Bending properties of carbon fiber 3D woven preforms

-

摘要: 异形结构复合材料构件成型过程中,其内部纤维预制体往往发生显著的宏观变形。预制体的弯曲性能对褶皱缺陷的形成和演化有着决定性影响。采用三点弯曲法对碳纤维3D机织预制体进行了测试,利用Micro-CT技术研究了预制体的微细观变形机制,分析了经纱密度和纬纱密度对预制体弯曲性能的影响规律。结果发现:3D机织预制体的临界弯曲能量随着组织点密度的增加大致呈线性增大的趋势。预制体弯曲变形主要由经纱屈曲度变化、局部压缩屈曲和经纬纱层间滑移等微细观变形构成。

-

关键词:

- 3D机织预制体 /

- 弯曲变形 /

- Micro-CT技术 /

- 微细观结构 /

- 变形机制

Abstract: During the forming process of composite components with complex-shaped geometries, the fiber preform would deform significantly in macro-scale. The bending performance of the preform has a decisive impact on the formation and evolution of wrinkle defects. The three-point bending method was employed to test the carbon fiber 3D woven preforms. Micro-scale deformation mechanisms of the preform were researched using the Micro-CT technology. Effects of structural parameters such as warp density and weft density on the bending property of the preforms were analyzed. It is shown that the critical bending energy of the preforms increases linearly with the increase of weaving point density. The macro-scale bending deformation of the preform is mainly composed of micro-scale deformations such as changing of warp yarn buckling degree, local compression buckling of warp yarns and slippage between warp and weft yarn layers.-

Keywords:

- 3D woven preform /

- bending deformation /

- micro-CT technology /

- mesostructure /

- deformation mechanism

-

3D机织复合材料具有优异的抗分层、抗冲击、耐疲劳性能及复杂构件近净成型等优点,在航空航天、海洋船舶、军事、建筑、车辆工程和体育等领域得到了广泛应用[1-2]。近年来,人们对大尺寸、复杂外形的3D机织复合材料提出了更多的应用需求[3-4]。

预制体的纤维结构对复合材料的力学性能有着决定性的影响,在大尺寸、异形复合材料结构件的制备过程中,预制体往往发生复杂的外形转换,其中弯曲变形是一种常见的变形模式[5-7]。研究表明,预制体的弯曲性能对变形过程中褶皱缺陷的形成、演化及最终形态有着决定性影响。弯曲性能是影响预制体适形性能和复合材料力学性能的重要因素[8-10]。

实验是研究预制体力学性能的最直接手段。目前预制体弯曲性能的测试方法主要包括Peirce悬臂弯曲、Kawabata弯曲及三点弯曲[11]。在Peirce悬臂弯曲测试中,预制体在自身重力作用下发生弯曲,并接触到特定倾角的斜面,通过测量悬臂长度计算弯曲刚度[12-13]。Bilbao等[14]设计了一种利用光学技术测量织物弯曲变形的悬臂梁实验方法,测试装置由两个模块组成:机械模块能够在自身质量下将样品置于悬臂结构中,也可以在样品的自由边缘添加质量,达到更大的曲率;光学模块可以拍摄弯曲试样的形状,通过图像处理计算试样的弯曲曲率。传统悬臂梁试验中预制体由于载荷分布不均有可能出现扭转现象。针对这一问题,Dangora等[15]采用垂直悬臂梁法对预制体进行了弯曲测试,该方法将预制体竖直悬挂,通过绑在自由端的绳子施加载荷,使用数码相机记录试样的位移并计算弯曲曲率。悬臂弯曲试样容易制备、实验操作简单,但高厚度预制体很难在自身重力作用下发生较大的弯曲变形,需要额外施加一定的载荷,容易造成较大误差[16]。Kawabata弯曲实验将试样夹持在特定的夹具中,通过旋转夹具实现试样的弯曲变形。Kawabata弯曲方法能够实现试样的往复弯曲-展平变形,获取试样的弯矩-曲率曲线,表征织物的非线性弯曲变形行为[17]。Ropers等[18]和Sachs等[19]在Kawabata弯曲法的基础上开发了一种基于流变仪的测试方法,可以实现摆动式旋转加载,这种加载方式同样能够确保试样发生纯弯曲变形。目前的Kawabata弯曲实验往往适用于较小尺寸的试样,难以保障大尺寸、高厚度试样变形时曲率的均匀性。预制体的三点弯曲测试方法借鉴了复合材料的测试标准,该方法简单易操作,主要适用于具有较大厚度和弯曲刚度的预制体[20]。Charmetant等[21]、Liang等[22]、Boisse等[23]和Margossian等[24]使用三点弯曲法对3D碳纤维层层角联锁预制体的弯曲行为进行了测试,通过光学图像记录弯曲变形前后预制体厚度的变化、计算试样的曲率。结果表明,由于纱线的抗拉刚度较大,预制体弯曲变形主要由横向剪切引起,原本与试样表面垂直的法线在变形之后不再与表面垂直。

目前的预制体弯曲实验主要关注试样的宏观力学响应,包括弯曲变形过程中的载荷、挠度和曲率等,对预制体内部各纱线系统的微细观变形机制仍然缺乏系统性的研究。本文采用三点弯曲实验研究了碳纤维3D机织预制体的弯曲行为。引入临界弯曲能量表征预制体的弯曲变形性能,通过Micro-CT技术观测试样弯曲变形前、后的内部纱线形态,分析预制体的弯曲变形机制,建立经纱密度和纬纱密度与弯曲性能的量化关系,为预制体工艺设计提供理论指导。

1. 试验材料及方法

1.1 原材料

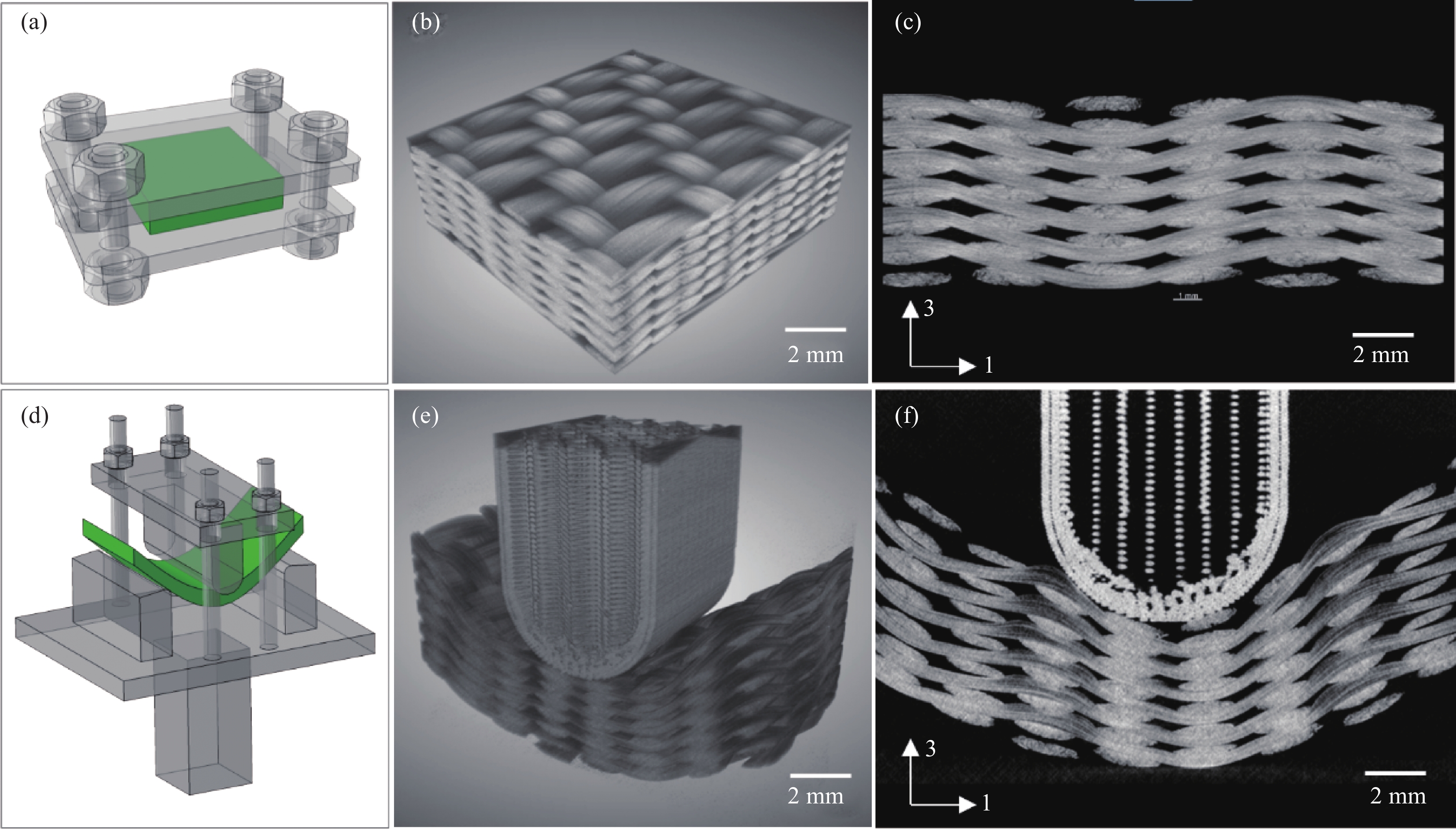

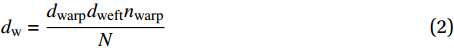

按照3种经纱密度(5.0根/cm、8.0根/cm、10.0根/cm)和3种纬纱密度(2.5根/cm、3.0根/cm、3.5根/cm)制备了9件碳纤维3D机织预制体样件。所有样件的经纱和纬纱均由T800-24 K碳纤维纱线组成,预制体交织方式为一三斜纹层层角联锁结构,如图1所示。预制体内部纬纱呈伸直状态,经纱呈屈曲状态,经、纬纱互相垂直,经纱将纬纱捆绑连接起来。预制体试样的具体参数如表1所示,试样编号中的J表示经纱密度、W表示纬纱密度。例如“J5W2.5”表示该试样经纱密度5根/cm,纬纱密度2.5根/cm。试样设计厚度为5 mm,该厚度指的是该试样被压缩至纤维体积含量55vol%时的厚度,实际上织物在纺织成形后(未受压力的状态下)的实际厚度往往会略高于设计厚度。

表 1 3D机织预制体结构参数Table 1. Structure parameters of 3D woven preformsSample Number of warp layer Number of weft layer Apparent thickness/mm Weaving point density/cm−2 J5W2.5 7 8 6.31 21.88 J5W3.0 6 7 5.89 22.50 J5W3.5 6 7 6.19 26.25 J8W2.5 5 6 6.78 25.00 J8W3.0 5 6 6.60 30.00 J8W3.5 4 5 5.97 28.00 J10W2.5 4 5 6.71 25.00 J10W3.0 4 5 7.00 30.00 J10W3.5 4 5 6.73 35.00 1.2 三点弯曲测试

采用电动裁切机(GD-H690)对预制体进行裁剪。参考标准GB/T 33621—2017[25](三维编织物及其树脂基复合材料弯曲性能试验方法),在岛津实验机(AGS-J1KN)上开展预制体样件的三点弯测试。预制体样件的跨距与厚度之比为8∶1,样件尺寸为100 mm×30 mm×5 mm。将预制体试样放置在三点弯曲支座上,保证左右对称,通过支座上的标尺调节至适当跨距,设定压头加载速率5 mm/min,测试过程中记录载荷-挠度数据。

1.3 Micro-CT测试

为了研究预制体的弯曲变形机制,通过Micro-CT技术获得样件弯曲变形前、后的内部纤维结构。参考三点弯曲夹具的尺寸设计了一种弯曲控形工装,如图2所示。将预制体试样放入控形工装中,通过调节压头位置可以实现不同程度的弯曲变形,锁紧螺栓使弯曲变形得以“固定”。扫描测试时将预制体试样连同控形工装一起放入Micro-CT扫描设备的观测腔室中。本文采用卡尔蔡司Xradia 510 Versa设备开展Micro-CT测试,X射线源的起始能量设置为80 kV/7 W,曝光时间为1 s,图像分辨率为25 μm。

2. 三点弯曲测试结果及分析

2.1 3D机织预制体宏观力学响应

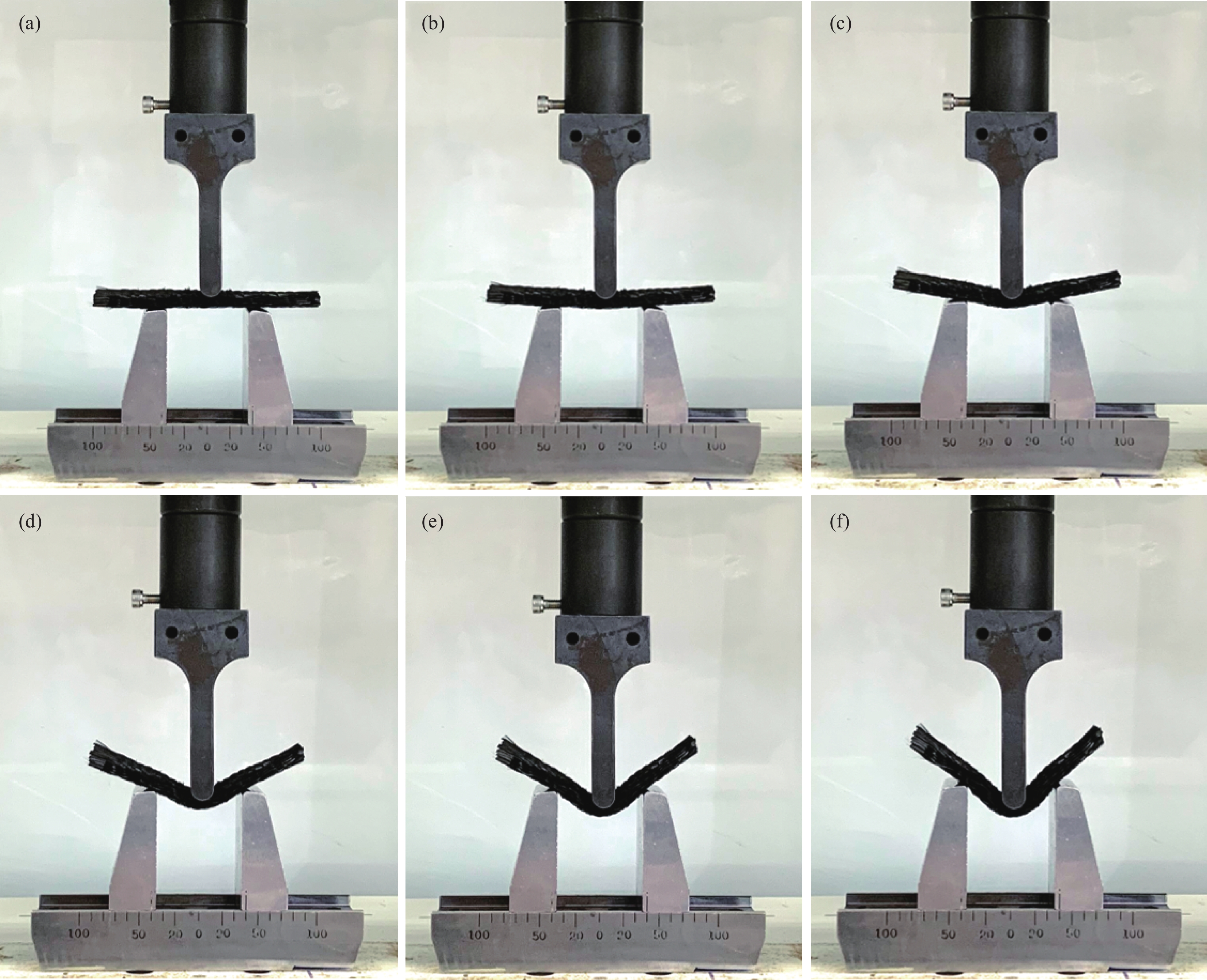

三点弯曲实验过程中,预制体样件的弯曲变形如图3所示。随着弯曲挠度的增大,试样两端逐渐翘起,变形后的预制体试样呈“V”字形。当弯曲挠度达到10 mm左右时,试样与支座之间开始发生显著滑移。三点弯曲载荷下预制体试样的变形曲率并不均匀,靠近压头的位置曲率较大,两端位置曲率很小,几乎呈平直状态。

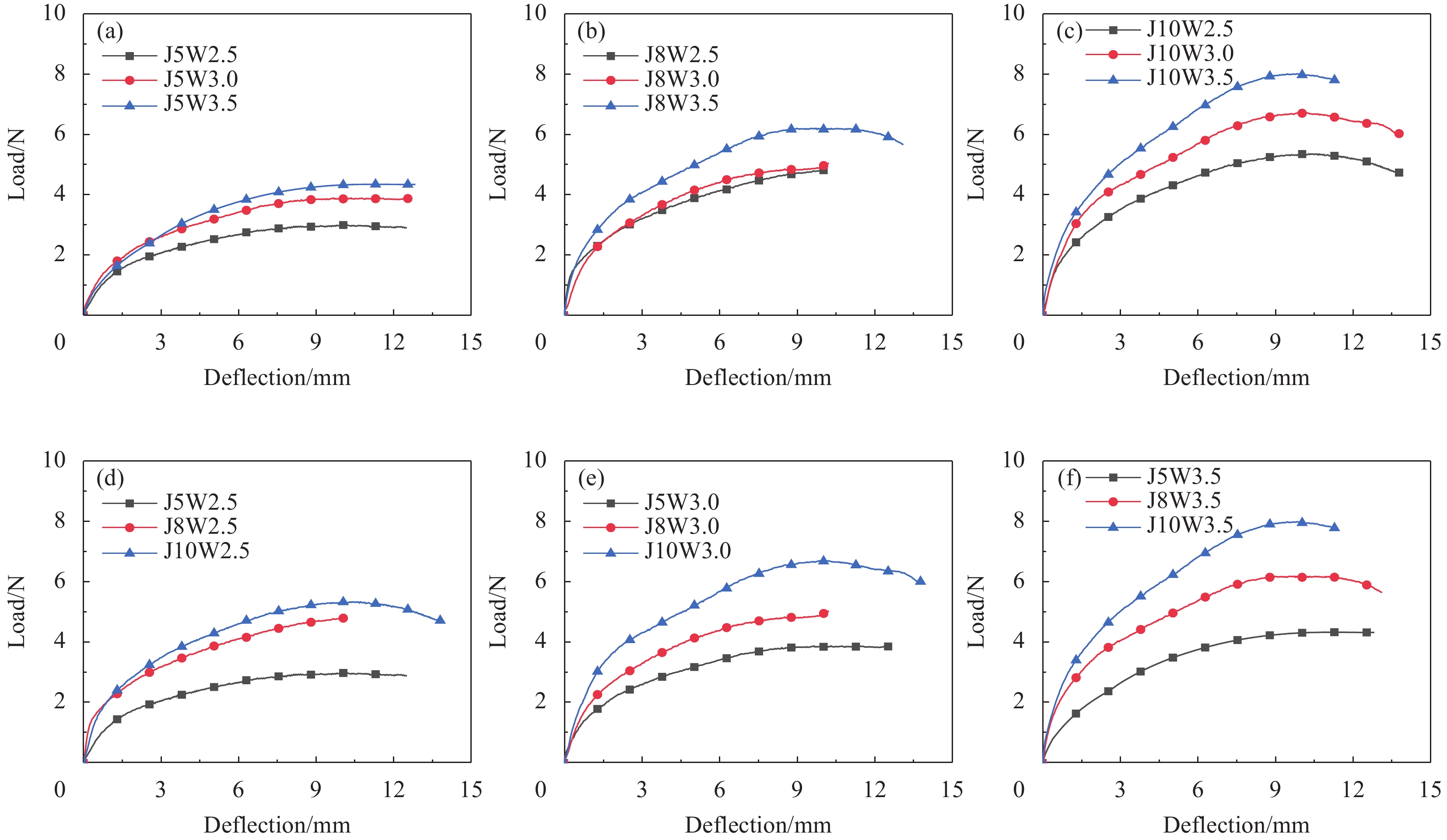

图4显示了不同结构参数的预制体弯曲载荷-挠度曲线。不同试样的载荷-挠度曲线变化趋势大致相同,曲线均表现出显著的非线性特征,当挠度达到10 mm左右时,弯曲载荷基本达到峰值,弯曲挠度继续增加时,弯曲载荷不再增加,随着试样与支座之间发生滑移,弯曲载荷逐渐下降,直到试样脱离支座。

![]() 图 4 3D机织预制体三点弯曲试样载荷-挠度曲线:((a)~(c)) 经纱密度5根/cm、8根/cm、10根/cm;((d)~(f)) 纬纱密度2.5根/cm、3.0根/cm、3.5根/cmFigure 4. Load-deflection curves of three-point bending samples of 3D woven preform: ((a)-(c)) Warp densities of 5 ends/cm, 8 ends/cm and 10 ends/cm; ((d)-(f)) Weft densities of 2.5 picks/cm, 3.0 picks/cm and 3.5 picks/cm

图 4 3D机织预制体三点弯曲试样载荷-挠度曲线:((a)~(c)) 经纱密度5根/cm、8根/cm、10根/cm;((d)~(f)) 纬纱密度2.5根/cm、3.0根/cm、3.5根/cmFigure 4. Load-deflection curves of three-point bending samples of 3D woven preform: ((a)-(c)) Warp densities of 5 ends/cm, 8 ends/cm and 10 ends/cm; ((d)-(f)) Weft densities of 2.5 picks/cm, 3.0 picks/cm and 3.5 picks/cm当试样经纱密度相同时,纬纱密度越大,弯曲载荷的峰值越大;同样地,当试样纬纱密度相同时,经纱密度越大,弯曲载荷的峰值也越大。这说明3D机织预制体的弯曲性能与试样内部的组织点密度(dw,单位体积内组织点的数量)密切相关,组织点密度越大,试样越不容易发生弯曲变形。

2.2 3D机织预制体临界弯曲能量

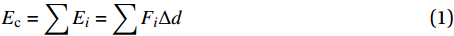

织物预制体是一种柔性材料,当弯曲挠度超过某一临界弯曲挠度值dc (dc约为10 mm)时,试样与三点弯曲支座开始发生滑移,随着弯曲挠度的继续增加,试样逐渐脱离支座。因此,本文认为试样弯曲挠度小于dc时为稳定弯曲状态。当弯曲挠度为dc时,载荷值为Fc、载荷累积做功为Ec (对应图5曲线下方的面积)。将Ec定义为试样的临界弯曲能量,表征其抗弯曲性能。

![]() 图 5 3D机织预制体三点弯曲试样临界弯曲能量Figure 5. Critical bending energy of three-point bending sample of 3D woven preformEi—Bending energy under a certain bending deflection; F—Bending load; Fc—Critical bending load value; Fi—Bending load value under a certain bending deflection; d—Bending deflection; dc—Critical bending deflection value; Δd—Unit bending deflection value

图 5 3D机织预制体三点弯曲试样临界弯曲能量Figure 5. Critical bending energy of three-point bending sample of 3D woven preformEi—Bending energy under a certain bending deflection; F—Bending load; Fc—Critical bending load value; Fi—Bending load value under a certain bending deflection; d—Bending deflection; dc—Critical bending deflection value; Δd—Unit bending deflection value将曲线覆盖区域分为n个宽Δd的狭长矩形,第i个矩形的高度为Fi,则临界弯曲能量Ec可由下式计算:

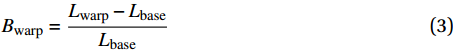

Ec=∑Ei=∑FiΔd (1) 预制体的弯曲性能与其组织点密度dw有关,dw由下式计算:

dw=dwarpdweftnwarpN (2) 其中:

dwarp 为经纱密度;dweft 为纬纱密度;nwarp 为经纱层数,N=4表示一根经纱上两个相邻组织点跨越的纬纱数量。不同预制体样件的组织点密度如表1中所示。图6给出了预制体临界弯曲能量Ec与组织点密度dw的关联关系。结果显示,Ec随着dw的增加而增大,二者大致呈线性关系。预制体组织点密度越大,纱线排布越紧密、彼此之间的相互约束力越强,因此弯曲变形时所需的临界弯曲能量越大。2.3 3D机织预制体经纱屈曲度变化

碳纤维3D机织预制体发生宏观弯曲变形后,其内部微细观结构也发生了显著变化。本文对典型结构的预制体试样(J5W3.0)开展了变形前、后的Micro-CT扫描测试。弯曲变形前,预制体内部的纱线排布比较规则:纬纱沿厚度方向排布成列,各纬纱列基本呈竖直状态;经纱与纬纱相互交织,一根经纱将上下相邻的两层纬纱连锁起来,各层经纱的路径基本一致。

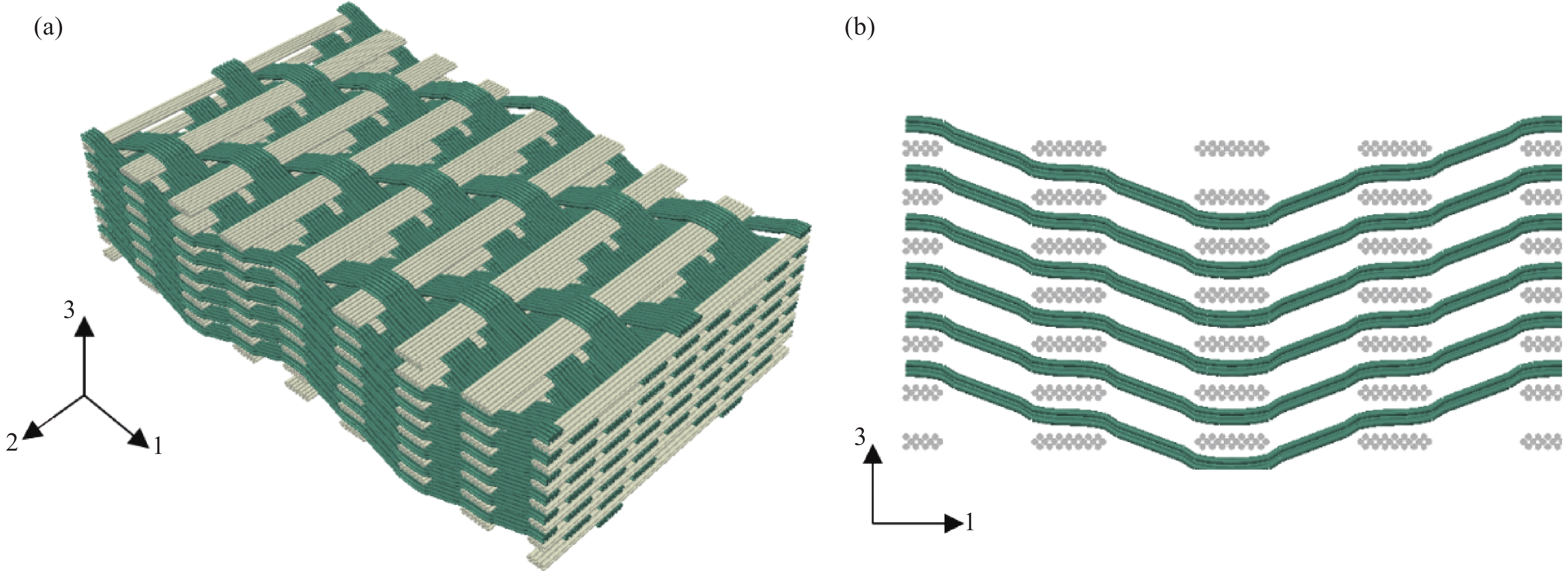

弯曲变形后,经纱的屈曲形态会发生显著变化。引入经纱屈曲度

Bwarp 来表征变形前后经纱屈曲形态的变化:Bwarp=Lwarp−LbaseLbase (3) 其中:

Lwarp 为经纱实际长度(图7实线长度);Lbase 为基准线长度(图7虚线长度)。弯曲变形前,Lbase 是纱线两端的直线间距。弯曲变形后,基准线随着试样变形为弧线,Lbase 为图7(b)所示的弧线长度,该弧线是连接上下两层纬纱各中心点的样条曲线。预制体弯曲变形前、后,其内部各层经纱的路径分别如图8(a)和图8(b)所示,其中L1~L6表示第1层~第6层经纱。弯曲变形后,预制体样件表层经纱受压、底层经纱受拉,因此不同位置处的经纱屈曲度发生了变化。预制体样件在变形前、后的经纱屈曲度如图8(c)所示。未变形前各层经纱长度基本相同,屈曲度均为0.025。弯曲变形后,底层经纱(L1~L2)在拉伸载荷下伸直,屈曲度降低;中间层经纱(L3~L4)的屈曲度与变形前相比变化不大;表层经纱(L5~L6)在压缩载荷下屈曲度进一步提高。由底层至表层,经纱的屈曲度明显增大,L6经纱的屈曲度比L1经纱提高了98.3%。

弯曲变形会引起表层经纱的局部屈曲现象,如图9所示。这些位置的经纱没有其他纱线的约束,处于自由状态,受到纵向压缩时容易产生横向膨胀,即“负泊松”效应。L1经纱的局部屈曲使试样表面产生褶皱。试样内部的经纱在弯曲变形时的屈曲度较低,而且与周围纱线相接触,处于受约束状态,一般不会产生屈曲现象。

2.4 3D机织预制体纬纱列偏转角度

弯曲变形前,纬纱列的排布呈竖直状态,穿过纬纱列的直线与试样表面大致垂直。弯曲变形后,纬纱列的排布仍然保持为直线,但不再与试样表面垂直。可见,高厚度的碳纤维3D机织预制体的弯曲行为不符合Kirchhoff薄板弯曲理论,预制体弯曲过程中发生了层间剪切变形,即纬纱和经纱之间发生了层间滑移。为了量化分析预制体试样的层间剪切变形,本文基于Micro-CT扫描图像统计了8列纬纱(C1~C8)的偏转角度,如图10(a)所示。其中,织物表面路径是沿着试样上表面轮廓线进行设定的,在压头附近,试样与压头紧密贴合,此处的轮廓线曲率与压头曲率一致。纬纱列偏转角度为预制体初始法向和纬纱列方向之间的夹角。初始法向为经过表层纬纱形心且垂直于织物表面路径的直线(图10(a)点虚线);纬纱列方向为连接表层和底层纬纱形心的直线(图10(a)虚线)。统计结果如图10(b)所示:压头左右两侧纬纱列的偏转角度大致对称分布;靠近压头的纬纱列偏转角较小,远离压头的纬纱列偏转角较大;随着与压头距离的增大,纬纱列偏转角度表现出先增大后减小的趋势,最大偏转角度为26.85°。

3. 结 论

研究了碳纤维3D机织预制体结构参数对其弯曲性能的影响,基于Micro-CT技术分析了弯曲变形前后预制体内部细观结构的变化,得出以下结论:

(1) 碳纤维3D机织预制体的弯曲载荷-挠度曲线表现出显著的非线性特征,经、纬密较大时,预制体结构紧密,不容易发生弯曲变形;

(2) 预制体样件在三点弯曲测试中挠度小于10 mm时为稳定弯曲变形,临界弯曲能量随着组织点密度的增加线性增大;

(3) 碳纤维3D机织预制体的弯曲变形由经纱屈曲度变化、局部压缩屈曲和经纬纱层间滑移等微细观变形构成;

(4) 预制体发生弯曲变形后,其内部的微细观变形并不均匀,不同位置的纤维结构差异较大,会导致最终复合材料力学性能的离散性。

-

图 4 3D机织预制体三点弯曲试样载荷-挠度曲线:((a)~(c)) 经纱密度5根/cm、8根/cm、10根/cm;((d)~(f)) 纬纱密度2.5根/cm、3.0根/cm、3.5根/cm

Figure 4. Load-deflection curves of three-point bending samples of 3D woven preform: ((a)-(c)) Warp densities of 5 ends/cm, 8 ends/cm and 10 ends/cm; ((d)-(f)) Weft densities of 2.5 picks/cm, 3.0 picks/cm and 3.5 picks/cm

图 5 3D机织预制体三点弯曲试样临界弯曲能量

Figure 5. Critical bending energy of three-point bending sample of 3D woven preform

Ei—Bending energy under a certain bending deflection; F—Bending load; Fc—Critical bending load value; Fi—Bending load value under a certain bending deflection; d—Bending deflection; dc—Critical bending deflection value; Δd—Unit bending deflection value

表 1 3D机织预制体结构参数

Table 1 Structure parameters of 3D woven preforms

Sample Number of warp layer Number of weft layer Apparent thickness/mm Weaving point density/cm−2 J5W2.5 7 8 6.31 21.88 J5W3.0 6 7 5.89 22.50 J5W3.5 6 7 6.19 26.25 J8W2.5 5 6 6.78 25.00 J8W3.0 5 6 6.60 30.00 J8W3.5 4 5 5.97 28.00 J10W2.5 4 5 6.71 25.00 J10W3.0 4 5 7.00 30.00 J10W3.5 4 5 6.73 35.00 -

[1] 陈利, 赵世博, 王心淼. 三维纺织增强材料及其在航空航天领域的应用[J]. 纺织导报, 2018(S1):80-87. DOI: 10.3969/j.issn.1003-3025.2018.z1.018 CHEN L, ZHEN S B, WANG X M. Three-dimensional textile reinforcement and its application in aerospace[J]. Textile Herald,2018(S1):80-87(in Chinese). DOI: 10.3969/j.issn.1003-3025.2018.z1.018

[2] 陈利, 焦伟, 王心淼, 等. 三维机织复合材料力学性能研究进展[J]. 材料工程, 2020, 48(8):62-72. DOI: 10.11868/j.issn.1001-4381.2020.000210 CHEN L, JIAO W, WANG X M, et al. Research progress on mechanical properties of 3D woven composites[J]. Jour-nal of Materials Engineering,2020,48(8):62-72(in Chinese). DOI: 10.11868/j.issn.1001-4381.2020.000210

[3] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. DOI: 10.3321/j.issn:1000-3851.2007.01.001 DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). DOI: 10.3321/j.issn:1000-3851.2007.01.001

[4] 杨志, 焦亚男, 谢军波, 等. 纺织复合材料纤维预制体力学性能测试方法的研究进展[J]. 复合材料学报, 2022, 39(4):1511-1533. YANG Z, JIAO Y N, XIE J B, et al. Research progress on testing methods for mechanical properties of textile compo-site fiber preforms[J]. Acta Materiae Compositae Sinica,2022,39(4):1511-1533(in Chinese).

[5] JIAO W, CHEN L, XIE J B, et al. Effect of weaving structures on the geometry variations and mechanical properties of 3D LTL woven composites[J]. Composite Structures,2020,252:112756. DOI: 10.1016/j.compstruct.2020.112756

[6] LABANIEH A R, GARNIER C, OUAGNE P, et al. Intra-ply yarn sliding defect in hemisphere preforming of a woven preform[J]. Composites Part A: Applied Science and Manufacturing, 2018, 107: 432-446.

[7] TURK M A, VERMES B, THOMPSON A J, et al. Mitigating forming defects by local modification of dry preforms[J]. Composites Part A: Applied Science and Manufacturing,2020,128:105643.

[8] BOISSE P, HAMILA N, VIDAL-SALLE E, et al. Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses[J]. Composites Science and Technology,2011,71(5):683-692. DOI: 10.1016/j.compscitech.2011.01.011

[9] SJOLANDER J, HALLANDER P, AKERMO M. Forming induced wrinkling of composite laminates: A numerical study on wrinkling mechanisms[J]. Composites Part A: Applied Science and Manufacturing, 2016, 81: 41-51.

[10] SULE G. Investigation of bending and drape properties of woven fabrics and the effects of fabric constructional parameters and warp tension on these properties[J]. Textile Research Journal,2012,82(8):810-819. DOI: 10.1177/0040517511433152

[11] SYERKO E, COMAS-CARDONA S, BINETRUY C. Models of mechanical properties/behavior of dry fibrous materials at various scales in bending and tension: A review[J]. Composites Part A: Applied Science and Manufacturing,2012,43(8):1365-1388. DOI: 10.1016/j.compositesa.2012.03.012

[12] BOISSE P, COLMARS J, HAMILA N, et al. Bending and wrinkling of composite fiber preforms and prepregs: A review and new developments in the draping simulations[J]. Composites Part B: Engineering,2018,141:234-249. DOI: 10.1016/j.compositesb.2017.12.061

[13] PEIRCE F T. 26—the “Handle” of cloth as a measurable quantity[J]. Journal of the Textile Institute Transactions,1930,21(9):T377-T416. DOI: 10.1080/19447023008661529

[14] DEBILBAO E, SOULAT D, HIVET G, et al. Experimental study of bending behaviour of reinforcements[J]. Experimental Mechanics,2009,50(3):333-351.

[15] DANGORA L M, MITCHELL C J, SHERWOOD J A. Predic-tive model for the detection of out-of-plane defects formed during textile-composite manufacture[J]. Composites Part A: Applied Science and Manufacturing,2015,78:102-112. DOI: 10.1016/j.compositesa.2015.07.011

[16] LAMMENS N, KERSEMANS M, LUYCKX G, et al. Improved accuracy in the determination of flexural rigidity of textile fabrics by the Peirce cantilever test (ASTM D1388)[J]. Textile Research Journal,2014,84(12):1307-1314. DOI: 10.1177/0040517514523182

[17] KAWABATA S. The standardization and analysis of hand evaluation[M]. Osaka: The Textile Machinery Society of Japan, 1980.

[18] ROPERS S, KARDOS M, OSSWALD T A. A thermo-viscoelastic approach for the characterization and modeling of the bending behavior of thermoplastic composites[J]. Composites Part A: Applied Science and Manufacturing,2016,90:22-32. DOI: 10.1016/j.compositesa.2016.06.016

[19] SACHS U, AKKERMAN R. Viscoelastic bending model for continuous fiber-reinforced thermoplastic composites in melt[J]. Composites Part A: Applied Science and Manufacturing,2017,100:333-341. DOI: 10.1016/j.compositesa.2017.05.032

[20] CALISKAN U, APALAK M K. Low velocity bending impact behavior of foam core sandwich beams: Experimental[J]. Composites Part B: Engineering,2017,112:158-175. DOI: 10.1016/j.compositesb.2016.12.038

[21] CHARMETANT A, ORLIAC J G, VIDAL-SALLÉ E, et al. Hyperelastic model for large deformation analyses of 3D interlock composite preforms[J]. Composites Science and Technology,2012,72(12):1352-1360. DOI: 10.1016/j.compscitech.2012.05.006

[22] LIANG B, COLMARS J, BOISSE P. A shell formulation for fibrous reinforcement forming simulations[J]. Compo-sites Part A: Applied Science and Manufacturing,2017,100:81-96. DOI: 10.1016/j.compositesa.2017.04.024

[23] BOISSE P, BAI R, COLMARS J, et al. The need to use generalized continuum mechanics to model 3D textile compo-site forming[J]. Applied Composite Materials,2018,25(4):761-771. DOI: 10.1007/s10443-018-9719-8

[24] MARGOSSIAN A, BEL S, HINTERHOELZL R. Bending characterisation of a molten unidirectional carbon fibre reinforced thermoplastic composite using a dynamic mecha-nical analysis system[J]. Composites Part A: Applied Science and Manufacturing,2015,77:154-163. DOI: 10.1016/j.compositesa.2015.06.015

[25] 中国国家标准化管理委员会. 三维编织物及其树脂基复合材料弯曲性能试验方法: GB/T 33621—2017[S]. 北京: 中国标准出版社, 2017. Standardization Administration of China. Test method for bending properties of 3D braided fabric and its polymer matrix composites: GB/T 33621—2017[S]. Beijing: Standards Press of China, 2017(in Chinese).

-

期刊类型引用(2)

1. 朱琬清,谢军波,吴兰芳,陈利,杨林,刘静妍. 3D机织预制体准纤维尺度建模方法. 复合材料学报. 2024(03): 1528-1538 .  本站查看

本站查看

2. 蔣永亮,马文锁,马振宇,许泳豪,朱梦蝶. 低捻纱三维角联锁机织预制体的不稳定结构变形模型. 棉纺织技术. 2024(12): 38-44 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: