Influence of uneven thickness of bonding layer on the bonding performance of CFRP-steel interface

-

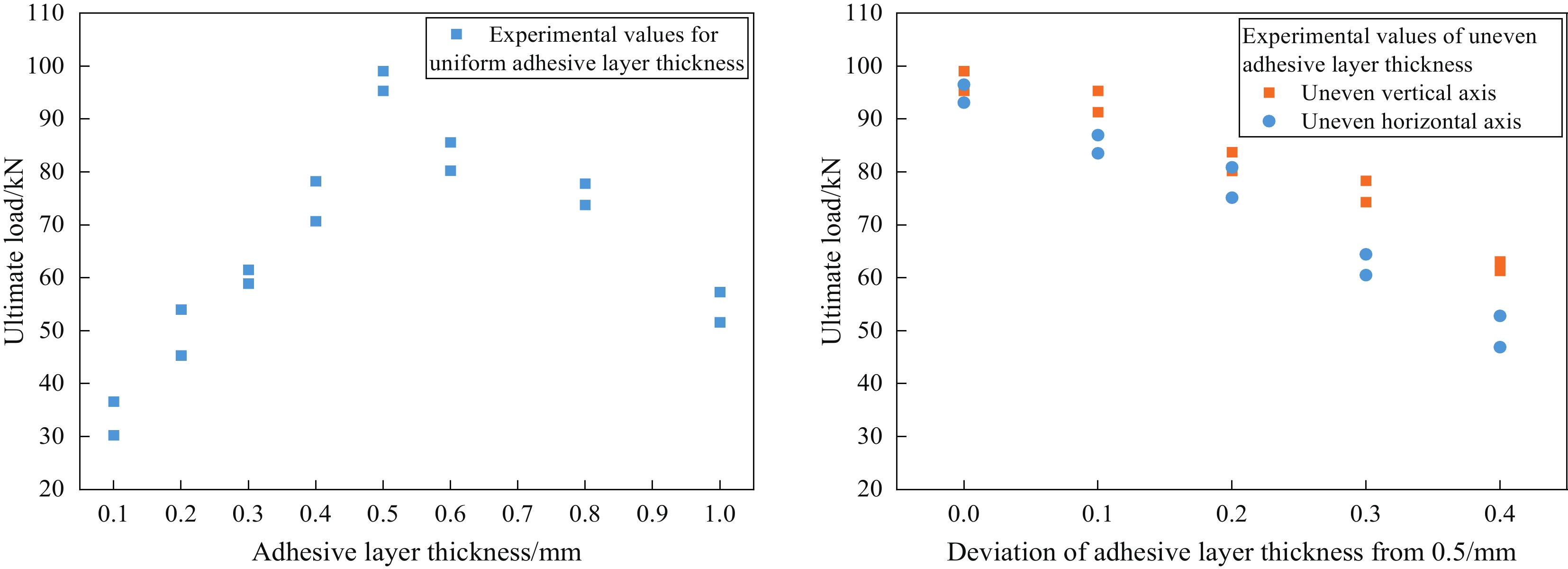

摘要: CFRP-钢界面的粘结性能决定CFRP材料的加固效果,其中粘结层厚度不均匀是影响粘结性能的重要因素。为揭示粘结层厚度不均匀情况下CFRP加固钢板的力学破坏机制,先开展16个粘结层厚度均匀的双剪试验,由试验结果得出粘结层厚度为0.5mm时的承载力最优。再围绕0.5mm开展粘结层厚度沿纵向和横向不均匀的18个双剪试验,研究粘结层厚度不均匀情况下的力学性能和破坏机理。结果表明粘结层厚度不均匀对承载力影响较大,随着粘结层厚度不均匀程度的增加,承载力呈递减趋势,纵向不均匀的承载力降低6.45%~36.55%,横向不均匀的承载力降低9.57%~47.38%。不均匀程度相同时,横向不均匀的承载力平均比纵向不均匀的承载力低9.8kN, 横向不均匀的承载力降低幅度平均比纵向不均匀大6.65%,横向不均匀的不利影响大于纵向不均匀。粘结层厚度纵向、横向不均匀的应变及剪应力变化规律与厚度均匀的试件相比存在较大差异。结合试验得到的粘结滑移关系建立粘聚力数值模型,通过分析数值模拟结果和试验结果,表明粘聚力模型可以很好的模拟粘结层厚度不均匀对粘结界面的非线性力学行为。Abstract: The bond performance at the CFRP-steel interface determines the reinforcement effectiveness of CFRP materials, with the uneven thickness of the adhesive layer being a critical factor affecting the bonding performance. To reveal the mechanical failure mechanism of CFRP-reinforced steel plates under conditions of uneven adhesive layer thickness, 16 double-shear tests with uniform adhesive layer thicknesses were conducted first. The test results showed that a thickness of 0.5 mm yielded the optimal bearing capacity. Then, 18 additional double-shear tests were performed with the adhesive layer thickness varied both longitudinally and transversely around 0.5 mm to study the mechanical performance and failure mechanisms under uneven adhesive layer thicknesses. The results indicated that the uneven thickness of the adhesive layer significantly impacts the bearing capacity. As the degree of unevenness increased, the bearing capacity showed a decreasing trend. Longitudinal unevenness reduced the bearing capacity by 6.45% to 36.55%, while transverse unevenness reduced it by 9.57% to 47.38%. When the degree of unevenness was the same, the bearing capacity for transverse unevenness was, on average, 9.8 kN lower than that of longitudinal unevenness. The reduction in bearing capacity for transverse unevenness was, on average, 6.65% greater than for longitudinal unevenness, indicating that transverse unevenness has a more detrimental effect than longitudinal unevenness. The strain and shear stress variation patterns of specimens with longitudinal and transverse unevenness also showed significant differences compared to those with uniform thickness. A cohesive numerical model was established based on the bond-slip relationship obtained from the experiments. By analyzing the results of the numerical simulation and the experimental data, it was shown that the cohesive model can effectively simulate the nonlinear mechanical behavior of the bond interface under uneven adhesive layer thickness conditions.

-

Keywords:

- thickness /

- uniformity deviation /

- shear test /

- numerical simulation /

- adhesive property

-

目前,我国钢桥建设发展迅速,同时钢桥损伤问题也日益凸显,疲劳裂纹和锈蚀损伤问题频发[1],严重影响桥梁安全运营。传统的钢桥常通过焊接、栓接、铆接等方式补强钢板,但存在诸多弊端[2-3]。

碳纤维增强复合材料(CFRP)凭借众多优异性能被广泛应用于钢结构加固领域[4-7]。其中粘结层是CFRP-钢加固体系中易损部位,该部位破坏是导致加固失效的主要原因[8]。近年来,大多学者对失效机理进行了广泛探索,验证了该技术在钢结构加固领域颇具发展前景[9-11]。

针对界面粘结性能、破坏模式和剥离特征开展研究。Pang等[12]通过单剪试验研究了CFRP分层破坏下界面的粘结滑移模型。李腾等[13]、杨怡等[14]通过单剪、双剪试验得出不同粘结层厚度下CFRP-钢的粘结界面剥离破坏特征及对应的破坏模式。He等[15]、李传习等[16]通过试验结合数值分析研究了多个粘结层厚度下CFRP-钢的界面粘结性能。

针对CFRP-钢的粘结性能有诸多影响因素,在钢材屈服、锈蚀、裂纹修复和疲劳性能方面,吴超等[17]采用粘结层厚度为0.4 mm的双剪试验研究钢板屈服对CFRP-钢界面的粘结性能影响,陈卓异等[18]研究了CFRP加固含中心裂纹钢板的静力性能,高立等[19]归纳了CFRP修复混合裂纹及抑制裂纹扩展的优异性能。李安邦等[20-21]采用双剪试验研究粘结层厚度为0.21~0.7 mm范围内CFRP-锈蚀钢板界面粘结性能及疲劳性能的影响。王海涛等[22]、陈涛等[23]研究了粘结层厚度0.5 mm和0.6 mm下含典型裂纹、混合型裂纹钢板的疲劳性能。在环境因素和粘结剂种类对粘结性能等方面,Heshmati等[24-25]、Grammatikos等 [26]研究了粘结层厚度为1.5 mm和6 mm下水分子和热循环对CFRP-钢粘结性能的影响。余倩倩等[27]、李传习等[28]研究了粘结层厚度为0.5 mm和1 mm下海洋大气环境、极端湿热环境对CFRP-钢界面粘结性能的影响。朱德举等[29]研究粘结层厚度为1 mm下动态拉伸荷载和温度共同作用下的破坏机理。李游等[30-31]、陈卓异等[32]研究了粘结层厚度为1 mm下高温和粘结剂种类对CFRP-钢界面粘结性能的影响。

总之,针对CFRP-钢界面粘结性能的试验及理论研究较为全面,但已有研究均只考虑粘结层厚度均匀且粘结良好的情况。在实际加固中受多种因素影响,无法保障粘结层厚度均匀,从而导致粘结传力机制与理想状态相比有较大偏差。因此粘结层厚度不均匀对CFRP-钢粘结传力机制的影响具有重要研究价值。

本文以粘结层厚度不均匀对CFRP-钢界面粘结性能的影响为研究重点,在试验得出最优厚度0.5 mm的基础上进行粘结层厚度沿CFRP板纵向和横向有偏差的双剪试验,得到承载力、应力、应变等变化特征,并基于试验得到的粘结滑移参数建立数值模型,以考察粘结层厚度不均匀对CFRP-钢界面粘结性能的影响。

1. 实验概况

1.1 实验材料

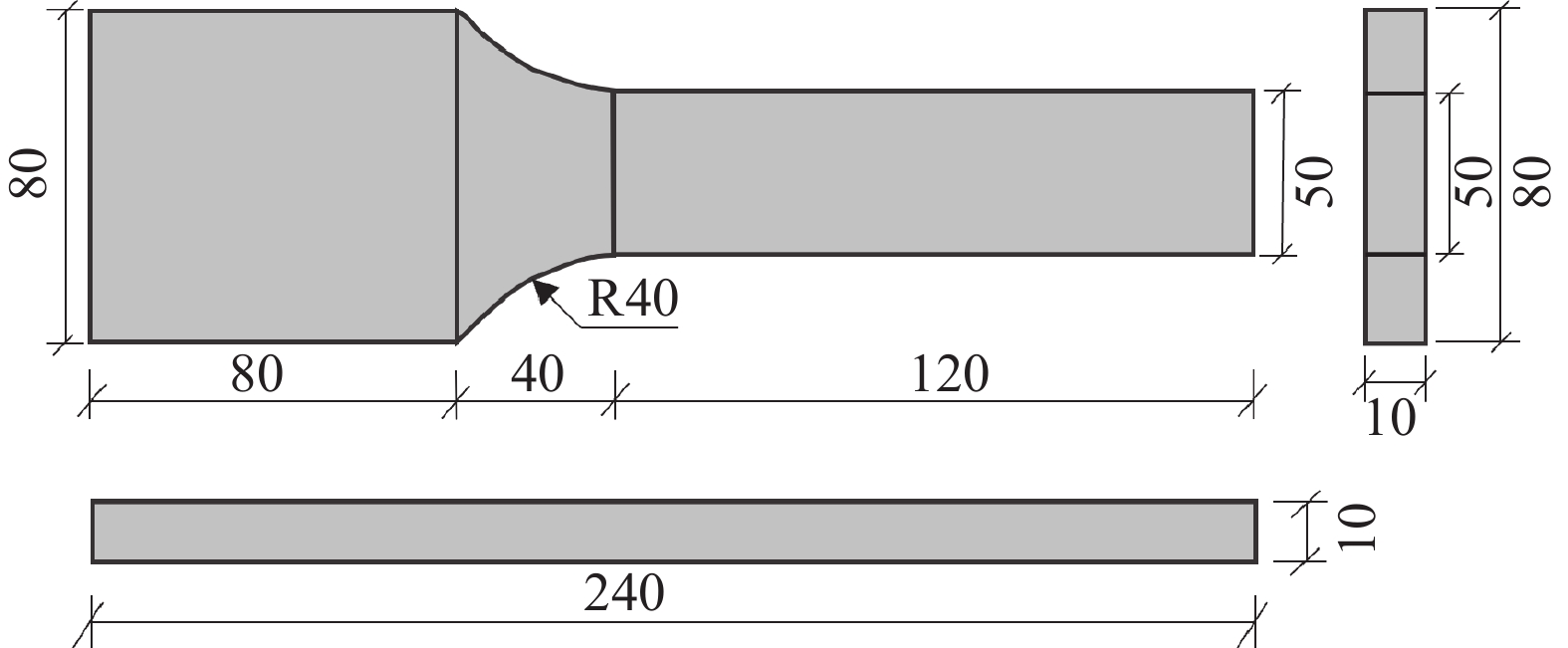

试验所用钢板型号为Q345 qC,用激光切割方式加工成型,尺寸见图1。CFRP的规格型号为CFP-Ⅰ-14,宽度50 mm,厚度为1.4 mm,为高强Ⅰ级纤维复合材条形单向板。配套的粘结剂为双组份环氧树脂碳板胶,产品型号为CFRP-A/B,技术指标为Ⅰ类胶A级,按质量A∶B=2∶1的比例混合使用,固化后形成脆性粘结层。二者由天津卡本科技集团股份有限公司生产,经建工测试部抽样检测后由厂家提供CFRP及碳板胶的力学性能参数如表1所示。

表 1 CFRP板、钢板及粘结剂材料参数Table 1. Material parameters of CFRP plate, steel plate and adhesivesMaterial parameter CFP-Ⅰ-14 CFRP-A/B Q345 qC Elasticity modulus/GPa 165 5.3 206 Tensile strength/MPa 2400 38 514 Shear strength/MPa 55 — 79000 Shear strength for

steel-to-steel joint/MPa— 41.6 — Poisson’s ratio 0.28 0.35 0.30 Elongation at break/% 1.6 1.13 21% 1.2 试件设计与制作

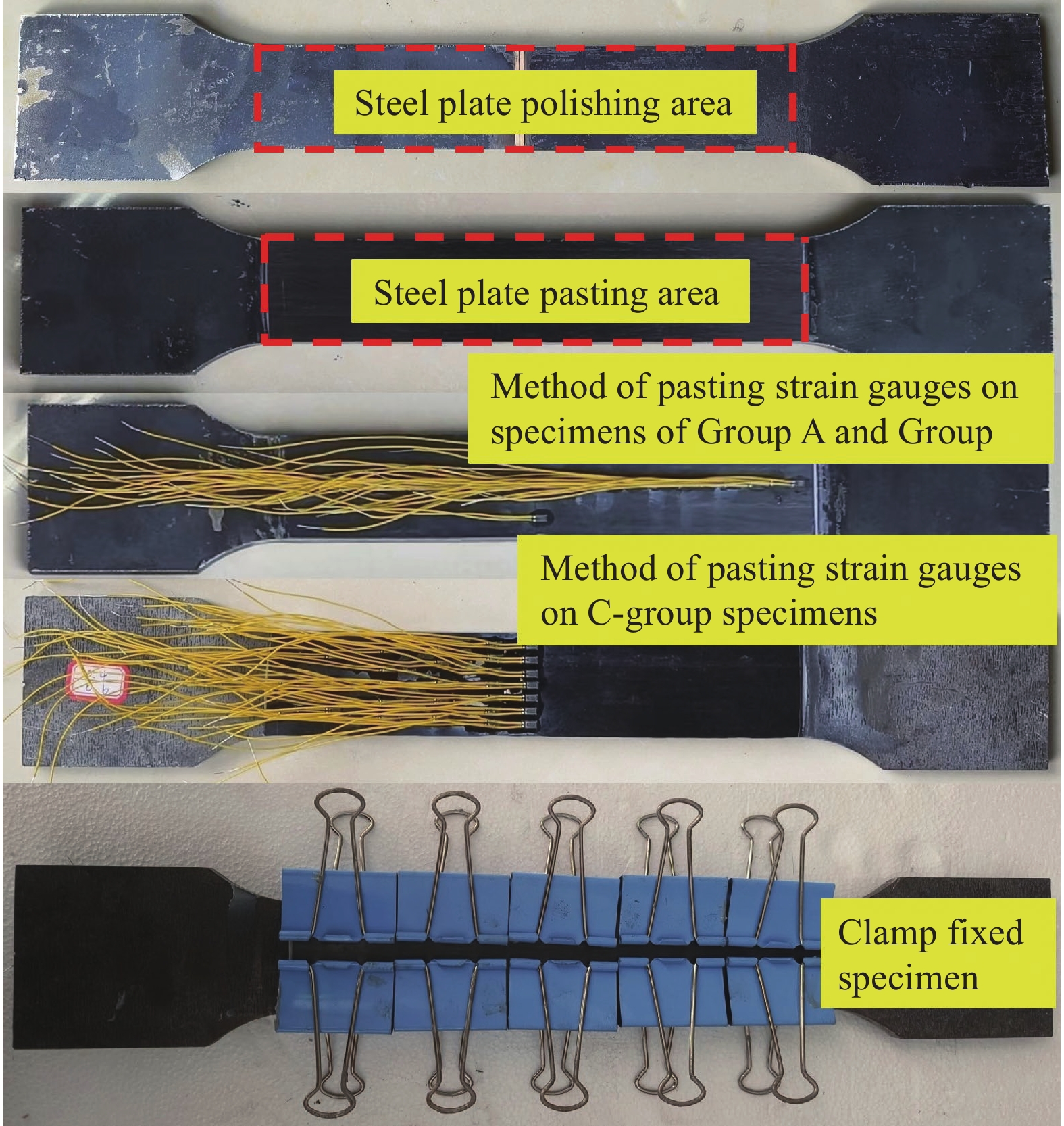

试件的设计与制作参考ASTM D3528—96(2008)[33]标准及已有的相关研究[14]。在制作试件前,用电动钢丝刷去除钢板表面的杂质,再通过机械打磨保证钢板粗糙度相同。粘贴前使用无水乙醇浸湿的脱脂棉布反复擦拭钢板和CFRP表面,去除钢板表面的油污及打磨过程中产生的杂质颗粒。经过处理后的钢板表面洁净且呈现一定的金属光泽和粗糙度,如图2所示。

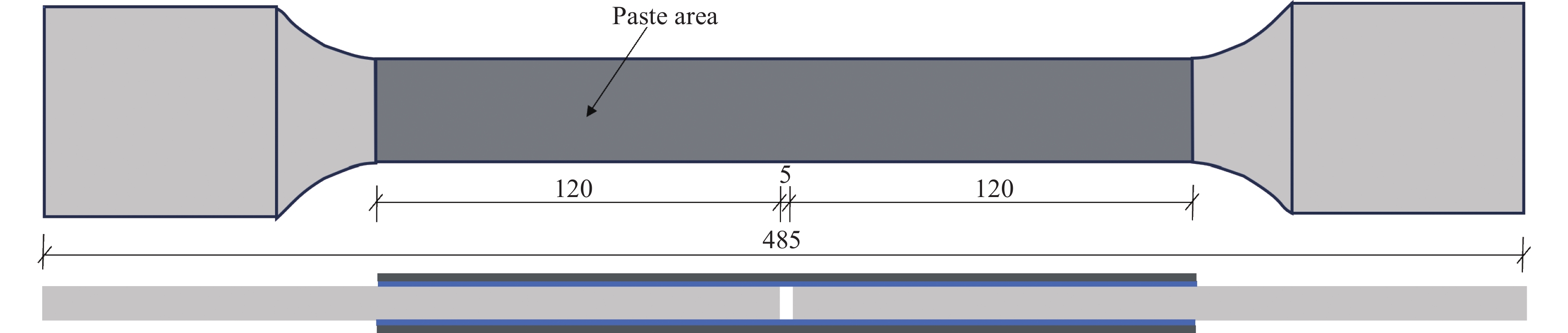

双剪试件由两块钢板拼接后双面对称粘贴CFRP板而成,中间间隙部位用软木条填充,如图3所示。将配置好的碳板胶涂在钢板表面,同时摆放不同直径的钢珠来控制粘结层厚度不均匀,钢珠数量极少,远小于粘贴面积,对粘贴效果不产生影响。将裁剪好的CFRP粘贴在钢板表面,施加适当压力使CFRP均匀受压并保证粘结层饱满,在粘结剂初固之前完全粘贴,去除溢胶后用夹子使粘结层稳定,如图2所示。

将试件置于常温常压下固化养护7天,再按照相同方法完成另一侧的粘贴。待固化完成后,用千分尺测量不同位置的粘结层厚度,测量结果与试验设计值的误差小于5%,满足试验要求。实测粘结层厚度由下式得到:

ta=ttotal−ts−2tp2 (1) 式中,ta为实测粘结层厚度,ttotal为实测试件总厚度,ts为实测钢板厚度,tp为CFRP板厚度。

本次试验制备34个试件,试验分三组进行,分别对应三种粘结层厚度形式,试件编号及参数列于表2。A组:粘结层厚度沿CFRP长边及短边方向均不发生变化(简称粘结层厚度均匀),试件共16个,设置8种粘结层厚度,每个粘结层厚度有2个试件,试件编号:JY-i-1/2,含义如下:JY-粘结层厚度均匀,i-粘结层厚度值,1/2-试件序号。B组:粘结层沿CFRP长边方向逐渐变厚(简称粘结层厚度纵向不均匀),试件共8个,设置4种粘结层厚度,每个粘结层厚度2个试件,试件编号:ZX-i-j-1/2, 含义如下:ZX-纵向粘结层厚度不均匀,i-粘结层厚度下限值,j-粘结层厚度上限值,1/2-试件序号。C组:粘结层沿CFRP短边方向逐渐变厚(简称粘结层厚度横向不均匀),试件共10个,设置5种粘结层厚度,每个粘结层厚度2个试件,试件编号:HX-i-j-1/2, 含义类似于B组。以粘结层最优厚度0.5 mm作为对照, B、C组粘结层厚度不均匀均是以A组0.5 mm厚度的粘结层展开的,用粘结层厚度与平均厚度(0.5 mm)的最大偏差值表征粘结层厚度的不均匀程度。

表 2 CFRP-钢双剪试件拉伸试验结果Table 2. Tensile test results of CFRP-steel double-shear specimensGrouping Specimen number DV Ultimate load/kN Limit displacement/mm Failure

modePmax Average ABAQUS Relative

errorDmax Average ABAQUS Relative

errorA JY-0.1-1 0 36.59 33.42 35. 26 5.5% 3.06 2.95 2.89 2.1% a JY-0.1-2 30.25 2.84 a JY-0.2-1 54.01 49.67 50.19 1.0% 4.27 4.1 4.13 0.7% a+b JY-0.2-2 45.33 3.92 a JY-0.3-1 60.50 59.7 62.34 4.4% 6.30 6.26 6.15 1.8% a+b JY-0.3-2 58.90 6.21 a JY-0.4-1 78.26 74.48 74.25 0.3% 8.16 7.9 7.76 1.80% a+b JY-0.4-2 70.70 7.64 a+b JY-0.5-1 99.05 98.7 101.24 2.6% 8.57 8.67 8.71 0.5% a+b+c JY-0.5-2 98.35 8.76 a+b+c JY-0.6-1 84.59 82.43 82.75 0.4% 7.28 7.16 7.21 0.7% a+b+c JY-0.6-2 80.27 7.03 a+b JY-0.8-1 77.80 75.78 74.15 2.2% 6.88 6.71 6.68 0.5% a+b+c JY-0.8-2 73.76 6.53 a+b+c JY-1.0-1 57.32 54.46 56.30 3.4% 6.11 5.84 5.72 2.1% a+b+c JY-1.0-2 51.60 5.56 a+b+c B ZX-0.4-0.6-1 0.1 91.3 92.33 96.50 4.5% 7.94 8.05 8.12 0.9% a+b+d ZX-0.4-0.6-2 95.35 8.16 a+b+c ZX-0.3-0.7-1 0.2 80.16 81.95 84.37 3.0% 6.50 6.54 6.46 1.2% a+b ZX-0.3-0.7-2 83.73 6.58 a+b+c ZX-0.2-0.8-1 0.3 74.64 76.5 78.8 3.0% 5.93 5.86 5.80 1.0% a+b+c ZX-0.2-0.8-2 78.36 5.79 a+b ZX-0.1-0.9-1 0.4 62.14 62.63 62.22 0.7% 5.28 5.26 5.18 1.5% a+b+c ZX-0.1-0.9-2 63.11 5.23 b+c C HX-0.5-1 0 95.6 94.25 101.24 7.4% 8.01 8.14 8.71 7.0% a+b+c HX-0.5-2 92.89 8.26 a+b+c HX-0.4-0.6-1 0.1 86.95 85.23 87.86 3.1% 6.83 6.53 6.62 1.4% a+b+c HX-0.4-0.6-2 83.5 6.22 a+b+c HX-0.3-0.7-1 0.2 75.56 77.92 78.26 0.4% 6.01 6.27 6.36 1.4% a+b+c+d HX-0.3-0.7-2 80.27 6.52 a+b+c HX-0.2-0.8-1 0.3 62.43 61.46 62.87 2.3% 4.93 4.85 4.91 1.2% a+b+c+d HX-0.2-0.8-2 60.49 4.76 a+b+c+d HX-0.1-0.9-1 0.4 46.88 49.59 50.23 1.3% 4.39 4.64 4.71 1.5% a+b+c+d HX-0.1-0.9-2 52.3 4.89 a+b+c Notes: Dmax−Limit displacement; Pmax−Ultimate load; ABAQUS−Numerical analysis results; DV−Maximum deviation between the thickness of the bond layer and the average thickness; Failure mode: a−CFRP and adhesive debonding failure; b−Steel and adhesive debonding failures; c−Adhesive shatter; d−CFRP tearing; JY-0.1-1−Thickness of the adhesive layer is uniform, and the thickness of the adhesive layer is 0.1 mm; ZX-0.4-0.6-1−Thickness of the adhesive layer is not uniform in the longitudinal direction, and the thickness of the adhesive layer increases from 0.4 mm to 0.6 mm for the first specimen; HX-0.4-0.6-1−Thickness of the adhesive layer is not uniform transversely, and the thickness of the adhesive layer increases from 0.4 mm to 0.6 mm for the first specimen. 1.3 实验加载及量测方法

利用电子万能试验机(最大荷载100 KN,精度为±0.5%kN)加载,严格控制夹持力保证试验加载过程中夹持端不出现脱离、滑移等情况。为准确捕捉破坏特征,以0.2 mm/min 的速率控制位移加载,采样频率1 Hz,在纯轴向拉伸作用下加载,直到试件完全破坏。试验器材如图4所示。

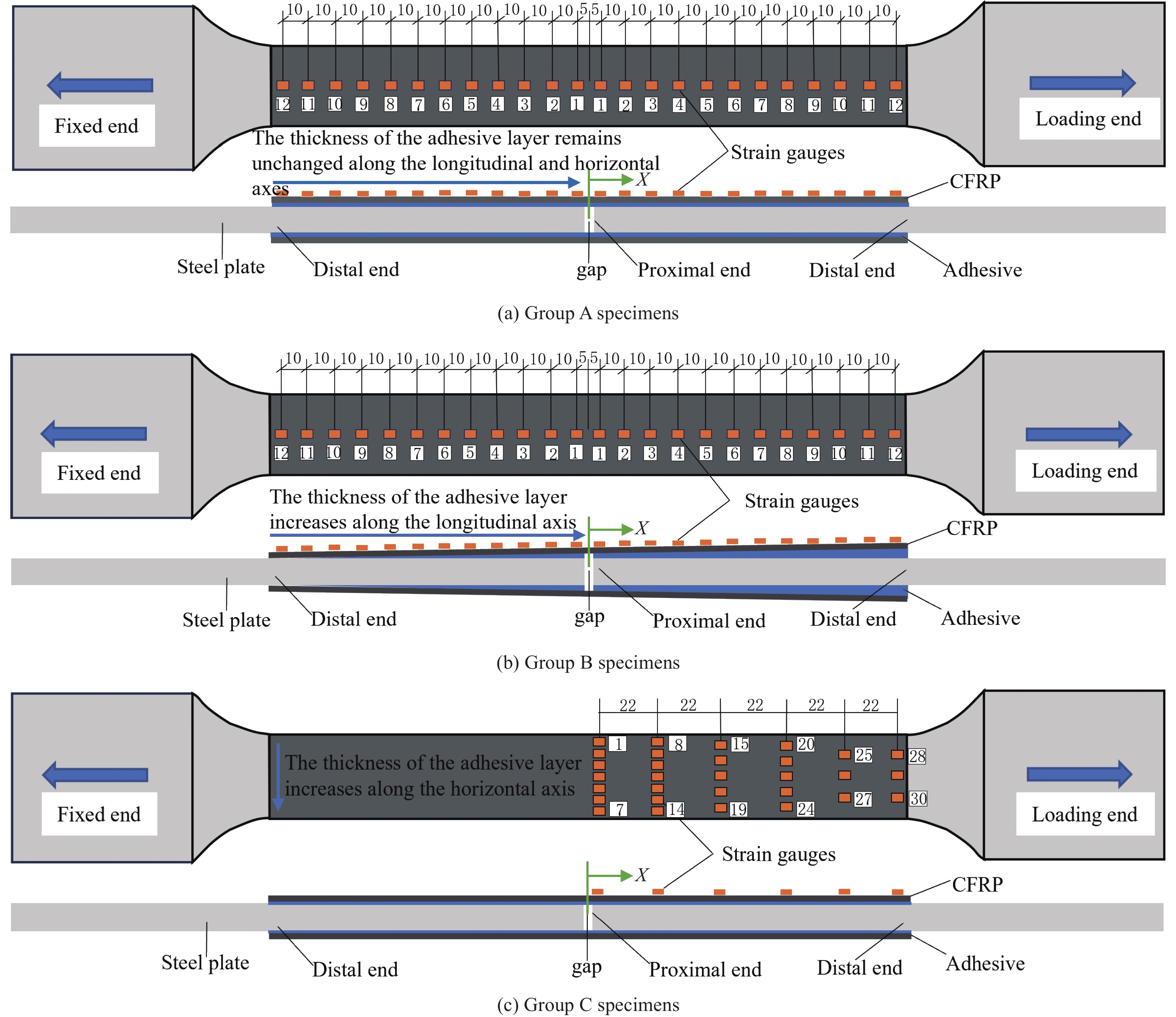

设定间隙中间为粘贴长度方向X轴的原点,把靠近原点的一端称为近端,远离原点且靠近固定端和加载端的两端均称为远端。选取试件一侧为试验区在CFRP板表面布置应变片,对于A组粘结层厚度均匀的试件,沿着CFRP板中轴线关于原点对称布置24片应变片。对于B组粘结层厚度纵向不均匀的试件,粘结层厚度沿固定端至加载端线性增加,交换粘结层厚度变化方向做了预实验,试验结果近似相等,因试件处于纯拉伸状态,故认为粘结层厚度变化的两种情况不存在差别,对实验结果不产生影响。故按加载端厚度大的方式制作试件,应变片粘贴方式与A组相同。对于C组试件,在试验区加载端布置30片应变片,粘结界面的应力在靠近近端较大,靠近远端较小,故在近端应变片布置较密,远端布置较稀疏。应变片布置方式如图5所示。选用江苏泰斯特电子设备制造有限公司的TST3828 EN无线静态应变分析系统采集数据,采集频率1 Hz,得到各组试件的应变分布情况,试验过程中密切观察与记录试件破坏情况。

2. 实验结果及其分析

2.1 破坏形态

各试件的破坏过程类似,大概呈现为:加载前期,肉眼观察试件无明显现象,达到剥离荷载时,产生数次轻微的“噼啪”声,说明CFRP板与钢板发生轻微的剥离。此时剥离程度极微小,肉眼无法捕捉。随着荷载增加,CFRP板在近端发生剥离并向远端延伸。达到极限荷载时,发出“砰”的一声巨响,CFRP板与钢板完全剥离,荷载瞬间归零,加载结束。试件剥离时间的长短与极限承载力的高低有关。

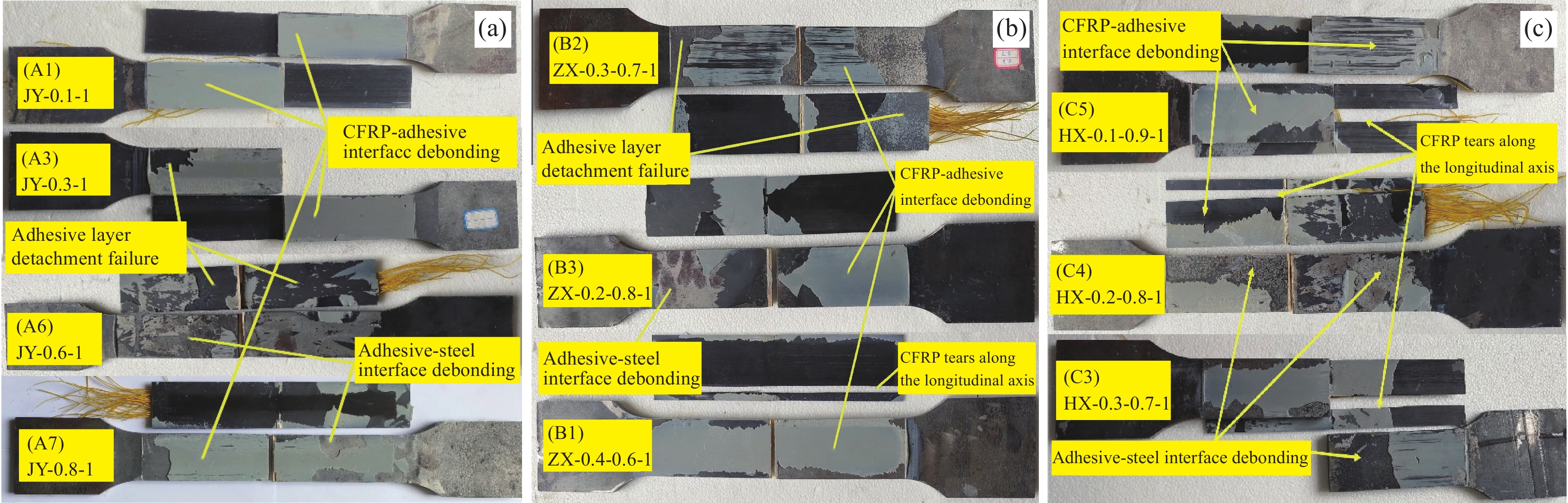

现有研究结果表明:CFRP-钢粘结界面有6种失效模式,即CFRP-粘结层界面脱粘、钢板-粘结层界面脱粘、粘结层内聚失效、CFRP断裂、CFRP层间剥离、钢板屈服[34],实际情况中多数以两种及以上破坏形式出现称为混合破坏。各试件的粘结层厚度情况、破坏位移、极限承载力和失效形式见表2,典型破坏特征如图6。

A组试件的破坏特征是:粘结层厚度小于0.5 mm的试件滑移痕迹明显,粘结层几乎全部依附在钢板表面,粘结层脱落极少且无明显裂缝,CFRP板表面有极少量粘结层附着,主要发生CFRP-粘结层界面脱粘。粘结层厚度大于0.5 mm的试件,粘结层脱落明显,钢板及CFRP板上附着残留粘结层,多表现为混合破坏。B组试件在近端两侧应力分布不对称,较容易出现一侧完全损伤而另一侧未出现剥离的现象,部分试件有明显的滑移痕迹,钢板上残留的粘结层较多,粘结层脱落不明显,主要发生混合破坏。C组试件的粘结层在横向上有较大的应力梯度,薄弱区先发生破坏,应力分布不均匀将CFRP沿纵向撕裂,钢板和CFRP表面均有残留粘结层,粘结层脱落明显,主要发生混合破坏。

2.2 极限承载力

由数值分析得到的各试件极限承载力及位移见表2“ABAQUS”列,通过计算相对误差表明数值计算结果与试验结果吻合度较高,说明内聚力单元可以较好的模拟该加固界面的极限承载性能。

由图7所示,可知粘结层厚度对极限承载力有显著影响,由图7(a)可知,随着粘结层厚度增加,极限承载力呈先增大后减小的趋势,平均增长率为31.65%,平均减小率为17.56%,当粘结层厚度为0.5 mm时有最大承载力,为0.1 mm时承载力的2.95倍,为1.0 mm时承载力的1.81倍,针对该粘结剂而言,在工程应用中建议以0.5 mm为最佳厚度。粘结层厚度不均匀的试件,极限承载力均低于试件JY-0.5,原因是粘结层厚度不均匀会导致剪应力沿近端向远端传递呈不对称性,在剪应力作用下薄弱部位的粘结层会先出现损伤,发生损伤后剥离破坏迅速扩展,导致承载能力大幅度降低。

由图7(b)可知,以各试件极限承载力的平均值计算,随着与平均厚度的最大偏差值由0.1增加至0.4时,纵向不均匀的试件承载力分别降低:6.45%、16.97%、22.49%、36.55%,横向不均匀的试件承载力分别降低9.57%、17.33%、34.79%、47.38%。粘结层厚度不均匀对极限承载力产生较大影响,且伴随着不均匀程度增大,极限承载力呈递减趋势,不均匀程度越大,承载力降低越显著。

最大偏差值相同时,横向不均匀的承载力降低幅度比纵向不均匀平均大6.65%,横向不均匀的承载力比纵向不均匀平均低9.8 kN。以最大偏差值0.3 mm为例,试件JY-0.2的承载力为49.67 kN,JY-0.5为98.7 kN,JY-0.8为75.78 kN,相比于增加粘结层厚度而言减小粘结层厚度承载力下降更明显,ZX-0.2-0.8为76.5 kN,HX-0.2-0.8为61.46 kN,二者的承载力低于JY-0.5,并介于JY-0.2和JY-0.8之间,可知粘结层厚度不均匀会导致承载力降低,当最大偏差值相同时,HX-0.2-0.8的承载力低于ZX-0.2-0.8,横向不均匀的不利影响大于纵向不均匀,且伴随着偏差值增大,横向不均匀的承载力下降越显著,不利影响越大。

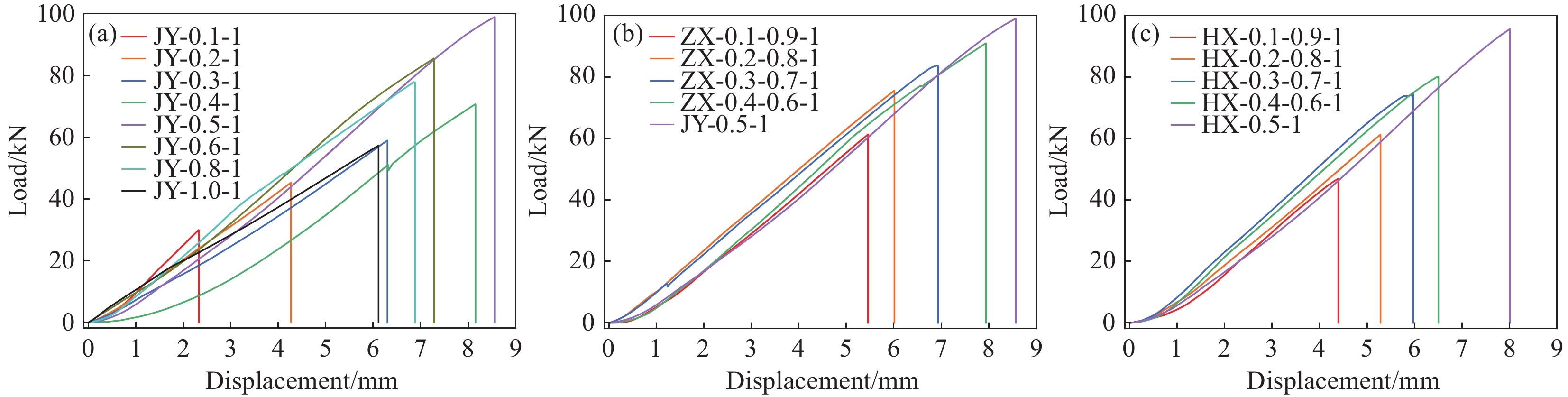

2.3 荷载-位移关系

各组试件的荷载-位移关系如图8所示。三组试验可归为近似线性无屈服段的荷载-位移曲线。可分为三个阶段:(1)刚度强化阶段,加载初期,随着荷载增加,曲线斜率变大。(2)弹性变形阶段,曲线呈线性增长,试件整体的弹性模量和刚度几乎保持不变。(3)刚度退化阶段,临近破坏前一段时间,曲线斜率略微变小,受剥离破坏影响,试件的整体刚度随荷载增加而减小,直至破坏时荷载骤降为0。粘结剂的延性较低使得刚度退化过程较短,屈服现象不明显,试件发生脆性破坏。JY-0.4-1试件、ZX-0.3-0.7-1试件出现加载过程中荷载突然降低的情况,原因是加载过程中粘结区域发生局部破坏导致的,继续加载,位移增加后荷载也逐步恢复。C组试件刚度强化阶段相较于A、B组更明显,主要是由于粘结层厚度横向不均匀导致刚度差较大,在加载过程中刚度强化时间较长。对照A组的JY-0.5-1试件和C组的HX-0.5-1试件,B、C组粘结层厚度不均匀的试件最大承载力和位移均降低,粘结层厚度不均匀性越大,降低程度越明显,但粘结层厚度不均匀性不影响荷载-位移曲线的形状。

3. 粘结破坏机制

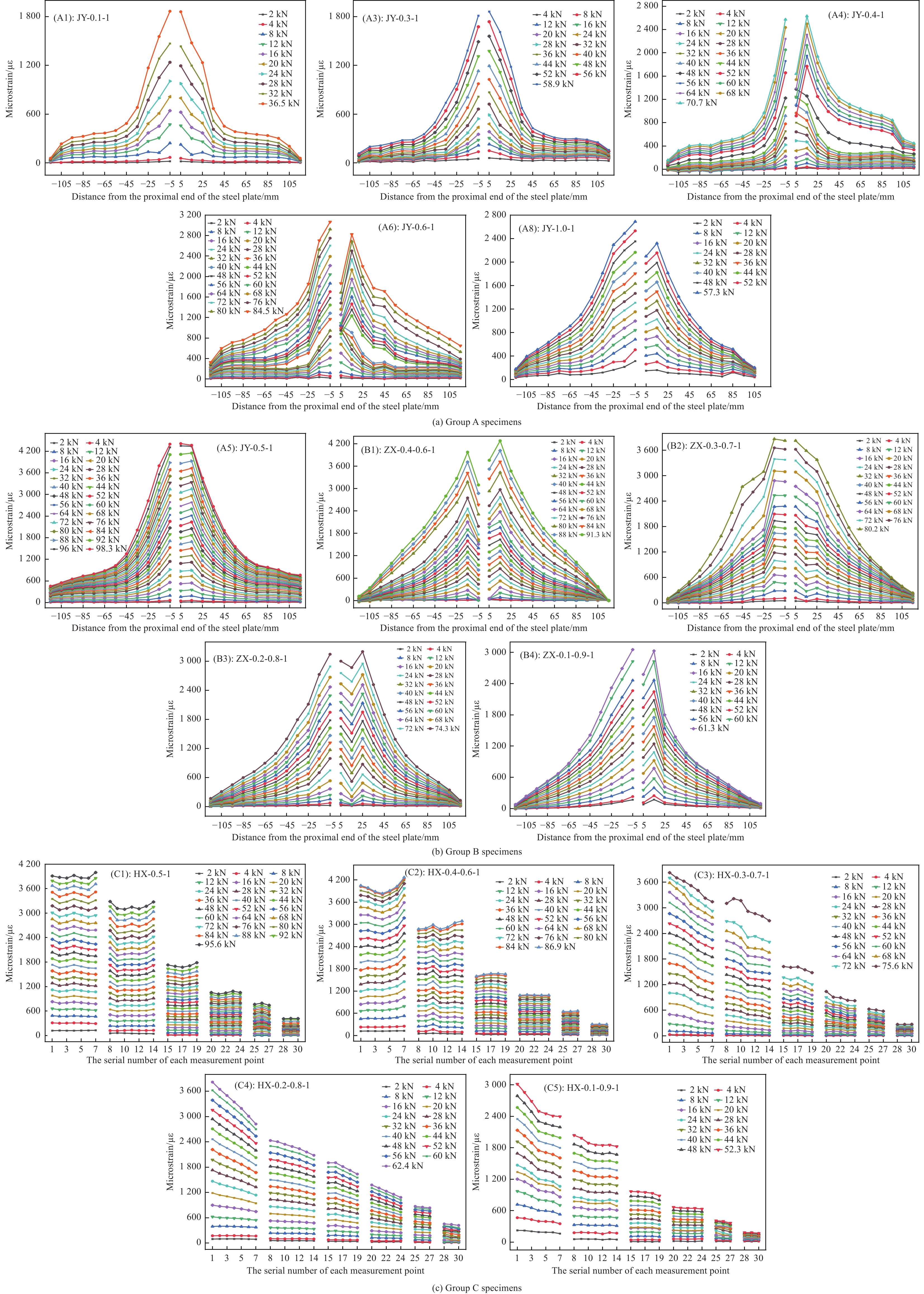

3.1 界面应变分布

CFRP板在加载过程中表面应变分布如图9所示,规律如下:(1) A、B组试件的应变分布特征总体相似,大致呈现指数形式分布,应变随着荷载的增加而增加,增量随着距近端距离的增加而减小,越靠近近端范围内,应变梯度越明显,当超过有效粘结长度后应变的递减趋势减缓并趋于均匀,粘结层厚度不均匀会导致有效粘结长度改变。(2)最大峰值应变出现在近端处,一是在距离近端最近5 mm处,剥离破坏由该处开始,并向远端扩展;二是部分试件的峰值应变出现在距离近端15 mm和25 mm处,与理论上峰值应变出现在近端不符,原因是在靠近近端位置粘结层存在初始缺陷,或在加载过程中近端的测点1处先发生初始剥离破坏,破坏后应力重分布,测点1两侧位置的粘结层继续受力,导致测点1未检测到峰值应变,随着荷载增加,剥离破坏由近端向远端扩展,使得应变片检测到的峰值应变出现在测点2、3处。(3)最大峰值应变与极限承载力和粘结层厚度不均匀程度相关,极限荷载增加,最大峰值应变增加,粘结层厚度的不均匀程度增大,最大峰值应变降低。(4) C组在距离近端同一位置,横向上有明显的应变梯度,而且粘结层厚度的不均匀程度越大,应变梯度越明显,说明剪应力传递在横向上存在较大的不均匀性。(5)部分试件出现了应变值突变,原因为伴随荷载增加CFRP板出现局部剥离或脱胶,失效后该处界面不在承担应力,界面应力向远端或失效点周围的区域转移。

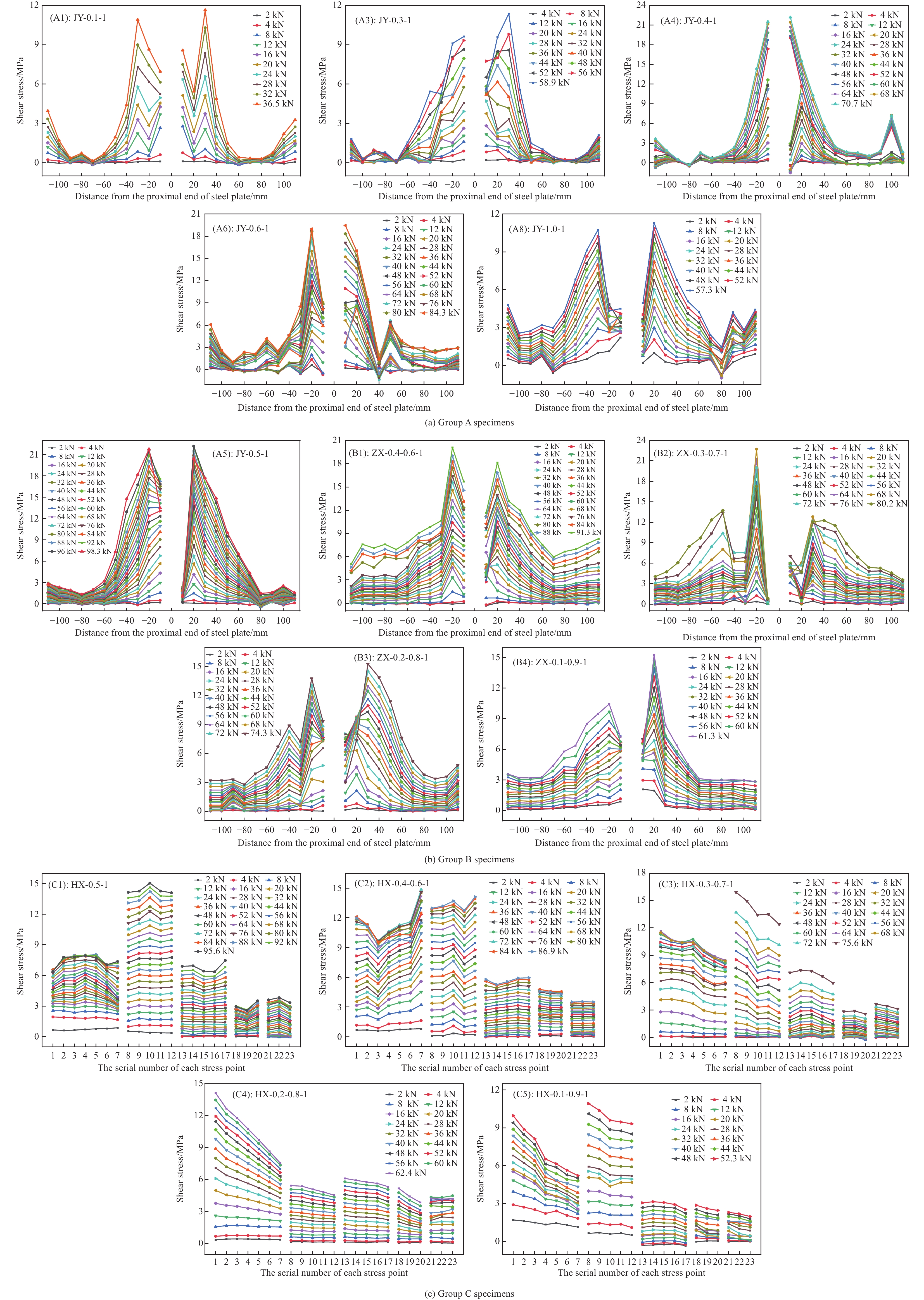

3.2 界面平均剪应力分布

通过采集CFRP板表面应变数据,可由差分方程得到测点i与测点i-1中间的界面剪应力:

τi=△εiEPtp△li=(εi−εi−1)Eptpli−li−1 (2) 式中,εi为CFRP板测点i处的应变,Δεi为测点i与测点i-1间的应变差值, li为测点距间隙近端的距离,Δli为测点i与测点i-1间的距离差值,Ep、tp分别为CFRP板的弹性模量和厚度。

各组试件的剪应力分布如图10所示。结果如下:(1)对于A、B两组试件,在加载过程中靠近近端和远端处的界面剪应力较大,峰值剪应力位于近端20 mm处,在加载后期,界面剪应力整体上近似呈指数递减。少量试件的峰值剪应力位于近端30 mm处,这是由于靠近近端处的粘结层存在初始缺陷,或是靠近近端的粘结层在剪应力和较小剥离应力的作用下先出现了损伤,最大剪应力出现的位置向远端转移,前端出现损伤后承担剪应力的界面长度进一步增大,也说明前端小范围的脱粘破坏对有效荷载的传递影响不大。(2)部分试件在前端10 mm位置处出现剪应力先增大后减小的现象,原因是试件中CFRP与钢板的拉伸刚度差异较大导致的,该位置处出现粘结破坏后前端粘结层的顶托作用使CFRP板承受反向的剪应力导致的。(3)剪应力关于近端分布的对称性与粘结层厚度的不均匀程度有关。A组剪应力分布关于近端基本呈对称分布,B组剪应力分布对称性降低,原因是A组粘结层厚度均匀,粘结面破坏由近端开始向两侧远端呈现对称扩展,而B组间隙两侧的粘结层厚度不同,破坏荷载差异较大,剪应力向两侧远端传递不统一,导致界面粘结破坏不同步。(4)C组试件,最大剪应力出现位置在靠近近端约30 mm范围内,在横向上剪应力呈现梯度变化,说明在拉伸过程中,剪应力沿着纵向往远端传递是不均匀的,且粘结层厚度的不均匀程度越大,横向上剪应力的梯度变化越大,剪应力分布的差异也是导致CFRP板沿纵向撕裂的原因。粘结层厚度的不均匀易导致拉伸过程中产生局部的应力集中,在应力集中区域的界面更容易发生破坏。

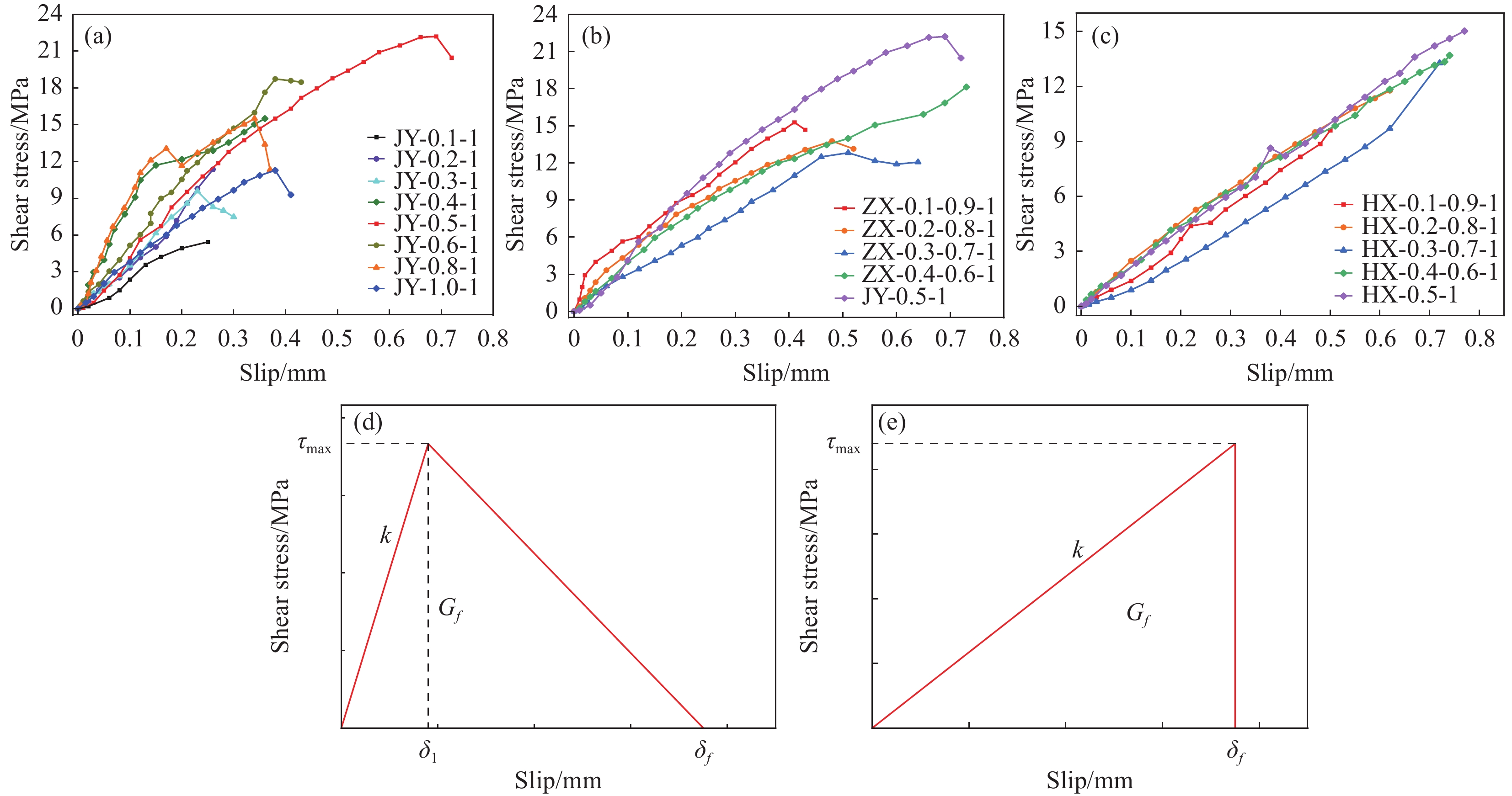

3.3 粘结-滑移关系

粘结-滑移本构关系用来表征界面的粘结失效过程。假定近端位置钢板与CFRP板相对滑移量为0,通过下式对CFRP板表面测点i与测点i-1之间的实测应变进行数值积分可以得到两测点中间处的相对滑移量:

si=i∑j=1(εi+εi−1)2Δlj (3) 式中,si为滑移值,εi、εi−1为测点i与测点i-1处的应变值,Δli为测点i与测点i−1间的距离差值。

为了便于分析,A、B组取距离近端20 mm位置,C组取距离近端38 mm位置处的剪应力和相对滑移值得到界面粘结滑移关系,见图11。按照试验结果,试件均发生脆性破坏,未进入屈服阶段,图11(d)所示的双线性特征的第二阶段表现不明显,故舍去第二阶段,将其拟合为图11(e)所示的粘结滑移曲线来获取内聚力模型的本构参数。A组试件,随着粘结层厚度的增加,峰值剪应力和滑移值呈现先增加后减小的趋势,达到峰值剪应力之前为弹性阶段,剪应力随滑移值近似呈现线性递增趋势;峰值剪应力之后,粘结区域进入了短暂的软化阶段,剪应力随滑移值递减,随后剪应力尚未减小到0时达到极限滑移量,粘结界面发生破坏。B、C组试件,因粘结层厚度不均匀的因素,使得屈服阶段不明显,横向不均匀的影响大于纵向不均匀,故屈服过程减短,甚至不表现出屈服。

粘结层厚度不均匀对界面的粘结滑移曲线的形状影响不大,均表现为屈服阶段不明显的双线性粘结滑移曲线,这与粘结剂的延性较低有关系。此外C组试件粘结层厚度横向不均匀,导致刚度差异较大,弹性阶段结束立刻发生破坏,这也说明粘结层厚度不均匀会影响双线性粘结滑移曲线的第二过程。

此外,只选取CFRP板中心轴线处的一个应变点计算,且加载过程中该点处的粘结剂发生局部破坏、CFRP板不均匀变形及测量误差等影响,会导致部分试件的粘结滑移曲线与双线性内聚力模型存在较大差异。文献[36]中也指出该问题:FRP的应变伴随着材料的不均匀变形会沿宽度方向发生变化,只采集FRP材料中心轴位置处的应变无法得到准确的粘结滑移曲线,建议将FRP沿宽度方向上的影响因素考虑到粘结滑移曲线中。

4. 有限元模拟

4.1 粘聚力理论本构模型及损伤准则

有限元方法是粘结界面应力计算的主要手段,目前采用内聚力单元模拟粘结层是应用较多的数值分析方法[37]。

CFRP与钢板间的粘结界面受力较复杂,呈现较强的非线性特征。将粘结剂近似为线弹性材料,考虑弹性、损伤两个阶段,弹性阶段的粘聚力本构关系假定法向应力与切向应力相独立,不存在耦合现象,其本构关系为

t={tntstt}=[Knn000Kss000Ktt]{δnδsδt}=Kδ (4) 式中,t为粘聚应力向量,tn、ts、tt为法向和两个切向应力分量,K为界面刚度,Knn、Kss、Ktt为对应的刚度分量,δ为界面张开位移,δn、δs、δt为对应的位移分量。

荷载达到剪切强度时粘结层开始发生损伤,基于双线性牵引分离定律完成界面损伤和失效。考虑应力对粘结层粘性接触损伤起始的复合效应,采用二次名义应力准则做为Cohesive单元的初始损伤判据,即材料各个方向的名义应力比的平方和等于1时材料刚度开始退化,出现界面损伤,满足:

{⟨tn⟩t0n}2+{tst0s}2+{ttt0t}=1 (5) 式中,tn、ts、和tt分别为粘结层三个方向上的应力,t0n、t0s和t0t分别为对应的破坏最大名义应力,n、s和t分别为垂直和平行粘结面的三个方向。

4.2 有限元模型

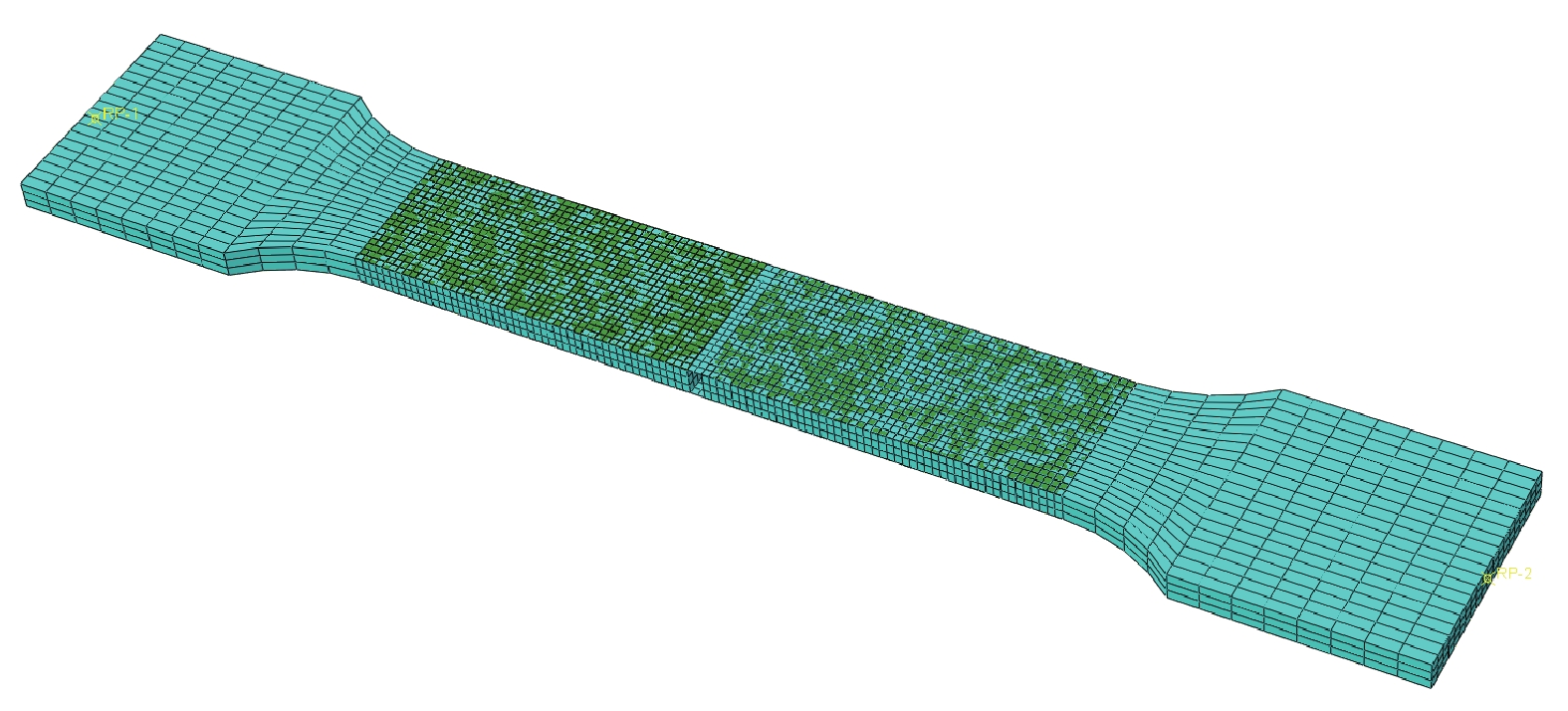

采用ABAQUS有限元模型对界面粘结破坏进行数值模拟。钢板基体采用八节点减缩积分实体单元C3D8 R模拟,CFRP采用四节点减缩积分壳单元S4R模拟,粘结层采用基于连续体的COH3D8 cohesive单元模拟,采用基于表面的 “Tie约束”方式使上下表面分别与钢板和CFRP共节点,各材料属性与试验相同。模型共划分C3D8 R单元

7200 个,COH3D8 R单元3840 个,S4R单元3920 个,节点18522 个。将试验得到的粘结滑移曲线按双线性内聚力模型进行拟合,得到内聚力单元的性能参数见表3。为兼顾计算效率和精度,采用粗细网格过渡的划分方式,模型如图12所示。采用钢板一端固定,一端施加位移荷载来控制边界条件。表 3 CFRP-钢界面粘结-滑移本构参数Table 3. Bond-slip constitutive parameters of CFRP-steel interfaceParameter τf/MPa K/MPa·mm−1 δf/mm Gf/MPa·mm JY-0.1 5.45 21.80 0.25 0.68 JY-0.2 11.25 43.27 0.26 1.46 JY-0.3 9.59 39.96 0.24 1.15 JY-0.4 15.51 43.08 0.36 2.79 JY-0.5 22.15 33.56 0.66 7.31 JY-0.6 18.48 42.98 0.43 3.97 JY-0.8 15.04 47.00 0.32 2.41 JY-1.0 11.58 29.69 0.39 2.26 ZX-0.4-0.6 18.74 26.39 0.71 6.65 ZX-0.3-0.7 12.73 22.73 0.56 3.56 ZX-0.2-0.8 13.77 28.69 0.48 3.30 ZX-0.1-0.9 15.28 36.38 0.42 3.21 HX-0.5 15.03 19.52 0.77 5.79 HX-0.4-0.6 13.7 18.51 0.74 5.07 HX-0.3-0.7 13.06 19.21 0.68 4.44 HX-0.2-0.8 11.78 19.00 0.62 3.65 HX-0.1-0.9 8.86 18.46 0.48 2.13 Notes: τf−Maximum shear stress; K−Interfacial stiffness; δf−Limit slip of failure; Gf−Interfacial fracture energy. 4.3 粘结层破坏规律

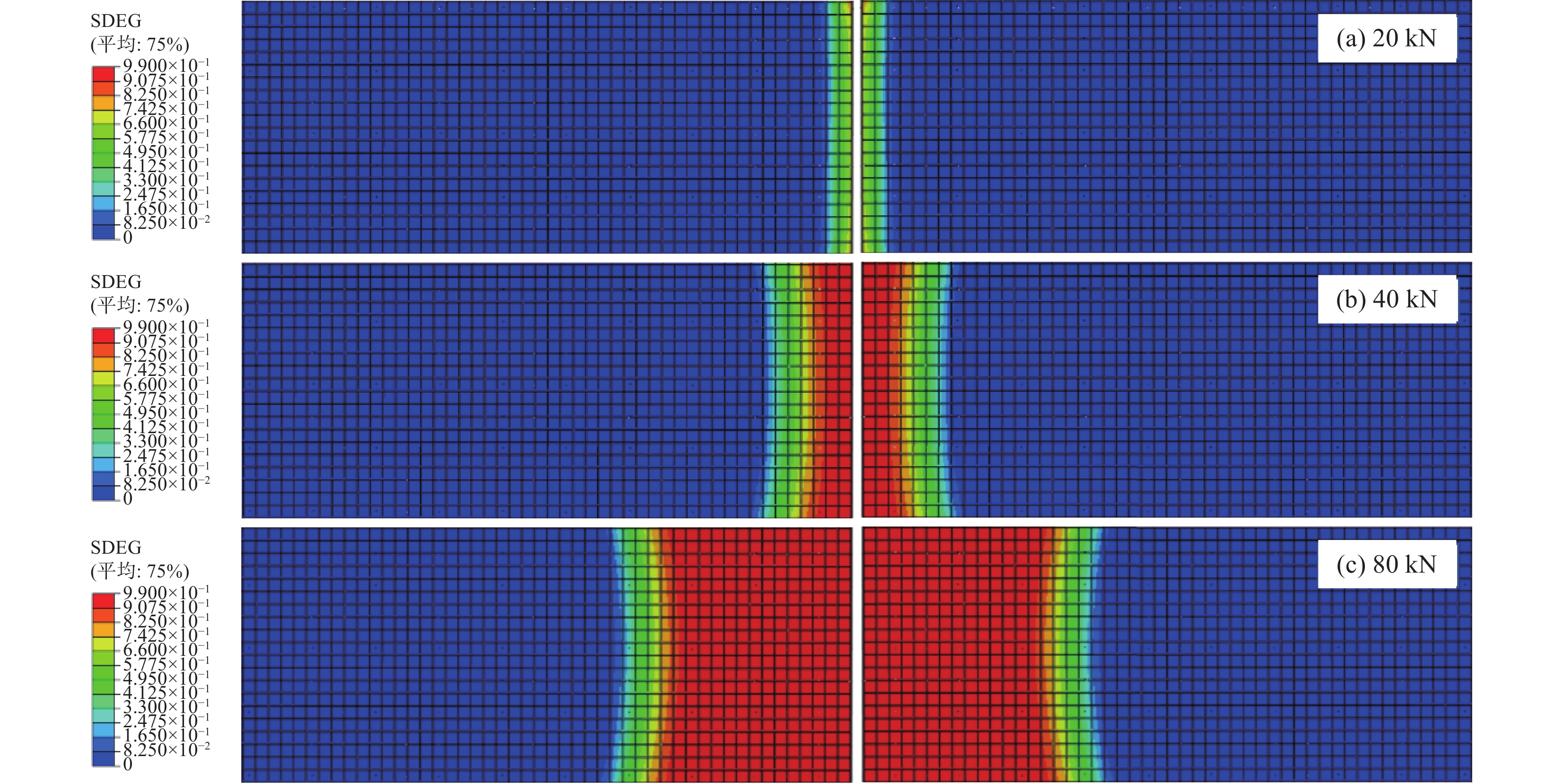

满足损伤准则后,粘结层进入损伤演化阶段。采用SDEG(标量刚度退化),数值上等于材料已退化刚度与原有刚度的比值,用于表征内聚力单元的状态及界面的损伤程度,当界面出现损伤时,SDEG开始由0~1逐渐增长,表征界面开始损伤到完全破坏阶段的演化过程,当SDEG=1时,粘结单元的性能完全损失,该粘结单元被删除。材料发生损伤后定义刚度线性退化,基于界面断裂能的BK准则控制单元刚度退化来做粘结层的损伤演化。例如试件JY-0.5(限于篇幅仅示一个试件)粘结层刚度退化过程如图13所示,粘结层的刚度退化始终由近端开始并向远端扩展,刚度退化过程与破坏同步发生。但粘结层厚度的不均匀性会导致刚度退化不均匀,不仅使承载力降低,还会使加固试件出现多种破坏模式。

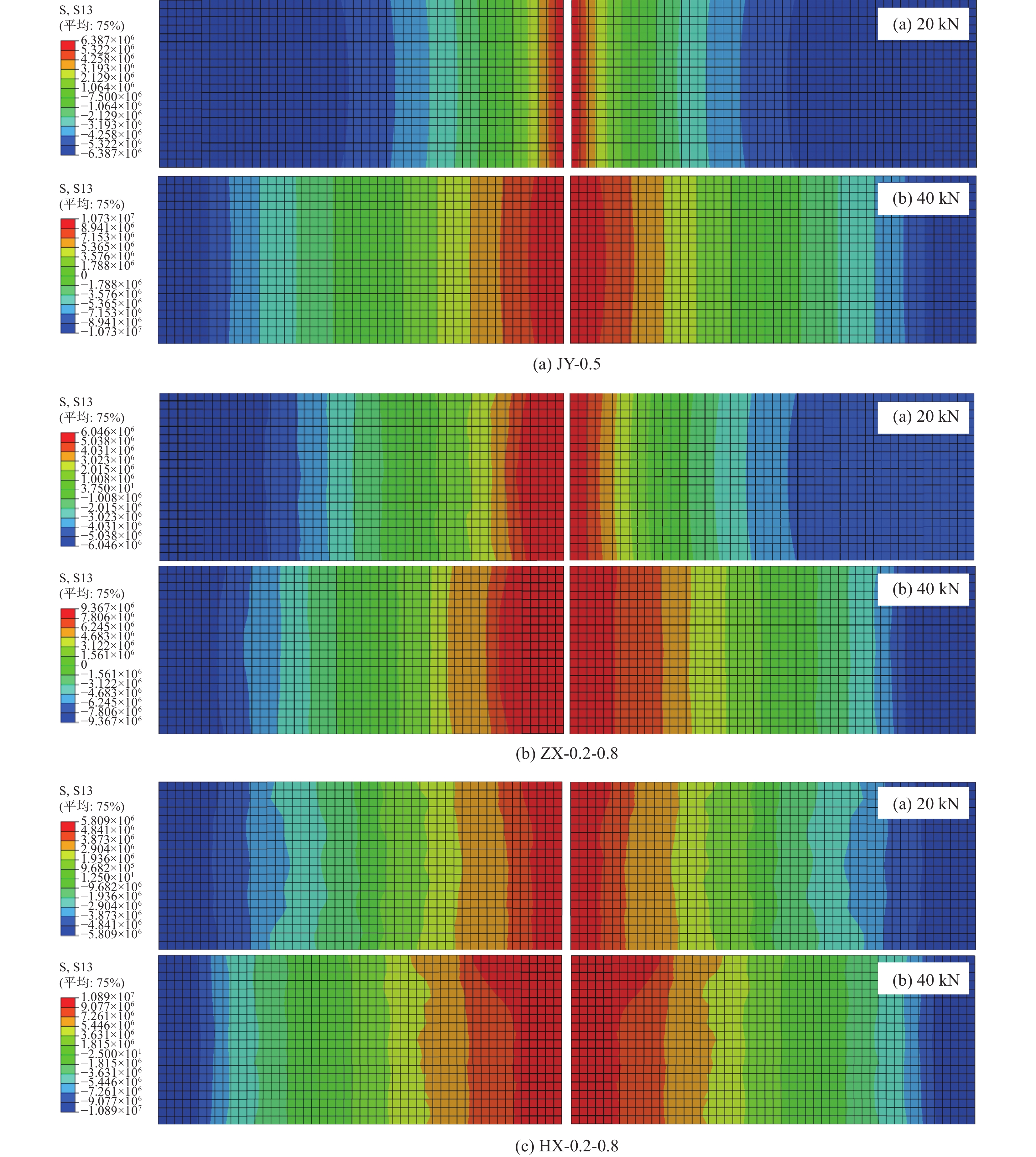

如图14所示,列举三个试件在两个荷载时刻下对应的粘结层应力云图,JY-0.5试件的剪应力关于间隙呈对称分布,ZX-0.2-0.8试件的剪应力沿纵向呈不对称分布,HX-0.2-0.8试件的剪应力关于间隙呈对称分布,在横向上应力有梯度变化,粘结层厚度不均匀会导致剪应力传递呈现不对称性,这与试验结果相吻合。粘结层厚度的不均匀性不影响剪应力的传递规律,剪应力均是由近端向远端传递,只是影响剪应力在传递过程中的分布,这种不均匀的应力分布正是导致承载力降低的主要原因。

4.4 数值模型验证

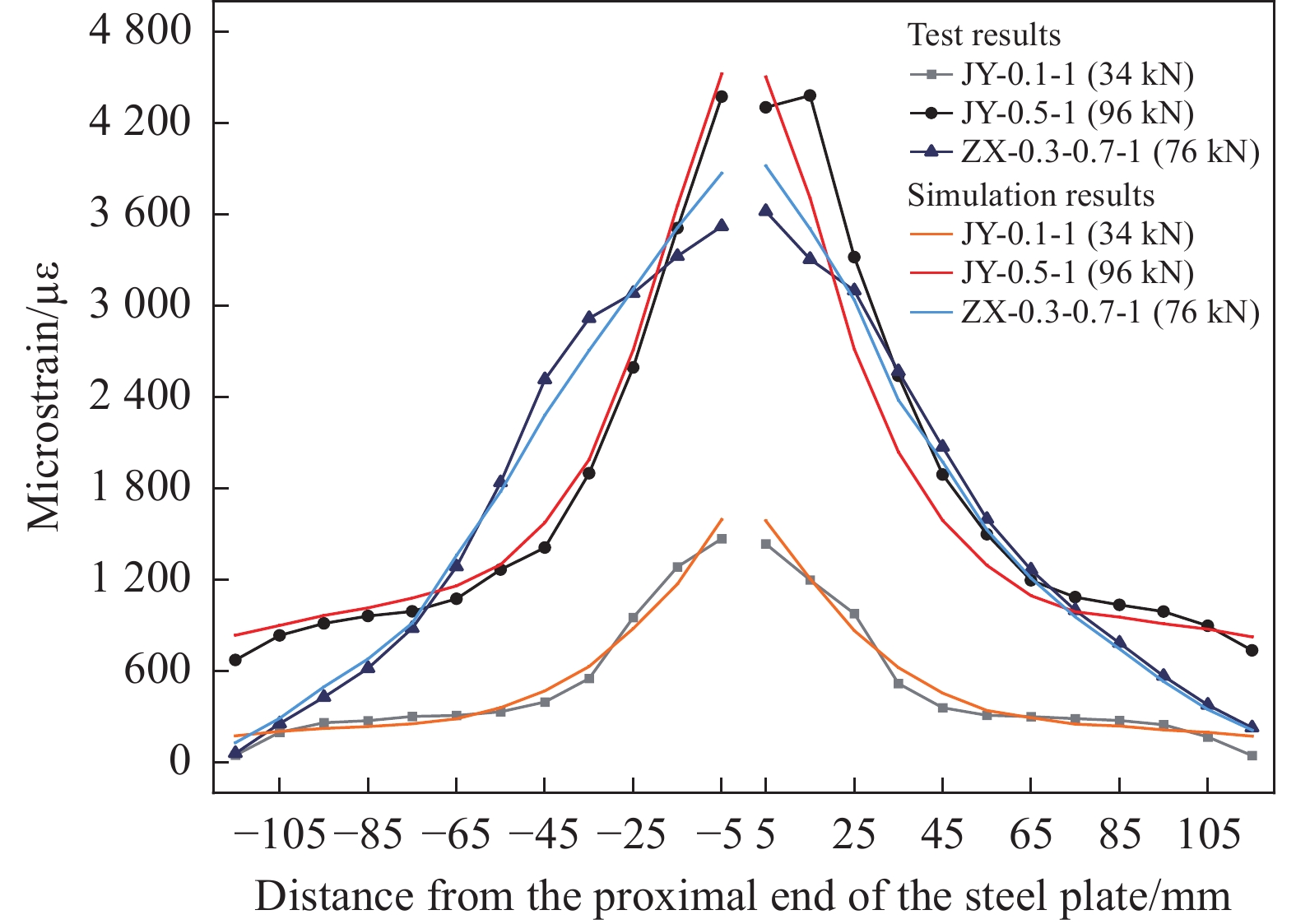

选择三个试件破坏前的某一荷载对应的应变与数值分析中的应变进行对比,如图15所示。可以看出:(1)随着与近端距离的增加,应变的数值呈现递减趋势,从整体趋势上分析,数值模拟结果是有效的;(2)数值模拟和试验结果均显示剪应力的传递只在有效粘结长度内,在该范围内应变的变化梯度比较明显,超过该有效粘结长度后应变梯度明显变缓,这与现有研究结果相吻合;(3)从近端两侧应变梯度变化的对称性来看, JY-0.1-1和JY-0.5-1试件的对称性要高于ZX-0.3-0.7-1试件,这与粘结层厚度的不均匀性有关。纵上所述,该数值模拟能够较好的反应粘结层厚度不均匀条件下CFRP-钢粘结界面的真实情况。

5. 结 论

(1)粘结层厚度均匀时,随着粘结层厚度增加,极限承载力先增大后减小,破坏模式由界面破坏向混合破坏转变,最佳粘结层厚度为0.5 mm。粘结层厚度不均匀时,随着不均匀程度增加,极限承载力逐渐降低,破坏模式多为混合破坏。不均匀程度相同时,横向不均匀的承载力平均比纵向不均匀的承载力低9.8 kN, 横向不均匀的承载力降低幅度平均比纵向不均匀大6.65%,横向不均匀的不利影响更大。

(2)应力、应变传递只在距近端80 mm的有效粘结长度范围内,在该范围内应变由近端开始向远端呈指数递减趋势,最大峰值应变在近端附近30 mm范围内,超过该范围应变的递减趋势减缓并趋于均匀,粘结层厚度的不均匀性会导致间隙两侧的有效粘结长度不相等,使应力分布不均匀,导致承载力降低。

(3)受粘结层厚度不均匀的影响,近端两侧的应力关于间隙两侧呈现不对称性,剪应力由近端向远端传递,且由近端向远端递减,在剪应力作用下,破坏由近端开始向远端扩展。

(4)粘结滑移曲线均表现为屈服阶段不明显的双线性特征,这与发生脆性破坏的试验结果相吻合。一方面是粘结剂的延性较低,其次只选取CFRP板沿中心轴的应变会导致计算所得的粘结滑移曲线存在较大误差,可将CFRP材料变形的不均匀性及应变沿宽度方向发生变化等因素考虑到粘结滑移模型中做进一步研究。

(5)基于试验数据得到的粘结滑移本构参数建立数值模型,该内聚力模型可用于分析粘结层厚度不均匀对CFRP-钢界面粘结性能的影响。

-

表 1 CFRP板、钢板及粘结剂材料参数

Table 1 Material parameters of CFRP plate, steel plate and adhesives

Material parameter CFP-Ⅰ-14 CFRP-A/B Q345 qC Elasticity modulus/GPa 165 5.3 206 Tensile strength/MPa 2400 38 514 Shear strength/MPa 55 — 79000 Shear strength for

steel-to-steel joint/MPa— 41.6 — Poisson’s ratio 0.28 0.35 0.30 Elongation at break/% 1.6 1.13 21% 表 2 CFRP-钢双剪试件拉伸试验结果

Table 2 Tensile test results of CFRP-steel double-shear specimens

Grouping Specimen number DV Ultimate load/kN Limit displacement/mm Failure

modePmax Average ABAQUS Relative

errorDmax Average ABAQUS Relative

errorA JY-0.1-1 0 36.59 33.42 35. 26 5.5% 3.06 2.95 2.89 2.1% a JY-0.1-2 30.25 2.84 a JY-0.2-1 54.01 49.67 50.19 1.0% 4.27 4.1 4.13 0.7% a+b JY-0.2-2 45.33 3.92 a JY-0.3-1 60.50 59.7 62.34 4.4% 6.30 6.26 6.15 1.8% a+b JY-0.3-2 58.90 6.21 a JY-0.4-1 78.26 74.48 74.25 0.3% 8.16 7.9 7.76 1.80% a+b JY-0.4-2 70.70 7.64 a+b JY-0.5-1 99.05 98.7 101.24 2.6% 8.57 8.67 8.71 0.5% a+b+c JY-0.5-2 98.35 8.76 a+b+c JY-0.6-1 84.59 82.43 82.75 0.4% 7.28 7.16 7.21 0.7% a+b+c JY-0.6-2 80.27 7.03 a+b JY-0.8-1 77.80 75.78 74.15 2.2% 6.88 6.71 6.68 0.5% a+b+c JY-0.8-2 73.76 6.53 a+b+c JY-1.0-1 57.32 54.46 56.30 3.4% 6.11 5.84 5.72 2.1% a+b+c JY-1.0-2 51.60 5.56 a+b+c B ZX-0.4-0.6-1 0.1 91.3 92.33 96.50 4.5% 7.94 8.05 8.12 0.9% a+b+d ZX-0.4-0.6-2 95.35 8.16 a+b+c ZX-0.3-0.7-1 0.2 80.16 81.95 84.37 3.0% 6.50 6.54 6.46 1.2% a+b ZX-0.3-0.7-2 83.73 6.58 a+b+c ZX-0.2-0.8-1 0.3 74.64 76.5 78.8 3.0% 5.93 5.86 5.80 1.0% a+b+c ZX-0.2-0.8-2 78.36 5.79 a+b ZX-0.1-0.9-1 0.4 62.14 62.63 62.22 0.7% 5.28 5.26 5.18 1.5% a+b+c ZX-0.1-0.9-2 63.11 5.23 b+c C HX-0.5-1 0 95.6 94.25 101.24 7.4% 8.01 8.14 8.71 7.0% a+b+c HX-0.5-2 92.89 8.26 a+b+c HX-0.4-0.6-1 0.1 86.95 85.23 87.86 3.1% 6.83 6.53 6.62 1.4% a+b+c HX-0.4-0.6-2 83.5 6.22 a+b+c HX-0.3-0.7-1 0.2 75.56 77.92 78.26 0.4% 6.01 6.27 6.36 1.4% a+b+c+d HX-0.3-0.7-2 80.27 6.52 a+b+c HX-0.2-0.8-1 0.3 62.43 61.46 62.87 2.3% 4.93 4.85 4.91 1.2% a+b+c+d HX-0.2-0.8-2 60.49 4.76 a+b+c+d HX-0.1-0.9-1 0.4 46.88 49.59 50.23 1.3% 4.39 4.64 4.71 1.5% a+b+c+d HX-0.1-0.9-2 52.3 4.89 a+b+c Notes: Dmax−Limit displacement; Pmax−Ultimate load; ABAQUS−Numerical analysis results; DV−Maximum deviation between the thickness of the bond layer and the average thickness; Failure mode: a−CFRP and adhesive debonding failure; b−Steel and adhesive debonding failures; c−Adhesive shatter; d−CFRP tearing; JY-0.1-1−Thickness of the adhesive layer is uniform, and the thickness of the adhesive layer is 0.1 mm; ZX-0.4-0.6-1−Thickness of the adhesive layer is not uniform in the longitudinal direction, and the thickness of the adhesive layer increases from 0.4 mm to 0.6 mm for the first specimen; HX-0.4-0.6-1−Thickness of the adhesive layer is not uniform transversely, and the thickness of the adhesive layer increases from 0.4 mm to 0.6 mm for the first specimen. 表 3 CFRP-钢界面粘结-滑移本构参数

Table 3 Bond-slip constitutive parameters of CFRP-steel interface

Parameter τf/MPa K/MPa·mm−1 δf/mm Gf/MPa·mm JY-0.1 5.45 21.80 0.25 0.68 JY-0.2 11.25 43.27 0.26 1.46 JY-0.3 9.59 39.96 0.24 1.15 JY-0.4 15.51 43.08 0.36 2.79 JY-0.5 22.15 33.56 0.66 7.31 JY-0.6 18.48 42.98 0.43 3.97 JY-0.8 15.04 47.00 0.32 2.41 JY-1.0 11.58 29.69 0.39 2.26 ZX-0.4-0.6 18.74 26.39 0.71 6.65 ZX-0.3-0.7 12.73 22.73 0.56 3.56 ZX-0.2-0.8 13.77 28.69 0.48 3.30 ZX-0.1-0.9 15.28 36.38 0.42 3.21 HX-0.5 15.03 19.52 0.77 5.79 HX-0.4-0.6 13.7 18.51 0.74 5.07 HX-0.3-0.7 13.06 19.21 0.68 4.44 HX-0.2-0.8 11.78 19.00 0.62 3.65 HX-0.1-0.9 8.86 18.46 0.48 2.13 Notes: τf−Maximum shear stress; K−Interfacial stiffness; δf−Limit slip of failure; Gf−Interfacial fracture energy. -

[1] 王春生, 翟慕赛, HOUANKPO T N O, 等. 正交异性钢桥面板冷维护技术及评价方法[J]. 中国公路学报, 2016, 29(8): 50-58. DOI: 10.3969/j.issn.1001-7372.2016.08.007 Wang Chun-sheng, Zhai Musai, HOUANKPO T N O, et al. Cold maintenance technique and assessment method for orthotropic steel bridge deck[J]. China Journal of Highway and Transport, 2016, 29(8): 50-58(in Chinese). DOI: 10.3969/j.issn.1001-7372.2016.08.007

[2] ROZUMEK D, MARCINIAK Z, LESIUK G, et al. Experimental and numerical investigation of mixed mode I + II and I + III fatigue crack growth in S355J0 steel[J]. International Journal of Fatigue, 2018, 113: 160-170. DOI: 10.1016/j.ijfatigue.2018.04.005

[3] 李传习, 李游, 陈卓异, 等. 钢箱梁横隔板疲劳开裂原因及补强细节研究[J]. 中国公路学报, 2017, 30(3): 122-131. DOI: 10.3969/j.issn.1001-7372.2017.03.013 LI Chuanxi, LI You, CHEN Zhuoyi, et al. Fatigue cracking reason and detail dimension of reinforcement about trans verse diaphragm of steel box girder[J]. China Journal of Highway and Transport, 2017, 30(3): 122-131(in Chinese). DOI: 10.3969/j.issn.1001-7372.2017.03.013

[4] YU Qianqian, WU Yufei. Fatigue retrofitting of cracked steel beams with CFRP laminates[J]. Composite Structures, 2018, 192: 232-244. DOI: 10.1016/j.compstruct.2018.02.090

[5] EL-TAWIL S, EKIZ E, GOEL S, et al. Retraining local and global buckling behavior of steel plastic hinges using CFRP[J]. Journal of Constructional Steel Research, 2011, 67(3): 261-269. DOI: 10.1016/j.jcsr.2010.11.007

[6] LEPRETRE E, CHATAIGNER S, DIENG L, et al. Fatigue strengthening of cracked steel plates with CFRP laminates in the case of old steel material[J]. Construction and Building Materials, 2018, 174: 421-432. DOI: 10.1016/j.conbuildmat.2018.04.063

[7] 吴刚, 刘海洋, 吴智深, 等. 不同纤维增强复合材料加固钢梁疲劳性能试验研究[J]. 土木工程学报, 2012, 45(4): 21-28. Wu Gang, Liu Haiyang, Wu Zhishen, et al. Experimental study of the fatigue performance of steel beams strengthened with different fiber reinforced polymers[J]. China Civil Engineering Journal, 2012, 45(4): 21-28(in Chinese).

[8] Jiao H, Mashiri F, Zhao X L. A comparative study on fatigue behaviour of steel beams retrofitted with welding, pultruded CFRP plates and wet layup CFRP sheets[J]. Thin Walled Structures, 2012, 59: 144-152. DOI: 10.1016/j.tws.2012.06.002

[9] WANG ZHEN, XIAN GUIJUN. Effects of thermal expansion coefficients discrepancy on the CFRP and steel bonding[J]. Construction and Building Materials, 2020(prepublish).

[10] Yu Q Q, Chen T, Gu X L, et al. Fatigue behaviour of CFRP strengthened steel plates with different degrees of damage[J]. Thin-Walled Structures, 2013, 69: 10-17. DOI: 10.1016/j.tws.2013.03.012

[11] HE J, XIAN G, Debonding of CFRP-to-steel joints with CFRP delamination[J]. Composite Structures, 2016, 153: 12-20.

[12] PANG Y, WU G, WANG H, et al. Bond-slip model of the CFRP-steel interface with the CFRP delamination failure[J]. Composite Structures, 2021, 256: 113015. DOI: 10.1016/j.compstruct.2020.113015

[13] 李腾, 宁志华, 吴嘉瑜. CFRP 加固钢板的粘结界面剥离破坏[J]. 复合材料学报, 2021, 38(12): 4090-4105. LI Teng, NING Zhihua, WU Jiayu. Interfacial debonding failure of CFRP-strengthened steel structures[J/OL][J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4090-4105(in Chinese).

[14] 杨怡, 黄炽辉 , 吴作栋 . 基于双剪实验的CFRP-钢板界面粘结性能研究[J]. 中山大学学报(自然科学版), 2020.07. 14.2020B082. YANG Yi, HUANG Chihui, WU Wuodong. Study on bonding performance of CFRP-steel plate interface based on double shear test[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni, 2020.07. 14.20B082. (in Chinese)

[15] HE JUN, XIAN GUIGUN, ZHANG Y. X. Numerical modelling of bond behaviour between steel and CFRP laminates with a ductile adhesive[J]. International Journal of Adhesion and Adhesives, 2021, 104.

[16] 李传习, 柯璐, 陈卓异, 等. CFRP-钢界面粘结性能试验与数值模拟[J]. 复合材料学报, 2018, 35(12): 3534-3546. LI Chuanxi, Kelu, CHEN Zhuoyi et al. Experimental study and numerical simulation for bond behavior of interface between CFRP and steel[J]. Acta Materiae Compositae Sinica, 2018, 35(12): 3534-3546(in Chinese).

[17] 吴超, 余洋喆, 雷昕弋, 等. 钢板屈服对 CFRP-钢界面粘接性能影响的试验研究[J]. 复合材料学报, 2022, 39(11): 5062-5073. WU Chao, YU Yangzhe, LEI Xinyi, et al. Experimental study on the effect of steel yielding on the bond behavior between CFRP and steel plate[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5062-5073 (in Chinese).

[18] 陈卓异, 彭岚, 李传习, 等. CFRP 全覆盖胶粘加固含中心裂纹钢板的静力性能[J]. 复合材料学报, 2022, 39(5): 2329-2339. CHEN Zhuoyi, PENG Lan, LI Chuanxi, et al. Static behavior of CFRP full cover adjusted steel plate with center crack[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 2329-2339 (in Chinese).

[19] 高立, 邓宗才. CFRP修复钢I/II混合型裂纹扩展研究进展及展望[J]. 工程力学. DOI: 10.6052/j.issn.1000-4750.2023.07.0519 Gao Li, DENG Zongcai. Research progress and prospect of I /II mixed crack propagation of steel repaired with CFRP[J]. Engineering Mechanices. (in Chinese) DOI: 10.6052/j.issn.1000-4750.2023.07.0519

[20] 李安邦, 徐善华, 吴成, 等. 外贴 CFRP 板加固锈蚀钢板疲劳性能试验研究[J]. 土木工程学报, 2021, 54(7): 62-72. LI Anbang, XU Shanhua, WU Cheng, et al. Experimental study on the fatigue performance of corroded steel plate strengthened with externally bonded CFRP plates[J]. China Civil Engineering Journal, 2021, 54(7): 62-72(in Chinese).

[21] 李安邦, 徐善华. 锈蚀对钢板表面特性及CFRP板-锈蚀钢板界面黏结性能的影响[J]. 复合材料学报, 2022, 39(2): 746-758. LI Anbang, XU Shanhua. Effect of corrosion on the surface properties of steel plate and interfacial bonding properties between CFRP plate and corroded steel plate[J]. Acta Materiae Compositae Sinica, 2022, 39(2): 746-758(in Chinese).

[22] 王海涛, 吴刚, 吴智深. FRP布置方式对含裂纹钢板加固后的疲劳性能影响分析[J]. 土木工程学报, 2015, 48(1): 56-63. Wang Haitao, Wu Gang, Wu Zhishen. Study on the effect of FRP configurations on the fatigue behavior of strengthened steel plate with an initial crack[J]. China Civil Engineering Journal, 2015, 48(1): 56-63(in Chinese).

[23] 陈涛, 摇铖. CFRP加固含混合型边裂纹钢板的疲劳性能试验研究[J]. 建筑结构学报, 2021, 42(2): 206-212 CHEN Tao, YAO Cheng. Experimental study on fatigue properties of CFRP-repaired steel plates with a mixed mode edge crack[J]. Journal of Building Structures, 2021, 42(2): 206-212(in Chinese).

[24] HESHMATI M, HAGHANI R, Al-EMRANI M. Durability of Bonded FRP-to-steel Joints Effects of Moisture, De-icing Salt Solution, Temperature and FRP Type[J]. Composites Part B: Engineering, 2017, 119: 153-167. DOI: 10.1016/j.compositesb.2017.03.049

[25] HESHMATI M, HAGHANI R, Al-EMRANI M. Durability of CFRP/steel joints under cyclic wet-dry and freeze-thaw conditions[J]. Composites Part B: Engineering, 2017: 211-226.

[26] GRAMMATIKOS S A, JONES R G, EVERNDEN M, et al. Thermal cycling effects on the durability of a pultruded GFRP material for off-shore civil engineering structures[J]. Composite Structures, 2016, 153: 297-310. DOI: 10.1016/j.compstruct.2016.05.085

[27] 余倩倩, 赵翊舟, 高瑞鑫. 海洋大气环境对 CFRP-钢界面粘结性能的影响[J]. 复合材料学报, 2022, 39(11): 5148-5157. YU Qianqian, ZHAO Yizhou, GAO Ruixin. Effect of marine atmosphere on the bond behaviour of CFRP-steel interface[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5148-5157(in Chinese).

[28] 李传习, 司睹英胡, 高有为. 极端湿热环境对 CFRP/钢界面性能的影响[J]. 建筑材料学报, 2024, 27(8): 757-763. LI Chuanxi, SI Duyinghu, GAO youwei. Influence of extreme Wet-Heat environment on the adhesive bonding performance of CFRP/steel interfaces[J]. Journal of Building Materials, 2024, 27(8): 757-763(in Chinese).

[29] 朱德举, 姚明侠, 张怀安, 等. 动态拉伸荷载下温度对CFRP/钢板单搭接剪切接头力学性能的影响[J]. 土木工程学报, 2016, 49(8): 28-35. ZHU Deju, YAO Mingxia, ZHANG Huaian, et al. Temperature effect on the mechanica properties of CFRP/steel single lap shear joints under dynamic tensile loading[J]. China Civil Engineering Journal, 2016, 49(8): 28-35(in Chinese).

[30] 李游, 李洪仪, 马小琬, 等. 高温对基于研发胶黏剂的 CFRP 板-钢板搭接界面力学性能的影响[J]. 复合材料学报, 2023, 40(12): 6596-6609. LI You, LI Hongyi, MA Xiaowan, et al. Effect of high temperature on mechanical properties of CFRP plate-steel plate lapping interface based on developed adhesive[J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6596-6609(in Chinese).

[31] 李游, 李传习, 郑辉, 等. 固化剂混掺对高温下 CFRP 板-钢板界面黏结性能的影响[J]. 复合材料学报, 2021, 38(12): 4073-4089. LI You, LI Chuanxi, ZHENG Hui, et al. Effect of curing agent mixing on interfacial bond behavior of glued CFRP plate-steel plate at elevated temperature[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4073-4089(in Chinese).

[32] 陈卓异, 彭彦泽, 李传习, 等. 高温下双搭接钢-CFRP 板胶粘界面力学性能试验[J]. 复合材料学报, 2021, 38(2): 449-460. CHEN Zhuoyi, PENG Yanze, LI Chuanxi, et al. Experimental study for the adhesive interface mechanical properties of double lapped steelCFRP plate at high temperature[J]. Acta Materiae Compositae Sinica, 2021, 38(2): 449-460(in Chinese).

[33] American Society for Testing and Materials. Standard test method for strength properties of double lap shear adhesive joints by tension loading: ASTM D3528−96[S]. West Con shohocken: ASTM, 2008

[34] Gao W Y, Dai J G, Teng J. G. eAnalysis of Mode II debonding behavior of fiber reinforced polymer-to-substrate bonded joints subjected to combined thermal and mechanical loading[J]. Engineering Fracture Mechanics, 2015, 136.

[35] Al-Mosawe A, Al-Mahaidi R, Zhao X L. Effect of CFRP properties, on the bond characteristics between steel and CFRP laminate under quasi-static loading[J]. Construction and Building Materials, 2015, 98: 489-501. DOI: 10.1016/j.conbuildmat.2015.08.130

[36] Peng-Da Li, Yao Zhao , Zhong Tao, Cheng Jiang. Nonuniformity in stress transfer across FRP width of FRP-concrete interface. Engineering Structures, 2024, 312: 118236

[37] 伍希志, 任会礼, 钟懿. 基于粘聚力理论的 CFRP 加固钢板剥离机理研究[J]. 固体力学学报, 2015, 36(3): 197-203. WU Xizhi, REN Huili, ZHONG Yi. Theoretical and experimental study on debonding mechanism of steel plate strengthened with CFRP[J]. Chinese journal of solid mechanices, 2015, 36(3): 197-203(in Chinese).

[38] Teng J G, Fernando D, Yu T. Finite element modelling of debonding failures in steel beams flexurally strengthened with CFRP laminates[J]. Engineering Structures, 2015, 86: 213-224. DOI: 10.1016/j.engstruct.2015.01.003

-

目的

钢结构桥梁的损伤问题日益凸显,传统的钢桥维护手段有诸多弊端,CFRP板补强成为颇具发展前景的钢结构加固技术。粘结层厚度不均匀是施工中常见的缺陷问题,该缺陷会导致CFRP-钢粘结传力机制与理想状态下相比有较大偏差,本文利用试验结合有限元两种手段探索粘结层厚度不均匀对CFRP-钢界面粘结性能的影响。

方法开展16个粘结层厚度均匀的双剪试验,得出粘结层厚度为0.5mm时有最大承载力,该厚度为最优粘结层厚度。围绕0.5mm的厚度,开展粘结层厚度沿纵向和横向分布线性不均匀的18个双剪试验,利用应变测试仪和电子万能试验机采集数据,用差分法计算界面剪应力,用数值积分计算界面的滑移值,并对破坏模式、荷载位移曲线、粘结层的应变和应力分布、粘结滑移曲线等试验结果进行分析,基于试验得到的粘结滑移参数建立粘聚力数值模型,二者结合探索粘结层厚度不均匀对CFRP-钢界面粘结性能的影响。

结果试验结果如下:①破坏模式:主要以混合破坏为主,纵向不均匀的试件沿间隙两侧破坏不对称,粘结层脱落不明显。横向不均匀的试件发生CFRP沿纵向撕裂,且沿横向的破坏不对称,粘结层脱落明显,混合破坏程度比纵向不均匀剧烈。②极限承载力:粘结层厚度不均匀对极限承载力产生较大影响,且伴随着不均匀程度增大,极限承载力呈递减趋势,不均匀程度越大,承载力降低越显著。当不均匀程度相同时,横向不均匀的不利影响大于纵向不均匀。③荷载-位移关系:均为近似线性无屈服段的荷载-位移曲线,刚度强化和刚度退化两个阶段不明显,这与粘结剂延性较低有关。粘结层厚度不均匀只影响极限承载力和位移,不影响荷载-位移曲线的形状。④界面应力、应变分布:应力、应变的峰值均出现在近端附近,并由近端向远端递减。纵向不均匀的应力和应变关于近端两侧不对称,横向不均匀的应力和应变在横向上较大的梯度变化,应力分布不均匀是导致承载力降低的主要原因。⑤粘结滑移关系:粘结层厚度不均匀对界面粘结滑移曲线的形状影响不大,均表现为屈服阶段不明显的双线性粘结滑移曲线。只采集CFRP材料中心轴位置处的应变无法得到准确的粘结滑移曲线,需考虑宽度方向上的影响因素。⑥有限元模拟:数值模拟分析与试验结果相吻合,解释了粘结层厚度不均匀下CFRP-钢界面的粘结传力机理。

结论在工程应用中,针对该种粘结剂,最佳粘贴厚度为0.5mm。粘结层厚度不均匀对CFRP-钢界面粘结性能的不利影响较大,粘结界面应力分布不均匀是承载力降低的主要原因,不均匀程度越大,粘结界面的承载力降低越明显。横向不均匀的不利影响大于纵向不均匀,在施工过程中应尽量避免粘结层厚度沿CFRP板横向分布不均匀。在加载过程中CFRP的应变伴随着材料的不均匀变形会沿宽度方向发生变化,建议将CFRP沿宽度方向上的影响因素考虑到粘结滑移曲线中。

-

CFRP因其轻质高强等优点被广泛应用于钢结构加固领域,该加固系统的薄弱部位常出现在粘结层,其中粘结层厚度不均匀对界面的粘结性能影响较大。现有的试验研究和数值分析均是在粘结层厚度均匀、粘结情况良好的条件下进行的,这与实际的施工情况相差较远,针对粘结层厚度不均匀对CFRP-钢界面粘结性能的影响还有较大的研究空间,仍需做进一步的探索。

本文先以粘结层厚度均匀的双剪试验确定粘结层最优厚度为0.5mm,接着围绕最优厚度做了两个厚度不均匀方向的双剪试验,并基于试验参数建立数值模型,结合两种手段对比分析粘结层厚度不均匀对承载力、应力、应变及粘结滑移曲线关系的影响。结果表明:粘结层厚度不均匀对承载力影响较大,随着粘结层厚度不均匀程度的增加,对承载力的不利影响愈发显著,且横向不均匀的不利影响明显大于纵向不均匀。与粘结层厚度均匀的情况相比,在粘结层厚度纵向不均匀的条件下,近端两侧的应力、应变及粘结层破坏模式均出现不对称现象,粘结层厚度横向不均匀条件下,横向上应力、应变则有明显的梯度变化。

粘结层厚度均匀(a)和粘结层厚度不均匀程度(b)下承载力的对比

下载:

下载: