Mechanical properties and strengthening mechanism of fully recycled aggregate concrete prepared by nano-SiO2 composite carbonated recycled aggregates

-

摘要:

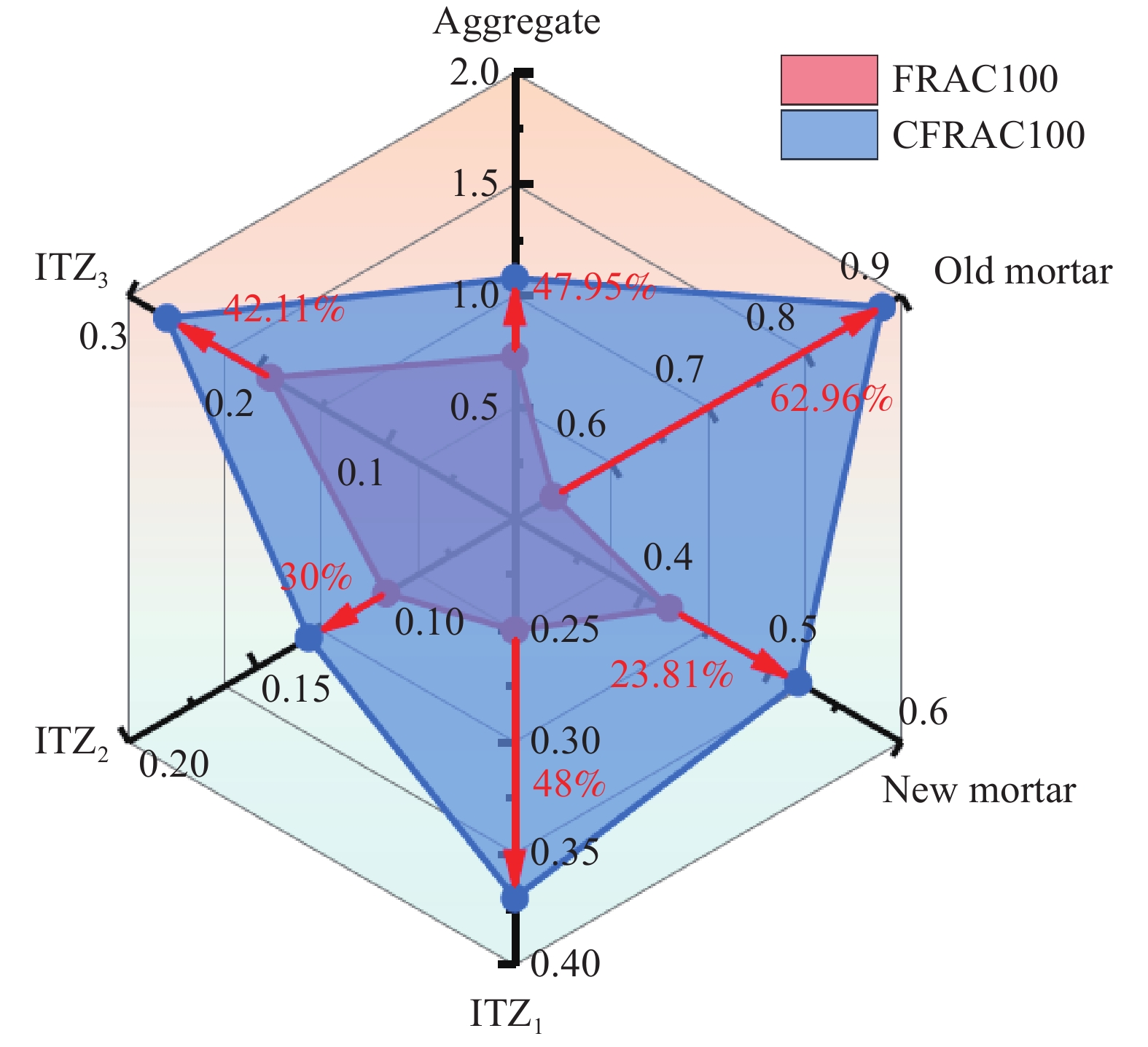

为探究碳化改性骨料对全再生骨料混凝土(FRAC)力学特性的影响规律,采用纳米SiO2 (NS)复合碳化改性再生骨料并制备FRAC,测试了其抗压性能、劈裂抗拉性能及抗折性能等宏观力学特性,采用纳米压痕测试了其微观力学性能,并结合SEM微观测试,揭示了碳化全再生骨料混凝土(CFRAC)多重界面强化机制。结果表明,NS复合碳化实现了再生粗骨料高效碳化改性,CFRAC力学特性均得到显著提高,其中抗压强度、劈裂抗拉强度及抗折强度最大提高幅度分别为33.12%、48.73%及24.53%;CFRAC各相平均弹性模量及显微硬度显著提高,最大提高幅度分别为171.05%、62.96%,其中旧砂浆及骨料-旧砂浆界面过渡区(ITZ1)微观力学性能提高幅度最显著;通过“骨料墙效应”及“ITZ碳化强化效应”揭示了CFRAC强化机制。成果为再生骨料品质提升研究及FRAC推广应用提供理论支撑。

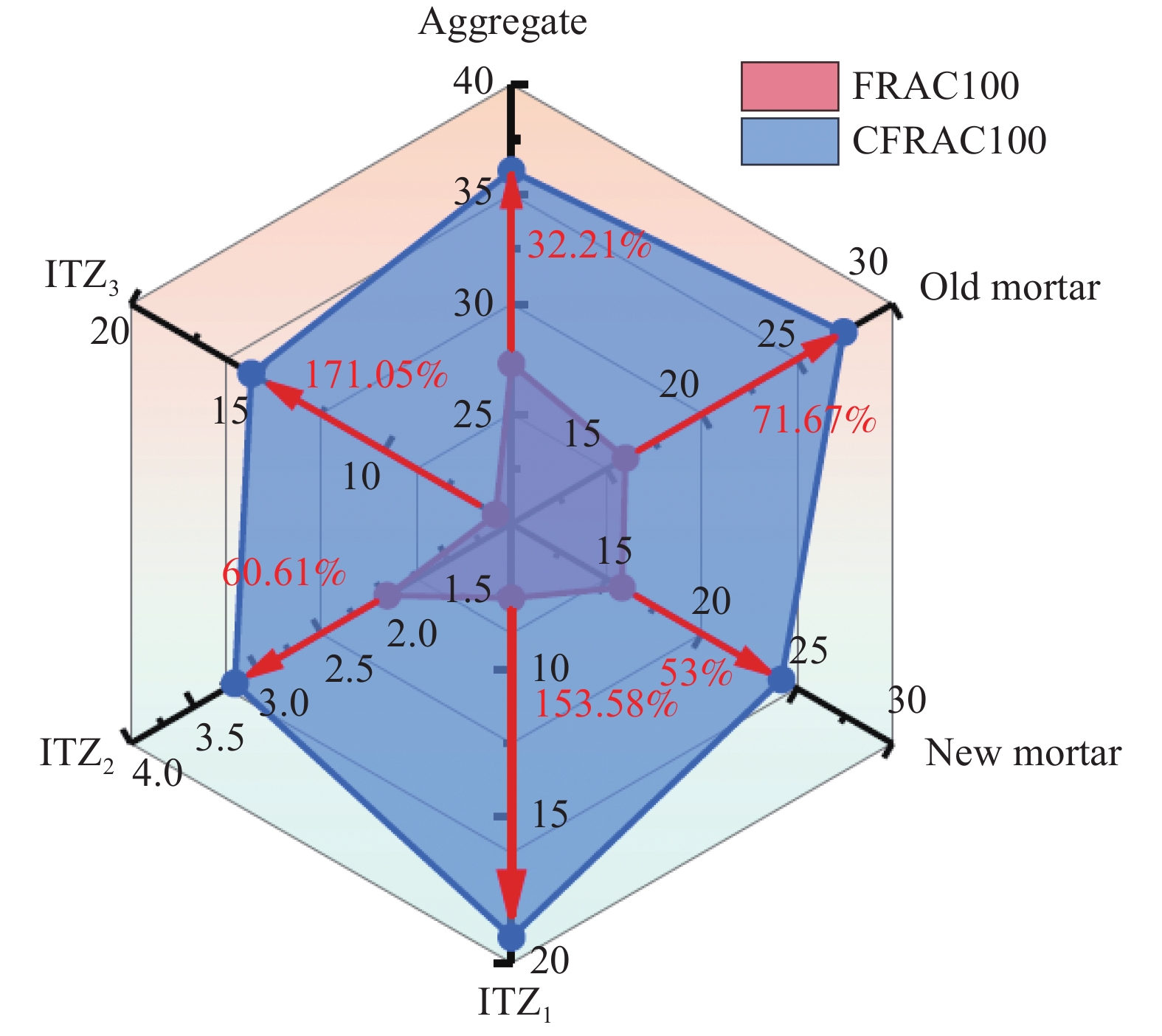

Abstract:To explore the influence of carbonated aggregate on the mechanical properties of fully recycled aggregate concrete (FRAC), FRAC using nano-SiO2 composite carbonated recycled aggregate was prepared in this paper. Macroscopic mechanical properties of FRAC including compressive strength, splitting tensile strength and flexural strength were tested, the microscopic mechanical properties of FRAC were tested by nano-indentation. Combined with SEM microscopic test, the multiple interface strengthening mechanism of carbonated fully recycled aggregate concrete (CFRAC) was revealed. The results show that nano-SiO2 composite carbonation can achieve efficient carbonation modification of recycled aggregate, and the mechanical properties of CFRAC are significantly improved. The maximum increase of compressive strength, splitting tensile strength and flexural strength are 33.12%, 48.73% and 24.53%, respectively. The average elastic modulus and micro-hardness of CFRAC are significantly improved, and the maximum increase are 171.05% and 62.96%, respectively. The micro-mechanical properties of old mortar and aggregate-old mortar interface transition zone (ITZ1) are increased most significantly. The strengthening mechanism of CFRAC is revealed by "aggregate wall effect" and "ITZ carbonation strengthening effect". The results can provide theoretical support for the research on the quality improvement of recycled aggregate and application of FRAC.

-

淡水资源短缺和能源危机已经严重影响到人类社会的可持续发展。淡水资源仅占地球水资源的2.5%[1],世界上约有24亿人常年面临严重水资源短缺的问题[2]。因此,探寻人类及工业用清洁脱盐水制备技术已成为研究热点。近年来利用太阳能生产脱盐水的技术发展成为低成本生产清洁淡水的有效途径[3-5]。太阳能蒸发是利用光吸收材料将太阳能转化为热能,从而进行水蒸发。传统的底部加热蒸发和纳米颗粒悬浮蒸发策略对体相水加热,导致光吸附效率较低。此外,两种系统都需要加热体相水,这导致热量损失,其蒸发效率在30%-70%之间,纳米颗粒悬浮蒸发策略高成本蒸发、纳米颗粒分散和回收问题使其难以大规模应用[6]。同时,界面蒸发器温度所需界面温度较低使得与热辐射和热对流有关的热损失降低[7]。因此,界面蒸发器作为一种成本低、效率高、结构简单的绿色环保型太阳能蒸发器展现出独特的优势。

水凝胶是一种通过物理或化学作用将聚合物分子链交联而成富水的具有三维网络结构的功能材料。基于其聚合物网络、交联位点和制备方法等多样性,其物理化学特性具有良好的可调控性[8-10]。此外水凝胶亲水性聚合物网络使其具有优异的吸水能力,这也使得水凝胶作为界面蒸发器提供了良好的基础[11-13]。水经由多孔结构传输到蒸发表面,结合吸光材料将太阳光吸收转化为热能以驱动水分蒸发。水凝胶界面蒸发器内部具有高度互连的多孔结构,这些多孔结构对外界是相对封闭的,而多孔结构的存在不但能够使热量集中在水凝胶界面蒸发器表面,还能够阻止热量传递到体相水及周围环境中。纤维素是一种绿色环保材料,其来源比较广泛,具有生物相容性好、储量丰富、可循环再生[14]、强度高等优点,已广泛应用于运输、医药、食品等领域。近年来,纤维素因其热膨胀系数低,刚度高,亲水性强,易改性等特点,已被广泛应用于水凝胶的制备中。将纤维素引入水凝胶中不仅可以有效地构筑3 D交联纤维网络,而且赋予水凝胶更多独特的物理性能[15]。

在水凝胶太阳能界面蒸发器的组成材料中,最不可缺的便是光热转换材料,光热转换材料有多种,包括光谱吸收范围广的碳基材料[16-18]、利用光产生等离子体共振作用[19-21]而发热的等离子体金属纳米颗粒[22-24]、半导体材料[25-27]、共轭聚合物[28-30]等材料。光热转换材料直接可以影响光热转换速率以及蒸发速率,因此选择合适的吸光材料尤为重要。MXene凭借良好的电磁波吸收能力和局部表面等离子体共振效应展现出优异的光热转换能力。

本文以纤维素纳米晶体(CNC)为原料,CNC作为力学性能增强材料,以氢键作用与琼脂糖交联网络相结合,增强琼脂糖水凝胶的力学性能,尿素和乙醇加入水中能够更充分的溶解琼脂糖,碳化钛(MXene)作为吸光材料,研究了纤维素纳米晶体加入量对纤维素纳米晶体-琼脂糖-碳化钛(Ce-CAM)复合水凝胶界面蒸发器结构与蒸发性能的影响,并对Ce-CAM复合水凝胶界面蒸发器的结构、孔径、升温曲线、海水淡化、废水净化等性能进行分析与评价。

1. 实验材料及方法

1.1 实验材料与试剂

纤维素纳米晶体(CNC,2.21%)购自天津市木精灵生物科技有限公司;尿素(Combamide)、琼脂糖(Agar)购自上海阿拉丁生化科技股份有限公司;MXene购自吉林省一一科技有限公司;乙醇(Ethyl Alcohol)购自上海国药化学试剂有限公司;氯化钠(NaCl)购自麦克林生化有限公司(上海,中国);所有化学药品均为分析级,无需进一步纯化。整个实验过程均使用的是实验室自制去离子水(18 MΩ·cm−1)。

1.2 实验方法

1.2.1 Ce-CAM复合水凝胶的制备

将一定量Agar加入去离子水配置成2%的Agar溶液,置于四个玻璃瓶内,将不同量的CNC溶液分别加入四个玻璃瓶中,使得CNC在四个玻璃瓶内的含量分别为0.5%、1%、1.5%、2%,搅拌均匀后加入0.1%的MXene溶液,搅拌均匀后超声1 h,使得MXene与溶液充分混合均匀,加入尿素、乙醇的量以Agar∶尿素∶乙醇的质量比为1∶10∶10进行添加,玻璃瓶内溶液混合均匀后将玻璃瓶置于85℃油浴中40 min,取出后将溶液倒入培养皿冷却1 h。

1.2.2 Ce-CAM复合水凝胶界面蒸发器的制备

铜柱置于液氮中充分冷却后,将在培养皿中冷却成型的Ce-CAM复合水凝胶置于底部浸泡在液氮中的铜柱顶端,以冰模板法铸造Agar水凝胶内部垂直孔结构,30 min后取出放置于冰箱内冷藏,所有样品冰模板铸造法完成后,放置于冷冻干燥机干燥48 h,取出后在去离子水中充分浸润进行测试,将CNC含量为0.5%、1%、1.5%、2%的CNC-Agar-MXene复合水凝胶分别命名为CAM1、CAM2、CAM3、CAM4,将添加尿素和乙醇的CNC含量为0.5%、1%、1.5%、2%的CNC-Agar-MXene复合水凝胶分别命名为Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4,如图1。

1.3 性能表征

1.3.1 Ce-CAM复合水凝胶界面蒸发器结构和化学的分析检测

(1)扫描电子显微镜分析

采用扫描电子显微镜(SEM,泰思肯贸易(上海)有限公司,Regulus 8220)对冷冻干燥后的Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶的截面形貌进行表征。用镊子撕取小块样品,将其粘贴在双面导电胶的表面,并固定在金属样品台上,在观察之前,将样品进行喷金处理。不同放大倍数下的加速电压为5 kV。

(2)流变仪分析

采用流变仪(德国赛默飞公司,ARES-G2,TA)测定水凝胶样品的流变性能,获得储能模量和损耗模量与角频率的相关曲线。水凝胶样品直径为25 mm,厚度为2 mm;采用直径为25 mm的不锈钢平行平板夹具,测试台温度为25℃,固定应变1%,角频率扫描范围为1-102 rad·s−1。

(3)红外光谱分析

利用扫描范围为

4000 -600 cm−1,样品分辨率和扫描次数分别为2 cm−1、32次的傅里叶红外光谱仪(FTIR,德国Bruker公司,ALPHA)对Agar水凝胶, CNC-Agar水凝胶, Ce-CAM2复合水凝胶等样品进行扫描。1.3.2 Ce-CAM复合水凝胶中的水状态研究

饱和水含量分析

饱和水含量是指完全干燥的水凝胶样品浸泡在去离子水中,样品吸水直完全润胀。即饱和水含量[31]Qs可表示为:

(1) W和Wd分别为充分膨胀样品中水分的重量和相应干燥气凝胶样品的重量。

1.3.3 Ce-CAM复合水凝胶的亲水性研究

采用动态吸收接触角(德国LAUDA Scientific公司,LSA 100)测定仪测定水凝胶样品的亲水性能。将体积为5 μL的水滴滴于样品的平整表面,以水滴在样品表面消失的时间长短反映样品的亲水性能。

1.3.4 Ce-CAM复合水凝胶的孔径研究

水凝胶样品的孔径通过全自动比表面及孔隙度分析仪BET(美国Quantachrome公司,KUBO X1000)检测,在检测之前,样品进行冷冻干燥,吸附质为N2,烘干温度为105℃,烘干时间为2 h。

1.3.5 Ce-CAM复合水凝胶的升温曲线研究

将去离子水、3.5%氯化钠溶液、制浆废液、PCr4复合水凝胶分别放置于1 kW·m−2的氙灯光源系统(北京中教金源科技有限公司,CEL-PF300-TBE)光照强度下,用红外热成像仪记录1 h内温度变化。

1.3.6 Ce-CAM复合水凝胶的太阳能吸收光谱研究

采用紫外可见近红外分光光度计(美国安捷伦科技有限公司,安捷伦Cary 7000 UV-Vis-NIR)表征水凝胶光吸收层的光谱反射率(R)和透射率(T),光谱测试范围为250-

2500 nm,采用积分球法进行基线/空白校正和暗校正,吸光率通过Kirchhoff定律(A=1-R-T)计算得到。由于材料具有一定的厚度,因此透射率几乎为0,可以忽略不计,吸光率用(1-R%)表示即可。1.3.7 Ce-CAM复合水凝胶用于制浆废液净化

(1)废液蒸发

将制浆废液、浓缩制浆废液(原浓度的2倍、3倍、4倍)倒入200 mL烧杯中,放置于电子天平,Ce-CAM2复合水凝胶充分润胀后,漂浮于制浆废液中,将氙灯光源系统调至光强为1 kW·m−2,天平连接至电脑,实时记录质量变化。

(2) COD测试主要分为以下步骤:

将样品稀释10倍,取5 mL样品放入M型COD检测管;对每个样品瓶重复以上步骤;将放入样品的M型COD检测管放入消解器(上海哈希水质分析仪器(上海)有限公司,DR3900),在105℃下消解2小时,冷却后取出;将装入样品等量去离子水的M型COD检测管放入COD氨氮总磷测试仪器(上海哈希水质分析仪器(上海)有限公司,DRB200)校准后,对其余装样品的M型COD检测管放入COD氨氮总磷测试仪器进行读数,得到的数据乘10即为样品的COD值;每个样品数据测三次,取平均值。

(3) BOD测试主要分为以下步骤:

将样品温度加热或冷却到19-21℃,如果样品中有沉淀或悬浮物,需要搅拌均匀;预估样品的BOD浓度后,将制浆废液样品稀释10倍后,用量筒量取95 mL废水样品,加入一包营养缓冲盐胶囊,混匀,加入干净、干燥的样品瓶中;在样品瓶中放入一个搅拌子;将密封杯插入样品瓶瓶口,用小勺往密封杯内添加2粒氢氧化钾;对每个样品瓶重复以上步骤;将样品瓶放在培养箱基座上,并与相应通道的管子连接,拧紧盖子,将仪器放入培养箱(唯意朴仪器(上海)有限公司,FOC 200I);培养箱温度必须为20土1℃,插上电源,仪器通电,确保所有搅拌子都在旋转;按与样品瓶对应的通道编号选择通道,按ON(开)键,此时将显示浓度范围选择菜单使用箭头键选择测试范围,使用左箭头键选择0-700 mg·L−1;按住ON(开)键5秒以上,仪器进入测量界面,开始测试,此时仪器状态显示为DELAY(延迟),有一个小时的样品均匀时间,一个小时后,仪器状态变成RUN(运行)将正式开始采集数据并显示曲线图;重复步骤8和9,为每个通道的样品瓶设置范围,开始测试,如样品少于6个,则不需要启动所有6个通道;五日培养结束后,直接读取仪器上各通道的五日数据,乘10即为样品的BOD值;每个样品数据测三次,取平均值。

1.3.8 Ce-CAM复合水凝胶用于海水淡化

利用氯化钠溶液模拟海水的环境,将不同浓度氯化钠溶液(3.5%、5%、10%、15%、20%)倒入200 mL烧杯中,放置于电子天平,Ce-CAM2复合水凝胶充分润胀后,漂浮于不同浓度的氯化钠溶液中,将氙灯光源系统调至光强为1 kW·m−2,天平连接至电脑,实时记录质量变化。

1.3.9 Ce-CAM复合水凝胶的抗盐、抗酸碱研究

(1)抗盐测试

Ce-CAM2复合水凝胶充分润胀后,厚度为1.5 cm,直径为5 cm,将其漂浮于去离子水中,表面撒一层氯化钠(2 g),记录氯化钠消失时间。

(2)抗酸碱测试

氙灯光源系统调至光强为1 kW·m−2,将Ce-CAM2复合水凝胶充分润胀后,分别漂浮于1 mol·L−1盐酸、1 mol·L−1氢氧化钠进行蒸发测试。

2. 结果与讨论

2.1 Ce-CAM复合水凝胶界面蒸发器结构和化学的分析检测

2.1.1 Ce-CAM复合水凝胶的微观形貌分析

如图2所示,(a1),(b1),(c1),(d1)分别为Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶样品的孔道截面扫描电镜图,(a2),(b2),(c2),(d2)为孔壁扫描电镜图,孔道内部表面粗糙,能够将入射的光线进行多次反射,增加对太阳光的吸收能力,从(a1),(b1),(c1),(d1)看出孔道结构高度互联,互联孔道一方面作为水的运输通道,另一方面作为排盐排污通道,迅速将表面的盐分以及污染物排除,防止盐分和污染物积累。

![]() 图 2 扫描电镜图 (a1),(b1),(c1),(d1)和(a2),(b2),(c2),(d2)分别为Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶样品的孔道和孔壁截面扫描电镜图Figure 2. Scanning electron micrographs (a1), (b1), (c1), (d1) and (a2), (b2), (c2), (d2) are scanning electron micrographs of pore channel and pore wall cross sections of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogel samples, respectively

图 2 扫描电镜图 (a1),(b1),(c1),(d1)和(a2),(b2),(c2),(d2)分别为Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶样品的孔道和孔壁截面扫描电镜图Figure 2. Scanning electron micrographs (a1), (b1), (c1), (d1) and (a2), (b2), (c2), (d2) are scanning electron micrographs of pore channel and pore wall cross sections of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogel samples, respectively2.1.2 Ce-CAM复合水凝胶的储能模量(G')、损耗模量(G'')分析

如图3所示,对Agar水凝胶,CNC-Agar水凝胶,Ce-CAM2复合水凝胶的储能模量(G')、损耗模量(G'')进行了检测,三种水凝胶的储能模量(G')均远远大于损耗模量(G''),证明三种水凝胶的具有稳定的交联网络,而且能够发生弹性形变,CNC-Agar水凝胶的储能模量(G')要高于Agar水凝胶储能模量(G'),说明CNC的加入提高了水凝胶网络的稳定性,而Ce-CAM2复合水凝胶的储能模量(G')有所降低,这是由于尿素作为增塑剂的加入,降低了CNC-Agar水凝胶的可塑性,同时Ce-CAM2复合水凝胶的孔结构不易塌陷,有着更稳定的运输水能力和排盐排污能力。

2.1.3 Ce-CAM复合水凝胶的化学成分分析

图4 显示了CNC,Agar水凝胶,Ce-CAM2复合水凝胶的傅里叶红外变换光谱图。Ce-CAM2复合水凝胶在

3365 cm−1、2898 cm−1、1060 cm−1出现了CNC的特征峰。其中位于3365 cm−1左右的吸收峰为—OH的伸缩振动峰,2898 cm−1左右的吸收峰为—CH的伸缩振动峰,1060 cm−1左右的吸收峰为C—H的伸缩振动峰,Agar中3417 cm−1、2902 cm−1和1647 cm−1的峰是由于—NH2和—OH基团的拉伸振动、—CH3的不对称拉伸、—NH2基团的弯曲振动和—C=O基团的拉伸振动[32],773、890和931 cm−1处的峰与3,6-脱水-β-半乳糖骨架弯曲有关[33],CNC含有的—OH以及Agar中的—OH和—NH2基团均为亲水基团,表明Ce-CAM2复合水凝胶具有极高的亲水性。1375 cm−1带属于−CH3对称变形,1163 cm−1和1072 cm−1的峰是C—O—C的伸缩振动和—C—O的弯曲振动[34],琼脂的特征峰均在Ce-CAM2复合水凝胶中得到体现。2.2 Ce-CAM复合水凝胶中的饱和水含量研究

如图5所示,测定了冷冻干燥后Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶的饱和水含量,Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶的饱和含水量分别为1.87 g·g−1、2.12 g·g−1、1.86 g·g−1、1.81 g·g−1,Ce-CAM复合水凝胶的孔道为由下向上的垂直径向孔通道,通道间紧密互连,孔通道间含有少量的小孔,因此饱和含水量较低,但Ce-CAM复合水凝胶具有大量的亲水基团,结合孔道的毛细力,使其具有优异的运输水能力,从而实现高效脱盐。

2.3 Ce-CAM复合水凝胶的亲水性研究

如图6所示,(a),(b),(c),(d)分别为5 μL的水珠滴落在Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶上,从开始滴落到完全消失的时间,Ce-CAM复合水凝胶中具有垂直分布的孔道结构和亲水基团-OH、-NH2使其具有极高的亲水性,随着CNC含量的增加,亲水基团的含量随之增加,良好的亲水性使得水珠在水凝胶表面快速消失,从侧面证明Ce-CAM复合水凝胶良好的水运输能力,为蒸发后的表面快速补充水分,有利于Ce-CAM复合水凝胶界面蒸发器实现快速蒸发。

2.4 Ce-CAM复合水凝胶的孔径研究

图7(a)为Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶的吸附等温线,其氮气吸附曲线为Ⅲ型等温线,吸附材料与吸附气体之间的相互作用相对薄弱,属于大孔固体材料,大孔的存在能够及时补充表面蒸发的水分。图7(b)为Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶的氮气吸附-解吸曲线,如表1所示,Ce-CAM1、Ce-CAM2、Ce-CAM3、Ce-CAM4复合水凝胶的比表面积分别为887.30 m2·g−1、5.68 m2·g−1、17.02 m2·g−1、53.50 m2·g−1,高比表面积能够为MXene纳米片提供附着位点,从而为Ce-CAM复合水凝胶提供高吸光能力。

![]() 图 7 (a). Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶的氮气吸附-解吸曲线, (b). Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶孔隙大小分布曲线Figure 7. (a). Nitrogen adsorption-desorption curves of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogels, (b). Pore size distribution curves of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogels表 1 Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶平均孔径和比表面积Table 1. Average pore size and specific surface area of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogels

图 7 (a). Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶的氮气吸附-解吸曲线, (b). Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶孔隙大小分布曲线Figure 7. (a). Nitrogen adsorption-desorption curves of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogels, (b). Pore size distribution curves of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogels表 1 Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4复合水凝胶平均孔径和比表面积Table 1. Average pore size and specific surface area of Ce-CAM1, Ce-CAM2, Ce-CAM3, Ce-CAM4 composite hydrogelsSample Pore Diameter/nm Specific Surface Area /(m2·g−1) Ce-CAM1 2.99 0.27 Ce-CAM2 3.13 5.68 Ce-CAM3 2.92 17.02 Ce-CAM4 3.02 53.50 2.5 Ce-CAM复合水凝胶的升温曲线研究

为了探究水凝胶界面蒸发器的热管理性能,采用红外热成像仪记录了纯水、3.5%氯化钠溶液、制浆废液、Ce-CAM2复合水凝胶在一个太阳光照强度下的升温曲线(图8(a)),同时记录了纯水及其纯水漂浮的Ce-CAM2复合水凝胶的整体升温情况(图8(b)),与水凝胶界面蒸发器相比,1小时内水凝胶界面蒸发器温度由20.8℃上升并稳定在33.9℃,而水凝胶界面蒸发器底部的水由20.8℃升温稳定在28.5℃(图9),这是由于Ce-CAM2复合水凝胶漂浮于水面上,太阳光被MXene吸收,然后迅速转换为热量,热量被保留于蒸发器界面,同时高度互连的径向孔道结构能够降低热导率,减少热损失,实现高效率的光热转换。

![]() 图 8 升温曲线:(a). 纯水, 3.5%氯化钠溶液, 制浆废液, Ce-CAM2复合水凝胶在一个太阳照射下升温曲线, (b). 漂浮在纯水中的Ce-CAM2复合水凝胶在一个太阳照射下的红外热成像图Figure 8. Warming curves: (a). Warming curves of Ce-CAM2 composite hydrogel in pure water, 3.5% NaCl solution, pulping waste, under one sun irradiation, (b). Infrared thermography of Ce-CAM2 composite hydrogel floating in pure water under one sun irradiation

图 8 升温曲线:(a). 纯水, 3.5%氯化钠溶液, 制浆废液, Ce-CAM2复合水凝胶在一个太阳照射下升温曲线, (b). 漂浮在纯水中的Ce-CAM2复合水凝胶在一个太阳照射下的红外热成像图Figure 8. Warming curves: (a). Warming curves of Ce-CAM2 composite hydrogel in pure water, 3.5% NaCl solution, pulping waste, under one sun irradiation, (b). Infrared thermography of Ce-CAM2 composite hydrogel floating in pure water under one sun irradiation2.6 Ce-CAM复合水凝胶的太阳能吸收光谱研究

图10显示了不同MXene量的Ce-CAM2复合水凝胶在250-

2500 nm波段的光吸收能力,不同MXene含量的Ce-CAM2复合水凝胶在整个光谱吸收范围中,平均光吸收率均达到90%以上。当MXene的添加量为0.1%时,复合水凝胶光吸收率达到最高为95.17%。MXene作为一种新型二维材料,具有高效的宽频吸收能力,MXene分散于Ce-CAM2复合水凝胶结构中一方面有利于提高太阳光吸收能力,同时太阳光在Ce-CAM2复合水凝胶的孔道中多次反射,从而提高了对光的吸收能力,另一方面MXene具有优异的热传导能力,能够及时将光转换为热量,用于水凝胶界面蒸发器的表面的快速蒸发。2.7 Ce-CAM复合水凝胶用于海水淡化

为了评估Ce-CAM2复合水凝胶的海水淡化能力,将Ce-CAM2复合水凝胶用于不同浓度的氯化钠溶液中进行蒸发,如图11(a)所示,并使用原子吸收分光光度计(HDHJ/YQ-J-001)对3.5%氯化钠溶液以及蒸发后收集冷凝液中的Na+、Mg2+、K+、Ca2+四种离子进行检测,如图11(b)所示,经过Ce-CAM2复合水凝胶蒸发后的蒸汽冷凝液中的四种金属离子浓度明显下降,离子去除率大于99.9%,证明Ce-CAM2复合水凝胶具有优异的海水淡化能力。

2.8 Ce-CAM复合水凝胶用于制浆废液净化

废水净化同样是水凝胶界面蒸发器的重要实际应用,采用制浆造纸产生的不同浓度制浆废如图12(a)所示,不同浓度的制浆废液蒸发速率如图12(b)所示,同时检测了制浆废液以及制浆废液净化后冷凝收集液的各项理化性质,包括pH、黏度、电导率、固含、悬浮物、灰分、生化需氧量(BOD)和化学需氧量(COD)等理化性质,如表1所示,经过Ce-CAM2复合水凝胶的净化收集得到的冷凝液黏度从3下降到1,而且固含、悬浮物大颗粒污染物均被完全净化掉,这一点从蒸发后收集得到的冷凝液灰分为0可得到证实,此外,在净化收集得到的冷凝液中,BOD、COD去除率分别为99.48%、99.53%,由此证明,Ce-CAM2复合水凝胶能够去除制浆废液中绝大部分的污染物,这为基于水凝胶界面蒸发用于制浆造纸废液处理指出了新的方向。

![]() 图 11 海水淡化:(a). Ce-CAM2复合水凝胶在不同浓度氯化钠溶液中的蒸发速率, (b). 3.5%氯化钠溶液经过Ce-CAM2复合水凝胶蒸发前后溶液中Na+, Mg2+, K+, Ca2+四种主要离子的浓度变化Figure 11. Desalination: (a). Evaporation rate of Ce-CAM2 composite hydrogel in different concentrations of NaCl solution, (b). Changes in the concentration of four major ions, Na+, Mg2+, K+ and Ca2+, in 3.5% NaCl solution before and after evaporation of Ce-CAM2 composite hydrogel

图 11 海水淡化:(a). Ce-CAM2复合水凝胶在不同浓度氯化钠溶液中的蒸发速率, (b). 3.5%氯化钠溶液经过Ce-CAM2复合水凝胶蒸发前后溶液中Na+, Mg2+, K+, Ca2+四种主要离子的浓度变化Figure 11. Desalination: (a). Evaporation rate of Ce-CAM2 composite hydrogel in different concentrations of NaCl solution, (b). Changes in the concentration of four major ions, Na+, Mg2+, K+ and Ca2+, in 3.5% NaCl solution before and after evaporation of Ce-CAM2 composite hydrogel![]() 图 12 废液蒸发: (a). C, 2 C, 3 C, 4 C分别为原制浆废液浓度, 原制浆废液浓度的两倍, 三倍, 四倍, (b). Ce-CAM2复合水凝胶在不同浓度制浆废液中的蒸发速率Figure 12. Pulping waste liquid evaporation: (a). C, 2 C, 3 C, 4 C are the original concentration of pulping waste liquid, double, triple and quadruple of the original concentration of pulping waste liquid, respectively, (b). Evaporation rate of Ce-CAM2 composite hydrogel in different concentrations of pulping waste liquid.表 2 制浆废液以及制浆废液净化后的冷凝收集液的各项理化性质Table 2. Physical and chemical properties of pulping waste liquid and condensate collection liquid after purification of pulping waste liquid

图 12 废液蒸发: (a). C, 2 C, 3 C, 4 C分别为原制浆废液浓度, 原制浆废液浓度的两倍, 三倍, 四倍, (b). Ce-CAM2复合水凝胶在不同浓度制浆废液中的蒸发速率Figure 12. Pulping waste liquid evaporation: (a). C, 2 C, 3 C, 4 C are the original concentration of pulping waste liquid, double, triple and quadruple of the original concentration of pulping waste liquid, respectively, (b). Evaporation rate of Ce-CAM2 composite hydrogel in different concentrations of pulping waste liquid.表 2 制浆废液以及制浆废液净化后的冷凝收集液的各项理化性质Table 2. Physical and chemical properties of pulping waste liquid and condensate collection liquid after purification of pulping waste liquidSample pH Viscosity/

(mPa·s)Conductivity/

(mS·cm−1)Solid/

(g·g−1)Suspension/

(g·L−1)Ash/

(g·g−1)BOD/

(mg·L−1)COD/

(mg·L−1)C 5.13 3 16.80 0.04 0.004 0.011 1726.67 40021.33 C′ 4.82 1 0.17 0 0 0 8.93 187.33 Notes: C is the concentration of the original pulping waste liquid, C′ is the condensate collected after the evaporation of the pulping waste liquid, BOD: biochemical oxygen demand, COD: chemical oxygen demand. 2.9 Ce-CAM复合水凝胶的抗盐、抗酸碱研究

(1)抗盐、抗酸碱测试

水凝胶界面蒸发器在实际应用于海水淡化、废水处理等方面,需要面对复杂的使用环境。Ce-CAM2复合水凝胶强酸强碱环境下的蒸发效率如图13(a)。Ce-CAM2复合水凝胶在1 mol L−1 HCl和1 mol L−1 NaOH的蒸发速率分别为1.35 kg·m−2·h−1、1.42 kg·m−2·h−1,这表明Ce-CAM2复合水凝胶在酸碱环境依然具有高效的蒸发速率,且收集处理后的冷凝液酸碱性大幅降低(图13(b)),这证明其具有处理酸性和碱性废水的能力。除此之外,若将Ce-CAM2复合水凝胶应用于海水淡化,需要其具有良好的排盐能力,此前已经将Ce-CAM2复合水凝胶用于不同氯化钠溶液中,其具有较高的蒸发速率,进一步将Ce-CAM2复合水凝胶漂浮于去离子水中,测试其抗盐能力,如图13(c)所示,表面的氯化钠在30 min内完全消失,这证明Ce-CAM2复合水凝胶具有快速高效的排盐能力。综上所述,Ce-CAM2复合水凝胶具有高效的排盐能力以及在废水的酸碱环境中的高速蒸发能力

![]() 图 13 抗酸碱、抗盐性能:(a). Ce-CAM2复合水凝胶在1 mol·L−1 HCl和1 mol·L−1 NaOH溶液中的蒸发速率, (b). 1 mol·L−1盐酸和1 mol·L−1氢氧化钠蒸发前以及蒸发后收集蒸发液体的pH对比, (c). Ce-CAM2复合水凝胶的排盐能力Figure 13. Acid, alkali and salt resistance: (a). Evaporation rate of Ce-CAM2 composite hydrogel in 1 mol·L−1 HCl and 1 mol·L−1 NaOH solutions, (b). Comparison of pH of the evaporated liquid collected before evaporation of 1 mol L−1 hydrochloric acid and 1 mol L−1 sodium hydroxide as well as after evaporation, (c). Salt exclusion capacity of Ce-CAM2 composite hydrogel

图 13 抗酸碱、抗盐性能:(a). Ce-CAM2复合水凝胶在1 mol·L−1 HCl和1 mol·L−1 NaOH溶液中的蒸发速率, (b). 1 mol·L−1盐酸和1 mol·L−1氢氧化钠蒸发前以及蒸发后收集蒸发液体的pH对比, (c). Ce-CAM2复合水凝胶的排盐能力Figure 13. Acid, alkali and salt resistance: (a). Evaporation rate of Ce-CAM2 composite hydrogel in 1 mol·L−1 HCl and 1 mol·L−1 NaOH solutions, (b). Comparison of pH of the evaporated liquid collected before evaporation of 1 mol L−1 hydrochloric acid and 1 mol L−1 sodium hydroxide as well as after evaporation, (c). Salt exclusion capacity of Ce-CAM2 composite hydrogel3. 结论

本文制备了纤维素纳米晶体-琼脂糖-碳化钛(MXene)(Ce-CAM)复合水凝胶界面蒸发器,并采用扫描电子显微镜、红外、流变仪对Ce-CAM复合水凝胶的性能进行分析表征,探究其在海水脱盐淡化、废水简化处理方面的性能,并进一步对其耐盐、耐酸碱性能进行了探究。得出如下结论:

(1) Ce-CAM复合水凝胶不需引发剂、交联剂,分子链之间通过氢键链接即可形成水凝胶,加入的MXene作为吸光材料使其具有宽频高效的光吸收性能,其在250-

2500 nm范围内的光吸收率为90%以上,在1 kW·m−2太阳光照下,其对3.5%氯化钠溶液和制浆废液的蒸发速率分别为1.44 kg·m−2·h−1、1.42 kg·m−2·h−1。(2) Ce-CAM复合水凝胶具有优异的耐盐、耐酸碱性能,其在3.5%、5%、10%、20%氯化钠溶液中连续运行10 h后,没有盐分积累,且在其表面撒一层氯化钠溶液后,在30 min内氯化钠完全消失,在1 mol·L−1的氢氧化钠和盐酸溶液中具有高效蒸发速率,这表明此复合水凝胶具有优异的耐盐和耐酸碱性能。

(3) Ce-CAM复合水凝胶脱盐淡化海水的能力较强,其对Na+、Mg2+、K+、Ca2+等离子去除率可达到99.9%,同时Ce-CAM复合水凝胶能够净化高固含制浆废液中的大部分污染物,BOD、COD去除率分别可达到99.48%、99.53%,研究可为基于水凝胶界面蒸发用于制浆废液净化处理提供了新思路和新途径。

-

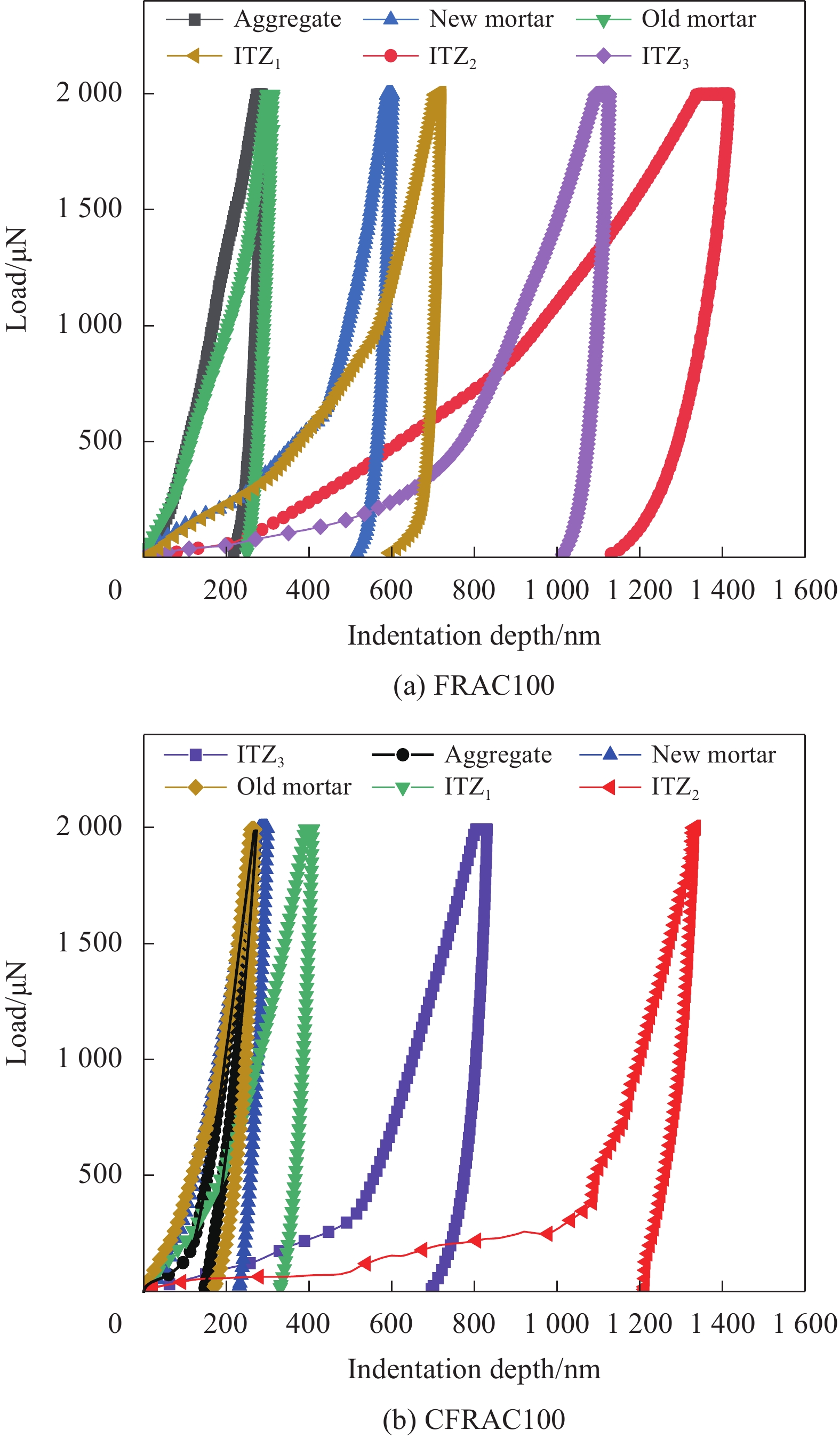

图 4 荷载-压痕深度典型曲线

Figure 4. Typical curve of load-indentation depth

Pmax represents the maximum load of the indenter; hf represents the indentation depth after unloading; hc represents the contact depth; hmax represents the maximum indentation depth; s represents the initial slope of the load-indentation depth unloading curve

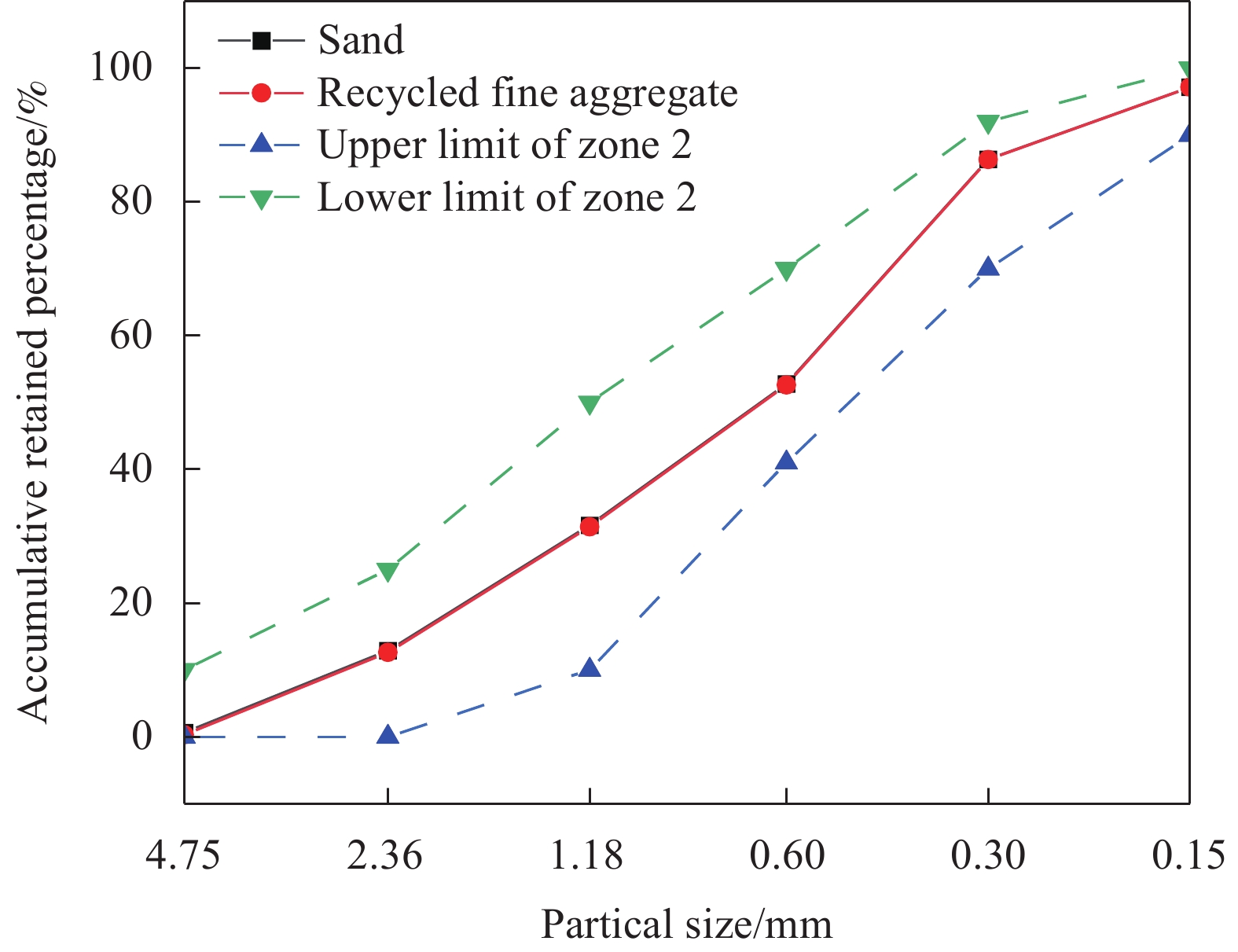

表 1 碳化前后再生骨料物理特性

Table 1 Physical properties of recycled aggregate before and after carbonation

Aggregate type Water absorption/% Crush value/% Apparent density/(kg·m−3) Natural aggregate 0.6 8.1 2760 Sand 0.5 10.2 2591 Recycled fine aggregate 9.0 25.93 2453 Carbonated recycled fine aggregate 6.84(↓24%) 23.40(↓9.76%) 2512 (↑2.41%)Recycled coarse aggregate 4.71 16.2 2648 Carbonated recycled coarse aggregate 3.63(↓22.93%) 15.60(↓3.70%) 2694 (↑1.74%)表 2 试验方案

Table 2 Test scheme

Series Recycled coarse aggregate

replacement percentageRecycled fine aggregate

replacement percentageCarbonation Number of test

blocks ( blocks )NA 0 0 — 3 RC 100% 0, 30%, 50%, 70%, 100% No 15 RF 0, 30%, 50%, 70%, 100% 100% No 15 CRC 100% 0, 30%, 50%, 70%, 100% Yes 15 CRF 0, 30%, 50%, 70%, 100% 100% Yes 15 Notes: NA represents concrete prepared by natural aggregates; RC represents fully recycled coarse aggregate concrete; RF represents fully recycled fine aggregate concrete; CRC represents carbonated fully recycled coarse aggregate concrete; CRF represents carbonated fully recycled fine aggregate concrete. 表 3 全再生骨料混凝土(FRAC)配合比(kg/m3)

Table 3 Mix proportion of fully recycled aggregate concrete (FRAC) (kg/m3)

Series Natural aggregate Recycled coarse aggregate Sand Recycled fine aggregate Water Cement NA 1220.36 0 703.38 0.00 167.31 371.80 RC0 0 579.96 1002.30 0.00 232.68 517.07 RC30 0 722.70 640.98 260.04 221.14 491.43 RC50 0 823.16 427.36 404.55 213.02 473.38 RC70 0 928.20 237.29 524.13 204.53 454.51 RC100 0 1095.05 0.00 652.91 191.04 424.54 RF0 1521.78 0.00 0 475.97 98.97 219.93 RF30 1065.41 445.05 0 475.97 130.81 290.68 RF50 761.94 742.93 0 482.18 149.82 332.92 RF70 403.47 918.13 0 554.58 167.30 371.77 Notes: In RC0, RC represents fully recycled coarse aggregate concrete, and 0 represents the replacement rate of recycled fine aggregate with 0%; In RF0, RF represents fully recycled fine aggregate concrete, and 0 represents the replacement rate of recycled coarse aggregate with 0%. -

[1] TANG Y X, XIAO J Z, ZHANG H H, et al. Mechanical properties and uniaxial compressive stress-strain behavior of fully recycled aggregate concrete[J]. Construction and Building Materials, 2022, 323: 126546. DOI: 10.1016/j.conbuildmat.2022.126546

[2] ZHANG H H, XIAO J Z, TANG Y X, et al. Long-term shrinkage and mechanical properties of fully recycled aggregate concrete: Testing and modelling[J]. Cement and Concrete Composites, 2022, 130: 104527. DOI: 10.1016/j.cemconcomp.2022.104527

[3] ZHAO M Z, GENG Y, WANG Y Y, et al. Compounding effect and an expanded theoretical model for recycled coarse and fine aggregate concretes under uniaxial loading[J]. Construction and Building Materials, 2022, 320: 126226. DOI: 10.1016/j.conbuildmat.2021.126226

[4] SHI C J, LI Y K, ZHANG J K, et al. Performance enhancement of recycled concrete aggregate—A review[J]. Journal of Cleaner Production, 2016, 112: 466-472. DOI: 10.1016/j.jclepro.2015.08.057

[5] 冯春花, 黄益宏, 崔卜文, 等. 建筑再生骨料强化方法研究进展[J]. 材料导报, 2022, 36(21): 88-95. FENG Chunhua, HUANG Yihong, CUI Buwen, et al. Research progress on treatment methods of building recycled concrete aggregates[J]. Materials Reports, 2022, 36(21): 88-95( in Chinese).

[6] FERNÁNDEZ BERTOS M, SIMONS S J R, HILLS C D, et al. A review of accelerated carbonation technology in the treatment of cement-based materials and sequestration of CO2[J]. Journal of Hazardous Materials, 2004, 112(3): 193-205. DOI: 10.1016/j.jhazmat.2004.04.019

[7] KOU S C, ZHAN B J, POON C S. Use of a CO2 curing step to improve the properties of concrete prepared with recycled aggregates[J]. Cement and Concrete Composites, 2014, 45: 22-28. DOI: 10.1016/j.cemconcomp.2013.09.008

[8] LIANG C F, PAN B H, MA Z M, et al. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review[J]. Cement and Concrete Composites, 2020, 105: 103446. DOI: 10.1016/j.cemconcomp.2019.103446

[9] 赵增丰, 姚磊, 肖建庄, 等. 再生骨料CO2碳化强化技术研究进展[J]. 硅酸盐学报, 2022, 50(8): 2296-2304. ZHAO Zengfeng, YAO Lei, XIAO Jianzhuang, et al. Development on accelerated carbonation technology to enhance recycled aggregates[J]. Journal of the Chinese Ceramic Society, 2022, 50(8): 2296-2304( in Chinese).

[10] LAGERBLAD B. Carbon dioxide uptake during concrete life cycle—State of the art[M]. Stockholm, Swedish: Swedish Cement and Concrete Research Institute, 2005.

[11] 高越青, 潘碧豪, 梁超锋, 等. CO2强化再生骨料的特性及其对再生混凝土性能的影响[J]. 土木与环境工程学报(中英文), 2021, 43(6): 95-102. GAO Yueqing, PAN Bihao, LIANG Chaofeng, et al. Properties of CO2-modified reinforced recycled aggregate and its effect on the performance of recycled aggregate concrete[J]. Journal of Civil and Environmental Engineering, 2021, 43(6): 95-102( in Chinese).

[12] LUO S R, YE S C, XIAO J Z, et al. Carbonated recycled coarse aggregate and uniaxial compressive stress-strain relation of recycled aggregate concrete[J]. Construction and Building Materials, 2018, 188: 956-965. DOI: 10.1016/j.conbuildmat.2018.08.159

[13] PU Y H, LI L, WANG Q Y, et al. Accelerated carbonation treatment of recycled concrete aggregates using flue gas: A comparative study towards performance improvement[J]. Journal of CO2 Utilization, 2021, 43: 101362. DOI: 10.1016/j.jcou.2020.101362

[14] FANG X L, XUAN D X, SHEN P L, et al. Fast enhancement of recycled fine aggregates properties by wet carbonation[J]. Journal of Cleaner Production, 2021, 313: 127867. DOI: 10.1016/j.jclepro.2021.127867

[15] JIANG Y, LI L, LU J X, et al. Mechanism of carbonating recycled concrete fines in aqueous environment: The particle size effect[J]. Cement and Concrete Composites, 2022, 133: 104655. DOI: 10.1016/j.cemconcomp.2022.104655

[16] ZHAN B J, XUAN D X, POON C S. Enhancement of recycled aggregate properties by accelerated CO2 curing coupled with limewater soaking process[J]. Cement and Concrete Composites, 2018, 89: 230-237. DOI: 10.1016/j.cemconcomp.2018.03.011

[17] ZHAO Z F. Improving the properties of recycled concrete aggregates by accelerated carbonation[J]. Proceedings of the Institution of Civil Engineers—Construction Materials, 2018, 171(3): 126-132. DOI: 10.1680/jcoma.17.00015

[18] ZHANG J Z, SHI C J, LI Y K, et al. Performance enhancement of recycled concrete aggregates through carbonation[J]. Journal of Materials in Civil Engineering, 2015, 27(11): 04015029. DOI: 10.1061/(ASCE)MT.1943-5533.0001296

[19] FANG X L, ZHAN B J, POON C S. Enhancement of recycled aggregates and concrete by combined treatment of spraying Ca2+ rich wastewater and flow-through carbonation[J]. Construction and Building Materials, 2021, 277: 122202. DOI: 10.1016/j.conbuildmat.2020.122202

[20] XUAN D X, ZHAN B J, POON C S. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates[J]. Cement and Concrete Composites, 2016, 65: 67-74. DOI: 10.1016/j.cemconcomp.2015.10.018

[21] XUAN D X, ZHAN B J, POON C S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates[J]. Cement and Concrete Composites, 2017, 84: 214-221. DOI: 10.1016/j.cemconcomp.2017.09.015

[22] GAO S, GUO J, GONG Y Y, et al. Study on the penetration and diffusion of chloride ions in interface transition zone of recycled concrete prepared by modified recycled coarse aggregates[J]. Case Studies in Construction Materials, 2022, 16: e01034. DOI: 10.1016/j.cscm.2022.e01034

[23] LIU H, ZHU X D, ZHU P H, et al. Carbonation treatment to repair the damage of repeatedly recycled coarse aggregate from recycled concrete suffering from coupling action of high stress and freeze-thaw cycles[J]. Construction and Building Materials, 2022, 349: 128688. DOI: 10.1016/j.conbuildmat.2022.128688

[24] FANG X L, XUAN D X, POON C S. Empirical modelling of CO2 uptake by recycled concrete aggregates under accelerated carbonation conditions[J]. Materials and Structures, 2017, 50(4): 200. DOI: 10.1617/s11527-017-1066-y

[25] FANG X L, ZHAN B J, POON C S. Enhancing the accelerated carbonation of recycled concrete aggregates by using reclaimed wastewater from concrete batching plants[J]. Construction and Building Materials, 2020, 239: 117810. DOI: 10.1016/j.conbuildmat.2019.117810

[26] LIU J, MA K L, SHEN J T, et al. Influence of CO2 enhancement of recycled aggregate on microstructure of ITZs in recycled concrete[J]. Journal of Building Engineering, 2023, 65: 130772.

[27] 陈旭勇, 周启, 程子扬, 等. 纳米SiO2对再生混凝土新旧砂浆界面过渡区的影响[J]. 材料导报, 2022, 36(S2): 191-195. CHEN Xuyong, ZHOU Qi, CHENG Ziyang, et al. Effect of nano-SiO2 on the interfacial transition zone between new and old mortar of recycled concrete[J]. Materials Reports, 2022, 36(S2): 191-195(in Chinese).

[28] LIU X Y, XIE X, LIU R D, et al. Research on the durability of nano-SiO2 and sodium silicate co-modified recycled coarse aggregate (RCA) concrete[J]. Construction and Building Materials, 2023, 378: 131185. DOI: 10.1016/j.conbuildmat.2023.131185

[29] LI L, XUAN D X, CHU S H, et al. Efficiency and mechanism of nano-silica pre-spraying treatment in performance enhancement of recycled aggregate concrete[J]. Construction and Building Materials, 2021, 301: 124093. DOI: 10.1016/j.conbuildmat.2021.124093

[30] ZHANG M X, YANG X L, DING Y H, et al. High-efficiency carbonation modification methods of recycled coarse aggregates[J]. Journal of Wuhan University of Technology (Materials Science), 2024(39): 386-398.

[31] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019. Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test methods of physical and mechanical properties of concrete: GB/T 50081—2019[S]. Beijing: China Building Industry Press, 2019(in Chinese).

[32] 沈奇真, 潘钢华, 占华刚, 等. 加速碳化条件下界面过渡区的纳米力学性能[J]. 东南大学学报(自然科学版), 2016(1): 146-151. DOI: 10.3969/j.issn.1001-0505.2016.01.024 SHEN Qizhen, PAN Ganghua, ZHAN Huagang, et al. Nanomechanical properties of interfacial transition zone under accelerated carbonation[J]. Journal of Southeast University (Natural Science Edition), 2016(1): 146-151(in Chinese). DOI: 10.3969/j.issn.1001-0505.2016.01.024

-

其他相关附件

-

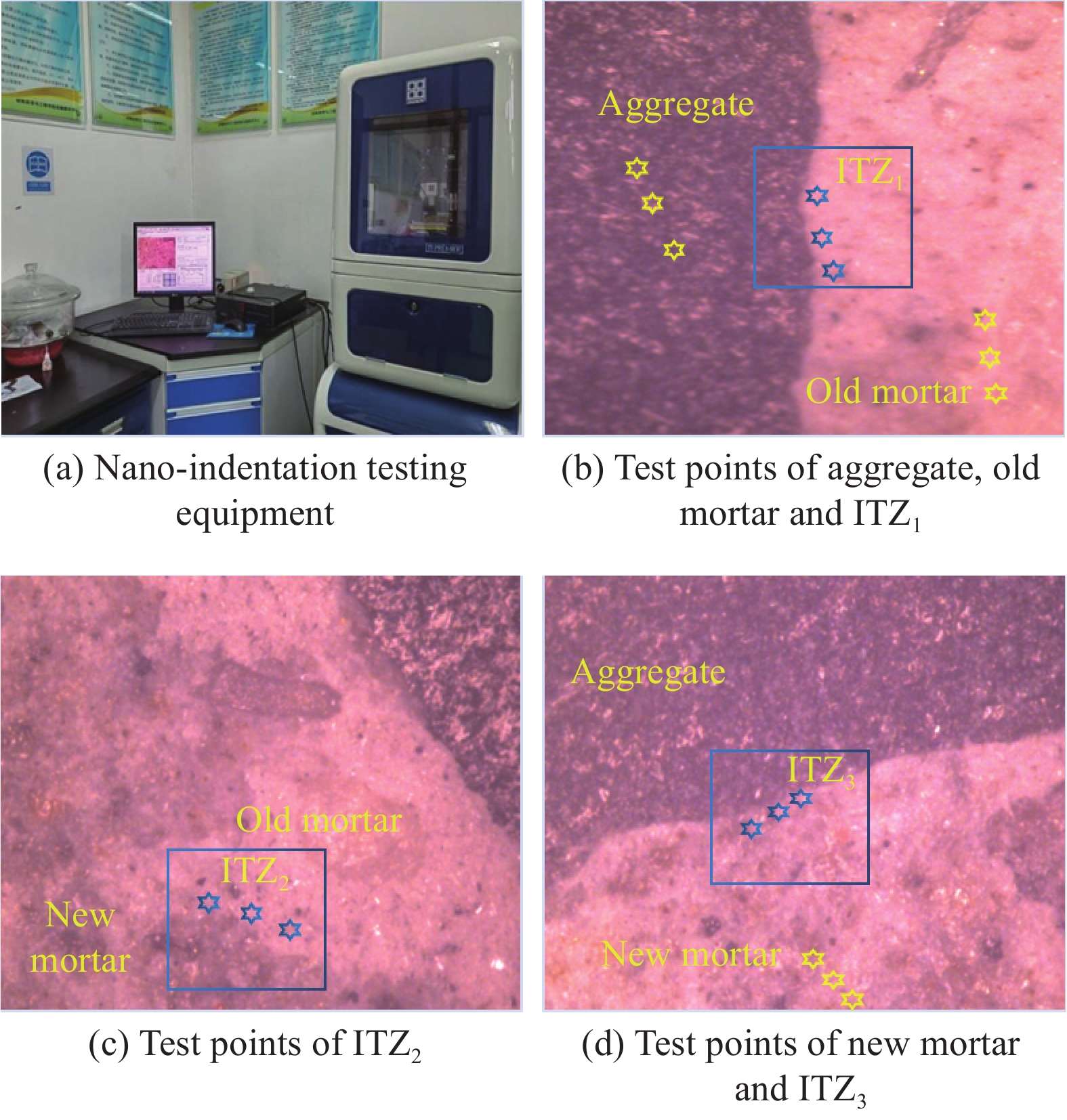

目的

随城市更新加速、基础设施扩建,建筑垃圾堆积如山的同时,巨量砂石亟待供给。全再生骨料混凝土(FRAC)能最大规模资源化利用建筑垃圾,但其性能缺陷显著。本文采用纳米SiO(NS)复合碳化改性再生骨料并制备FRAC,测试了其抗压性能、劈裂抗拉性能及抗折性能等宏观力学特性,采用纳米压痕测试了其微观力学性能,并结合SEM微观测试,揭示了碳化全再生骨料混凝土(CFRAC)多重界面强化机制。

方法为实现再生骨料高效碳化改性,采用纳米SiO复合碳化改性再生粗细骨料,测试碳化前后再生骨料的碳化程度及物理特性。基于再生粗细骨料紧密湿堆积模型开展FRAC配合比设计,并浇筑FRAC试块,测试其28d立方体抗压强度、劈裂抗拉强度及抗折强度等宏观力学特性;采用纳米压痕技术及SEM等微观测试手段分析FRAC的微观力学特性及微观形貌,研究碳化全再生骨料混凝土(CFRAC)宏微观力学特性,揭示其强化机制。

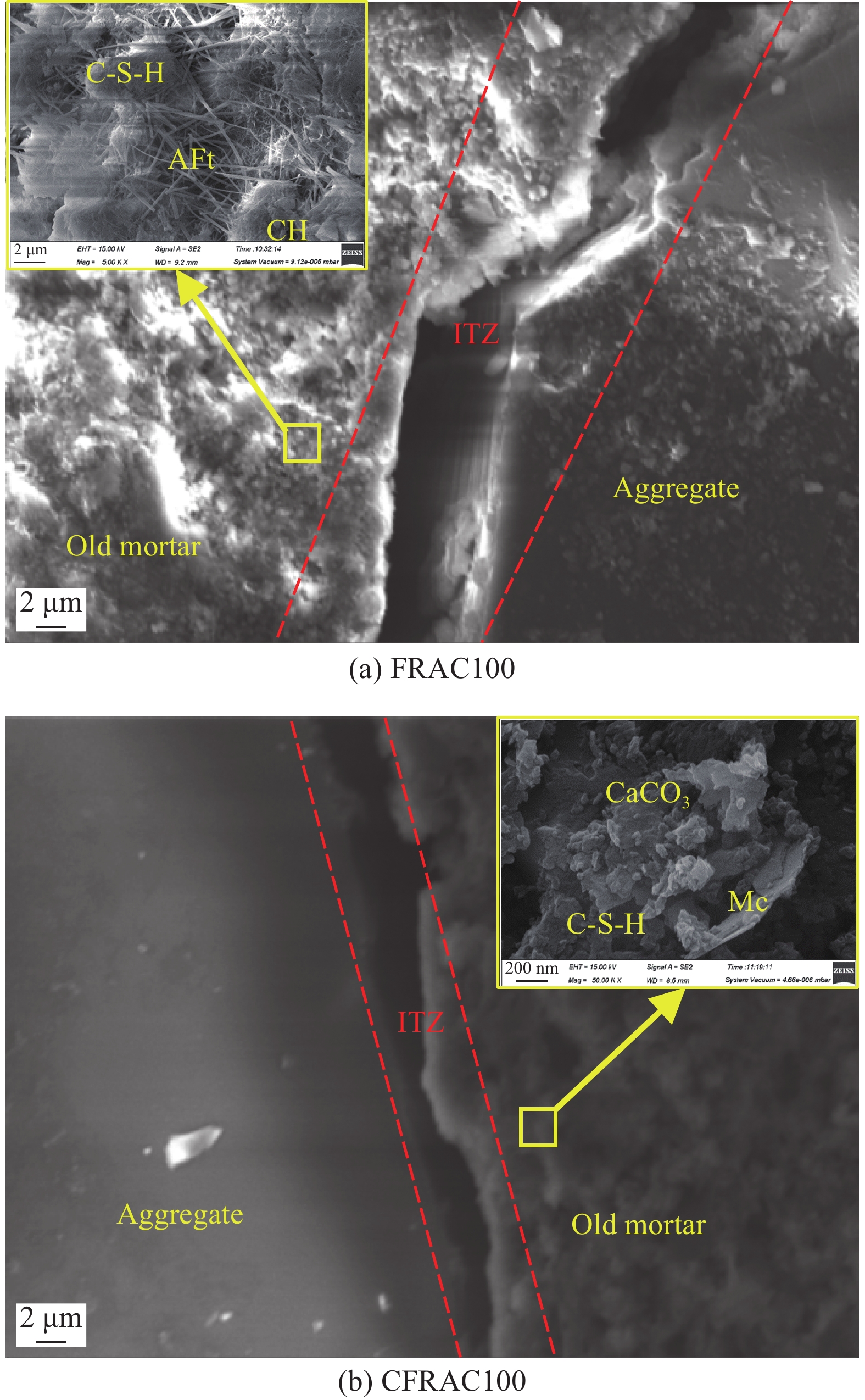

结果(1)NS复合碳化再生骨料表面及内部喷涂酚酞颜色均未变色,表明NS复合碳化实现了再生骨料的高效碳化改性,且碳化再生骨料吸水率、压碎值显著降低,表观密度提高,其中碳化再生粗骨料吸水率降低幅度最显著达22.93%。(2)FRAC力学特性明显低于普通混凝土,NS复合碳化再生骨料显著提高了FRAC力学特性,其中抗压强度最大提高33.12%,劈裂抗拉强度最大提高48.73%,抗折强度最大提高44.79%。(3)NS复合碳化再生骨料同时提高了CFRAC各相平均弹性模量及显微硬度,其中对旧砂浆及骨料-旧砂浆的ITZ增强效应最显著。(4)多重ITZ是FRAC最弱的相,NS复合碳化改性显著增强再生骨料附着旧砂浆的同时,改善了ITZ、ITZ及ITZ等多重ITZ微观结构特性,CFRAC微观结构更致密,ITZ裂隙宽度明显减小。

结论(1)NS复合碳化再生骨料显著提高了FRAC宏微观力学特性。(2)NS复合碳化改性同时发挥了NS及碳化强化的双重增强效应。其强化机制为:NS具有微填充及高火山灰特性,有效填充再生骨料表面旧砂浆孔隙及微裂纹,同时又与旧砂浆水化产物Ca(OH)反应生成纳米C-S-H;CO作用下,旧砂浆水化产物、未水化产物及额外生成的C-S-H与CO反应生成固体体积增大的CaCO及无定形硅胶,其中NS作为C-S-H的成核点,加速水化反应进行,使其反应更加充分,强化再生骨料旧砂浆及ITZ性能,进而提高FRAC整体性能。(3)CFRAC微观结构更密实,其各相平均弹性模量及显微硬度等微观力学特性均得到提高,特别是旧砂浆及骨料-旧砂浆的ITZ增强效应最显著。(4)多重ITZ是FRAC最弱的相,NS复合碳化再生骨料显著增强其附着旧砂浆的同时,改善了ITZ、ITZ及ITZ等多重ITZ微观结构特性,降低了骨料“墙效应”带来的负面影响,进而提高FRAC多尺度力学性能。

-

碳化强化是一种高效环保的再生骨料改性方法,但随着碳化反应进行,再生骨料微观结构致密的同时也减缓了CO2向内渗入速率,特别是粒径较大的再生粗骨料仅发生表面碳化,影响其碳化效果。而纳米SiO2(NS)具有强渗透性、微填充效应及火山灰效应等优点,将再生骨料预浸泡NS溶液,再将其预处理适宜温湿度,置于压力罐进行压力碳化改性,有望实现再生骨料高效碳化强化。全再生骨料混凝土(FRAC)可实现建筑垃圾最大资源化利用,但目前有关碳化改性骨料对FRAC力学特性影响规律研究不够系统,对NS复合碳化FRAC强化机制尚不明晰。

本文首先对再生骨料进行NS复合碳化改性处理,然后将100%改性再生粗/细骨料制备全再生粗/细骨料混凝土,并在此基础上,掺入不同取代率(0、30%、50%、70%及100%)的再生细/粗骨料,探究再生细/粗骨料取代率及碳化骨料对全再生粗/细骨料混凝土多尺度力学特性影响规律。NS与富集在再生骨料多重界面的Ca(OH)2发生火山灰反应,生成C-S-H凝胶,其晶格结构发生变化的同时微观结构更加致密,降低了界面过渡区(ITZ)负面效应。碳化作用下,CO2与再生骨料表面附着旧砂浆水化产物及未水化产物均发生反应,生成固体体积增大的CaCO3及无定形硅胶,而NS又可作为C-S-H的成核点,促使水化反应更加充分,填充其表面旧砂浆孔隙及微裂纹,再生骨料性能得以强化。与此同时,再生骨料表面游离的NS可继续与水泥水化产物反应,加速水化反应进行,增强了新旧界面性能,进而提升了FRAC整体性能。碳化全再生骨料混凝土(CFRAC)力学性能均得到显著增强,且全再生细骨料混凝土碳化增强效应更显著,其中抗压强度、劈裂抗拉强度及抗折强度最大提高幅度分别为33.12%、48.73%及24.53%,CFRAC各相平均弹性模量及显微硬度显著提高,其中旧砂浆及骨料-旧砂浆界面过渡区(ITZ1)微观力学性能提高幅度最显著。

NS复合碳化FRAC显微硬度(a)及强化机制(b)

下载:

下载: