| [1] |

NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview[J]. Composites Science & Technology, 2004, 64(2): 155-170.

|

| [2] |

LI L B. Modeling the effect of oxidation on fatigue life of carbon fiber-reinforced ceramic-matrix composites at elevated temperature[J]. Materials Science and Engineering A, 2015, 640: 106-117. doi: 10.1016/j.msea.2015.06.007

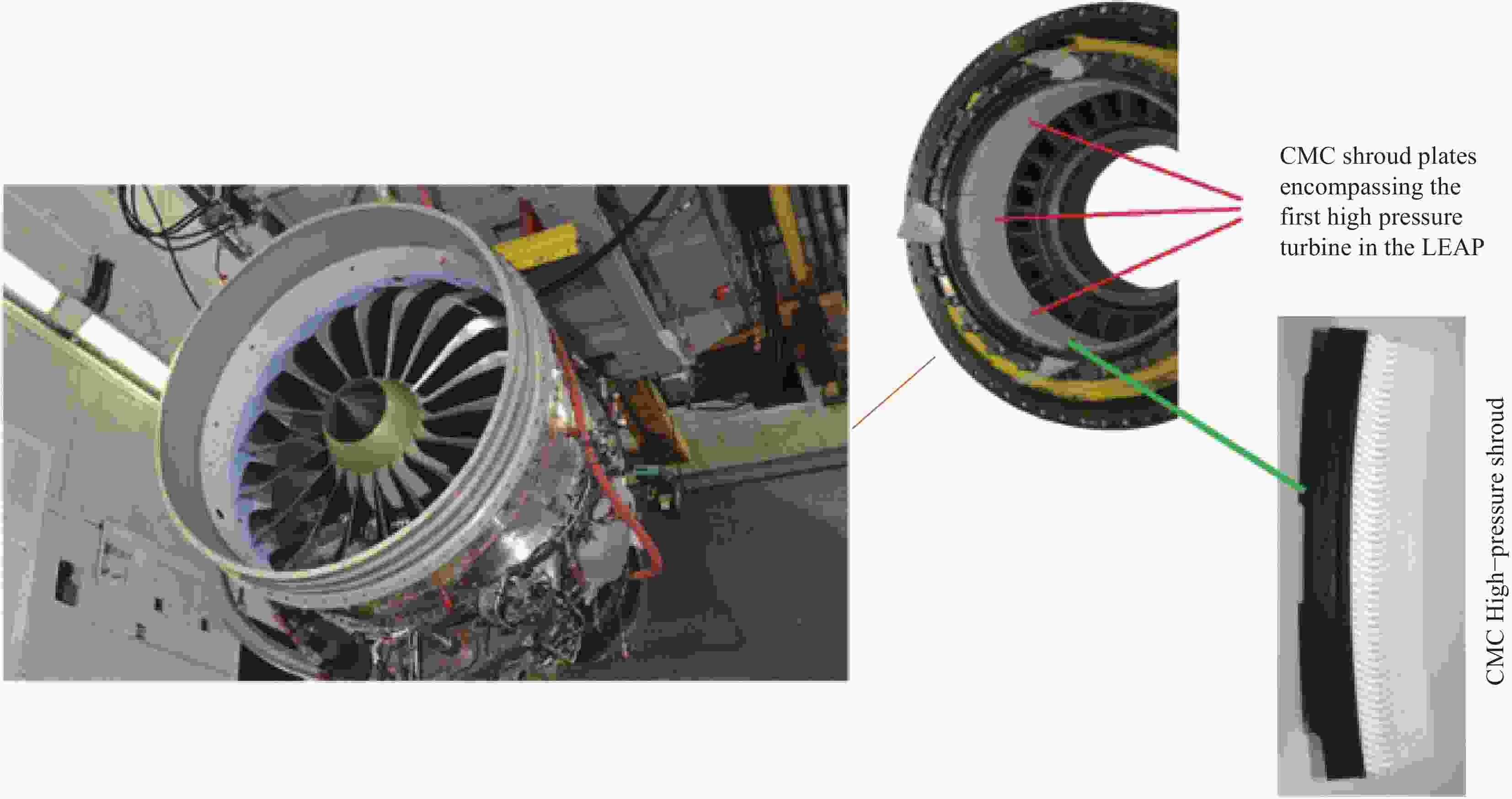

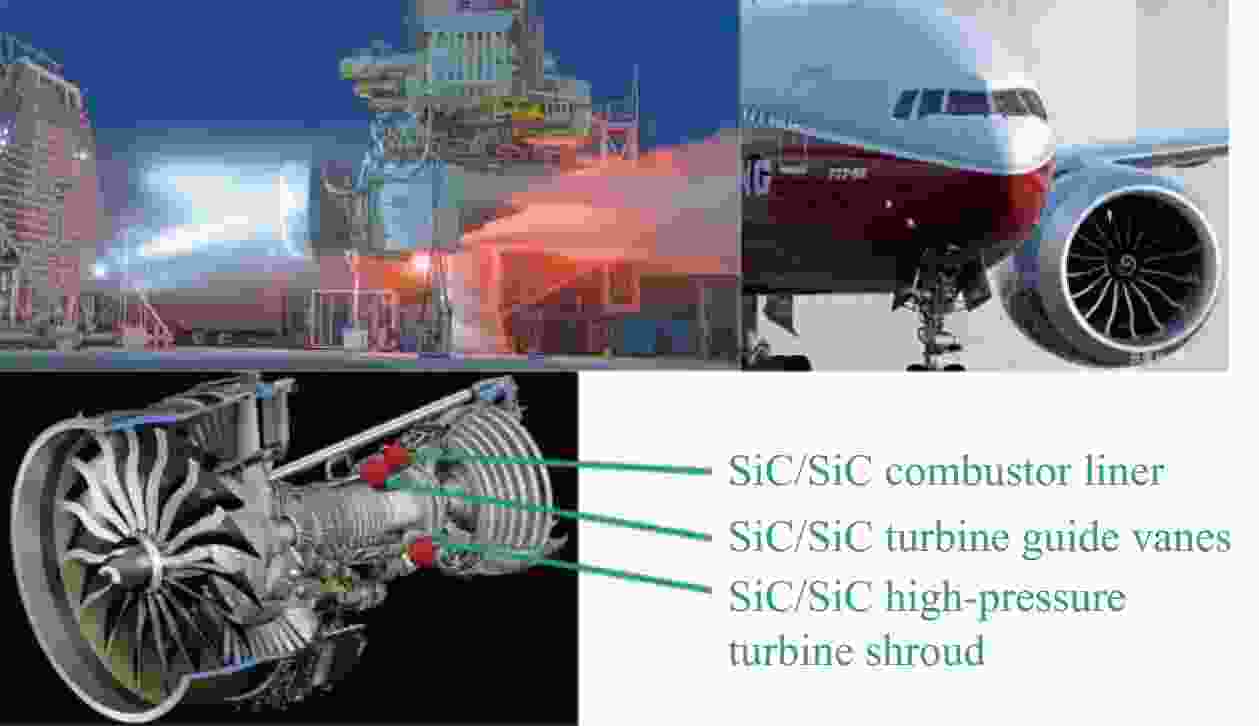

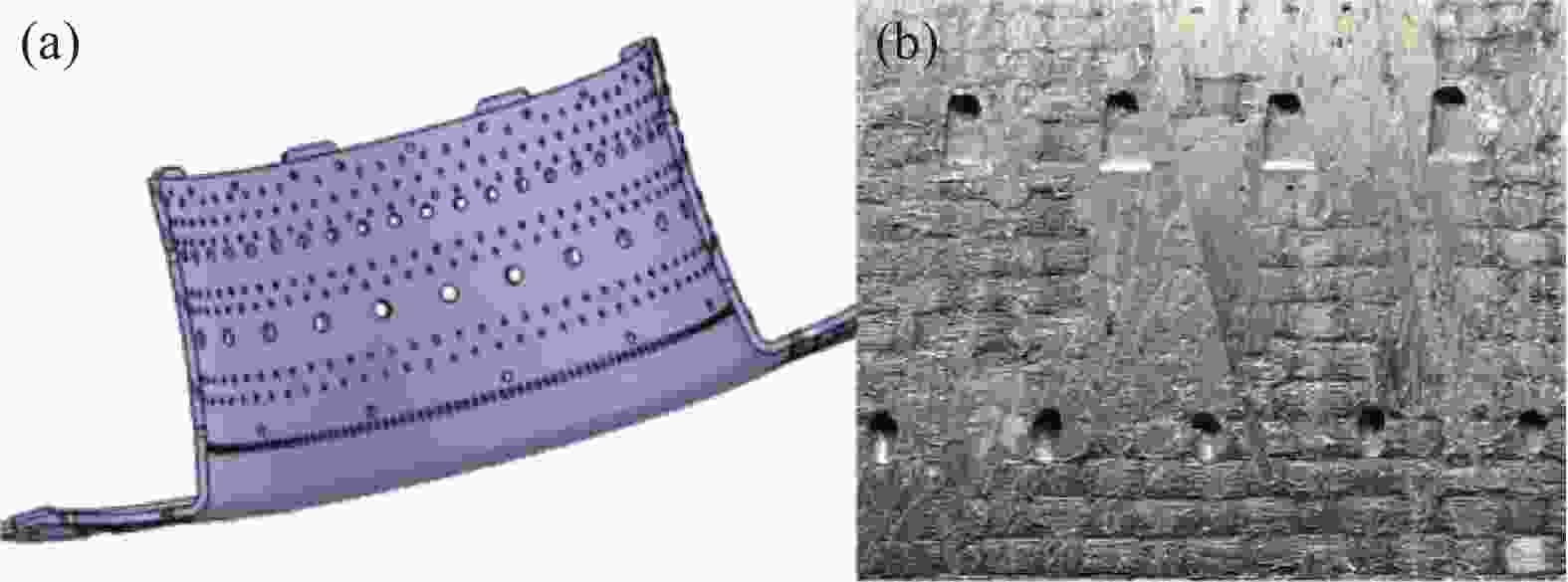

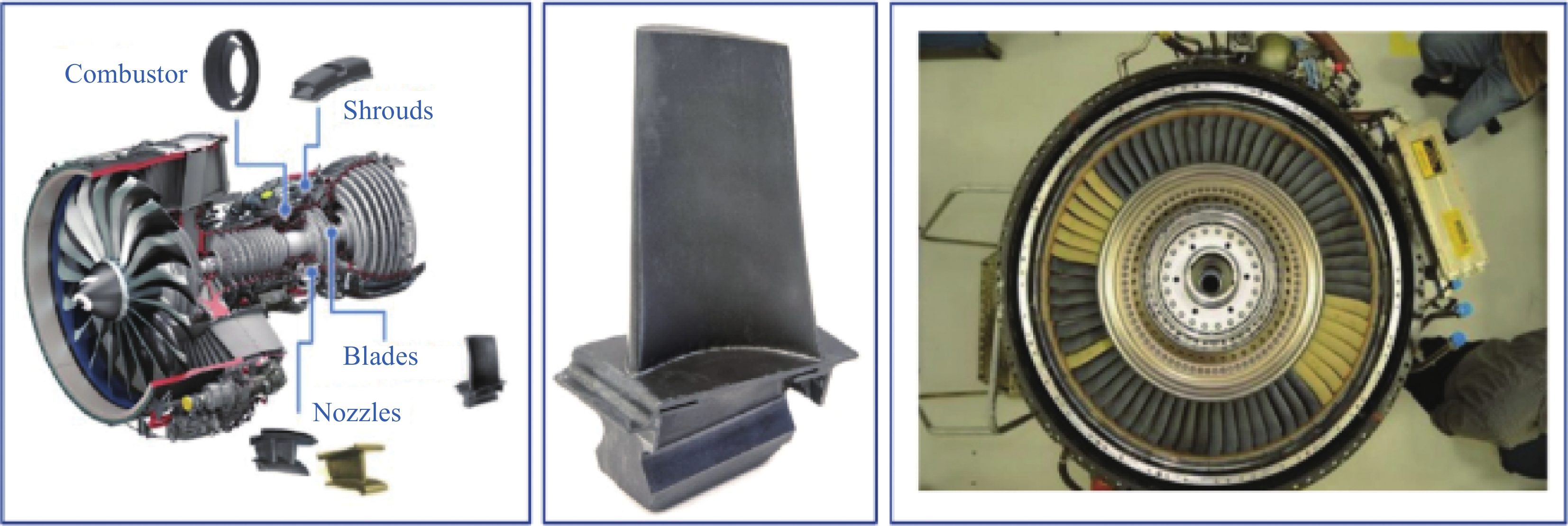

|

| [3] |

LI L B. Durability of ceramic matrix composites [M]. Oxford: Elsevier, 2020.

|

| [4] |

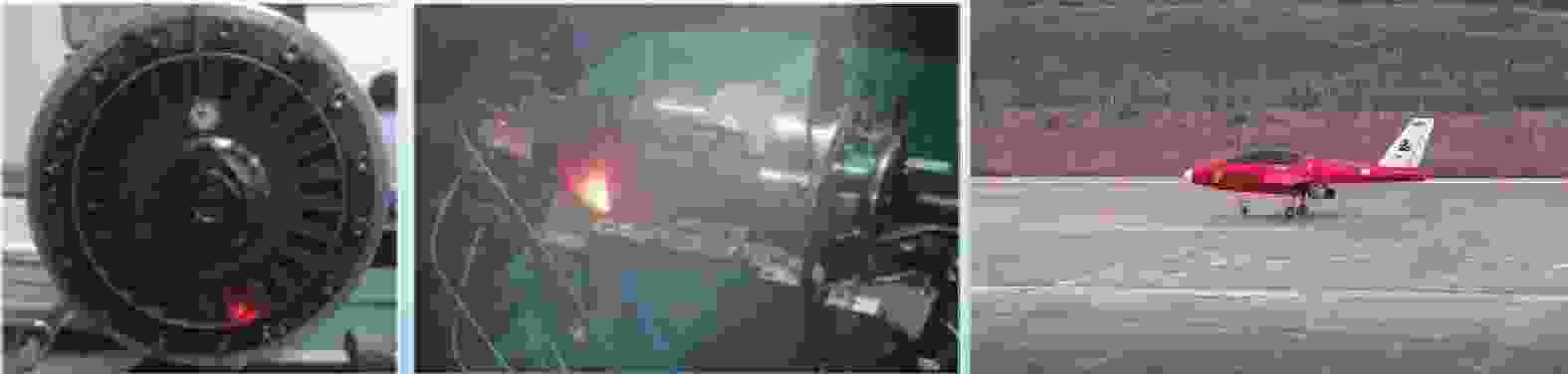

张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨[J]. 复合材料学报, 2007(2): 1-6.ZHANG Litong, CHENG Laifei. Discussion on strategies of sustainable development of continuous fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica, 2007(2): 1-6(in Chinese).

|

| [5] |

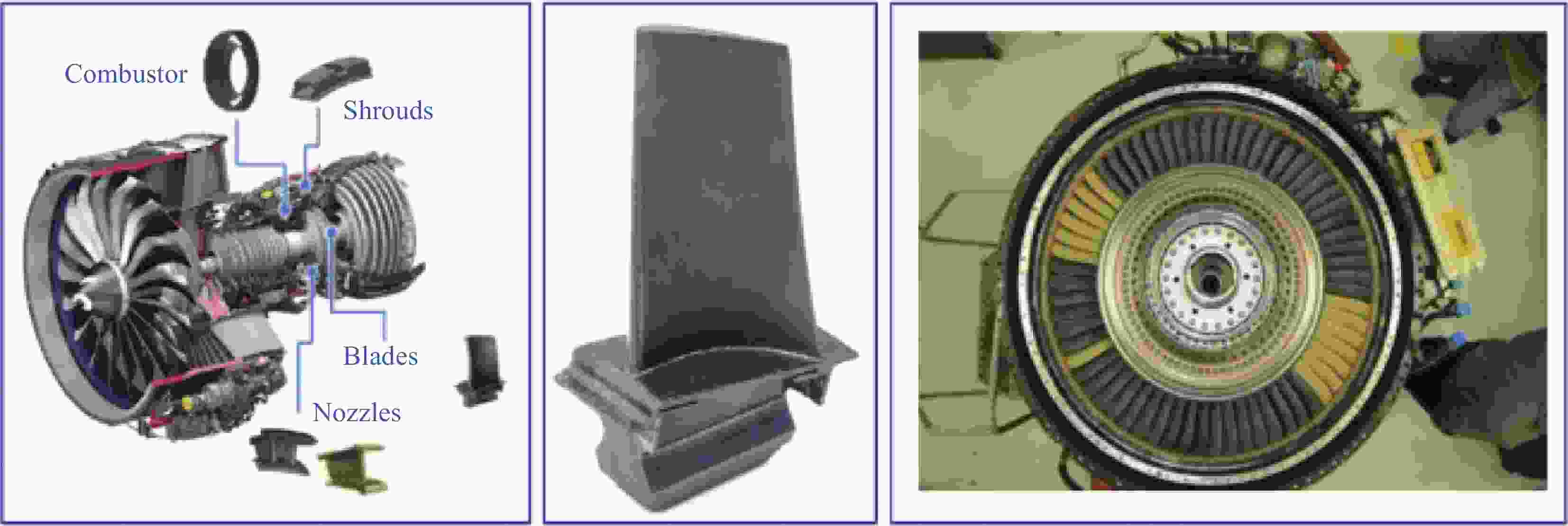

杜昆, 陈麒好, 孟宪龙, 等. 陶瓷基复合材料在航空发动机热端部件应用及热分析研究进展[J]. 推进技术, 2022, 43(2): 113-131.DU Kun, CHEN Qihao, MENG Xianlong, et al. Advancement in application and thermal analysis of ceramic matrix composites in aeroengine hot components[J]. Journal of Propulsion Technology, 2022, 43(2): 113-131(in Chinese).

|

| [6] |

焦健, 孙世杰, 焦春荣, 等. SiCf/SiC复合材料涡轮导向叶片研究进展[J]. 复合材料学报, 2023, 40(8): 4342-4354.JIAO Jian, SUN Shijie, JIAO Chunrong, et al. Research progress of SiCf/SiC turbine guide vanes: A review[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4342-4354(in Chinese).

|

| [7] |

马雪寒, 王守财, 陈旭, 等. 陶瓷基复合材料紧固件制造技术及其连接性能研究进展[J]. 复合材料学报, 2023, 40(6): 3075-3089.MA Xuehan, WANG Shoucai, CHEN Xu, et al. Review of preparation processes and joining performance of ceramic matrix composite fasteners[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3075-3089(in Chinese).

|

| [8] |

邹豪, 王宇, 刘刚, 等. 碳化硅纤维增韧碳化硅陶瓷基复合材料的发展现状及其在航空发动机上的应用[J]. 航空制造技术, 2017(15): 76-84.ZOU Hao, WANG Yu, LIU Gang, et al. Development situation and application of SiC/SiC ceramic matrix composites in aeroengine[J]. Aeronautical Manufacturing Technology, 2017(15): 76-84(in Chinese).

|

| [9] |

谭米. 首台XA100自适应循环发动机完成测试[J]. 航空动力, 2021(3): 8-10.TAN Mi. First XA100 adaptive cycle engine completes test[J]. Aerospace Power, 2021(3): 8-10(in Chinese).

|

| [10] |

刘小冲, 徐友良, 李坚, 等. 陶瓷基复合材料涡轮叶盘设计、制备与考核验证[J]. 复合材料学报, 2023, 40(3): 1702-1712.LIU Xiaochong, XU Youliang, LI Jian, et al. Design, fabrication and testing of ceramic-matrix composite turbine blisk[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1702-1712(in Chinese).

|

| [11] |

LIU X C, ZHAO W L, GUO H Q, et al. XCT damage evaluation and analysis of SiC/SiC turbine guide vanes after thermal shocks[J]. International Journal of Applied Ceramic Technology, 2023, 20(5): 2919-2929. doi: 10.1111/ijac.14423

|

| [12] |

刘彦杰, 马武军, 吴建军, 等. C/SiC陶瓷基复合材料燃烧室壁厚设计与验证[J]. 国防科技大学学报, 2012, 34(6): 121-124.LIU Yanjie, MA Wujun, WU Jianjun, et al. Wall thickness design of combustion chamber for C/SiC composites rocket engine[J]. Journal of National University of Defense Technology, 2012, 34(6): 121-124(in Chinese).

|

| [13] |

刘鑫, 乔逸飞, 董少静, 等. SiCf/SiC陶瓷基复合材料涡轮导叶热疲劳试验研究与损伤分析[J]. 燃气涡轮试验与研究, 2020, 33(4): 26-30.LIU Xin, QIAO Yifei, DONG Shaojing, et al. Thermal fatigue test and damage analysis of SiCf/SiC ceramic matrix composite turbine guide vane[J]. Gas Turbine Experiment and Research, 2020, 33(4): 26-30(in Chinese).

|

| [14] |

石多奇, 刘长奇, 程震, 等. SiC/SiC复合材料涡轮叶片结构设计及静强度评价[J]. 航空动力学报, 2023, 38(1): 1-12.SHI Duoqi, LIU Changqi, CHENG Zhen, et al. Structural design and static strength evaluation of SiC/SiC-composite turbine blade[J]. Journal of Aerospace Power, 2023, 38(1): 1-12(in Chinese).

|

| [15] |

LI L B. Ceramic matrix composites: Lifetime and strength prediction under static and stochastic loading [M]. Oxford: Elsevier, 2023.

|

| [16] |

罗潇, 李坚, 李敏, 等. 蛛网式骨架增强陶瓷基复合材料涡轮叶盘设计及验证[J]. 航空动力, 2021(1): 54-56.LUO Xiao, LI Jian, LI Min, et al. Design and test of the CMC blisk reinforced by spider-web-like framework[J]. Aerospace Power, 2021(1): 54-56(in Chinese).

|

| [17] |

刘虎, 束小文, 洪智亮, 等. 航空发动机用SiC/SiC复合材料典型元件设计及性能评价研究进展[J]. 材料导报, 2023, 37(4): 22010147.LIU Hu, SHU Xiaowen, HONG Zhiliang, et al. Research progress on design and evaluation of typical SiC/SiC composite sub-elements used for aero engines[J]. Materials Report, 2023, 37(4): 22010147(in Chinese).

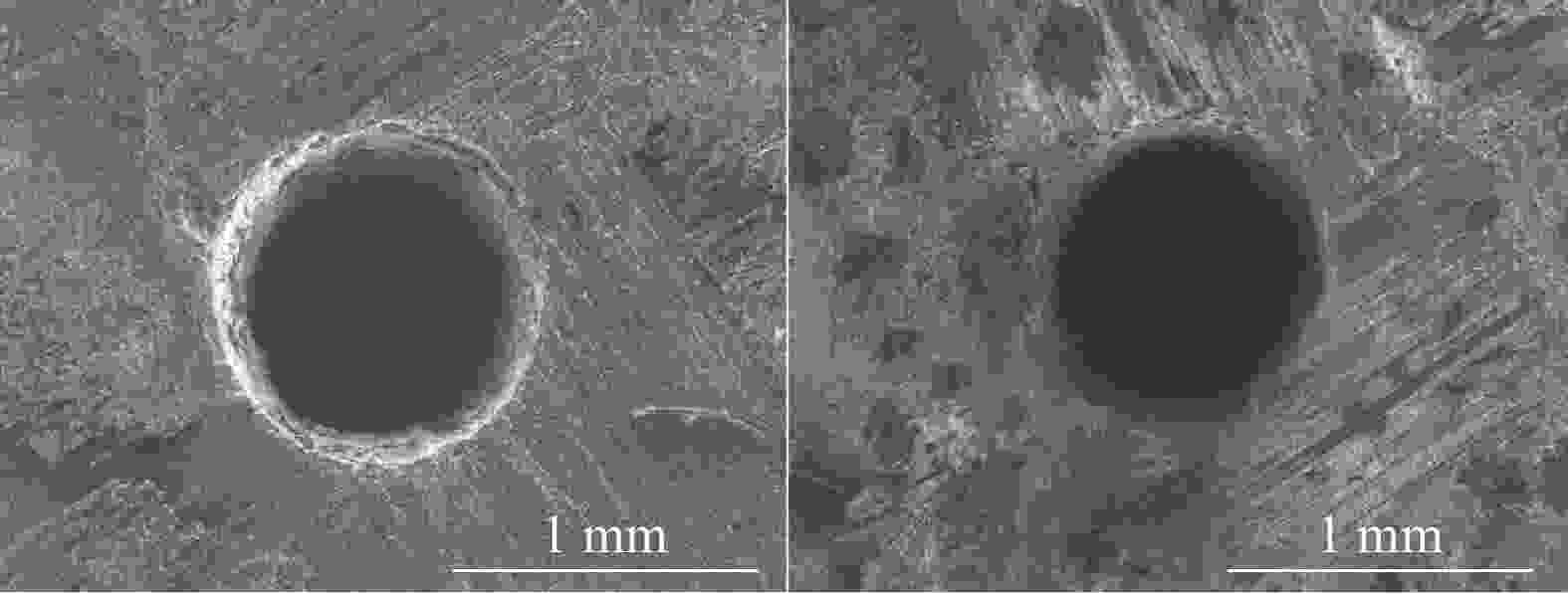

|

| [18] |

焦健, 杨金华, 侯金涛, 等. SiC/SiC复合材料切割方法对比研究[J]. 中国陶瓷, 2023, 59(6): 57-67.JIAO Jian, YANG Jinhua, HOU Jintao, et al. Comparative study on cutting methods of SiC/SiC composites[J]. China Ceramics, 2023, 59(6): 57-67(in Chinese).

|

| [19] |

孙明, 史一宁, 邱海鹏, 等. PIP法制备陶瓷基复合材料构件的弯曲性能研究[J]. 稀有金属材料与工程, 2011, 40(S1): 631-634.SUN Ming, SHI Yining, QIU Haipeng, et al. Studies of flexural strength of ceramic matrix composite component prepared by PIP process[J]. Rare Metal Materials and Engineering, 2011, 40(S1): 631-634(in Chinese).

|

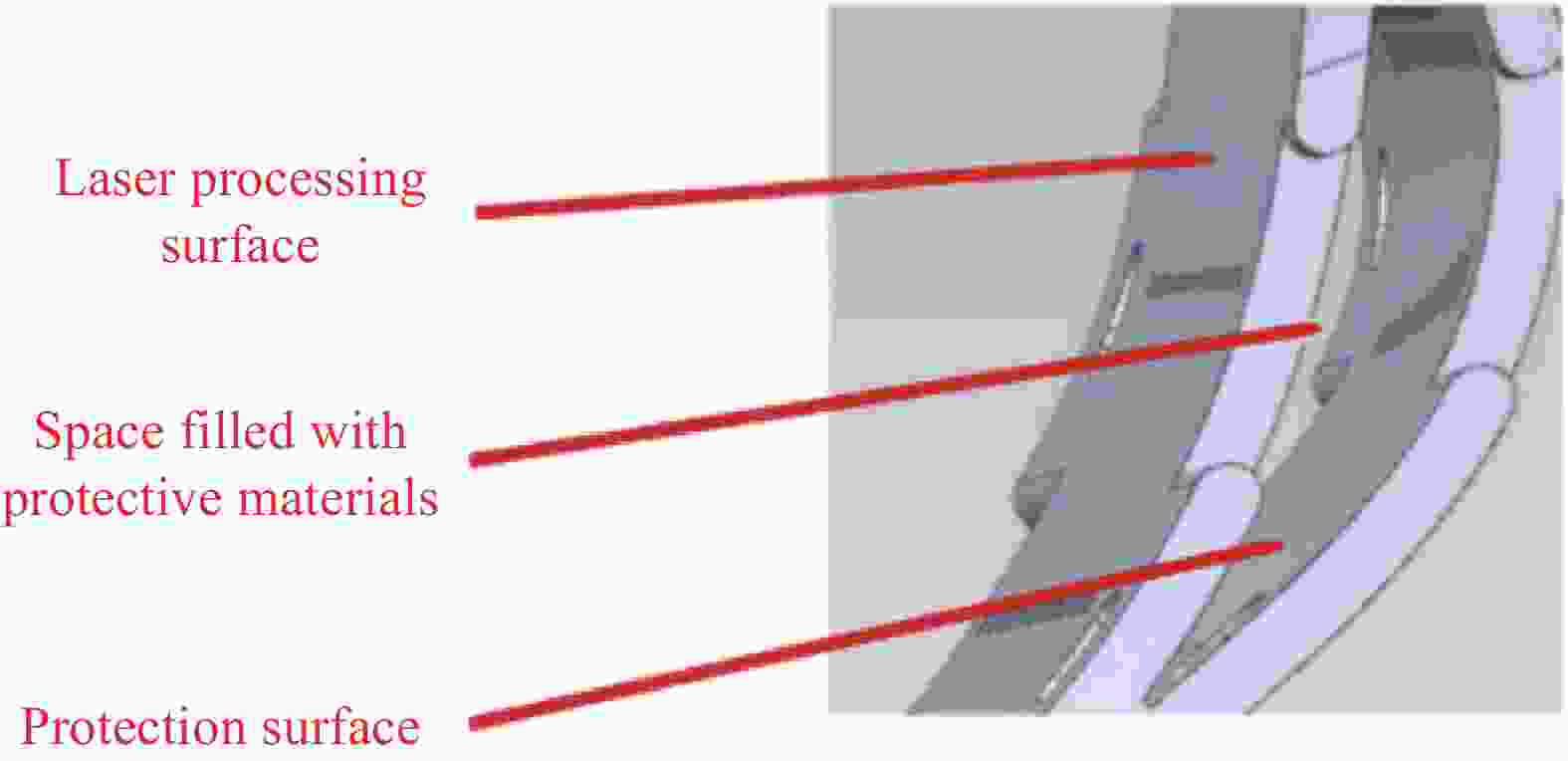

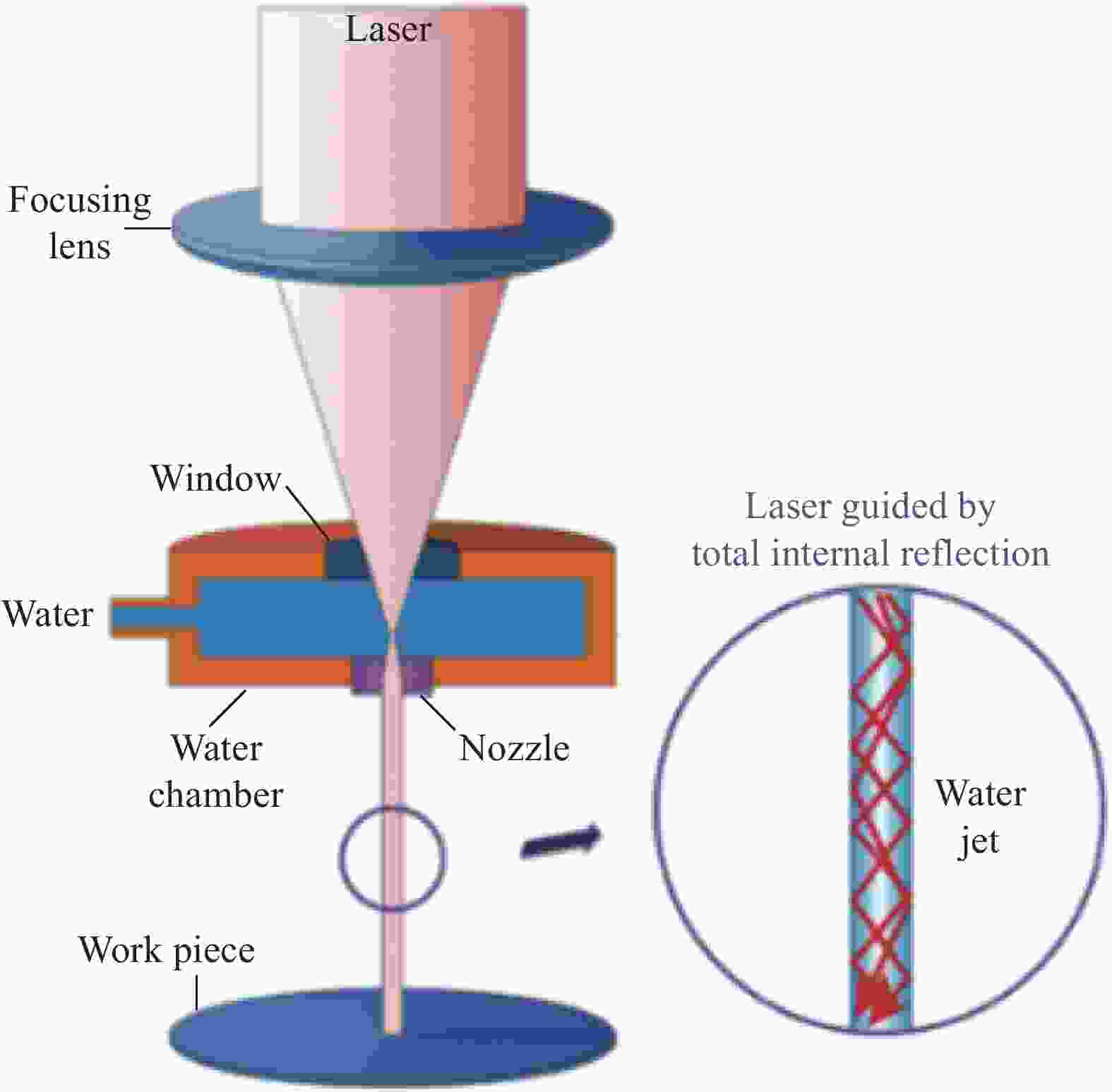

| [20] |

房金铭, 袁泽帅, 王俊山, 等. 碳纤维增强陶瓷基复合材料高温拉伸性能研究[J]. 导弹与航天运载技术, 2022(4): 77-79.FANG Jinming, YUAN Zeshuai, WANG Junshan, et al. Study on the high temperature tensile properties of carbon fiber reinforced ceramic matrix composites[J]. Missles and Space Vehicles, 2022(4): 77-79(in Chinese).

|

| [21] |

MEI H, CHENG L F. Comparison of the mechanical hystersis of carbonc/ceramic-matrix composites with different fiber preforms[J]. Carbon, 2009, 47: 1034-1042. doi: 10.1016/j.carbon.2008.12.025

|

| [22] |

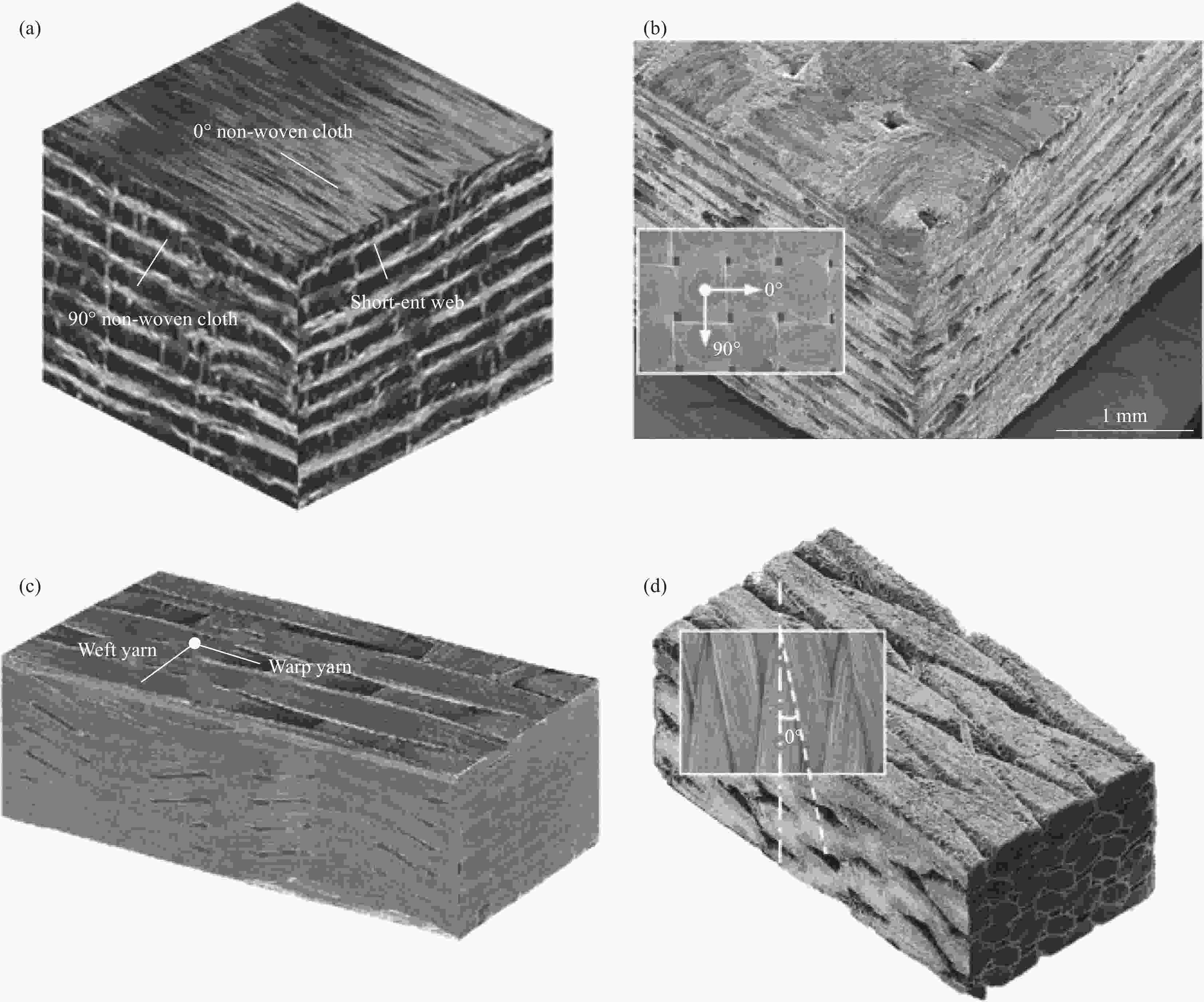

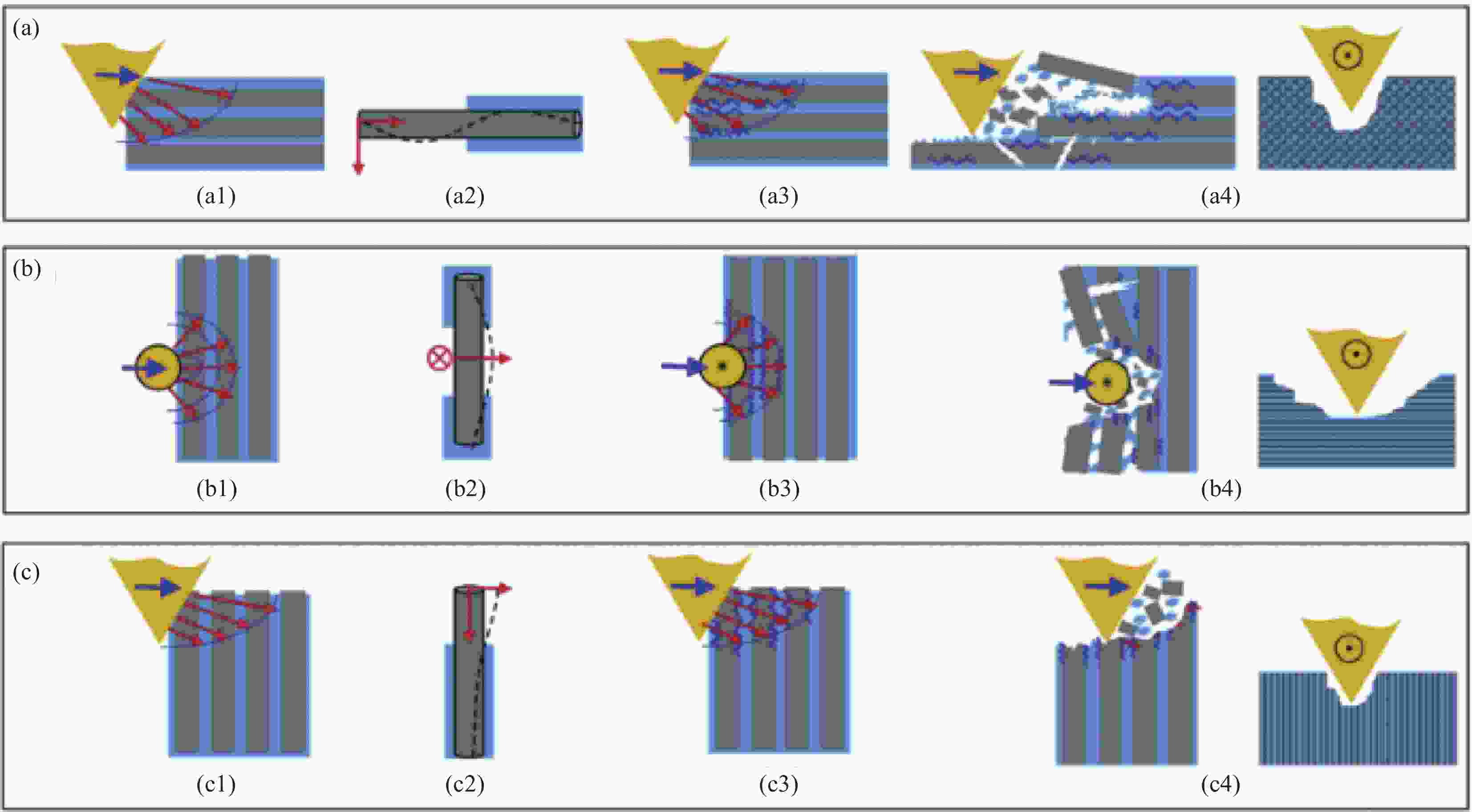

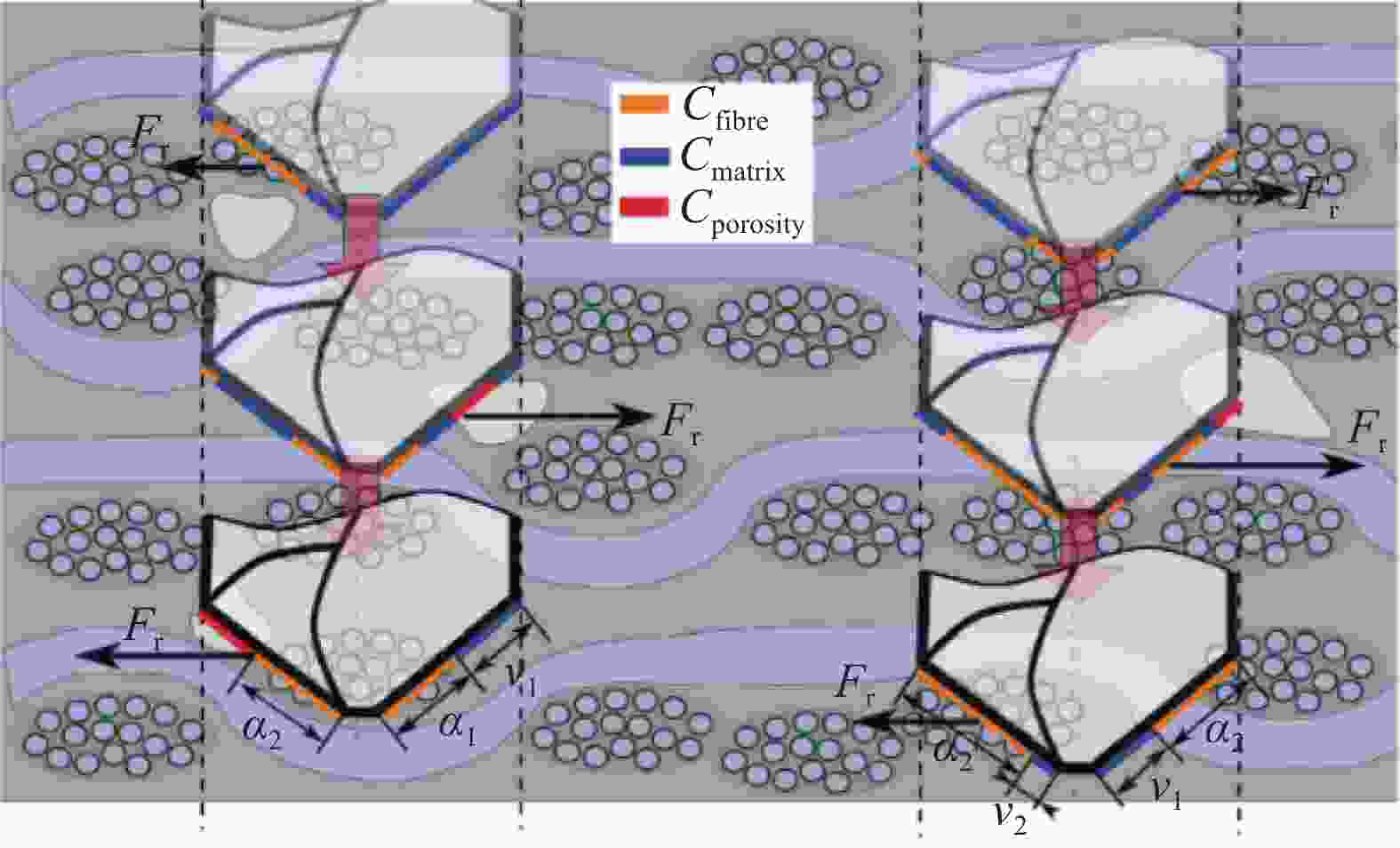

CAO X, LIN B, ZHANG X. Investigations on grinding process of woven ceramic matrix composite based on reinforced fiber orientations[J]. Composites Part B: Engineering, 2015, 71: 184-192.

|

| [23] |

张立峰, 王盛, 乔伟林, 等. 单向复合材料C/SiC平面磨削力实验研究[J]. 硅酸盐通报, 2019, 38(4): 1155-1159.ZHANG Lifeng, WANG Sheng, QIAO Weilin, et al. Experimental study on surface grinding force of unidirectional C/SiC composites[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(4): 1155-1159(in Chinese).

|

| [24] |

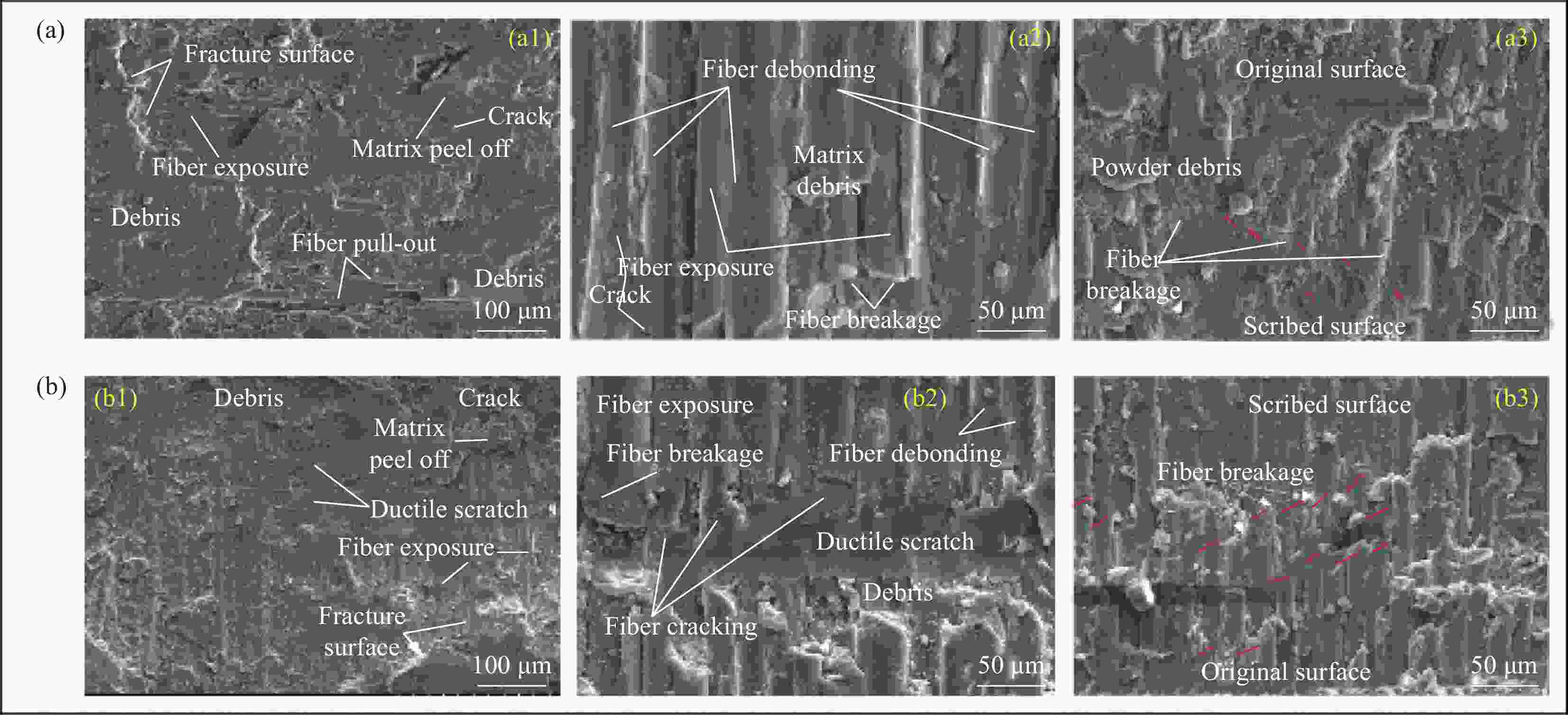

ZHANG L F, REN C Z, JI C H, et al. Effect of fiber orientations on surface grinding process of unidiectional C/SiC composites[J]. Applied Surface Science, 2016, 366: 424-431. doi: 10.1016/j.apsusc.2016.01.142

|

| [25] |

张立峰, 王盛, 李战, 等. 纤维方向对单向C/SiC复合材料磨削加工性能的影响[J]. 中国机械工程, 2020, 31(3): 373-377.ZHANG Lifeng, WANG Sheng, LI Zhan, et al. Effects of fiber direction on grinding performance for undirectional C/SiC composites[J]. China Mechanical Engineering, 2020, 31(3): 373-377(in Chinese).

|

| [26] |

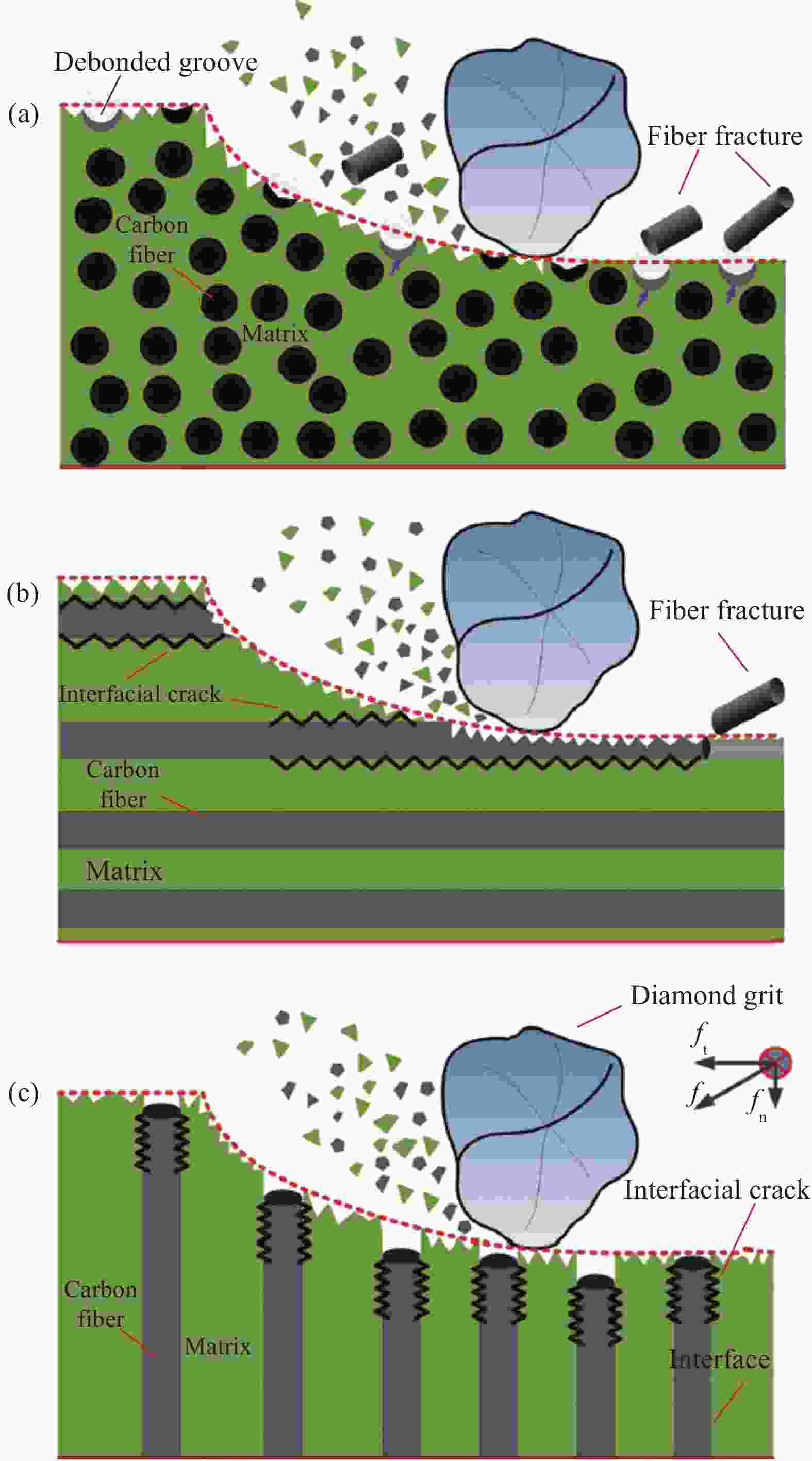

LIU Q, HUANG G Q, CUI C C, et al. Investigation of grinding mechanism of a 2D C/C-SiC composite by single grain scratching[J]. Ceramics International, 2019, 45(10): 13422-13430. doi: 10.1016/j.ceramint.2019.04.041

|

| [27] |

舍跃斌. 碳纤维增强碳化硅陶瓷基复合材料(Cf/SiC)磨削机制及工艺优化研究[D]. 沈阳: 东北大学, 2019.SHE Yuebin. Research on grinding mechanism and process optimization of carbon fiber reinforced silicon carbide ceramic matrix composites (Cf/SiC) [D]. Shenyang: Northeastern University, 2019(in Chinese).

|

| [28] |

LIU Y, QUAN Y, WU C J, et al. Single diamond scribing of SiCf/SiC composite: Force and material removal mechanism study[J]. Ceramics International, 2021, 47(19): 27702-27709. doi: 10.1016/j.ceramint.2021.06.195

|

| [29] |

权宇. SiCf/SiC陶瓷基复合材料磨削实验研究[D]. 太原: 中北大学, 2022.QUAN Yu. Experimental study on grinding of SiCf/SiC ceramic matrix composites [D]. Taiyuan: North University of China, 2022(in Chinese).

|

| [30] |

周雯雯. 单颗磨粒划擦碳化硅陶瓷基复合材料划擦力及表面损伤研究[D]. 太原: 中北大学, 2021.ZHOU Wenwen. Resarch on scratch force and surface damage of single abrasive particle scratching silicon carbide ceramic matrix composite [D]. Taiyuan: North University of China, 2021(in Chinese).

|

| [31] |

殷景飞, 徐九华, 丁文锋, 等. SiCf/SiC陶瓷基复合材料单颗磨粒磨削实验研究[J]. 中国机械工程, 2022, 33(15): 1765-1771.YIN Jingfei, XU Jiuhua, DING Wenfeng, et al. Experimental study of single grain grinding for SiCf/SiC ceramic matrix composites[J]. China Mechanical Engineering, 2022, 33(15): 1765-1771(in Chinese).

|

| [32] |

何涛, 傅玉灿, 苏宏华, 等. C/SiC复合材料铣削表面完整性研究[J]. 南京航空航天大学学报, 2014, 46(5): 701-706. doi: 10.3969/j.issn.1005-2615.2014.05.006HE Tao, FU Yucan, SU Honghua, et al. Study on surface integrity in milling of C/SiC composite[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2014, 46(5): 701-706(in Chinese). doi: 10.3969/j.issn.1005-2615.2014.05.006

|

| [33] |

钟翔福. C/SiC复合材料旋转超声振动辅助铣削实验研究[D]. 南昌: 南昌航空大学, 2019.ZHONG Xiangfu. Experimental research on rotating ultrasonic vibration assisted milling of C/SiC composites [D]. Nanchang: Nanchang Hangkong University, 2019(in Chinese).

|

| [34] |

HU M, MING W W, AN Q L, et al. Experimental study on milling performance of 2D C/SiC composites using polycrystalline diamond tools[J]. Ceramics International, 2019, 45(8): 10581-10588. doi: 10.1016/j.ceramint.2019.02.124

|

| [35] |

孔宪俊, 王文武, 赵明, 等. 陶瓷基复合材料铣削力优化及刀具磨损研究[J]. 工具技术, 2022, 56(3): 9-13.KONG Xianjun, WANG Wenwu, ZHAO Ming, et al. Research on milling force optimization and tool wear of ceramic matrix composites[J]. Tool Engineering, 2022, 56(3): 9-13(in Chinese).

|

| [36] |

SHAN C W, WANG X, YANG X X, et al. Prediction of cutting forces in ball-end milling of 2.5D C/C composites[J]. Chinese Journal of Aeronautics, 2016, 29(3): 824-830. doi: 10.1016/j.cja.2015.12.015

|

| [37] |

YUAN S, LI Z, ZHANG C, et al. Research into the transition of material removal machanism for C/SiC in rotary ultrasonic face machining[J]. International Journal of Advanced Manufacturing Technology, 2018, 95: 1751-1761. doi: 10.1007/s00170-017-1332-8

|

| [38] |

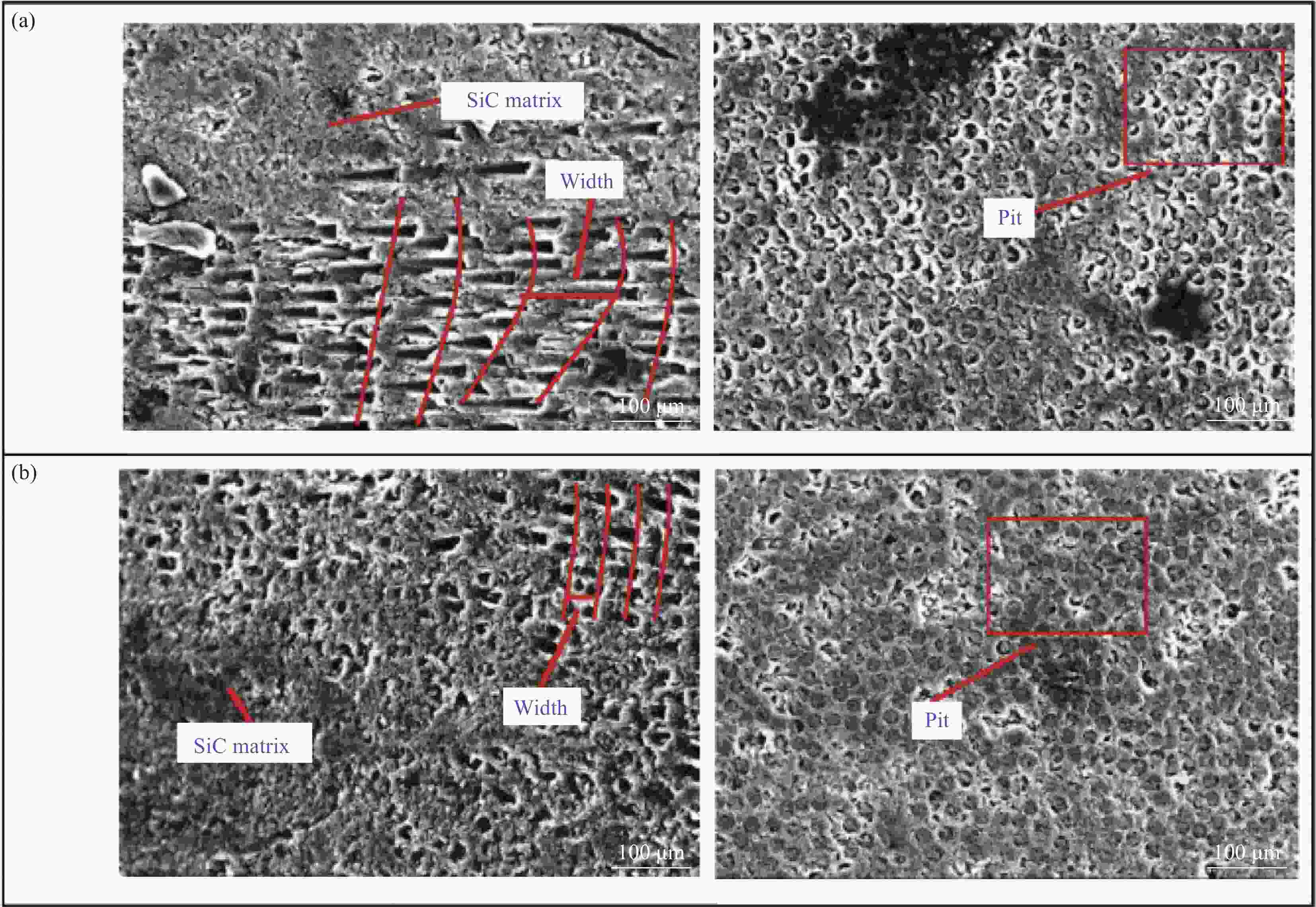

DIAZ O G, AXINTE D A, SMITH P B, et al. On understanding the microstructure of SiC/SiC ceramic matrix composites (CMCs) after a material removal process[J]. Materials Science and Engineering A, 2019, 743: 1-11. doi: 10.1016/j.msea.2018.11.037

|

| [39] |

DIAZ O G, AXINTE D A, NOVOVIC D. Probabilistic modelling of tool unbalance during cutting of hard-heterogeneous materials: A case study in ceramic matrix composites (CMCs)[J]. Composites Part B: Engineering, 2018, 148: 217-226.

|

| [40] |

张瑾瑜, 王宁, 赵建设, 等. C/SiC复合材料螺旋铣削与钻削制孔效果对比[J]. 宇航材料工艺, 2020, 50(5): 39-40.ZHANG Jinyu, WANG Ning, ZHAO Jianshe, et al. Comparison between helical milling and drilling of C/SiC composite materials[J]. Aerospace Materials & Technology, 2020, 50(5): 39-40(in Chinese).

|

| [41] |

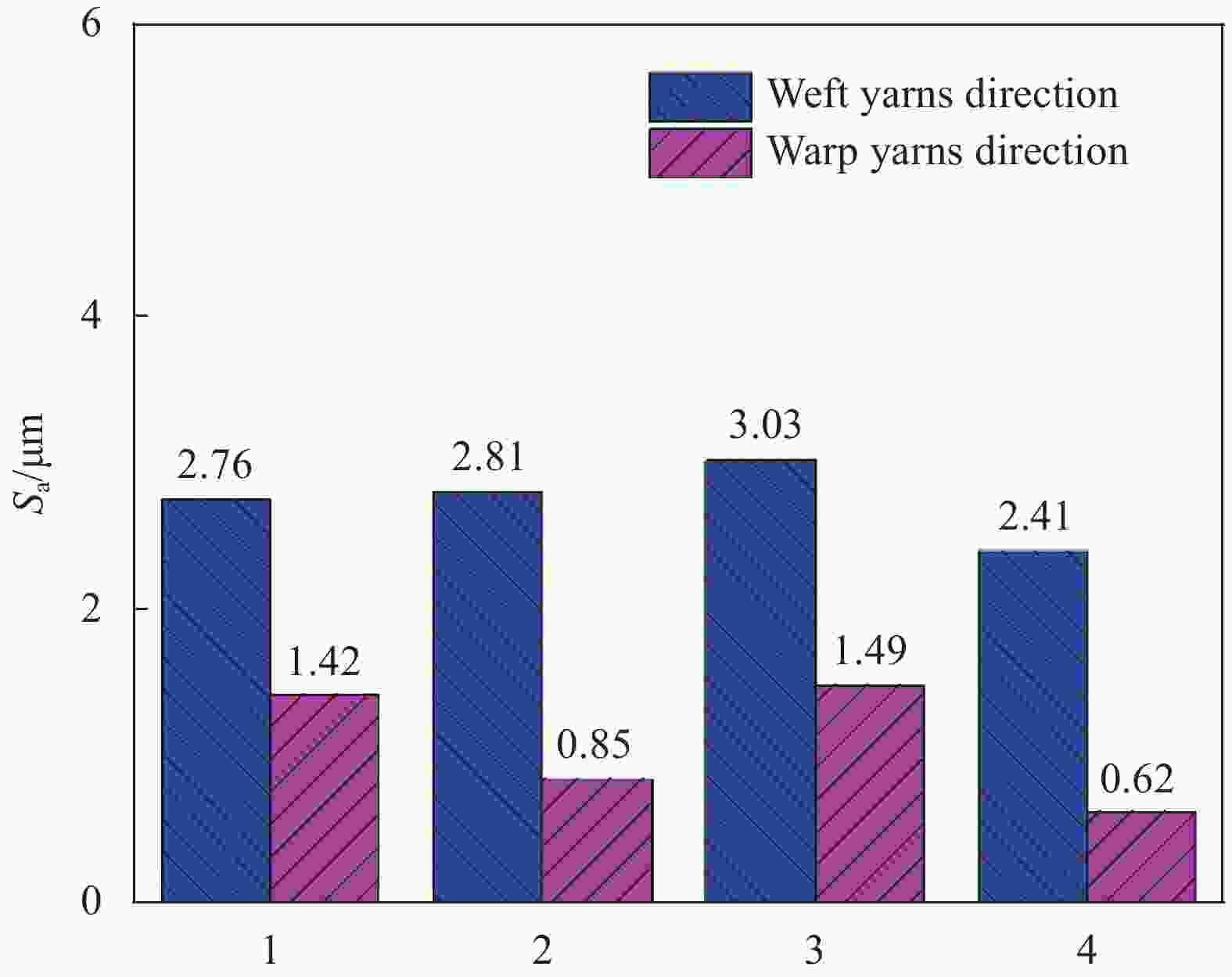

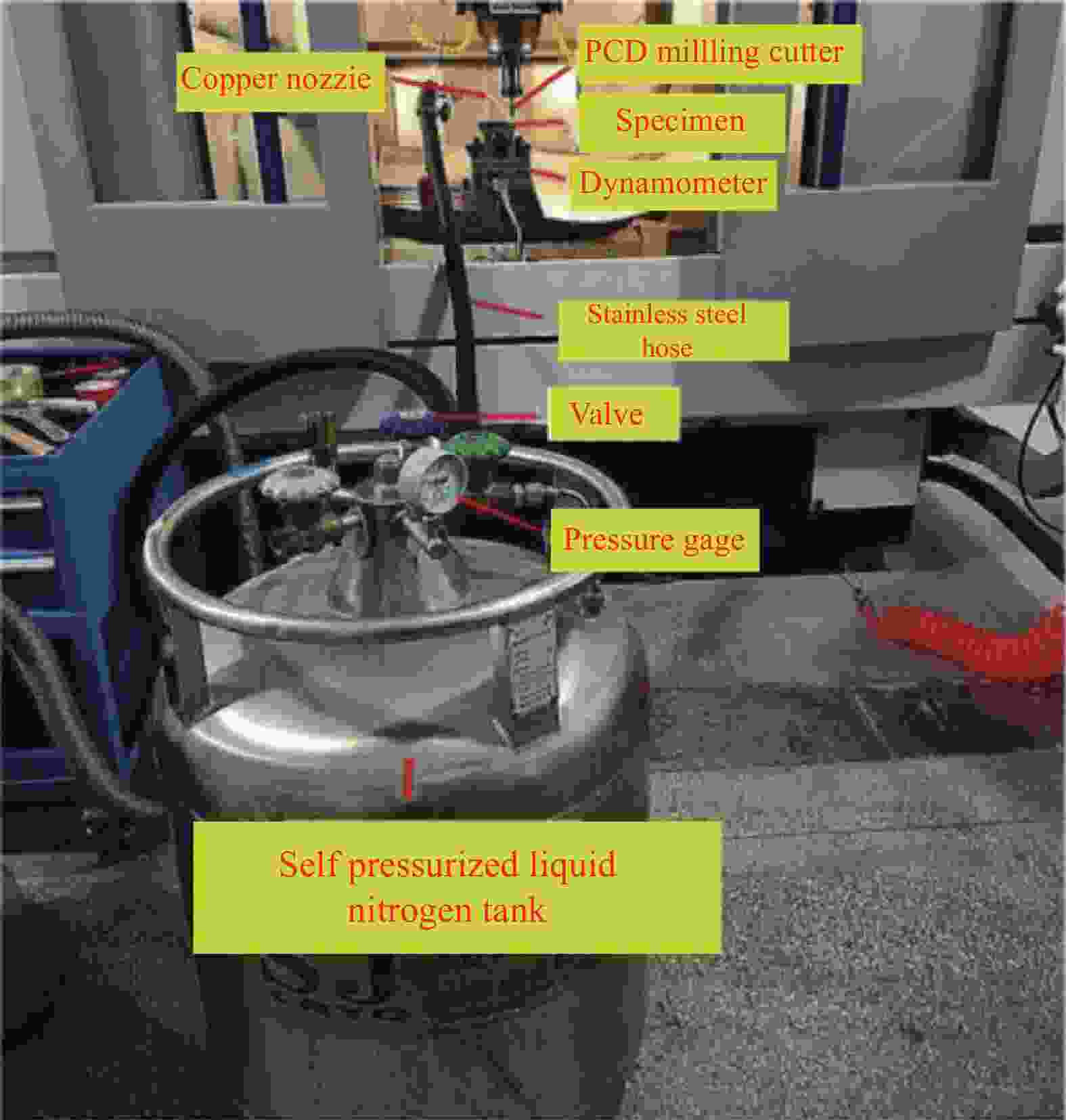

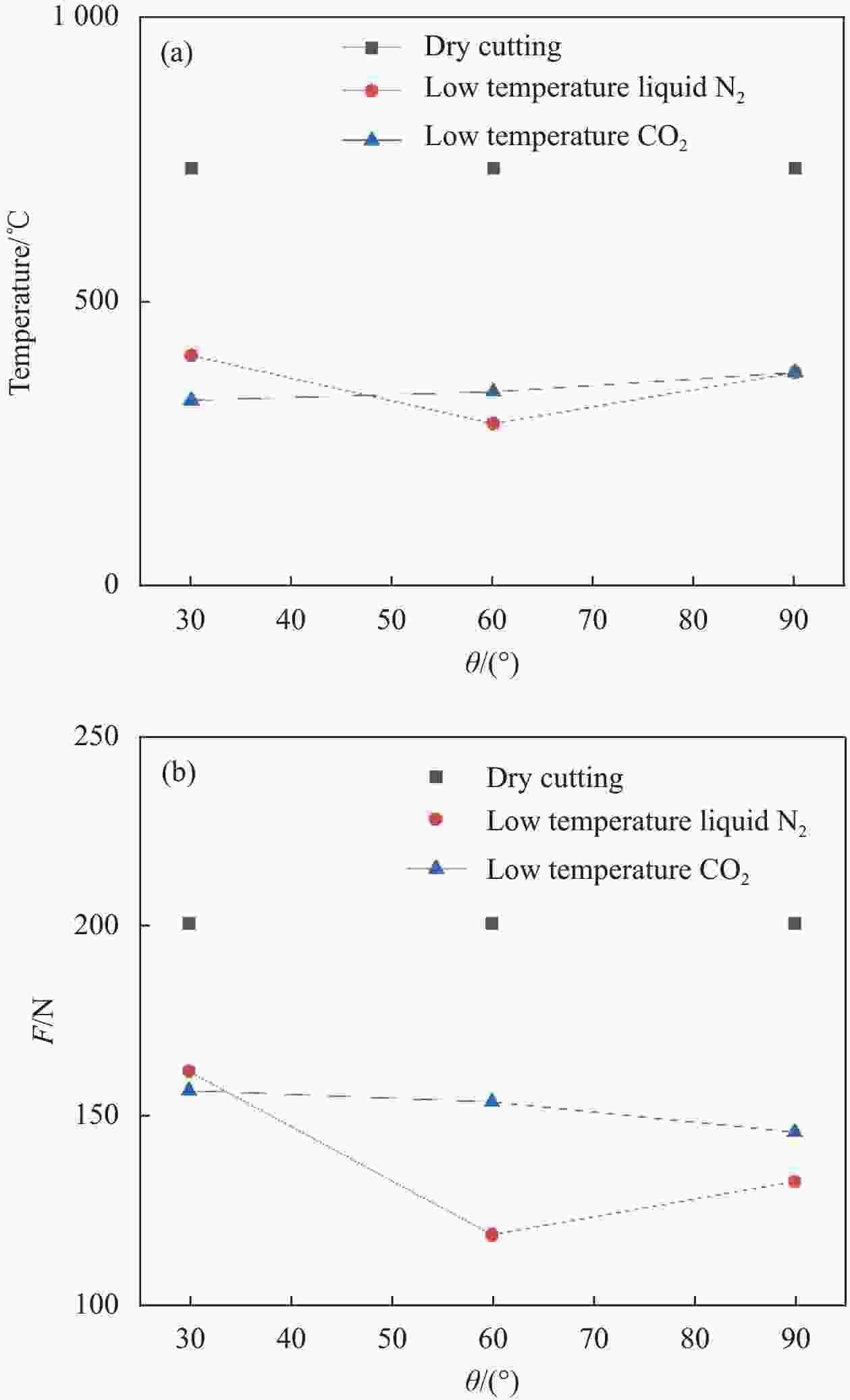

徐亮, 王凯, 王新永, 等. Cf/SiC复合材料低温铣削工艺优化研究[J]. 机械制造, 2021(1): 36-40.XU Liang, WANG Kai, WANG Xinyong, et al. Experimental study on cryogenic cooling milling performance of Cf/SiC composites[J]. Machinery, 2021(1): 36-40(in Chinese).

|

| [42] |

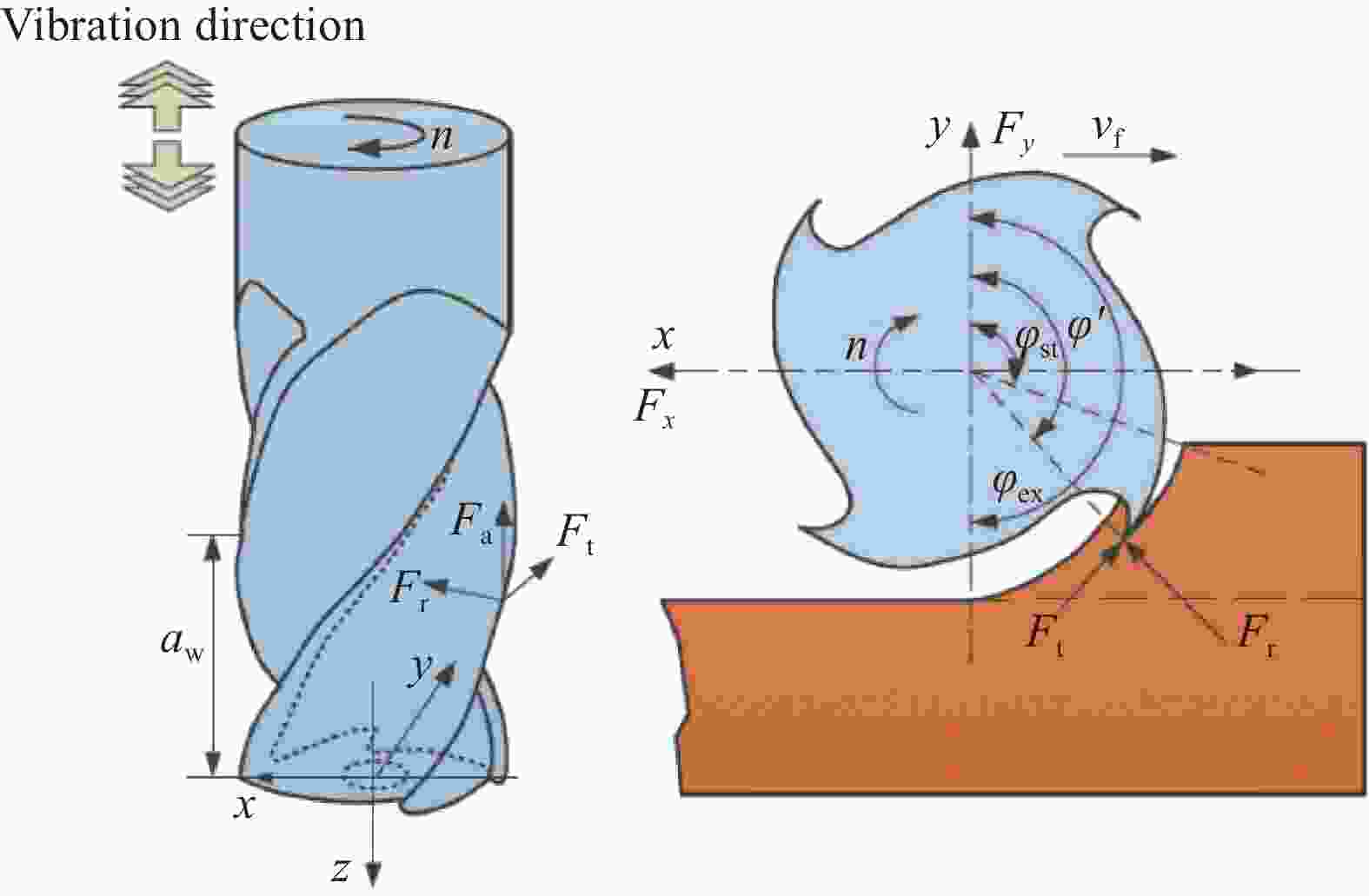

LIU Y, LIU Z B, WANG X B, et al. Experimental study on cutting force and surface quality in ultrasonic vibration-assisted milling of C/SiC composites[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112: 2003-2014. doi: 10.1007/s00170-020-06355-x

|

| [43] |

BERTSCHE E, EHMANN K, MALUKHIN K. Ultrasonic slot machining of a silicon carbide matrix composite[J]. The International Journal of Advanced Manufacturing Technology, 2013, 66(5-8): 1119-1134. doi: 10.1007/s00170-012-4394-7

|

| [44] |

DING K, FU Y C, SU H H, et al. Experimental studies on drilling tool load and machining quality of C/SiC composites in rotary ultrasonic machining[J]. Journal of Materials Processing Technology, 2014, 214(12): 2900-2907. doi: 10.1016/j.jmatprotec.2014.06.015

|

| [45] |

WANG J J, FENG P F, ZHENG J Z, et al. Improving hole exit quality in rotary ultrasonic machining of ceramic matrix composites using a compound step-taper drill[J]. Ceramics International, 2016, 42(12): 13387-13394. doi: 10.1016/j.ceramint.2016.05.095

|

| [46] |

XUE F, ZHENG K, LIAO W H, et al. Experimental investigation on fatigue property at room temperature of C/SiC composites machined by rotary ultrasonic milling[J]. Journal of the European Ceramic Society, 2021, 41(6): 3341-3356. doi: 10.1016/j.jeurceramsoc.2021.01.046

|

| [47] |

XUE F, ZHENG K, LIAO W H, et al. Investigation on fiber fracture mechanism of C/SiC composites by rotary ultrasonic milling[J]. International Journal of Mechanical Sciences, 2021, 191: 106054. doi: 10.1016/j.ijmecsci.2020.106054

|

| [48] |

WANG J J, ZHANG J F, FENG P F. Effects of tool vibration on fiber fracture in rotary ultrasonic machining of C/SiC ceramic matrix composites[J]. Composites Part B: Engineering, 2017, 129: 233-242. doi: 10.1016/j.compositesb.2017.07.081

|

| [49] |

ISLAM S, YUAN S, LI Z. A cutting force prediction model, experimental studies, and optimization of cutting parameters for rotary ultrasonic face milling of C/SiC composites[J]. Applied Composite Materials, 2020, 27: 407-431. doi: 10.1007/s10443-020-09815-5

|

| [50] |

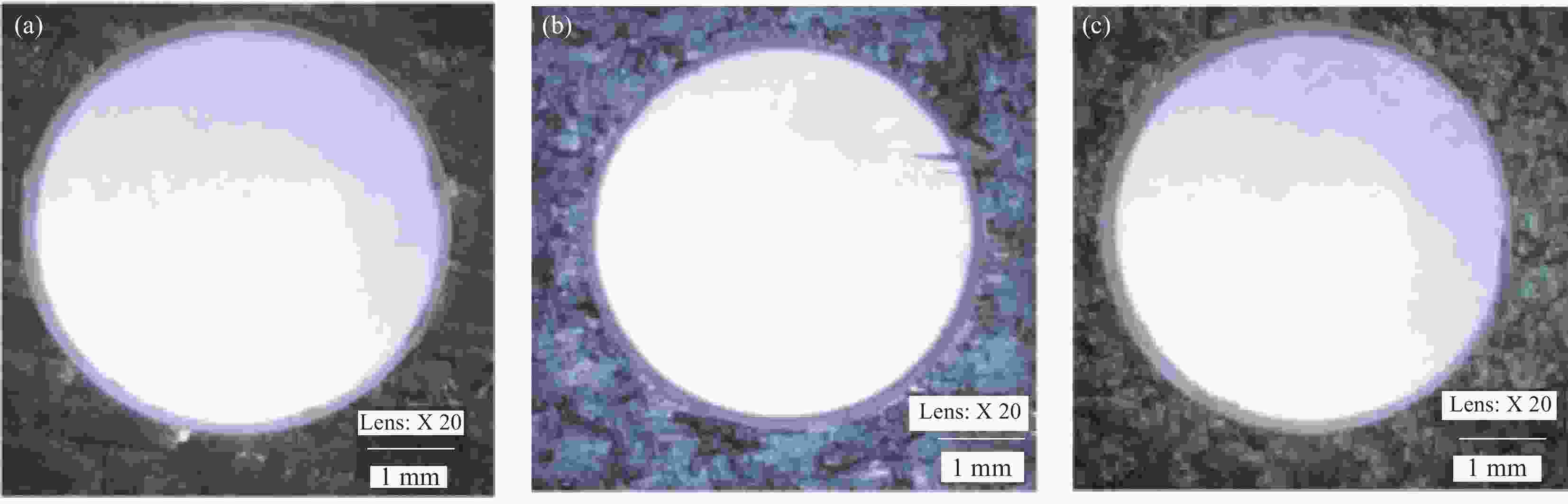

杨金华, 黄望全, 冯晓性, 等. 激光类型对SiC/SiC复合材料孔加工的影响[J]. 航空材料学报, 2023, 43(1): 80-86.YANG Jinhua, HUANG Wangquan, FENG Xiaoxing, et al. Effect of laser type on hole machining of SiC/SiC composites[J]. Journal of Aeronautical Materials, 2023, 43(1): 80-86(in Chinese).

|

| [51] |

ZHANG R H, LI W N, LIU Y S, et al. Machining parameter optimization of C/SiC composites using high power picosecond laser[J]. Applied Surface Science, 2015, 330: 321-331. doi: 10.1016/j.apsusc.2015.01.010

|

| [52] |

LIU Y S, WANG C H, LI W N, et al. Effect of energy density and feeding speed on micro-hole drilling in C/SiC composites by picosecond laser[J]. Journal of Materials Processing Technology, 2014, 214: 3131-3140. doi: 10.1016/j.jmatprotec.2014.07.016

|

| [53] |

ZHAI Z Y, WANG W J, ZHAO J, et al. Influence of surface morphology on processing of C/SiC composites via femtosecond laser[J]. Composites Part A: Applied Science and Manufacturing, 2017, 102: 117-125. doi: 10.1016/j.compositesa.2017.07.031

|

| [54] |

WANG J, LIU Y, WANG C, et al. Character and mechanism of surface micromachining for C/SiC composites by ultrashort plus laser[J]. Advances in Applied Ceramics, 2017, 116(2): 99-107. doi: 10.1080/17436753.2016.1257101

|

| [55] |

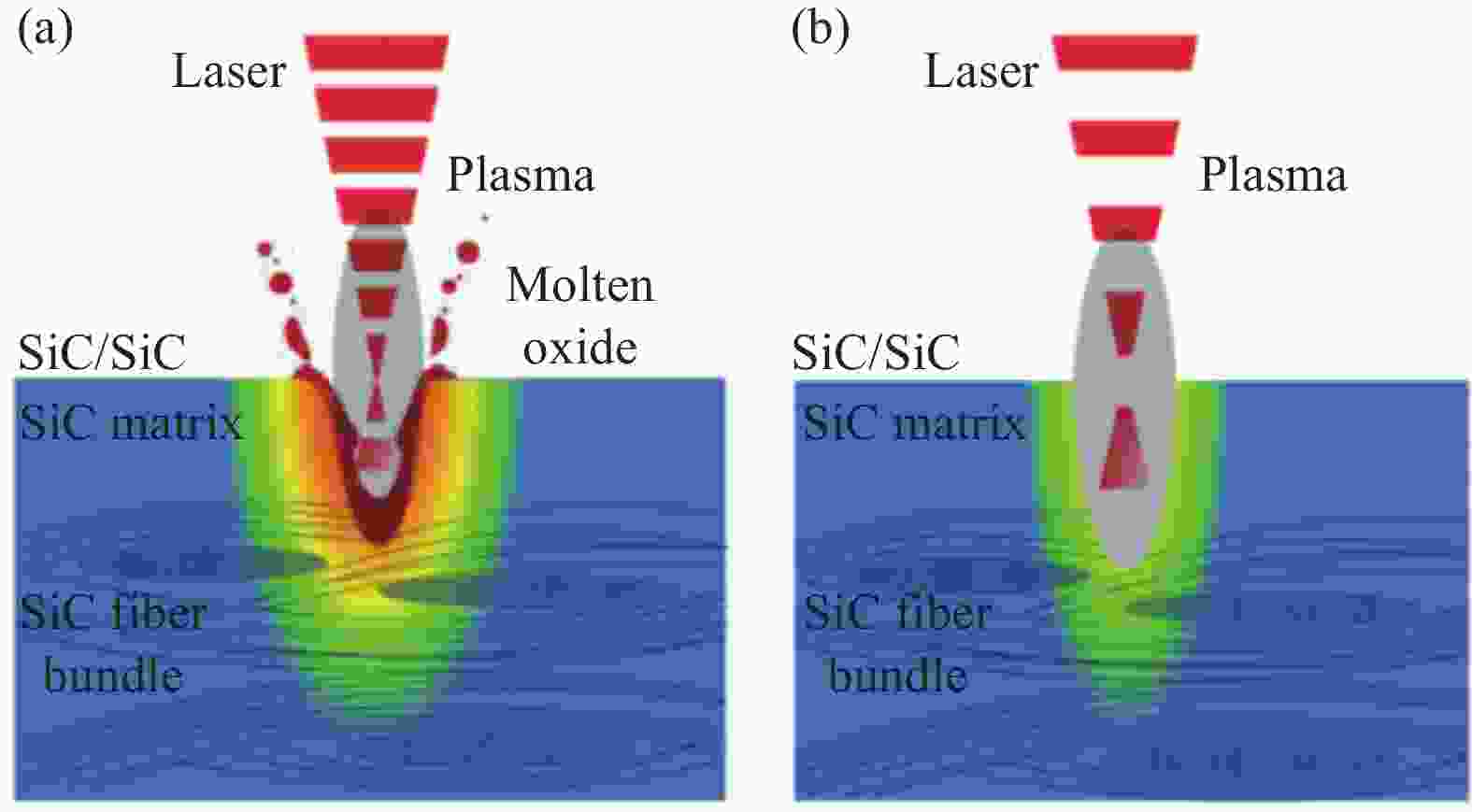

ZHAI Z Y, WEI C, ZHANG Y C, et al. Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser[J]. Applied Surface Science, 2020, 502: 144131. doi: 10.1016/j.apsusc.2019.144131

|

| [56] |

GOBET M, OBI S, PAVIUS M, et al. Implementation of short-pulse lasers for wafer scribing and grooving applications[J]. Journal of Laser Micro/Nanoengineering, 2010, 5(1): 16-20. doi: 10.2961/jlmn.2010.01.0004

|

| [57] |

徐俊杰. SiCf/SiC复合材料的水导激光加工工艺基础研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.XU Junjie. Basic research on the water-jet guided laser processing technology of SiC/SiC composites [D]. Harbin: Harbin Institute of Technology, 2019(in Chinese).

|

| [58] |

CHENG B, DING Y, LI Y, et al. Coaxial helical gas assisted laser water jet machining of SiC/SiC ceramic[J]. Journal of Materials Processing Technology, 2021, 293: 117067. doi: 10.1016/j.jmatprotec.2021.117067

|

下载:

下载: