Effect of graphene-oxide coated sand on the properties of cement mortar

-

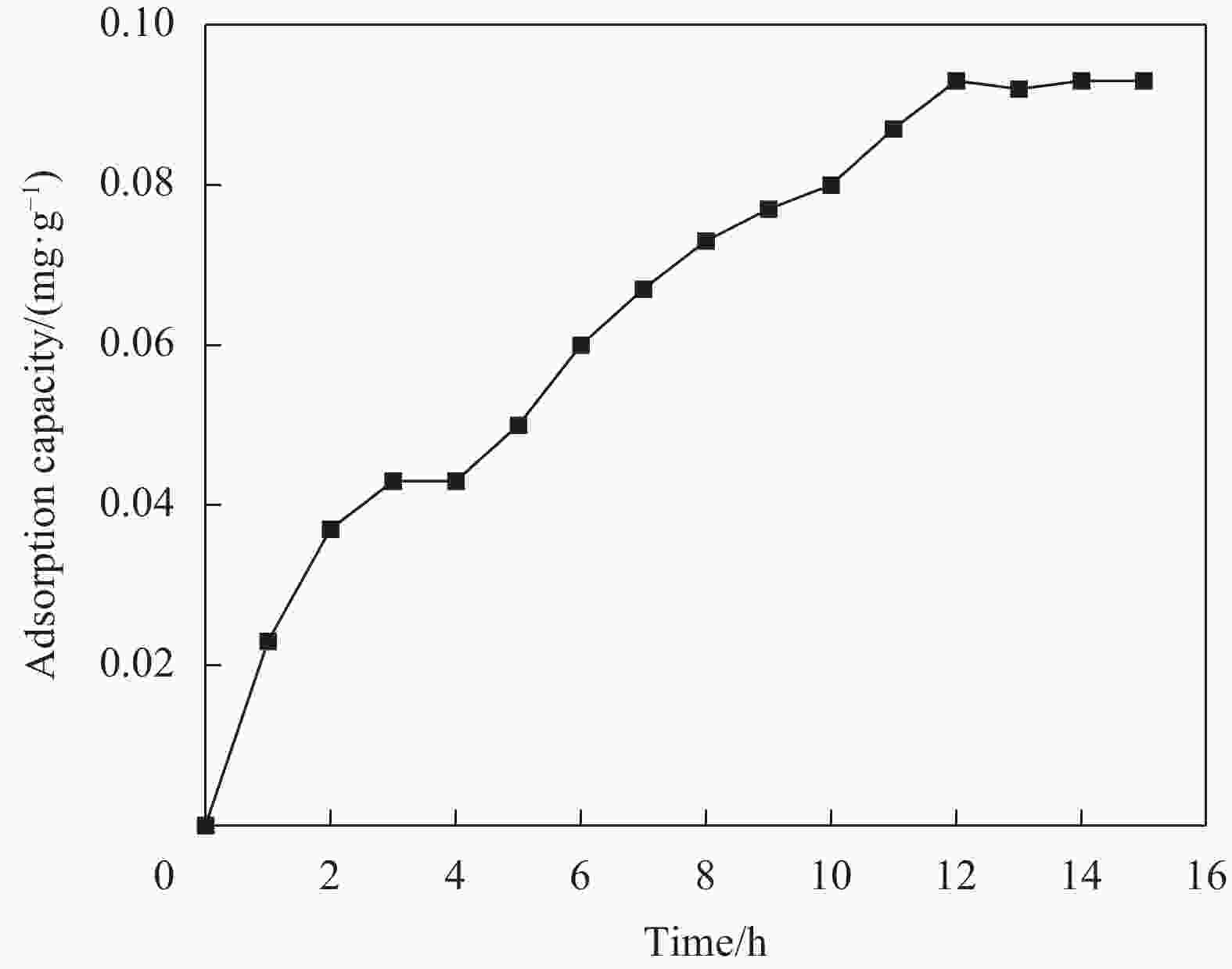

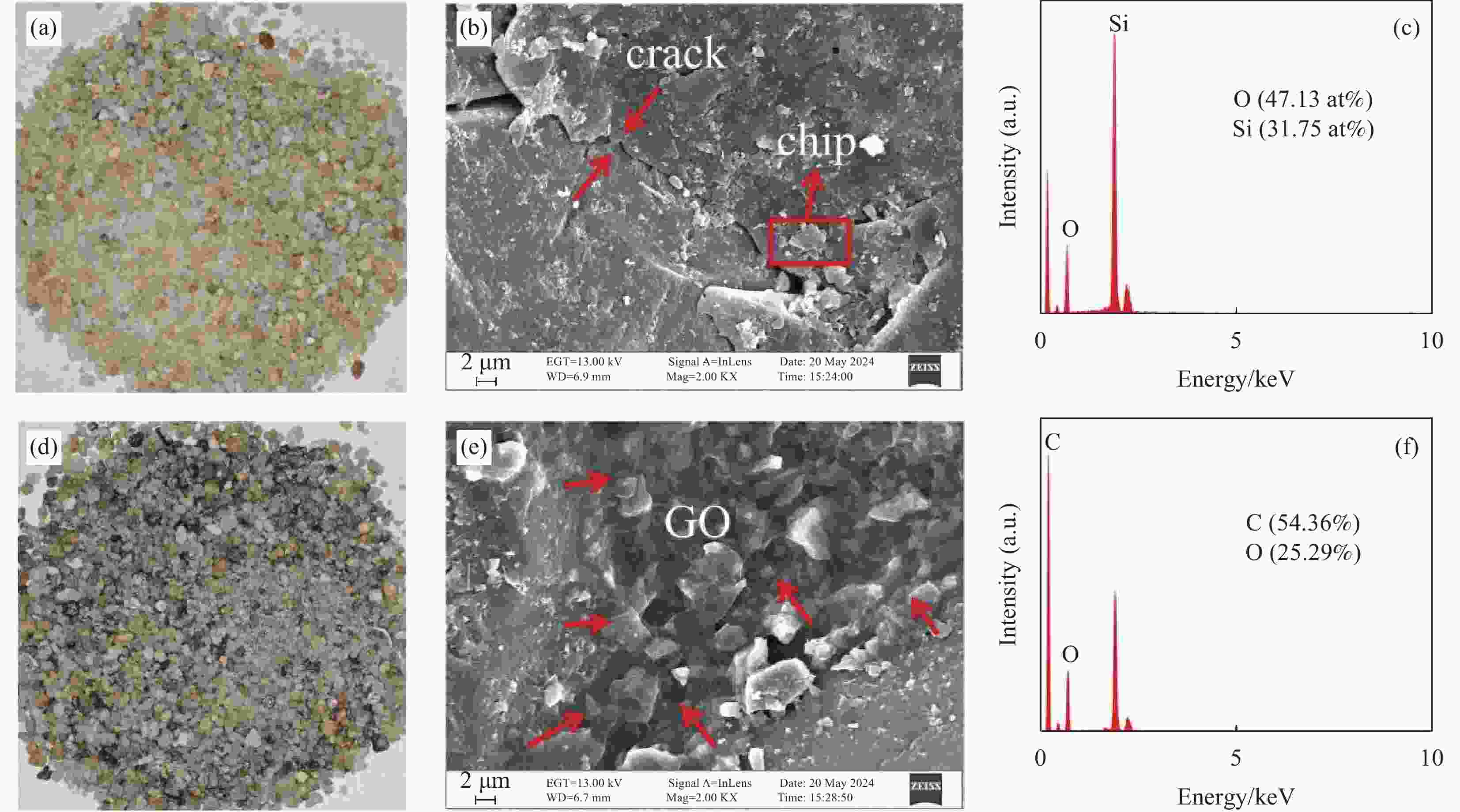

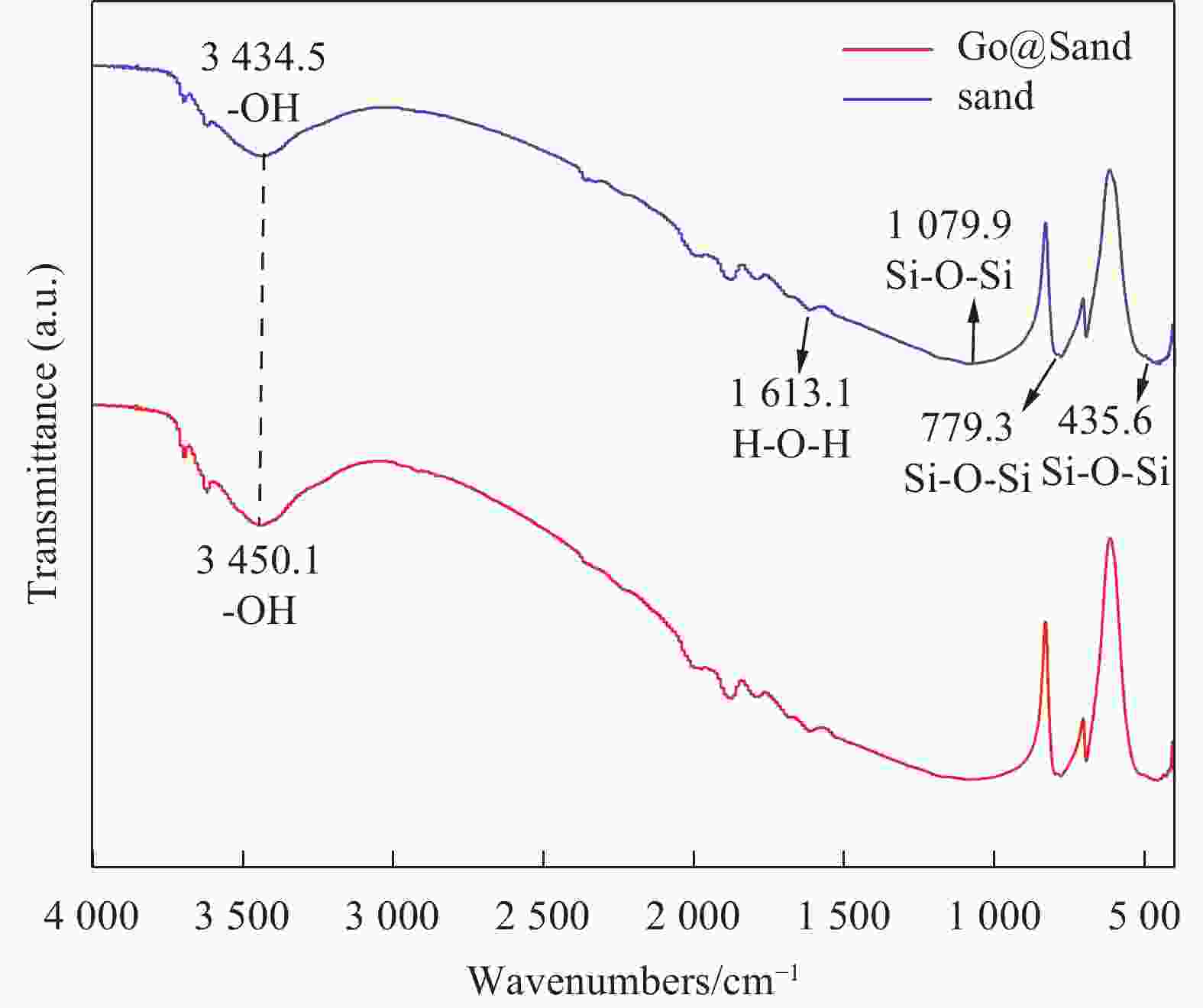

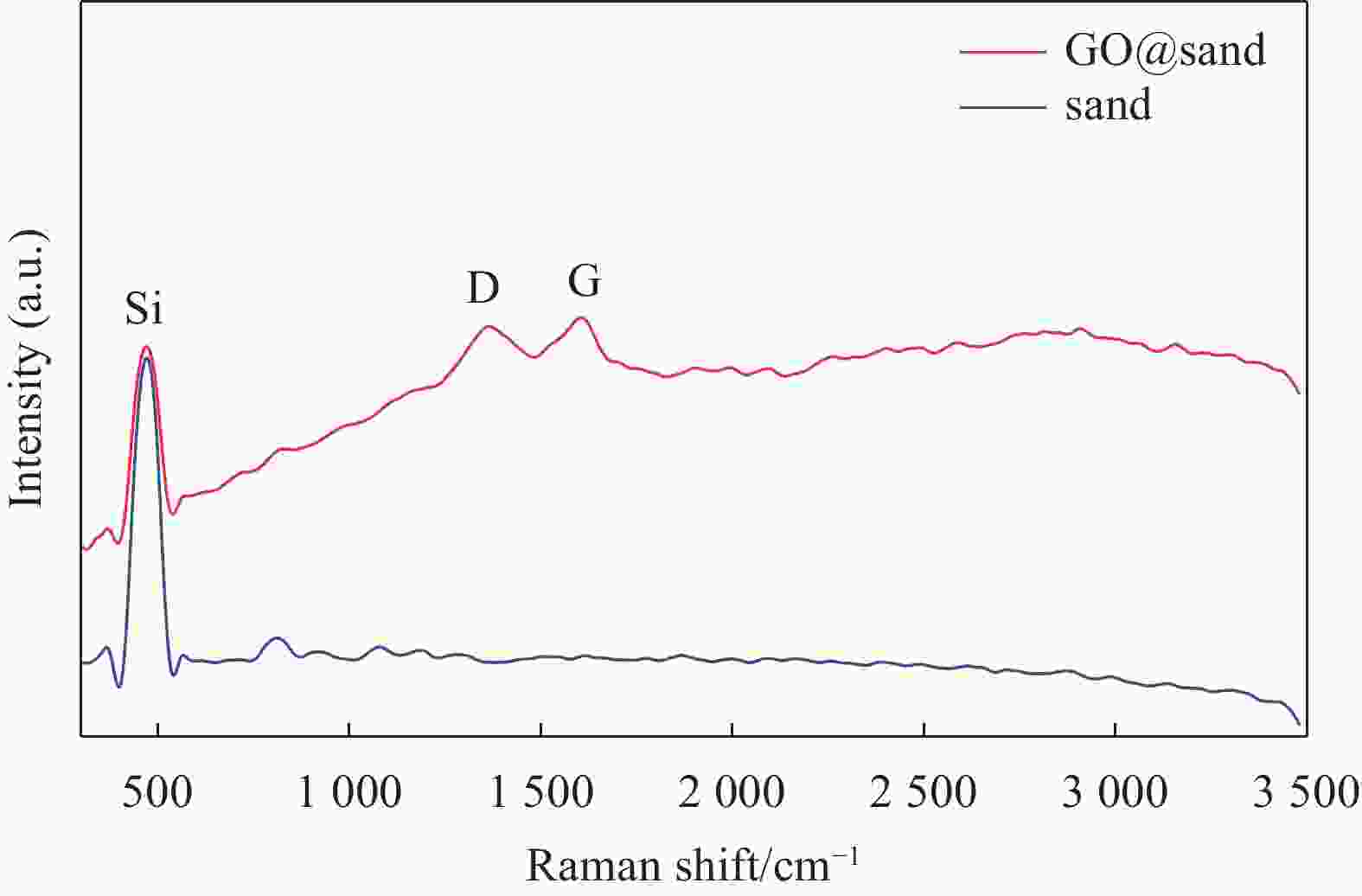

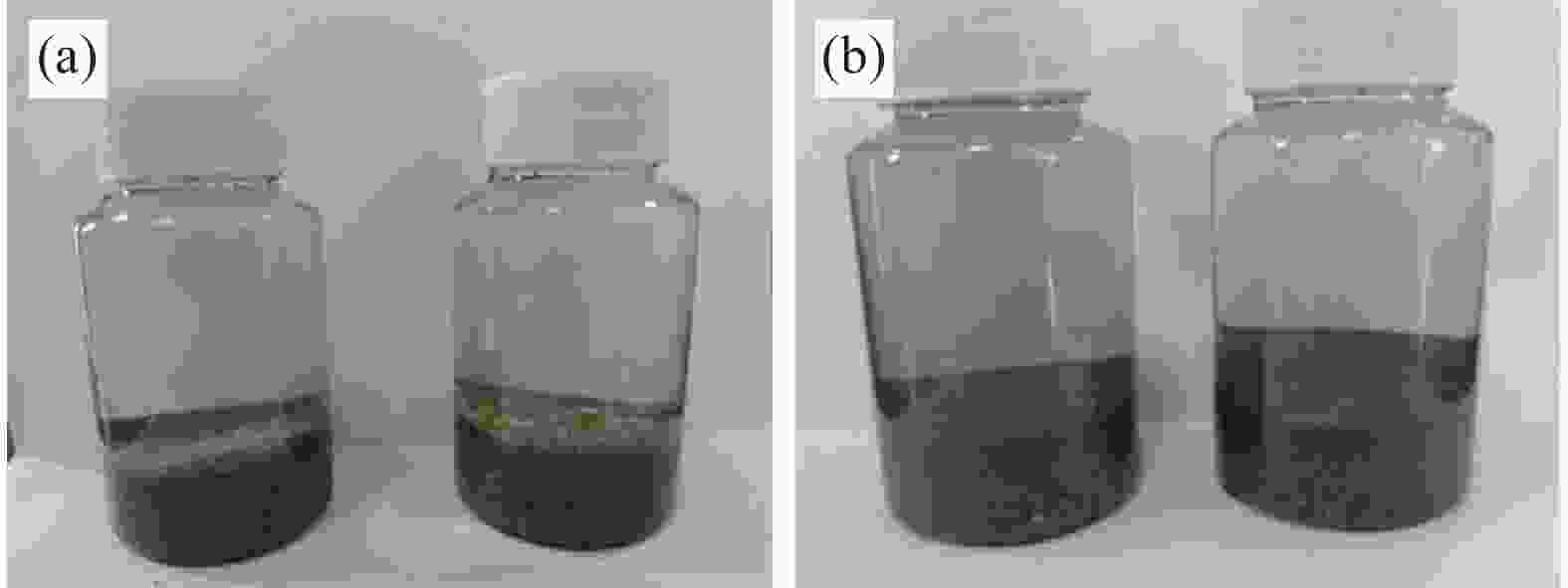

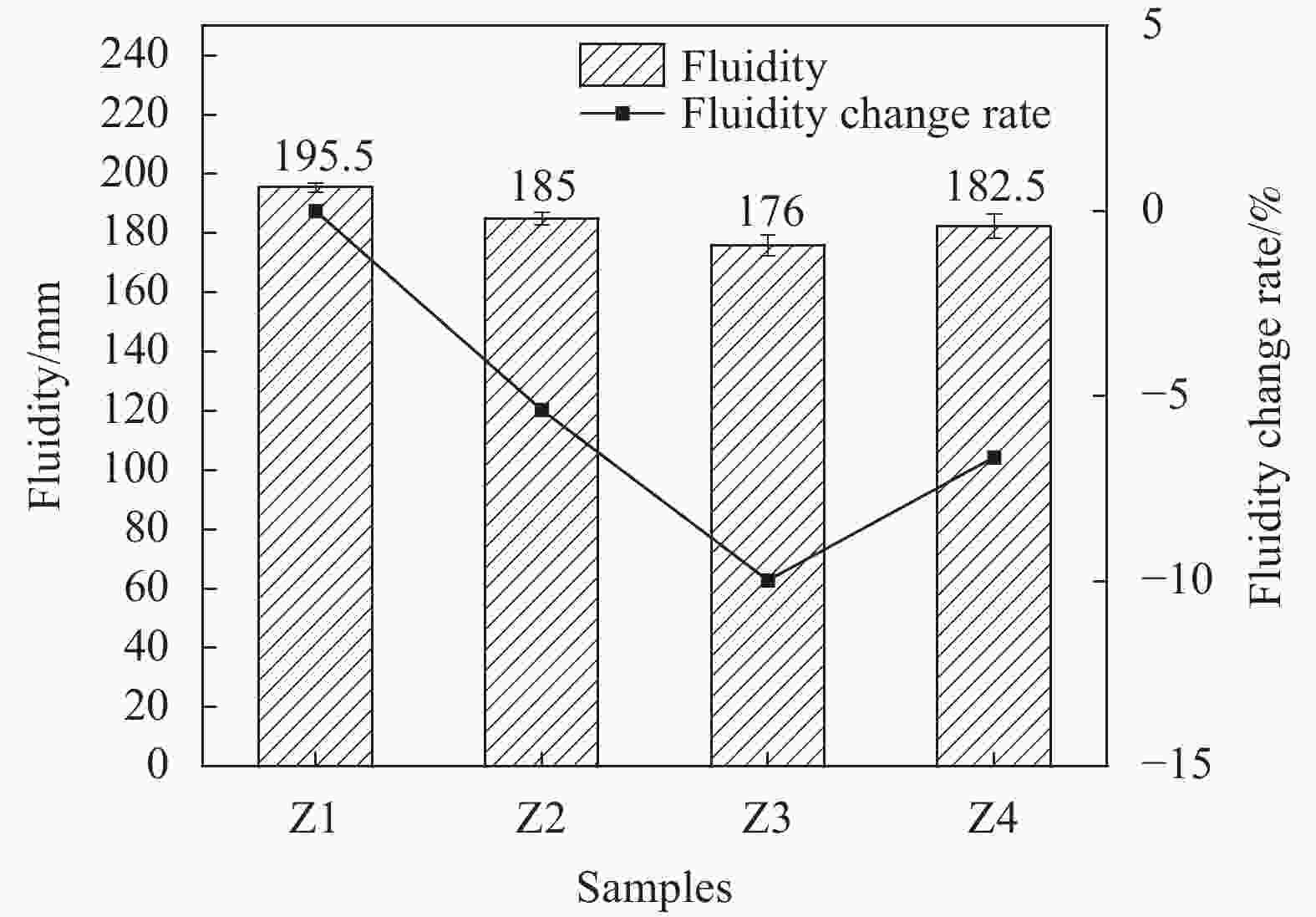

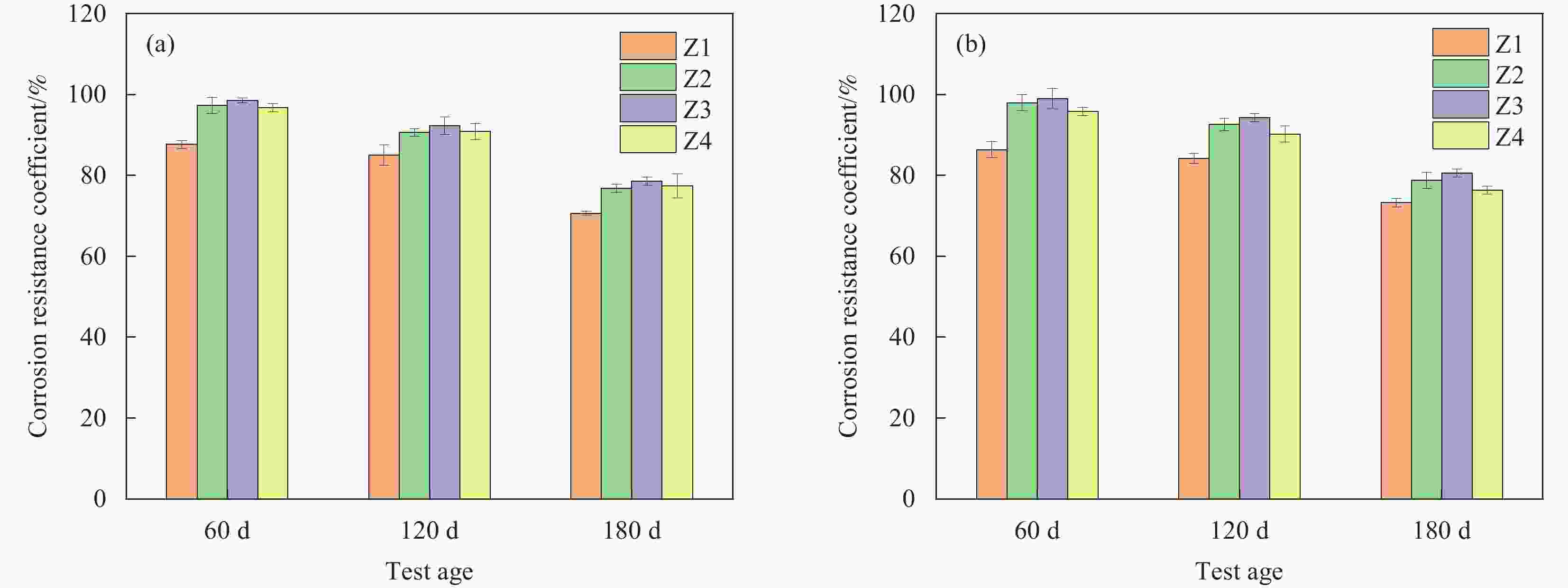

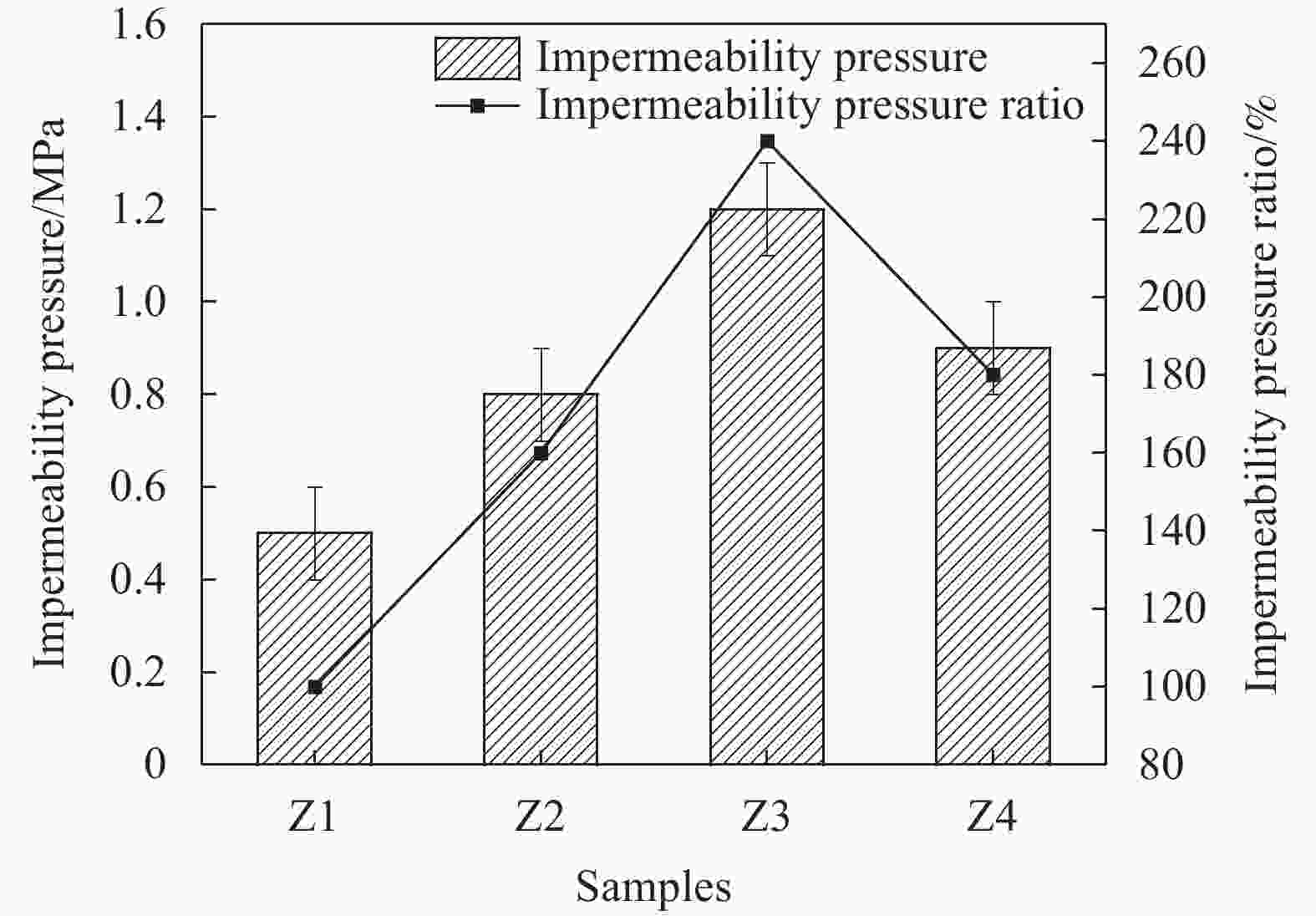

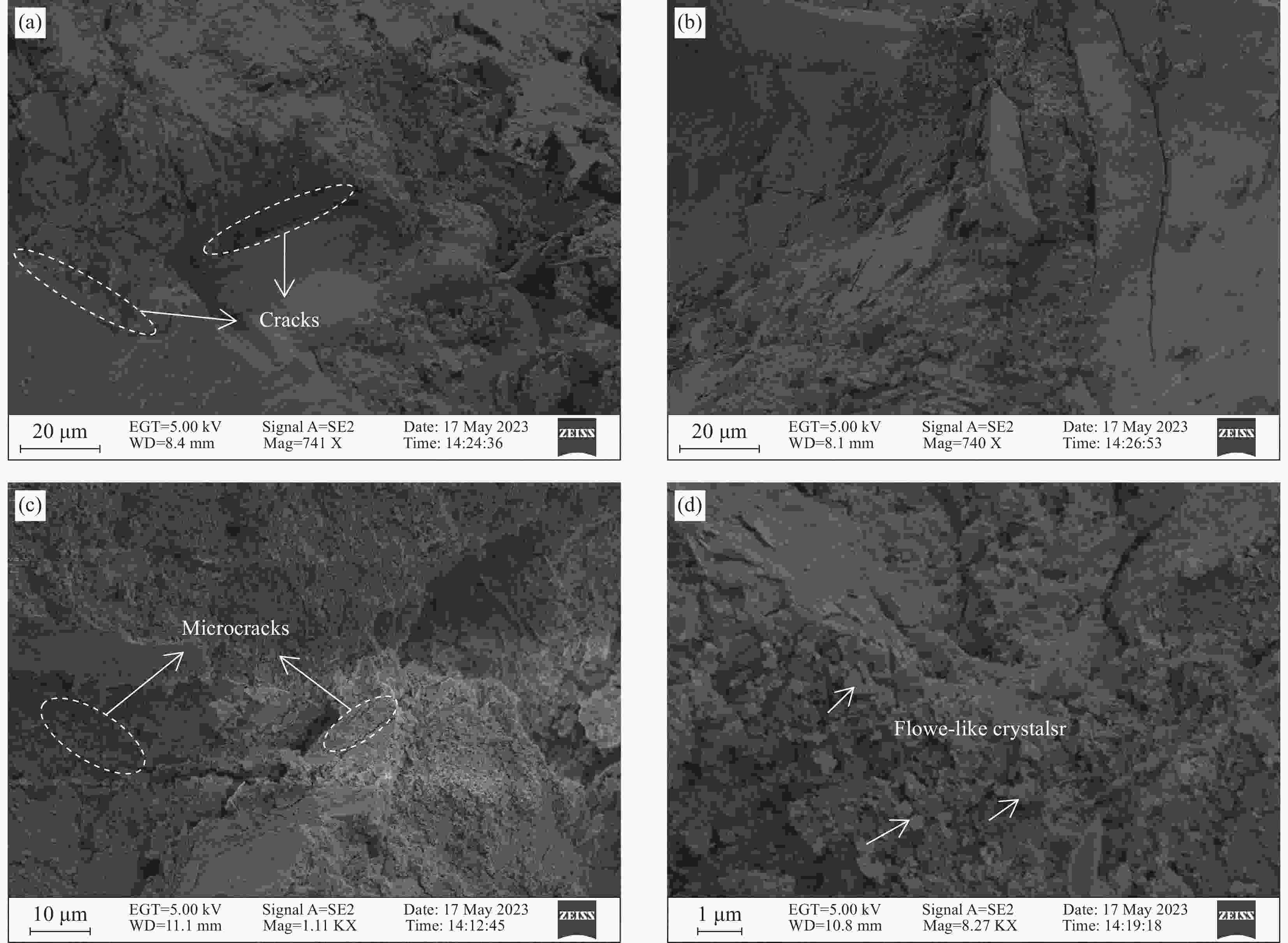

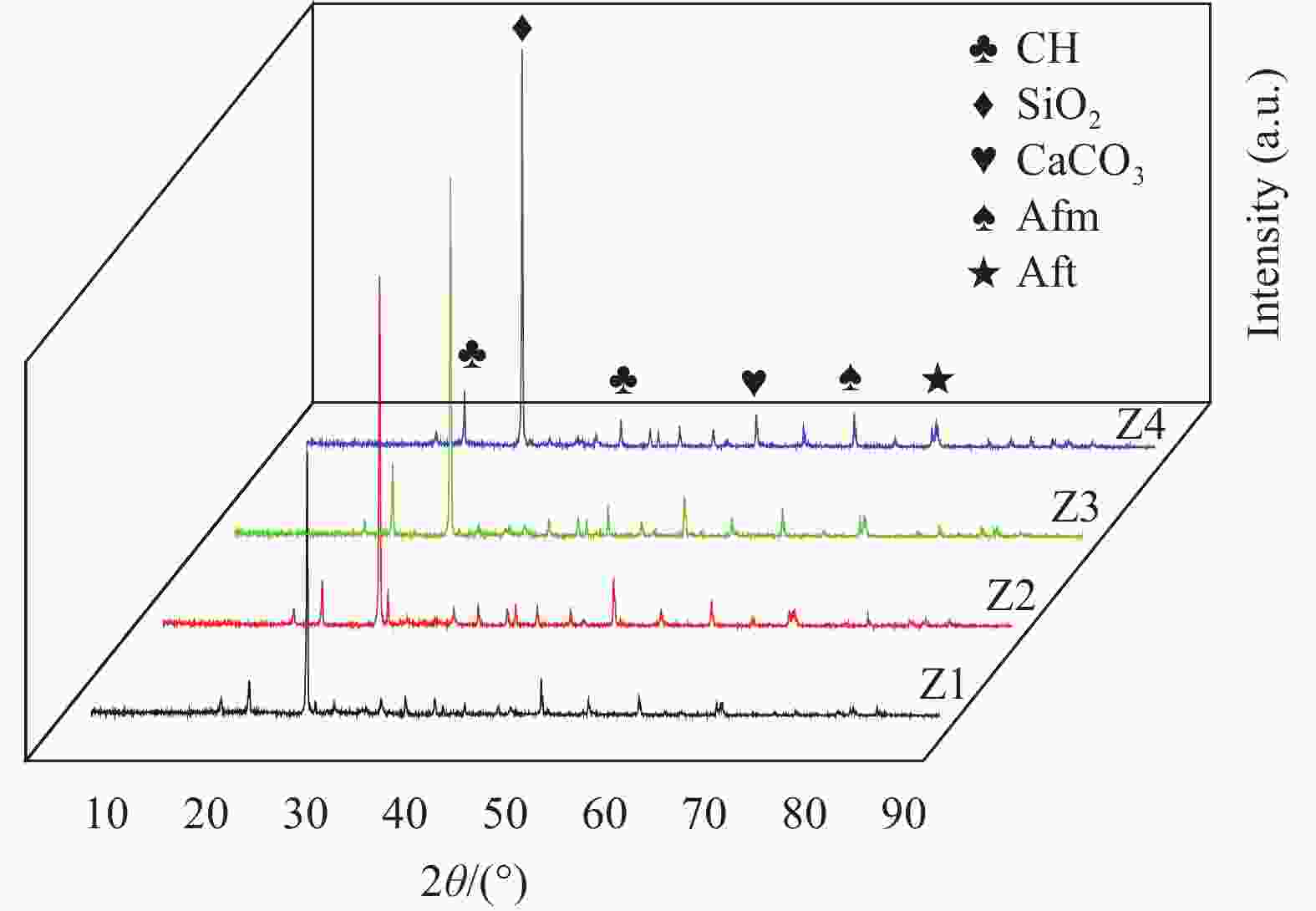

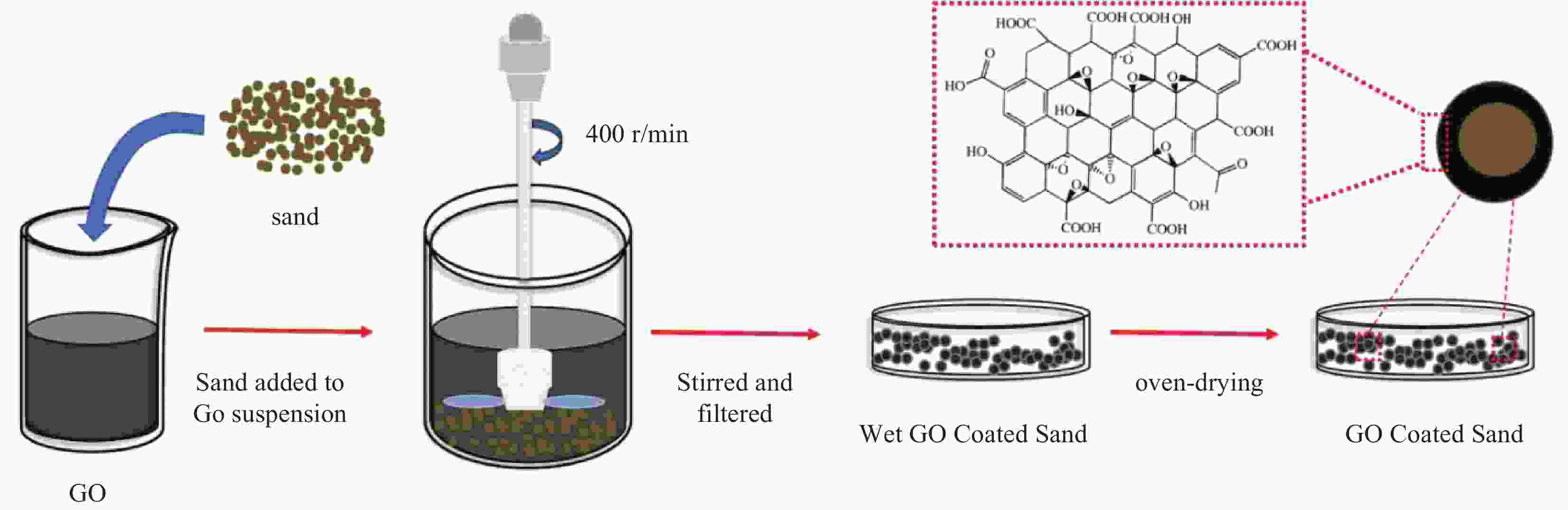

摘要: 界面过渡区(ITZ)是水泥基材料中最为薄弱的部分,对水泥砂浆和混凝土的力学性能和耐久性有决定性的作用。本研究通过将氧化石墨烯(GO)附着在砂粒表面,探究GO包覆砂(GO@sand)对水泥砂浆性能的影响。结果表明,砂在GO悬浮液中搅拌12 h后,GO吸附量达到最大值0.093 mg/g;当GO掺量为0.024%时,可以显著改善水泥砂浆的力学性能和耐久性能,相比基准试件,3d抗压强度和抗折强度分别提高了31.12%、23.21%;28 d抗压强度和抗折强度也提高了11.76%、17.65%;砂浆抗渗压力提高了140%,抗硫酸盐侵蚀性能也有较大提升。通过对硬化后的水泥砂浆试块的XRD和SEM测试结果分析,表明吸附在砂表面的GO能加速ITZ区域的水泥水化进程、提高水化产物含量,增强ITZ的密实度,抑制微裂纹的扩展,从而增强水泥砂浆的力学性能和耐久性能。本文提供了一种GO@sand的方法来提升水泥砂浆的性能,凸显了GO@sand对ITZ纳米工程的有效性,可推广到其他水泥基材料。Abstract: The interface transition zone (ITZ) is the weakest part in cement-based materials and plays a decisive role in the mechanical properties and durability of cement mortar and concrete. This study explored the impact of graphene oxide coated sand (GO@sand) on the performance of cement mortar by attaching graphene oxide to the surface of sand particles. The results indicate that after stirring the sand in a GO suspension for 12 hours, the amount of GO adsorbed by the sand reaches the maximum value of 0.093 mg/g; When the dosage of GO is 0.024%, it significantly improves the mechanical and durability properties of the cement mortar, Compared to the control specimens, the 3-day compressive strength and flexural strength increase by 31.12% and 23.21%, respectively; the 28-day compressive strength and flexural strength also increase by 11.76% and 17.65%, respectively; the mortar's resistance to permeation is enhanced by 140%, and the resistance to sulfate erosion also shows a significant improvement. The analysis of the XRD and SEM test results from the hardened cement mortar specimens indicates that the GO adsorbed on the surface of the sand has accelerated the hydration process in the ITZ, increased the content of hydration products, enhanced the compactness of the ITZ, and inhibited the propagation of micro-cracks, thereby enhancing the mechanical properties and durability of the cement mortar. This paper provides a method for enhancing the performance of cement mortar using GO@sand, highlighting the effectiveness of GO@sand in ITZ nano-engineering, and indicating that this approach can be extended to other cement-based materials.

-

Key words:

- grapheme oxide /

- cement mortar /

- mechanical properties /

- durability /

- interface transition zone

-

表 1 水泥的物理性能

Table 1. Physical properties of cement

Stability/mm Fineness/% Density/(g·mm−3) Specific Surface

Area/(m2·kg−1)Standard

Consistency/%Coagulation Time /min Initial coagulation Final coagulation 0.50 0.60 3.15 350 25.60 132 198 表 2 水泥化学成分

Table 2. Chemical composition of cement

Mineral Al2O3 SiO2 Fe2O3 CaO MgO SO3 NaO f-CaO C3S C2S C3A C4AF Content/wt% 4.47 21.5 3.37 65.84 3.18 0.3 0.49 0.78 58.92 20.19 8.12 8.21 Note: f-CaO−Free calcium oxide. 表 3 GO@sand改性水泥砂浆配合比

Table 3. Mix ratio of GO@sand modified cement mortar

Sample① Cement/g PCE/g Water/g Sand/g GO②/% Z1(0 h-GO@sand) 450 1.5 171 1350 g0 Z2(5 h-GO@sand) 450 1.5 171 1350 g0.015 Z3(10 h-GO@sand) 450 1.5 171 1350 g0.024 Z4(15 h-GO@sand) 450 1.5 171 1350 g0.028 Notes: ①—Cement mortar specimens prepared by substituting standard sand with xh-GO@sand(stirred for x hours of GO@sand); ②—Dosage of GO was calculated as the weight percentage of the cement. 表 4 GO@sand对水泥砂浆抗折抗压强度影响

Table 4. Effect of GO@sand on flexural and compressive strength of cement mortar

Sample Flexural strength (MPa)/growth rate (%) Compressive strength (MPa)/growth rate (%) 3 d 28 d 3 d 28 d Z1 5.6/0 6.8/0 34.7/0 42.5/0 Z2 6.7/19.64 7.8/14.71 41.7/20.21 43.7/2.82 Z3 6.9/23.21 8/17.65 45.5/31.12 47.5/11.76 Z4 6.6/17.86 7.3/7.35 45.4/30.84 46.2/8.71 表 5 GO改性砂浆28 d抗压抗折强度的文献比较分析

Table 5. Comparative literature analysis of 28 d compressive and flexural strength of GO modified mortar

-

[1] 李少飞, 魏智强, 乔宏霞, 等. 纳米氧化石墨烯与聚合物改性水泥基复合材料性能研究进展[J]. 材料导报, 2024: 1–22.LI Shaofei, WEI Zhiqiang, QIAO Hongxia, et al. Research progress on properties of polymer cement-based composites modified by nano-graphene oxide[J]. Materials Review, 2024: 1-22(in Chinese). [2] Tam VWY, Gao XF, Tam CM. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach[J]. Cement and Concrete Research, 2005, 35(6): 1195-1203. doi: 10.1016/j.cemconres.2004.10.025 [3] Kucharczyková B, Keršner Z, Pospíchal O, et al. The porous aggregate pre-soaking in relation to the freeze–thaw resistance of lightweight aggregate concrete[J]. Construction and Building Materials, 2012, 30: 761-766. doi: 10.1016/j.conbuildmat.2011.12.067 [4] Shen D, Feng Z, Zhu P, et al. Effect of pre-wetted lightweight aggregates on residual stress development and stress relaxation in restrained concrete ring specimens[J]. Construction and Building Materials, 2020, 258: 119151. doi: 10.1016/j.conbuildmat.2020.119151 [5] Lyu K, Sun B, Liu X, et al. Evaluation of the ITZ modification efficiency via aggregate surface coating with nano SiO2 (NS) and its influence on properties[J]. Case Studies in Construction Materials, 2022, 17: e01488. doi: 10.1016/j.cscm.2022.e01488 [6] 王宝民, 姜瑞双, 赵汝英. 石墨烯的分散性及石墨烯水泥基复合材料的研究进展[J]. 混凝土, 2016, (12): 68-72+75. doi: 10.3969/j.issn.1002-3550.2016.12.018WANG Baomin, JIANG Ruishuang, ZHAO Ruying. Research progress of the dispersibility of graphene and graphene cement-based composite materials[J]. Concrete, 2016, (12): 68-72+75(in Chinese). doi: 10.3969/j.issn.1002-3550.2016.12.018 [7] 高飞, 田宝振, 张晔, 等. 石墨烯掺配水泥材料及其应用研究进展[J]. 山东化工, 2024, 53(2): 127-130,133.GAO Fei, TIAN Baozhen, ZHANG Ye, et al. Progress of graphene blended cement materials and its application[J]. Shandong Chemical Industry, 2024, 53(2): 127-130,133(in Chinese). [8] Wei X-X, Pei C, Zhu J-H. Towards the large-scale application of graphene-modified cement-based composites: A comprehensive review[J]. Construction and Building Materials, 2024, 421: 135632. doi: 10.1016/j.conbuildmat.2024.135632 [9] Mukherjee K, Rajender A, Samanta AK. A review on the fresh properties, mechanical and durability performance of graphene-based cement composites[J]. Materials Today: Proceedings, 2023. In Press. [10] 吕生华, 孙婷, 刘晶晶, 等. 氧化石墨烯纳米片层对水泥基复合材料的增韧效果及作用机制[J]. 复合材料学报, 2014, 31(3): 644-652.Lv Shenghua, Sun Ting, Liu Jingjing, et al. Toughening effect and mechanism of graphene oxide nanoflakes on cementitious composites[J]. Library Theory and Practice, 2014, 31(3): 644-652(in Chinese). [11] 张婷婷, 王荣政, 孔祥清, 等. 石墨烯及其衍生物对水泥基复合材料性能的影响研究进展[J]. 混凝土与水泥制品, 2022, (11): 30-34.ZHANG Tingting, WANG Rongzheng, KONG Xiangqing, et al. Research progress on the effect of graphene and its derivatives on the properties of cementitious composites[J]. China Concrete and Cement Products, 2022, (11): 30-34(in Chinese). [12] 张瑞君, 陈国良, 宋春草, 等. 氧化石墨烯对再生砂超高性能混凝土力学及抗氯离子渗透性能的影响[J]. 无机盐工业, 2023: 1–9.ZHANG Ruijun, CHEN Guoliang, SONG Chuncao, et al. Influence of graphene oxide on the mechanical and chloride ion penetration resistance of ultra-high performance concrete with recycled sand[J]. Inorganic Chemicals Industry, 2023: 1-9(in Chinese). [13] Nguyen HD, Zhang Q, Sagoe-Crentsil K, et al. Graphene oxide-coated sand for improving performance of cement composites[J]. Cement and Concrete Composites, 2021, 124: 104279. doi: 10.1016/j.cemconcomp.2021.104279 [14] 袁小亚, 杨雅玲, 周超, 等. 氧化石墨烯改性水泥砂浆力学性能及微观机理研究[J]. 重庆交通大学学报(自然科学版), 2017, 36(12): 36-42.YUAN Xiaoya, YANG Yaling, ZHOU Chao, et al. Mechanical properties and micro-mechanism of graphene oxide modified cement mortar[J]. Journal of Chongqing Jiaotong University(Natural Sciences), 2017, 36(12): 36-42(in Chinese). [15] 袁小亚, 高军, 王远贵, 等. 氧化石墨烯分散方式及其对水泥砂浆力学性能的影响[J]. 混凝土与水泥制品, 2020, (8): 18-22,26.YUAN Xiaoya, GAO Jun, WANG Yuangui, et al. Dispersion mode of graphene oxide and its effect on mechanical properties of cement mortar[J]. China Concrete and Cement Products, 2020, (8): 18-22,26(in Chinese). [16] 全国水泥标准化技术委员会. 水泥胶砂强度检验方法(ISO法)[J]. 2021.National Technical Committee for Cement Standardisation. Test method of cement mortar strength(ISO method)[J]. 2021(in Chinese). [17] 全国水泥制品标准化技术委员会. 混凝土外加剂匀质性试验方法[J]. 2012.National Technical Committee for the Standardisation of Cement Products. Methods for testing uniformity of concrete admixture[J]. 2012(in Chinese). [18] 普通混凝土长期性能和耐久性能试验方法标准[J]. 2009.Standard for test methods of long-term performance and durability of ordinary concrete[J]. 2009(in Chinese). [19] 建筑砂浆基本性能试验方法标准[J]. 2009.Standard for test method of basic properties of construction mortar[J]. 2009(in Chinese). [20] Lu D, Shi X, Zhong J. Nano-engineering the interfacial transition zone in cement composites with graphene oxide[J]. Construction and Building Materials, 2022, 356: 129284. doi: 10.1016/j.conbuildmat.2022.129284 [21] Jiao L, Seow JYR, Skinner WS, et al. Metal–organic frameworks: Structures and functional applications[J]. Materials Today, 2019, 27: 43-68. doi: 10.1016/j.mattod.2018.10.038 [22] 朱振亚, 王磊, 姜家良, 等. 纳米SiO2-氧化石墨烯/聚偏氟乙烯杂化膜的制备及特性[J]. 复合材料学报, 2018, 35(4): 785-792.Zhenya Zhu, Lei Wang, Jialiang Jiang, et al. Preparation and properties of nano SiO2-GO/polyvinylidene fluoride hybrid membrane[J]. Library Theory and Practice, 2018, 35(4): 785-792(in Chinese). [23] 袁小亚, 曾俊杰, 牛佳伟, 等. 不同减水剂对氧化石墨烯掺配水泥胶砂力学性能及微观结构的影响[J]. 功能材料, 2018, 49(10): 10184-10189. doi: 10.3969/j.issn.1001-9731.2018.10.032YUAN Xiaoya, ZENG Junjie, NIU Jiawei, et al. Effect of different water-reducing agents on mechanical properties andmicrostructure of graphite oxide-blended cement mortar[J]. Journal of Functional Materials, 2018, 49(10): 10184-10189(in Chinese). doi: 10.3969/j.issn.1001-9731.2018.10.032 [24] 谢晓丹. 氧化石墨烯表面吸附态Pb(Ⅱ)在碱性环境中解吸附特征研究[D]. 2020.Xie Xiaodan, Desorption of Adsorbed Pb(II) on Graphene Oxide under Alkaline Conditions[D]. 2020. (in Chinese). [25] Hasanzadeh B, Liu F, Sun Z. Monitoring hydration of UHPC and conventional paste by quantitative analysis on Raman patterns[J]. Construction and Building Materials, 2016, 114: 208-214. doi: 10.1016/j.conbuildmat.2016.03.178 [26] Ferrari AC, Basko DM. Raman spectroscopy as a versatile tool for studying the properties of graphene[J]. NATURE NANOTECHNOLOGY, 2013, 8(4): 235-246. doi: 10.1038/nnano.2013.46 [27] Lu D, Shi X, Wong HS, et al. Graphene coated sand for smart cement composites[J]. Construction and Building Materials, 2022, 346: 128313. doi: 10.1016/j.conbuildmat.2022.128313 [28] Birenboim M, Nadiv R, Alatawna A, et al. Reinforcement and workability aspects of graphene-oxide-reinforced cement nanocomposites[J]. Composites Part B: Engineering, 2019, 161: 68-76. doi: 10.1016/j.compositesb.2018.10.030 [29] 罗素蓉, 李欣, 林伟毅, 等. 氧化石墨烯分散方式对水泥基材料性能的影响[J]. 硅酸盐通报, 2020, 39(3): 677-684.LUO Su-rong, LI Xin, LIN Wei-yi, et al. Effect of Graphene Oxide Dispersion Method on Properties of Cement-based Materials[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(3): 677-684(in Chinese). [30] Wang M, Yao H, Wang R, et al. Chemically functionalized graphene oxide as the additive for cement–matrix composite with enhanced fluidity and toughness[J]. Construction and Building Materials, 2017, 150: 150-156. doi: 10.1016/j.conbuildmat.2017.05.217 [31] Wang M, Yao H. Comparison Study on the Adsorption Behavior of Chemically Functionalized Graphene Oxide and Graphene Oxide on Cement[J]. Materials (Basel, Switzerland), 2020, 13(15): 3274. doi: 10.3390/ma13153274 [32] 王月, 赵思毅, 俞佩瑶. 氧化石墨烯及其分散方法对水泥基材料微观结构和力学性能的影响研究进展[J]. 功能材料, 2024, 55(3): 3023-3034. doi: 10.3969/j.issn.1001-9731.2024.03.004WANG Yue, ZHAO Siyi, YU Peiyao. Progress in research on the effect ofgraphene oxide and its dispersionmethod on the microstructure and mechanical properties ofcement-based materials[J]. Journal of Functional Materials, 2024, 55(3): 3023-3034(in Chinese). doi: 10.3969/j.issn.1001-9731.2024.03.004 [33] 魏致强, 王远贵, 齐孟, 等. 没食子酸协同聚羧酸减水剂分散氧化石墨烯及其对水泥砂浆性能的影响[J]. 材料导报, 2021, 35(10): 10042-10047. doi: 10.11896/cldb.20040258WEI Zhiqiang, WANG Yuangui, QI Meng, et al. The Synergistic Effect of Gallic Acid and Polycarboxylic Water-reducer on AqueousGO Dispersion and the Enhanced Mechanical Properties of Cement Mortar Composites[J]. Materials Reports, 2021, 35(10): 10042-10047(in Chinese). doi: 10.11896/cldb.20040258 [34] 刘文娟. 氧化石墨烯改性混凝土的制备及力学性能和抗冻性能的研究[J]. 功能材料, 2022, 53(8): 8159-8164. doi: 10.3969/j.issn.1001-9731.2022.08.024LIU Wenjuan. Preparation of graphene oxide modified concrete and research on mechanical properties and freezing resistance[J]. Journal of Functional Materials, 2022, 53(8): 8159-8164(in Chinese). doi: 10.3969/j.issn.1001-9731.2022.08.024 [35] 王奕璇, 柴军瑞, 曹靖, 等. 多层氧化石墨烯-水泥基复合材料的力学性能与微观结构[J]. 应用力学学报, 2020, 37(2): 860-865,948. doi: 10.11776/cjam.37.02.B114WANG Yixuan, CHAI Junrui, CAO Jing, et al. Mechanical properties and microstructure of multilayer graphene oxide-cement composites[J]. Chinese Journal of Applied Mechanics, 2020, 37(2): 860-865,948(in Chinese). doi: 10.11776/cjam.37.02.B114 [36] 袁小亚, 蒲云东, 桂尊曜, 等. 羟基化石墨烯对粉煤灰-水泥基复合材料性能的影响[J]. 材料导报, 2023: 1–17.YUAN Xiaoya, PU Yundong, GUI Zunyao, et al. Effect of Hydroxylated Graphene on Properties of Fly Ash-cement Matrix Composites[J]. Materials Reports, 2023: 1-17. [37] Huang K, Jing H, Gao Y, et al. Study on the properties of graphene oxide reinforced cement-based materials at high temperature[J]. Construction and Building Materials, 2024, 421: 135704. doi: 10.1016/j.conbuildmat.2024.135704 [38] Prasuna B, Ravella DP. Durability assessment of high-performance concretes containing graphene oxide[J]. Materials Today: Proceedings, 2022, 60: 526-533(in Chinese). doi: 10.1016/j.matpr.2022.01.427 [39] 齐孟. 木质素磺酸钠分散水性石墨烯及其对水泥基材料的性能研究[D]. 2023.Qi Meng. Study on Waterborne Graphene Dispersedby Sodium Lignosulfonate and itsPerformance on Cement-based Materials [D]. 2023(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 52

- HTML全文浏览量: 18

- 被引次数: 0

下载:

下载: