Preparation and bending properties of curved structure composite reinforced with multi-axial warp-knitted glass fabric

-

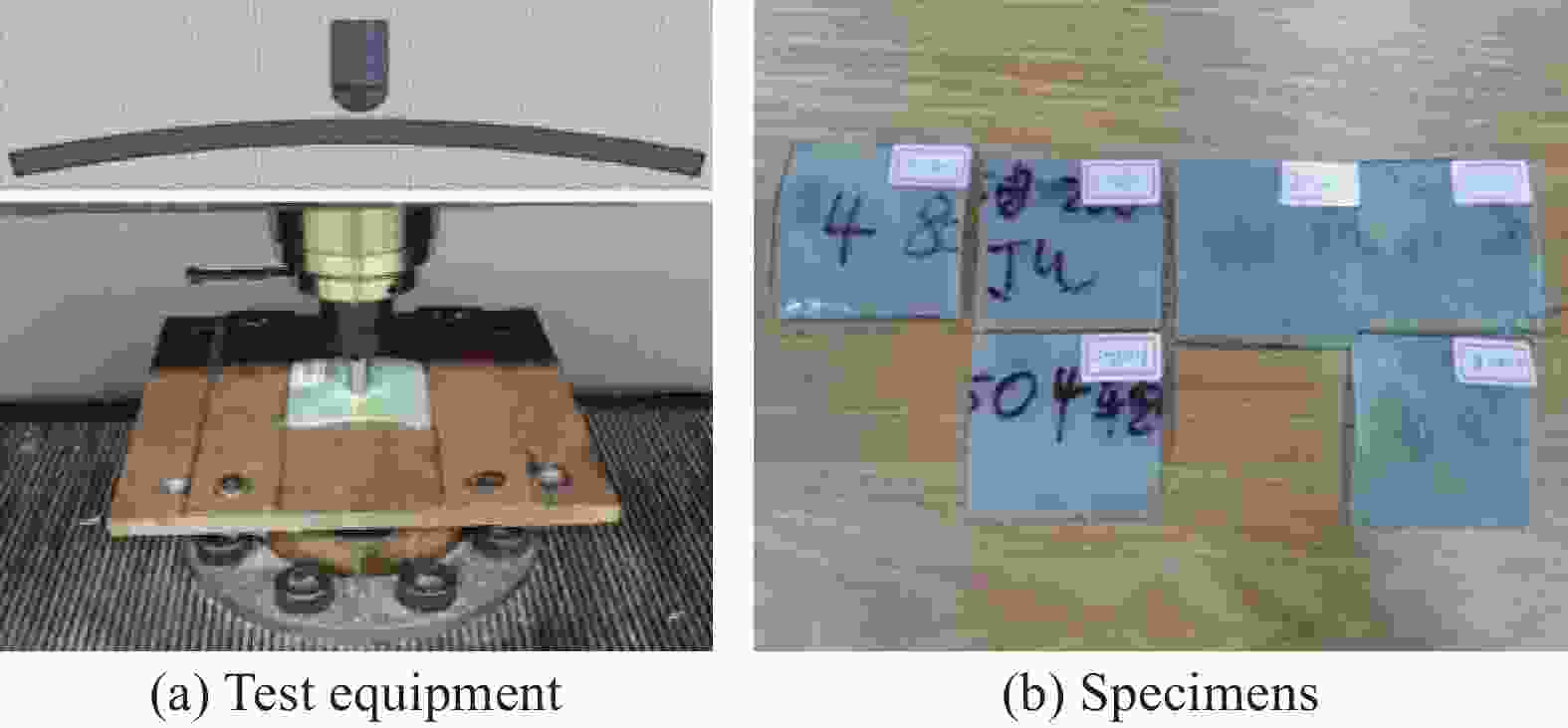

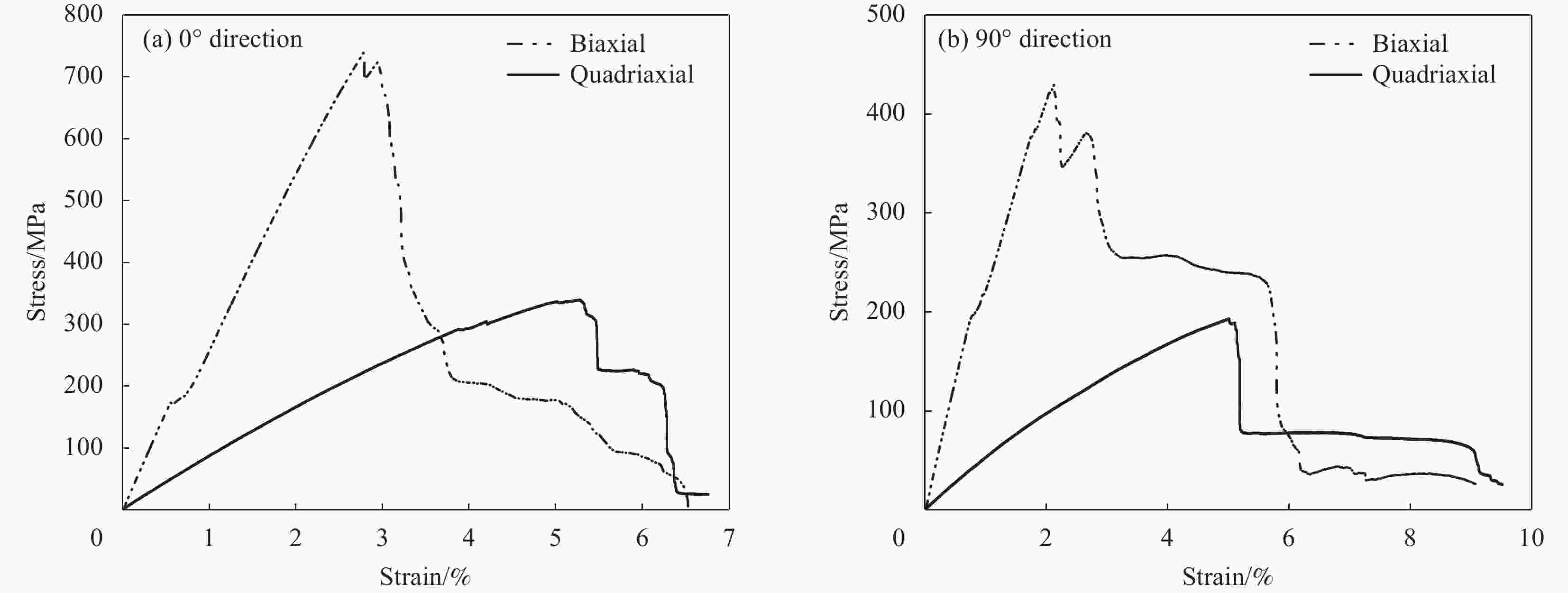

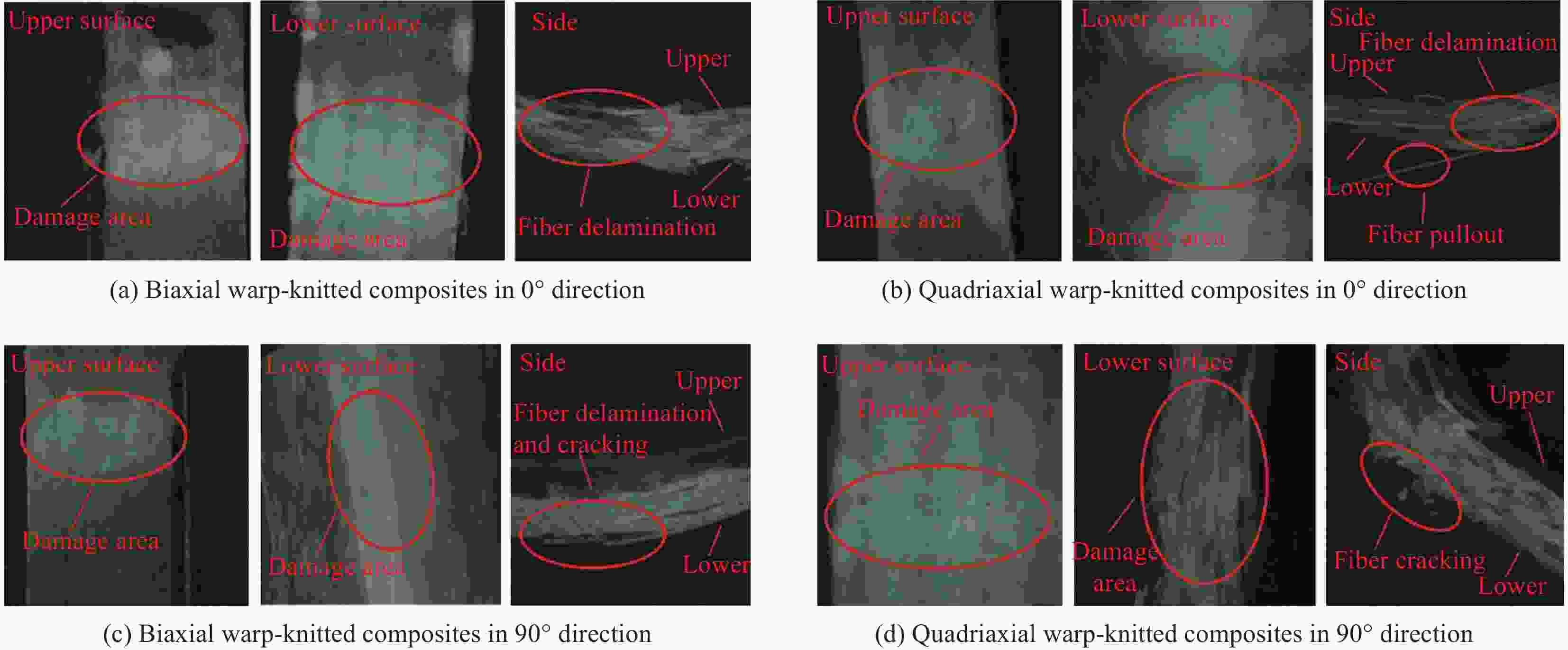

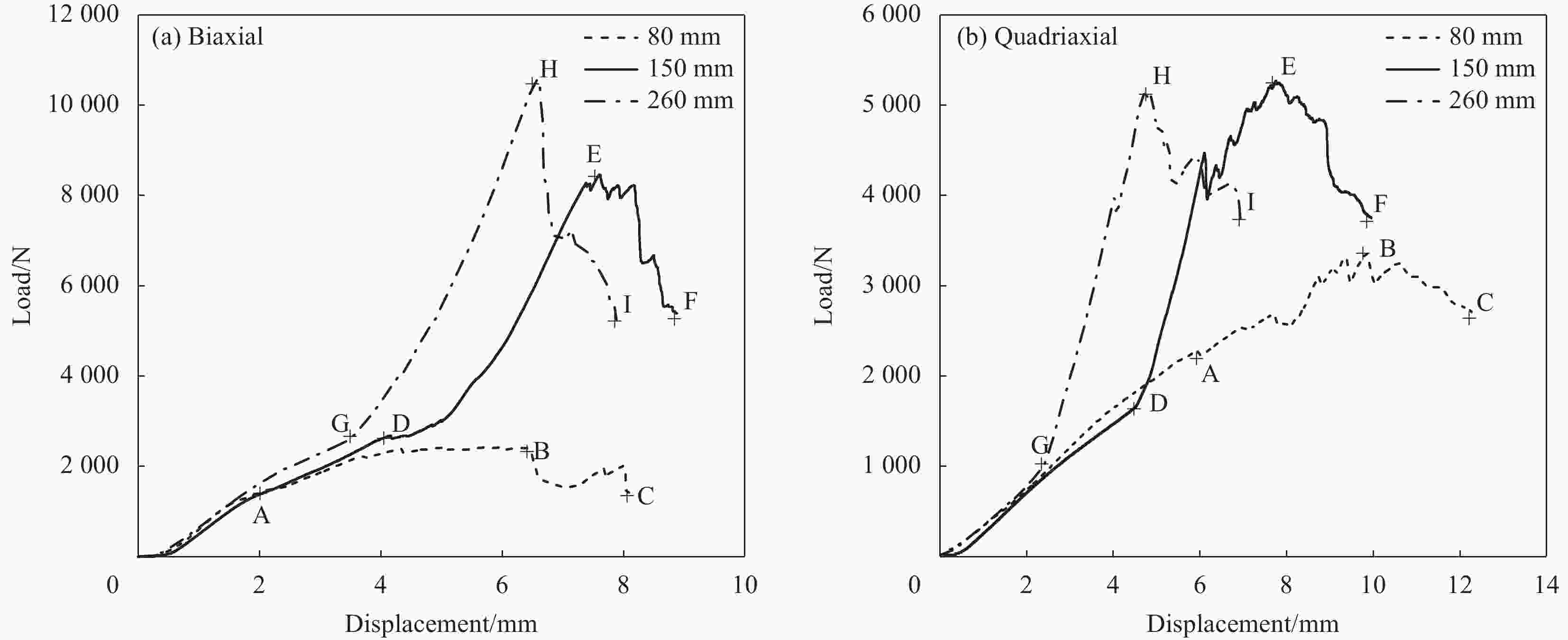

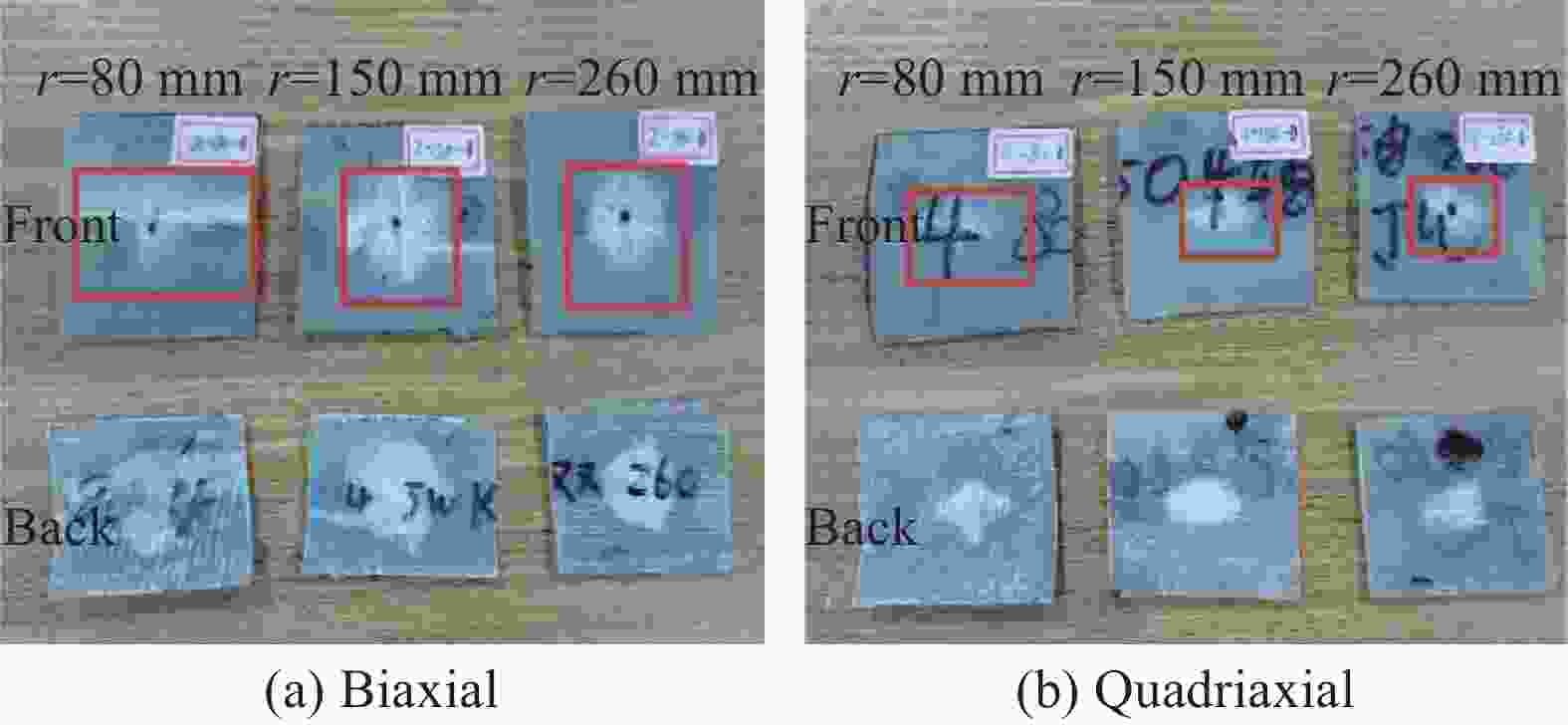

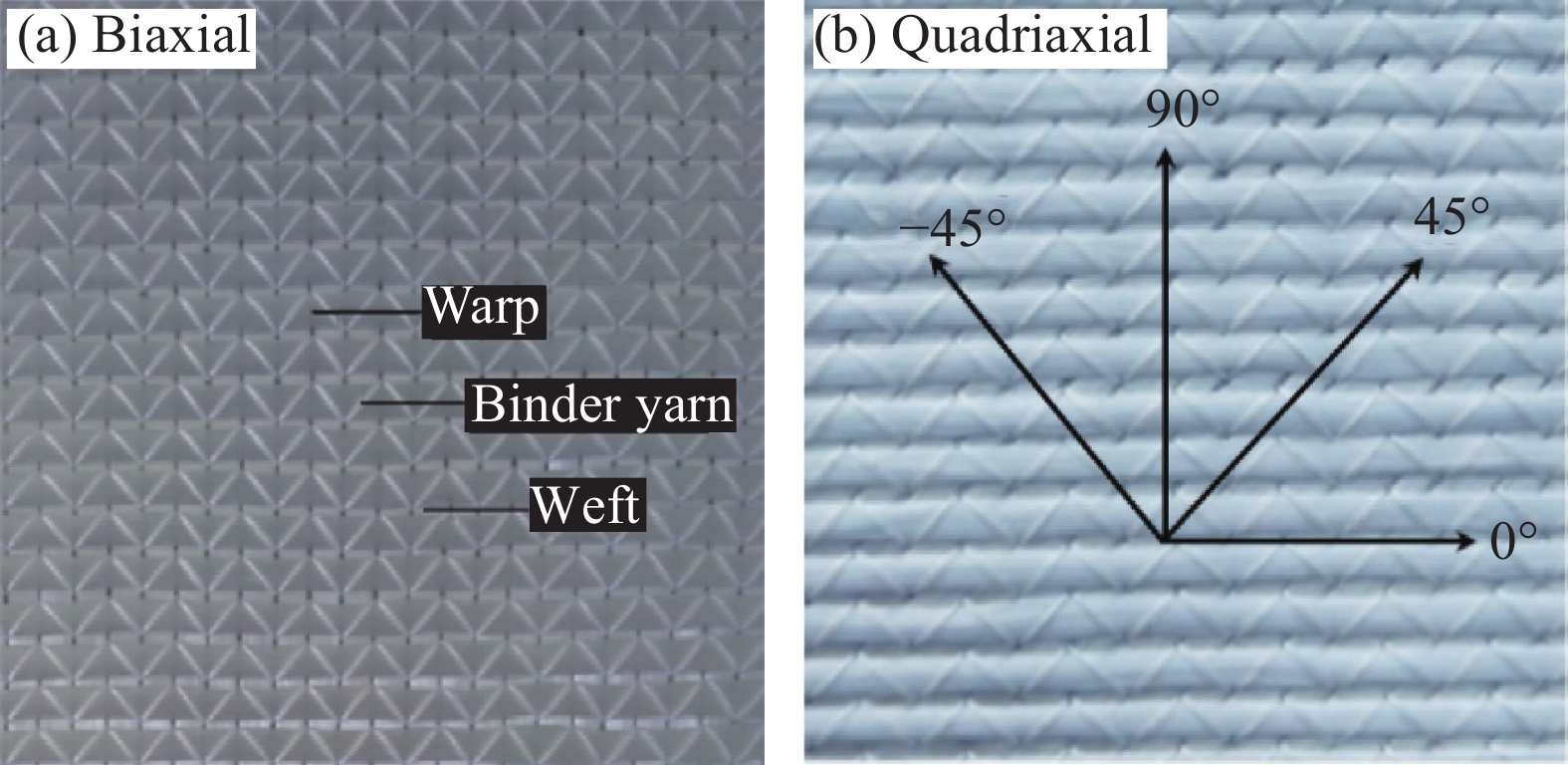

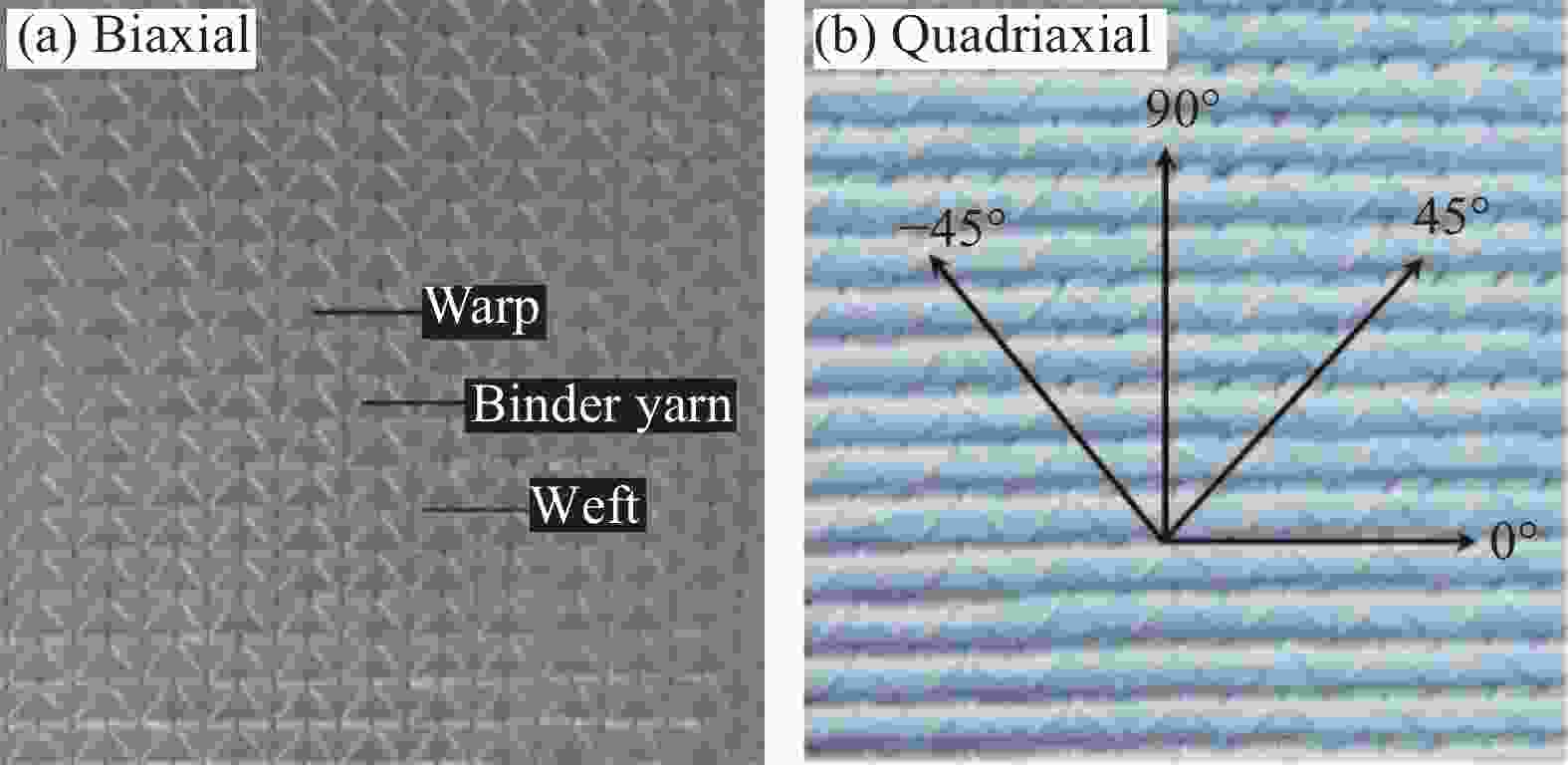

摘要: 分别以双轴向和四轴向经编玻璃纤维织物为增强体,基于真空辅助树脂传递模塑成型工艺制备平板和曲面结构复合材料试样。实验测试复合材料弯曲性能和准静态压痕特性,实验测试不同铺层结构试样沿不同方向(0°和 90°)的弯曲性能。在此基础上,分析增强体铺层结构、曲率半径对曲面结构复合材料准静态压痕特性的影响。结果表明:双轴向经编玻璃纤维复合材料试样沿0°和90°方向当量弯曲强度分别比四轴向编玻璃纤维复合材料增加94.74%、98.37%,四轴向经编玻璃纤维复合材料试样沿0°和90°方向的最大断裂应变分别是双轴向经编玻璃纤维复合材料试样的1.9倍和2.4倍。当双轴向复合材料曲率半径为260 mm、四轴向复合材料曲率半径为150 mm时,承载能力最优;当双轴向复合材料曲率半径为150 mm、四轴向复合材料曲率半径为80 mm时,应变特性最优。实验结果为曲面结构玻璃纤维复合材料在各类室外建筑穹顶构件的应用提供借鉴。Abstract: Biaxial warp-knitted glass fabric and quadriaxial warp-knitted glass fabric were used as reinforcement, respectively. The flat and curved structure samples were prepared by applying the vacuum assisted resin transfer molding process. The bending behavior and quasi-static indentation characteristics of composite specimen were experimentally tested, and the influence of the reinforcement structure on the bending behavior of the composite in 0° and 90° directions was analyzed. On this basis, the influences of the reinforcement structure and the radius of curvature of the sample on the quasi-static indentation characteristics were also analyzed. Results show that the equivalent bending strength of the composite reinforced with biaxial warp-knitted fabric in 0° and 90° directions increase by 94.74% and 98.37%, respectively in comparison with that of the quadriaxial warp-knitted fabric, and the maximum fracture strain of the quadriaxial warp-knitted fabric in 0° and 90° directions are 1.9 times and 2.4 times than that of the biaxial warp-knitted fabric. When the curvature radius of biaxial composite is 260 mm and the curvature radius of quadriaxial composite is 150 mm, the bending strength of the two materials are optimal. When the curvature radius of biaxial composite is 150 mm and the curvature radius of quadriaxial composite is 80 mm, the fracture strain of the two composites are optimal. The experimental results will provide guidance for application of curved structure composite in various large outdoor building domes.

-

表 1 多轴向玻璃纤维经编织物基本参数

Table 1. Basic parameters of multi-axial warp-knitted fabric

Fabric structure Axial/(°) Linear density/tex Layer number Weaving density/(yarn·10 cm−1) Surface density/(g·m−2) Thickness/mm Biaxial 0° 2400 2 27 1200 1.0 90° 1500 22 Quadriaxial 0° 600 3 39 800 0.7 45° 300 55 90° 300 55 −45° 300 40 表 2 复合材料试样及性能测试

Table 2. Composite material specimens and performance tests

Specimen structure Fabric

structureTest direction Type of

testFlat Biaxial 0°/90° Bending properity Quadriaxial 0°/90° Curved Biaxial — Quasi-static indentation Quadriaxial — 表 3 弯曲试样实际尺寸

Table 3. Actual size of bending sample

Specimen Test direction Average width/mm Average thickness/mm Average span/mm Biaxial 0° 12.79 3.20 51.20 90° 12.63 3.17 50.72 Quadriaxial 0° 12.85 2.98 47.68 90° 12.71 3.06 48.96 表 4 准静态压痕测试试件参数

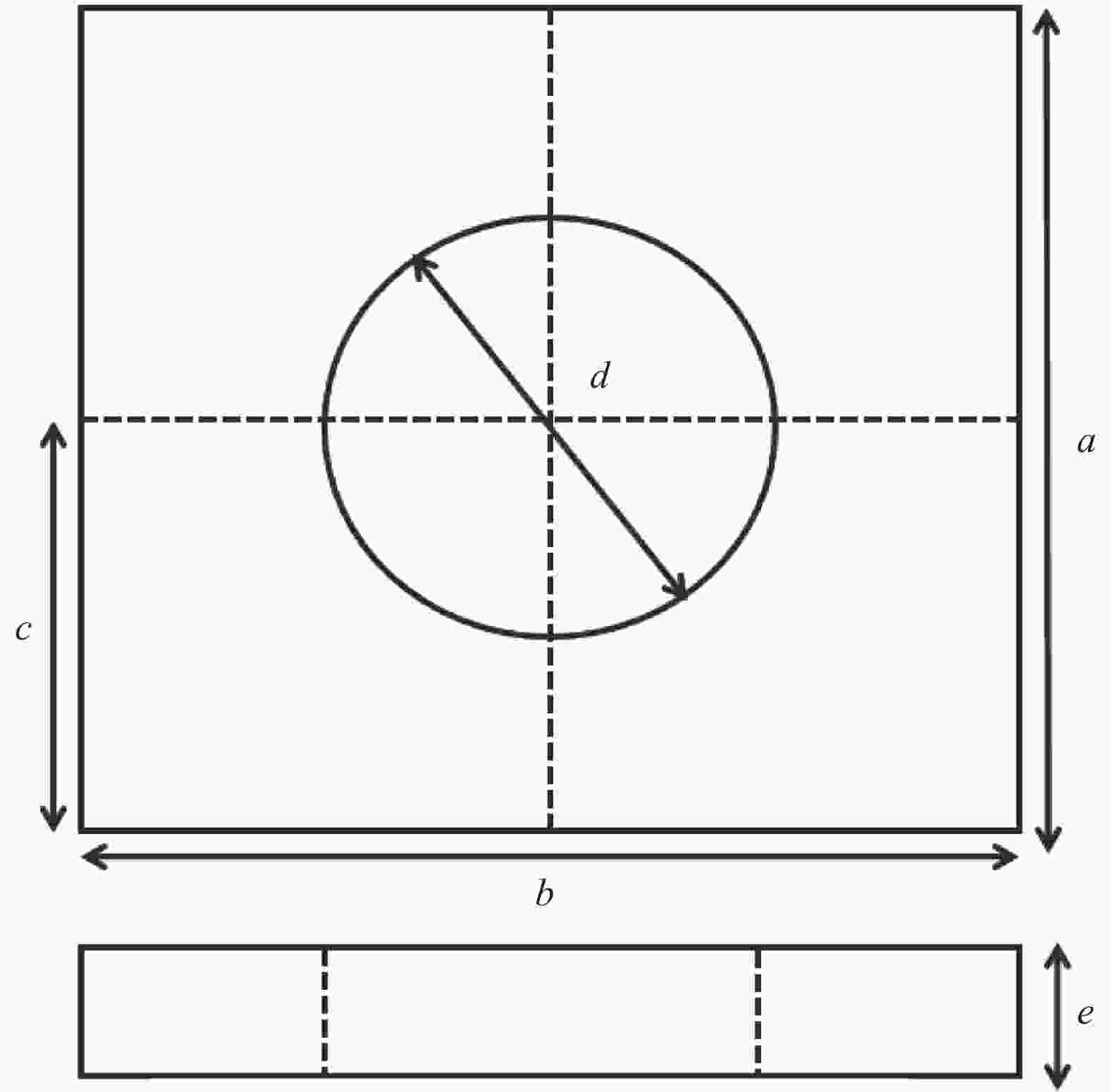

Table 4. Quasi-static indentation test specimen parameters

Designation Value/mm Length a 75±1 Width b 75±1 Half length c 40±0.5 Diameter d 50±1 Thickness e 15±1 表 5 经编多轴向玻璃纤维复合材料试样灼烧前后的质量、体积和纤维体积分数

Table 5. Mass, volume before and after burning and fiber volume fractions of composite reinforced with multi-axial warp-knitted glass fabric

Specimen Specimen volume/cm3 Specimen mass/g Mass after burning/g Matrix mass

/gFiber volume fraction/% Biaxial 1.482 3.217 2.402 0.815 56.68 Quadriaxial 1.468 3.196 2.235 0.961 50.80 表 6 经编多轴向玻璃纤维复合材料弯曲性能参数

Table 6. Parameters of bending performance of composite reinforced with multi-axial warp-knitted glass fabric

Specimen Direction/(°) Maximum load/N Maximum strain/% Bending strength/MPa Bending modulus/GPa Equivalent strength/MPa Equivalent modulus/GPa Biaxial 0 1255.59 2.78 741.49 32.89 588.69 26.11 90 729.58 2.10 430.85 29.98 342.07 23.80 Quadriaxial 0 541.75 5.27 341.26 9.42 302.30 8.34 90 329.64 4.99 194.67 5.54 172.44 4.91 表 7 曲面结构经编多轴向玻璃纤维复合材料准静态压痕实验结果

Table 7. Results of quasi-static indentation experiment of curved structure composite reinforced with multi-axial warp-knitted glass fabric

Specimen Curvature

radius/mmMaximum

displacement/mmMaximum

load/NBiaxial 80 5.75 2431.3 150 7.61 8462.5 260 6.59 10587.5 Quadriaxial 80 9.81 3337.5 150 7.73 5250.0 260 4.70 5150.0 -

[1] BLONDER A, GROBMAN Y J. Design and fabrication with fibre-reinforced polymers in architecture: A case for complex geometry[J]. Architectural Science Review,2016,59(4):257-268. doi: 10.1080/00038628.2015.1020479 [2] 摩西·萨夫迪, 相南. 准则、秩序与复杂性[J]. 世界建筑, 2011(8):19-31.MOSHE Safdie, XIANG Nan. On ethics, order and comple-xity[J]. World Architecture,2011(8):19-31(in Chinese). [3] 徐进, 张伟. 多轴向经编复合材料在风电叶片制造中的应用[J]. 玻璃钢/复合材料, 2010(5):78-80. doi: 10.3969/j.issn.1003-0999.2010.05.018XU Jin, ZHANG Wei. Application of multi-axial warp-kitted technology in wind turbing blade design[J]. Compo-sites Science and Engineering,2010(5):78-80(in Chinese). doi: 10.3969/j.issn.1003-0999.2010.05.018 [4] 姜永恺. 高性能纤维的现状及应用[J]. 棉纺织技术, 2000(6):6-9. doi: 10.3969/j.issn.1001-7415.2000.06.001JIANG Yongkai. The status-quo and application of high-performance fibers[J]. Cotton Textile Technology,2000(6):6-9(in Chinese). doi: 10.3969/j.issn.1001-7415.2000.06.001 [5] GURUNATHAN T, MOHANTY S, NAYAK S K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives[J]. Composites Part A: Applied Science and Manufacturing,2015,77:1-25. [6] 钟文鑫, 马丕波. 风电叶片用多轴向经编织物发展现状[J]. 玻璃纤维, 2015(6):35-39. doi: 10.3969/j.issn.1005-6262.2015.06.008ZHONG Wenxin, MA Pibo. Development of multi-axial warp-knitted fabrics for wind turbine blades[J]. Fiber Glass,2015(6):35-39(in Chinese). doi: 10.3969/j.issn.1005-6262.2015.06.008 [7] 沈军, 谢怀勤. 航空用复合材料的研究与应用进展[J]. 玻璃钢/复合材料, 2006(5):48-54. doi: 10.3969/j.issn.1003-0999.2006.05.013SHEN Jun, XIE Huaiqin. Recent progress in study and application of composite materials for aeronautical engineering[J]. Composites Science and Engineering,2006(5):48-54(in Chinese). doi: 10.3969/j.issn.1003-0999.2006.05.013 [8] 党乐, 张梦雨, 成艳娜, 等. 3D打印技术在复合材料中的应用与发展[J]. 科技创新与应用, 2022, 12(24):166-169.DANG Le, ZHANG Mengyu, CHENG Yanna, et al. Application and development of 3D printing technology in composite materials[J]. Technology Innovation and Application,2022,12(24):166-169(in Chinese). [9] 陈晓明, 陆承麟, 龚明, 等. 超大尺度高分子复合材料3D打印技术研发与应用[J]. 施工技术, 2021, 50(21):41-45.CHEN Xiaoming, LU Chenglin, GONG Ming, et al. Research and application of 3D printing technology for super large-scale polymer composite material[J]. Construction Technology,2021,50(21):41-45(in Chinese). [10] JEON K W, SHIN K B, KIMC J S. A study on fatigue life and strength of a GFRP composite bogie frame for urban subway trains[J]. Procedia Engineering,2011,10:2405-2410. doi: 10.1016/j.proeng.2011.04.396 [11] 张霓, 郑晨阳, 羡丽娜, 等. 玻璃纤维增强树脂复合材料管-钢筋/混凝土空心构件抗弯性能[J]. 复合材料学报, 2020, 37(12):3052-3063. doi: 10.13801/j.cnki.fhclxb.20200417.001ZHANG Ni, ZHENG Chenyang, XIAN Lina, et al. Flexural behavior of glass fiber reinforced polymer tube filled with steel bars/concrete hollow members[J]. Acta Materiae Compositae Sinica,2020,37(12):3052-3063(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200417.001 [12] KASSEGNE S K, CHUN K. Erratum to: Buckling characteris-tic of multi-laminated composite elliptical cylindrical shells[J]. International Journal of Advanced Structural Engineering,2015,7(4):1-10. doi: 10.1007/s40091-015-0105-6 [13] 孟鑫淼. 复合材料曲面夹芯板受力性能及应用技术研究[D]. 北京: 清华大学, 2017.MENG Xinmiao. Mechanical behavior and application technology of FRP curved sandwich panels[D]. Beijing: Tsinghua University, 2017(in Chinese). [14] 李晓英. 三维横编间隔结构曲面复合材料制备及低速冲击性能[D]. 无锡: 江南大学, 2019.LI Xiaoying. Preparation of three-dimensional curved flat-knitted spacer fabric composites and its low-velocity impact property[D]. Wuxi: Jiangnan University, 2019(in Chinese). [15] 汪浩, 徐珍珍, 阮芳涛, 等. 增强体织物组织结构对曲面复合材料力学性能的影[J]. 中国塑料, 2019, 33(3):22-27. doi: 10.19491/j.issn.1001-9278.2019.03.005WANG Hao, XU Zhenzhen, RUAN Fangtao, et al. Effect of reinforced fabrics structure on mechanical properties of curved composites[J]. China Plastics,2019,33(3):22-27(in Chinese). doi: 10.19491/j.issn.1001-9278.2019.03.005 [16] 郭绍华, 张东致, 冉安国, 等. VARI工艺在大型曲面复合材料制件上的工程化应用研究[J]. 粘接, 2017, 38(8):64-67. doi: 10.3969/j.issn.1001-5922.2017.08.012GUO Shaohua, ZHANG Dongzhi, RAN Anguo, et al. Engi-neering application of VARI process in manufacturing of large curve-surface composite parts[J]. Adhesion,2017,38(8):64-67(in Chinese). doi: 10.3969/j.issn.1001-5922.2017.08.012 [17] 李帅, 姚盛杰, 何文涛, 等. GFRP约束微珠泡沫柱准静态受压性能[J]. 材料科学与工程学报, 2022, 40(1):129-134.LI Shuai, YAO Shengjie, HE Wentao, et al. Compressive behavior of GFRP confined syntactic foam columns under quasi-static loads[J]. Journal of Materials Science & Engi-neering,2022,40(1):129-134(in Chinese). [18] 高哲. 多轴向经编曲面复合材料低速冲击性能研究[D]. 无锡: 江南大学, 2017.GAO Zhe. Research on low-velocity impact mechanism of curved multi-axial warp-knitted composites[D]. Wuxi: Jiangnan University, 2017(in Chinese). [19] MUSCAT-FENECH C D M, CORTIS J, CASSAR C. Characterizing QSLVII damage of composite sandwich hulls[J]. Procedia Engineering,2014,88:141-148. doi: 10.1016/j.proeng.2014.11.137 [20] 李鹤, 张超, 季宏丽, 等. 基于导波检测的带曲率复合材料板损伤识别技术研究[J]. 国外电子测量技术, 2019, 38(5):75-80. doi: 10.19652/j.cnki.femt.1801318LI He, ZHANG Chao, JI Hongli, et al. Damage identification technology of composite plate with curvature based on guided wave detection[J]. Foreign Electronic Measurement Technology,2019,38(5):75-80(in Chinese). doi: 10.19652/j.cnki.femt.1801318 [21] SEIFOORI S, MAHDIAN P A, MIRZARAHMANI S. Impact damage detection in CFRP and GFRP curved composite laminates subjected to low-velocity impacts[J]. Compo-site Structures,2021,261:113278. doi: 10.1016/j.compstruct.2020.113278 [22] 董云龙, 梅志远, 张二, 等. 大曲率复合材料壳板弯曲试验及仿真[J]. 舰船科学技术, 2020, 42(13):40-44. doi: 10.3404/j.issn.1672-7649.2020.07.008DONG Yunlong, MEI Zhiyuan, ZHANG Er, et al. Research on bending test and simulation study of large curature composite shell plate[J]. Ship Science and Technology,2020,42(13):40-44(in Chinese). doi: 10.3404/j.issn.1672-7649.2020.07.008 [23] 高哲, 蒋高明. 多轴向经编曲面复合材料汽车门低速碰撞数值模拟[J]. 纺织学报, 2018, 39(2):43-48. doi: 10.13475/j.fzxb.20171006206GAO Zhe, JIANG Gaoming. Finite element analysis of curved multi-axial warp-knitted composite car door under low-velocity impact[J]. Journal of Textile Research,2018,39(2):43-48(in Chinese). doi: 10.13475/j.fzxb.20171006206 [24] 郑晓霞, 郑锡涛, 沈真, 等. 低速冲击与准静态压痕力下复合材料层合板的损伤等效性[J]. 航空学报, 2010, 31(5):928-933.ZHENG Xiaoxia, ZHENG Xitao, SHEN Zhen, et al. Damage equivalent of composite laminates subjected to drop-weight impact and quasi-static indentation force[J]. Acta Aeronautica et Astronautica Sinica,2010,31(5):928-933(in Chinese). [25] 沈真, 杨胜春, 陈普会. 复合材料抗冲击性能和结构压缩: 设计许用值[J]. 航空学报, 2007, 28(3):561-566. doi: 10.3321/j.issn:1000-6893.2007.03.010SHEN Zhen, YANG Shengchun, CHEN Puhui. Behaviors of composite materials to withstand impact and structural compressive design allowablene[J]. Acta Aeronautica et Astronautica Sinica,2007,28(3):561-566(in Chinese). doi: 10.3321/j.issn:1000-6893.2007.03.010 [26] XU S, CHEN P H. Prediction of low velocity impact damage in carbon/epoxy laminates[J]. Procedia Engineering,2013,67:489-496. doi: 10.1016/j.proeng.2013.12.049 [27] ASTM. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: ASTM D790—2015[S]. West Conshohocken: ASTM, 2015. [28] ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer-matrix composite to a concentrated quasi-static indentation force: ASTM D6264/D6264 M-17[S]. West Conshohocken: ASTM, 2017. [29] ASTM. Standard test methods for constituent content of composite materials: ASTM D3171—2015[S]. West Conshohocken: ASTM, 2015. [30] CARLSSON L A, ADAMS D F, PIPES R B. Experimental characterization of advanced composite materials[M]. Boca Raton: CRC Press, 2014. [31] 杨晓日. 多轴向玻璃纤维复合材料力学性能的温度效应研究[D]. 呼和浩特: 内蒙古工业大学, 2019.YANG Xiaori. Research of temperature effect on mechani-cal properties of multi-axial glass fiber composites[D]. Hohhot: Inner Mongolia University of Technology, 2019(in Chinese). [32] 黄光启, 程鹏飞, 杨胜春, 等. 准静态压痕力作用下复合材料层压板损伤分析方法[J]. 纤维复合材料, 2018, 35(3):48-52. doi: 10.3969/j.issn.1003-6423.2018.03.011HUANG Guangqi, CHENG Pengfei, YANG Shengchun, et al. The analysis method of quasi-static indentation force damage of composite laminate[J]. Fiber Composites,2018,35(3):48-52(in Chinese). doi: 10.3969/j.issn.1003-6423.2018.03.011 -

下载:

下载: