Preparation of flame-retardant functionalized boron nitride hybrids and their properties in epoxy resin

-

摘要:

氮化硼(BN)因表面呈惰性与环氧树脂(EP)相容性较差,而且其阻燃效率也不高。通过将9, 10-二氢-9-氧杂-10-磷杂菲-10-氧化物衍生物(DMZ)与Fe(NO3)3反应得到的配位化合物(FeD)在BN表面进行原位生长,制备出阻燃功能化氮化硼(FeD/BN)。将FeD/BN加入到EP中,制备导热阻燃的EP复合材料。通过极限氧指数(LOI)、垂直燃烧(UL-94)测试和锥形量热测试对复合材料的阻燃性能进行了研究,发现含有15wt%的FeD/BN的EP复合材料(15(Fe/B)/EP)的LOI为33.2%,达到了UL-94的V-0级;该复合材料峰值热释放速率(pHRR)、总热释放量(THR)和总烟释放量(TSR)相较于纯EP分别降低28.2%、18.9%和30.1%。导热系数测试表明,15(Fe/B)/EP的导热系数相较于纯EP的导热系数提高了235%。此外,与纯EP相比,该复合材料的拉伸强度与冲击强度都有所提高。

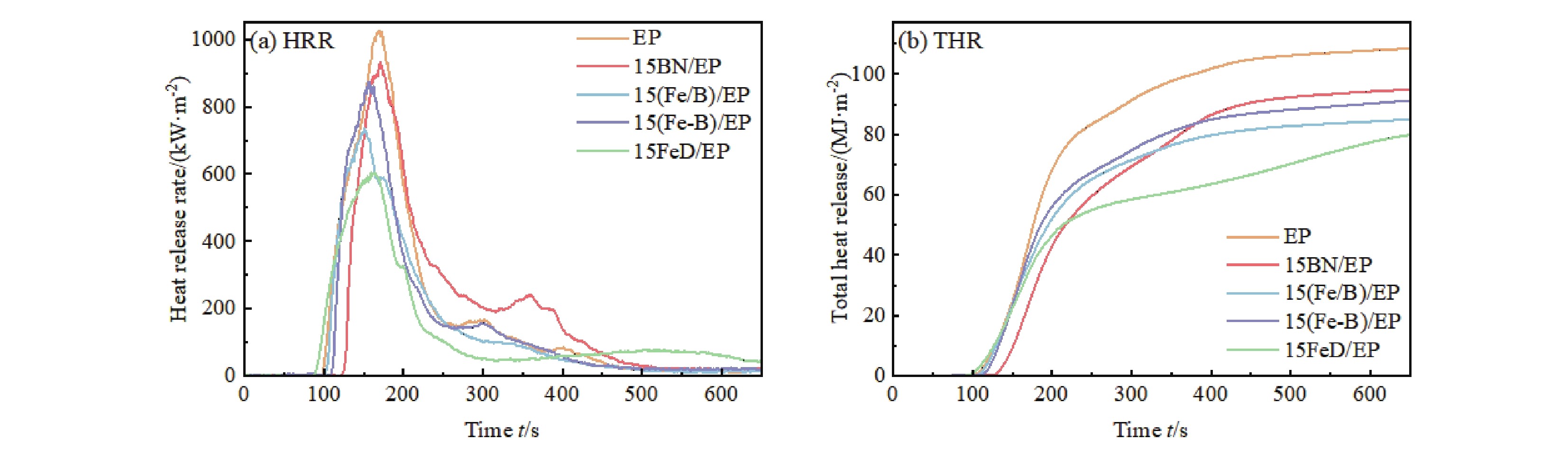

Abstract:Boron nitride (BN) exhibited poor compatibility with epoxy resin (EP) due to its inert surface, and its flame-retardant efficiency in EP was low. In this study, a coordination compound (FeD) was synthesized by a reaction between 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide derivative (DMZ) and Fe(NO3)3. FeD was grown in situ on the surface of BN to prepare a flame-retardant functionalized boron nitride hybrid (FeD/BN). FeD/BN was incorporated into EP to prepare thermally conductive and flame-retardant EP composites. Limiting oxygen index (LOI) and vertical burning (UL-94) tests indicate that EP composite with 15wt%FeD/BN achieves a V-0 rating in the UL-94 test with a LOI value of of 33.2%. Cone calorimetry test results show that the peak heat release rate, total heat release and total smoke release of the composite decrease by 28.2%, 18.9% and 30.1%, respectively compared to those of pure EP. Thermal conductivity of 15(Fe/B)/EP is 235% higher than that of pure EP. Tensile and impact strengths of 15(Fe-B)/EP are enhanced compared with those of pure EP.

-

乙烯-四氟乙烯(ETFE)薄膜凭借其良好的物理特性及力学性能,在新型建筑、能源等领域中已被广泛应用。在实际工程应用中,ETFE膜结构的撕裂破坏可归结为内部因素与外部环境因素的协同作用。膜面处膜材在制造与安装过程中,不可避免地会存在微小孔洞、细微折痕和微裂纹等初始缺陷,以及偶发的外来飞致物刺穿引起的切缝;这使膜材在预应力、极端风荷载及雨雪荷载的复合作用下,极易产生应力集中而诱发缺陷不断扩展,最终膜材撕裂损伤,严重情况下甚至会引发膜结构的整体失效,对结构安全构成重大威胁。并且当膜材在中心区域处受到集中载荷或存在制造缺陷时,极有可能会出现显著的中心撕裂行为[1, 2]。因此,除了需对ETFE薄膜的常规力学性能进行研究,也有必要对其撕裂力学行为开展深入研究。

吴明儿[3-5]、崔家春[6, 7]、胡建辉[8]、Zhang[9]、Surholt[10]和Zhao[11-13]等分别对ETFE薄膜进行了系列试验与分析,揭示了薄膜的单轴和双轴力学行为,研究了弹性模量、屈服强度、断裂强度和徐变等力学参数和规律。整体上,现有研究多集中在ETFE母材的粘-弹塑性行为及本构关系等,在撕裂性能的研究尚十分欠缺。而随着ETFE膜结构的社会需求增长,对其撕裂性能研究的欠缺势必会阻碍ETFE膜结构的进一步应用和发展。另外,国内外学者已对织物类膜材的撕裂强度及破坏规律开展了深入研究[14-20],可为ETFE薄膜撕裂力学性能的研究提供一定参考。Chen等[14, 15]对层压织物进行了系统的单轴撕裂试验,分析了切缝长度、切缝角度、偏轴角对其撕裂行为和撕裂强度的影响;Sun等[18, 19]深入研究了单轴拉伸下切缝长度和切缝角度对PTFE涂层织物撕裂性能的影响;Zhang等[20]论证了切口样式、切缝尺寸和试样尺寸对PVC涂层织物单轴中心撕裂特性的影响。

鉴于此,本文针对典型ETFE薄膜,进行单轴中心撕裂试验,研究切缝长度、切缝角度和切口样式对ETFE薄膜的破坏形态特征及撕裂力学行为的影响。另外,数字图像相关(DIC)技术具有全场测量、非接触、高分辨率等优势[21-23],可为撕裂力学行为分析提供准确可靠的数据支撑,将用于薄膜撕裂全过程薄膜位移场和应变场的测量与重构。所得结论可为ETFE薄膜材料的撕裂力学性能研究和ETFE膜结构的安全性评估提供有益参考。

1. 试验概况

1.1 试验材料及试件尺寸

试验采用ETFE #250/NJ/

1600 /NT薄膜,其厚度为250μm,密度为1.75 g·cm−3。材料由乙烯和四氟乙烯聚合生成,无色透明,具有优秀的耐化学腐蚀性能和自洁性能[24]。考虑到当前暂无专门的ETFE膜材撕裂性能检测标准,因此参照GB/T 1040.3-2006[25],以ETFE薄膜单轴拉伸试验的长条形试件的尺寸,直接作为单轴中心撕裂试验的试样尺寸,以实现测试需求。试件尺寸为150 mm×25 mm,夹持端长为25 mm,有效测试区域为100 mm×25 mm。散斑区域设置为50 mm×25 mm,散斑直径为0.5 mm。其中,切缝长度为5 mm,切缝方向角以膜材机器展开方向(MD)的垂直线为基准线,逆时针旋转θ。试件示意图如图1所示。另外,为保证试件在拉伸过程中的滑移量可控,采用在试件夹持端处使用粘结剂粘附砂纸的方法,通过增大夹具与试件接触面之间的摩擦系数,提升夹持的稳定性与可靠性。1.2 试验设备

试验选用深圳三思UTM4000型电子万能试验机和尼康D3200高像素照相机。其中,试验机位移速率范围为0.001~500.000 mm·min−1;变形测量范围为10~800 mm,±1‰变形精度;拉压力传感器量程为200 N、精度为0.2 N;尼康D3200高像素照相机拥有

2400 万像素。含中心切缝的ETFE薄膜加载过程中的夹持示意图如图2所示。试验中先对试件施加5 N的预张力,再匀速(50 mm·min−1)加载至试件破坏,并记录试件在试验过程中的变形、荷载和图像数据。1.3 试验工况及环境

试验工况设置为切缝长度、切缝角度和切口样式。其中,切缝长度以2.5 mm为梯度,选取为2.5、5.0、7.5、10.0、12.5和15.0 mm;切缝角度以MD方向为基准,逆时针每旋转15°为一个梯度,选取0°、15°、30°、45°、60°、75°和90°七个角度;切口样式则将典型试件的“一”形切缝更换为其它切口样式,且切口样式可分为开放性切缝(如“一、V、X和十”形等)和封闭性切口(如圆形、椭圆形和矩形切口等)[26];不同切缝角度和切口样式的示意图如图3所示。每个工况的有效试件为3个,以保证试验的有效性。

试验温度控制在(20±2.0)℃,相对湿度控制在(65±4.0)%。

2. 试验结果及分析

2.1 撕裂过程及破坏形态

ETFE薄膜在不同工况下典型撕裂过程如图4所示,其膜面含散斑贴膜以便于观察,三种工况下的ETFE薄膜的撕裂过程均呈现出4个特征状态:

(ⅰ)切缝初始状态:在外加5 N预张力时,因其外加荷载较小,切缝保持未张开状态。

(ⅱ)切缝张开状态:随着外加荷载不断增加,切缝逐渐张开,切缝张开形状近似呈现椭圆形;薄膜在切缝尖端上下邻域展现出显著的面外屈曲现象。

(ⅲ)极限撕裂状态:随着外加荷载进一步增大,切缝开口进一步扩大,面外屈曲现象也变得更加明显,薄膜的塑性变形显著增加;其切缝尖端处由于应力集中效应显著,会形成撕裂三角区,出现明显的颈缩现象,并且切缝开始沿着垂直于加载方向扩展。

(ⅳ)完全破坏状态:在薄膜到达极限撕裂状态以后,随着荷载的增大,切缝扩展速度加剧,薄膜的承载能力不断下降,薄膜最终达到完全破坏状态,丧失所有承载能力,并且不同切口样式导致薄膜呈现的破坏形态各异。

图5为ETFE薄膜在切缝张开状态下的切缝邻域εxy应变云图,该云图可直观的展现出薄膜面外屈曲的位置分布及其方向。据图可知,薄膜的面外屈曲的位置集中分布于切口上下邻域;εxy应变云图集中区呈现“X”型分布,其中,“X”型的中心点与切口的中心点重合。在构成“X”型的同一边上,面外屈曲的方向相同;而在构成“X”型的不同边上,面外屈曲的方向相反。随着切缝长度变化,薄膜面外屈曲的位置几乎保持不变。随着切缝角度变化,面外屈曲的位置仍处于切口上下邻域,随之发生相同角度的倾斜。随着切口样式变化,切口会沿着拉伸方向发生不同的张开变形,从而使薄膜面外屈曲的位置随之变化。

2.2 切缝长度影响

不同切缝长度的ETFE薄膜的撕裂抗力-位移曲线如图6(a)所示,撕裂曲线随切缝长度改变存在规律性衍变,但存在典型共同特征,不妨提取典型撕裂曲线对ETFE薄膜撕裂力学行为进行深入阐释(见图6(b))。

如图6(a)所示,随着切缝长度增大,撕裂抗力-位移曲线的撕裂前段的斜率不发生变化。在撕裂抗力上升阶段,曲线斜率增加的部分随切缝长度增大而逐渐消失;当切缝长度为2.5 mm、5.0 mm时,可明显观察到曲线斜率上升的趋势,而当切缝长度增大至7.5 mm后,曲线的斜率随着位移的增大而越来越小,无法观察到曲线斜率上升。在撕裂后段,当薄膜的切缝长度从2.5 mm增大到15.0 mm,薄膜有效承载截面不断减小,其极限撕裂抗力从130.74 N下降至57.94 N,下降55.68%;断裂位移由45.48 mm下降至11.05 mm,下降75.70%。

如图6(b)所示,典型撕裂曲线以4个特征点为界,可分为3个特征阶段。其中,初始点O为曲线与纵轴的交点,类屈服点A为曲线斜率首次发生变化点,峰值点B为曲线撕裂抗力最大点和破坏点C为曲线与横轴的交点;4特征点分别与典型撕裂过程的4个特征状态相对应。

(OA)撕裂前段:曲线从不为零的初始点O开始,对应着试验前施加的预张力状态;在该阶段ETFE薄膜呈现出显著的线弹性行为,薄膜的初始弹性模量较大。

(AB)撕裂抗力上升阶段:曲线到达类屈服点A后,斜率迅速减小,明显小于撕裂前段的斜率,开始出现较大的塑性变形;随着位移增大,薄膜内部结构会充分发生变化,撕裂抗力不断增加,曲线斜率明显上升;随后由于变形继续增大导致刚度下降,撕裂抗力增加的速度变缓,曲线斜率又开始下降至零。

(BC)撕裂后段:曲线到达峰值点B时,薄膜达到极限撕裂抗力,开始发生显著的撕裂扩展;随着位移增加,撕裂抗力不断下降,并且撕裂扩展的速度不断加快,撕裂抗力下降幅度逐渐变大,最终下降到破坏点C,对应着薄膜完全破坏。

2.3 切缝角度影响

不同切缝角度的ETFE薄膜撕裂抗力-位移曲线如图7所示。随着切缝角度增大,撕裂抗力-位移曲线的撕裂前段的斜率不发生变化,并且类屈服点对应的位移由1.52 mm上升至1.57 mm,撕裂前段所历经的位移仅增加1.97%,曲线几乎同时进入下一阶段。在撕裂抗力上升阶段,不同切缝角度的薄膜的曲线均会呈现出斜率增大的趋势,并且撕裂抗力上升阶段随切缝角度增加而显著变长。在撕裂后段,当切缝角度由0°增大至90°时,对应的等效切缝长度[27]由5 mm减少至0 mm,其极限撕裂抗力由107.69 N上升至134.25 N,断裂位移由24.39 mm上升至79.90 mm。

可见,随着切缝角度的增大,对应的等效切缝长度随之减小,薄膜的承载途径逐渐恢复,用来承受拉伸荷载的有效截面增大,薄膜的极限撕裂强度增强,使薄膜不易到达极限撕裂状态,使得其断裂位移也随之增大。并且当切缝长度保持为5 mm时,切缝角度由0°增大到90°,其极限撕裂抗力和断裂位移分别上升了24.66%和227.59%,断裂位移的变化率远大于极限撕裂抗力的变化率。因此,切缝角度的改变对薄膜的极限撕裂抗力影响较小,而会显著影响薄膜完全破坏时对应的断裂位移。

图8为不同切缝角度的ETFE薄膜的切缝尖端邻域的竖向应变场云图。据图可知,当预制切缝长度为5 mm的“一”形切缝时,薄膜在切缝邻域出现明显的应变集中区(红色区域),并且其应变集中区分布于切缝尖端邻域上,随切缝角度的增加而发生相应的偏转。这是由于薄膜在预制初始切缝后,在切缝尖端邻域,随着拉伸应力的增大,切缝张开导致薄膜沿着切缝方向发生横向收缩,并且在切缝上下邻域处发生面外屈曲,薄膜会向面外凸出,导致切缝尖端邻域处承受的应力远高于其它区域,从而使薄膜在该区域处的竖向应变较大而出现应变集中区。因此,随着切缝角度的增大,薄膜切缝张开所致的横向收缩效应及面外屈曲现象发生相应的变化,使薄膜的应变集中区始终分布于切缝尖端邻域,从而使得薄膜的应变集中区发生相应的偏转。

2.4 切口样式影响

图9为不同切口样式的ETFE薄膜的撕裂抗力-位移曲线。不同切口样式对薄膜撕裂曲线的撕裂后段影响显著,导致含不同切口样式的薄膜在完全破坏时,整体上表现出两种破坏模式:类脆性破坏和类延性破坏。如图9(a)和图9(f)所示,对于无切缝和含圆形切口的ETFE薄膜,撕裂曲线到达峰值点后立即发生破坏,在撕裂后段历经的位移占整个撕裂过程发生的位移比例极小;并且在试验过程中可听到轻脆的崩断声,薄膜突然发生破坏,展现出类脆性破坏特性。而对于图9其它切口样式的ETFE薄膜,则呈现类延性破坏特性。撕裂曲线到达峰值点后,薄膜虽然达到了极限撕裂强度,但并不会立即发生断裂破坏;薄膜的切缝不断扩展,有效承载截面逐渐减小,薄膜在历经较大的位移后才完全破坏,可观察到明显预兆。

图10为撕裂试样典型损伤模式示意图。可知,含切口的ETFE薄膜,在拉伸撕裂过程中,切口破坏了薄膜的完整性,使薄膜较易出现面外屈曲和颈缩,从而使薄膜在切口邻域处出现显著的大变形区。这会导致薄膜的应力分布不均匀,在大变形区出现应力集中,从而引发撕裂,使薄膜在切口尖端处出现撕裂三角区,薄膜的承载性能下降。并随着撕裂三角区的逐渐扩展,薄膜的有效承载区域不断减小,薄膜的承载性能逐渐下降为零。并且,不同切口样式会使薄膜的大变形区不同,从而使其应力集中各不相同,导致不同切口样式使薄膜承载性能的衰减程度各异。

图11为不同切口样式的ETFE薄膜对应的极限撕裂抗力。对于含开放性切缝的薄膜,相较于无切缝薄膜,含“V、X和十”形切缝的薄膜的极限撕裂抗力均约为138.13 N,下降40.58%,而含“一”形切缝的薄膜仅为107.25 N,下降53.86%。因此,当切缝的横向尺寸相同时,“一”形切缝贯穿了薄膜的主要受力方向,应力集中显著,对薄膜的极限撕裂强度的不利影响最大。对于含封闭性切口的薄膜,相较于无切缝薄膜,含圆形和椭圆形切口的薄膜的极限撕裂强度约为151.88 N,下降34.66%,含矩形-I切口的薄膜仅为115.19 N,下降50.44%。因此,当切口的横向尺寸相同时,矩形-I切口由于具有直角边缘等特性,使薄膜的应力集中程度远大于含圆形和椭圆形切口的薄膜,使薄膜承载性能的衰减程度更大。另外,含矩形-II切口的薄膜的极限撕裂强度为129.63 N,相较于无切缝薄膜的下降44.23%。可见,当切口几何外形相同时,对于横向尺寸较大的切口,其周围的应力集中区域较大,薄膜较易产生撕裂扩展,故对薄膜极限撕裂强度的不利影响更大。

3. 结 论

结合系列试验与数字图像相关(DIC)技术,深入分析了乙烯-四氟乙烯(ETFE)薄膜的单轴中心撕裂行为,主要结论如下:

(1) ETFE薄膜的典型撕裂扩展过程呈现出4个特征状态;不同切缝参数显著影响薄膜面外屈曲的位置和破坏形态,但不影响薄膜切缝扩展的方向始终为垂直于加载方向;

(2) ETFE薄膜的撕裂抗力-位移曲线随不同工况的变化而发生非线性衍变,但存在典型共同特征,可划分为3个特征阶段:撕裂前段、撕裂抗力上升阶段和撕裂后段;

(3)当切缝长度从2.5 mm增大到15.0 mm时,薄膜的有效承载截面变小,其极限撕裂强度和断裂位移分别减小了55.75%和75.70%;当切缝角度从0°增大到90°时,薄膜承载途径逐渐恢复,其极限撕裂强度增大了24.67%,而断裂位移却增大了227.59%;

(4)切口样式使薄膜在完全破坏时呈现出类脆性破坏特征或类延性破坏特征。当横向尺寸相同时,在开放性切缝中,“一”形切缝贯穿薄膜主要受力方向,应力集中显著,对薄膜极限撕裂强度的不利影响最大;在封闭性切口中,与光滑边缘切口相比,直角边缘切口使薄膜的应力集中效应更显著,使薄膜易在切口尖角处发生撕裂,造成薄膜承载性能的显著衰减。所得结论可为相关均质性膜材的撕裂力学性能研究和膜结构的安全性评估提供有益参考。

-

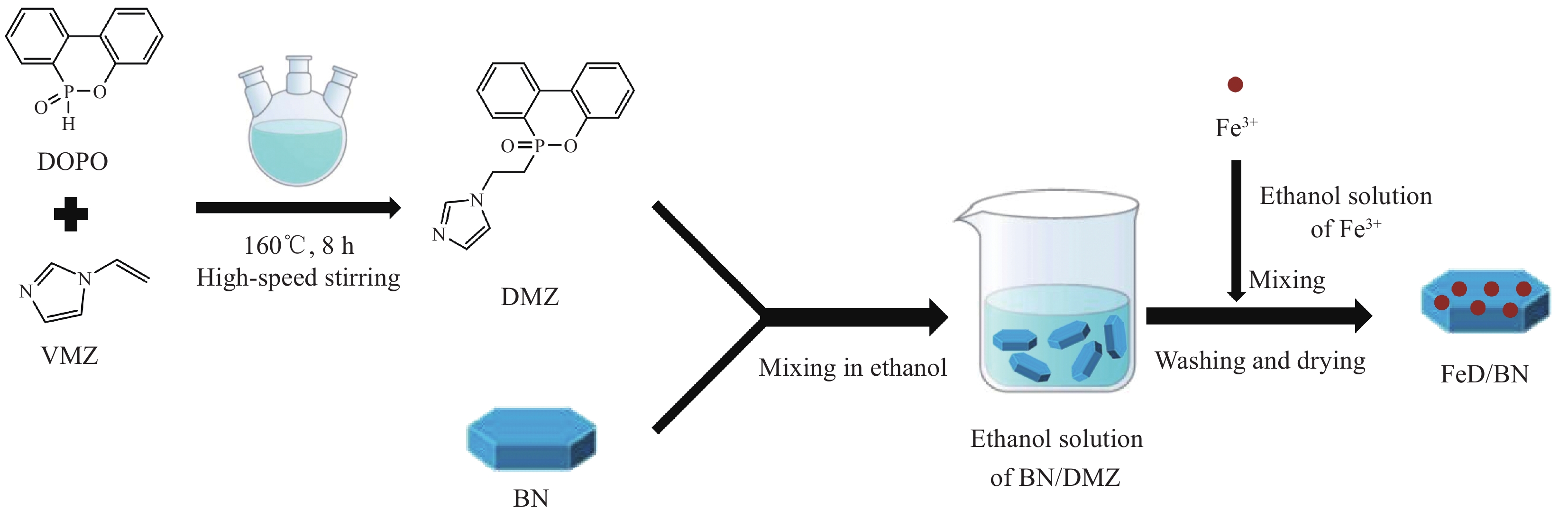

图 1 9, 10-二氢-9-氧杂-10-磷杂菲-10-氧化物(DOPO)的衍生物与Fe(NO3)3反应得到配位化合物(FeD)的制备过程示意图

DOPO—9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide; VMZ—1-vinylimidazole; DMZ—9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide vinyl imidazole derivatives

Figure 1. Schematic illustration of preparation of iron ion coordination compound of 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide vinyl imidazole derivatives (FeD)

表 1 环氧树脂(EP)复合材料的配方

Table 1 Formulations of epoxy resin (EP) composites

Sample EP/wt% DDM/wt% FeD/BN/wt% BN/wt% FeD/wt% EP 80 20 0 0 0 5(Fe/B)/EP 76 19 5 0 0 10(Fe/B)/EP 72 18 10 0 0 15(Fe/B)/EP 68 17 15 0 0 15(Fe-B)/EP 68 17 0 11.38 3.62 15BN/EP 68 17 0 15 0 15FeD/EP 68 17 0 0 15 Notes: FeD/BN—FeD functionalized BN; n(Fe/B)/EP—Epoxy composite with nwt%FeD/BN; 15(Fe-B)/EP—Epoxy composite with 15wt% FeD and BN compound (The compound ratio is calculated according to the load ratio); 15FeD/EP—Epoxy composite with 15wt%FeD; DDM—4, 4-diaminodiphenylmethane. 表 2 EP及其复合材料的锥形量热仪(CCT)测试结果

Table 2 Cone calorimeter (CCT) test results of EP composites

Sample TTI/s pHRR/(kW·m−2) THR/(MJ·m−2) TSR/(m2·s−1) EP 85 1026 111 2770 15BN/EP 125 932 105 2143 15(Fe/B)/EP 109 737 90 1937 15(Fe-B)/EP 102 873 99 2146 15FeD/EP 99 606 91 1655 Notes: TTI—Time to ignition; pHRR—Peak of heat release rate; TSR—Total smoke rate. 表 3 本工作和其他类似导热阻燃EP复合材料的性能比较[17-18, 29]

Table 3 Comparisons of this work and other typical thermal conductive and flame retardant EP composites[17-18, 29]

Filler Size Loading TC/(W·m−1·K−1) LOI/% pHRR Tensile strength Ref. h-BN 1-2 μm 2wt% 0.23 34.3 −44.7% — [29] h-BN 3-5 μm 12.1vol% 1.04 — −68.9% — [18] h-BN 1-2 μm 16wt% 0.69 — −58.2% +31.3% [17] h-BN 5 μm 11.3wt% 0.47 33.2 −28.2% +4.4% This work Notes: TC—Thermal conductivity; LOI—Limiting oxygen index. -

[1] TIAN S. Preparation and properties of nano-SiO2/grapheme flame retardant epoxy resin composites[J]. Journal of Functional Materials, 2020, 51(6): 6052-6056, 6095.

[2] XING W, CHEN L, ZHOU M, et al. Preparation of boron nitride/graphene composite thermal conductive filler and study on flame retardant, thermal conductivity and insulation properties of epoxy resin composites[J]. Scientia Sinica Chimica, 2023, 53(2): 207-216.

[3] WANG Y D, MA L, YUAN J, et al. A green flame retardant by elaborate designing towards multifunctional fire-safety epoxy resin composites[J]. Reactive & Functional Polymers, 2023, 191: 137823.

[4] LU J Y, WANG B B, JIA P F, et al. Designing advanced OD-2D hierarchical structure for epoxy resin to accomplish exceeding thermal management and safety[J]. Chemical Engineering Journal, 2022, 427: 132046. DOI: 10.1016/j.cej.2021.132046

[5] JIANG G Y, XIAO Y L, QIAN Z Y, et al. A novel phosphorus-, nitrogen- and sulfur-containing macromolecule flame retardant for constructing high-performance epoxy resin composites[J]. Chemical Engineering Journal, 2023, 451: 137823. DOI: 10.1016/j.cej.2022.137823

[6] XIAO Y L, MU X W, CHEN S Q, et al. Biomass-derived polyphosphazene toward simultaneously enhancing the flame retardancy and mechanical properties of epoxy resins[J]. Chemosphere, 2023, 311: 137058. DOI: 10.1016/j.chemosphere.2022.137058

[7] ZHANG W J, ZHOU M T, KAN Y C, et al. Synthesis and flame retardant efficiency study of two phosphorus-nitrogen type flame retardants containing triazole units[J]. Polymer Degradation and Stability, 2023, 208: 110236. DOI: 10.1016/j.polymdegradstab.2022.110236

[8] JIA Y, SHI R, HU X, et al. Research progress on thermal conductive epoxy resin composites[J]. Engineering Plastics Application, 2020, 48(4): 139-143, 149.

[9] YANG J, YANG Y, JIA Y, et al. The development in preparation and application of thermal conductive composites[J]. Polymer Bulletin, 2021, 8: 1-8.

[10] NIU W, ZHANG X, QIAO J, et al. Optimization formula design of thermal conductive insulating silicone rubber filler[J]. New Chemical Materials, 2020, 48(1): 115-119.

[11] MIAO Z C, WU Z X, WANG T, et al. In situ synthesis of boron nitride "nanonoodles" based epoxy nanocomposites with enhanced thermal and dielectric properties[J]. Polymer Composites, 2022, 43(8): 5344-5352. DOI: 10.1002/pc.26836

[12] LI Z, LIRA S, ZHANG L, et al. Bio-inspired engineering of boron nitride with iron-derived nanocatalyst toward enhanced fire retardancy of epoxy resin[J]. Polymer Degradation and Stability, 2018, 157: 119-130. DOI: 10.1016/j.polymdegradstab.2018.10.005

[13] WANG C, HAO Z, SHEN Z, et al. Research progress of filler-filled polymer-based thermal conductive materials[J]. Polymer Bulletin, 2022, 1: 18-23.

[14] ZHANG Y R, TUO R, YANG W, et al. Improved thermal and electrical properties of epoxy resin composites by dopamine and silane coupling agent modified hexagonal BN[J]. Polymer Composites, 2020, 41(11): 4727-4739. DOI: 10.1002/pc.25746

[15] HUA Y F, LIU J, ZHANG J Y, et al. A compound with boron and phosphorus towards epoxy resin with excellent flame retardancy, smoke suppression, transparency, and dielectric properties[J]. Chemical Engineering Journal, 2024, 483: 149212.

[16] HE Y F, CUI X Y, LIU Z S, et al. A new approach to prepare flame retardant epoxy resin with excellent transmittance, mechanical properties, and anti-aging performance by the incorporation of DOPO derivative[J]. Polymer Degradation and Stability, 2023, 218: 110579.

[17] BAO Q R, HE R, LIU Y, et al. Multifunctional boron nitride nanosheets cured epoxy resins with highly thermal conductivity and enhanced flame retardancy for thermal management applications[J]. Composites Part A: Applied Science and Manufacturing, 2023, 164: 107309. DOI: 10.1016/j.compositesa.2022.107309

[18] LI X W, FENG Y Z, CHEN C, et al. Highly thermally conductive flame retardant epoxy nanocomposites with multifunctional ionic liquid flame retardant-functionalized boron nitride nanosheets[J]. Journal of Materials Chemistry A, 2018, 6(41): 20500-20512. DOI: 10.1039/C8TA08008A

[19] LIU D Y, CUI Y H, ZHANG T L, et al. Improving the flame retardancy and smoke suppression of epoxy resins by introducing of DOPO derivative functionalized ZIF-8[J]. Polymer Degradation and Stability, 2021, 194: 109749. DOI: 10.1016/j.polymdegradstab.2021.109749

[20] KOROGLU L, AYAS E, AY N. BNNS formation through surface modification of hBN nanopowders with a silane coupling agent[J]. Journal of Dispersion Science and Technology, 2023, 45(8): 2222806.

[21] CHEN Q, WANG Z Z. A copper organic phosphonate functionalizing boron nitride nanosheet for PVA film with excellent flame retardancy and improved thermal conductive property[J]. Composites Part A: Applied Science and Manufacturing, 2022, 153: 106738. DOI: 10.1016/j.compositesa.2021.106738

[22] CAI W, FENG X M, WANG B B, et al. A novel strategy to simultaneously electrochemically prepare and functionalize graphene with a multifunctional flame retardant[J]. Chemical Engineering Journal, 2017, 316: 514-524. DOI: 10.1016/j.cej.2017.01.017

[23] OU M Y, LIAN R C, LI R J, et al. A high-efficient DOPO-based flame retardant as a Co-curing agent for simultaneously enhancing the fire safety and mechanical properties of epoxy resin[J]. Macromolecular Rapid Communications, 2023, 44(18): 202300262.

[24] LI L, LI X W, WAN S B, et al. High-efficiency flame-retardant epoxy resin using phosphoraphenanthrene/thiazole-based co-curing agent[J]. Journal of Thermal Analysis and Calorimetry, 2023, 148(19): 10115-10124. DOI: 10.1007/s10973-023-12363-2

[25] LI J W, ZHENG P L, LIU H Y, et al. An organometallic flame retardant containing P/N/S-Cu2+ for epoxy resins with reduced fire hazard and smoke toxicity[J]. ACS Omega, 2023, 8(18): 16080-16093. DOI: 10.1021/acsomega.2c08226

[26] WANG W, LIU Y, WANG Q. Adjustable boron nitride segregated framework in epoxy resin for high performance thermal management and flame retardant applications[J]. Composites Science and Technology, 2023, 242: 110161. DOI: 10.1016/j.compscitech.2023.110161

[27] JIAO L M, WANG Y, WU Z H, et al. Effect of gamma and neutron irradiation on properties of boron nitride/epoxy resin composites[J]. Polymer Degradation and Stability, 2021, 190: 109643. DOI: 10.1016/j.polymdegradstab.2021.109643

[28] LI G H, MA Y J, XU H Y, et al. Hydroxylated hexagonal boron nitride nanoplatelets enhance the mechanical and tribological properties of epoxy-based composite coatings[J]. Progress in Organic Coatings, 2022, 165: 106731. DOI: 10.1016/j.porgcoat.2022.106731

[29] FENG T T, CUI J H, OU M Y, et al. 0D-2D nanohybrids based on binary transitional metal oxide decorated boron nitride enabled epoxy resin efficient flame retardant coupled with enhanced thermal conductivity at ultra-low additions[J]. Composites Communications, 2023, 41: 101649.

-

其他相关附件

-

目的

随着电子设备及微电子器件逐渐向智能化、集成化和微型化方向发展,其工作频率和热流密度急剧增加,导致大量的热量在设备上积聚,因此对在电子电气领域应用的材料在导热性能、电绝缘性和阻燃性能提出了更高要求。环氧树脂(EP)的导热性能和阻燃性能均较差,为拓宽EP在电子电气领域的应用,在很多应用场合亟需开发高导热、阻燃的EP复合材料。氮化硼(BN)作为绝缘性好、且具有较高导热系数的陶瓷类导热填料,在热管理领域得到了广泛应用,但是其惰性以及与EP基体相容性较差限制了它的应用,另外其阻燃效率也不高。本文通过将一种有机膦酸金属盐阻燃剂负载在BN表面,实现了其阻燃功能化,以期制备导热、阻燃的EP/BN复合材料。

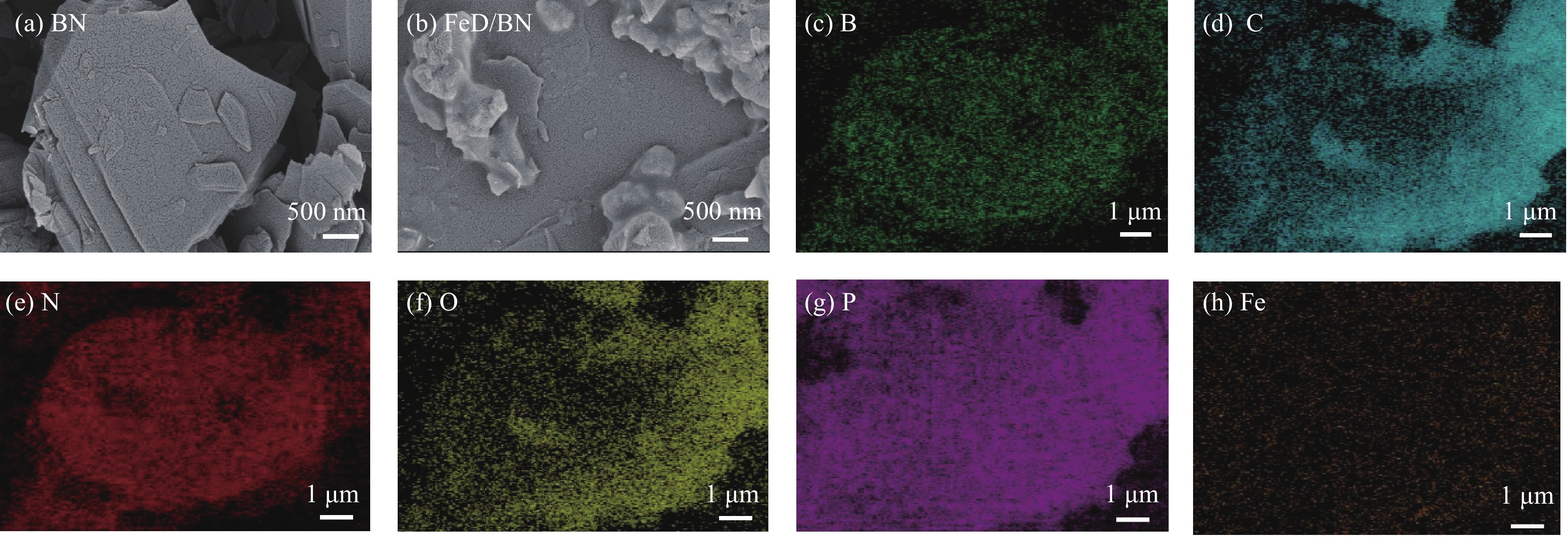

方法利用9,10-二氢-9-氧杂-10-磷杂菲-10-氧化物(DOPO)具有反应活性的P-H键与1-乙烯基咪唑的C=C键进行加成,得到有机膦酸DMZ,进而与Fe(NO)反应得到一种有机膦酸铁阻燃剂(FeD)。通过原位生长的方式将其沉积到BN表面,得到阻燃功能化的BN杂化物(FeD/BN),将FeD/BN加入到EP基体中,制得导热、阻燃的FeD/BN/EP复合材料。利用傅里叶红外(FT-IR)光谱、X射线衍射(XRD)图谱、场发射扫描电子显微镜(SEM)和能谱仪(EDS)对FeD/BN进行了表征。利用垂直燃烧(UL-94)测试、极限氧指数(LOI)测试、利用锥形量热(CCT)测试、导热性能测试和力学性能测试对FeD/BN/EP复合材料综合性能进行评估,并对该复合材料相关的阻燃和导热机理进行了探讨。

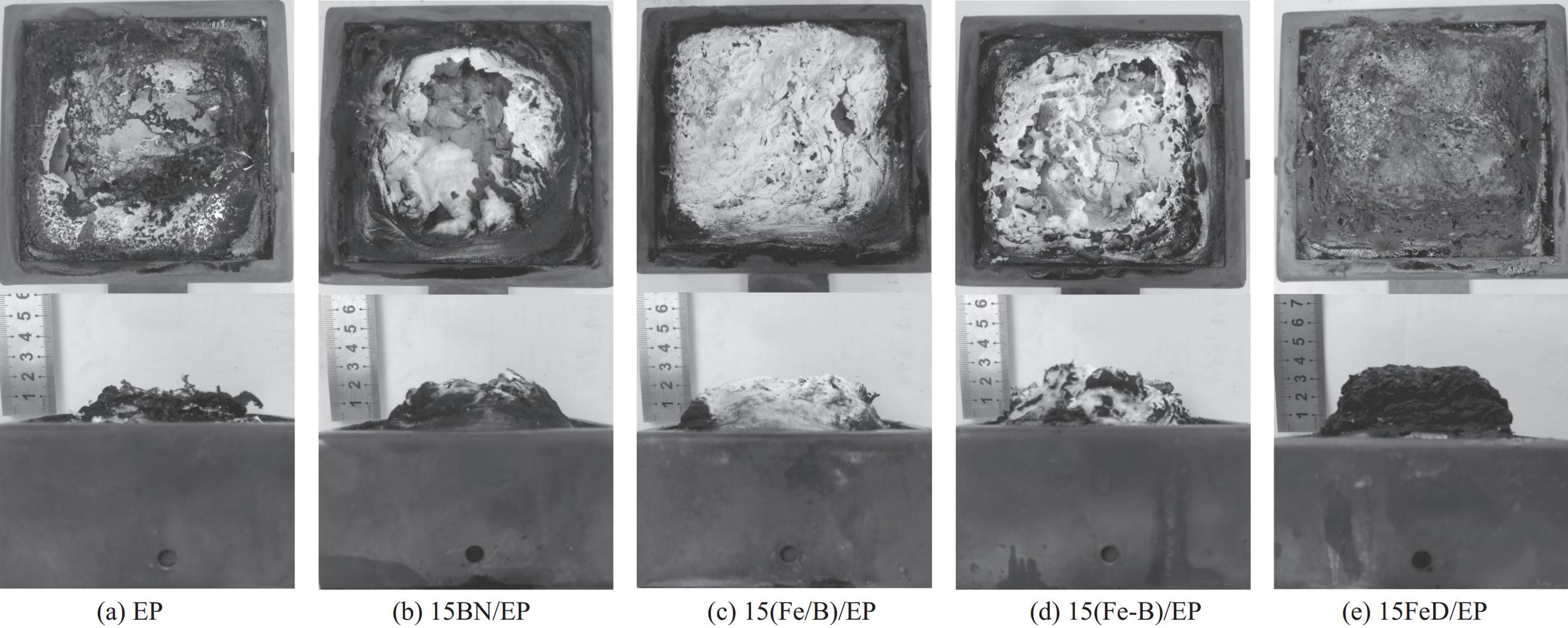

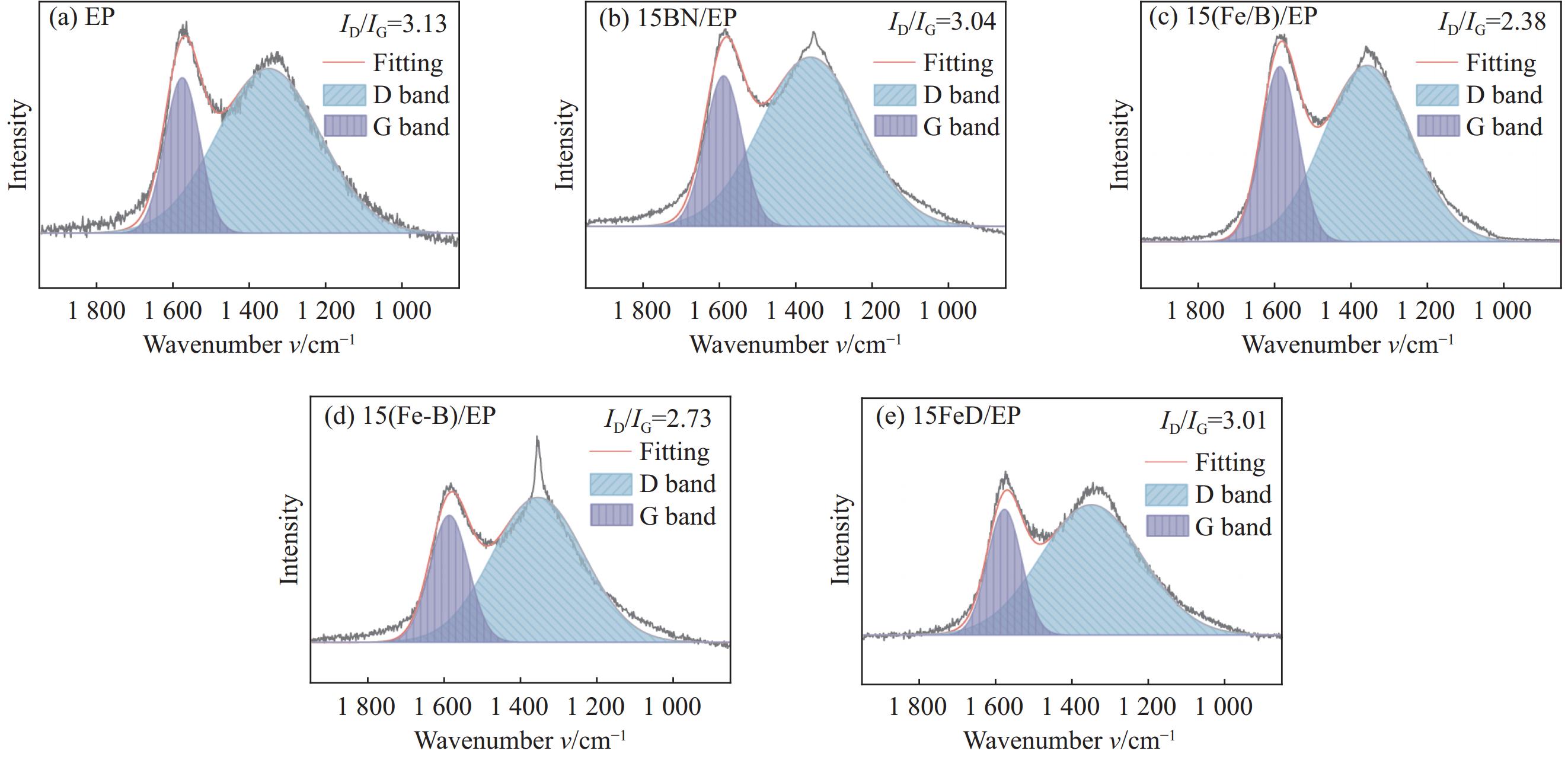

结果从研究结果可以看出:① FT-IR结果反映FeD/BN的表面检测出FeD,同时没有新的化学键生成,表明FeD与BN之间为非共价键左右,初步验证FeD的负载。② XRD结果表明FeD的负载不会影响BN的晶格结构。③ SEM和EDS结果进一步验证了FeD的成功负载。④ FeD/BN/EP复合材料性能研究表明,含有15 wt%的FeD/BN的EP复合材料(15(Fe/B)/EP)的LOI为33.2%,达到了UL-94的V-0级,其峰值热释放速率(pHRR)、总热释放量(THR)和总烟释放量(TSR)相较于纯EP分别降低28.2%、18.9%和30.1%,具有显著的阻燃效果;15(Fe/B)/EP的导热系数相较于纯EP的导热系数提高了235%;此外,与纯EP相比,该复合材料的拉伸强度与冲击强度都有所提高。⑤ 15(Fe/B)/EP在燃烧时能够形成很好的炭层。

结论本文将一种有机膦酸铁阻燃剂(FeD)负载到BN表面,制备阻燃功能化的BN杂化物(FeD/BN),将其应用于EP,制备出导热、阻燃FeD/BN/EP复合材料。相较于EP,含有15 wt%的FeD/BN的EP复合材料(15(Fe/B)/EP)在具有较好的阻燃性能和导热性能的同时,其力学性能也有所提高。FeD/BN在EP中气相和凝聚相均起到一定的阻燃作用。与其它类似工作的导热阻燃EP复合材料相比,本文所合成的FeD/BN因与EP之间具有较好的相容性,在相对较少的添加量下其EP复合材料的阻燃性能、导热性能和力学性能都得到了显著的改善。

-

随着电子设备及微电子器件逐渐向智能化、集成化和微型化方向发展,其工作频率和热流密度急剧增加,导致大量的热量在设备上积聚,因此,在电子电气领域应用的材料需要同时具有优异的导热性能、电绝缘性和阻燃性能。环氧树脂导热和阻燃性能均表现较差,极大限制了其在电子电气领域的应用。

本文通过将9,10-二氢-9-氧杂-10-磷杂菲-10-氧化物衍生物(DMZ)与Fe(NO3)3反应得到的配位化合物(FeD)在BN表面进行原位生长,制备出阻燃功能化氮化硼(FeD/BN),将FeD/BN加入到EP中,制备导热阻燃的EP复合材料。在惰性的BN表面上负载FeD不仅改善了BN与EP的相容性,同时也改善其在EP中的导热与阻燃性能。在15% FeD/BN的添加量下,EP复合材料的LOI达到33.2%, UL-94达到V-0级,峰值热释放速率(pHRR)、总热释放量(THR)和总烟释放量(TSR)相较于纯EP分别降低28.2%、18.9%和30.1%,阻燃性能得到显著改善;该EP复合材料的导热系数相较于纯EP的导热系数提高了235%。

EP复合材料的(a)HRR曲线,(b)THR曲线

下载:

下载: