Experimental on the shear behavior of pre-damaged RC beams strengthened by textile reinforced highly ductile concrete

-

摘要: 为研究二次受力对纤维织物增强高延性混凝土(TRHDC)加固钢筋混凝土(RC)梁受剪性能的影响,对8根TRHDC加固梁和1根对比梁进行了静载试验,分析了纤维织物层数、损伤程度及持载水平对梁破坏形态、荷载-挠度曲线、荷载-箍筋应变曲线及荷载-织物应变曲线的影响。试验结果表明:所有梁均发生了剪压破坏,仅一根梁出现剥离现象;TRHDC可有效限制斜裂缝的发展,延缓箍筋屈服和刚度退化;TRHDC加固显著地提高了梁的受剪承载力和变形能力,最高分别达67%和54%;加固效果未完全随纤维织物层数的增大而提高,与TRHDC面层利用率有关;原梁箍筋屈服之前,损伤程度对加固梁受剪性能的影响不明显,原梁箍筋屈服之后,加固梁受剪承载力随损伤程度的增大而降低;加固效果随持载水平的提高而降低;两层纤维织物的TRHDC可有效修复完全受损RC梁的受剪性能;建立了考虑二次受力的TRHDC加固RC梁受剪承载力的计算公式,且计算值与试验结果吻合较好。

-

关键词:

- 纤维织物增强高延性混凝土 /

- 受损RC梁 /

- 受剪加固 /

- 二次受力 /

- 受剪承载力

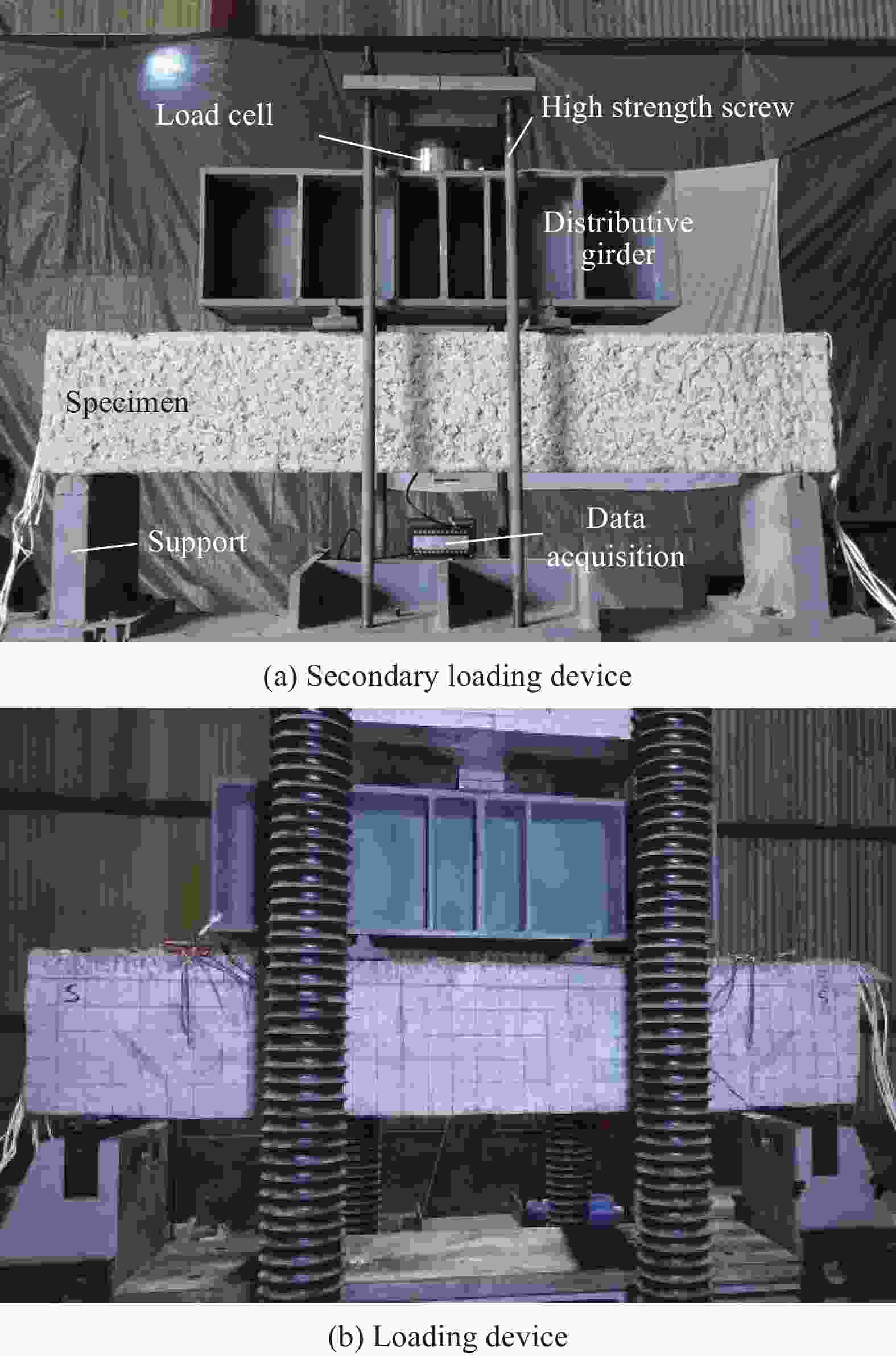

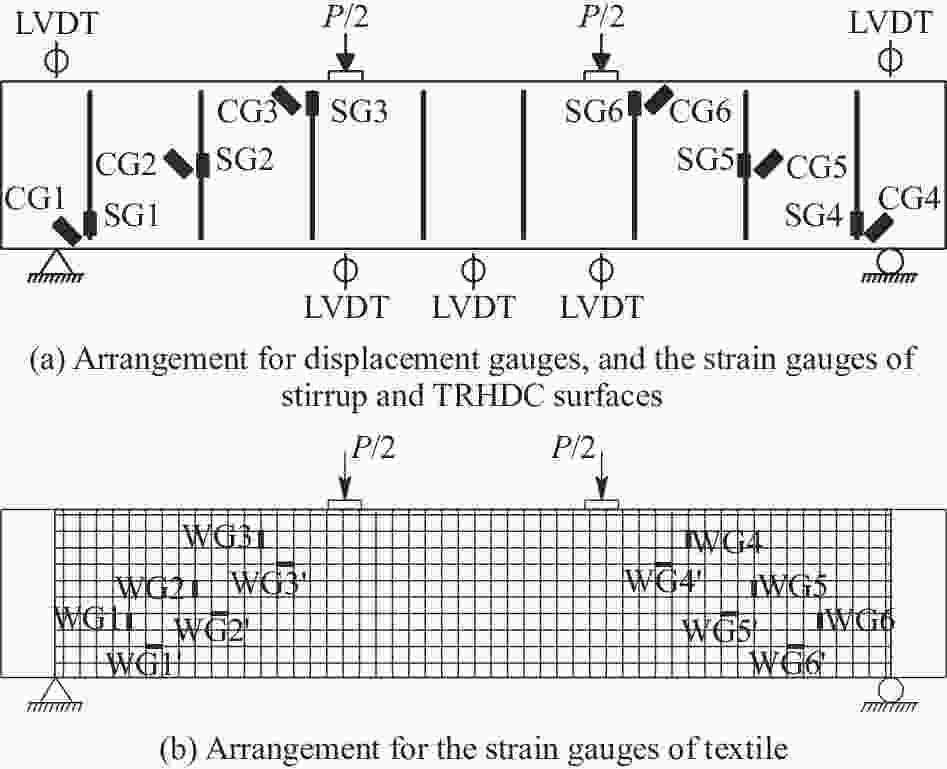

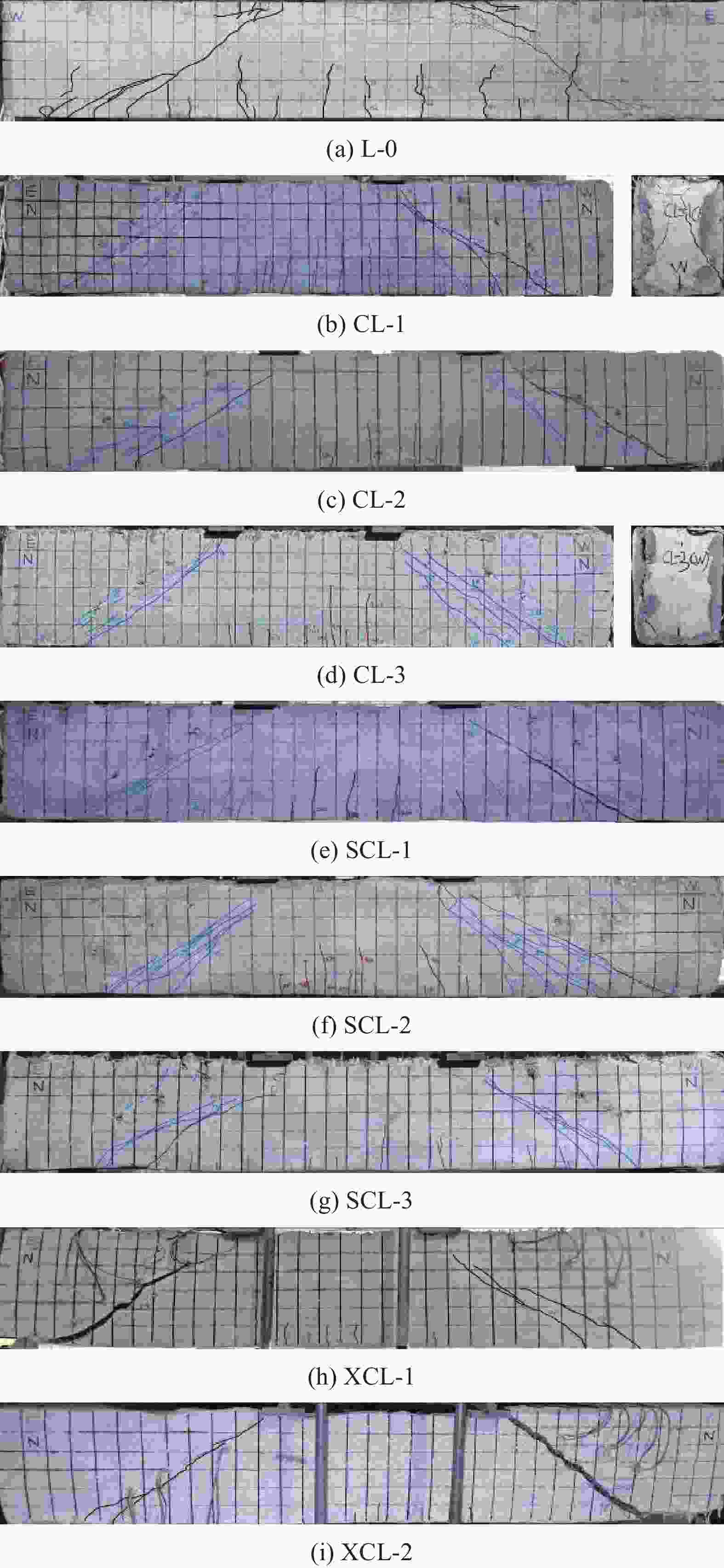

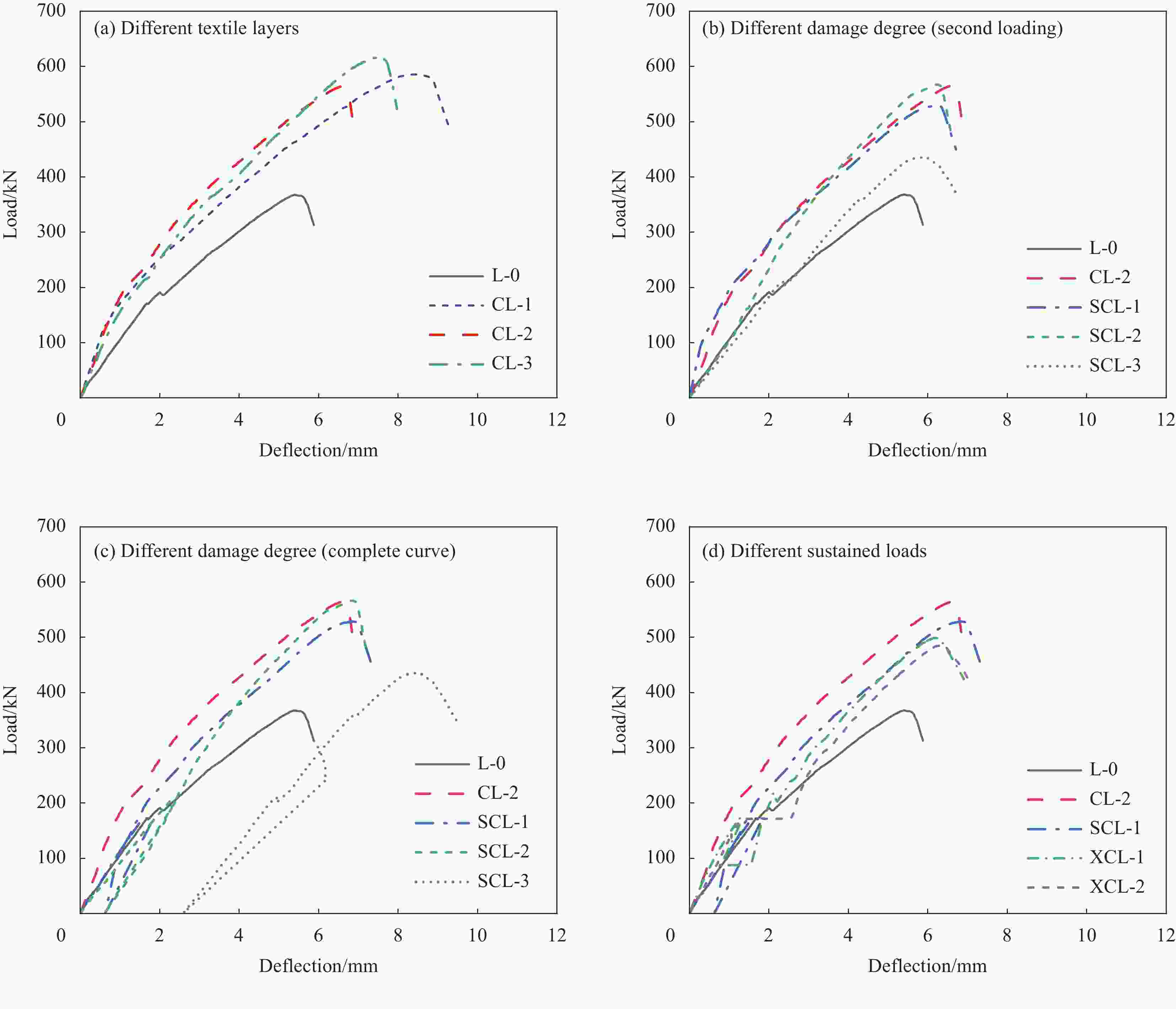

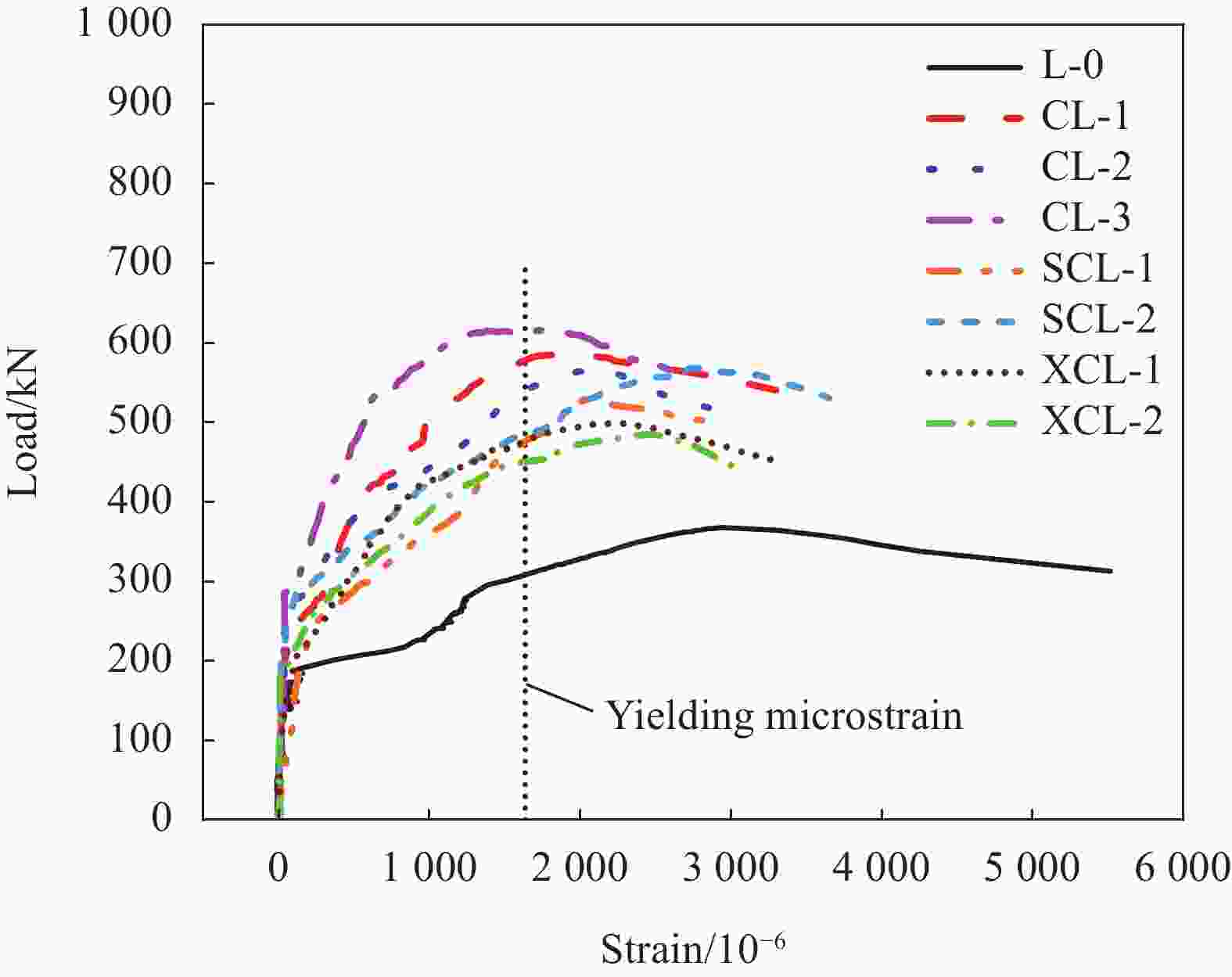

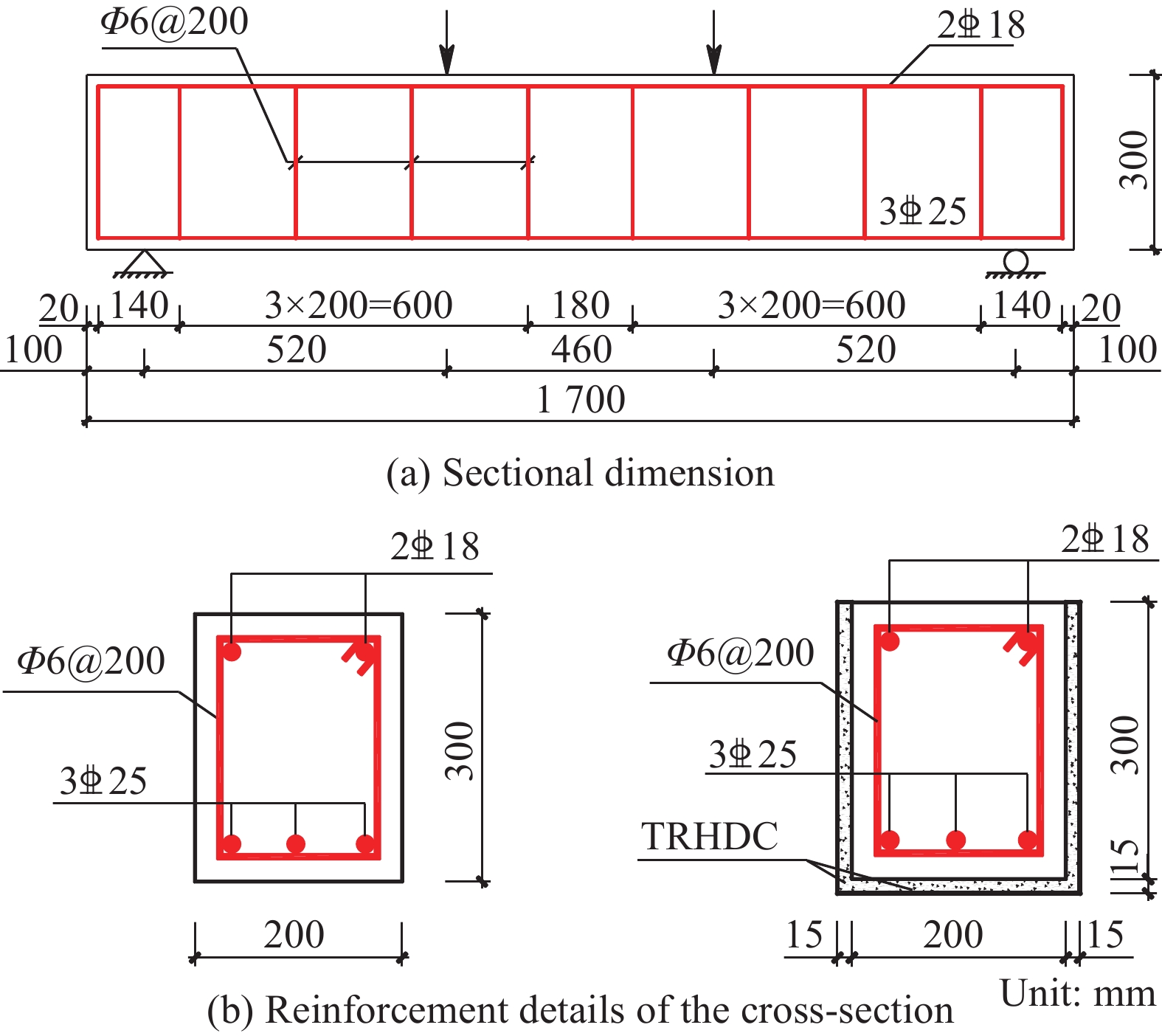

Abstract: Static load tests were conducted on eight reinforced concrete (RC) beams strengthened by textile reinforced high ductile concrete (TRHDC) and one control beam to study the effect of secondary loading on the shear behavior of TRHDC-strengthened beams. The influence of the number of the textile layer, damage degree of beams, and different sustained loads on the failure mode, load-deflection curves, load-strain curves of stirrups, and load-strain curves of textile were analyzed. The results indicate that all beams fail in shear compression mode, and the debonding phenomenon is only observed in one beam. TRHDC can effectively restrain the development of shear cracks, delay the yielding of stirrups and the stiffness degradation. This strengthening method can significantly improve the shear strength and deformation capacity of RC beams by up to 67% and 54%, respectively. The strengthening effectiveness does not completely increase with the number of the textile layer increase, which is related to the utilization rate of the TRHDC layer. When the stirrup of the original beam does not reach its yielding strength, the damage degree has no obvious influence on the shear behavior of strengthened beams. On the contrary, the shear strength of strengthened beams decreases with the increase of the damage degree. The strengthening effectiveness decreases with the sustained load increasing. The completely damaged RC beams can be restored by the TRHDC with two numbers of the textile layer. A calculation formula for the shear strength of TRHDC-strengthened beams considering the secondary loading was proposed. The calculation values are in good agreement with the test results. -

图 11 RC梁拉-压杆模型

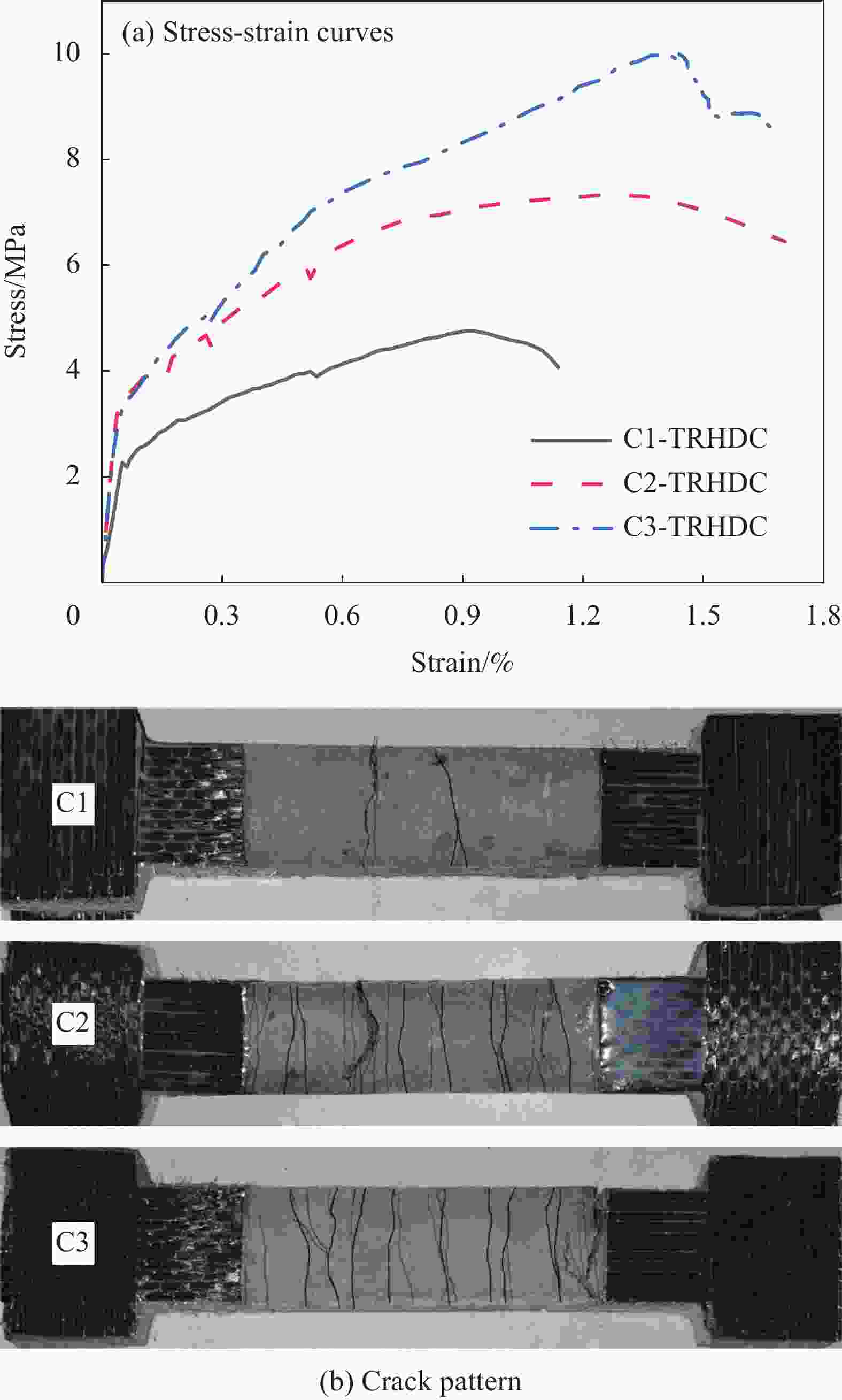

Figure 11. Strut-and-tie model of RC beams

$ {f_1} $ and $ {f_2} $—Principal tensile and compressive stresses at the node B zone, respectively; $ {\theta _{\text{s}}} $—Angle between the longitudinal tension reinforcement and the diagonal strut; h—Depth of RC beams; $ {d_{\text{c}}} $—Distance from the centroid of the nodal A zone to the centroid of the nodal B zone; $ {l_{\text{d}}} $ and $ {l_{\text{c}}} $—Depths of the nodal A and B zones, respectively; a—Distance from loading point to support; $ {l_{\text{b}}} $—Width of the nodal B zone; $ {V_{{\text{RC}}}} $—Shear strength of RC beams; $ {C_{\text{C}}} $—Compressive force of the concrete in the shear compression zone; $ {T_{\text{s}}} $—Tensile force of longitudinal reinforcements; $ {F_{\text{c}}} $—Compressive force of the concrete diagonal struts

表 1 钢筋混凝土(RC)梁试件加固参数

Table 1. Strengthening parameters of reinforced concrete (RC) beam specimens

Specimen Damage

degreeUnloading

levelNumber of the

textile layer in

TRHDCL-0 – – – CL-1 – – 1 CL-2 – – 2 CL-3 – – 3 SCL-1 Shear cracks occurred

(47%Pu,0)Unloading completely 2 SCL-2 Stirrups yielded (56%Pu,0) Unloading completely 2 SCL-3 Failure (the load drops to 85%Pu,0) Unloading completely 2 XCL-1 Shear cracks occurred

(47%Pu,0)Unloading 23.5%Pu,0 2 XCL-2 Shear cracks occurred

(47%Pu,0)Not unloading 2 Notes: Pu,0—Peak load of the control beam; L—Control beam; CL—Strengthened beams without initial stress; SCL—Strengthened beams with different damage degrees; XCL—Strengthened beams under sustained loads; TRHDC—Fiber reinforced high ductility concrete. 表 2 钢筋力学性能

Table 2. Mechanical properties of reinforcement

Type Diameter/mm Yielding strength/MPa Ultimate strength/MPa HPB300 6 343 508 HRB400 18 438 610 HRB400 25 450 620 表 3 织物力学性能

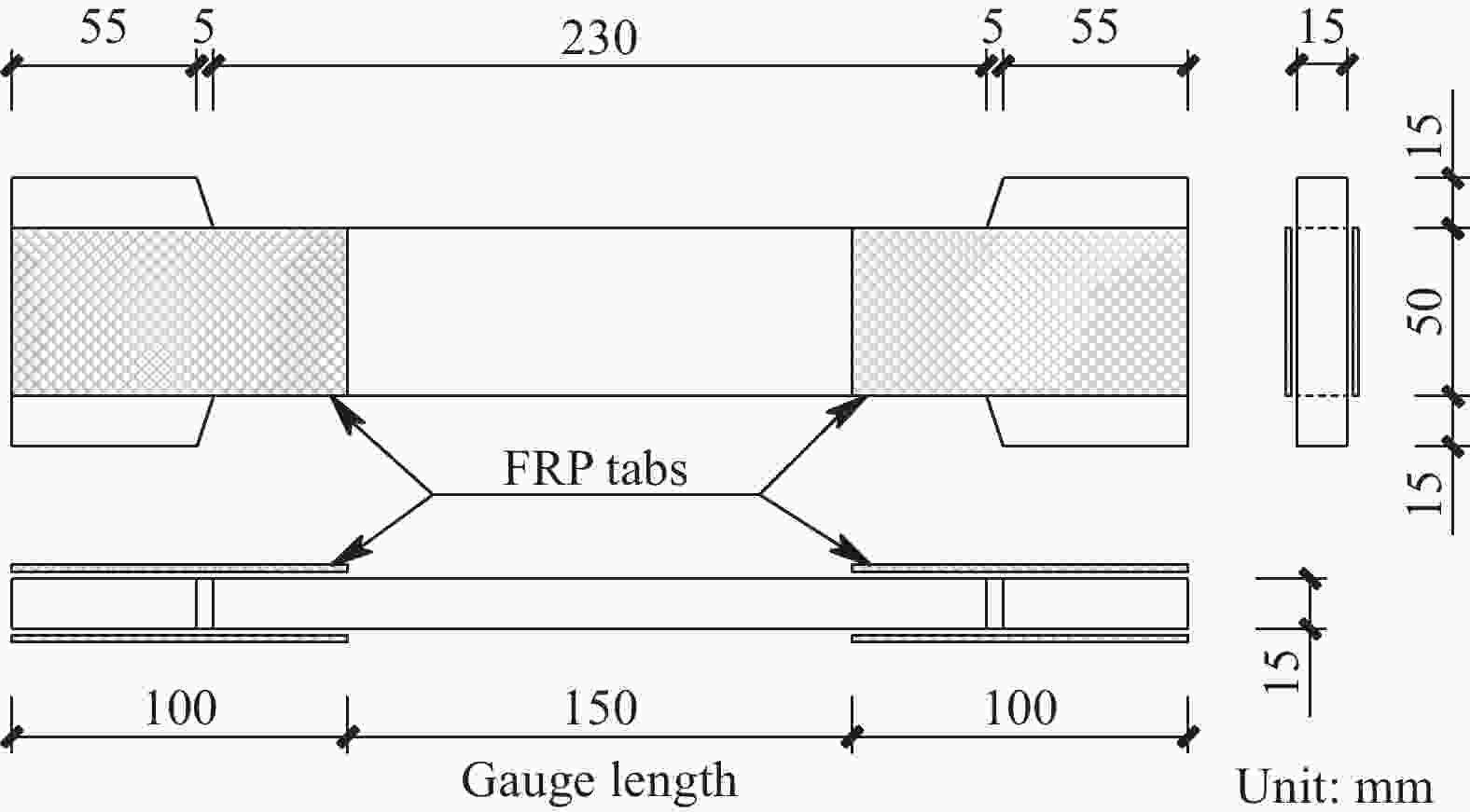

Table 3. Mechanical properties of textile

Type of textile ft/MPa Ef/GPa $ {\varepsilon _{\text{t}}} $/% $ {\rho _{\text{f}}} $/(g·cm−3) A/(mm2·bundle−1) Carbon 3600 230 1.5 1.74 0.88 Notes: ft—Tensile strength; Ef—Elastic modulus; $ {\varepsilon _{\text{t}}} $—Tensile elongation; $ {\rho _{\text{f}}} $—Density; A—Cross-sectional area of each bundle of yarns. 表 4 高延性混凝土(HDC)的基体配合比

Table 4. Mixed proportions of matrices in high ductile concrete (HDC)

(kg/m3) Cement Flyash Mineral powder River sand Water Water reducer 235 764 177 424 376 8 表 5 聚乙烯醇(PVA)纤维的力学性能指标

Table 5. Mechanical properties of polyvinyl alcohol (PVA) fibers

Fiber type L/mm D/μm E/GPa f/MPa $ \varepsilon $/% $ \rho $/(g·cm−3) PVA 12 39 40 1600 7 1.3 Notes: L—Length; D—Diameter; E—Elastic modulus; f—Tensile strength; $ \varepsilon $—Tensile elongation; $ \rho $—Density. 表 6 各RC梁试验结果

Table 6. Test results of RC beams

Specimen

number$ {P_{{\text{cr}}}} $/kN $\dfrac{ { {P_{ {\text{cr} } } } } }{ { {P_{ {\text{cr,0} } } } } }$ $ {P_{\text{r}}} $/kN $\dfrac{ { {P_{\text{r} } } }}{ { {P_{ {\text{r,0} } } } } }$ $ {P_{\text{u}}} $/kN $\dfrac{ { {P_{\text{u} } } }}{ { {P_{ {\text{u,0} } } } } }$ $ {\varDelta _{\text{u}}} $/mm $\dfrac{ { {\varDelta _{\text{u} } } }}{ { {\varDelta _{ {\text{u,0} } } } } }$ Failure

modeL-0 42 — 172 — 367.56 — 5.88 — S CL-1 250 5.95 335 1.95 585.54 1.59 9.05 1.54 S CL-2 190 4.52 330 1.92 563.90 1.53 6.96 1.18 S CL-3 300 7.14 410 2.38 615.49 1.67 7.97 1.36 S+PD SCL-1 180 4.29 300 1.74 528.38 1.44 6.71(0.63) 1.14 S SCL-2 165 3.93 280 1.63 565.22 1.54 6.60(0.61) 1.12 S SCL-3 160 3.81 223 1.30 434.91 1.18 6.71(2.59) 1.14 S XCL-1 210 5.00 320 1.86 498.76 1.36 5.62(1.29) 0.96 S XCL-2 200 4.76 280 1.63 485.03 1.32 5.24(1.86) 0.89 S Notes: $ {P_{{\text{cr}}}} $ and $ {P_{{\text{cr,0}}}} $—Cracking load of the strengthened beam and control beam, respectively; $ {P_{\text{r}}} $ and $ {P_{{\text{r,0}}}} $—Loads corresponding to the yielding of stirrups of the strengthened beam and control beam, respectively; $ {P_{\text{u}}} $ and $ {P_{{\text{u,0}}}} $—Peak load of the strengthened beam and control beam, respectively; $ {\varDelta _{\text{u}}} $ and $ {\varDelta _{{\text{u,0}}}} $—Ultimate deflection corresponding to the load dropping to 85% of the peak load of the strengthened beam and control beam, respectively; $ {\varDelta _{\text{u}}} $ of specimens SCL-1, SCL-2, SCL-3, XCL-1, and XCL-2 is the midspan deflection under secondary loading, while the values in parentheses are the residual midspan deflection before secondary loading; S—Shear-compression failure; PD—Debonding failure between the concrete and the TRHDC layer. 表 7 各RC梁受剪承载力计算值与试验值比较

Table 7. Comparison for the calculation values and test results of shear strength of RC beams

Resource Strengthening method Specimen number $ {P_{{\text{u,t}}}} $/kN $ {P_{{\text{u,cal}}}} $/kN ${ { {P_{ {\text{u,cal} } } } } }/{ { {P_{ {\text{u,t} } } } } }$ This study — L-0 183.78 218.02 1.19 Non-damaged strengthened beams CL-1 292.77 259.43 0.89 CL-2 281.95 281.50 1.00 CL-3 307.74 301.64 0.98 Pre-damaged strengthened beams SCL-1 264.19 281.50 1.06 SCL-2 282.61 281.50 1.00 SCL-3 217.45 217.40 1.00 Pre-damaged strengthened beams under sustained load XCL-1 249.38 242.53 0.97 XCL-2 242.52 242.53 1.00 Literature [31] Pre-damaged strengthened beams J3 B 212 200.89 0.95 J3 C 200 189.78 0.95 J3 D 178 178.86 1.00 Pre-damaged strengthened beams under sustained load J6 C 166 175.64 1.06 J6 D 160 171.20 1.07 Literature [32] Pre-damaged strengthened beams under sustained load L1Rd2P2A212-70 342.00 288.200 0.84 L1Rd2P2A211-70 410.50 332.950 0.81 L2Rd2P2A212-70 344.50 275.033 0.80 L2Rd2P2A211-70 440.50 323.608 0.74 Notes: $ {P_{{\text{u,t}}}} $—Experimental value of the specimen; $ {P_{{\text{u,cal}}}} $—Calculated value of the specimen. -

[1] AWANI O, EL-MAADDAWY T, ISMAIL M. Fabric-reinforced matrix: A promising strengthening technique for concrete structures[J]. Construction and Building Materials,2017,132:94-111. doi: 10.1016/j.conbuildmat.2016.11.125 [2] BOURNAS D A. Concurrent seismic and energy retrofitting of RC and masonry building envelopes using inorganic textile-based composites with insulation materials: A new concept[J]. Composite Part B: Engineering,2018,148:166-179. doi: 10.1016/j.compositesb.2018.04.002 [3] 李赫, 徐世烺. 纤维编织网增强混凝土薄板力学性能的研究[J]. 建筑结构学报, 2007, 28(4):117-122. doi: 10.3321/j.issn:1000-6869.2007.04.016LI He, XU Shilang. A study on thin concrete plate reinforced with textile[J]. Journal of Building Structures,2007,28(4):117-122(in Chinese). doi: 10.3321/j.issn:1000-6869.2007.04.016 [4] 徐世烺, 阎轶群. 低配网率纤维编织网增强混凝土轴拉力学性能[J]. 复合材料学报, 2011, 28(5):206-213.XU Shilang, YAN Yiqun. Mechanical properties of textile reinforced concrete plate at low textile ratios[J]. Acta Materiae Compositae Sinica,2011,28(5):206-213(in Chinese). [5] D'ANTINO T, PAPANICOLAOU C. Mechanical characterization of textile reinforced inorganic-matrix composites[J]. Composite Part B: Engineering,2017,127(15):78-91. [6] KOUTAS L N, TETTA Z, BOURNAS D A, et al. Strengthening of concrete structures with textile reinforced mortars: State-of-the-art review[J]. Journal of Composites for Construction,2019,23(1):03118001. doi: 10.1061/(ASCE)CC.1943-5614.0000882 [7] TRIANTAFILLOU T C. Innovative textile-based compo-sites for strengthening and seismic retrofitting of concrete and masonry structures[C]. 5th International Conference on FRP Composites in Civil Engineering. Beijing: 2010. [8] ELSANADEDY H, ABBAS H, ALMUSALLAM T, et al. Orga-nic versus inorganic matrix composites for bond-critical strengthening applications of RC structures-State-of-the-art review[J]. Composite Part B: Engineering,2019,174:106947. doi: 10.1016/j.compositesb.2019.106947 [9] RAOOF S M, BOURNAS D A. TRM versus FRP in flexural strengthening of RC beams: Behaviour at high tempera-tures[J]. Construction and Building Materials,2017,154:424-437. doi: 10.1016/j.conbuildmat.2017.07.195 [10] 沈玲华, 王激扬, 徐世烺. 掺入短切纤维的纤维编织网增强混凝土薄板弯曲力学性能试验研究[J]. 建筑结构学报, 2016, 37(10):98-107.SHEN Linghua, WANG Jiyang, XU Shilang. Experimental study on bending mechanical behavior of textile reinforced concrete thin-plates with short dispersed fibers[J]. Journal of Building Structures,2016,37(10):98-107(in Chinese). [11] BARHUM R, MECHTCHERINE V. Effect of short, dispersed glass and carbon fibres on the behaviour of textile-reinforced concrete under tensile loading[J]. Engineering Fracture Mechanics,2012,92:56-71. doi: 10.1016/j.engfracmech.2012.06.001 [12] 董志芳, 邓明科, 张聪. 纤维织物增强高延性混凝土单轴拉伸性能试验研究[J]. 土木工程学报, 2020, 53(10):13-25.DONG Zhifang, DENG Mingke, ZHANG Cong. Experimental investigation on uniaxial tension behavior of textile-reinforced highly ductile concrete[J]. China Civil Engineering Journal,2020,53(10):13-25(in Chinese). [13] 寇佳亮, 邓明科, 梁兴文. 延性纤维增强混凝土单轴拉伸性能试验研究[J]. 建筑结构, 2013, 43(1):59-64.KOU Jialiang, DENG Mingke, LIANG Xingwen. Experimental study of uniaxial tensile properties of ductile fiber reinforced concrete[J]. Building Structure,2013,43(1):59-64(in Chinese). [14] 邓明科, 刘海勃, 秦萌, 等. 高延性纤维混凝土抗压韧性试验研究[J]. 西安建筑科技大学学报(自然科学版), 2015, 47(5):660-665.DENG Mingke, LIU Haibo, QIN Meng, et al. Experimental research on compressive toughness of the high ductile fiber reinforced concrete[J]. Journal of Xi'an University of Architecture & Technology (Natural Science Edition),2015,47(5):660-665(in Chinese). [15] DENG M K, DONG Z F, ZHANG C. Experimental investigation on tensile behavior of carbon textile reinforced mortar (TRM) added with short polyvinyl alcohol (PVA) fibers[J]. Construction and Building Materials,2020,235:117801. [16] DONG Z F, DENG M K, ZHANG C, et al. Tensile behavior of glass textile reinforced mortar (TRM) added with short PVA fibers[J]. Construction and Building Materials,2020,260:119897. doi: 10.1016/j.conbuildmat.2020.119897 [17] ZHENG Y Z, WANG W W, BRIGHAM J C. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC[J]. Construction and Building Materials,2016,115:424-437. doi: 10.1016/j.conbuildmat.2016.04.038 [18] YANG X, GAO W Y, DAI J G, et al. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix[J]. Composite Structures,2018,189:9-26. doi: 10.1016/j.compstruct.2018.01.048 [19] 滕锦光, 陈建飞, 史密斯 S T, 等. FRP 加固混凝土结构[M]. 李荣, 滕锦光, 顾磊, 译. 北京: 中国建筑工业出版社, 2005: 100-101.TENG Jinguang, CHEN Jianfei, SMITH S T, et al. FRP strengthened RC structures[M]. Translated by LI Rong, TENG Jinguang, GU Lei. Beijing: China Architecture & Building Press, 2005: 100-101(in Chinese). [20] 郑宇宙, 王文炜, 戴建国, 等. FRP-UHTCC复合层抗剪增强RC梁受力性能试验研究[J]. 建筑结构学报, 2019(8):118-126.ZHENG Yuzhou, WANG Wenwei, DAI Jianguo, et al. Experimental study on mechanical performance of reinforced concrete beams shear-strengthened with FRP-UHTCC composite[J]. Journal of Building Structures,2019(8):118-126(in Chinese). [21] GUO R, REN Y, LI M Q, et al. Experimental study on flexural shear strengthening effect on low-strength RC beams by using FRP grid and ECC[J]. Engineering Structures,2021,227:111434. doi: 10.1016/j.engstruct.2020.111434 [22] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB/T 50010—2010[S]. Beijing: China Architectures & Building Press, 2010(in Chinese). [23] 《高延性混凝土应用技术规程》编制组. 高延性混凝土应用技术规程: DBJ 61/T 112−2016[S]. 北京: 中国建材工业出版社, 2016.Compilation Group of Technical Specification for Application of High Ductile Concrete. Technical specification for application of high ductile concrete: DBJ 61/T 112−2016[S]. Beijing: China Building Materials Press, 2016(in Chinese). [24] TAN K H, TONG K, TANG C Y. Direct strut-and-tie model for prestressed deep beams[J]. ASCE Journal of Structural Engineering,2001,127(9):1076-1084. doi: 10.1061/(ASCE)0733-9445(2001)127:9(1076) [25] TANG C Y, TONG K, TAN K H. A direct method for deep beams with web reinforcement[J]. Magazine of Concrete Research,2003,55(1):53-63. doi: 10.1680/macr.2003.55.1.53 [26] COOK R D, YOUNG W C. Advanced mechanics of materials[J]. Text-Interdisciplinary Journal for the Study of Discourse, 1954, 7(4): 435-436. [27] ZHANG N, TAN K H. Direct strut-and-tie model for single span and continuous deep beams[J]. Engineering Structures,2007,29(11):2987-3001. doi: 10.1016/j.engstruct.2007.02.004 [28] 邓明科, 马福栋, 李勃志, 等. 基于修正拉-压杆模型的型钢混凝土深梁受剪承载力分析[J]. 工程力学, 2017, 34(12):95-103.DENG Mingke, MA Fudong, LI Bozhi, et al. Analysis on shear capacity of SRC deep beams based on modified strut-and-tie model[J]. Engineering Mechanics,2017,34(12):95-103(in Chinese). [29] DENG M K, MA F D, YE W, et al. Investigation of the shear strength of HDC deep beams based on a modified direct strut-and-tie model[J]. Construction and Building Materials,2018,172:340-348. doi: 10.1016/j.conbuildmat.2018.03.274 [30] HEGGER J, VOSS S, PRISCO M D, et al. Textile reinforced concrete under biaxial loading[C]. 6th International RILEM Symposium on Fibre Reinforced Concretes. Varenna: Publikationsserver der RWTH Aachen University, 2004. [31] 张海霞, 孙闯, 黄妍. 考虑二次受力的内嵌BFRP筋加固混凝土T形梁受剪性能试验研究[J]. 建筑结构学报, 2019, 40(6):56-63.ZHANG Haixia, SUN Chuang, HUANG Yan. Experimental study on shear behavior of RC T-beams strengthened with near-surface mounted BFRP bars considering effect of secondary loading[J]. Journal of Building Structures,2019,40(6):56-63(in Chinese). [32] 刘君, 周朝阳, 宋朋. 持载混凝土梁端锚无黏结预应力U形碳纤维带受剪加固试验研究[J]. 建筑结构学报, 2019, 40(12):96-104.LIU Jun, ZHOU Chaoyang, SONG Peng. Experimental research on shear strengthening of concrete beams under sustained load with end-anchored and unbonded prestressed CFRP U-strips[J]. Journal of Building Structures,2019,40(12):96-104(in Chinese). -

下载:

下载: