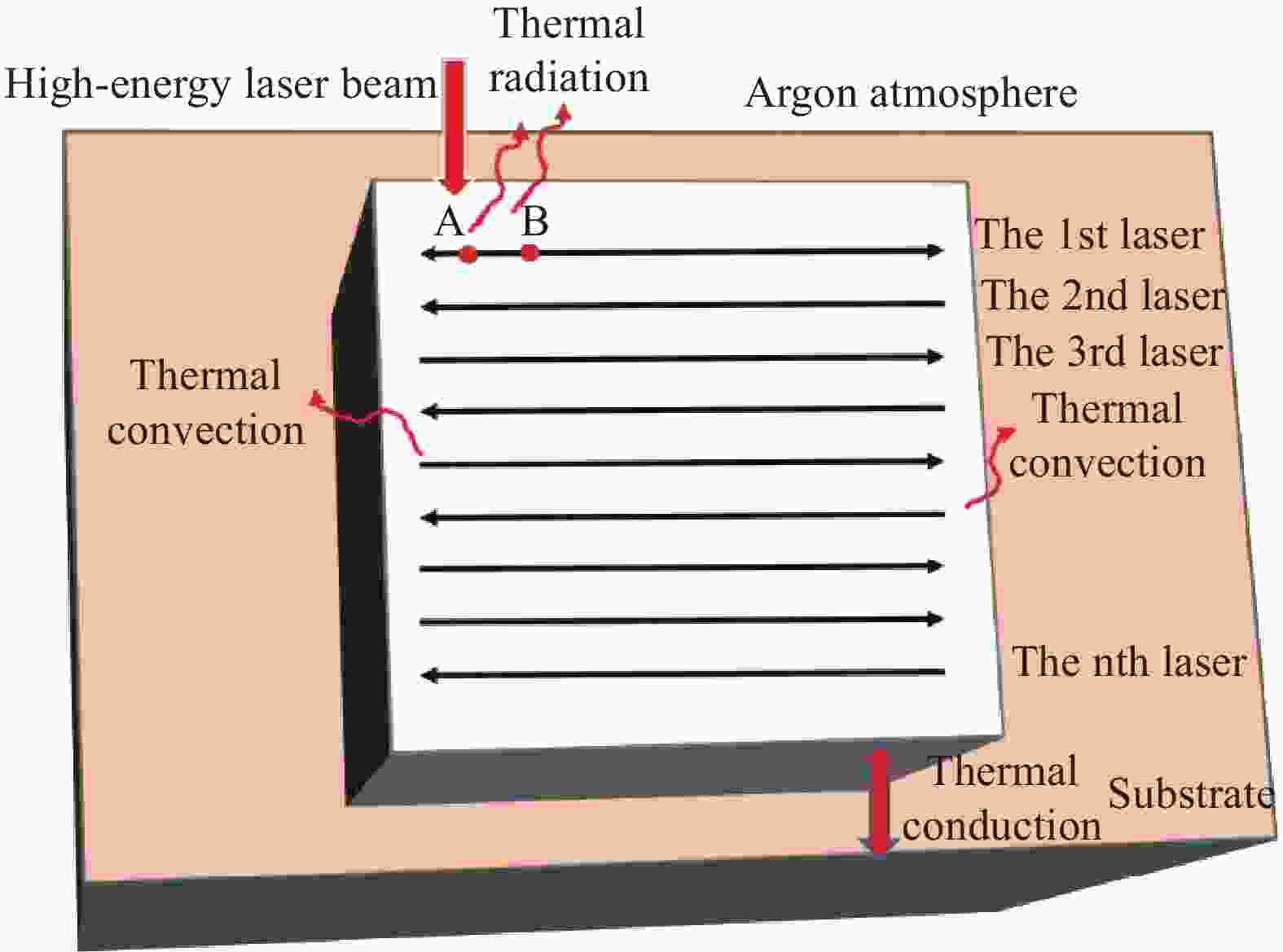

Forming process and microwave post-treatment of WC-12 Co cemented carbide cylindrical-shaped inner structure structure by selective laser melting

-

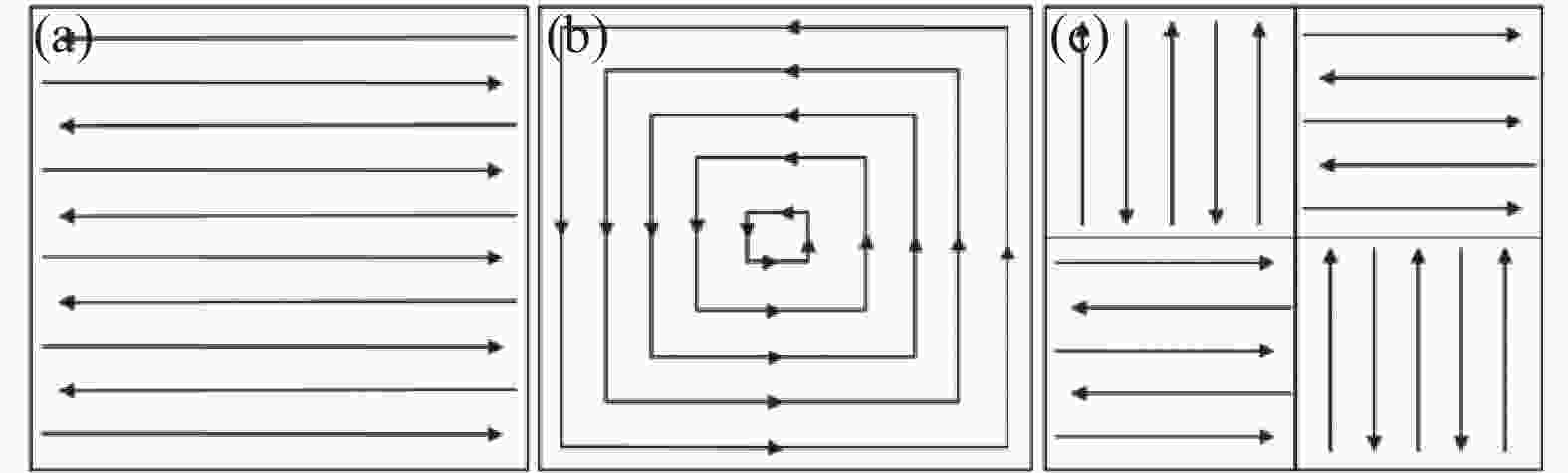

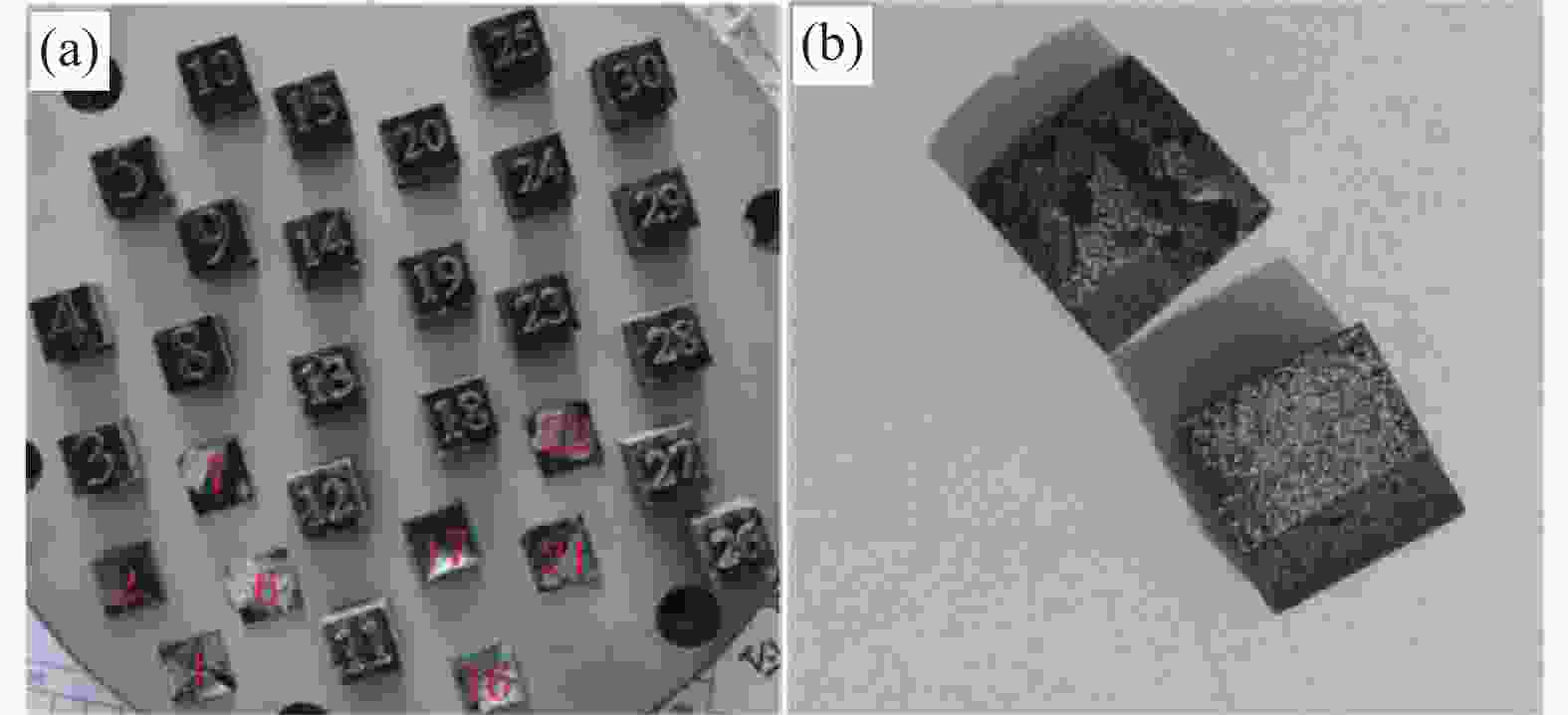

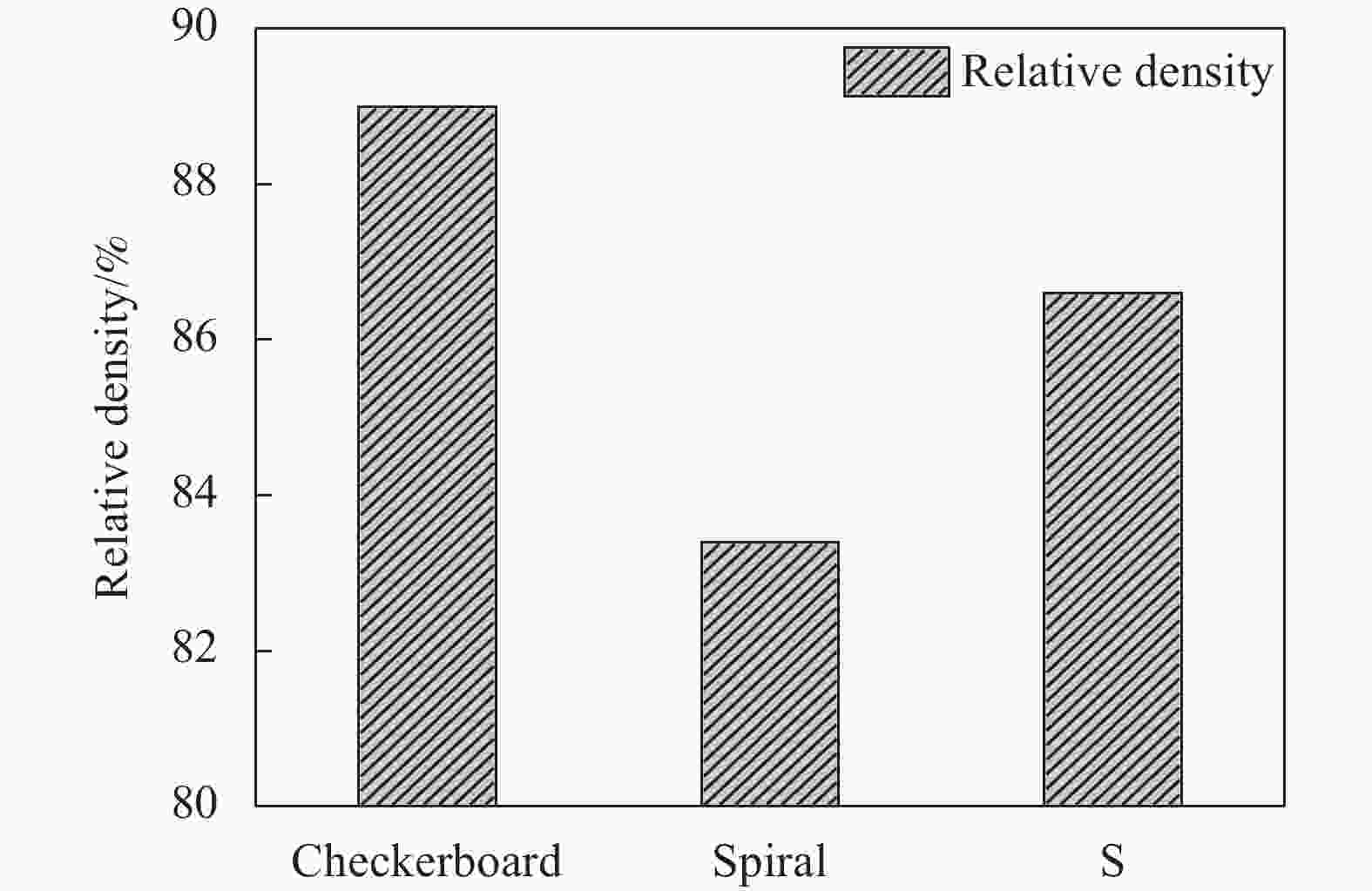

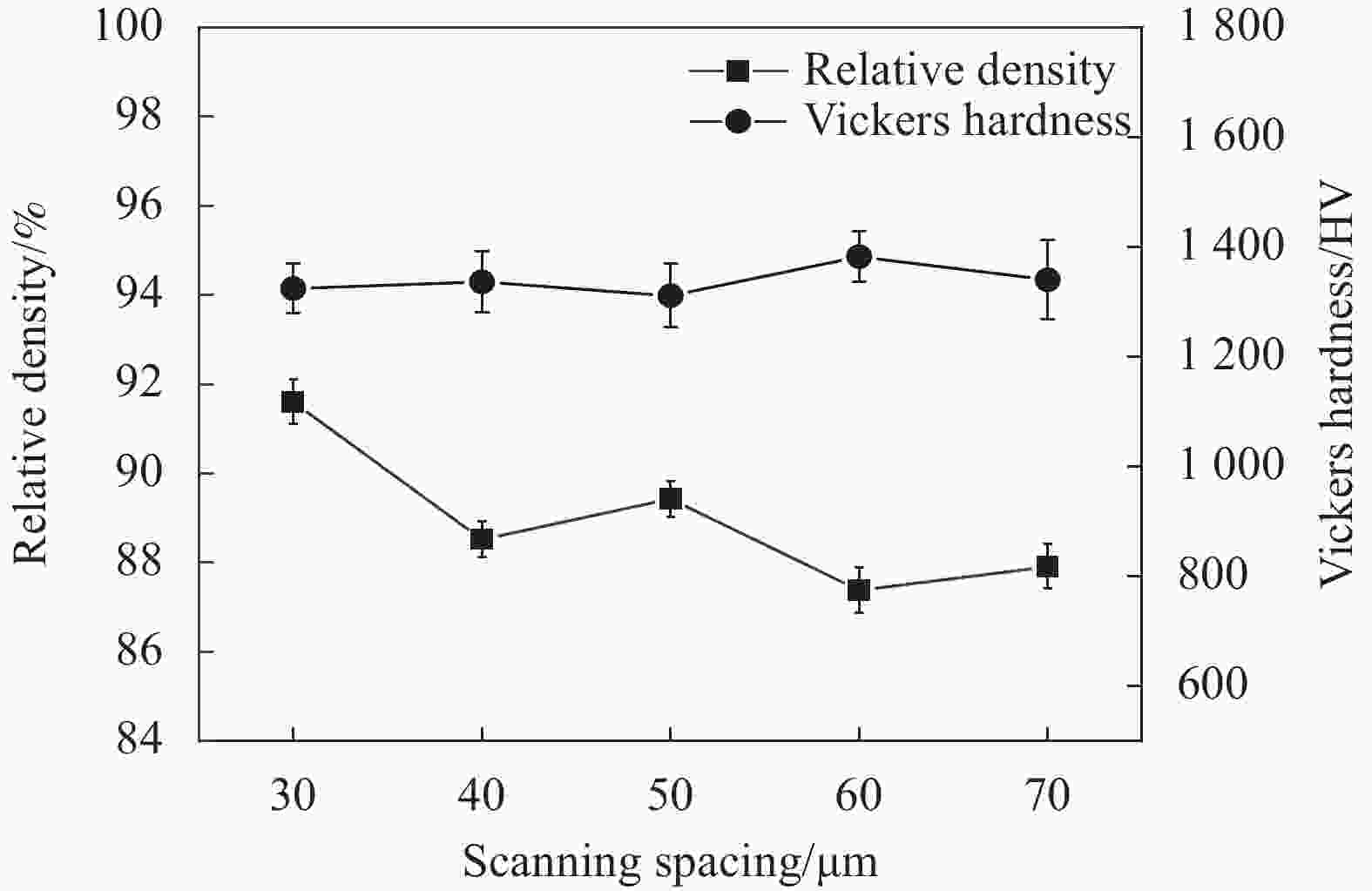

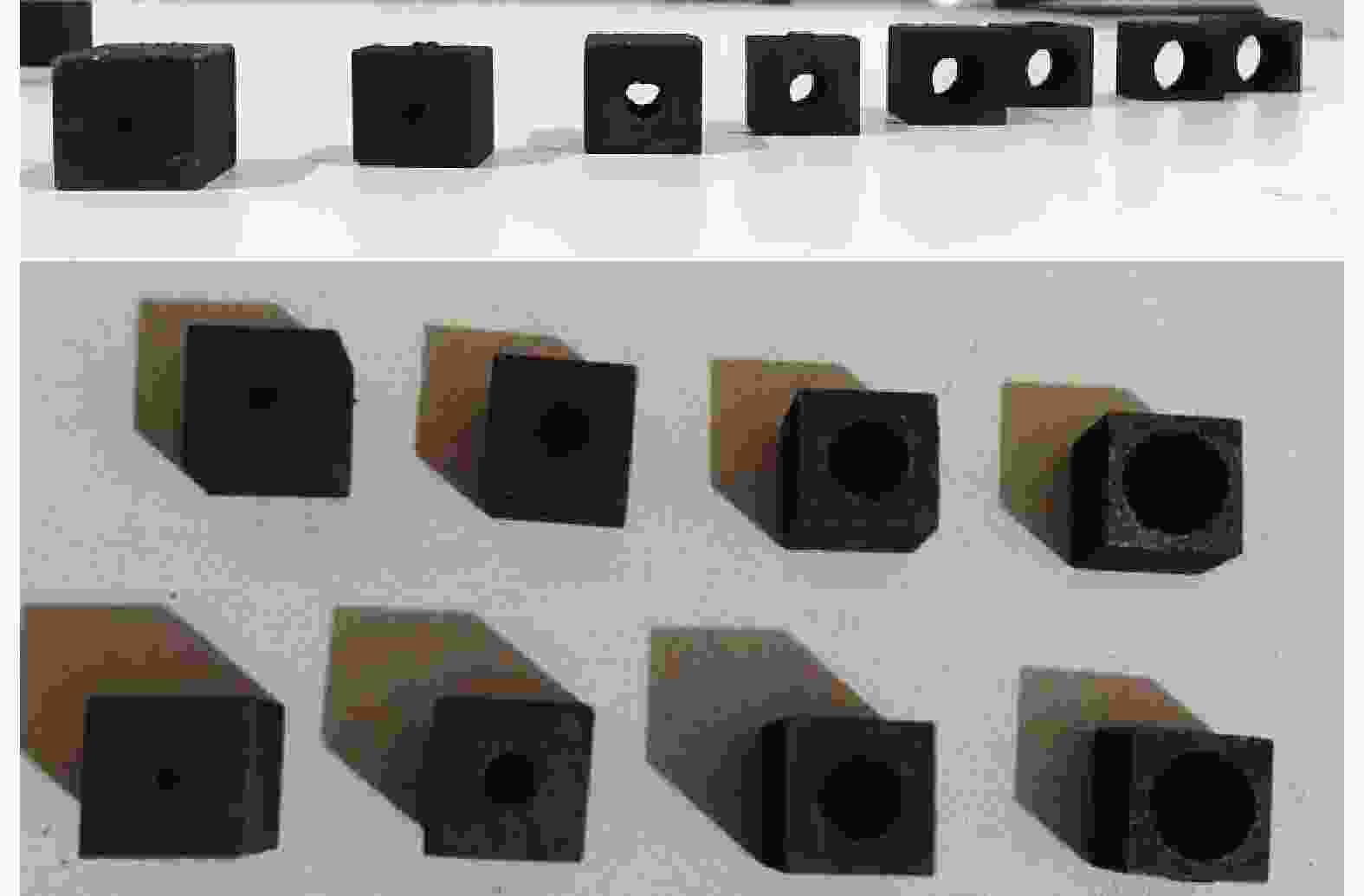

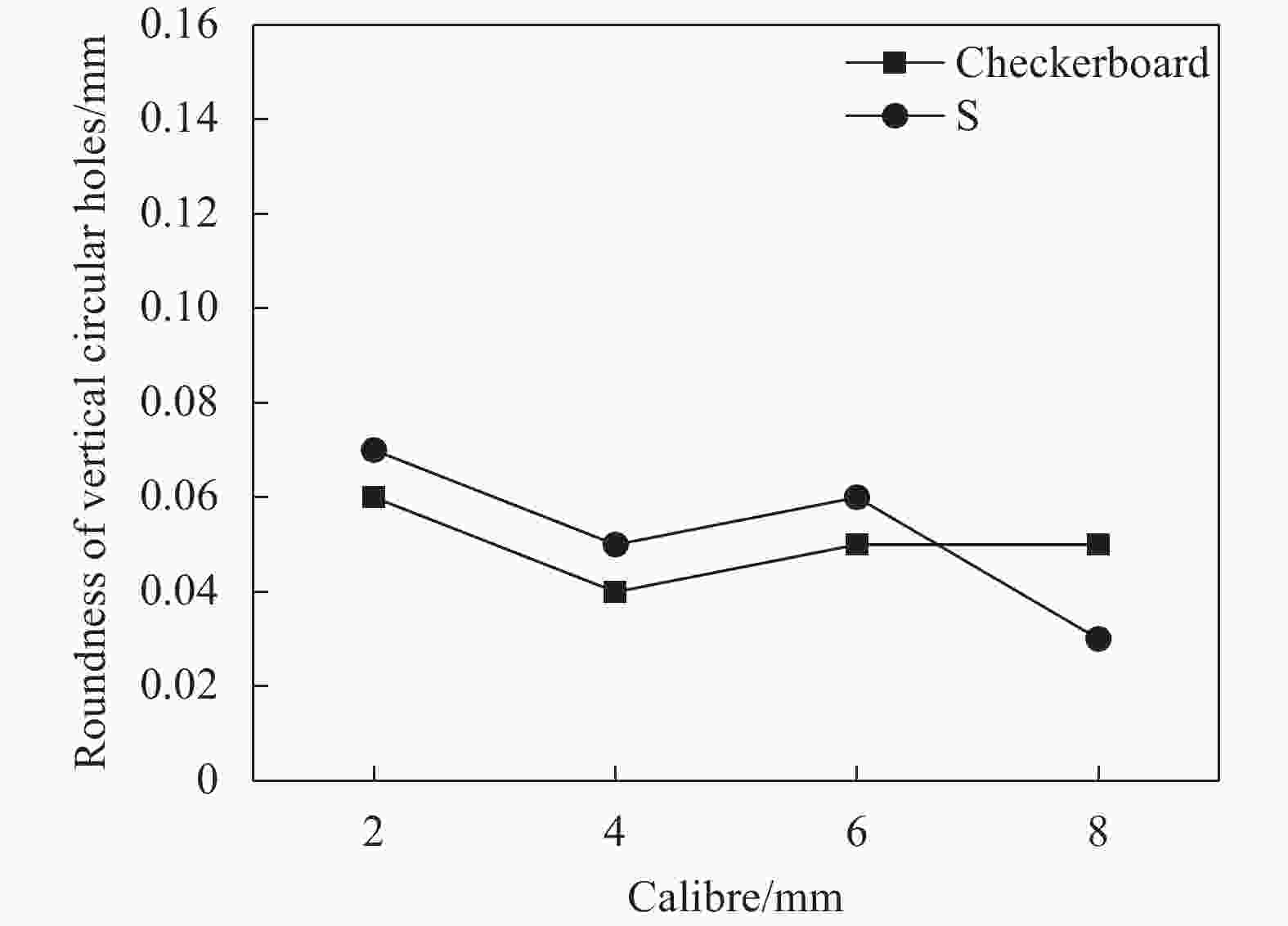

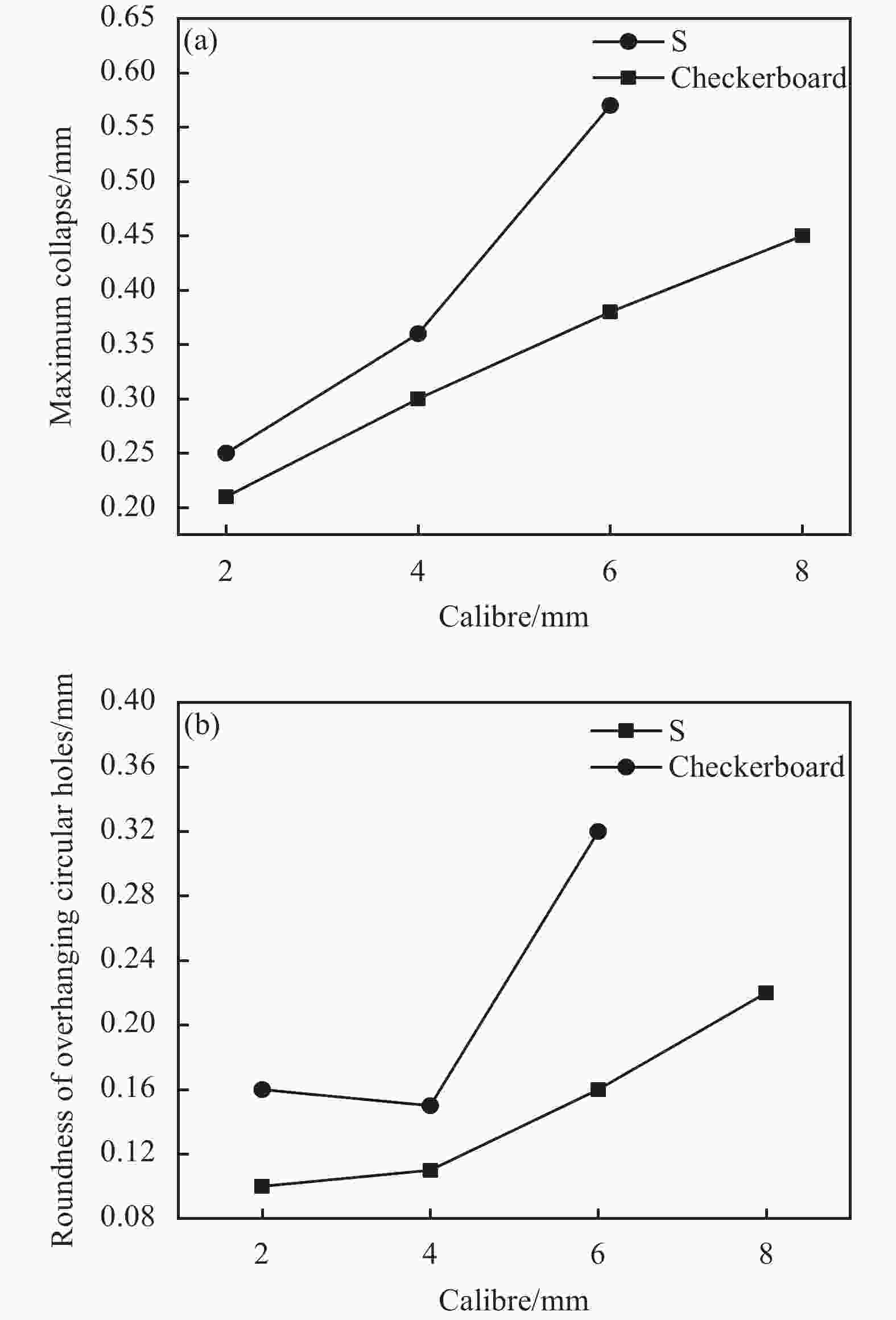

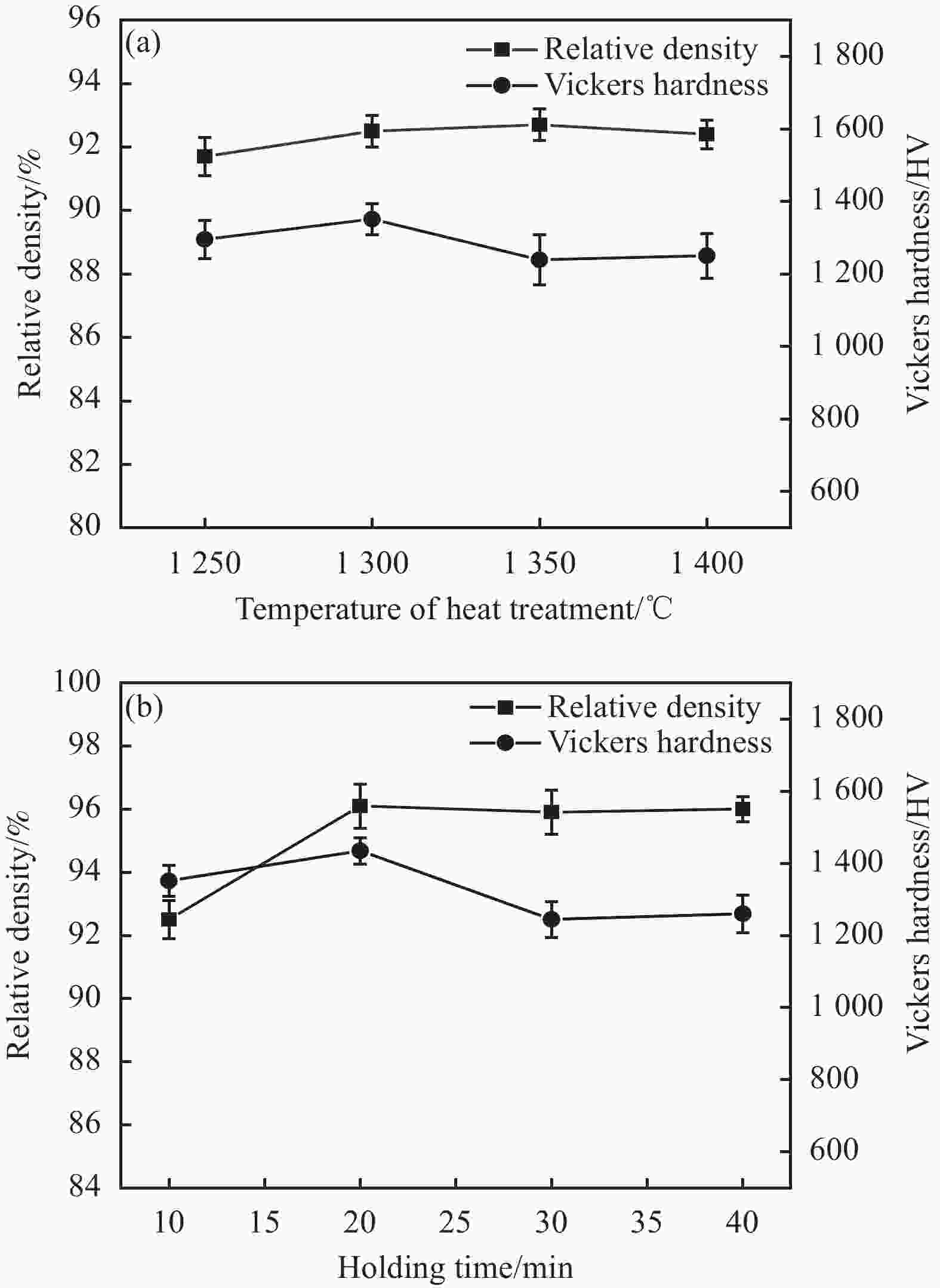

摘要: 首先采用了SLM不同扫描策略制备了WC-12Co硬质合金试样,研究了扫描策略对成形试样的影响规律,优化出最佳成形工艺。使用优化后的参数成形了圆柱形内部结构试样并进行微波后处理,分析微波后处理工艺对试样相对密度、维氏硬度和形状精度的影响规律。结果表明,最适用于打印WC-12Co硬质合金是棋盘格扫描策略,在成形能力、相对密度、维氏硬度和组织均匀性方面均优于其他扫描策略,调整扫描间距为30 μm后,试样相对密度达到最高91.6%,维氏硬度则达到

1324 HV,且棋盘格扫描策略成形圆柱形内部结构的精度也更佳;当微波热处理升温速率为40 ℃/min、温度为1300 ℃、保温时间为20 min时,试样微观缺陷数量与热处理前相比大幅减少,材料相对密度与维氏硬度显著提高,但热处理会导致部分WC晶粒尺寸增大,此时试样相对密度达到96.1%,维氏硬度达到1435 HV,且热处理后圆柱形内部结构试样的精度没有被破坏。Abstract: Firstly, different scanning strategies of SLM were used to prepare WC-12Co cemented carbide specimens, and the influence of scanning strategies on the formed specimens was investigated to optimize the best forming process. The optimized parameters were used to form the specimens with cylindrical-shaped inner structure and microwave post-treatment, to analyze the influence of microwave post-treatment process on the relative density, Vickers hardness and shape accuracy of the specimen. The results show that the most suitable for printing WC-12Co cemented carbide is the checkerboard scanning strategy, which is better than other scanning strategies in terms of forming ability, relative density, Vickers hardness and tissue uniformity. After adjusting the scanning spacing to 30 μm, the relative density of the specimen reaches the highest 91.6%, and the Vickers hardness is up to1324 HV, and the checkerboard scanning strategy has a better precision of forming the cylindrical-shaped inner structure; when the microwave heat treatment heat treatment rate is 40 ℃/min, the temperature is1300 ℃ and the holding time is 20 min, the number of microscopic defects of the specimen is greatly reduced compared with that before heat treatment, and the relative density, Vickers hardness of the material are significantly improved, but some of the WC grain sizes increase because of heat treatment, at this time, the relative density of the specimen reaches 96.1%, and the Vickers hardness reaches1435 HV, and the precision of the specimen of cylindrical-shaped inner structure is not destroyed after the heat treatment. -

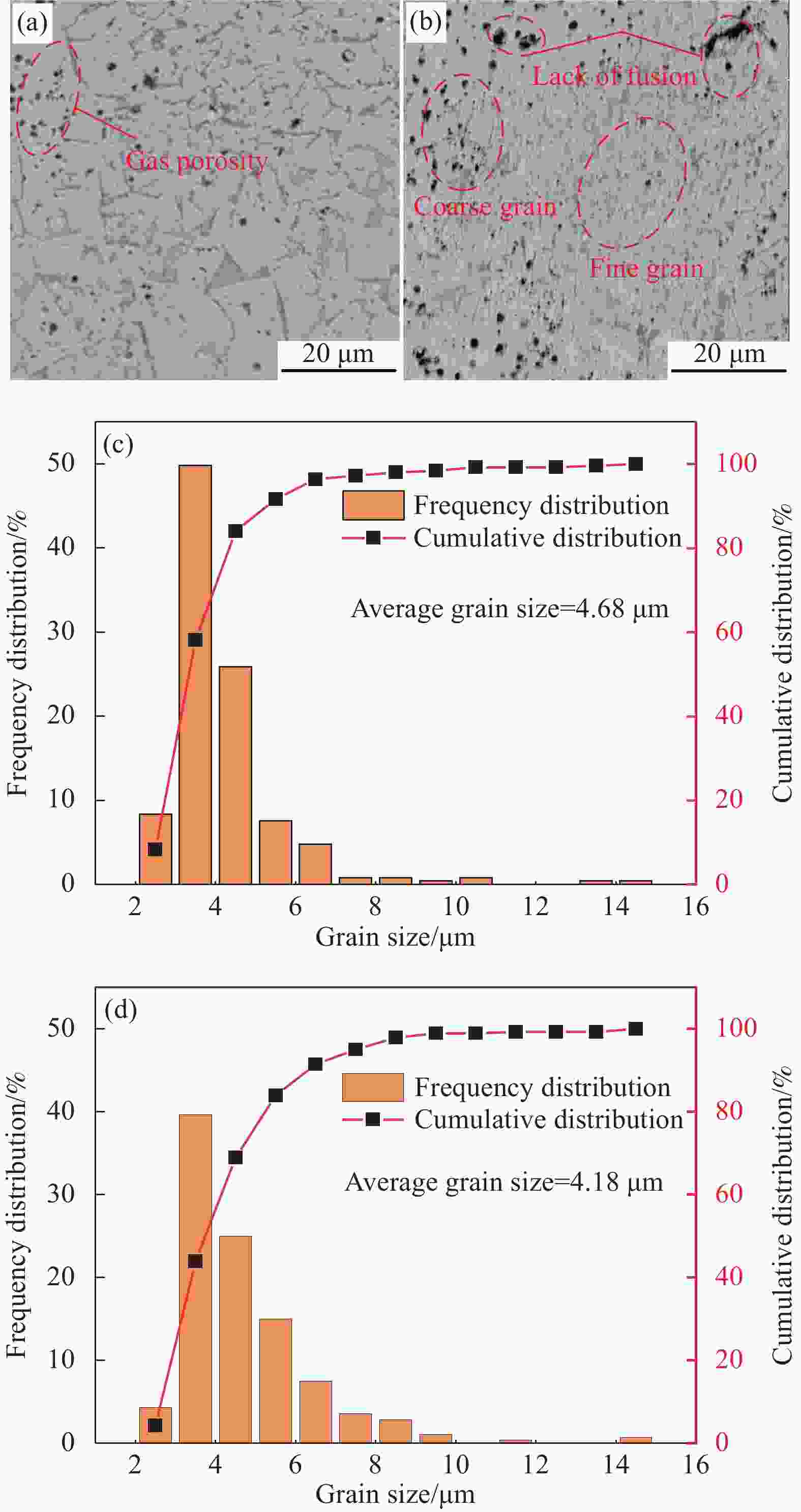

图 5 不同扫描策略下WC-12 Co硬质合金试样表面微观组织和WC晶粒尺寸分布图:(a) 棋盘格;(b) S形;(c) 棋盘格晶粒尺寸分布图;(d) S形晶粒尺寸分布图

Figure 5. Microstructure and WC grain size distribution of the surface of the WC-12 Co cemented carbide specimens under different scanning strategies: (a) checkerboard scanning; (b) S-shape scanning; (c) grain size distribution of checkerboard; (d) grain size distribution of S-shape

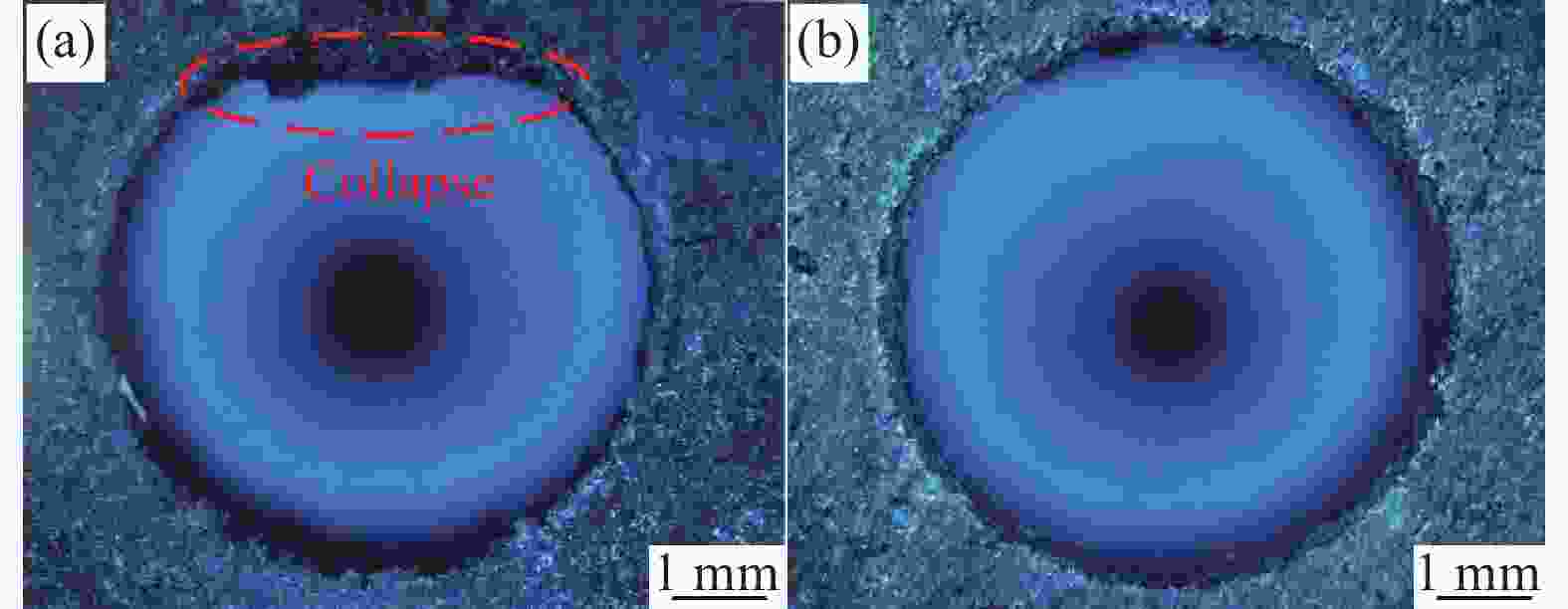

图 12 不同扫描策略成形圆柱形内部结构对比:(a) 棋盘格扫描策略成形的Φ6悬垂圆孔;(b) S形扫描策略成形的Φ6悬垂圆孔;(c) 棋盘格扫描策略成形的Φ6竖直圆孔;(d) S形扫描策略成形的Φ6竖直圆孔

Figure 12. Comparison of the structure of holes formed by different scanning strategies: (a) Φ6 overhanging circular hole shaped by checkerboard scanning strategy; (b) Φ6 overhanging circular hole shaped by S scanning strategy;(c) Φ6 vertical hole shaped by the checkerboard scanning strategy; (d) Φ6 vertical hole shaped by the S-shape scanning strategy

图 15 不同温度热处理后WC-12 Co硬质合金试样表面微观组织和WC晶粒尺寸分布图:(a)

1300 ℃热处理后微观组织;(b)1400 ℃热处理后微观组织;(c)1300 ℃热处理后晶粒分布;(d)1400 ℃热处理后晶粒分布Figure 15. Microstructure and WC grain size distribution on the surface of the WC-12 Co cemented carbide specimens after heat treatment at different temperatures: (a) microstructure after heat treatment at

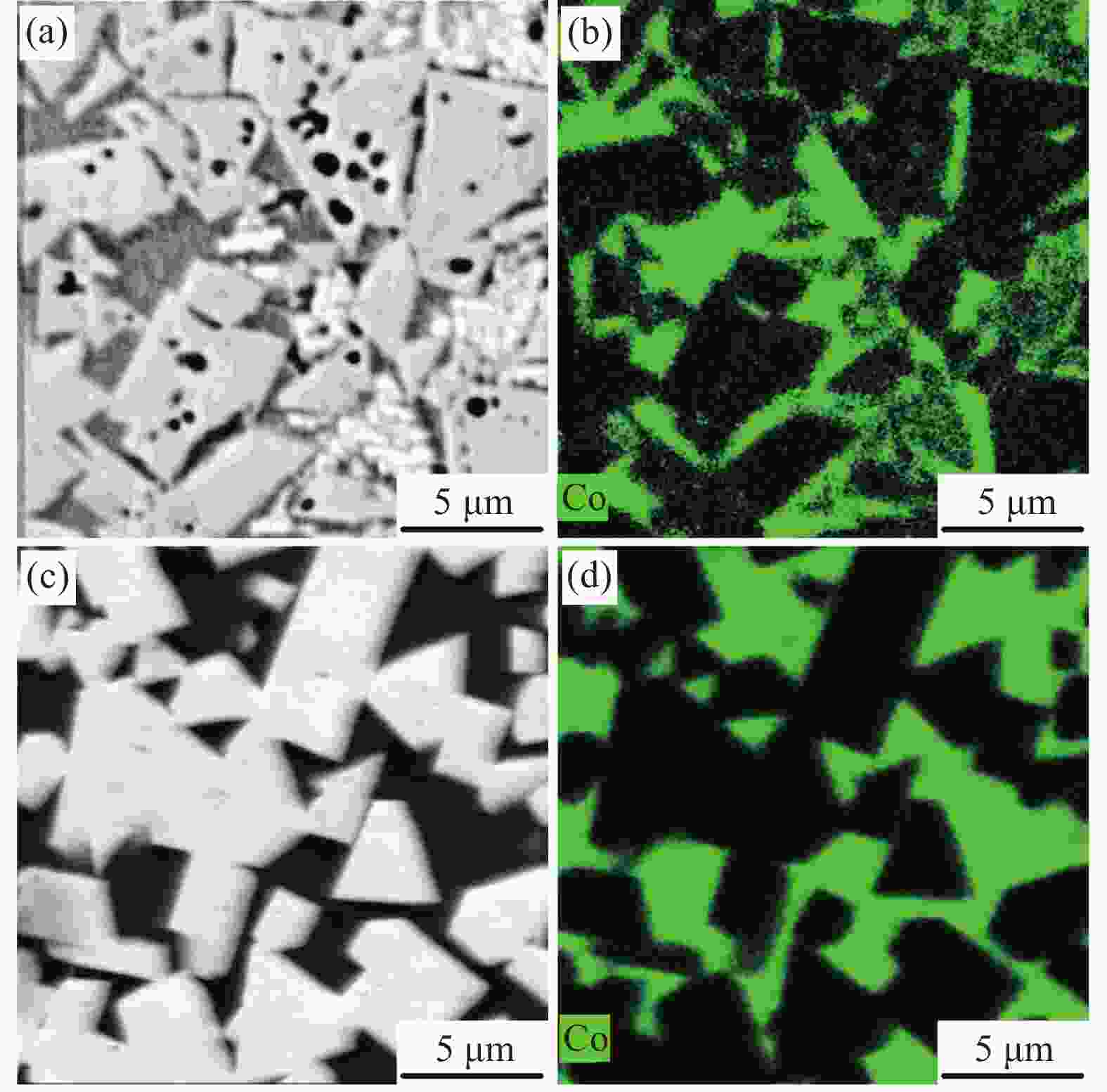

1300 °C; (b) microstructure after heat treatment at1400 °C; (c) grain size distribution after heat treatment at1300 °C; (d) grain size distribution after heat treatment at1400 °C图 16 热处理前后WC-12 Co硬质合金试样表面微观组织和Co元素分布:(a)热处理前微观组织;(b)热处理前Co元素分布;(c)热处理后微观组织;(d)热处理后Co元素分布

Figure 16. Microstructure and Co element distribution on the WC-12 Co cemented carbide specimens surface before and after heat treatment: (a) microstructure before heat treatment; (b) Co element distribution before heat treatment; (c) microstructure after heat treatment; (d) Co element distribution after heat treatment

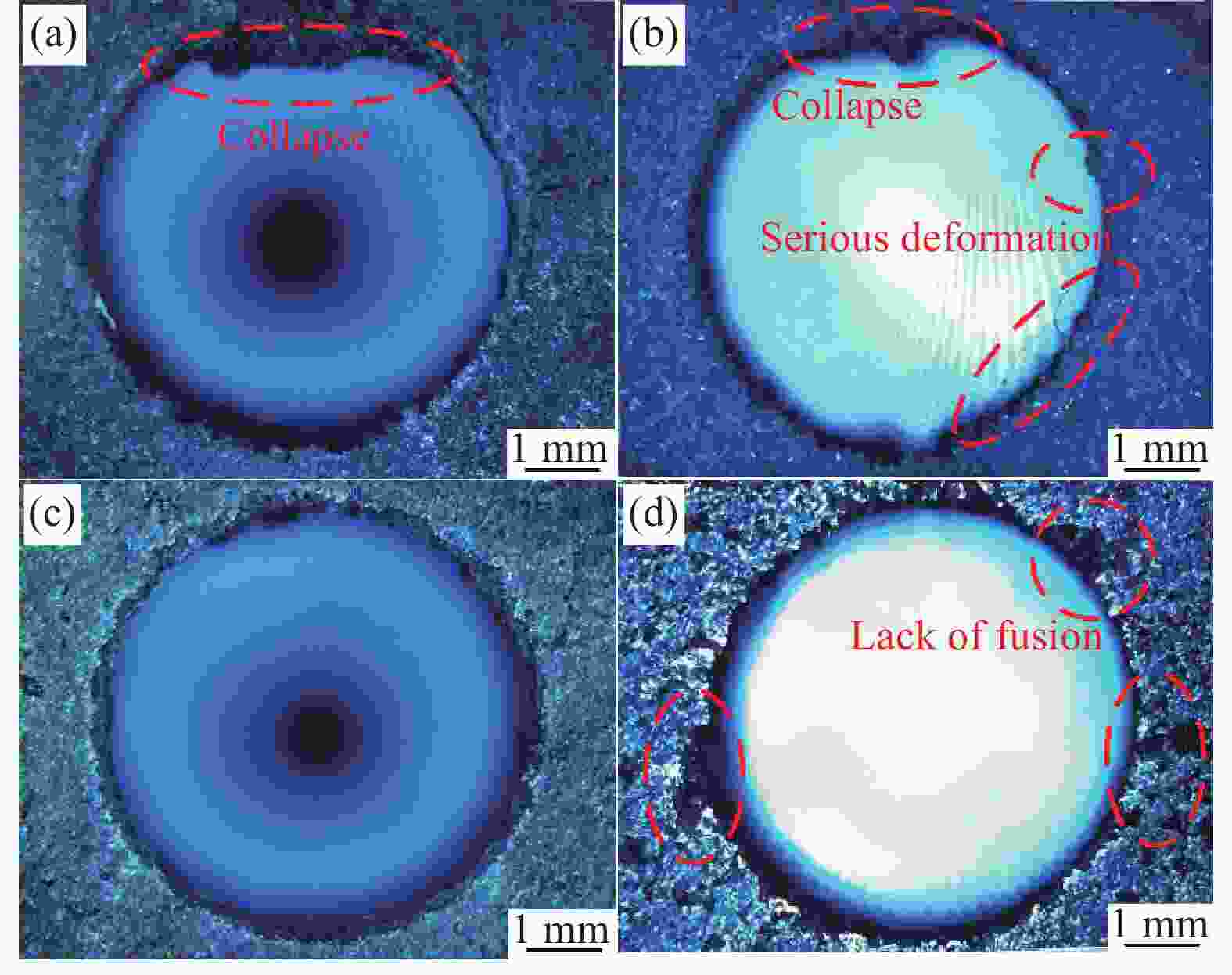

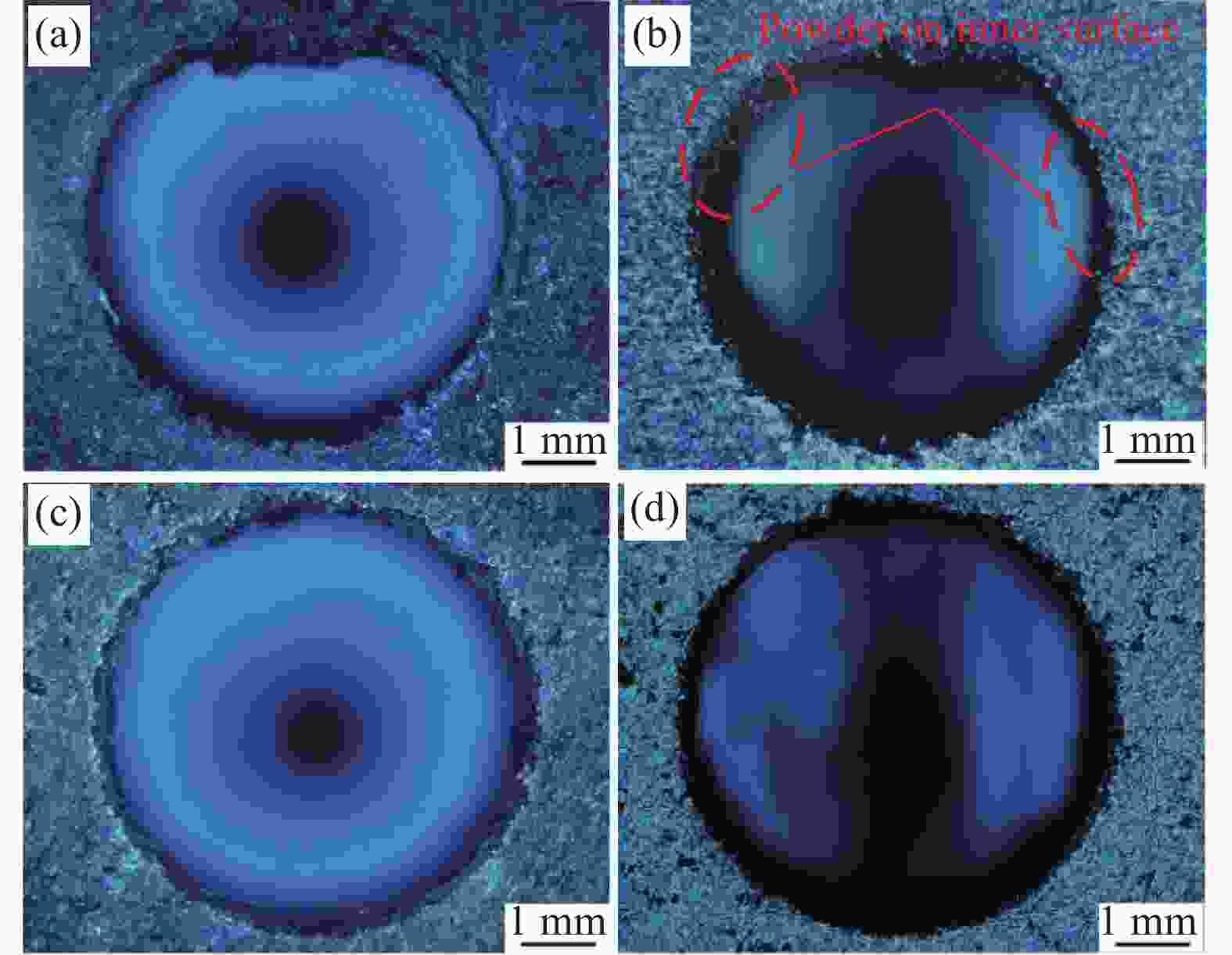

图 17 热处理前后圆柱形内部结构对比:(a) 热处理前Φ6悬垂圆孔;(b) 热处理后Φ6悬垂圆孔;(c) 热处理前Φ6竖直圆孔;(d) 热处理后Φ6竖直圆孔

Figure 17. Comparison of the structure of round holes before and after heat treatment:(a) Φ6 overhanging round hole before heat treatment; (b) Φ6 overhanging round hole after heat treatment; (c) Φ6 vertical round hole before heat treatment; (d) Φ6 vertical round hole after heat treatment

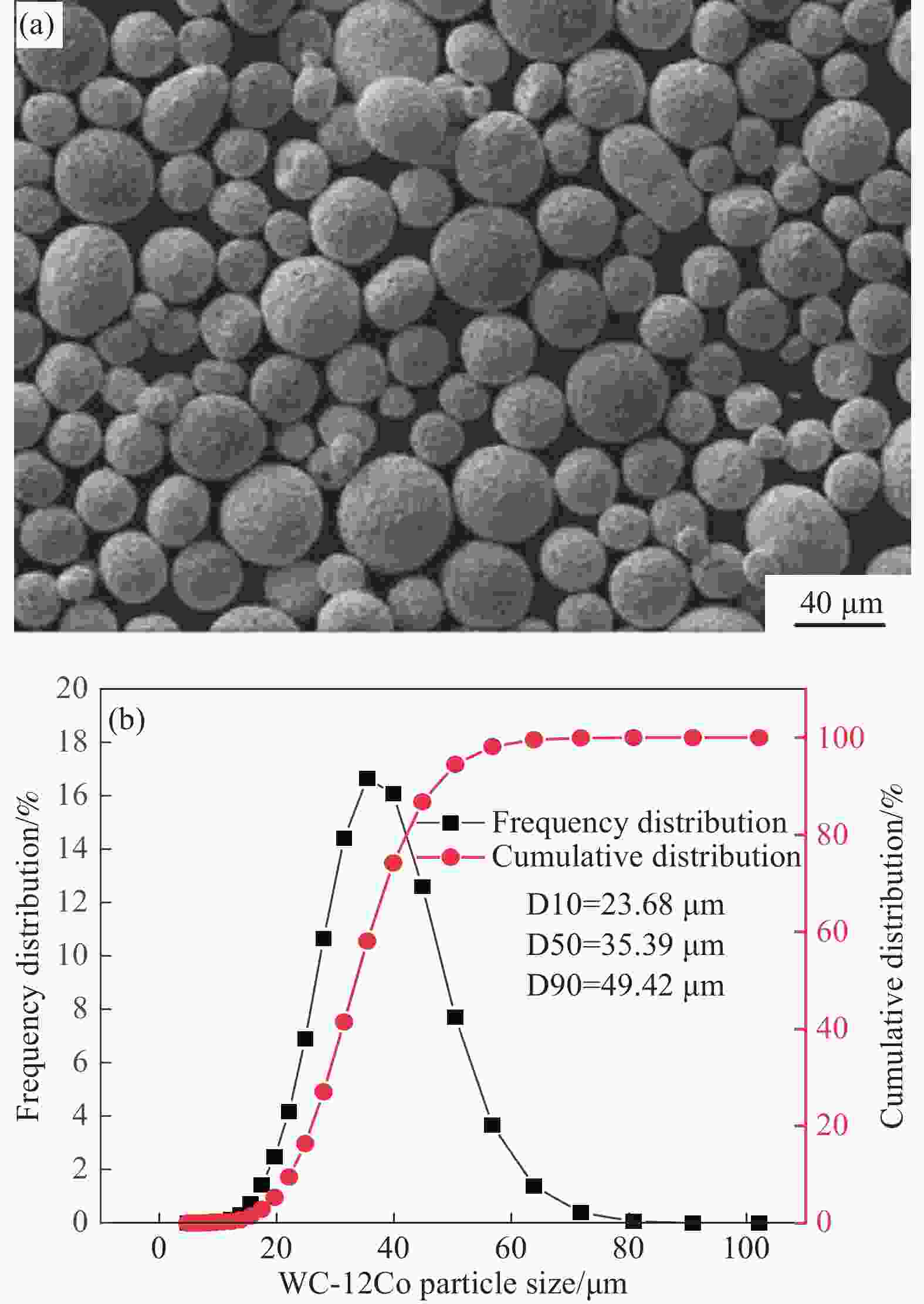

表 1 WC-12 Co粉末化学成分

Table 1. WC-12 Co powder chemical composition

Element Fe Co Ct Cf O W Mass fraction/% 0.015% 11.92% 5.38% 0.06% 0.03% Bal. 表 2 WC-12 Co粉末物理性能

Table 2. WC-12 Co powder physical properties

Testing Program Test results Particle size distribution/μm D10 23.68 D50 35.39 D90 49.42 Bulk density/(g·cm-3) 4.64 Flowability(s/50 g) 13.6 表 3 预实验工艺参数

Table 3. Pre-experimentation process parameters

Laser power p/W Scanning speed v/(mm·s−1) Thickness h/mm Scanning spacing l/mm 100 390 0.04 0.03~0.07 表 4 圆柱形内部结构成形参数

Table 4. Forming parameters for cylindrical-shaped inner structures

Scanning Strategy Scanning spacing

l /mmDiameter of the

round hole /mmChessboard 0.03 2、4、6、8 S 0.06 2、4、6、8 表 5 热处理实验参数表

Table 5. Heat treatment experiment parameter table

Heating rate/

(℃·min-1)Heat treatment

temperature/℃Holding

time/min40 1250 10 40 1300 10 40 1350 10 40 1400 10 40 1300 20 40 1300 30 40 1300 40 -

[1] KATIYAR K P, MAURYA R, SINGH K P. Failure Behavior of Cemented Tungsten Carbide Materials: A Case Study of Mining Drill Bits[J]. Journal of Materials Engineering and Performance, 2021, 30(8): 1-17. [2] 刘云, 郭子傲, 王行, 等. 3D打印硬质合金研究进展[J]. 稀有金属, 2021, 45(4): 484-492.LIU Yun, GUO Ziao, WANG Xing, et al. Research progress of 3D printed cemented carbide[J]. Rare Metals, 2021, 45(4): 484-492(in Chinese). [3] 罗来马, 汤俊宇, 吴玉程. WC-Co硬质合金的成型工艺研究进展[J]. 机械工程学报, 2023, 59(8): 60-73. doi: 10.3901/JME.2023.08.060LUO Laima, TANG Junyu, WU Yucheng. Progress of molding process of WC-Co cemented carbide[J]. Journal of Mechanical Engineering, 2023, 59(8): 60-73(in Chinese). doi: 10.3901/JME.2023.08.060 [4] 魏青松. 金属粉床激光增材制造技术[M]. 北京: 化学工业出版社, 2019: 1-20.WEI Qingsong. Metal powder bed laser additive manufacturing technology[M]. Beijing: Chemical Industry Press, 2019: 1-20(in Chinese). [5] KUMAR S, CZEKANSKI A. Optimization of parameters for SLS of WC-Co[J]. Rapid Prototyping Journal, 2017, 23(6): 1202-1211. doi: 10.1108/RPJ-10-2016-0168 [6] KU N, PITTARI J J, KILCZEWSKI S, et al. Additive Manufacturing of Cemented Tungsten Carbide with a Cobalt-Free Alloy Binder by Selective Laser Melting for High-Hardness Applications[J]. JOM, 2019, 71(4): 1535-1542. doi: 10.1007/s11837-019-03366-2 [7] KONYASHIN I, HINNERS H, RIES B, et al. Additive manufacturing of WC-13% Co by selective electron beam melting: Achievements and challenges[J]. International Journal of Refractory Metals and Hard Materials, 2019, 84: 105028. doi: 10.1016/j.ijrmhm.2019.105028 [8] CRAMER C L, NANDWANA P, LOWDEN R A, et al. Infiltration studies of additive manufacture of WC with Co using binder jetting and pressureless melt method[J]. Additive Manufacturing, 2019, 28: 333-343. doi: 10.1016/j.addma.2019.04.009 [9] 季文彬, 邓日清, 戴士杰, 等. 铣削对SLM增材TC4钛合金表面完整性和疲劳性能的影响[J]. 中国机械工程, 2023, 34(2): 208-217+225. doi: 10.3969/j.issn.1004-132X.2023.02.011JI Wenbin, DENG Riqing, DAI Shijie, et al. Effect of milling on surface integrity and fatigue properties of SLM-augmented TC4 titanium alloy[J]. China Mechanical Engineering, 2023, 34(2): 208-217+225(in Chinese). doi: 10.3969/j.issn.1004-132X.2023.02.011 [10] 崔浩, 闫群, 王向明, 等. 激光选区熔化成形铝合金板与CFRP复合材料层合板螺栓连接结构失效分析方法评估[J]. 复合材料学报, 2017, 34(12): 2762-2769.CUI Hao, YAN Qun, WANG Xiangming, et al. Evaluation of structural failure analysis method for bolted joint structure of laser-selective melt-forming aluminum alloy plate and CFRP composite laminate[J]. Journal of Composite Materials, 2017, 34(12): 2762-2769(in Chinese). [11] 周玥丞, 赵阳. 选择性激光熔融增材制造不锈钢力学性能研究进展及统计分析[J]. 建筑结构学报, 2021, 42(6): 15-25.ZHOU Yuecheng, ZHAO Yang. Progress and statistical analysis of mechanical properties of selective laser melting additively fabricated stainless steel[J]. Journal of Building Structures, 2021, 42(6): 15-25(in Chinese). [12] CHEN C, HUANG B, LIU Z, et al. Additive manufacturing of WC-Co cemented carbides: Process, microstructure, and mechanical properties[J]. Additive Manufacturing, 2023, 63: 103410. doi: 10.1016/j.addma.2023.103410 [13] PAPY K, JEAN-MARC S, ALEXEY S, et al. Additive manufacturing feasibility of WC-17Co cermet parts by laser powder bed fusion[J]. procedia CIRP, 2022, 111: 153-157. doi: 10.1016/j.procir.2022.08.049 [14] UHLMANN E, BERGMANN A, BOLZ R. Manufacturing of carbide tools by Selective Laser Melting[J]. Procedia Manufacturing, 2018, 21: 765-773. doi: 10.1016/j.promfg.2018.02.182 [15] FRIES S, VOGELPOTH A, KALETSCH A, et al. Influence of post heat treatment on microstructure and fracture strength of cemented carbides manufactured using laser-based additive manufacturing[J]. International Journal of Refractory Metals and Hard Materials, 2023, 111: 106085. doi: 10.1016/j.ijrmhm.2022.106085 [16] BRICIN D, ACKERMANN M, JANSA Z, et al. Development of the structure of cemented carbides during their processing by SLM and HIP[J]. Metals, 2020, 10(11): 1477-1493. doi: 10.3390/met10111477 [17] JIA H, SUN H, WANG H, et al. Scanning strategy in selective laser melting (SLM): a review[J]. The International Journal of Advanced Manufacturing Technology, 2021, 113(9-10): 1-23. [18] OGHBAEI M, MIRZAEE O. Microwave versus conventional sintering: A review of fundamentals[J]. advantages and applications. Journal of Alloys and Compounds, Lausanne, 2010, 494(1-2): 175-189. [19] SINGH R, SHARMA V, PANDEY P M. Microstructural characteristics and mechanical behaviour of microwave-assisted sintered novel WC-Co ceramic based internally cooled turning tool[J]. Materials Characterization, 2023, 200: 112855. doi: 10.1016/j.matchar.2023.112855 [20] LIU C, CAI Z, DAI Y, et al. Experimental comparison of the flow rate and cooling performance of internal cooling channels fabricated via selective laser melting and conventional drilling process[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96: 2757-2767. doi: 10.1007/s00170-018-1799-y [21] LIM B, PROVOSTY R, DONG G. Investigation of the cooling performance of chemically etched millimeter-scale channels made by selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2024: 1-11. [22] KEMPEN K, WELKENHUYZEN F, QIAN J, et al. Dimensional accuracy of internal channels in SLM produced parts[C]//2014 ASPE Spring Topical Meeting: Dimensional Accuracy and Surface Finish in Additive Manufacturing. San rancisco, 2014: 13-16. [23] 辛艳喜. 铝合金悬垂圆孔结构选区激光熔化成形质量研究及工艺优化[D]. 杭州: 浙江理工大学, 2023.XIN Yanxi. Quality study and process optimization of selected zone laser melting and forming of aluminum alloy overhanging circular hole structure[D]. Hangzhou: Zhejiang Sci-Tech University, 2023. [24] PAKKANEN J, CALIGNANO F, TREVISAN F, et al. Study of internal channel surface roughnesses manufactured by selective laser melting in aluminum and titanium alloys[J]. Metallurgical and Materials Transactions A, 2016, 47: 3837-3844. doi: 10.1007/s11661-016-3478-7 [25] MAO Y, LV X, SHEN X. A study on the surface quality of selective laser melted cylindrical-and parallelepipedic-shaped inner structure[J]. Materials, 2023, 16(13): 4649. doi: 10.3390/ma16134649 -

点击查看大图

点击查看大图

计量

- 文章访问数: 31

- HTML全文浏览量: 14

- 被引次数: 0

下载:

下载: