Effect of monodoped/multi-doped carbon nanotubes and nano-titanium dioxide on mechanical and self-sensing properties of sulfoaluminate cementitious composites

-

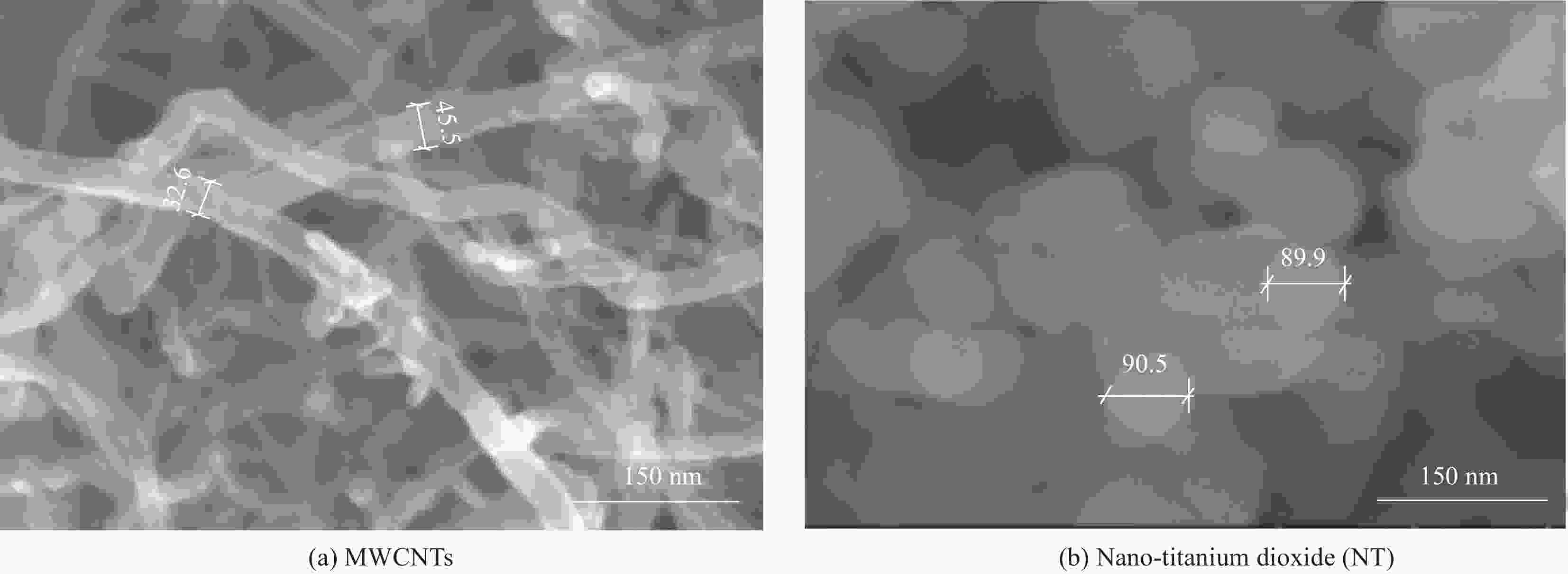

摘要: 多壁碳纳米管(MWCNTs)和锐钛型纳米二氧化钛(NT)是制备自感知水泥基材料的两种优异纳米填料。与普通硅酸盐水泥比,硫铝酸盐水泥具有低碳、耐腐蚀和强度发展快等优点,作为胶凝材料时水泥基复合材料可获得更稳定的自感知性能。因此,本文使用锐钛型纳米二氧化钛和多壁碳纳米管分别以单掺和复掺的方式复合硫铝酸盐水泥砂浆,研究了复合导电填料类型对硫铝酸盐水泥复合材料3d力学、电学和自感知性能的影响规律,并结合SEM-EDS分析了影响机制。研究结果表明:NT可显著提高硫铝酸盐水泥复合材料的3d力学性能,单掺NT的试件抗压强度、抗折强度、劈拉强度和压缩韧性较不掺NT试件分别提高了28.36%、10.67%、47.76%和9.53%。单掺MWCNTs对复合材料的导电性能改善效果最为显著,直流电阻率和频率为100 kHz时的交流电阻率较对照组分别下降了46.91%和63.87%。复掺MWCNTs-NT对复合材料自感知性能改善效果最为明显:相比于对照组,在单调压缩荷载和劈拉荷载作用下,复掺MWCNTs-NT复合材料的最大电阻率变化率、应力灵敏度和应变灵敏度分别提高了235%、211%、313%和44%、65%、648%。通过SEM-EDS观察到,就密实程度而言,单掺NT组>对照组>复掺MWCNTs-NT组>单掺MWCNTs组;就导电网络变化的敏感度而言,复掺MWCNTs-NT组>单掺NT组>单掺MWCNTs组>对照组。Abstract: The multi-walled carbon nanotubes (MWCNTs) and anatase nano-titanium dioxide (NT) are excellent fillers for the preparation of self-sensing cement-based materials. Moreover, compared with ordinary Portland cement, sulfoaluminate cement has the advantages of low carbon, corrosion resistance and rapid strength development, and the cement-based material can obtain more stable self-sensing performance when used as a matrix. Therefore, this paper prepared sulfoaluminate cement mortar specimens using NT and MWCNTs in either single-addition or double-addition form. Then, the effects of different conductive fillers on the mechanical properties, electrical properties and self-sensing properties of the sulfoaluminate cementitious composites were studied at 3d, and the mechanisms were analyzed by SEM-EDS. The results show that the early mechanical properties of sulphoaluminate cementitious composites were significantly improved by adding NT. Compared to the control group, the compressive strength, flexural strength, splitting tensile strength, and compressive toughness of the cementitious composites with NT increased by 28.36%, 10.67%, 47.76%, and 9.53% , respectively. The single-addition of MWCNTs has the most significant effect on improving the conductivity. Compared with the control group, the DC resistivity and AC resistivity at a frequency of 100 kHz decreased by 46.91% and 63.87%, respectively. The double-addition of MWCNTs-NT has the most significant effect on improving the self-sensing properties of the sulfoaluminate cementitious composites. Compared with the control group, the maximum fractional change in resistivity, stress and strain sensitivity of the sulfoaluminate cementitious composites with MWCNTs-NT under monotonic compression load and splitting tensile load increased by 235%, 211%, 313%, and 44%, 65%, 648%, respectively. SEM-EDS showed that in terms of compactness, the mortar with NT> control group> mortar with MWCNTs-NT > mortar with MWCNTs, and in terms of the sensitivity of conductive network changes, the mortar with MWCNTs-NT > mortar with NT > mortar with MWCNTs.

-

表 1 低碱度硫铝酸盐水泥的物理性能

Table 1. Physical properties of low alkalinity sulfoaluminate cement

Stability Setting time/min Flexural strength /MPa Compressive strength/MPa Special surface are/(m2·kg−1) Initial setting time Final setting time 1 d 1 d Qualified 25 30 6.30 36.20 420 表 2 多壁碳纳米管(MWCNTs)物理参数

Table 2. Physical properties of multi-walled carbon nanotubes (MWCNTs)

Outer diameter /nm Inner diameter

/nmLength/μm Special surface area/(m2·g−1) Purity/% Color 30-80 5-15 <10 >60 >95% Black 表 3 硫铝酸盐水泥复合材料配合比

Table 3. Mix proportions of sulfoaluminate cementitious composites

Number Cement CTFA Water MWCNTs(vol%) NT(vol%) Superplasticizer(wt%) C0 T0 1 1 0.40 0 0 0 C0 T1 1 1 0.40 0 3.00 0 C1 T0 1 1 0.40 0.67 0 2.00 C1 T1 1 1 0.40 0.67 3.00 2.00 Notes: CTFA are ceramic tile fine aggregates; MWCNTs are multi-walled carbon nanotubes; NT are anatase nano-titanium dioxide. -

[1] 张洋洋, 张群力, 赵庆新, 等. 硫铝酸盐水泥水化产物-铝凝胶的研究进展[J/OL]. 材料导报. https://link.cnki.net/urlid/50.1078.TB.20240118.0953.004.ZHANG Yangyang, ZHANG Qunli, ZHAO Qingxin, et al. Research progress on aluminum hydroxide gel in calcium sulfoaluminate cement[J/OL]. Materials Reports. https://link.cnki.net/urlid/50.1078.TB.20240118.0953.004.(in Chinese). [2] SHI C J, JIMÉNEZ A F, PALOMO A. New cements for the 21st century: The pursuit of an alternative to Portland cement[J]. Cement and Concrete Research, 2011, 41(7): 750-763. doi: 10.1016/j.cemconres.2011.03.016 [3] SHAKOURI M, AHMED A A, TEYMOURI M, et al. Corrosion resistance of calcium sulfoaluminate cementitious systems[J]. Journal of Materials in Civil Engineering, 2023, 35(8): 4023238. doi: 10.1061/JMCEE7.MTENG-15178 [4] XIAO M, JU F, NING P, et al. Effects of filler type and aging on self-sensing capacity of cement paste using eddy current-based nondestructive detection[J]. Measurement, 2021, 182: 109708. doi: 10.1016/j.measurement.2021.109708 [5] HAN B G, DING S Q, YU X. Intrinsic self-sensing concrete and structures: A review[J]. Measurement, 2015, 59: 110-128. doi: 10.1016/j.measurement.2014.09.048 [6] CHEN P, CHUNG D D L. Carbon fiber reinforced concrete for smart structures capable of non-destructive flaw detection[J]. Smart Materials and Structures, 1993, 2(1): 22. doi: 10.1088/0964-1726/2/1/004 [7] DINESH A, SUJI D, PICHUMANI M. Electro-mechanical investigations of steel fiber reinforced self-sensing cement composite and their implications for real-time structural health monitoring[J]. Journal of Building Engineering, 2022, 51: 104343. doi: 10.1016/j.jobe.2022.104343 [8] 张立卿, 边明强, 郭绵珍, 等. 不同破坏荷载下镀铜钢纤维增强废弃陶瓷超高性能混凝土的压敏性[J/OL]. 复合材料学报. https://doi.org/10.13801/j.cnki.fhclxb.20230921.001.ZHANG Liqing, BIAN Mingqiang, GUO Mianzhen, et al. Piezoresistivity of copper-plated steel fibers reinforced ultra high performance concrete with ceramic waste powder under different failure load types[J/OL]. Acta Materiae Compositae Sinica, https://doi.org/10.13801/j.cnki.fhclxb.20230921.001.(in Chinese). [9] DONG S F, ZHANG W H, D'ALESSANDRO A, et al. Developing highly conductive asphalt concrete by incorporating stainless steel fibers/wires for smart pavement[J]. Journal of Materials Science, 2023, 58(27): 11062-11084. doi: 10.1007/s10853-023-08736-5 [10] DENG L, MA Y, HU J, et al. Preparation and piezoresistive properties of carbon fiber-reinforced alkali-activated fly ash/slag mortar[J]. Construction and Building Materials, 2019, 222: 738-749. doi: 10.1016/j.conbuildmat.2019.06.134 [11] 刘金涛, 洪宇超, 周煜, 等. 高强高韧机敏混凝土的制备及其性能[J/OL]. 复合材料学报. https://doi.org/10.13801/j.cnki.fhclxb.20240320.001.LIU Jintao, Hong Yuchao, ZHOU Yi, et al. Preparation and performance of smart high strength and high ductile concrete[J/OL]. Acta Materiae Compositae Sinica. https://doi.org/10.13801/j.cnki.fhclxb.20240320.001.(in Chinese). [12] LE H V, DAO P L, NGUYEN S D, et al. Improvement of the stress sensing ability of ultra-high-performance concrete using short steel fibers and steel slag aggregates under high compression[J]. Sensors and Actuators A-Physical, 2023, 362: 114616. doi: 10.1016/j.sna.2023.114616 [13] PIRO N S, MOHAMMED A S, HAMAD S M. Compressive strength and piezoresistivity of smart cement paste modified with waste steel slag[J]. Journal of Building Engineering, 2023, 70: 106393. doi: 10.1016/j.jobe.2023.106393 [14] HAN B G, HAN B Z, OU J P. Experimental study on use of nickel powder-filled Portland cement-based composite for fabrication of piezoresistive sensors with high sensitivity[J]. Sensors and Actuators A-Physical, 2009, 149(1): 51-55. doi: 10.1016/j.sna.2008.10.001 [15] DING S Q, XIANG Y, NI Y Q, et al. In-situ synthesizing carbon nanotubes on cement to develop self-sensing cementitious composites for smart high-speed rail infrastructures[J]. Nano Today, 2022, 43: 101438. doi: 10.1016/j.nantod.2022.101438 [16] 韩宝国, 关新春, 欧进萍. 纳米水泥石导电性与压敏性的试验研究[J]. 硅酸盐通报, 2004, (6): 87-90. doi: 10.3969/j.issn.1001-1625.2004.06.023HAN Baoguo, GUAN Xinchun, OU Jinping. Experimental study on conductivity and pressure sensitivity of nano-concrete[J]. Bulletin of the Chinese Ceramic Society, 2004, (6): 87-90(in Chinese). doi: 10.3969/j.issn.1001-1625.2004.06.023 [17] LIEW K M, KAI M F, ZHANG L W. Carbon nanotube reinforced cementitious composites: An overview[J]. Composites Part A-Applied Science and Manufacturing, 2016, 91: 301-323. doi: 10.1016/j.compositesa.2016.10.020 [18] LI L, WEI H, HAO Y Z, et al. Carbon nanotube (CNT) reinforced cementitious composites for structural self-sensing purpose: A review[J]. Construction and Building Materials, 2023, 392: 131384. doi: 10.1016/j.conbuildmat.2023.131384 [19] MARDANI M, LAVASSANI S, ADRESI M, et al. Piezoresistivity and mechanical properties of self-sensing CNT cementitious nanocomposites: Optimizing the effects of CNT dispersion and surfactants[J]. Construction and Building Materials, 2022, 349: 128127. doi: 10.1016/j.conbuildmat.2022.128127 [20] ISFAHANI F T, LI W W, REDAELLI E. Dispersion of multi-walled carbon nanotubes and its effects on the properties of cement composites[J]. Cement and Concrete Composites, 2016, 74: 154-163. doi: 10.1016/j.cemconcomp.2016.09.007 [21] 施韬, 朱敏, 李泽鑫, 等. 碳纳米管改性水泥基复合材料的研究进展[J]. 复合材料学报, 2018, 35(5): 1033-1049.SHI Tao, ZHU Min, LI Zexin, et al. Review of research progress on carbon nanotubes modified cementitious composites[J]. Acta Materiae Compositae Sinica, 2018, 35(5): 1033-1049(in Chinese). [22] PARK S H, HWANG J, PARK G S, et al. Modeling the electrical resistivity of polymer composites with segregated structures[J]. Nature Communications, 2019, 10: 2537. doi: 10.1038/s41467-019-10514-4 [23] JANG D, YOON H N, YANG B, et al. Synergistic effects of CNT and CB inclusion on the piezoresistive sensing behaviors of cementitious composites blended with fly ash[J]. Smart Structures and Systems, 2022, 29(2): 351-359. [24] KRAINOI A, KUMMERLOEWE C, NAKARAMONTRI Y, et al. Novel natural rubber composites based on silver nanoparticles and carbon nanotubes hybrid filler[J]. Polymer Composites, 2020, 41(2): 443-458. doi: 10.1002/pc.25378 [25] ZHANG L Q, LI L W, WANG Y L, et al. Multifunctional cement-based materials modified with electrostatic self-assembled CNT/TiO2 composite filler[J]. Construction and Building Materials, 2020, 238: 117787. doi: 10.1016/j.conbuildmat.2019.117787 [26] HU M J, LI S C, CHEN X, et al. Influences of titanium dioxide nanoparticles on regulation of crystalline growth and early carbonation of cementitious composites[J]. Ceramics Internationa, 2023, 49(23): 37366-37376. doi: 10.1016/j.ceramint.2023.09.061 [27] MOUSAVI M A, SADEGHI-NIK A, BAHARI A, et al. Strength optimization of cementitious composites reinforced by carbon nanotubes and Titania nanoparticles[J]. Construction and Building Materials, 2021, 303: 124510. doi: 10.1016/j.conbuildmat.2021.124510 [28] 张立卿, 占小静, 韩宝国, 等. 静电自组装碳纳米管/二氧化钛水泥基复合材料的自感知性能[J]. 复合材料学报, 2023, 40(9): 5225-5240.ZHANG Liqing, ZHAN Xiaojing, HAN Baoguo, et al. Self-sensing performance of cementitious composites with electrostatic self-assembly carbon nanotube/titanium dioxide[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5225-5240(in Chinese). [29] 赵昕, 黄存旺, 傅佳丽, 等. 石墨烯水泥基复合材料的电学性能[J]. 建筑材料学报, 2022, 25(1): 8-15. doi: 10.3969/j.issn.1007-9629.2022.01.002ZHAO Xin, HUANG Cunwang, FU Jiali, et al. Electrical properties of graphene cement based composites[J]. Journal of Building Materials, 2022, 25(1): 8-15(in Chinese). doi: 10.3969/j.issn.1007-9629.2022.01.002 [30] KAUR R, KOTHIYAL N C. Comparative effects of sterically stabilized functionalized carbon nanotubes and graphene oxide as reinforcing agent on physico-mechanical properties and electrical resistivity of cement nanocomposites[J]. Construction and Building Materials, 2019, 202: 121-138. doi: 10.1016/j.conbuildmat.2018.12.220 [31] LI W G, LI X Y, CHEN S J, et al. Effects of graphene oxide on early-age hydration and electrical resistivity of Portland cement paste[J]. Construction and Building Materials, 2017, 136: 506-514. doi: 10.1016/j.conbuildmat.2017.01.066 [32] DING S Q, WANG X Y, QIU L S, et al. Self-sensing cementitious composites with hierarchical carbon fiber-carbon nanotube composite fillers for crack development monitoring of a maglev girder[J]. Small, 2023, 19(9): 2206258. doi: 10.1002/smll.202206258 [33] 秦煜, 阮鹏臻, 唐元鑫, 等. 碳纳米管水泥基复合材料导电特性影响因素研究进展[J]. 硅酸盐学报, 2021, 49(2): 411-419.QIN Yu, RUAN Pengzhen, TANG Yuanxin, et al. Research progress on influencing factors on electrical conductive properties of carbon nanotubes-reinforced cement based composite materials[J]. Journal of the Chinese Ceramic Society, 2021, 49(2): 411-419(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 66

- HTML全文浏览量: 25

- 被引次数: 0

下载:

下载: