Effect of ultra-low temperature and chloride on carbonation performance of ultra-high toughness cement-based composite

-

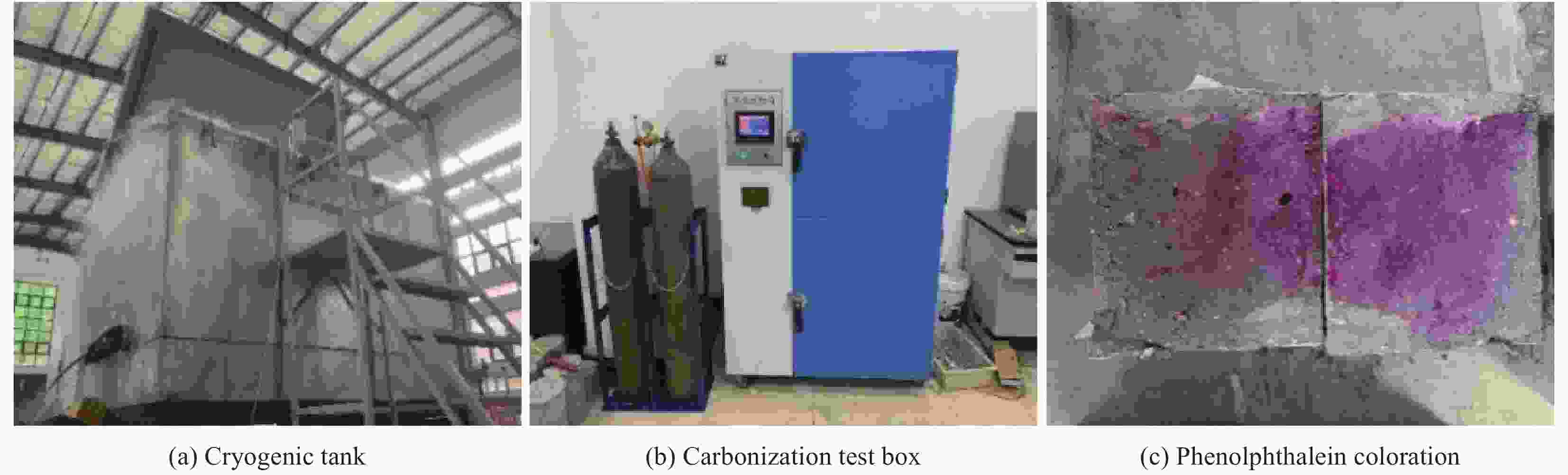

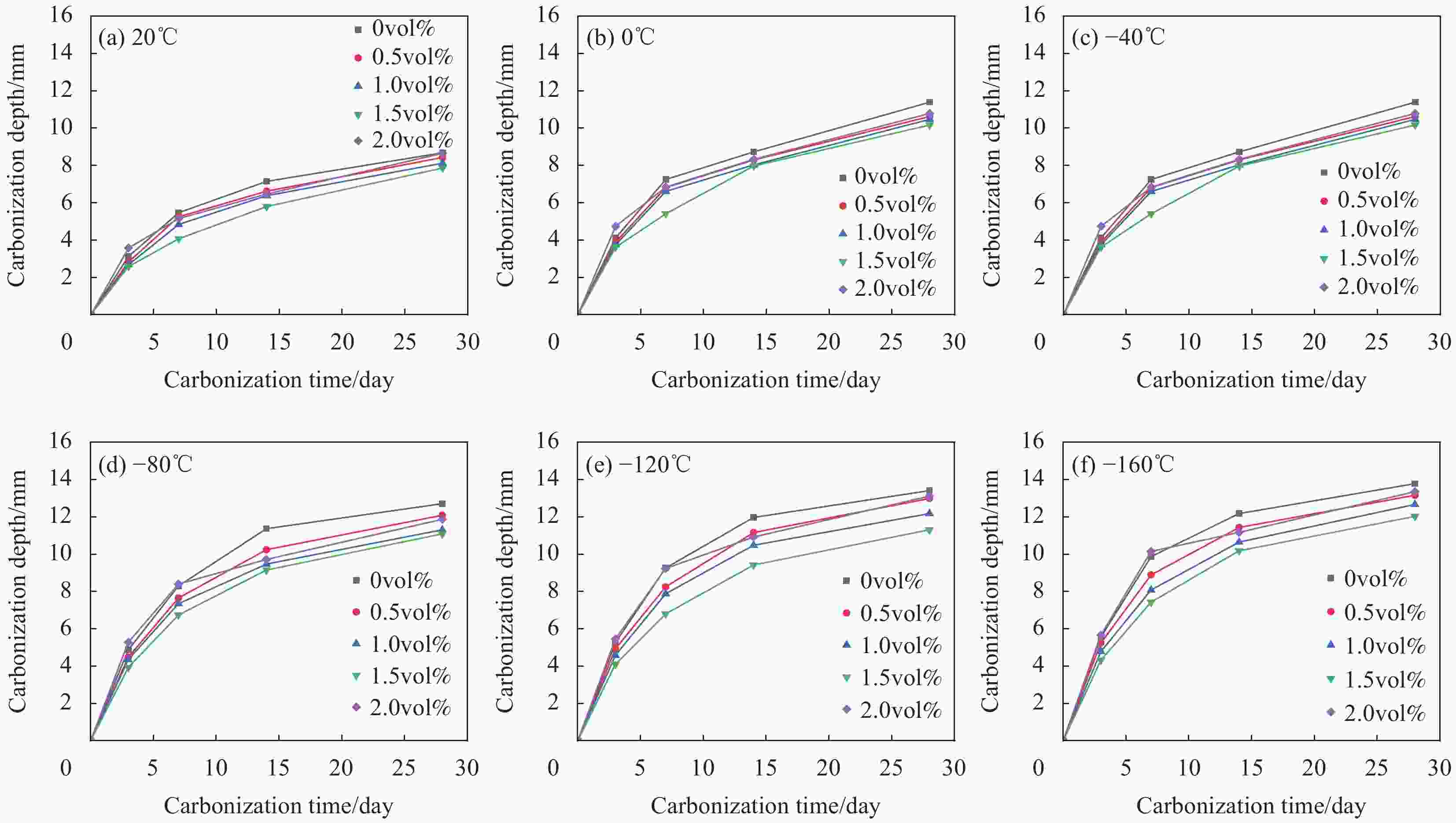

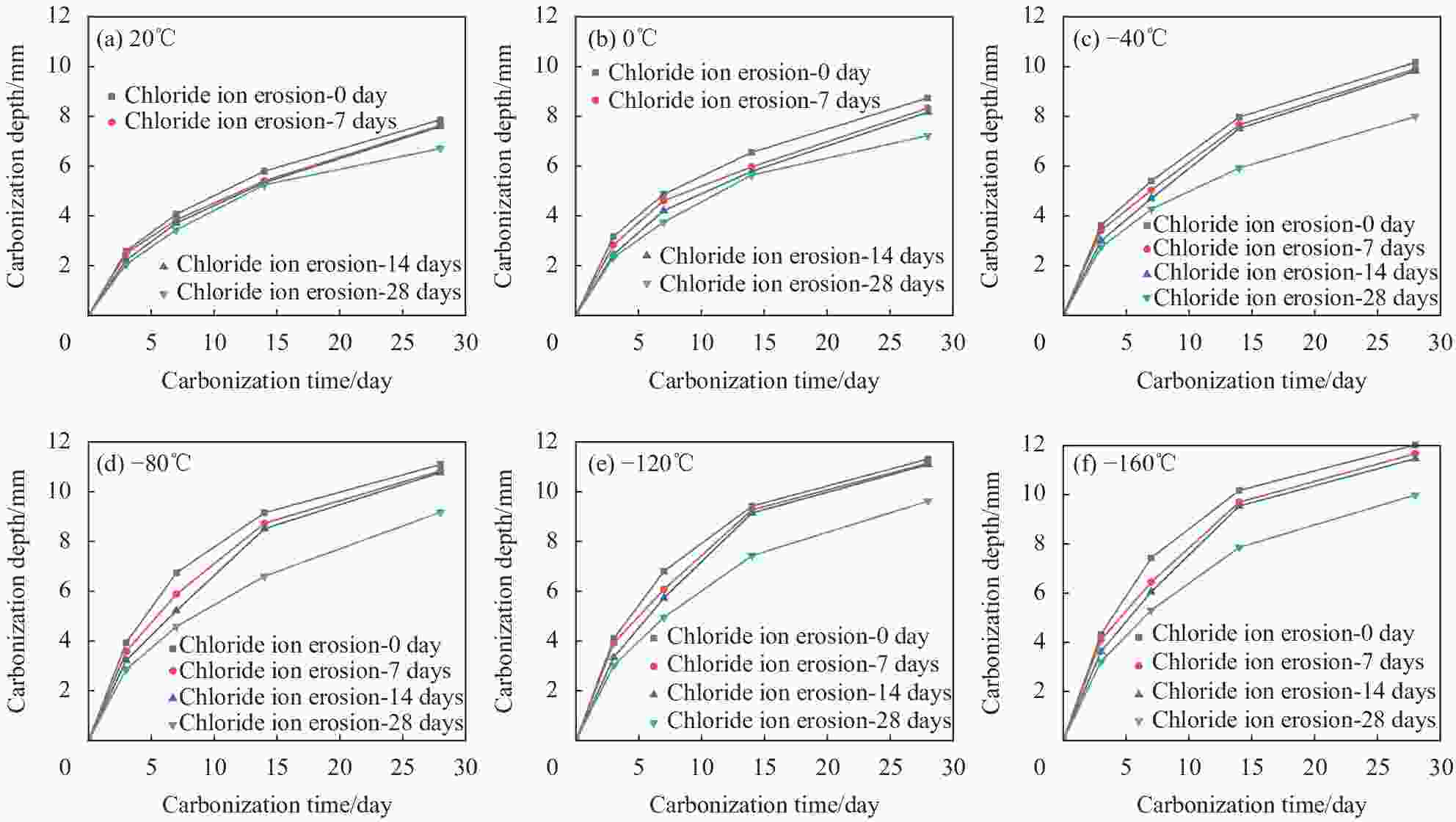

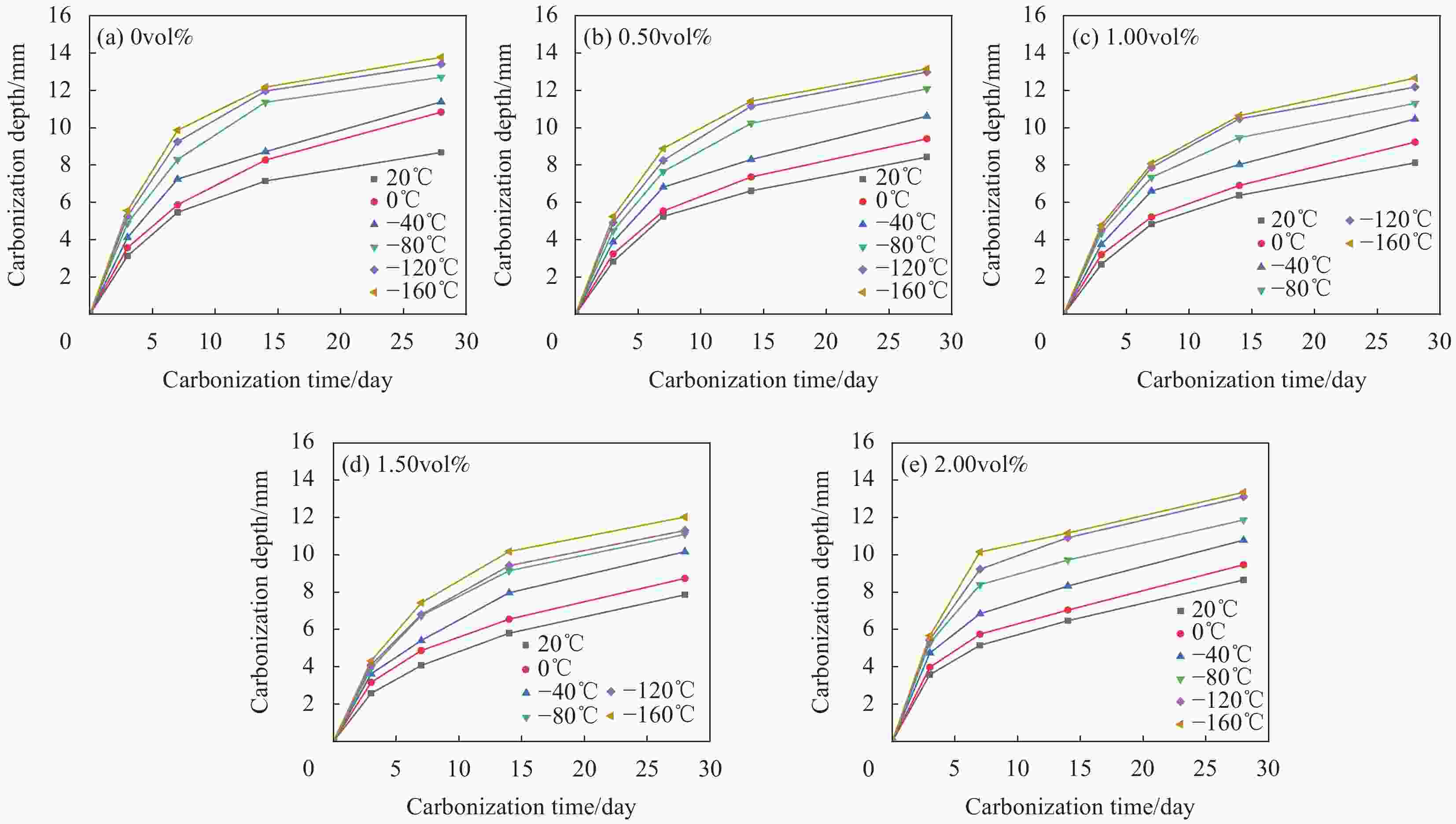

摘要: 极地地区及海洋环境下的资源开采导致混凝土结构受到低温、碳化和氯离子渗透的共同作用,加剧了混凝土材料及其结构的劣化。超高韧性水泥基复合材料(UHTCC)作为一种新型复合材料,其耐久性是评价其工作性能的重要指标。通过对UHTCC材料在超低温作用和氯离子侵蚀后的快速碳化试验,研究了复杂环境作用下不同纤维体积掺量的UHTCC的抗碳化性能变化规律。结果表明:随着温度的降低,UHTCC材料的抗碳化性能明显降低,温度达到−160℃时其碳化深度最大增加约58.76%,适量的纤维掺入对UHTCC材料的抗碳化性能具有明显的提升作用,而超过最优掺量后其抗碳化性能反而有所降低,同时SEM表明氯离子能够细化混凝土内部孔隙,阻碍CO2在材料内部的进一步扩散。提出了极端复杂环境下UHTCC的碳化深度回归模型,研究结论为UHTCC在复杂环境中的工程应用提供参考。

-

关键词:

- 超低温 /

- 超高韧性水泥基复合材料 /

- 氯离子侵蚀 /

- 碳化作用 /

- 碳化因子

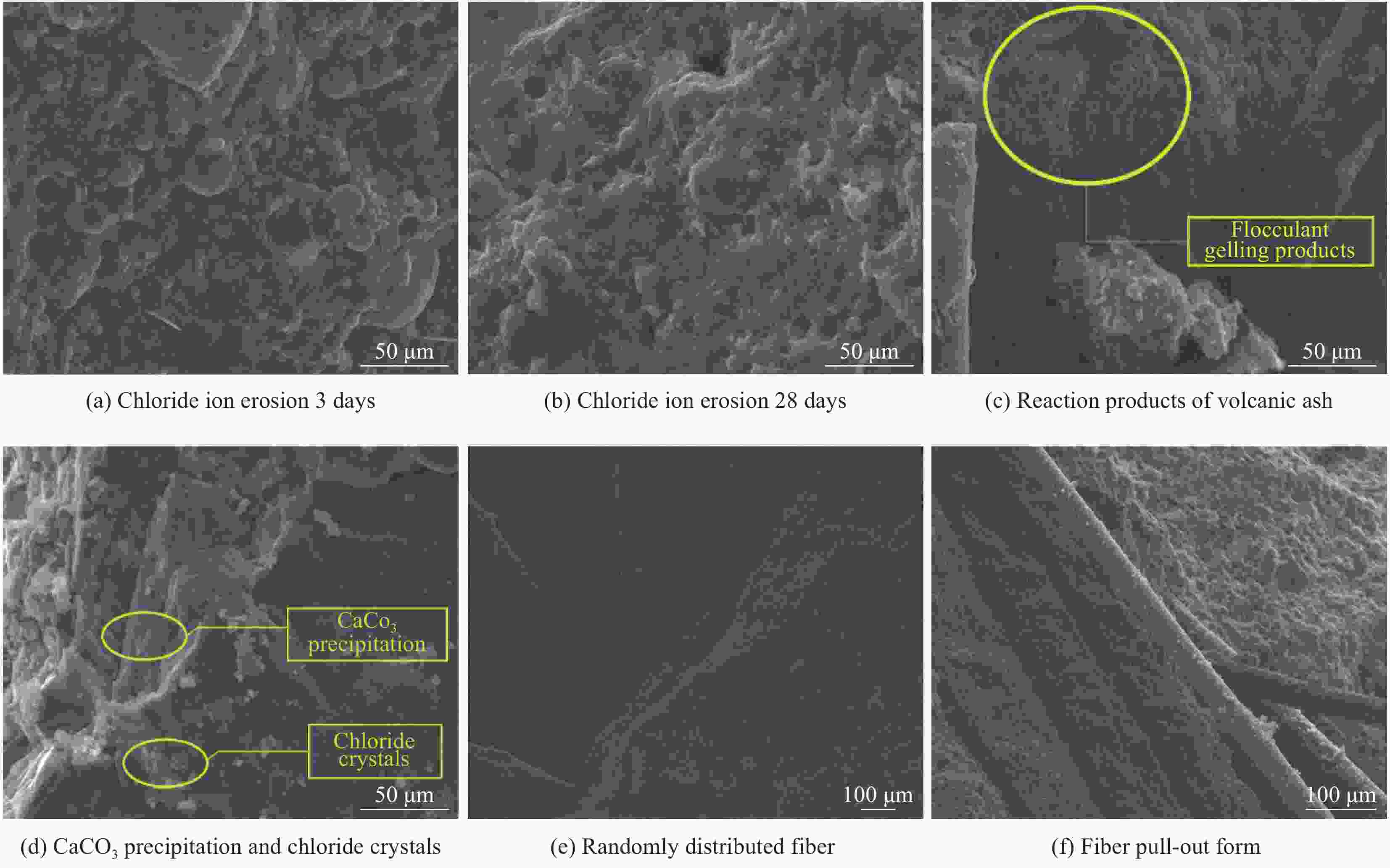

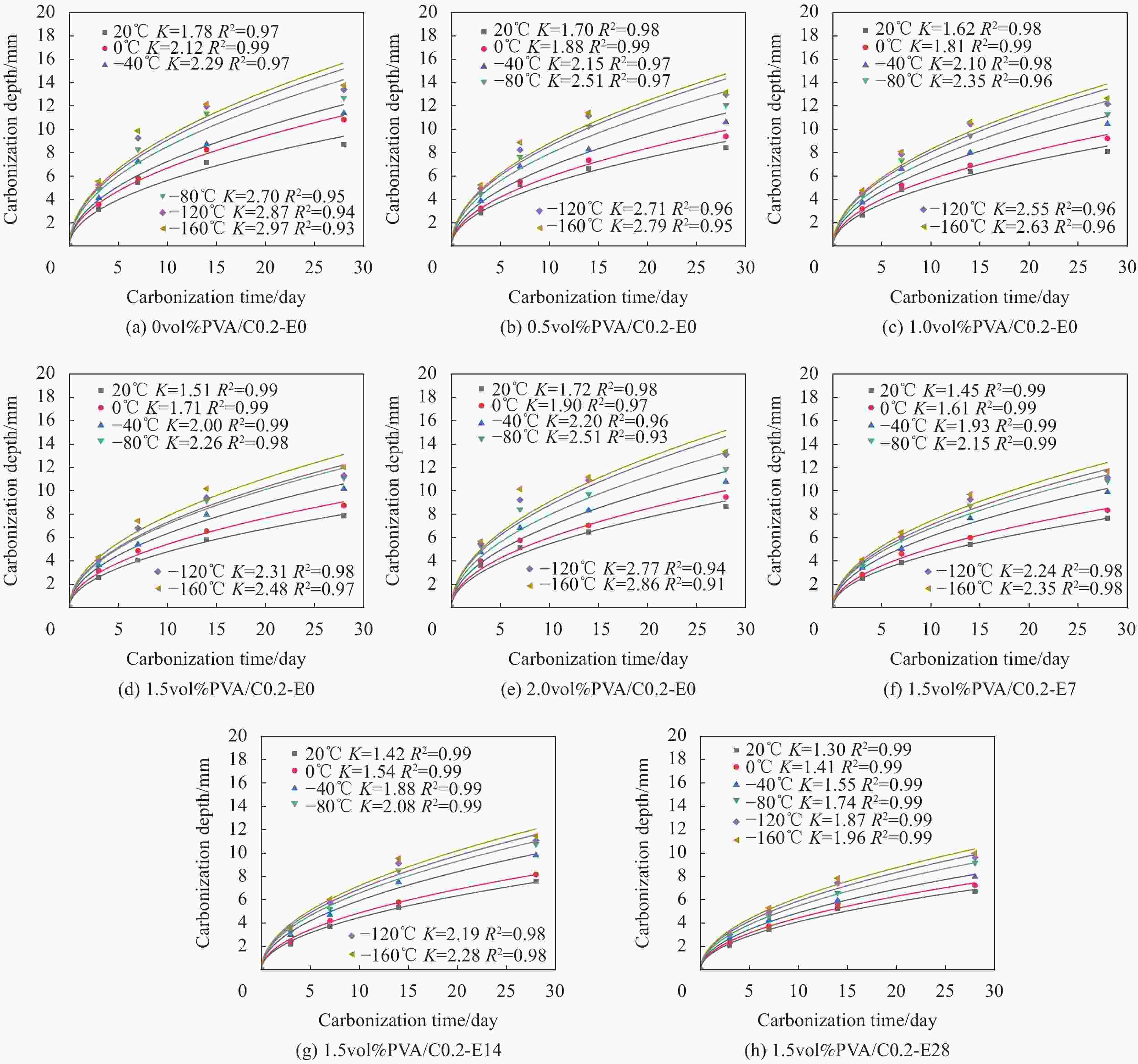

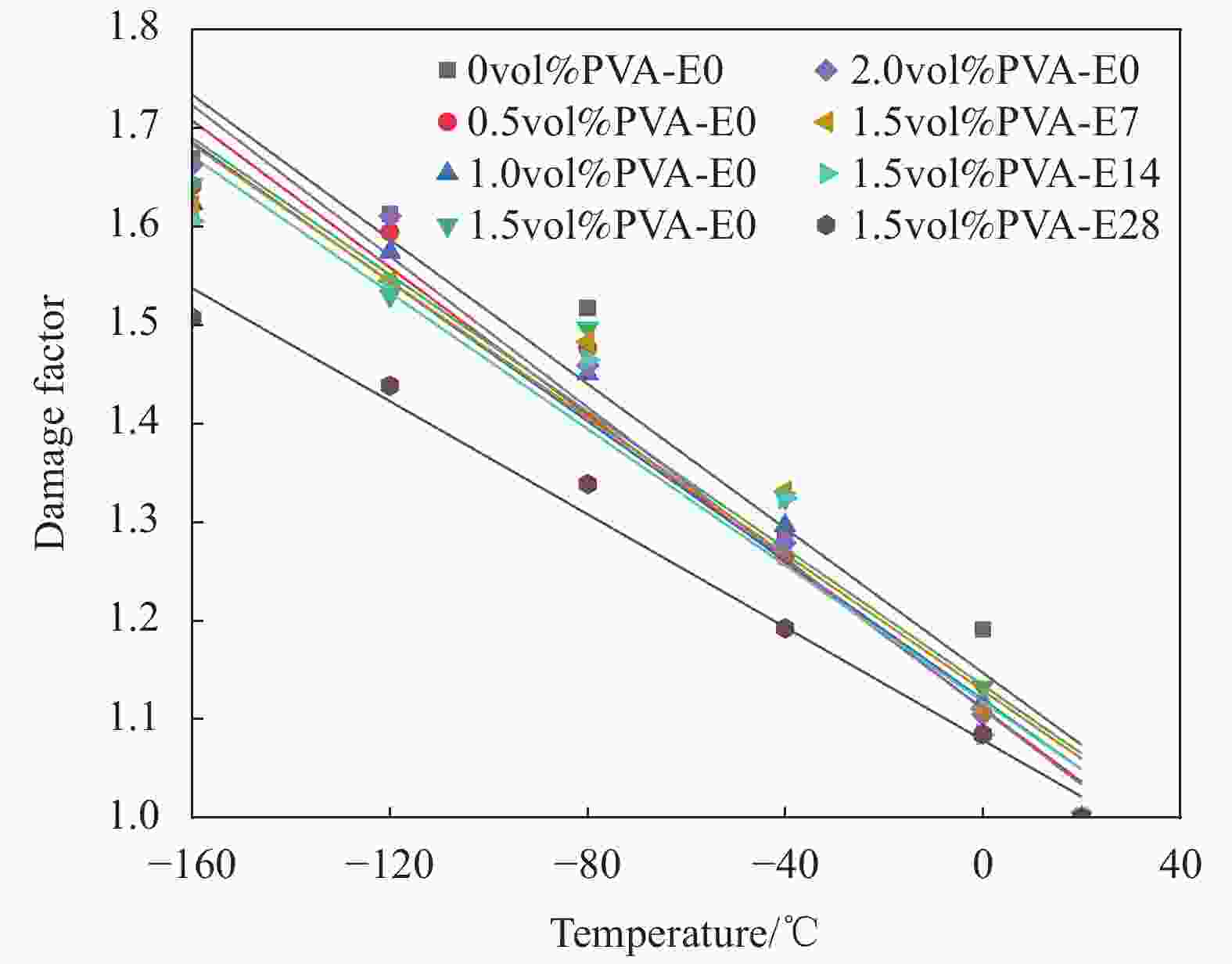

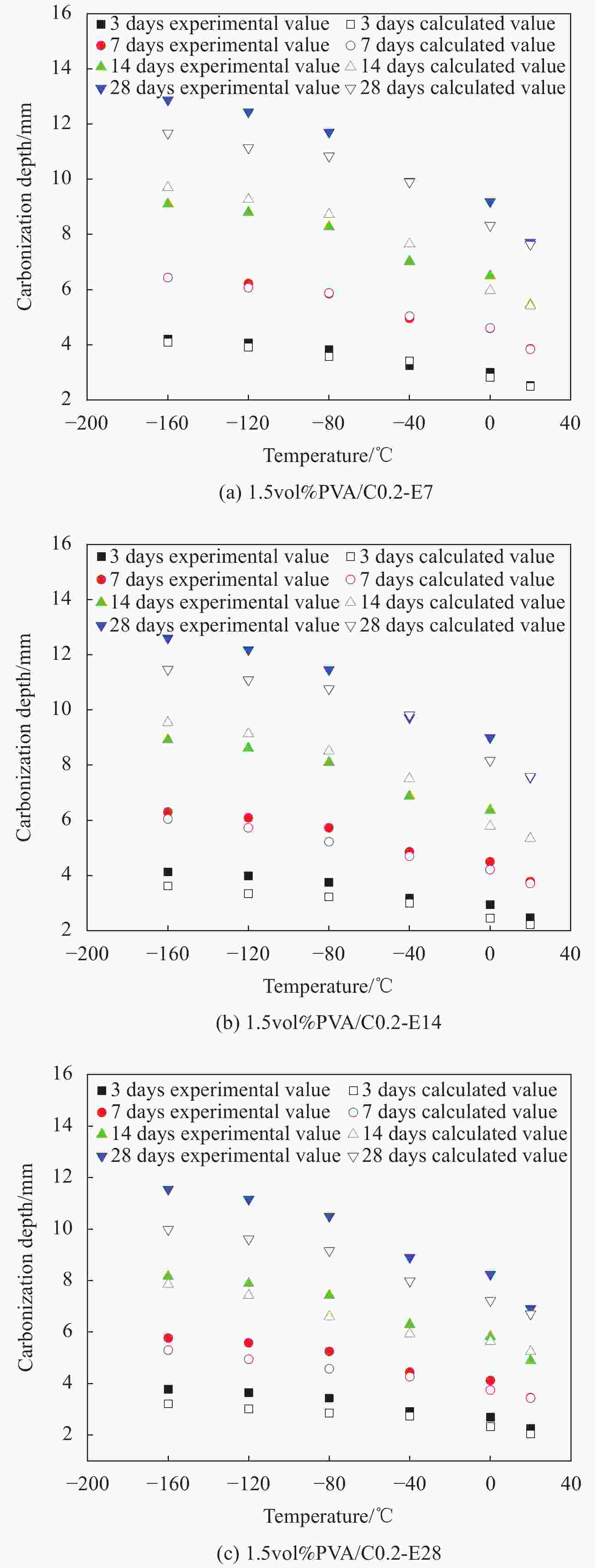

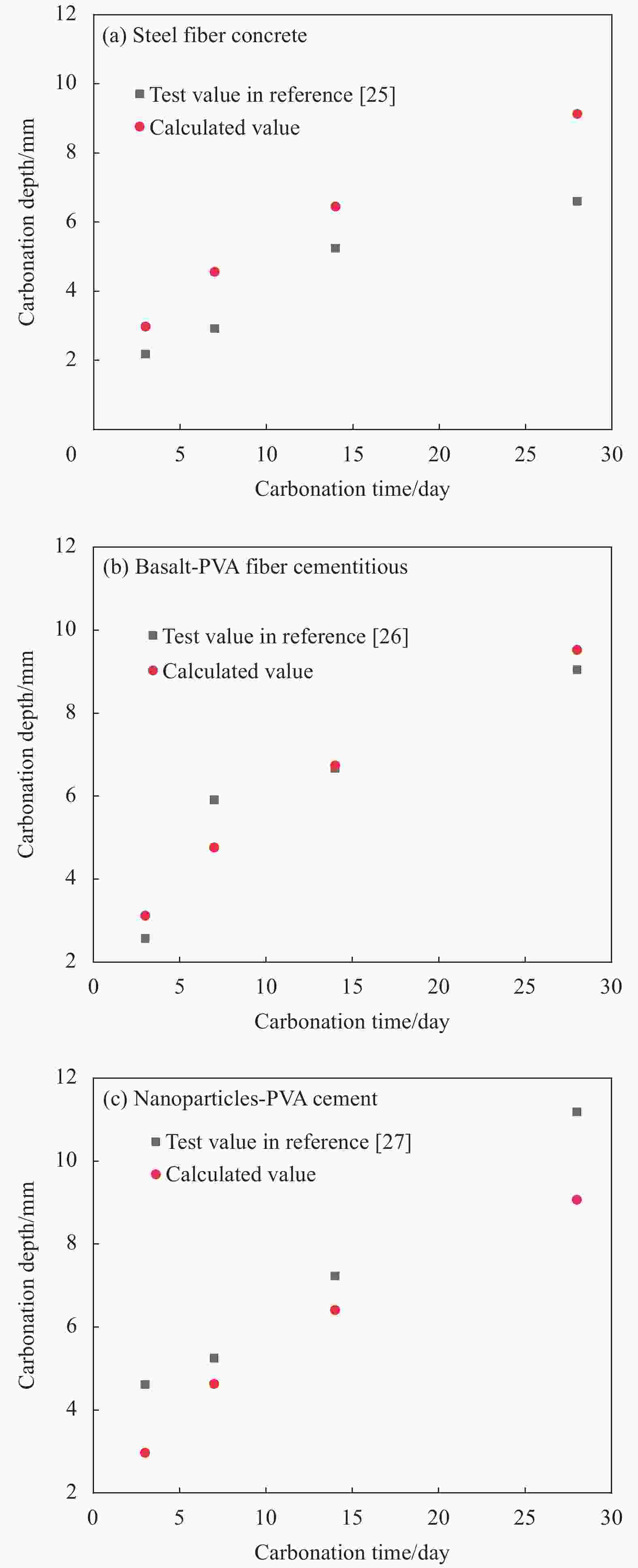

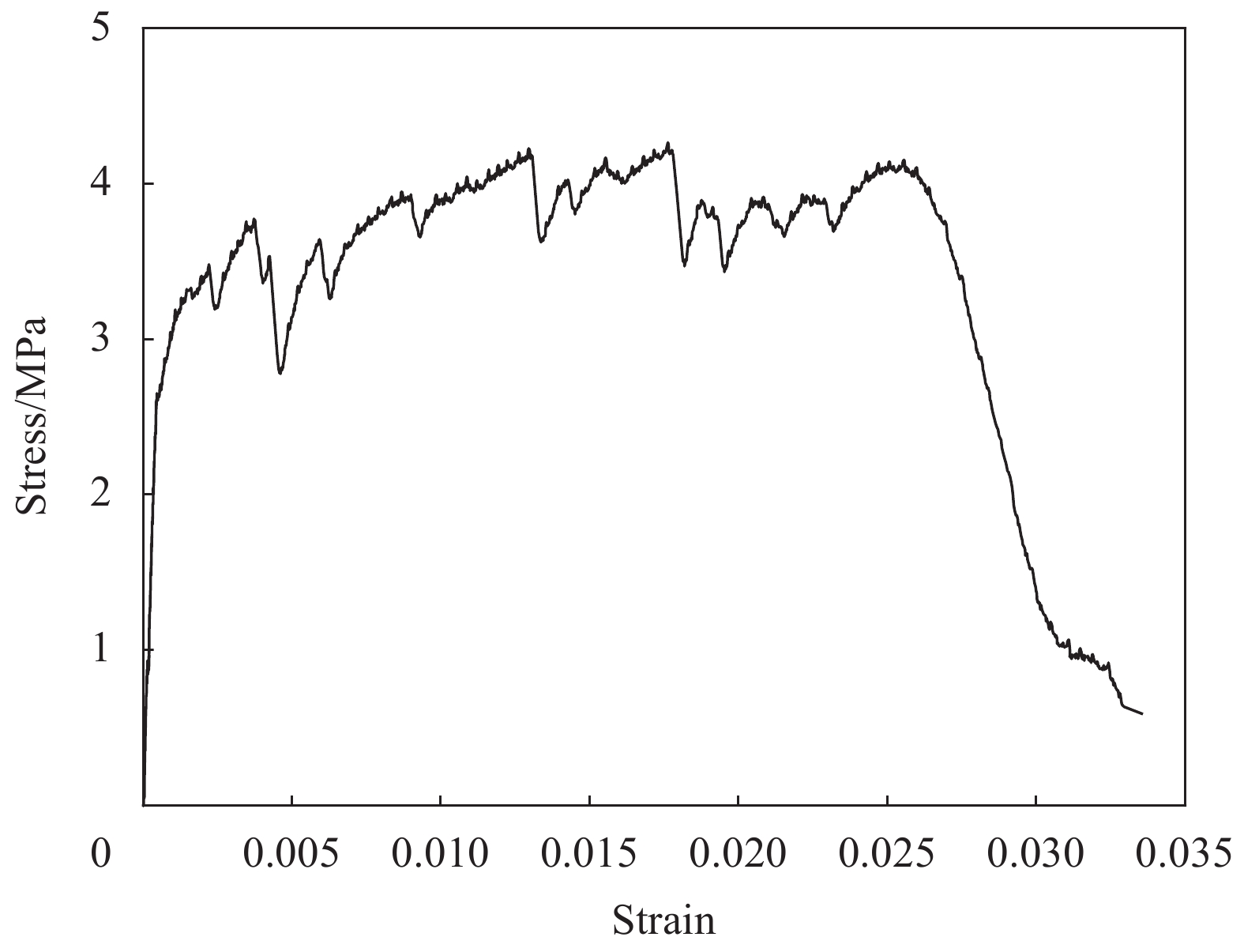

Abstract: The exploitation of resources in polar regions and marine environment leads to the joint action of low temperature, carbonation and chloride ion penetration on concrete structures, which aggravates the deterioration of concrete materials and structures. As a new type of composite material, the durability of ultra-high toughness cementitious composite (UHTCC) is an important index to evaluate its working performance. Through the rapid carbonization test of UHTCC material under ultra-low temperature and chloride ion erosion, the change law of carbonization resistance of UHTCC with different fiber volume contents under complex environment was studied. The results show that with the decrease of temperature, the carbonation resistance of UHTCC material is significantly reduced. When the temperature reaches −160℃, the carbonation depth of UHTCC material increases by about 58.76%. The appropriate amount of fiber has a significant effect on the carbonation resistance of UHTCC material. However, the carbonation resistance of UHTCC material decreases when the content exceeds the optimal content. At the same time, SEM shows that chloride ions can refine the internal pores of concrete and hinder the further diffusion of CO2 inside the material. The regression model of UHTCC carbonation depth in extremely complex environment is proposed, and the research conclusion provides reference for the engineering application of UHTCC in complex environment. -

表 1 聚乙烯醇(PVA)纤维性能指标

Table 1. Polyvinyl alcohol (PVA) fiber performance index

Name Density

/(g·cm−3)Diameter

/mmLength

/mmElastic modulus

/MPaTensile strength

/MPaREC15×12 1.3 0.04 12 1200 526 表 2 试件分组

Table 2. Specimen grouping

Group Volume fraction

φ/vol%Temperature/℃ Chloride ion

erosion

time/dayCarbonation

time/dayFly ash/

(kg·m−3)Cement/

(kg·m−3)Sand/

(kg·m−3)Silica fume/

(kg·m−3)0vol%PVA/C0.2-E0 0 20/0/−40/−80/−120/−160 0 0/7/14/28 533.3 120 133.3 13.3 0.5vol%PVA/C0.2-E0 0.5 20/0/−40/−80/−120/−160 0 0/7/14/28 533.3 120 133.3 13.3 1.0vol%PVA/C0.2-E0 1.0 20/0/−40/−80/−120/−160 0 0/7/14/28 533.3 120 133.3 13.3 1.5vol%PVA/C0.2-E0 1.5 20/0/−40/−80/−120/−160 0 0/7/14/28 533.3 120 133.3 13.3 2.0vol%PVA/C0.2-E0 2.0 20/0/−40/−80/−120/−160 0 0/7/14/28 533.3 120 133.3 13.3 1.5vol%PVA/C0.2 -E7 1.5 20/0/−40/−80/−120/−160 7 0/7/14/28 533.3 120 133.3 13.3 1.5vol%PVA/C0.2 -E14 1.5 20/0/−40/−80/−120/−160 14 0/7/14/28 533.3 120 133.3 13.3 1.5vol%PVA/C0.2 -E28 1.5 20/0/−40/−80/−120/−160 28 0/7/14/28 533.3 120 133.3 13.3 Notes: C0.2—Cement mass ratio; E—Chloride ion erosion time. 表 3 典型混凝土碳化经验模型

Table 3. Typical empirical carbonation models for concrete

Name Calculation expression Parameter note Huang Shiyuan Carbonization Model[21] $\begin{array}{l}x_{\mathrm{c}}=104 k_{\rm v} k_{\mathrm{c}}^{0.54} k_{\mathrm{w}}^{0.47} \sqrt{t} \;\;\; (W / C> 0.6) \\x_{\mathrm{c}}=73.54 k_{\rm v} k_{\mathrm{c}}^{0.81} k_{\mathrm{w}}^{0.13} \sqrt{t}\;\;\; (W / C<0.6)\end{array} $ kc—Influence coefficient of cement dosage;

kw—Influence coefficient of water cement ratio;

kv—Cement variety coefficient;

xc—Carbonation depth; W/C—Water cement ratio; t—Carbonation timeBin tian-AnGu Model[22] $\begin{array}{l}x_{\mathrm{c}}=k_{\rm R} (W / C-0.25) \sqrt{\dfrac{t}{0.3(1.15+3 W / C)}} \quad(W / C > 0.6) \\x_{\mathrm{c}}=k_{\rm R} (4.6 W / C-1.76) \sqrt{\dfrac{t}{7.2}} \quad(W / C<0.6)\end{array} $ kR—Relative carbonation depth, coefficients related to cement type, aggregate and admixture Shandong Research Institute Model[23] $x_{\mathrm{c}}=(12.1 W / C-3.2) \sqrt{t} $ Soviet Union strength Model[24] $x_{\mathrm{c}}=k_{\rm A} \sqrt{\dfrac{0.639 f_{\mathrm{ce}}}{f_{\mathrm{cu} 28}+0.5 A f_{\mathrm{ce}}}}-0.245 \sqrt{t} $ fce—Cement strength;

fcu28—Concrete 28 days strength;

kA—Cement, aggregate variety, fluidity related coefficient;Niu Ditao strength Model[20] $ x_{\mathrm{c}}=K \left(\dfrac{24.48}{\sqrt{f_{\text {cuk }}}}-2.74\right) \sqrt{t}$ K—Considering the coefficient of environment and maintenance time;

fcuk—Characteristic value of compressive strength of concrete cube -

[1] TOUTANJI H A, EVANS S, GRUGEL R. Performance oflunar sulfur concrete in lunar environments[J]. Construction and Building Materials, 2012, 29: 444-448. [2] 程旭东, 朱兴吉. LNG储罐外墙温度应力分析及预应力筋设计[J]. 石油学报, 2012, 33(3):499-505. doi: 10.7623/syxb201203024CHENG Xudong, ZHU Xingji. LNG tank exterior wall temperature stress analysis and prestressed reinforcement design[J]. Acta Petrolei Sinica,2012,33(3):499-505(in Chinese). doi: 10.7623/syxb201203024 [3] 韩广忠. 中国新建 LNG 接收站的经营困境及其对策[J]. 天然气工业, 2014, 34(5):168-173.HAN Guangzhong. The operation dilemma and countermeasures of new LNG receiving stations in China[J]. Natural Gas Industry,2014,34(5):168-173(in Chinese). [4] 徐世烺, 李贺东. 超高韧性水泥基复合材料研究进展及其工程应用[J]. 土木工程学报, 2008, 41(22):45-60. doi: 10.3321/j.issn:1000-131X.2008.06.008XU Shilang, LI Hedong. Research progress and engineering application of ultra-high toughness cementitious composites[J]. China Civil Engineering Journal,2008,41(22):45-60(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.06.008 [5] 张秀芳, 徐世烺, 侯利军. 采用超高韧性水泥基复合材料提高钢筋混凝土梁弯曲抗裂性能研究(II): 试验研究[J]. 土木工程学报, 2009, 42(10):53-66. doi: 10.3321/j.issn:1000-131X.2009.10.008ZHANG Xiufang, XU Shilang, HOU Lijun. Using ultra-high toughness cementitious composites to improve the flexural crack resistance of reinforced concrete beams (II): Experimental study[J]. China Civil Engineering Journal,2009,42(10):53-66(in Chinese). doi: 10.3321/j.issn:1000-131X.2009.10.008 [6] 蔡新华. 超高韧性水泥基复合材料耐久性能试验研究[D]. 大连: 大连理工大学, 2010.CAI Xinhua. Experimental study on durability of ultra-high toughness cementitious composites[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [7] SAHMARAN M, ÖZBAY E, YÜCEL H. Effect of fly ash and PVA fiber on microstructural damage and residual properties of engineered cementitious composites exposed to high temperatures[J]. Journal of Materials in Civil Engi-neering,2011,23(12):1735-1745. doi: 10.1061/(ASCE)MT.1943-5533.0000335 [8] LAI J Z, YANG H R, WANG H F, et al. Properties and modeling of ultra-high-performance concrete subjected to multiple bullet impacts[J]. Journal of Materials in Civil Engi-neering,2018,30(10):04018256. [9] DAHMANI L, KHENANE A, KACI S. Behavior of the reinforced concrete at cryogenic temperatures[J]. Cryogenics,2007,47(9-10):517-525. doi: 10.1016/j.cryogenics.2007.07.001 [10] DANIELLE D, NEIL A, HOULT M. Effects of varying temperature on the performance of reinforced concrete[J]. Materials and Structure,2015,48(4):1109-1123. doi: 10.1617/s11527-013-0218-y [11] 王阵地, 姚燕, 王玲. 冻融循环与氯盐侵蚀作用下混凝土变形和损伤分析[J]. 硅酸盐学报, 2012, 40(8):1133-1138.WANG Zhendi, YAO Yan, WANG Ling. Deformation and damage analysis of concrete under freeze-thaw cycles and chloride attack[J]. Journal of the Chinese Ceramic Society,2012,40(8):1133-1138(in Chinese). [12] 乔宏霞, 杨振清, 王鹏辉, 等. 利用Wiener过程探究镁水泥混凝土中涂层钢筋在盐类环境下的腐蚀寿命[J]. 建筑材料学报, 2021, 24(5):986-993. doi: 10.3969/j.issn.1007-9629.2021.05.012QIAO Hongxia, YANG Zhenqing, WANG Penghui, et al. Study on corrosion life of coated steel bars in magnesium cement concrete under salt environment by Wiener process[J]. Journal of Building Materials,2021,24(5):986-993(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.05.012 [13] SHEN X, LIU Q F, HU Z, et al. Combine ingress of chloride and carbonation in marine-exposed concrete under unsaturated environment: A numerical study[J]. Ocean Engineering, 2019, 189: 106350. [14] SHEN X, JIANG W, HOU D S, et al. Numerical study of carbonation and its effect on chloride binding in concrete[J]. Cement and Concrete Composites, 2019, 104: 103402. [15] 许晨, 王传坤, 金伟良. 混凝土中氯离子侵蚀与碳化的相互影响[J]. 建筑材料学报, 2011, 14(3):376-380. doi: 10.3969/j.issn.1007-9629.2011.03.017XU Chen, WANG Chuankun, JIN Weiliang. Interaction between chloride ion erosion and carbonation in concrete[J]. Journal of Building Materials,2011,14(3):376-380(in Chinese). doi: 10.3969/j.issn.1007-9629.2011.03.017 [16] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing, Urban and Rural Construction of the People's Republic of China. Standard test method for long-term performance and durability of ordinary concrete: GB/T 50082—2009[S]. Beijing: China Construction Industry Press, 2009(in Chinese). [17] 孙丛涛. 氯离子侵蚀环境下混凝土耐久性研究及寿命预测[D]. 西安: 西安建筑科技大学, 2010.SUN Congtao. Durability research and life prediction of concrete under chloride ion erosion environment[D]. Xi'an: Xi'an University of Architecture and Technology, 2010(in Chinese). [18] 齐广政. 海洋大气环境下混凝土氯离子侵蚀性能的试验研究[D]. 西安: 西安建筑科技大学, 2012.QI Guangzheng. Experimental study on chloride ion erosion performance of concrete in marine atmospheric environment[D]. Xi'an: Xi'an University of Architecture and Technology, 2012(in Chinese). [19] SKAPSKI A, BILLUPS R, ROONEY A. Capillary cone method for determination of surface tension of solids[J]. Journal of Chemical Physics,1957,26(5):1350-1351. [20] 牛荻涛, 陈亦奇, 于澍. 混凝土结构的碳化模式与碳化寿命分析[J]. 西安建筑科技大学学报, 1995(4):365-369.NIU Ditao, CHEN Yiqi, YU Shu. Analysis of carbonation mode and carbonation life of concrete structure[J]. Jour-nal of Xi'an University of Architecture and Technology,1995(4):365-369(in Chinese). [21] 许丽萍, 黄士元. 预测混凝土中碳化深度的数学模型[J]. 上海建材学院学报, 1991(4):347-357.XU Liping, HUANG Shiyuan. Mathematical model for predicting carbonation depth in concrete[J]. Journal of Building Materials,1991(4):347-357(in Chinese). [22] 肖佳, 勾成福. 混凝土碳化研究综述[J]. 混凝土, 2010(1):40-44,52. doi: 10.3969/j.issn.1002-3550.2010.01.014XIAO Jia, GOU Chengfu. Summary of concrete carbonation research[J]. Concrete,2010(1):40-44,52(in Chinese). doi: 10.3969/j.issn.1002-3550.2010.01.014 [23] 朱安民. 混凝土碳化与钢筋混凝土耐久性[J]. 混凝土, 1992(6):18-22.ZHU Anmin. Concrete carbonation and durability of reinforced concrete[J]. Concrete,1992(6):18-22(in Chinese). [24] 金祖权. 西部地区严酷环境下混凝土的耐久性与寿命预测[D]. 南京: 东南大学, 2006.JIN Zuquan. Durability and life prediction of concrete under harsh environment in western China[D]. Nanjing: Southeast University, 2006(in Chinese). [25] 郭艳华, 潘慧敏, 李志业. 钢纤维混凝土碳化性能的研究[J]. 混凝土, 2007(2):45-47. doi: 10.3969/j.issn.1002-3550.2007.02.014GUO Yanhua, PAN Huimin, LI Zhiye. Carbonation properties of steel fiber reinforced concrete[J]. Concrete,2007(2):45-47(in Chinese). doi: 10.3969/j.issn.1002-3550.2007.02.014 [26] 李珊珊. 高延性再生微粉混凝土(HDRPC)耐久性研究[D]. 济南: 山东建筑大学, 2022.LI Shanshan. The durability of high ductility recycled powder concrete (HDRPC)[D]. Ji'nan: Shandong Jianzhu University, 2022(in Chinese). [27] 代小兵. 纳米粒子和PVA纤维增强水泥基复合材料耐久性能研究[D]. 郑州: 郑州大学, 2017.DAI Xiaobing. Durability of nanoparticles and PVA fiber reinforced cementitious composites[D]. Zhengzhou: Zhengzhou University, 2017(in Chinese). -

下载:

下载: