Preparation and Anti-icing Performance of a Photothermal Self-Healing Superhydrophobic Membrane

-

摘要: 针对柔性超疏水膜基材料在户外防冰应用中面临动态抗润湿能力、机械耐久性和因紫外线氧化引起的化学耐久性不足等问题。本文通过对石墨烯、TiO2和SiO2等纳米颗粒氟化修饰,并将修饰后的颗粒分布在热塑性聚氨酯(TPU)基质内,通过优化激光加工参数,制备了一种可大变形的光热自愈合超疏水膜(Photothermal self-healing superhydrophobic, PTHSHM)。本文研究了PTHSHM的动态抗润湿性、机械耐久性、防/除冰性能以及在物理/化学损伤下的愈合性能。PTHSHM在400%应变下,经1000次循环拉伸后表面水接触角不低于156.4°。同时,断裂后的PTHSHM在0.4 W/cm2红外光照射下8分钟后愈合效率达到97.6%。此外,在化学损伤-愈合方面,经过10次氧等离子刻蚀-修复循环后,其表面水接触角仍在(5±2)°和155°之间可逆转换。此外,在−15℃的环境下,PTHSHM表面延迟结冰时间为350 s,冰粘附强度低至55 kPa,20 μL冰滴在0.1 W/cm2的太阳光下的融化并滚落时间为77 s。综上,PTHSHM表现出良好的机械和化学耐久性,在延迟结冰时间和降低冻结粘附方面优势显著。Abstract: To address challenges related to dynamic anti-wetting, mechanical durability, and chemical resistance due to UV oxidation faced by flexible superhydrophobic membrane materials in outdoor anti-icing applications, this paper presents a study on the fabrication and performance of a photothermal self-healing superhydrophobic membrane (PTHSHM). The membrane was prepared by fluorinated-graphene/TiO2/ SiO2 nanoparticles and dispersing them in a thermoplastic polyurethane (TPU) matrix, followed by optimizing laser processing parameters to achieve the hydrophobic modification. The PTHSHM exhibited impressive performance in terms of dynamic anti-wetting, maintaining a water contact angle of 156.4° even after 1000 cycles of stretching with a 400% strain. Moreover, it demonstrated efficient self-healing abilities, achieving a healing efficiency of 97.6% in 8 minutes under 0.4 W/cm−2 infrared illumination. Moreover, the membrane showed strong resistance to chemical damage, retaining a water contact angle of at least 155° after 10 cycles of oxygen plasma etching and repair. In anti-icing tests, the delayed freezing time and ice adhesion strength of PTHSHM is measured as 350 s and 55 kPa. A 20 μL ice droplet melted and rolled off in 77 s under 0.1 W/cm2 sunlight. Overall, the PTHSHM displays excellent mechanical and chemical durability, along with significant advantages in delaying ice formation and facilitating ice removal, making it a promising candidate for various outdoor anti-icing applications.

-

Key words:

- superhydrophobic /

- fluorinated graphene /

- high strain /

- self-healing /

- photo-thermal de-icing /

- Self-cleaning

-

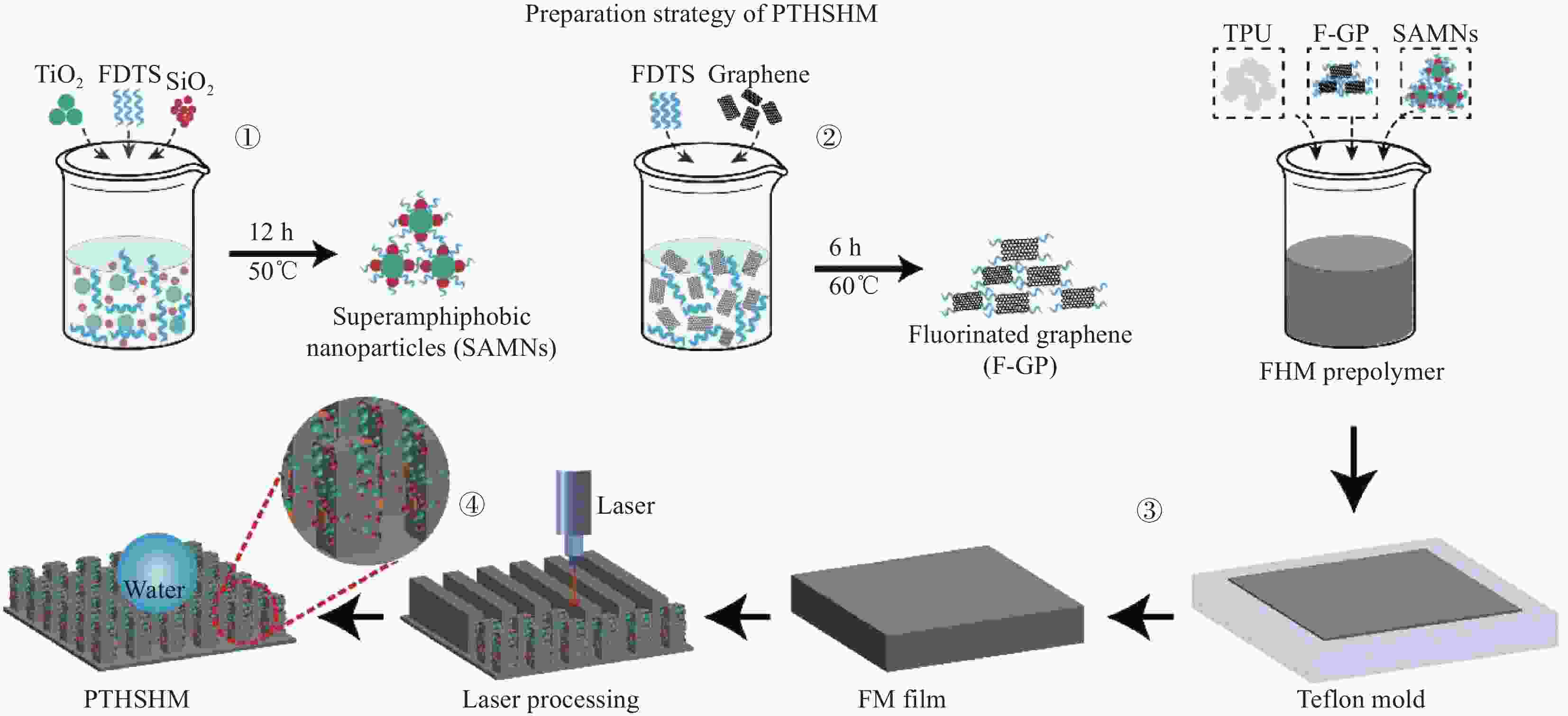

图 1 光热自愈合超疏水膜(PTHSHM)制备流程示意图。其中,① 、②分别为TiO2/SiO2纳米粒子和石墨烯改性过程,③为复合薄膜(FM)预聚物制膜过程,④为激光加工过程

Figure 1. Schematic diagram of the photothermal self-healing superhydrophobic (PTHSHM) fabrication process. Here, ① and ② represent the TiO2/SiO2 nanoparticle and graphene modification processes, respectively, ③ is the pre-polymer film (FM) formation process, and ④ is the laser irradiation process

图 2 (a)PTHSHM的SEM图,插图为对应的接触角图像;(b)在倾斜1°的PTHSHM表面上表征WSA(c)纯热塑性聚氨酯(TPU)、FM、PTHSHM的FTIR光谱;(d) FM和PTHSHM表面化学元素的EDS能谱分析

Figure 2. (a) SEM images of PTHSHM, with insets showing the corresponding contact angle images; (b) Characterization of WSA on the PTHSHM surface at a 1° tilt angle; (c) FTIR spectra of pure thermoplastic polyurethane (TPU), FM, and PTHSHM; (d) EDS elemental analysis of the chemical composition on the surfaces of FM and PTHSHM

图 9 (a)PTHSHM光热性能,(b)、(c)PTHSHM的断裂损伤和愈合过程及相应的SEM图,(b)中插图为局部放大图,(c1)(c2)插图为对应的接触角图像,(c3)为(c2)修复位置的高分辨图;(d)自修复机制图

Figure 9. (a) Photothermal Performance of PTHSHM, (b), (c) Fracture damage and healing process of PTHSHM and corresponding SEM images, with the inset in (b) being a zoomed-in view, the insets in (c1) and (c2) showing the corresponding contact angle images, and (c3) being a magnified view of the repaired area in (c2); (d) Self-healing mechanism image

图 14 (a)铝、玻璃、I-PSHM、D-PSHM、H-PSHM表面的延迟结冰过程;(b)铝、玻璃、I-PSHM、D-PSHM、H-PSHM表面在-16.5℃下的冰粘附强度;(c)PTHSHM和铝的光热除冰性能比较

Figure 14. (a) Delayed icing process on the surface of aluminum, glass, I-PSHM, D-PSHM, and H-PSHM; (b) ice adhesion strength on the surfaces of aluminum, glass, I-PSHM, D-PSHM, and H-PSHM at -16.5°C; (c) comparison of the photothermal de-icing performance between PTHSHM and aluminum

-

[1] MUHAMMED M, VIRK M S. Ice Accretion on Rotary-Wing Unmanned Aerial Vehicles-A Review Study[J]. Aerospace, 2023, 10(3): 1-26. [2] CAO Y H, TAN W Y, WU Z L. Aircraft icing: An ongoing threat to aviation safety[J]. Aerospace Science and Technology, 2018, 75: 353-385. doi: 10.1016/j.ast.2017.12.028 [3] 超 邱, 杨京龙, 祎 寇. 飞机防冰除冰技术的研究进展[J]. 西安航空学院学报, 2023, 41(3): 1-8.CHAO Qiu, YANG Jinglong, KOU Yi. Research progress of anti-icing and de-icing technology for aircraft[J]. Journal of Xi'an Aeronautical Institute, 2023, 41(3): 1-8(in Chinese). [4] 贾佳, 龚欢, 叶兆艺, 等. 冰冻灾害条件下集电线路塔架稳定性数值模拟研究[J]. 科技通报, 2023, 39(12): 90-94.JIA Jia, GONG Huan, YE Zhaoyi, et al. Numerical simulation study on stability of sransmission sine tower under freezing disaster condition[J]. Bulletin of Science and Technology, 2023, 39(12): 90-94(in Chinese). [5] HUANG Q Z, LIU J W, ZHOU Y, et al. A Study on De-icing Technology for Electric Transmission Line[J]. Advanced Materials Research, 2012, 479: 2339-2342. [6] HOU M T, JIANG Z Y, SUN W, et al. Efficient Photothermal Anti-/Deicing Enabled by 3D Cu2-xS Encapsulated Phase Change Materials Mixed Superhydrophobic Coatings[J]. Advanced Materials, 2024, 36(3): 1-12. [7] ZHOU M L, ZHANG L, ZHONG L S, et al. Robust Photothermal Icephobic Surface with Mechanical Durability of Multi-Bioinspired Structures[J]. Advanced Materials, 2024, 36(3): 1-10. [8] WANG D H, SUN Q Q, HOKKANEN M J, et al. Design of robust superhydrophobic surfaces[J]. Nature, 2020, 582(7810): 55-59. doi: 10.1038/s41586-020-2331-8 [9] WANG L, LUO J C, CHEN Y, et al. Fluorine-free Superhydrophobic and Conductive Rubber Composite with Outstanding Deicing Performance for Highly Sensitive and Stretchable Strain Sensors[J]. Acs Applied Materials & Interfaces, 2019, 11(19): 17774-17783. [10] JIA L C, SUN W J, XU L, et al. Facile Construction of a Superhydrophobic Surface on a Textile with Excellent Electrical Conductivity and Stretchability[J]. Industrial & Engineering Chemistry Research, 2020, 59(16): 7546-7553. [11] WANG J W, ZHANG Y B, HE Q. Stretchable superhydrophobic fluororubber fabricated by transferring mesh microstructures[J]. Soft Matter, 2023, 19(8): 1560-1568. doi: 10.1039/D2SM01677J [12] OH M S, RYU J, JEON M, et al. A Fully Transparent, Stretchable Multi-Layered Water Barrier Thin Film for the Passivation of Underwater Device Applications[J]. Advanced Materials Interfaces, 2022, 9(27): 1-9. [13] LIN L, CHOI Y, CHEN T, et al. Superhydrophobic and wearable TPU based nanofiber strain sensor with outstanding sensitivity for high-quality body motion monitoring[J]. Chemical Engineering Journal, 2021, 419: 1-10. [14] LIU M, TAN X Y, LI X Y, et al. Transparent superhydrophobic EVA/SiO2/PTFE/KH-570 coating with good mechanical robustness, chemical stability, self-cleaning effect and anti-icing property fabricated by facile dipping method[J]. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 2023, 658: 1-12. [15] LI B F, XUE S Y, MU P, et al. Robust Self-Healing Graphene Oxide-Based Superhydrophobic Coatings for Efficient Corrosion Protection of Magnesium Alloys[J]. Acs Applied Materials & Interfaces, 2022, 14(26): 30192-30204. [16] WANG J L, KAPLAN J A, COLSON Y L, et al. Stretch-Induced Drug Delivery from Superhydrophobic Polymer Composites: Use of Crack Propagation Failure Modes for Controlling Release Rates[J]. Angewandte Chemie-International Edition, 2016, 55(8): 2796-2800. doi: 10.1002/anie.201511052 [17] PENG Y J, HU J P, FAN Z, et al. A stretchable superhydrophobic coating with electrothermal ability for anti-icing application[J]. Materials Research Express, 2021, 8(4): 1-9. [18] 张应轩, 鲁浈浈, 葛倩倩, 等. 光催化型超疏水自清洁涂层研究现状[J]. 表面技术, 2023, 52(12): 298-314.ZHANG Yingxuan, LU Zhenzhen, GE Qianqian, et al. Overview of photocatalytic superhydrophobic self-cleaning coatings[J]. Surface Technology, 2023, 52(12): 298-314(in Chinese). [19] JIAO X, LI M T, YU X Q, et al. Mechanically robust superamphiphobic ceramic coatings with releasable nanoparticle-capsules[J]. Chemical Engineering Journal, 2022, 446: 1-9. [20] FU Y H, XU F C, WENG D H, et al. Superhydrophobic Foams with Chemical- and Mechanical-Damage-Healing Abilities Enabled by Self-Healing Polymers[J]. Acs Applied Materials & Interfaces, 2019, 11(40): 37285-37294. [21] LIN L W, WANG L, LI B, et al. Dual conductive network enabled superhydrophobic and high performance strain sensors with outstanding electro-thermal performance and extremely high gauge factors[J]. Chemical Engineering Journal, 2020, 385: 1-11. [22] DING Y R, XUE C H, GUO X J, et al. Fabrication of TPE/CNTs film at air/water interface for flexible and superhydrophobic wearable sensors[J]. Chemical Engineering Journal, 2021, 409: 1-9. [23] DAI Z Y, CHEN G, DING S, et al. Facile Formation of Hierarchical Textures for Flexible, Translucent, and Durable Superhydrophobic Film[J]. Advanced Functional Materials, 2021, 31(7): 1-12. [24] LI B, LUO J C, HUANG X W, et al. A highly stretchable, super-hydrophobic strain sensor based on polydopamine and graphene reinforced nanofiber composite for human motion monitoring[J]. Composites Part B-Engineering, 2020, 181: 1-10. [25] RATHER A M, MANNA U. Stretchable and durable superhydrophobicity that acts both in air and under oil[J]. Journal of Materials Chemistry A, 2017, 5(29): 15208-15216. doi: 10.1039/C7TA04073C [26] JU J, YAO X, HOU X, et al. A highly stretchable and robust non-fluorinated superhydrophobic surface[J]. Journal of Materials Chemistry A, 2017, 5(31): 16273-16280. doi: 10.1039/C6TA11133E [27] CHO S J, NAM H, RYU H, et al. A Rubberlike Stretchable Fibrous Membrane with Anti-Wettability and Gas Breathability[J]. Advanced Functional Materials, 2013, 23(45): 5577-5584. doi: 10.1002/adfm.201300442 [28] YUAN R X, LIU H, CHEN Y G, et al. Design ambient-curable superhydrophobic/electroactive coating toward durable pitting corrosion resistance[J]. Chemical Engineering Journal, 2019, 374: 840-851. doi: 10.1016/j.cej.2019.05.209 [29] HUANG L, YI N, WU Y, et al. Multichannel and Repeatable Self-Healing of Mechanical Enhanced Graphene-Thermoplastic Polyurethane Composites[J]. Advanced Materials, 2013, 25(15): 2224-2228. doi: 10.1002/adma.201204768 [30] GHOSH B, CHELLAPPAN K V, URBAN M W. Self-healing inside a scratch of oxetane-substituted chitosan-polyurethane (OXE-CHI-PUR) networks[J]. Journal of Materials Chemistry, 2011, 21(38): 14473-14486. doi: 10.1039/c1jm12321a [31] YANG Y, URBAN M W. Self-healing polymeric materials[J]. Chemical Society Reviews, 2013, 42(17): 7446-7467. doi: 10.1039/c3cs60109a [32] WANG S Y, URBAN M W. Self-healing polymers[J]. Nature Reviews Materials, 2020, 5(8): 562-583. doi: 10.1038/s41578-020-0202-4 [33] YANG Y, PEI Z Q, ZHANG X Q, et al. Carbon nanotube-vitrimer composite for facile and efficient photo-welding of epoxy[J]. Chemical Science, 2014, 5(9): 3486-3492. doi: 10.1039/C4SC00543K [34] LI C Y, WANG P, ZHANG D, et al. Near-Infrared Responsive Smart Superhydrophobic Coating with Self-Healing and Robustness Enhanced by Disulfide-Bonded Polyurethane[J]. Acs Applied Materials & Interfaces, 2022, 14(40): 45988-46000. [35] MAO T Y, FENG H, WU J R, et al. Waterborne organic silicone polyurethane with excellent self-healing performance for oil/water-separation and oil-recovery applications[J]. Sustainable Materials and Technologies, 2023, 36: 1-11. [36] ZHANG D J, CHEN J J, LIU X F, et al. A general tape-coating strategy to construct multifunctional superhydrophobic surfaces with self-adhesion, self-healing, and conductivity on various substrates[J]. Chemical Engineering Journal, 2022, 441: 1-9. [37] XU H, TU J, LI H Z, et al. Room-temperature self-healing, high ductility, recyclable polyurethane elastomer fabricated via asymmetric dynamic hard segments strategy combined with self-cleaning function application[J]. Chemical Engineering Journal, 2023, 454: 1-11. [38] QIN L M, CHEN N, ZHOU X, et al. A superhydrophobic aerogel with robust self-healability[J]. Journal of Materials Chemistry A, 2018, 6: 4424-4431. doi: 10.1039/C8TA00323H [39] WU L S, LIU P, HUA X C, et al. Photothermal superhydrophobic membrane based on breath figure: Anti-icing and deicing[J]. Chemical Engineering Journal, 2024, 480: 1-8. -

点击查看大图

点击查看大图

计量

- 文章访问数: 54

- HTML全文浏览量: 61

- 被引次数: 0

下载:

下载: