Freeze-thaw damage characteristics and evolution law of foam concrete based on acoustic emission-digital image correlation technique

-

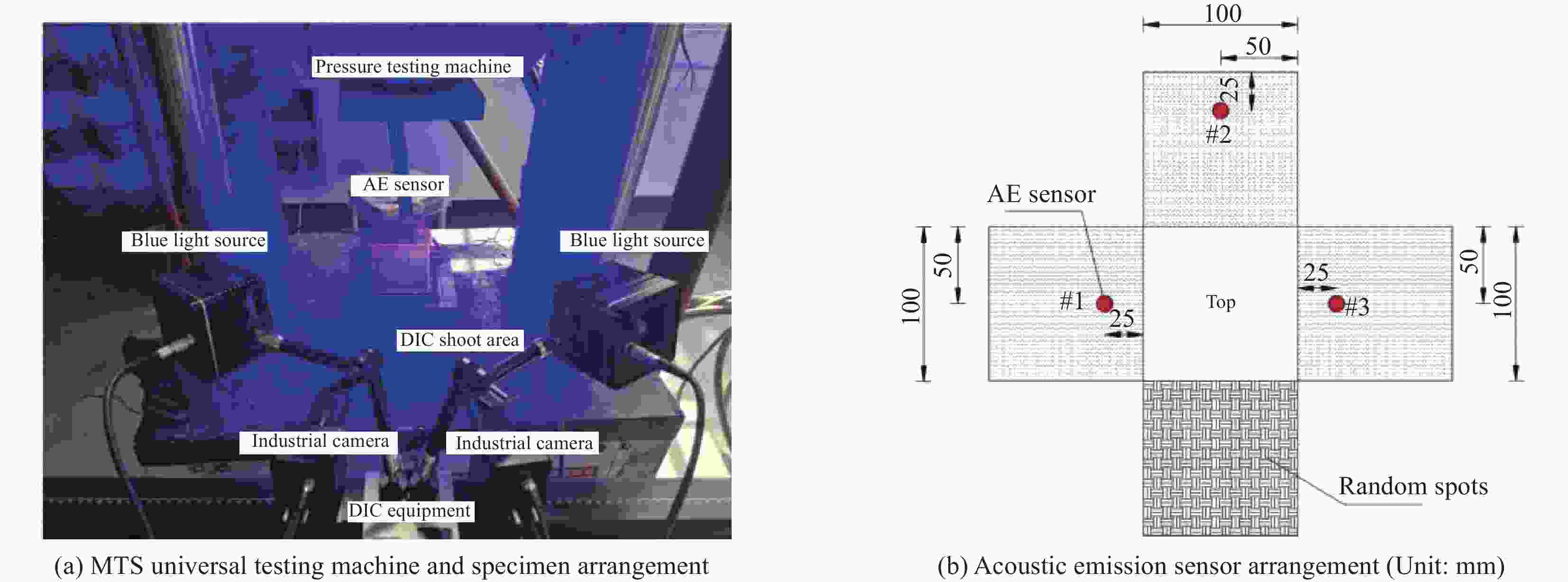

摘要: 为研究冻融环境下泡沫混凝土压缩破坏特征及损伤演化规律,对密度为800 kg/m3的泡沫混凝土开展了单轴压缩-声发射(AE)-数字图像相关(DIC)技术联合测试试验,获取了泡沫混凝土加载过程中的应变演化云图以及声发射参数变化特征。结果表明:泡沫混凝土的压缩破坏过程曲线呈现明显的阶段效应,且试件经历的冻融循环次数越多,延性破坏特征越明显;随着冻融循环次数的增加,DIC监测到试件应变集中带面积逐渐递增,应变场均值逐渐下降,同时,试件表面裂缝的形态由最初的垂直型单一裂缝向倾斜的剪切型多裂缝演变;冻融为0、20、40、60和80次的泡沫混凝土试件最终破坏时剪切裂缝所占比例分别为52.5%、57.8%、59.2%、65.3%和69.2%,声发射b值下降阶段分别出现在加载进程的92.3%、89.1%、88.5%、76.5%和72.3%;冻融环境可以促进泡沫混凝土由拉伸破坏向剪切破坏的转变,加剧泡沫混凝土内部损伤,从而在材料内部诱发大尺度破裂现象; AE和DIC的结果相辅相成,它们的结合有助于全面了解泡沫混凝土中微裂缝的发展规律和损伤破坏机制。Abstract: To study the compression damage characteristics and damage evolution law of foam concrete under a freeze-thaw environment, a joint test combining uniaxial compression, acoustic emission (AE), and digital image correlation (DIC) technology was carried out on foam concrete with a density of 800 kg/m3. The strain evolution cloud diagram and acoustic emission parameter change characteristics of the foam concrete during the loading process were obtained. The results show that the compression damage process curve of foam concrete presents an obvious staged effect. The more freeze-thaw cycles the specimen experiences, the more pronounced the ductile damage characteristics become. With the increase in the number of freeze-thaw cycles, the area of the strain concentration zone of the specimen monitored by the DIC gradually increases, while the average value of the strain field gradually decreases. Meanwhile, the morphology of surface cracks in the specimen evolves from initial vertical single cracks to tilted shear-type multi-fractures. The proportion of shear cracks in the final damage of foam concrete specimens with 0, 20, 40, 60, and 80 freeze-thaw cycles are 52.5%, 57.8%, 59.2%, 65.3%, and 69.2%, respectively. The stages of decreasing acoustic emission b-value appear in 92.3%, 89.1%, 88.5%, 76.5%, and 72.3% of the loading process, respectively. The freeze-thaw environment can promote the transition from tensile to shear damage in foam concrete, exacerbates the internal damage of foam concrete, and thus induces large-scale rupture phenomena within the material. The results of AE and DIC complement each other, and their combination contributes to a comprehensive understanding of the developmental pattern of microcracks and damage mechanisms in foam concrete.

-

表 1 不同冻融循环次数下A08试样平静段-陡增段分界点特征参数

Table 1. Characteristic parameters of the boundary between the quiet stage and the steep increase stage of A08 specimen under different freeze-thaw cycles

Freeze-thaw cycles Breakpoint load/kN Peak load /kN Relative peak load 0 29.88 31.33 0.95 20 21.82 24.24 0.90 40 17.81 20.24 0.88 60 12.15 14.47 0.84 80 7.16 9.30 0.75 Note: Relative peak load = Breakpoint load/Peak load. -

[1] 王小娟, 崔浩儒, 周宏元, 等. 玄武岩纤维增强泡沫混凝土的单轴拉伸及准静态压缩性能[J]. 复合材料学报, 2023, 40(3): 1569-1585.WANG Xiaojuan, CUI Haoru, ZHOU Hongyuan, et al. Uniaxial tensile and quasi-static compressive properties of basalt fiber reinforced foam concrete[J]. Journal of Composite Materials, 2023, 40(3): 1569-1585(in Chinese). [2] SHI X N, HUANG J J, SU Q. Experimental and numerical analyses of lightweight foamed concrete as filler for widening embankment[J]. Construction and Building Materials, 2020, 250: 11889 [3] 刘鑫, 姚云龙, 张思卿, 等. 浇筑期温度对泡沫混凝土性能和微孔结构的影响[J/OL]. 西南交通大学学报: 1-10.LIU Xin, YAO Yunlong, ZHANG Siqing, et al. Influence of temperature on the performance and microporous structure of foamed concrete during the pouring period [J/OL]. Journal of Southwest Jiaotong University: 1-10(in Chinese). [4] 苏步云. 泡沫混凝土力学性能及其弹塑性损伤本构研究[D]. 太原理工大学, 2017.SU Buyun. Mechanical properties of foam concrete and its elastic-plastic damage intrinsic study [D]. Taiyuan University of Technology, 2017(in Chinese). [5] 尚帅旗, 李丹, 陈星明, 等. 泡沫混凝土的单轴抗压力学特性研究[J]. 武汉理工大学学报, 2012, 34(12): 24-29. doi: 10.3963/j.issn.1671-4431.2012.12.006SHANG Shuaiqi, LI Dan, CHEN Xingming, et al. Uniaxial compressive properties of foam concrete[J]. Journal of Wuhan University of Technology, 2012, 34(12): 24-29(in Chinese). doi: 10.3963/j.issn.1671-4431.2012.12.006 [6] 周宏元, 王业斌, 王小娟, 等. 泡沫混凝土压缩性能尺寸效应研究[J]. 材料导报, 2021, 35(18): 18076-18082+18095. doi: 10.11896/cldb.20090009ZHOU Hongyuan, WANG Yebin, WANG Xiaojuan, et al. Size effect of foam concrete subjected to quasi-static compression[J]. Materials Reports, 2021, 35(18): 18076-18082+18095(in Chinese). doi: 10.11896/cldb.20090009 [7] 袁志颖, 陈波, 陈家林, 等. 泡沫混凝土孔结构表征及其对力学性能的影响[J]. 复合材料学报, 2023, 40(7): 4117-4127.YUAN Zhiying, CHEN Bo, CHEN Jialin, et al. Characterization of pore structure of foamed concrete and its influenceon performance[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 4117-4127(in Chinese). [8] 李升涛, 陈徐东, 张锦华, 等. 不同密度等级泡沫混凝土的单轴压缩破坏特征[J]. 建筑材料学报, 2021, 24(6): 1146-1153. doi: 10.3969/j.issn.1007-9629.2021.06.004LI Shengtao, CHEN Xudong, ZHANG Jinhua, et al. Failure Characteristics of Foam Concrete with Different Density under Uniaxial Compression[J]. Journal of Building Materials, 2021, 24(6): 1146-1153(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.06.004 [9] Chao S, Yu Z, Jian G, et al. Effects of foaming agent type on the workability, drying shrinkage, frost resistance and pore distribution of foamed concrete[J]. Construction and Building Materials, 2018, 186: 833-839. [10] Bayraktar O Y, Soylemez H, Kaplan G, et al. Effect of cement dosage and waste tire rubber on the mechanical, transport and abrasion characteristics of foam concretes subjected to H2SO4 and freeze-thaw[J]. Construction and Building Materials, 2021, 302. [11] 高志涵, 陈波, 陈家林, 等. 冻融环境下泡沫混凝土的孔结构与力学性能[J]. 复合材料学报, 2024, 41(2): 827-838.GAO Zhihan, CHEN Bo, CHEN Jialin, et al. Pore structure and mechanical properties of foam concrete under freeze-thaw environment[J]. Journal of Composite Materials, 2024, 41(2): 827-838(in Chinese). [12] 叶林杰, 夏新华, 吴迪高, 等. 基于冻融循环和疲劳荷载共同作用下泡沫混凝土的微观力学性能研究[J]. 混凝土, 2022, (9): 56-61.YE Linjie, XIA Xinhua, WU Di Gao, et al. Study on the micromechanical properties of foam concrete based on the combined effect of freeze-thaw cycle and fatigue loading[J]. Concrete, 2022, (9): 56-61(in Chinese). [13] 段力群, 董璐, 马林建, 等. 泡沫混凝土单轴压缩下声发射特征试验研究[J]. 中国矿业大学学报, 2018, 47(4): 742-747.DUAN Liqun, DONG Lu, MA Linjian, et al. Experimental study on acoustic emission characteristics of foam concrete under uniaxial compression[J]. Journal of China University of Mining & Technology, 2018, 47(4): 742-747(in Chinese). [14] 郭玉柱, 陈徐东, 胡良鹏, 等. 花岗岩-喷射混凝土梁损伤的声发射可视化表征[J]. 哈尔滨工业大学学报, 2022, 54(8): 90-99. doi: 10.11918/202106018GUO Yuzhu, CHEN Xudong, HU Liangpeng, et al. Visualized characterization of damagein granite-shotcrete beams based on acoustic emission[J]. Journal of Harbin Institute of Technology, 2022, 54(8): 90-99(in Chinese). doi: 10.11918/202106018 [15] 张伟光, 钟靖涛, 于建新, 等. 基于机器学习和图像处理的路面裂缝检测技术研究[J]. 中南大学学报: 自然科学版, 2021, 52(7): 2402-2415. ZHANG Weiguang, ZHONG Jingtao, YU Jianxin, et al. Research on pavement crack detection technology based on convolution neural network[J]. Journal of Central South University: Science and Technology, 2021, 52(7): 2402 – 2415. (in Chinese). [16] 许颖, 樊悦, 王青原, 等. 基于DIC的聚丙烯纤维增强混凝土断裂过程分析[J]. 华中科技大学学报(自然科学版), 2024, 52(02): 103-111.XU Ying, FAN Yue, WANG Qingyuan, et al. Fracture process analysis of polypropylene fiber reinforced concrete based on DIC[J]. Huazhong Univ. of Sci. & Tech. (Natural Science Edition) 2024, 52(02): 103-111 (in Chinese). [17] 中华人民共和国住房和城乡建设部. 泡沫混凝土: JG/T266−2011[S]. 北京: 中国标准出版社, 2011.Ministry of Housing and Urban-Rural Development, People's Republic of China. Foam concrete [S]. Beijing: China Standard Press, 2011(in Chinese). [18] 中华人民共和国水利部. 水工混凝土试验规程: SL/T 352-2020[S]. 北京: 中国标准出版社, 2020Ministry of Water Resources, PRC. Test procedure for hydraulic concrete: SL/T 352-2020 [S]. Beijing: China Standard Press, 2020(in Chinese). [19] 苏占东, 孙进忠, 夏京, 等. 冻融循环对花岗岩声发射特性影响的试验研究[J]. 岩石力学与工程学报, 2019, 38(5): 865-874.SU Zhandong, SUN Jinzhong, XIA Jing, et al. Experimental study on the effect of freeze-thaw cycles on the acoustic emission properties of granite[J]. Journal of Rock Mechanics and Engineering, 2019, 38(5): 865-874(in Chinese). [20] 刘慧, 蔺江昊, 杨更社, 等. 冻融循环作用下砂岩受拉损伤特性的声发射试验[J]. 采矿与安全工程学报, 2021, 38(4): 830-839.LIU Hui, LIN Jianghao, YANG Gengshe, et al. Acoustic emission test on tensile damage characteristics of sandstone under freeze-thaw cycle[J]. Journal of Mining and Safety Engineering, 2021, 38(4): 830-839(in Chinese). [21] 宋彦琦, 马宏发, 刘济琛, 等. 冻融灰岩单轴声发射损伤特性试验研究[J]. 岩石力学与工程学报, 2022, 41(S1): 2603-2614.SONG Yanqi, MA Hongfa, LIU Jichen, et al. Uniaxial acoustic emission damage characterization of freeze-thawed chert[J]. Journal of Rock Mechanics and Engineering, 2022, 41(S1): 2603-2614(in Chinese). [22] Choi W C, Yun H D. Acoustic emission activity of CFRP-strengthened reinforced concrete beams after freeze-thaw cycling[J]. Cold Regions Science and Technology, 2015, 110: 47-58. doi: 10.1016/j.coldregions.2014.11.004 [23] Qiu J, Pan D, Guan X, et al. Acoustic emission characteristics of compression damage of coal gangue concrete after freeze-thaw cycles[J]. Journal of Building Materials, 2018, 21(2): 196-201. [24] 陈波, 陈家林, 强晟, 等. 冻融环境下泡沫混凝土声发射试验研究[J]. 华中科技大学学报(自然科学版), 2023, 51(08): 41-46.CHEN Bo, CHEN Jialin, QIANG Sheng, et al. Acoustic emission test study of vaporized concrete under freeze-thaw environment[J] Huazhong Univ. of Sci. & Tech. (Natural Science Edition) 2023, 51(08): 41-46(in Chinese). [25] Zhou X, Yang Y, Li X, et al. Acoustic emission characterization of the fracture process in steel fiber reinforced concrete[J]. Computers and Concrete, 2016, 18(4): 923-936. [26] 李京军, 闫珺, 牛建刚. 冻融作用对自密实轻骨料混凝土声发射特性影响[J]. 工程力学, 2022, 39(9): 133-140+169. doi: 10.6052/j.issn.1000-4750.2021.05.0373LI Jingjun, YAN Jun, NIU Jianguang. Effect of freezing and thawing on acoustic emission characteristics of self-compacting lightweight aggregate concrete[J]. Engineering Mechanics, 2022, 39(9): 133-140+169(in Chinese). doi: 10.6052/j.issn.1000-4750.2021.05.0373 [27] 刘伟琪, 陈波, 陈家林. 基于声发射的泡沫混凝土受压损伤特性试验研究[J]. 水利水电科技进展, 2023, 43(1): 50-55+62. doi: 10.3880/j.issn.1006-7647.2023.01.008LIU Weiqi, CHEN Bo, CHEN Jialin. Experimental study on compressive damage characteristics of autoclaved concrete based on acoustic emission[J]. Progress of Water Resources and Hydropower Science and Technology, 2023, 43(1): 50-55+62(in Chinese). doi: 10.3880/j.issn.1006-7647.2023.01.008 [28] 甘一雄, 吴顺川, 任义, 等. 基于声发射上升时间/振幅与平均频率值的花岗岩劈裂破坏评价指标研究[J]. 岩土力学, 2020, 41(7): 2324-2332GAN Yixiong, WU Shunchuan, REN Yi, et al. Research on the evaluation index of granite splitting damage based on acoustic emission rise time/amplitude and average frequency value[J]. Geotechnics, 2020, 41(7): 2324-2332(in Chinese). [29] 宋勇军, 程柯岩, 孟凡栋. 冻融作用下裂隙岩石损伤破坏声发射特性研究[J]. 采矿与安全工程学, 2023, 40(2): 408-419.SONG Yongjun, CHENG Keyan, MENG Fandong. Acoustic emission characterization of fractured rock damage under freeze-thaw[J]. Journal of Mining and Safety Engineering, 2023, 40(2): 408-419(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 31

- HTML全文浏览量: 19

- 被引次数: 0

下载:

下载: