of transcrystalline interphase in advanced polymer composites[J]. Polymer Engineering & Science, 1992, 32(4): 280-286.

[43] LUSTIGER A. Morphological aspects of the interface in the PEEK-carbon fiber system[J]. Polymer Composites, 1992, 13(5): 408-412. DOI: 10.1002/pc.750130511

[44] XU H, XIE L, JIANG X, et al. Toward stronger transcrystalline layers in poly(L-lactic acid)/natural fiber biocomposites with the aid of an accelerator of chain mobility[J]. Journal of Physical Chemistry B, 2014, 118(3): 812-823. DOI: 10.1021/jp409021q

[45] ZENG H, ZHANG Z, ZHANG M, et al. Young's modulus of transcrystallinities in semicrystalline thermoplastic composites[J]. Journal of Applied Polymer Science, 1994, 54(5): 541-551. DOI: 10.1002/app.1994.070540504

[46] CHATTERJEE A M, PRICE F P, NEWMAN S. Heterogeneous nucleation of crystallization of high polymers from the melt. III. Nucleation kinetics and interfacial energies[J]. Journal of Polymer Science: Polymer Physics Edition, 1975, 13(12): 2391-2400. DOI: 10.1002/pol.1975.180131213

[47] LEE Y, PORTER R S. Crystallization of poly(etheretherketone) (PEEK) in carbon fiber composites[J]. Polymer Engineering & Science, 1986, 26(9): 633-639.

[48] WADDON A J, HILL M J, KELLER A, et al. On the crystal texture of linear polyaryls (PEEK, PEK and PPS)[J]. Journal of Materials Science, 1987, 22(5): 1773-1784. DOI: 10.1007/BF01132406

[49] DAVIES P, CANTWELL W J. Fracture of glass/polypropylene laminates: Influence of cooling rate after moulding[J]. Composites, 1994, 25(9): 869-877. DOI: 10.1016/0010-4361(94)90028-0

[50] DOUMENG M, BERTHET F, DELBÉ K, et al. Effect of size, concentration, and nature of fillers on crystallinity, thermal, and mechanical properties of polyetheretherketone composites[J]. Journal of Applied Polymer Science, 2021, 139(5).

[51] ZHU K, TAN H, WANG Y, et al. Crystallization and mechanical properties of continuous carbon fiber reinforced polyether-ether-ketone composites[J]. Fibers and Polymers, 2019, 20(4): 839-846. DOI: 10.1007/s12221-019-8791-5

[52] ABDOU J P, REYNOLDS K J, PFAU M R, et al. Interfacial crystallization of isotactic polypropylene surrounding macroscopic carbon nanotube and graphene fibers[J]. Polymer, 2016, 91: 136-145. DOI: 10.1016/j.polymer.2016.03.055

[53] LUO B, LI H, ZHOU C, et al. Mechanistic insights into the shear-induced β-form crystal formation of iPP[J]. Macromolecular Chemistry and Physics, 2016, 217(12): 1354-1360. DOI: 10.1002/macp.201500542

[54] WANG C, LIU C R. Transcrystallization of polypropylene composites: Nucleating ability of fibres[J]. Polymer, 1999, 40(2): 289-298. DOI: 10.1016/S0032-3861(98)00240-7

[55] ZHOU M, XU S M, LI Y H, et al. Transcrystalline formation and properties of polypropylene on the surface of ramie fiber as induced by shear or dopamine modification[J]. Polymer, 2014, 55(13): 3045-3053. DOI: 10.1016/j.polymer.2014.05.013

[56] SU Y A, LIU P P, JING D Q, et al. Improved interfacial adhesion in carbon fiber/poly (ether ether ketone) composites with the sulfonated poly (ether ether ketone) sizing treatment[J]. Journal of Applied Polymer Science, 2021, 138(45): 51326. DOI: 10.1002/app.51326

[57] MARTIN A, ADDIEGO F, MERTZ G, et al. Pitch-based carbon fibre-reinforced PEEK composites: Optimization of interphase properties by water-based treatments and self-assembly[J]. Journal of Materials Science and Engineering, 2016, 6: 1-9.

[58] FU Y, LI H, CAO W. Enhancing the interfacial properties of high-modulus carbon fiber reinforced polymer matrix composites via electrochemical surface oxidation and grafting[J]. Composites Part A: Applied Science and Manufacturing, 2020, 130: 105719. DOI: 10.1016/j.compositesa.2019.105719

[59] ZHOU M, LI Y, HE C, et al. Interfacial crystallization enhanced interfacial interaction of poly(butylene succinate)/ramie fiber biocomposites using dopamine as a modifier[J]. Composites Science and Technology, 2014, 91: 22-29. DOI: 10.1016/j.compscitech.2013.11.019

[60] SUN B, QIN Y, XU Y, et al. Study of shear-induced interfacial crystallization in polymer-based composite through in situ monitoring interfacial shear stress[J]. Journal of Materials Science, 2013, 48(15): 5354-5360. DOI: 10.1007/s10853-013-7330-9

[61] LI T Q, ZHANG M Q, ZHANG K, et al. Long-range effects of carbon fiber on crystallization of semicrystalline thermoplastics[J]. Polymer, 2000, 41(1): 161-168. DOI: 10.1016/S0032-3861(99)00140-8

[62] WANG W, QI Z, JERONIMIDIS G. Studies on interface structure and crystal texture of poly(ether-ether-ketone)-carbon fibre composite[J]. Journal of Materials Science, 1991, 26(21): 5915-5920. DOI: 10.1007/BF01130134

[63] ZHANG M, XU J, ZHANG Z, et al. Effect of transcrystallinity on tensile behaviour of discontinuous carbon fibre reinforced semicrystalline thermoplastic composites[J]. Polymer, 1996, 37(23): 5151-5158. DOI: 10.1016/0032-3861(96)00341-2

[64] 李博澜, 张凤, 焦梦晓, 等. PEEK/CF复合材料中PEEK结晶行为研究进展[J]. 合成树脂及塑料, 2024, 41(1): 68-74. LI Bolan, ZHANG Feng, JIAO Mengxiao, et al. Research progress of crystallization behavior of PEEK in PEEK/CF composites[J]. China Synthetic Resins and Plastics, 2024, 41(1): 68-74(in Chinese).

[65] ZHANG Z, ZENG H. Nucleation and crystal growth of PEEK on carbon fiber[J]. Journal of Applied Polymer Science, 1993, 48(11): 1987-1995. DOI: 10.1002/app.1993.070481112

[66] ZHANG Z, ZENG H. Interfacial crystallization of PEEK/PES-C blends on carbon fibre[J]. European Polymer Journal, 1993, 29(12): 1647-1650. DOI: 10.1016/0014-3057(93)90260-M

[67] JAR P Y, CANTWELL W J, KAUSCH H H. Study of the crystal morphology and the deformation behaviour of carbon fibre reinforced PEEK (APC-2)[J]. Composites Science and Technology, 1992, 43(3): 299-306. DOI: 10.1016/0266-3538(92)90100-H

[68] 曾汉民, 张志毅. 结晶性高聚物基体复合材料的界面结晶效应[J]. 材料工程, 1992(1): 6-10. ZENG Hanmin, ZHANG Zhiyi. The Interface crystal effect of crystalline polymer matrix composites[J]. Journal of Materials Engineering, 1992(1): 6-10(in Chinese).

[69] LI N, CHEN J, LIU H, et al. Effect of preheat treatment on carbon fiber surface properties and fiber/PEEK interfacial behavior[J]. Polymer Composites, 2018, 40(S2): E1407-E1415.

[70] 陈平, 于祺, 孙明, 等. 高性能热塑性树脂基复合材料的研究进展[J]. 纤维复合材料, 2005(2): 52-57. DOI: 10.3969/j.issn.1003-6423.2005.02.016 CHEN Ping, YU Qi, SUN Ming, et al. Advances in high performance FRTP composites[J]. Fiber Composites, 2005(2): 52-57(in Chinese). DOI: 10.3969/j.issn.1003-6423.2005.02.016

[71] QUIROGA CORTÉS L, CAUSSÉ N, DANTRAS E, et al. Morphology and dynamical mechanical properties of poly ether ketone ketone (PEKK) with meta phenyl links[J]. Journal of Applied Polymer Science, 2016, 133(19).

[72] 孙永周. 开展我国聚醚酮酮研究的建议[J]. 塑料工业, 1990(2): 25-31. SUN Yongzhou. Suggestions for development of polyetherketoneketones in China[J]. China Plastics Industry, 1990(2): 25-31(in Chinese).

[73] PÉREZ-MARTÍN H, MACKENZIE P, BAIDAK A, et al. Crystallinity studies of PEKK and carbon fibre/PEKK composites: A review[J]. Composites Part B: Engineering, 2021, 223: 109127. DOI: 10.1016/j.compositesb.2021.109127

[74] PÉREZ-MARTÍN H, MACKENZIE P, BAIDAK A, et al. Crystallisation behaviour and morphological studies of PEKK and carbon fibre/PEKK composites[J]. Composites Part A: Applied Science and Manufacturing, 2022, 159: 106992. DOI: 10.1016/j.compositesa.2022.106992

[75] CHELAGHMA S, PASSIEUX J C, DE ALMEIDA O, et al. Modélisation Pixel Coloring de la cristallisation du PEKK [C]. Comptes Rendus JNC 21 - Bordx INP 2019: 9.

[76] 崔永丽, 应鹏展, 王晓虹. 特种工程塑料聚芳醚酮[J]. 塑料工业, 2006(S1): 295-298. DOI: 10.3321/j.issn:1005-5770.2006.z1.087 CUI Yongli, YING Pengzhan, WANG Xiaohong. Special engineering plastics of polyaryletherketone[J]. China Plastics Industry, 2006(S1): 295-298(in Chinese). DOI: 10.3321/j.issn:1005-5770.2006.z1.087

[77] 徐利敏, 赵剑锋, 雷玉平, 等. 特种工程塑料PAEK的性能及应用[J]. 塑料科技, 2006(5): 66-68. DOI: 10.3969/j.issn.1005-3360.2006.05.011 XU Limin, ZHAO Jianfeng, LEI Yuping, et al. Application and properties of special engineering plastic PAEK[J]. Plastics Science and Technology, 2006(5): 66-68(in Chinese). DOI: 10.3969/j.issn.1005-3360.2006.05.011

[78] 赵晓刚, 冀克俭, 邓卫华, 等. 高性能聚芳醚酮的发展及应用[J]. 工程塑料应用, 2009, 37(3): 80-83. DOI: 10.3969/j.issn.1001-3539.2009.03.022 ZHAO Xiaogang, JI Kejian, DENG Weihua, et al. Development and application of high performance polyaryletherketones[J]. Engineering Plastics Applications, 2009, 37(3): 80-83(in Chinese). DOI: 10.3969/j.issn.1001-3539.2009.03.022

[79] 倪志春. 国内外聚醚醚酮开发应用进展[J]. 国外塑料, 2013, 31(10): 32-36. DOI: 10.3969/j.issn.1002-5219.2013.10.010 NI Zhichun. Development and application of domestic and foreign PEEK[J]. World Plastics, 2013, 31(10): 32-36(in Chinese). DOI: 10.3969/j.issn.1002-5219.2013.10.010

[80] YE L, SCHEURING T, FRIEDRICH K. Matrix morphology and fibre pull-out strength of T700/PPS and T700/PET thermoplastic composites[J]. Journal of Materials Science, 1995, 30(19): 4761-4769. DOI: 10.1007/BF01154482

[81] YU L, WANG K, SUN M, et al. Hydrothermal aging behavior and effects on carbon fabric/polyphenylene sulfide composite[J]. Polymer Composites, 2024, 45(1): 836-846. DOI: 10.1002/pc.27819

[82] REN Y, YU M, LI Z, et al. Exploring the self-nucleation effect: Transforming crystalline morphology for improved mechanical performance of carbon fiber reinforced polyphenylene sulfide composites[J]. Composites Part B: Engineering, 2024, 272: 111231. DOI: 10.1016/j.compositesb.2024.111231

[83] WANG S, WANG T, ZHANG S, et al. Enhancing fiber-matrix interface in carbon fiber/poly ether ether ketone (CF/PEEK) composites by carbon nanotube reinforcement of crystalline PEEK sizing[J]. Composites Part B: Engineering, 2023, 251: 110470. DOI: 10.1016/j.compositesb.2022.110470

[84] ZENG L, LIU X, CHEN X, et al. π-π interaction between carbon fibre and epoxy resin for interface improvement in composites[J]. Composites Part B: Engineering, 2021, 220: 108983. DOI: 10.1016/j.compositesb.2021.108983

[85] SCHULZ E, KALINKA G, AUERSCH W. Effect of transcrystallization in carbon fiber reinforced poly(p-phenylene sulfide) composites on the interfacial shear strength investigated with the single fiber pull-out test[J]. Journal of Macromolecular Science, Part B Physics, 1996, 35: 527-546. DOI: 10.1080/00222349608220393

[86] 张立峰, 王盛, 乔伟林, 等. 单向碳纤维复合材料界面力学性能测试研究[J]. 机械科学与技术, 2019, 38(8): 1296-1300. ZHANG Lifeng, WANG Sheng, QIAO Weilin, et al. Experimental study on interface mechanical properties of unidirectional carbon fiber composites[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(8): 1296-1300(in Chinese).

[87] 顾洋洋, 姚佳楠, 王力风, 等. 聚芳醚酮树脂基体特性对复合材料界面性能和层间性能的影响[J]. 复合材料学报, 2023, 40(8): 4481-4490. GU Yangyang, YAO Jianan, WANG Lifeng, et al. Influence of poly aryl ether ketone resin matrix properties on interfacial properties and interlayer properties of composites[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4481-4490(in Chinese).

[88] 嵇醒, 戴瑛. 复合材料界面剪切强度试验方法评定[C]. 2009年度海峡两岸工程力学研讨会论文集. 2009: 167-173. JI Sheng, DAI Ying. Evaluation of test methods for interfacial shear strength of composites[C]. 2009 Proceedings of Cross-Strait Engineering Mechanics. 2009: 167-173(in Chinese).

[89] GAO Y, XIE M, LIU L, et al. Effect of supra-molecular microstructures on the adhesion of SWCNT fiber/iPP interface[J]. Polymer, 2013, 54(1): 456-463. DOI: 10.1016/j.polymer.2012.11.043

[90] 戴瑛, 嵇醒. 单纤维段裂试验评述[J]. 力学进展, 2006, 36(2): 211-221. DOI: 10.3321/j.issn:1000-0992.2006.02.005 DAI Ying, JI Sheng. Review of single fiber fragmentation test[J]. Advances in Mechanics, 2006, 36(2): 211-221(in Chinese). DOI: 10.3321/j.issn:1000-0992.2006.02.005

[91] KOBAYASHI H, HAYAKAWA E, KIKUTANI T, et al. Effect of quenching and annealing on fiber pull-out from crystalline polymer matrices[J]. Advanced Composite Materials, 1991, 1(2): 155-168. DOI: 10.1163/156855191X00252

[92] YANG Y, WANG T, WANG S, et al. Strong interface construction of carbon fiber-reinforced PEEK composites: An efficient method for modifying carbon fiber with crystalline PEEK[J]. Macromolecular Rapid Communications, 2020, 41(24): 2000001. DOI: 10.1002/marc.202000001

[93] JENG C C, CHEN M. Flexural failure mechanisms in injection-moulded carbon fibre/PEEK composites[J]. Composites Science and Technology, 2000, 60(9): 1863-1872. DOI: 10.1016/S0266-3538(00)00076-2

[94] YU K, ZHANG J, LIU G, et al. Inverse effects of cooling rates on the interfacial shear strength of carbon fiber/PEEK composites with and without presence of transcrystal layers[J]. Polymer, 2024, 302: 127067. DOI: 10.1016/j.polymer.2024.127067

-

目的

自90年代以来,伴随着科技的进步,为满足人们对材料的需求,以通用工程塑料和高性能特种工程塑料为基体的热塑性复合材料逐渐受到广泛关注。其中,高性能热塑性树脂基复合材料因其优异的机械强度、良好的生物相容性以及较高的使用温度,在航空航天和医疗器械领域备受关注。然而,纤维与热塑性树脂的界面一直是影响复合材料力学性能的重要因素,而高性能热塑性树脂在纤维周围的结晶行为对复合材料的界面性能具有至关重要的作用。因此,系统研究纤维在树脂中的诱导结晶行为显得尤为必要。

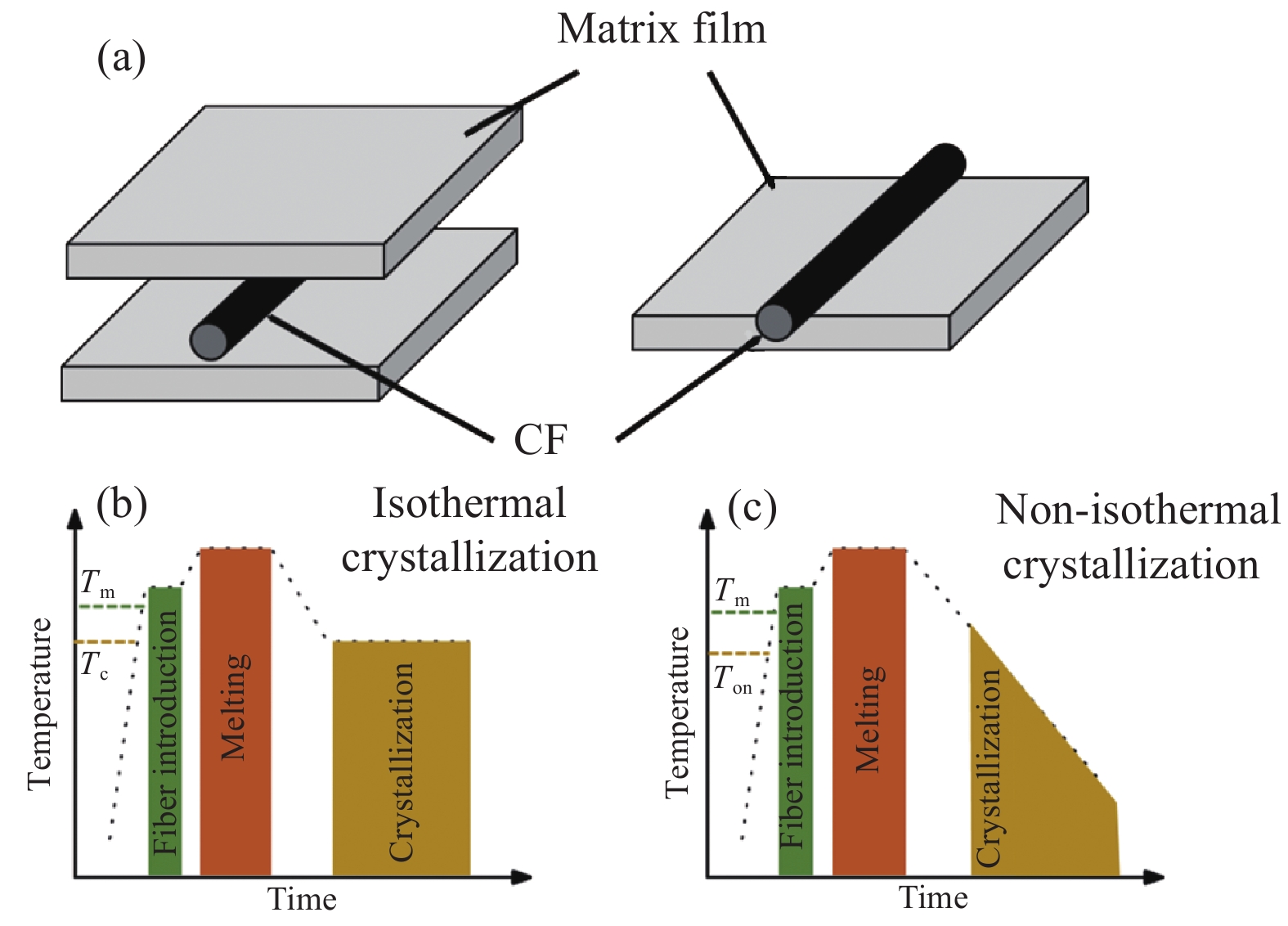

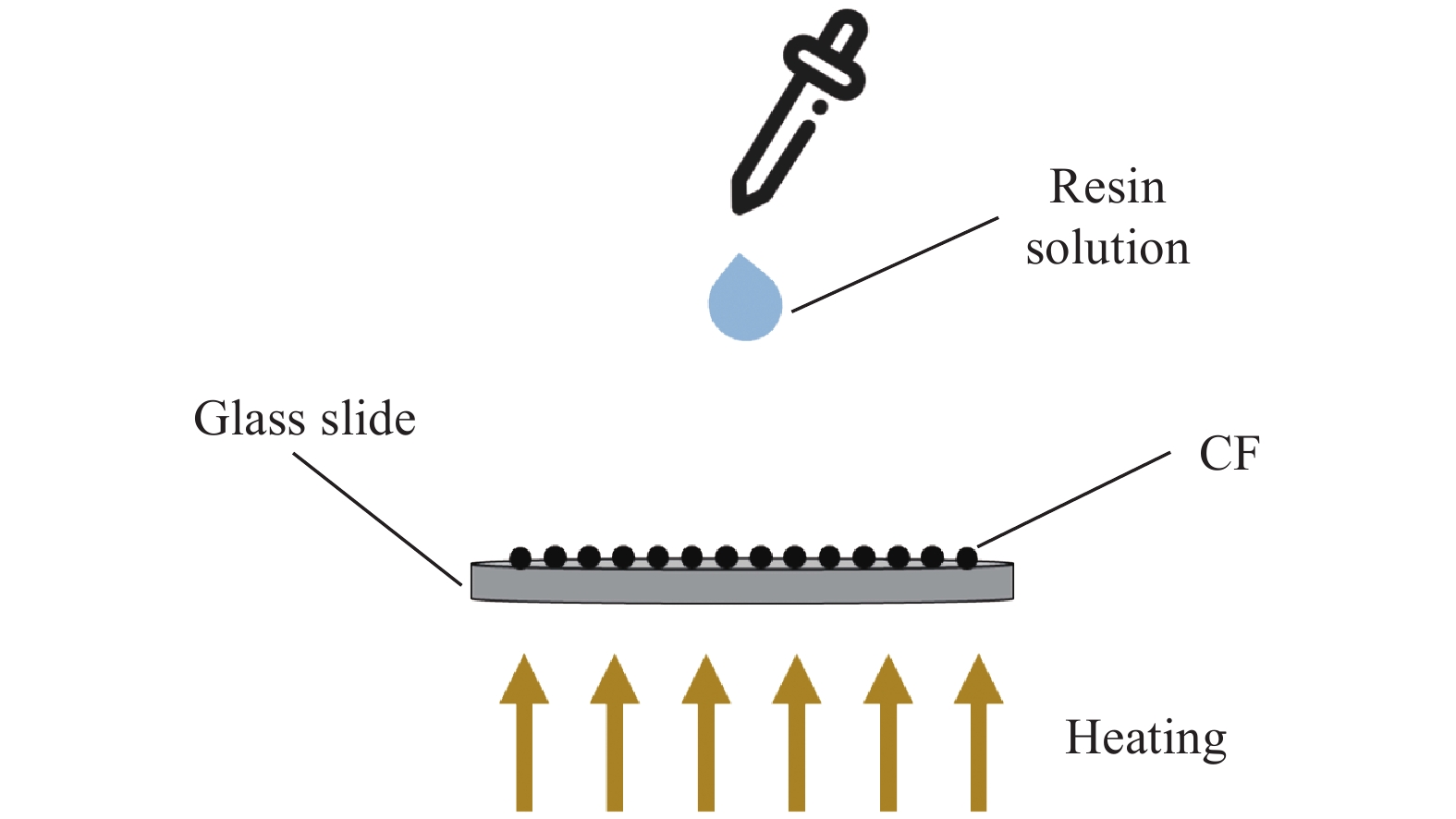

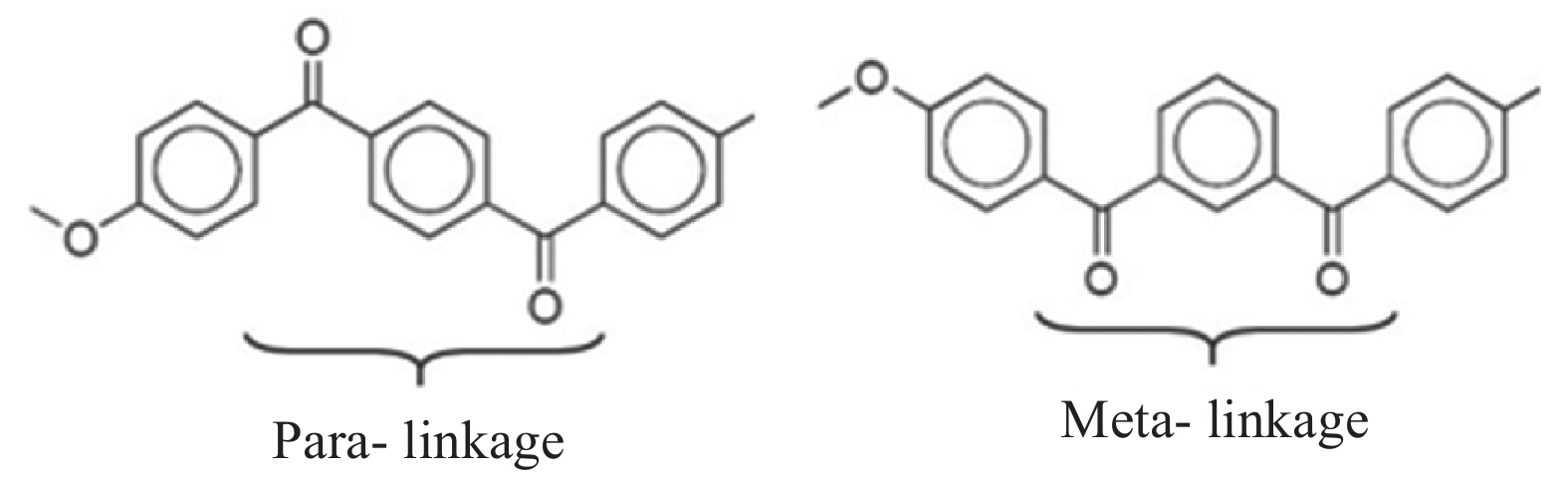

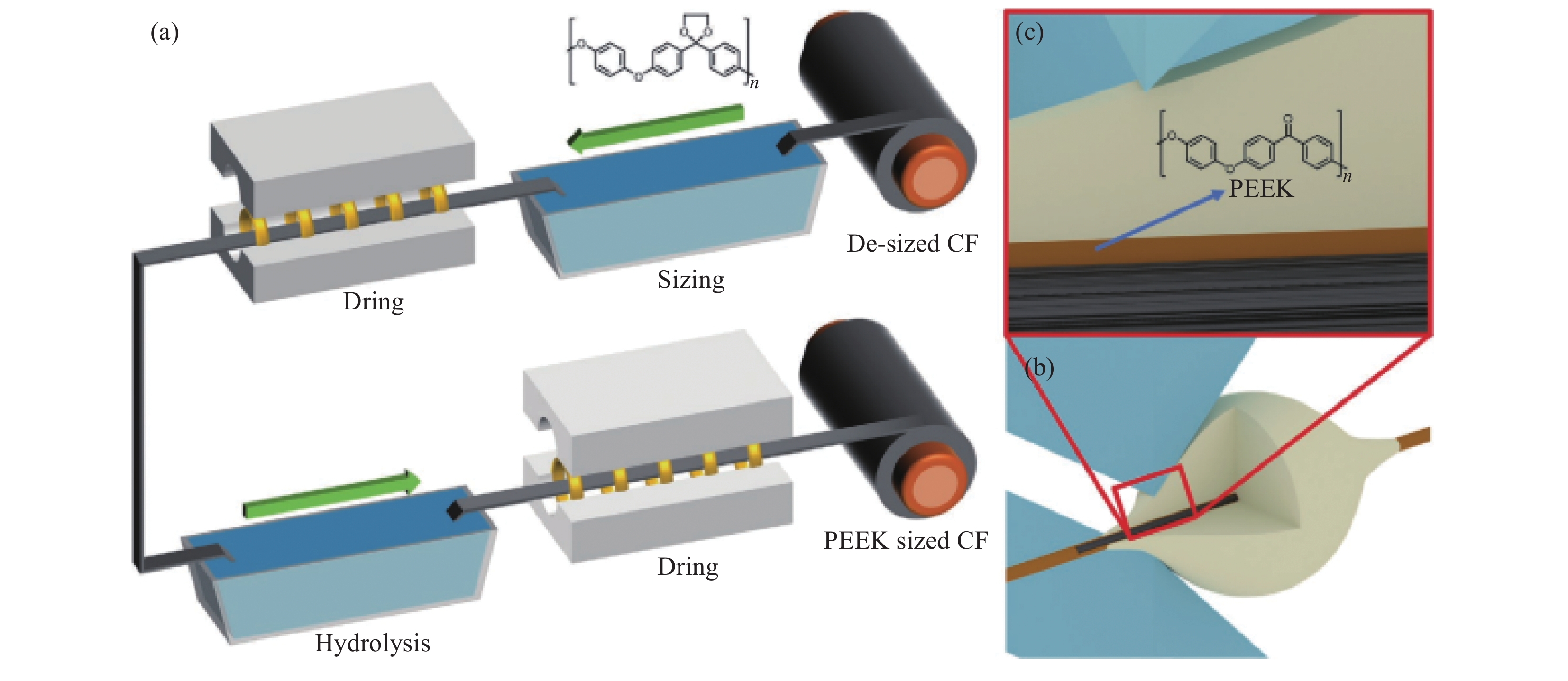

方法本文依托复合材料中诱导结晶问题的研究进展,对已有文献进行了系统的整合。文章首先从诱导结晶样品的制备方法入手,描述了不同制备方法的原理、步骤及其优缺点。进而,文章讨论了诱导结晶的分类,并进行了细致的划分,有助于理解诱导结晶的本质。在此基础上,详细介绍了影响诱导结晶的主要因素,包括温度、压力、时间等工艺参数,以及树脂和纤维的性质等。此外,为了充分了解不同树脂诱导结晶的差异,对几种使用较为广泛的高性能热塑性树脂,如聚醚醚酮(PEEK)、聚醚酮酮(PEKK)、聚芳醚酮(PAEK)和聚苯硫醚(PPS)等进行了总结。最后,文章以诱导结晶对复合材料的界面性能影响为落脚点,构建整个综述的框架。

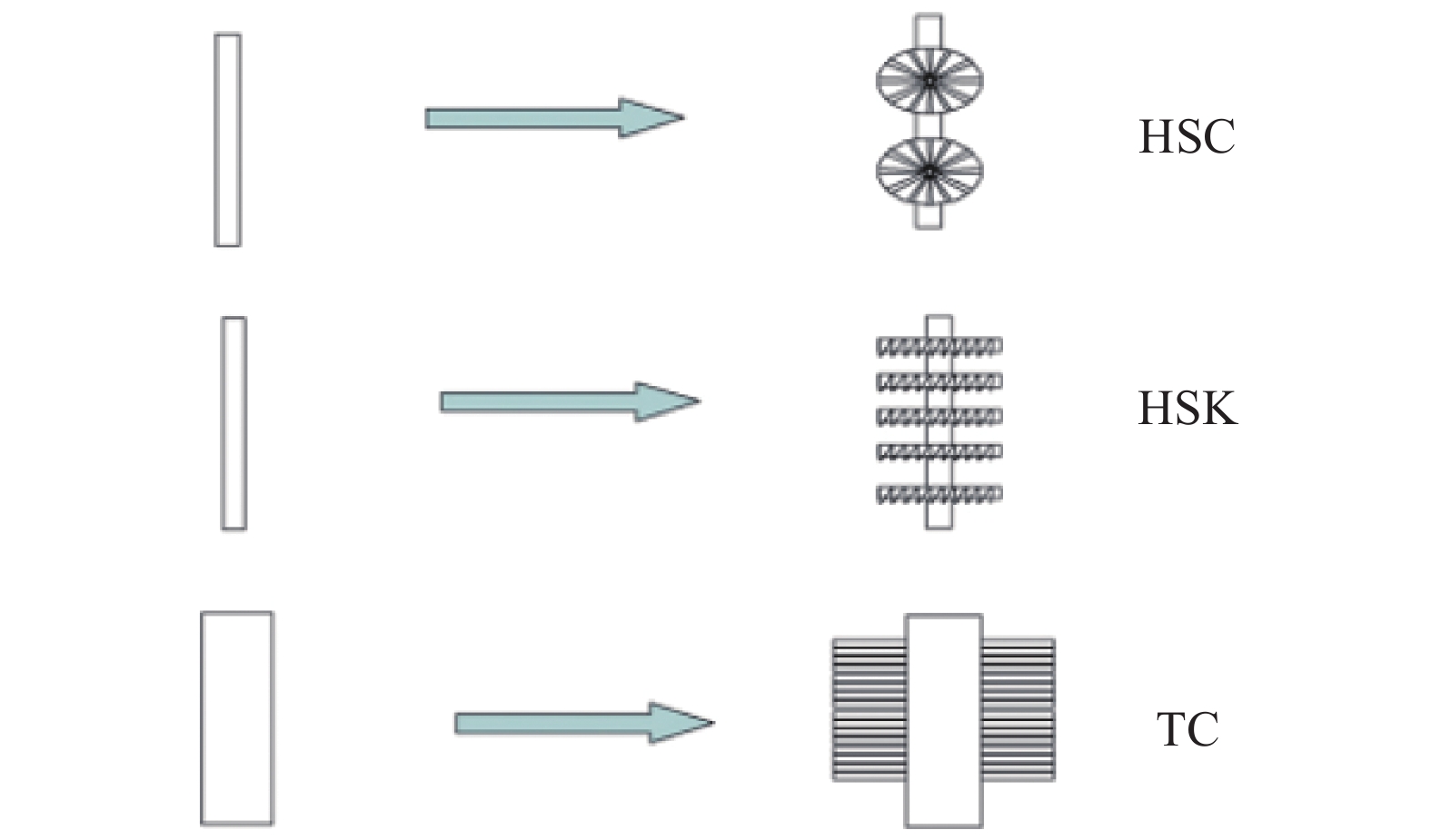

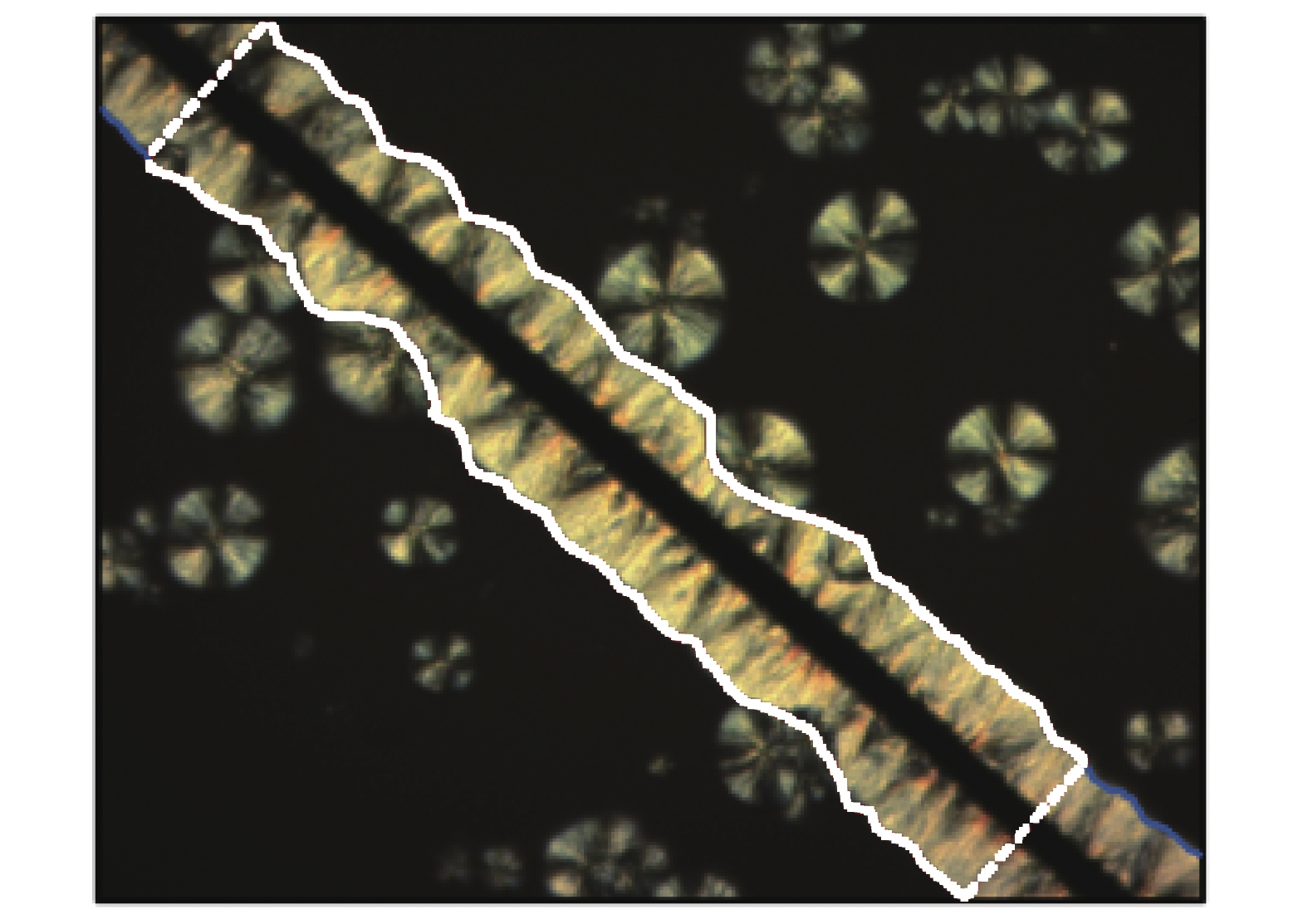

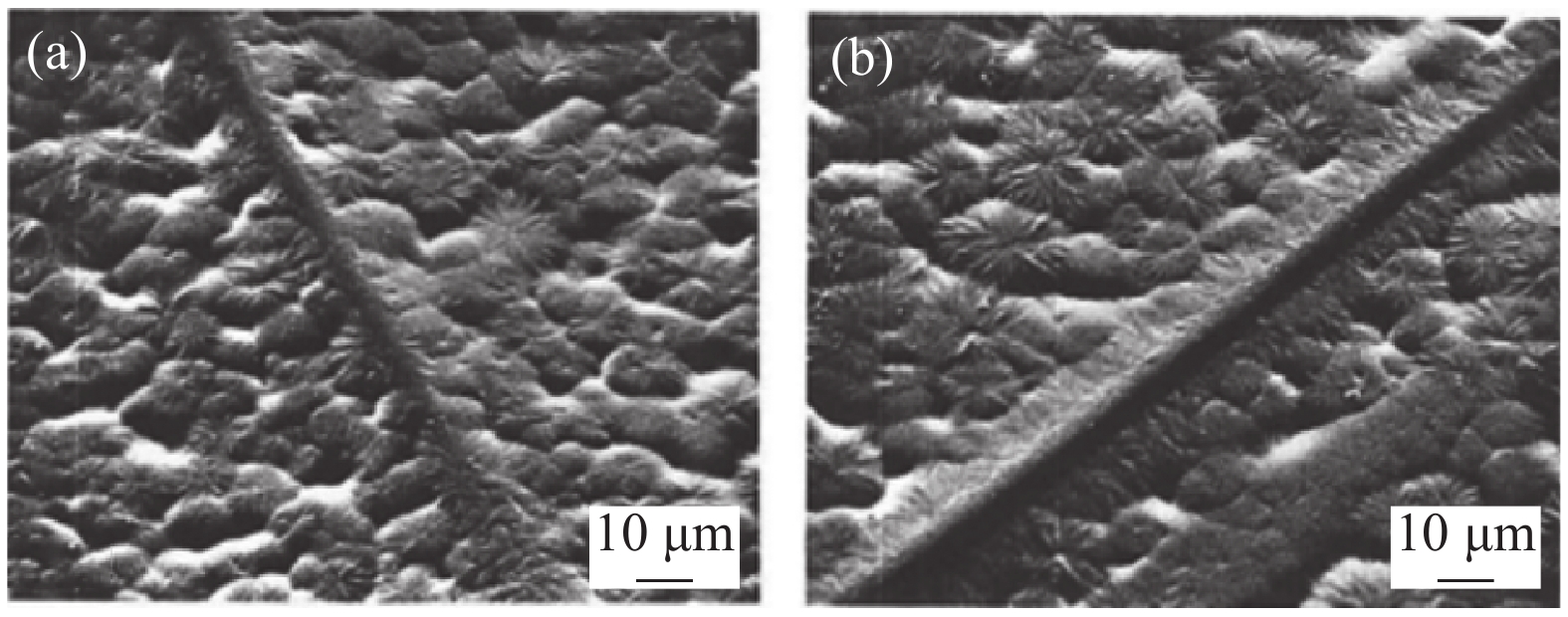

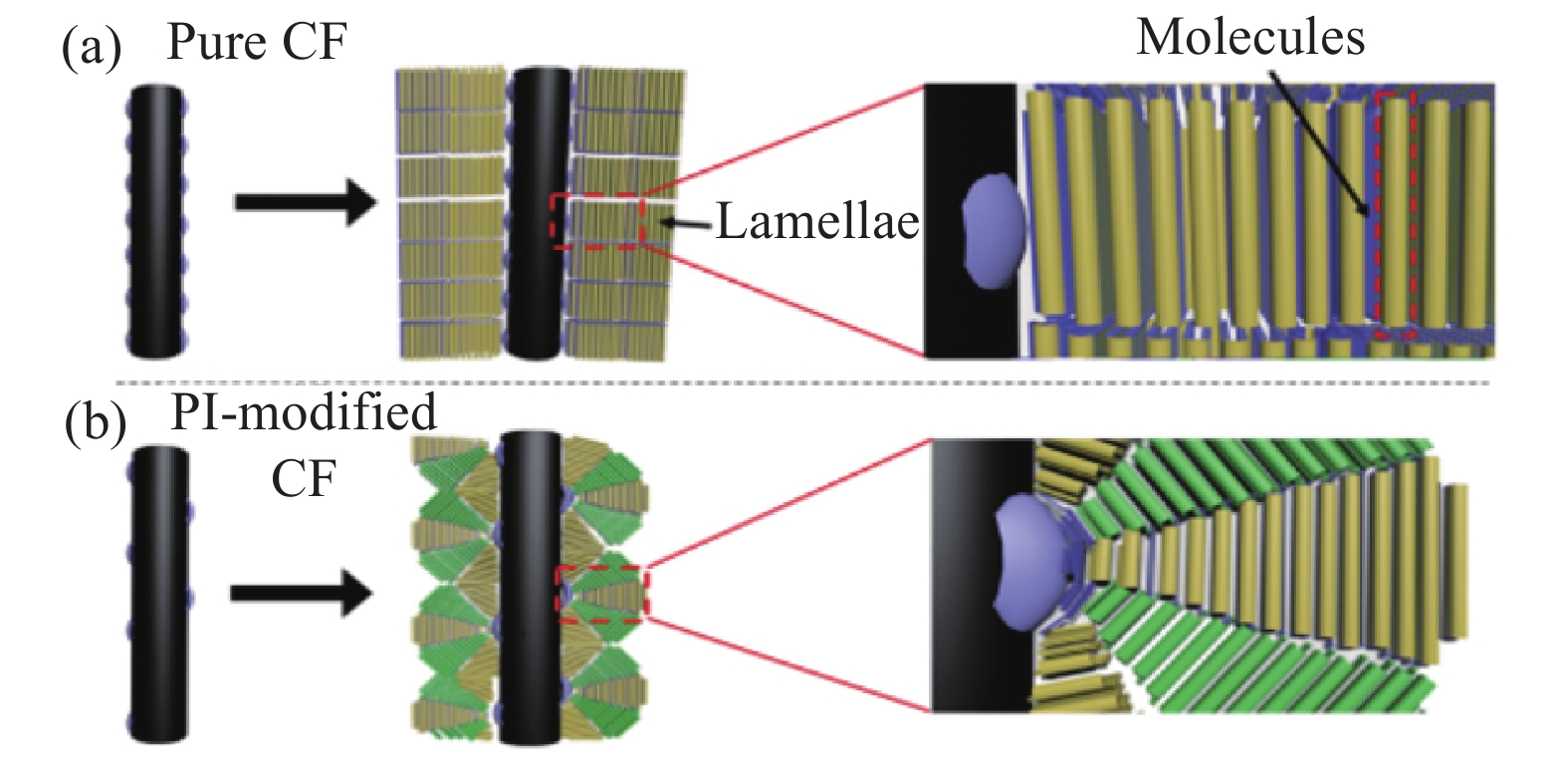

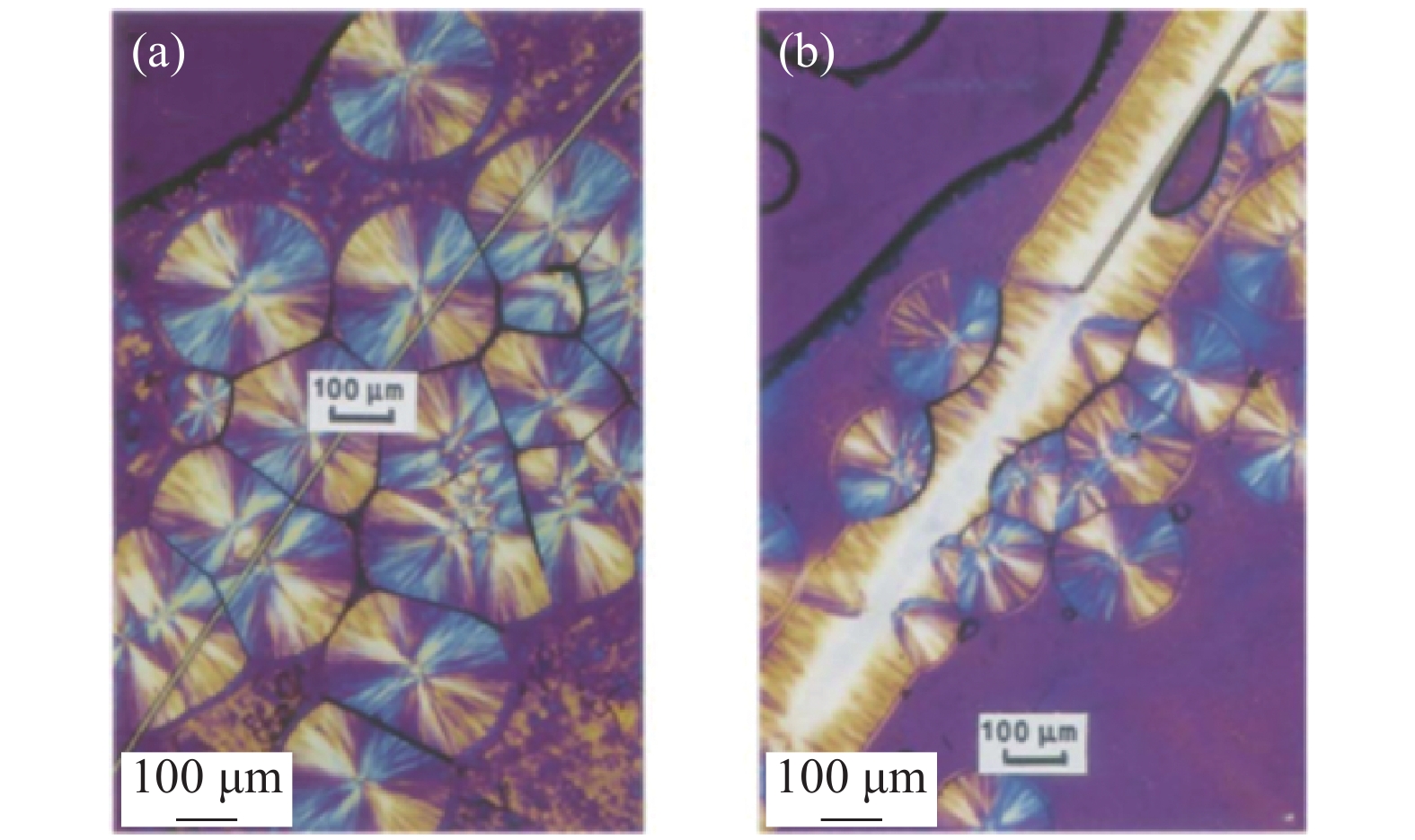

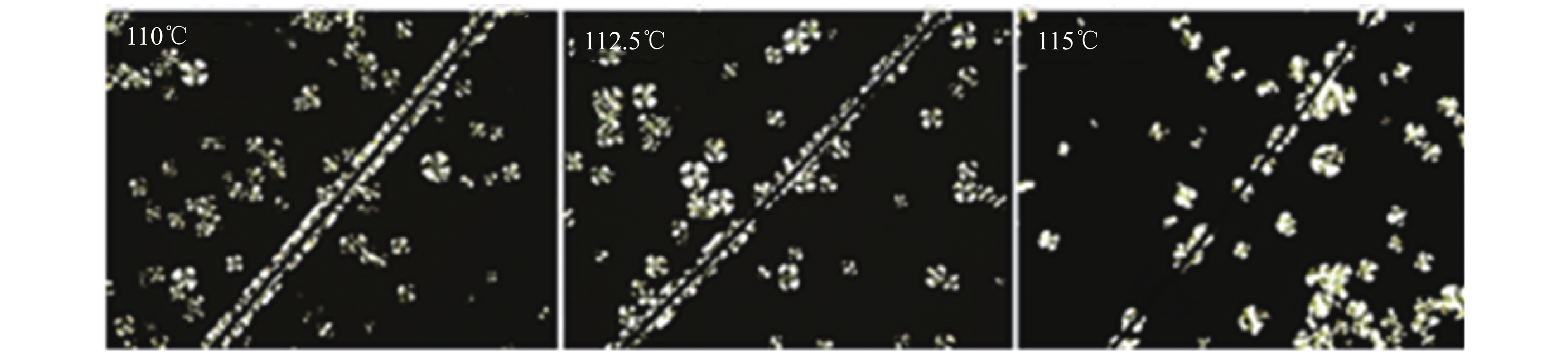

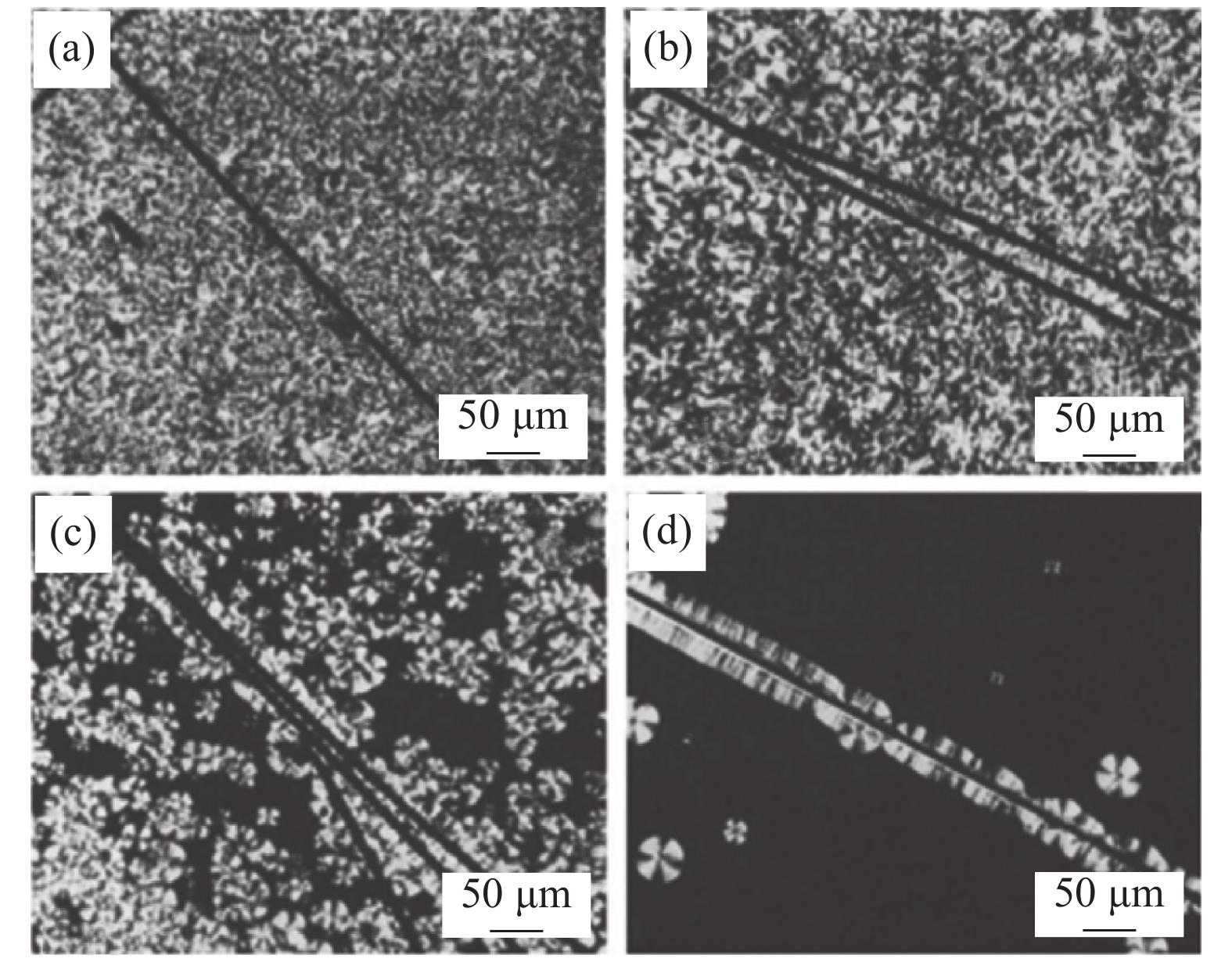

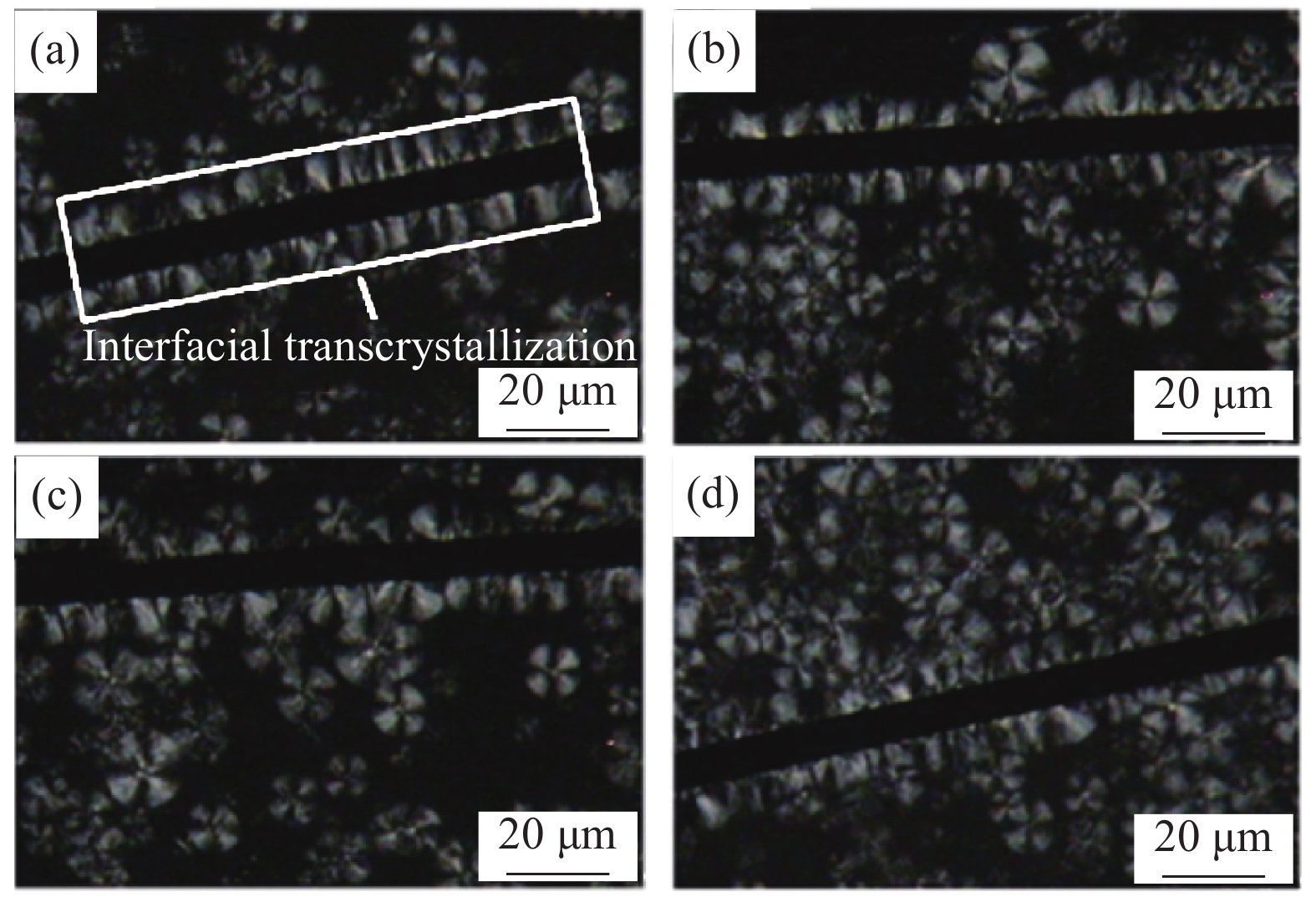

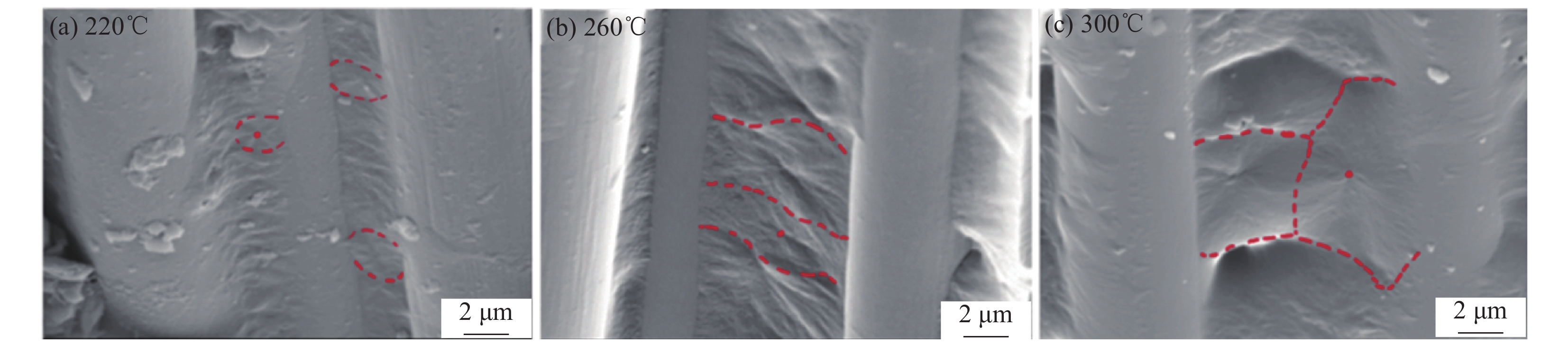

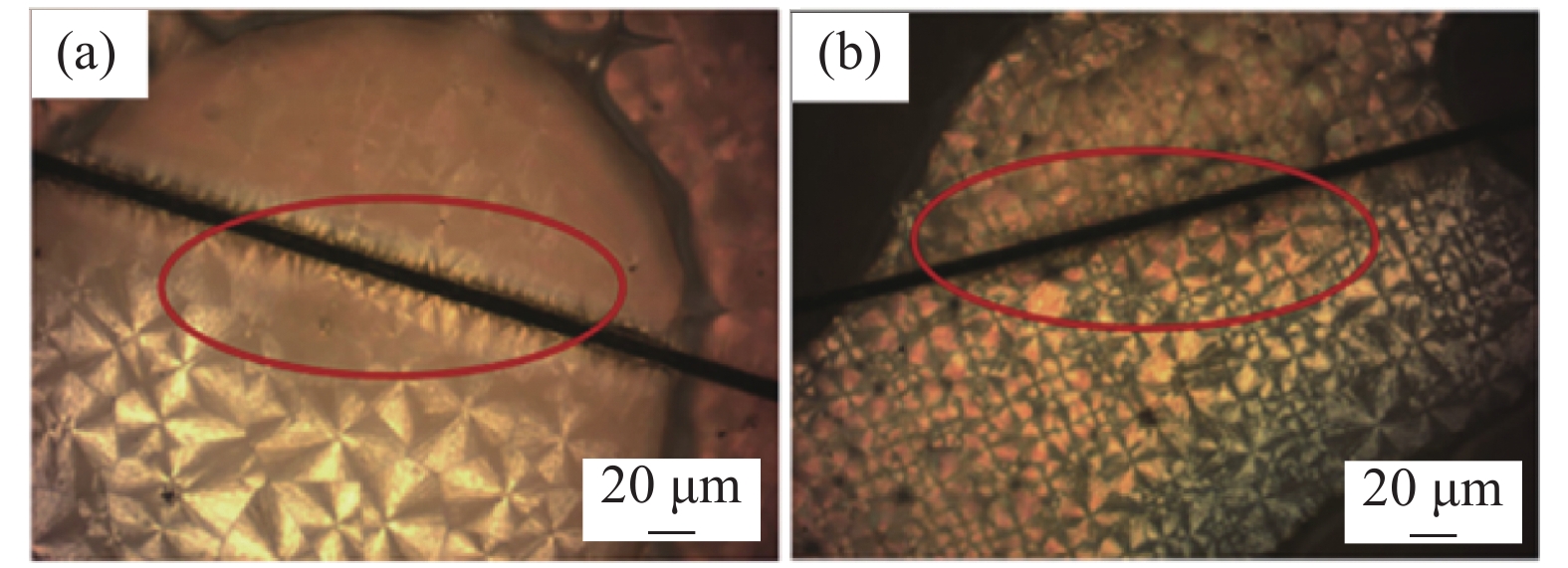

结果使用偏光显微镜观察诱导结晶是少数方法之一,而制备样品的方法大致可分为两种:压膜法和溶液法。其中,溶液法制膜更为简单且易于控制膜的厚度。观察到的诱导结晶也有较大区别,可根据纤维的成核密度从低到高详细分为杂化葫芦晶(hybrid shish-calabash,简称HSC)、杂化串晶(hybrid shish-kebab,简称HSK)以及横晶(Transcrystallinity,简称TC)结构。在高性能热塑性树脂中,纤维诱导的结晶以TC结构为主。根据已有文献中对诱导结晶的描述,可把影响因素归为以下4点:纤维结构与特性、纤维与树脂的导热性差异、纤维周围应力和复合材料成型工艺参数。这些因素都会影响复合材料中TC结构的生长,但在实际加工过程中,通常采用控制成型工艺参数来提高复合材料的力学性能。碳纤维在PEEK、PEKK、PAEK和PPS等树脂中的TC结构相差不大,上述描述的影响因素都可作用于这些高性能树脂中。当然,最为重要的还是TC结构对复合材料界面性能的影响,而微滴脱粘试验由于其操作简便、结果可靠,被广泛采用来评估复合材料的界面剪切强度。综合分析已有文献发现,在PEEK树脂中的TC结构可有效提高复合材料的界面剪切强度,但是对于PPS的研究则没有统一的意见。此外,在一些研究较少的PAEK树脂中,TC结构有可能还会对复合材料产生负面影响。

结论高性能热塑性复合材料在众多领域展现出广泛的应用前景,而纤维与树脂界面所产生的TC结构,能够显著提升复合材料的力学性能。尽管仍有一些文献指出TC结构对性能的影响不大,但大多数研究已证实,在外力作用下,TC结构能够分散剪切应力,使复合材料能够承受更大的载荷。然而,研究复合材料板材中树脂的结晶行为以及纤维的作用机制仍然是一个难点。因此,开发出一种高效、可行的研究方法,以深入研究TC结构的形成机制及其在复合材料中的作用,显得尤为迫切。

下载:

下载: