Research progress in carbon-based fibrous materials for interfacial photothermal steam generation

-

摘要: 淡水资源日益匮乏已成为严峻的世界性难题。为了促进界面光热水蒸发系统的发展和碳基纤维材料在界面光热水蒸发领域的应用,本文对界面光水蒸发用碳基纤维材料的最新研究进展进行综述。首先介绍了界面光热水蒸发系统的设计原理,其次系统分析了不同碳基材料的光热转换机制和结构特点及纤维材料用于水蒸发系统的性能优势。并以不同碳基纤维材料为切入点,重点介绍了碳基纤维材料的制备方法、性能优势。最后对碳基纤维材料在界面光热水蒸发领域所面临的挑战进行了探究。Abstract: The increasing scarcity of freshwater resources has become a serious global problem. In order to promote the development of interfacial photothermal steam generation systems and the application of carbon-based fibrous materials in the field of interfacial steam generation. This paper reviews the latest research progress on carbon-based fibrous materials for interfacial photothermal steam generation. Firstly, the design principle of the interfacial steam generation system is introduced, followed by the systematic analysis of the photothermal conversion mechanism and structural characteristics of different carbon-based materials, as well as the performance advantages of fibrous materials applied to steam generation. With different carbon-based fiber materials as the entry point, the preparation methods and performance advantages of carbon-based fiber materials are elaborated. Finally, the challenges faced by carbon-based fibrous materials in the field of interfacial photothermal steam generation are explored.

-

随着人口快速增长和工业化发展加快,水资源匮乏已经成为二十一世纪备受关注的环境问题。据估计,到2025年,全球3/4的人口将面临缺水问题,超过1/2的国家将陷入的淡水短缺的困境。此外,水资源分布极不平衡,淡水资源占全球水资源的2.7%,而海水占总资源的97.3%[1-3]。目前反渗透[4]、膜蒸馏[5]和电渗透[6]技术已经投入工业化使用,但存在高能耗高成本问题,并且在使用过程会中产生的CO2会加剧温室效应[7-8]。太阳能作为取之不尽、用之不竭的可再生清洁能源,高效利于太阳能有望实现零能耗、低成本的海水淡化[9],光热水蒸发技术结合海水资源和太阳能资源,可应用于海水淡化。但是传统的太阳能蒸发体系采用底部加热和整体加热,蒸发效率不足40%,是由于加热整个水体会造成大量的热损失[10]。而界面光热水蒸发系统将光热转换过程集中在空气-水界面,转换的热量直接用于加热表面水,最大程度上减少热量损失,提高水蒸发效率[11]。

界面光热水蒸发系统需要高效的光热材料,碳基材料在较宽的波长范围内具有高光吸收率和优异的光热效应,且导热性好、性能稳定[12]。此外,碳基材料具有出色的结构可调性和良好的加工性能,并可与其它材料复合,进一步提高光热转换性能[13]。碳基界面光热水蒸发系统可以分为一体式[14]和多层式[15],一体式如碳泡沫[16]和石墨烯气凝胶[17]等。多层式是将光热层固定在柔性或刚性基材上,集成界面光热水蒸发系统。但一体式和刚性基材存在灵活性差、易碎的缺点,当刚性基材受到盐污染时,会对材料造成破坏从而削弱水蒸发的速率[18]。此外,一体式结构对复合材料通道垂直度要求较高,由于垂直对齐的通道更有利于水传输[19]。因此碳材料通常与柔性亲水基材结合以制备界面光热水蒸发系统[20]。纤维材料具有微纳米尺度物理结构,因而呈现出出色的毛细管力[21],表面的亲水基团 (—OH、—COOH) 则进一步加强了亲水性,促进了水分供给和盐浓度管理。独特的机械柔性和可裁剪性、赋予光热材料出色的便携性和易加工性。纤维材料成本低、来源广泛并已望实现规模化地生产。因此碳基纤维材料在界面光热水蒸发领域具有广阔的应用前景。

1. 界面光热水蒸发系统的工作原理

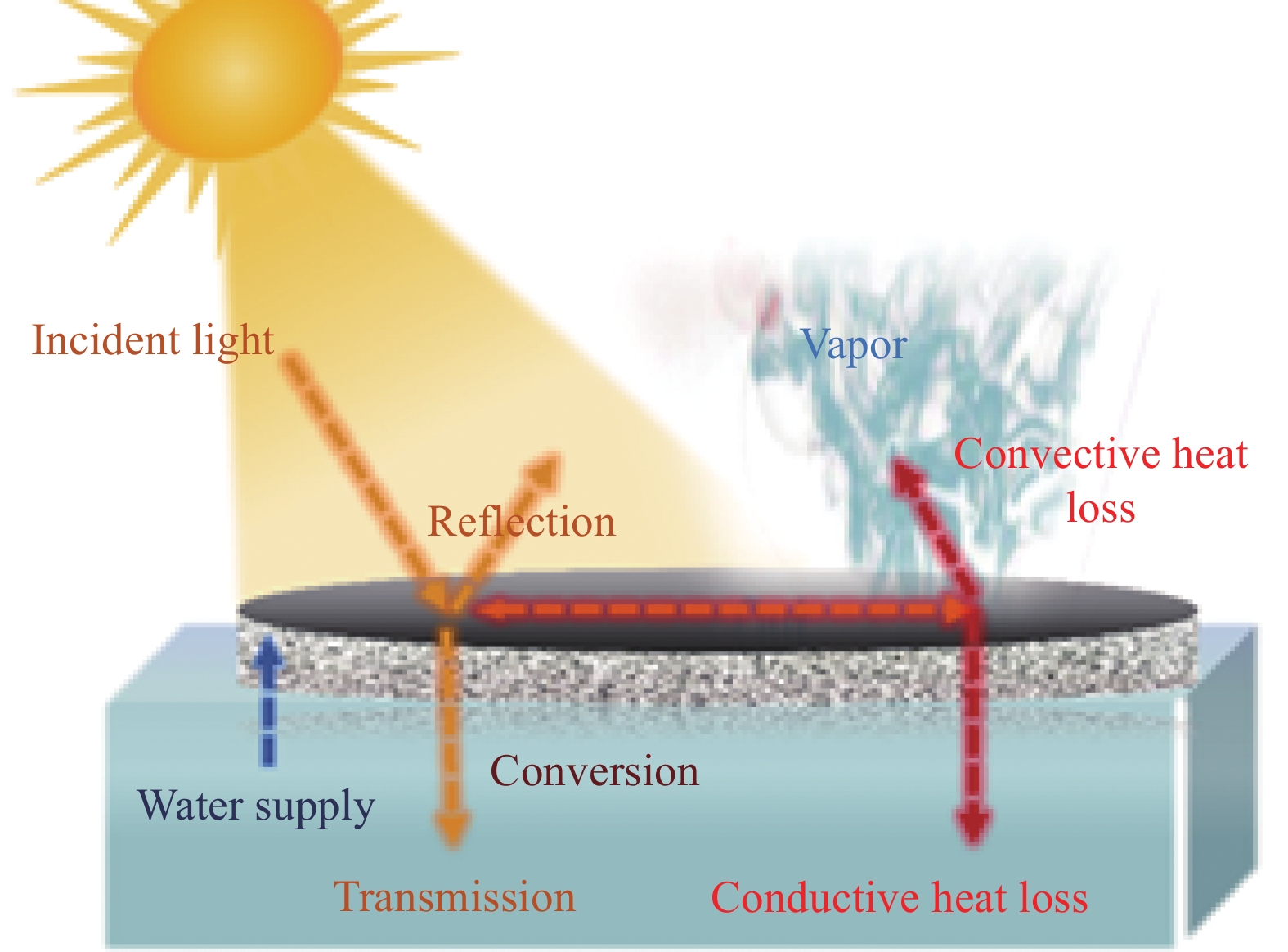

界面光热水蒸发工作原理如图1所示,太阳光照射到光热层表面,部分入射光被转换为热量,而另一部分光线则被反射和透射到环境中。光热材料产生的热量一部分用于加热表层海水,另一部分则通过向下的热传导传递到底层海水中,向上的热辐射散失到周围环境中,因此通常引入隔热材料阻止热量损失。输水材料将适量水分传输至光热材料表面用于蒸发。供水量与蒸发速率应该实现动态平衡。供水量过大会造成热量损失,而供水量不足难以连续产生蒸汽。

界面光水蒸发系统的工作效率可由太阳光吸收率和蒸发效率来表征。太阳光吸收率取决于吸收光与入射光能量之比,是衡量光热材料吸收太阳能力的重要指标。太阳光吸收率可通过下式计算[22]:

A(λ)=1−R(λ)−T(λ) (1) As=∫λmin (2) 其中:

A\left(\lambda \right) 表示在波长λ下的吸收性能;{R}\left(\mathrm{\lambda }\right) 表示在波长λ下的反射性能;{T}\left(\mathrm{\lambda }\right) 表示在波长λ下的传输性能;I\left(\lambda \right) 表示在波长λ下的能量密度;{A}_{{\rm{s}}} 表示样本在AM 1.5 G标准太阳光谱下的太阳光吸收率。水蒸发速率可以用下式表示:

{\dot{m}}_{{\rm{c}}}=\frac{\Delta m}{A\Delta t} (3) 其中:

\Delta m 表示光热转换过程中水的蒸发质量及从环境中吸收能量促进的水的蒸发质量(kg);A 表示膜面积(m−2);\Delta t 表示蒸发稳定过程中的时间(h);{\dot{m}}_{{\rm{c}}} 表示蒸发速率。蒸发效率可以用下式表示:

{n}_{{\rm{s}}}=\frac{\dot{m}{h}_{{\rm{L}}}}{{q}_{{\rm{s}}}}\times 100\mathrm{\%} (4) {h}_{{\rm{L}}}=C\Delta T+{h}_{{\rm{v}}} (5) 其中:

{n}_{{\rm{s}}} 表示蒸发效率;\dot{m} 表示蒸发速率(kg·m−2·s−1);C 是水的比热容(J/(kg·℃));\Delta T 是水表面温度的变化/是蒸汽温度和环境温度的差值(℃);{q}_{{\rm{s}}} 表示入射太阳能通量(kw·m−2);蒸发总焓变包括显热焓(C\Delta T ) 汽化潜热焓变({h}_{{\rm{v}}} )。基于上述指标,可以从以下4个方面进行优化。第一、使用在全光谱(250~2500 nm)范围内具有高光热转换能力的光热材料[23]。第二、使用隔热能力优异的材料,将热量限制在光热层,减少热辐射和热传导[24]。第三、使用具有稳定、持续的供水能力的材料,保证连续的水传输和蒸发[25]。第四、使用具有丰富微通道的多孔材料保证蒸汽逸散[26]。因此光热材料与基材的选择和合理制备对于实现高效水蒸发至关重要。

2. 界面水蒸发用碳基材料

碳基材料通过晶格振动将太阳能转换为热能。由于π键结合强度较弱,电子可以在较小能量的作用下,从π轨道激发到π*轨道。当入射光能与电子转变能量相匹配时,吸收光的电子会从最低的未占分子轨道被激发到最高的已占分子轨道,并在回到基态时释放能量,从而使局部温度升高,并向周围材料扩散[26-28]。无定形碳[29]、石墨烯家族[30]、碳纳米管(CNT)[31]已经被广泛用于界面光热水蒸发。

2.1 无定形碳材料

活性碳、炭黑(CB),近似非晶状态,具有灵活制备、结构可调、易于复合的特点[32],炭黑在宽带上有很强的吸收能力,并且原料丰富、成本低,Xu等[33]将CB沉积在聚甲基丙烯酸甲酯(PMMA)表面用于光热转换,基于CB疏水性,蒸发装置能浮在水面上。底面的聚丙烯腈(PAN)用于输水,在一个标准太阳光强照射下(1 kW·m−2),CB/PMMA-PAN表现出高效率(72%)和稳定蒸发量(1.3 kg·m−2·h−1)。但CB的稳定性较差,因此Gao等[34]通过引入海藻酸钠(SA)增加炭黑与苎麻织物间的结合力。在自然界中,许多生物材料具有精妙的输水和蒸腾作用[35],并且含有丰富的碳元素。因此,经过高温碳化可以促使生物材料表面产生活性碳,从而改善光吸收能力。Xu等[36]通过碳化蘑菇得到了伞状蒸发装置。Liu等[37]通过炭化丝瓜得到双层结构的蒸发装置,顶部炭化丝瓜蒸发效率可达89.9%。

2.2 石墨烯家族

石墨烯家族材料主要分为3类:石墨烯、氧化石墨烯(GO)、氧化还原石墨烯(rGO)。石墨烯材料表现出比表面积大、质量轻、摩尔比热小、德拜温度高,光吸收高的优点,是一种极具开发前景的光热材料[38]。石墨烯加工性高,可通过简单掺杂进行优化。如Ito等[39]通过气相沉积制备了3D多孔氮掺杂石墨烯,实验表明氮掺杂能显著提高石墨烯的亲水性和降低其导热系。GO含有极性官能团,如羟基、羧基,在水溶液中具有良好的分散性,因此GO常与聚合物结合制备光热膜。Li等[40]将GO和CB配制成复合溶液,采用3D打印和冷冻干燥的方法,将GO/CB溶液制备成光热膜,该光热膜在全光谱范围内表现出99%的吸收率。GO进一步还原为rGO可以提高其光热转换能力。Hu等[41]通过掺入多壁碳纳米管和海藻酸钠增强GO气凝胶的光吸收性和亲水性,最后通过热处理将

\mathrm{G}\mathrm{O} 还原为rGO,增加了气凝胶的光吸收率2.3 碳纳米管

除了优异的光吸收能力,CNT还具有良好的物理、化学稳定性,因此CNT能够和各种聚合物进行复合[42]。Yang等[43]制备了基于MoS2纳米片的单壁碳纳米管超薄多孔光热膜,由于局部的热封闭效应,光热薄膜能够快速升温。对CNT进行亲水性改性处理,有助于增加薄膜状态下的液体,提高蒸发量[44]。Hu等[45]对多壁碳纳米管表面进行O2-等离子亲水改性处理,超亲水光热层具有快速水分供应和溶解盐的特点,在一个标准太阳光强下,蒸发速率可达到1.72 kg·m−2·h−1。除了亲水改性处理,CNT与天然亲水基质结合也是一种常见的制备方法。Chen等[46]将CNTs涂覆在柔性木膜上,借助木材内部的微通道现实快速水分运输。Zhang等[47]在棉织物表面交替沉积CNT膜和金属纳米粒子膜开发了一体式蒸发装置。基于棉织物的亲水性,可以实现充分供水而加速蒸汽的产生。

3. 界面水蒸发用碳基纤维材料

碳基材料具有高强高模、化学性能稳定、吸收波段宽的优点,但单一碳基材料的光热转换效率有限。因此,纤维材料和碳基材料的复合与结构设计是目前研究的热点。碳基纤维材料成本低可满足大规模生产的需求,此外,其生物相容性、可再生性和可降解性也受到了广泛关注。碳基纤维材料毛细作用及亲水性有利于高效的供水,低导热性提高了隔热性能。高结晶度赋予了出色的力学性能,能够抵抗外界作用力。碳基纤维材料可加工成多孔结构,保证蒸汽及时逸散到空气中,并且多孔粗糙表面能够增加光反射和散射。图2总结了碳基材料的性能优势、碳基纤维材料的分类及碳基纤维材料的制备方法。

3.1 碳化织物

纤维材料大多由纤维素和木质素组成,它们含碳量丰富,通过高温处理、激光灼烧、热压等方法,可以促使生物质热解生成无定形碳。随着碳化温度升高,纤维材料中的C—O和C—H键被破坏,产生C=C键,纤维材料表面变黑形成无定形碳,进而增加了纤维材料的光吸收能力[51]。无定形的孔径可以通过热解温度、时间、催化剂和热解后活化来控制。

Wu等[52]将棉纤维通过火焰碳化,促使棉纤维表面形成碳质层,增加光吸收。随后通过聚多巴胺(PDA)负载处理,进一步提高碳化棉纤维的亲水性和光吸收率,最终得到碳化织物的光吸收率可达93.8%。Lin等[53]通过“一步碳化法”制备了一种碳化纤维素纸,将商用纤维产品浸入硫酸、水和乙醇的混合溶液,在烘箱中加热后洗涤、干燥得到碳化膜。碳化后的纤维材料有着较高的光吸收率(92.20%)、较低的导热率。Fang等[54]采用了一种活性碳纤维布,由粘胶纤维经高温碳化和活化而成,在全光谱范围表现出大于95%的高吸收率。高温碳化使松散排列的π电子能级间隔变得紧密,赋予活性碳布宽带光吸收能力。此外,活性碳布中的单根纤维表面具有规则的沟槽结构,如图3所示,这些微观结构能够抑制光逸出,入射光能在微槽壁的表面发生多次锯齿形反射,实现5%以下的低反射,从而产生高光收收。

3.2 碳基负载织物

传统的刚性基材与碳基材料间的结合力弱,在外部机械力作用下,光热材料易脱落,并且刚性基材存在不灵活易碎的缺点。而纤维材料凭借以下优势,被广泛用作基材。第一、纤维材料表面存在大量的极性基团,因此纳米颗粒可以生长到纤维素表面[55],由于织物多孔结构和较大的比表面积,碳纳米材料与纤维材料间存在一定的界面结合力,通过简单的浸渍、涂层处理就能得到碳基负载光热织物。第二、纤维材料机械强度高、结构柔韧性好,能够在外部作用下,保持原始形态。

Zhang等[50]通过浸渍-还原的方法得到rGO-丝织物。丝织物可以通过毛细作用将水分快速运输到光热层。丝织物独特的织物结构能够延长光路,增加多重散射和提高光吸收。开放的多孔结构赋予丝织物的高透气性,为蒸汽逸散到空气中提供足够的通道。基于丝织物出色的力学性能,确保了rGO-丝织物的耐用性能,经过反复揉搓折叠,蒸发装置没有明显的损坏。洗涤30次后,rGO-丝织物的光热转化效率保持稳定,表明rGO牢固地黏附在丝织物上。Sun等[56]选择聚丙烯(PP)织物为基材,经过浸渍和原位复合的方法依次沉积CB和PDA,开发了PDA/CB@PP织物。CB纳米颗粒能够在PP纤维上构建多级结构,PDA涂层能够增加CB与PP纤维之间的附着力,并且使疏水织物表面转变为超亲水性。PDA/CB与PP织物结合稳定,可以在不分离纳米颗粒的情况下扭曲成各种形状。

3.3 碳纤维织物

碳纤维(CF)是由纤维经碳化及石墨化处理而得到的微晶石墨材料纤维,具有宽带光吸收、优异的力学性能和高化学热稳定性的特点[57]。但CF光滑而致密的表面结构和低表面能抑制了光吸收和水传输[58],碳纤维织物单独用于界面光热材料水蒸发效率不高,可以通过与吸水性强的纱线进行织造或经过后处理增加碳纤维织物的亲水性等方式提高碳纤维织物的水蒸发效率。

传统的编织工艺可以通过组织结构设计、经纬纱线选择来实现光热表面成分精准调控。Zhang等[59]采用机织工艺制造了可调控碳纤维-棉纱混纺织物(CCMF)。如图4所示,采用吸水性好、光吸收率低的棉纱为经线,具有强稳定性、高吸光性的碳纤维为纬线编织成光热织物。通过织物组织结构设计,改变织物表面碳纤维和棉纱的比例,控制蒸发速率与供水量之间的平衡。随着表面碳纤维比例的增加,CCMF的光热转换能力逐步提升,但一段时间后,盐沉积现象明显,因此引入额外的棉纱水通道,通过调整编织参数改变盐离子扩散回流的速度,实现拒盐的目的。控制经纱的数量和宽度还可以轻松构建基于CCMF的一体式大型光热水蒸发系统。Li等[60]将碳纤维放置在葡萄糖溶液中的进行水热碳化处理,成功在碳纤维表面引入羧基、羰基,改性之后的碳纤维可以通过良好的毛细管力使碳纤维高效输送包括水和有机溶剂在内的多种物质。同时水热碳化涂层增强了光的折射,光吸收率提高至93%,在1 kW·m−2强度照射下,编织碳纤维织物蒸发速率可达1.47 kg·m−2·h−1。

3.4 静电纺丝网膜

静电纺丝网膜是由纳米纤维定向或随机排列而形成纤维网状结构,相互贯通的微孔结构赋予其优异的优越的润湿性,网膜可以通过毛细管作用自动将水输送到光热层。更重要的是,静电纺丝工艺可以直接将碳基材料作为原料与聚合物进行复合纺丝,实现对光热材料成分和结构的调控。得到的光热静电纺丝织物具有巨大潜力,在各种恶劣环境中仍保持高机械强度和化学稳定性,碳材料不易从聚合物基材中脱落。

Zhu等[61]利用静电纺丝技术实现了聚合物和光热材料的复合。使用浓硫酸和硝酸的混合溶液对CNT进行氧化,改善其在有机溶剂中的分散性,再将氧化CNT和PAN混合制备前体溶液,最后对前体溶液进行静电纺丝制备CNT@PAN非织造布(图4)。CNT@PAN无纺布在宽光谱范围内表现出很强的太阳光吸收能力,光吸收效率为90.8%,在1 kW·m−2强度照射下的水蒸发速率为1.44 kg·m−2·h−1。Guo等[62]通过混合静电纺丝开发了GO功能化聚乙烯醇(PVA)光热膜(图5)。PVA和GO的结合可以改善单一组分的缺陷,GO可以作为光吸收剂分散均匀地固定在聚合物纤维中,PVA能够保证光热膜的机械强力和亲水性能。另一方面,3D纤维网状结构具有高比表面积和高孔隙率的特性,为连续供水和蒸汽逸散提供了天然优势。

3.5 3D结构织物

纤维材料的机械柔性赋予织物可加工裁剪的特点,因此织物可以被加工成任意结构以满足3D设计的需求,实现同步多维度调控以提高蒸发效率。增加太阳光吸收、增加实际蒸发面积、实现水分与热量有效管理等。

受到荷花的启发,Bu等[63]采用传统的篮子编织方法,设计了一种3D碳纤维棉基锥型蒸发系统(图6),该锥型结构能够通过改变棉棒的数量,实现供水量和蒸发效率之间的平衡,由于供水量过大会造成热量损失,而供水量不足难以连续产生蒸汽,还会导致蒸发面形成盐结晶,从而影响光吸收和蒸发速率。基于棉棒的低导热性,增加棉棒的长度可以有效减少热量向底部海水传递。同时,由于蒸发吸热,棉棒底部温度低于环境温度,可以作为第二冷蒸发区,从环境中吸取能量用于水蒸发。因此该蒸发系统的蒸发效率突破理论极限,高达194.4%。纤维材料具有出色的柔韧性,可以被折叠成各种形状,Qin等[64]将碳化胡萝卜粉负载的棉布折叠成波浪立(W)体构型,入射光能在W结构内壁发生多次反射,使光吸收达到最大化,另一方面W结构可以增加有效蒸发面积,实现高吸收率(95%)。

表1总结了近年来应用于界面水蒸发系统的碳基纤维材料应用及其相关性能指标。

表 1 碳基纤维材料性能总结Table 1. Summary of the properties of carbon-based fibrous materialsType Composition Preparation

methodSolar absorption efficiency/% Evaporation rate/(kg·m−2·h−1)* Evaporation efficiency/% Stability Ref Carbonized fabrics PDA-carbonized cotton Carbonization 93.8 1.54 88.8 10 cycles [52] Carbonized cellulose papers Carbonization 92.2 0.96 65.8 20 cycles [53] Activated carbon fiber cloth Carbonization and activation >95 1.59 93.3 12 h [54] Silk one-step Carbonization process 82 1.25 — 3 days [65] Carbon loaded fabrics RGO-silk-fabric Immersing in the GO and reduced >90 1.48 102 30 cycles [50] PDA/CB@PP

non-woven

fabricDip-coating in CB and situ polymerizing with PDA >95 1.67 91.5 — [56] CB/SA ramie

fabricImmersing in CB/SA solution 92.9-95.3 1.81 96.6 — [34] Cotton-CNT fabrics Dyeing in CNT ink 95.7 1.59 89.6 20 cycles [31] Carbon fiber based fabrics Carbon fiber and cotton yarn mixture fabric The craft of textile weaving >90 1.87 83.7 10 h [59] Carbon fiber Hydrothermal carbonization in glucose solution 93 1.47 92.5 20 cycles [60] Electrostatic

spinning

fabricsCNT@PAN nonwoven fabrics Electrospinning 90.8 1.44 81 15 cycles [61] GO/PVA membrane Blend electrospinning 91.7 1.42 94.2 16 cycles [62] CB/PMMA-PAN Sequential electrospinning

and spraying97 1.30 72 More than 16 days [33] 3D fabrics Carbon fiber-cotton based cone Basket-weaving strategy 90 3.27 194.4 6 cycles [63] W-cotton cloth-NCC Depositing carbonized carrot 95.5 1.57 85.9 7 cycles [64] 3D rGO/SA aerogel

sheetSpray coating and freezing drying 97 7.60 178.6 40 cycles [66] Active carbon Juncus effusus Decorating with activated carbon particles 97-98 2.23 — 8 h [67] Notes: *—Water evaporation rates were measured under 1 kW·m−2; PDA—Polydopamine; CB—Carbon black; PP—Polypropylene; SA—Sodium alginate; PVA—Polyvinyl alcohol; PMMA—Polymethyl methacrylate; NCC—Carbonized carrot powder modified cotton cloth with Nafion coating on one side; GO—Graphene oxide; rGO—Reduced graphene oxide. 4. 界面光热水蒸发系统的发展与展望

目前,常见的光热材料还包括等离子金属材料和半导体。纳米金属材料通过局部表面等离子共振(LSPR)产生光热效应[68],但其成本较高,与基底之间的附着力较弱,耐久性较差。此外,金属离子具有高活性因此容易腐蚀,不适合在阳光下长期使用[69]。半导体借助光吸收过程中激发电子-空穴对的松弛过程,将太阳光转换为热能。但带隙能量决定了它们的光热转换,宽带隙半导体吸光谱窄,往往需要复杂的改性提高其光热转换效率。碳基材料凭借在较宽的光吸收波段拥有较强的太阳光吸收能力和优秀的稳定性,近年来成为了一种热门的光热转换材料。但目前界面光热水蒸发系统仍存在一些突出的问题有待解决。

界面光热水蒸发系统的可延展性是实现实际应用的前提,基于部分材料的可加工性,有望实现低成本、大规模生产,但目前依旧局限于实验阶段。并且大多研究缺少对蒸发装置生产成本,后期维护等相关成本及可延展性的系统分析。未来工作应该集中于开发低成本、可规模化生产的蒸发装置。

户外耐腐蚀性是界面光热水蒸发系统满足实际应用中的一个关键因素,尽管大部分光热材料都具有优异的力学性能和化学稳定性,但海水中的微生物长期堆积在蒸发装置表面,会对蒸发装置造成腐蚀;长期暴露在阳光、风和雨中,会降低其力学性能。并且对于水蒸发系统在户外使用的耐腐蚀性缺少系统评价。未来应该进一步提高碳基纤维材料力学性能和化学稳定性。

蒸发装置上的盐积累是障碍长期稳定蒸发的关键难题。目前虽然开发了具有防污性能的蒸发装置,但稳定运行时间有限。未来应该开发在户外使用中仍具有自清洁能力的蒸发装置及探究在实际使用中如何及时、快速地除去表面积累的盐分而不中断蒸发过程。

蒸发过程中高效的淡水收集是最终目的,目前的淡水主要在密闭空间中收集,但水蒸气冷凝不完全会在蒸发罩表面产生水雾,从而增加了光反射,降低了蒸发效率。未来需要开发新型蒸发罩,在实现淡水收集的同时保证高效的蒸发效率。

目前对蒸发效率的系统评估大多在恒温和无风的实验条件下。而户外运行中,可能会面临风速、温湿度及太阳光强度等变量的影响。因此需要制定标准化的测试方法和指标,以便客观地评价其户外蒸发效率。

5. 总结

作为界面光热水蒸发材料,碳材料具有高化学稳定性、宽光吸收范围、高光热转换效率、比表面积大、具有亲水性和良好的水传输性能等优点;而纤维材料作为基材具有以下优势:(1) 低导热性可以抑制热量散失;(2) 亲水性和毛细管效应能够构建输水通路,保证水体及时被补充到蒸发表面;(3) 高孔隙率较好地保留织物的透气性,加速蒸汽能逸散;(4) 与刚性基材相比,纤维材料的高强度和机械柔性有利于稳定负载,易加工和便携。因此碳基纤维材料的应用能有效结合两者优势,有望推动界面光热水蒸发领域的发展。

-

表 1 碳基纤维材料性能总结

Table 1 Summary of the properties of carbon-based fibrous materials

Type Composition Preparation

methodSolar absorption efficiency/% Evaporation rate/(kg·m−2·h−1)* Evaporation efficiency/% Stability Ref Carbonized fabrics PDA-carbonized cotton Carbonization 93.8 1.54 88.8 10 cycles [52] Carbonized cellulose papers Carbonization 92.2 0.96 65.8 20 cycles [53] Activated carbon fiber cloth Carbonization and activation >95 1.59 93.3 12 h [54] Silk one-step Carbonization process 82 1.25 — 3 days [65] Carbon loaded fabrics RGO-silk-fabric Immersing in the GO and reduced >90 1.48 102 30 cycles [50] PDA/CB@PP

non-woven

fabricDip-coating in CB and situ polymerizing with PDA >95 1.67 91.5 — [56] CB/SA ramie

fabricImmersing in CB/SA solution 92.9-95.3 1.81 96.6 — [34] Cotton-CNT fabrics Dyeing in CNT ink 95.7 1.59 89.6 20 cycles [31] Carbon fiber based fabrics Carbon fiber and cotton yarn mixture fabric The craft of textile weaving >90 1.87 83.7 10 h [59] Carbon fiber Hydrothermal carbonization in glucose solution 93 1.47 92.5 20 cycles [60] Electrostatic

spinning

fabricsCNT@PAN nonwoven fabrics Electrospinning 90.8 1.44 81 15 cycles [61] GO/PVA membrane Blend electrospinning 91.7 1.42 94.2 16 cycles [62] CB/PMMA-PAN Sequential electrospinning

and spraying97 1.30 72 More than 16 days [33] 3D fabrics Carbon fiber-cotton based cone Basket-weaving strategy 90 3.27 194.4 6 cycles [63] W-cotton cloth-NCC Depositing carbonized carrot 95.5 1.57 85.9 7 cycles [64] 3D rGO/SA aerogel

sheetSpray coating and freezing drying 97 7.60 178.6 40 cycles [66] Active carbon Juncus effusus Decorating with activated carbon particles 97-98 2.23 — 8 h [67] Notes: *—Water evaporation rates were measured under 1 kW·m−2; PDA—Polydopamine; CB—Carbon black; PP—Polypropylene; SA—Sodium alginate; PVA—Polyvinyl alcohol; PMMA—Polymethyl methacrylate; NCC—Carbonized carrot powder modified cotton cloth with Nafion coating on one side; GO—Graphene oxide; rGO—Reduced graphene oxide. -

[1] GAO S W, DONG X L, HUANG J Y, et al. Bioinspired soot-deposited janus fabrics for sustainable solar steam generation with salt-rejection[J]. Glob Chall,2019,3(8):1800117.

[2] LI G P, LU L. Modeling and performance analysis of a fully solar-powered stand-alone sweeping gas membrane distillation desalination system for island and coastal households[J]. Energy Conversion and Management,2020,205:112375.

[3] MENG X Y, XU W L, LI Z H, et al. Coupling of hierarchical Al2O3/TiO2 nanofibers into 3D photothermal aerogels toward simultaneous water evaporation and purification[J]. Advanced Fiber Materials,2020,2(2):93-104. DOI: 10.1007/s42765-020-00029-9

[4] KIM H, KIM T, ABD AZIZ A, et al. Structural heterogeneity yet high similarity of the microbial community on reverse osmosis membrane-driven biofilms during seawater desalination[J]. Environmental Science: Water Research& Technology,2020,6(11):3066-3079.

[5] CHANG J, ZUO J, LU K J, et al. Membrane development and energy analysis of freeze desalination-vacuum membrane distillation hybrid systems powered by LNG regasification and solar energy[J]. Desalination,2019,449:16-25. DOI: 10.1016/j.desal.2018.10.008

[6] GIACALONE F, CATRINI P, GURRERI L, et al. Exergy analysis of electrodialysis for water desalination: Influence of irreversibility sources[J]. Energy Conversion and Management,2022,258:115314.

[7] DONG X Y, SI Y, CHEN C J, et al. Reed leaves inspired silica nanofibrous aerogels with parallel-arranged vessels for salt-resistant solar desalination[J]. ACS Nano,2021,15(7):12256-12266. DOI: 10.1021/acsnano.1c04035

[8] BIAN Y, TANG K, TIAN L Y, et al. Sustainable solar evaporation while salt accumulation[J]. ACS Applied Materials & Interfaces,2021,13(4):4935-4942. DOI: 10.1021/acsami.0c17177

[9] HUANG L, WANG Y P, HE R J, et al. Solar-driven co-generation of electricity and water by evaporation cooling[J]. Desalination,2020,488:114533.

[10] TAO P, NI G, SONG C Y, et al. Solar-driven interfacial evaporation[J]. Nature Energy,2018,3(12):1031-1041. DOI: 10.1038/s41560-018-0260-7

[11] HAN X H, DING S Q, FAN L W, et al. Janus biocomposite aerogels constituted of cellulose nanofibrils and MXenes for application as single-module solar-driven interfacial evaporators[J]. Journal of Materials Chemistry A,2021,9(34):18614-18622. DOI: 10.1039/D1TA04991G

[12] CHEN Z C, LI A, CHEN X M. Porous graphene/polyimide membrane with a three-dimensional architecture for rapid and efficient solar desalination via interfacial evaporation[J]. ACS Sustainable Chemistry & Engineering,2020,8(36):13850-13858. DOI: 10.1021/acssuschemeng.0c05306

[13] WANG C B, WANG J L, LI Z T, et al. Superhydrophilic porous carbon foam as a self-desalting monolithic solar steam generation device with high energy efficiency[J]. Journal of Materials Chemistry A,2020,8(19):9528-9535. DOI: 10.1039/D0TA01439G

[14] GE C, SONG Z H, YUAN Y, et al. Solar steam generation by porous conducting polymer hydrogel[J]. Solar Energy,2022,240:237-245. DOI: 10.1016/j.solener.2022.05.038

[15] ZHANG D, CAI Y X, LIANG Q Q, et al. Scalable, flexible, durable, and salt-tolerant CuS/bacterial cellulose gel membranes for efficient interfacial solar evaporation[J]. ACS Sustainable Chemistry& Engineering,2020,8(24):9017-9026. DOI: 10.1021/acssuschemeng.0c01707

[16] FU Y, WANG G, MEI T, et al. Accessible graphene aerogel for efficiently harvesting solar energy[J]. ACS Sustainable Chemistry & Engineering,2017,5(6):4665-4671. DOI: 10.1021/acssuschemeng.6b03207

[17] ZHAO X Z, LIU C K. Enhanced solar evaporation efficiency based on the inserted preheating zone of silver nanowires[J]. Solar Energy,2020,195:304-309. DOI: 10.1016/j.solener.2019.11.054

[18] HAO L, LIU N, NIU R, et al. High-performance salt-resistant solar interfacial evaporation by flexible robust porous carbon/pulp fiber membrane[J]. Science China Materials,2022,65(1):201-212. DOI: 10.1007/s40843-021-1721-6

[19] HE J X, FAN Y K, XIAO C H, et al. Enhanced solar steam generation of hydrogel composite with aligned channel and shape memory behavior[J]. Composites Science and Technology,2021,204:108633.

[20] 李成欣, 高助威, 刘钟馨, 等. 氧化石墨烯负载无纺布复合膜的制备及光热转换性能[J]. 复合材料学报, 2021, 38(12):4255-4262. DOI: 10.13801/j.cnki.fhclxb.20210304.001 LI C X, GAO Z W, LIU Z X, et al. Preparation of graphene oxide supported non-woven fabric composite membrane and its photothermal conversion performance[J]. Acta Materiae Compositae Sinica,2021,38(12):4255-4262(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210304.001

[21] HAN J, XING W Q, YAN J, et al. Stretchable and superhydrophilic polyaniline/halloysite decorated nanofiber compo-site evaporator for high efficiency seawater desalination[J]. Advanced Fiber Materials, 2022, 4(5): 1233-1245.

[22] ZHAO F, GUO Y H, ZHOU X Y, et al. Materials for solar-powered water evaporation[J]. Nature Reviews Materials,2020,5(5):388-401. DOI: 10.1038/s41578-020-0182-4

[23] LUO Y Q, SONG F, WU J M, et al. A nature-inspired suspended solar evaporator for water desalination of high-salinity brines[J]. Chemical Engineering Journal,2021,421(1):129824.

[24] FAN X Q, YANG Y, SHI X L, et al. A MXene-based hierarchical design enabling highly efficient and stable solar-water desalination with good salt resistance[J]. Advanced Functional Materials,2020,30(52):2007110.

[25] LI Y, HONG W P, LI H R, et al. Solar absorber with tunable porosity to control the water supply velocity to accelerate water evaporation[J]. Desalination,2021,511:115113.

[26] ZHANG Y X, XIONG T, NANDAKUMAR D K, et al. Structure architecting for salt-rejecting solar interfacial desalination to achieve high-performance evaporation with in situ energy generation[J]. Advanced Science,2020,7(9):1903478.

[27] XIE Z J, ZHU J T, ZHANG L B. Three-dimensionally structured polypyrrole-coated setaria viridis spike composites for efficient solar steam generation[J]. ACS Applied Materials & Interfaces,2021,13(7):9027-9035. DOI: 10.1021/acsami.0c22917

[28] PHAM T T, NGUYEN T H, NGUYEN T A H, et al. Durable, scalable and affordable iron (III) based coconut husk photothermal material for highly efficient solar steam generation[J]. Desalination,2021,518:115280.

[29] LI S Y, QIU F, XIA Y G, et al. Integrating a self-floating janus TPC@CB sponge for efficient solar-driven interfacial water evaporation[J]. ACS Applied Materials & Interfaces,2022,14(17):19409-19418. DOI: 10.1021/acsami.2c01359

[30] FINNERTY C, ZHANG L, SEDLAK D L, et al. Synthetic graphene oxide leaf for solar desalination with zero liquid discharge[J]. Environmental Science & Technology,2017,51(20):11701-11709. DOI: 10.1021/acs.est.7b03040

[31] KOU H, LIU Z X, ZHU B, et al. Recyclable CNT-coupled cotton fabrics for low-cost and efficient desalination of seawater under sunlight[J]. Desalination,2019,462:29-38. DOI: 10.1016/j.desal.2019.04.005

[32] ZHANG Q, XU W L, WANG X B. Carbon nanocomposites with high photothermal conversion efficiency[J]. Science China Materials,2018,61(7):905-914. DOI: 10.1007/s40843-018-9250-x

[33] XU W C, HU X Z, ZHUANG S D, et al. Flexible and salt resistant janus absorbers by electrospinning for stable and efficient solar desalination[J]. Advanced Energy Materials,2018,8(14):1702884.

[34] GAO C, ZHU J J, BAI Z Q, et al. Novel ramie fabric-based draping evaporator for tunable water supply and highly efficient solar desalination[J]. ACS Applied Materials & Interfaces,2021,13(6):7200-7207. DOI: 10.1021/acsami.0c20503

[35] CHEN C J, KUANG Y D, HU L B. Challenges and opportunities for solar evaporation[J]. Joule,2019,3(3):683-718. DOI: 10.1016/j.joule.2018.12.023

[36] XU N, HU X Z, XU W C, et al. Mushrooms as efficient solar steam-generation devices[J]. Advanced Materials,2017,29(28):1606762.

[37] LIU C, HONG K V, SUN X, et al. An 'antifouling' porous loofah sponge with internal microchannels as solar absorbers and water pumpers for thermal desalination[J]. Journal of Materials Chemistry A,2020,8(25):12323-12333. DOI: 10.1039/D0TA03872E

[38] DAO V D, CHOI H S. Carbon-based sunlight absorbers in solar-driven steam generation devices[J]. Global Challenges,2018,2(2):1700094.

[39] ITO Y, TANABE Y, HAN J H, et al. Multifunctional porous graphene for high-efficiency steam generation by heat localization[J]. Advanced Materials,2015,27(29):4302-4307. DOI: 10.1002/adma.201501832

[40] LI Y J, GAO T T, YANG Z, et al. Graphene oxide-based evaporator with one-dimensional water transport enabling high-efficiency solar desalination[J]. Nano Energy,2017,41:201-209. DOI: 10.1016/j.nanoen.2017.09.034

[41] HU X Z, XU W C, ZHOU L, et al. Tailoring graphene oxide-based aerogels for efficient solar steam generation under one sun[J]. Advanced Materials,2017,29(5):1604031.

[42] GUAN W X, GUO Y H, YU G H. Carbon materials for solar water evaporation and desalination[J]. Small,2021,17(48):2007176.

[43] YANG X D, YANG Y B, FU L N, et al. An ultrathin flexible 2D membrane based on single-walled nanotube-MoS2 hybrid film for high-performance solar steam generation[J]. Advanced Functional Materials,2018,28(3):1704505.

[44] WANG Y C, ZHANG L B, WANG P. Self-floating carbon nanotube membrane on macroporous silica substrate for highly efficient solar-driven interfacial water evaporation[J]. ACS Sustainable Chemistry & Engineering,2016,4(3):1223-1230. DOI: 10.1021/acssuschemeng.5b01274

[45] HU T, LI L X, YANG Y F, et al. A yolk@shell superhydrophobic/superhydrophilic solar evaporator for efficient and stable desalination[J]. Journal of Materials Chemistry A,2020,8(29):14736-14745. DOI: 10.1039/D0TA04917D

[46] CHEN C J, LI Y J, SONG J W, et al. Highly flexible and efficient solar steam generation device[J]. Advanced Materials,2017,29(30):1701756.

[47] ZHANG C, XIAO P, NI F, et al. Programmable interface asymmetric integration of carbon nanotubes and gold nanoparticles toward flexible, configurable, and surface-enhanced raman scattering active all-in-one solar-driven evaporators[J]. Energy Technology: Generation, Conversion, Storage, Distribution,2019,7(11):1900787.

[48] XIAO P, GU J C, ZHANG C, et al. A scalable, low-cost and robust photo-thermal fabric with tunable and programmable 2D/3D structures towards environmentally adaptable liquid/solid-medium water extraction[J]. Nano Energy,2019,65:104002.

[49] WAN P, GU X B, OUYANG X L, et al. A versatile solar-powered vapor generating membrane for multi-media purification[J]. Separation and Purification Technology,2021,260:117952.

[50] ZHANG Q, XIAO X F, WANG G, et al. Silk-based systems for highly efficient photothermal conversion under one sun: Portability, flexibility, and durability[J]. Journal of Materials Chemistry A,2018,6(35):17212-17219. DOI: 10.1039/C8TA05193C

[51] ZHANG J, LONG H R, ZHANG P H. Structure and characterization of carbonized cotton knitted fabric[J]. Textile Research Journal, 2022, 92(19-20) : 3719-3732.

[52] WU X, WU L M, TAN J, et al. Evaporation above a bulk water surface using an oil lamp inspired highly efficient solar-steam generation strategy[J]. Journal of Materials Chemistry A,2018,6(26):12267-12274. DOI: 10.1039/C8TA03280G

[53] LIN X F, YANG M J, HONG W, et al. Commercial fiber products derived free-standing porous carbonized-membranes for highly efficient solar steam generation[J]. Frontiers in Materials,2018,5:6217-6221. DOI: 10.3389/fmats.2018.00008

[54] FANG Q L, LI T T, LIN H B, et al. Highly efficient solar steam generation from activated carbon fiber cloth with matching water supply and durable fouling resistance[J]. ACS Applied Energy Materials,2019,2(6):4354-4361. DOI: 10.1021/acsaem.9b00562

[55] SHANG M Y, XU S H, LI J L, et al. CuS hollow nanospheres/cellulose composite film as a recyclable interfacial photothermal evaporator for solar steam generation[J]. Energy Technology,2022,10(2): 2100805.

[56] SUN S J, SUN B B, WANG Y M, et al. Carbon black and polydopamine modified non-woven fabric enabling efficient solar steam generation towards seawater desalination and wastewater purification[J]. Separation and Purification Technology,2022,278:119621.

[57] 陈根余, 陶能如, 李明全, 等. 碳纤维复合材料激光制孔技术研究进展[J]. 复合材料学报, 2022, 39(4):1395-1410. DOI: 10.13801/j.cnki.fhclxb.20211115.002 CHEN G Y, TAO N R, LI M Q, et al. Research progress of laser drilling technology for carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica,2022,39(4):1395-1410(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20211115.002

[58] TONG D D, SONG B. A high-efficient and ultra-strong interfacial solar evaporator based on carbon-fiber fabric for seawater and wastewater purification[J]. Desalination,2022,527:115586.

[59] ZHANG Q, XIAO X F, ZHAO G M, et al. An all-in-one and scalable carbon fibre-based evaporator by using the weaving craft for high-efficiency and stable solar desalination[J]. Journal of Materials Chemistry A,2021,9(17):10945-10952. DOI: 10.1039/D1TA01295A

[60] LI T T, FANG Q L, XI X F, et al. Ultra-robust carbon fibers for multi- media purification via solar- evaporation[J]. Journal of Materials Chemistry A,2019,7(2):586-593. DOI: 10.1039/C8TA08829B

[61] ZHU B, KOU H, LIU Z X, et al. Flexible and washable CNT-embedded PAN nonwoven fabrics for solar-enabled evaporation and desalination of seawater[J]. ACS Applied Materials & Interfaces,2019,11(38):35005-35014. DOI: 10.1021/acsami.9b12806

[62] GUO X X, GAO H, WANG S Y, et al. Scalable, flexible and reusable graphene oxide-functionalized electrospun nanofibrous membrane for solar photothermal desalination[J]. Desalination,2020,488:114535.

[63] BU Y M, ZHOU Y H, LEI W W, et al. A bioinspired 3D solar evaporator with balanced water supply and evaporation for highly efficient photothermal steam generation[J]. Jour-nal of Materials Chemistry A,2022,10(6):2856-2866. DOI: 10.1039/D1TA09288J

[64] QIN Z, SUN H, TANG Y N, et al. Bioinspired hydrophilic-hydrophobic janus composites for highly efficient solar steam generation[J]. ACS Applied Materials & Interfaces,2021,13(16):19467-19475. DOI: 10.1021/acsami.1c02026

[65] QI P, REN J, LING S J. Animal silk-derived amorphous carbon fibers for electricity generation and solar steam evaporation[J]. Frontiers in Chemistry,2021,9:669797.

[66] GAO T, WU X, WANG Y D, et al. A hollow and compressible 3D photothermal evaporator for highly efficient solar steam generation without energy loss[J]. Solar RRL,2021,5(5):2100053.

[67] ZHANG Q, REN L P, XIAO X F, et al. Vertically aligned Juncus effusus fibril composites for omnidirectional solar evaporation[J]. Carbon,2020,156:225-233. DOI: 10.1016/j.carbon.2019.09.067

[68] XU J T, JIANG S X, WANG Y X, et al. Photo-thermal conversion and thermal insulation properties of ZrC coated polyester fabric[J]. Fibersand Polymers,2017,18(10):1938-1944. DOI: 10.1007/s12221-017-1237-z

[69] TESSEMA A A, WU C M, MOTORA K G, et al. Highly-efficient and salt-resistant CsxWO3@g-C3N4/PVDF fiber membranes for interfacial water evaporation, desalination, and sewage treatment[J]. Composites Science and Technology,2021,211:108865. DOI: 10.1016/j.compscitech.2021.108865

-

期刊类型引用(2)

1. 吴浩,王洪杰,王赫,苏永生,胡侨乐,阮芳涛. 碳纤维基太阳能驱动界面水蒸发器件研究进展. 复合材料学报. 2025(02): 692-703 .  本站查看

本站查看

2. 洪勋,陆少锋,师文钊,姚东霞,孙远见,黄镇恒. 光热转换相变微胶囊的制备及研究进展. 上海纺织科技. 2024(09): 7-12+17 .  百度学术

百度学术

其他类型引用(3)

-

下载:

下载: