Influence of temperature and humidity curing environments on the bonding performance of CFRP-steel plate interfaces

-

摘要:

为了揭示温湿度共同养护作用下对碳纤维增强聚合物(CFRP)粘贴钢板界面破坏模式和剥离机制的影响,本文通过CFRP-钢双剪粘结试验,综合考虑温度、湿度、粘结长度和胶层厚度多因素对CFRP-钢板界面粘结性能的影响,采用3D-DIC技术获得CFRP板表面的应变场,分析了静载拉伸过程中CFRP-钢粘结界面力学性能及破坏过程。研究结果表明:在60℃与60%相对湿度养护条件下粘结峰值荷载较高;低温和高湿环境都更易导致钢-胶界面失效;温度升高和湿度增加均会导致界面剪应力峰值降低与滑移量增加;粘结长度的增加有助于更广泛分散区域应力,而较薄(0.5 mm)的胶层有助于提高界面剪应力峰值和改善应力分布。最后,基于试验数据通过平滑法得到了简化的三折线剪切-滑移模型,为CFRP加固钢板结构的工程应用提供了理论支持和设计参考。

Abstract:To investigate the impact of combined temperature and humidity curing conditions on the failure modes and delamination mechanisms of carbon fiberreinforced polymer (CFRP)-bonded steel interfaces, this study conducted double-shear bonding tests on CFRP-steel composites, considering multiple factors such as temperature, humidity, bonding length, and adhesive layer thickness. The influence on the interfacial bonding performance of CFRP-steel interfaces was analyzed comprehensively, and the axial strain distribution of CFRP during static tensile processes was monitored using 3D-DIC technology. The findings reveal that peak bonding load is higher under curing conditions of 60℃ and 60% relative humidity, whereas low temperature and high humidity environments are more prone to cause failure at the steel-adhesive interface. Both increased temperature and humidity resulted in a reduction in interfacial shear stress peak values and an increase in slip, illustrating the impact of temperature and humidity on the ductility and adhesive properties of the interface. Additionally, it was found that an increase in bonding length helps disperse stress across a wider area, and a thinner adhesive layer contributes to higher interfacial shear stress peaks and improved stress distribution. Lastly, based on the experimental data, a simplified trilinear shear-slip model was derived using the smoothing method, providing theoretical support and design reference for the engineering application of CFRP-reinforced steel structures.

-

Keywords:

- CFRP-steel plate /

- double-lap shear test /

- 3D-DIC /

- smoothing method /

- shear-slip

-

近年来,碳纤维增强聚合物(Carbon fiber reinforced polymer,CFRP)因其卓越的力学性能和耐腐蚀性被广泛应用于钢结构的加固工程中。有研究表明CFRP与钢结构之间的界面粘结性能是两者共同工作的基础,对于加固的效果影响较大,其界面剪切滑移性能一直是研究的重点和热点。目前,对于两者界面性能的研究焦点主要集中在以下几个方面[1]:一是探讨在不同荷载条件下,包括静态和疲劳载荷,CFRP与钢板界面的粘结机制[2-3];二是研究温度变化对界面粘结性能的影响[4];三是评估环境因素,如盐雾、碱性环境以及水浸泡条件下,CFRP-钢板界面的粘结强度及其耐久性[5]。在现代土木工程中,加固构件常面临恶劣的环境条件,因此,其使用的材料,尤其是粘结界面的耐久性成为确保结构长期稳定性的关键。已有研究指出[6-7],环境因素中的温度和湿度是影响粘结结构耐久性的两大主要因素。

目前,对于CFRP-钢之间的粘结滑移性能的研究主要聚焦于低温、高温及盐碱极端服役环境下,通过单搭接、双搭接试验以及钢梁构件的测试,深入探讨了不同类型胶粘剂对CFRP-钢粘结界面性能的影响,并基于胶粘剂的物理性质,衍生了一系列的本构模型来描述CFRP-钢界面的粘结行为[8-10]。此外,针对高温环境下CFRP-钢界面性能的研究,揭示了服役阶段下温度对粘结性能的显著影响,尤其是当环境温度接近或超过胶粘剂的玻璃化转变温度时,粘结强度和界面断裂能的显著下降[11-12]。Nguyen等[13]通过实验发现,Araldite 420环氧胶粘剂在养护阶段为高温高湿环境下表现出较好的稳定性。而其他研究则表明[14-17],胶粘剂在特定环境条件下,如海水浸泡后的强度和刚度会显著降低,从而影响到整个粘结系统的性能。Yu等[18]通过研究一系列单剪或双剪试验分别探讨了张开型和滑开型破坏机制发现,胶层性能、厚度以及CFRP的轴向刚度等因素对粘结界面的破坏模式有显著影响,指出建立针对不同粘结剂的粘结-滑移模型的必要性。这些研究虽然为理解CFRP-钢界面粘结性能提供了基础,但在养护阶段对温湿度联合作用下CFRP-钢界面粘结性能的系统性研究仍相对缺乏。因此,深入探索CFRP-钢板在不同温湿度养护下的性能变化,对于指导实际应用具有重大意义。

在CFRP-钢板界面粘结的试验研究中,测量CFRP轴向应变用来分析粘结-滑移关系至关重要。传统的测量方式是通过在CFRP表面粘贴应变片完成的,但由于成本和方法的考虑,应变片的粘贴往往存在较大的间距,使得测试的应变存在较大的不连续性。数字图像相关技术(Digital image correlation,DIC)作为一种无接触式光学测量手段,通过数字图像相关和立体相机观察原理的测量方法能够重建被测物表面点在变形前后的三维空间坐标,从而获取物体表面形貌及其三维变形信息。与传统应变片方法相比具有可视化和精确度高的特点和优势,在多个研究领域[19-22]得到了广泛应用。众多学者[23-24]已成功利用3D-DIC技术在探究CFRP与钢板粘结的研究中获得了理想的测定结果,为本次CFRP-钢板界面粘结的研究提供了重要参考。

基于前文的介绍,前人多研究于服役阶段单一温度因素或者极端环境下(浸于某溶液下)的类似研究。考虑到结构室外环境的多变性,本文主要通过双剪试验,研究CFRP-钢粘结界面在养护阶段对3类温度(−10℃、25℃、60℃)与3类相对湿度下(30%、60%、90%),探究4种粘结长度(40 mm、60 mm、80 mm、100 mm)、2种胶层厚度(0.5 mm、1 mm)对界面粘结-滑移、界面剪应力分布,峰值荷载及界面破坏模式等的影响。最终通过平滑法拟合得到考虑温湿度养护环境下,CFRP-钢界面三折线剪切-滑移本构关系,为CFRP应用在复杂温湿度环境下的钢结构加固工程应用提供相应的参考依据。

1. 试验方案

1.1 原材料

本文试验采用的钢板型号为Q345B,尺寸为200 mm×50 mm×10 mm。粘结剂类型为Huntsman Corporation公司生产的Araldite-2015。CFRP板型号为东丽T300,碳纤维型号M40J,环氧树脂含量33%。3种材料的力学性能指标见表1所示。

表 1 材料力学性能Table 1. Material propertiesMaterial Tensile

strength/

MPaYield

strength/

MPaShear

strength/

MPaTensile

modulus/

MPaElasticity

modulus/

GPaBending

strength/

MPaBending

modulus/

MPaInterlayer shear

strength/GPaPoisson’s

ratioElongation of

fractureSteel plate 455 345 – – 206 – – – 0.3 – Adhesive 31 – 23 1600 1.6 43 1800 – – 4.2% CFRP plate 2050 – – – 117 1710 117000 76.6 – – Notes: The adhesive parameter indicators were cured for 16 h at 40℃ and tested at 23℃; CFRP—Carbon fiber reinforced polymer. 1.2 试件设计与制作

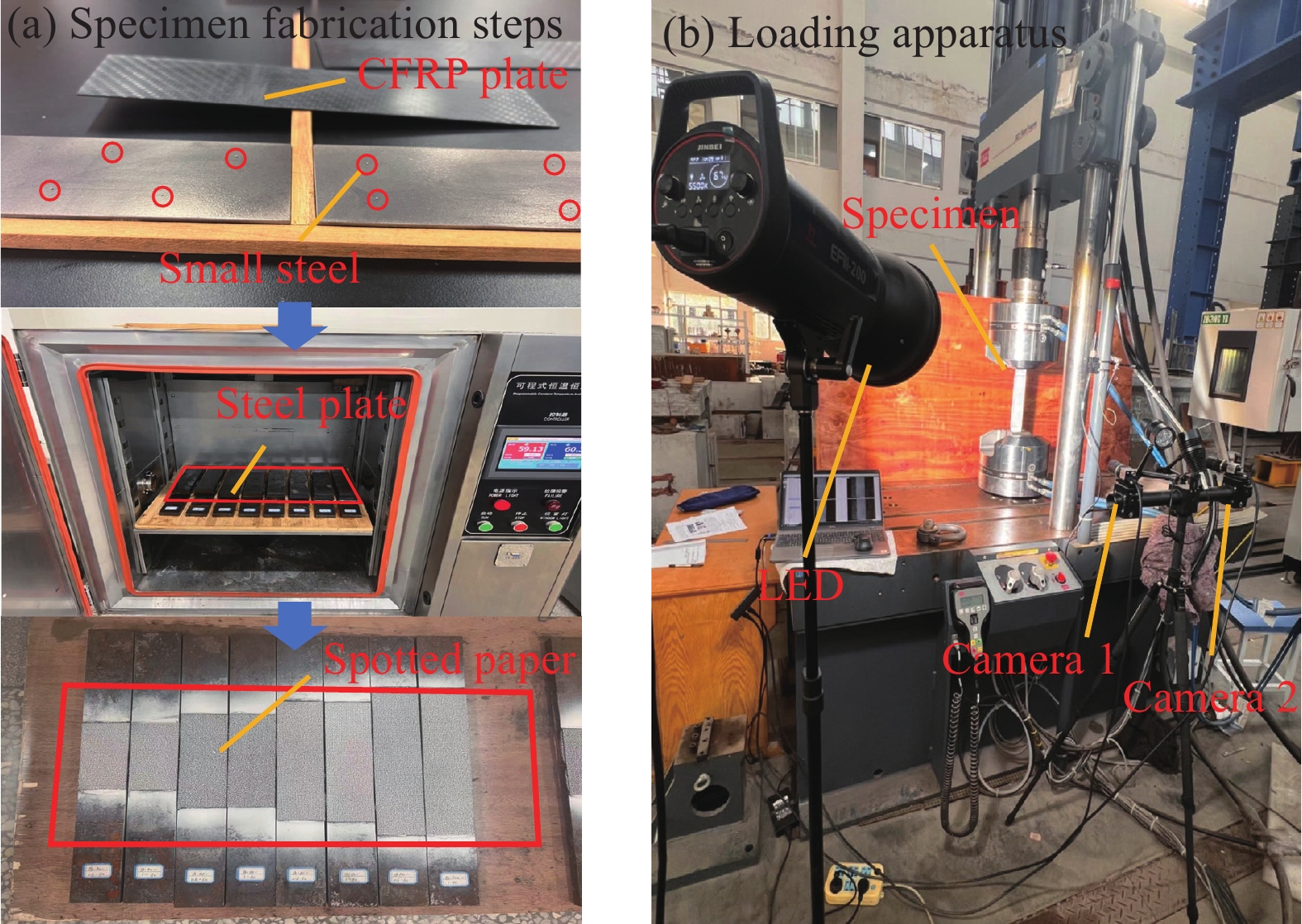

双剪试件由两块钢板、两块CFRP板通过粘结剂粘结组成,两块钢板横向间隙为8 mm。本次试验所设计的CFRP-钢板试件的粘结尺寸参考文献[25]中的不等长CFRP加固对接钢板,其目的是让试件的破坏都发生在粘结长度L的一边。其中单块CFRP板长度分别为100 mm、140 mm、180 mm、220 mm,分别对应粘结长度40 mm、60 mm、80 mm、100 mm,宽度均为50 mm,胶层厚度[26]分别取0.5 mm和1 mm。试件具体设计尺寸见图1所示。本次试验制作双剪[27]试件共56个,对试验数据处理后离散性较大的试件进行了补做和替换,保证了试验的可靠度。试件编号采用温度-粘结长度-胶层厚度-相对湿度表示,例如:A-40-0.5-30代表A组(养护温度A组为−10℃,B组为25℃、C组为60℃)粘结长度40 mm,胶层厚度0.5 mm,相对湿度30%,具体参数详见表2。

表 2 CFRP-钢板试件及试验结果Table 2. CFRP-steel plate specimens and test resultsSpecimen number Ultimate load/kN Failure mode τmax/MPa s1/mm s2/mm sf/mm Gf/(N·mm−1) A-40-0.5-30 67.29 d 30.13 0.0139 0.1093 0.2065 4.5489 A-60-0.5-30 74.35 d+c 23.93 0.0154 0.0442 0.3298 4.2893 A-80-0.5-30 69.52 d 18.38 0.0180 0.0720 0.4220 4.3752 A-100-0.5-30 76.11 d 14.02 0.0271 0.2158 0.5061 4.8704 A-40-1-30 47.04 c 19.06 0.0216 0.0537 0.1588 1.8191 A-60-1-30 72.34 d 23.87 0.0057 0.1324 0.3116 5.2311 A-80-1-30 72.44 d 18.50 0.0207 0.2262 0.4757 6.3012 A-100-1-30 81.08 d 15.86 0.0257 0.0459 0.6624 5.4115 B-40-0.5-30 59.56 c 32.65 0.0219 0.1121 0.1533 3.9750 B-60-0.5-30 84.09 d 22.07 0.0159 0.2394 0.3866 6.7324 B-80-0.5-30 86.50 b 30.64 0.0273 0.0770 0.5250 8.8029 B-100-0.5-30 85.40 a 33.98 0.0404 0.1163 0.2516 5.5646 B-40-1-30 71.93 d 26.74 0.0070 0.0300 0.2026 3.0164 B-60-1-30 73.38 d 22.37 0.0491 0.0953 0.2866 3.7215 B-80-1-30 87.98 b 23.03 0.0292 0.3653 0.4954 9.5767 B-100-1-30 57.21 b 24.95 0.1078 0.1351 0.4667 6.1613 B-40-0.5-60 57.12 d 27.92 0.0081 0.0501 0.2337 3.8495 B-60-0.5-60 84.45 a 30.47 0.0259 0.2859 0.4528 10.8612 B-80-0.5-60 65.77 b 34.35 0.0857 0.1773 0.3018 6.7566 B-100-0.5-60 80.90 a 29.64 0.0943 0.1865 0.4257 7.6737 B-40-1-60 52.96 d 27.69 0.0030 0.1004 0.1912 3.9953 B-60-1-60 64.99 c 25.12 0.0017 0.2172 0.3255 6.7948 B-80-1-60 85.35 a+b 23.23 0.0074 0.3458 0.4834 9.5441 B-100-1-60 66.94 a 25.35 0.0639 0.1783 0.3427 5.7938 B-40-0.5-90 62.78 c 37.98 0.0057 0.0710 0.2870 6.6892 B-60-0.5-90 63.00 b+d 30.63 0.0128 0.1979 0.3512 8.2143 B-80-0.5-90 88.32 a 27.33 0.0569 0.2586 0.3678 7.7814 B-100-0.5-90 81.84 b 36.33 0.0971 0.1761 0.4318 9.2786 B-40-1-90 65.98 d 28.58 0.0087 0.1280 0.2168 4.8008 B-60-1-90 79.41 d 20.66 0.0136 0.2150 0.3070 5.2518 B-80-1-90 58.88 a+b+d 29.42 0.0779 0.1786 0.2869 5.7010 B-100-1-90 81.63 a 28.37 0.0895 0.2477 0.4425 8.5191 C-40-0.5-30 68.81 a+c+d 31.16 0.0105 0.1313 0.2109 5.1678 C-60-0.5-30 77.71 a+c 34.25 0.0602 0.2017 0.3410 8.2637 C-80-0.5-30 68.80 a+d 33.73 0.1037 0.1691 0.3123 6.3685 C-100-0.5-30 78.83 a+d 26.69 0.1521 0.2635 0.4790 7.8810 C-40-1-30 63.82 a+c+d 29.84 0.0989 0.1398 0.2459 4.2798 C-60-1-30 85.15 a 31.29 0.0328 0.2751 0.4459 10.7671 C-80-1-30 71.38 a+d 22.53 0.0741 0.1995 0.3641 5.5140 C-100-1-30 67.91 d 17.92 0.0833 0.1780 0.2939 3.4820 C-40-0.5-60 69.81 a+c 24.23 0.0613 0.1075 0.1917 2.8820 C-60-0.5-60 81.95 a 27.03 0.0777 0.2885 0.3990 8.2411 C-80-0.5-60 93.97 b 26.10 0.0804 0.3073 0.4559 8.9127 C-100-0.5-60 73.67 a+b 32.20 0.0896 0.1911 0.3407 7.1183 C-40-1-60 73.90 a+c 33.70 0.0077 0.0247 0.2588 4.6481 C-60-1-60 94.26 a 32.89 0.0182 0.2193 0.4691 11.0239 C-80-1-60 88.98 a 23.23 0.0482 0.3268 0.5113 9.1776 C-100-1-60 83.96 a+b 28.01 0.1358 0.2581 0.4303 7.7389 C-40-0.5-90 50.65 d 14.61 0.0224 0.0809 0.1257 1.3463 C-60-0.5-90 44.04 d 12.26 0.0019 0.1080 0.1563 1.6087 C-80-0.5-90 41.31 d 14.82 0.0094 0.0316 0.1627 1.3706 C-100-0.5-90 70.26 a+d 10.47 0.0235 0.2705 0.3916 3.3420 C-40-1-90 58.59 c+d 23.65 0.0204 0.1056 0.1973 3.3410 C-60-1-90 52.88 d 11.96 0.0051 0.0799 0.2413 1.8898 C-80-1-90 39.81 c+d 15.00 0.0140 0.3404 0.5040 6.2288 C-100-1-90 63.81 b+d 16.74 0.0517 0.2081 0.3681 4.3897 Notes:A-40-0.5-30—Group A (−10℃), 40 mm bonding, 0.5 mm adhesive, 30% RH; τmax—Max shear stress; s1—Slip at max stress; s2—Slip at plateau end; sf—Max interface slip; Gf—Fracture energy; a—CFRP delamination; b—CFRP fracture; c—Adhesive failure; d—Steel-adhesive failure; Group A's humidity was ~30% due to curing chamber limitations. 制作试件时,首先将切割好的钢板经磨光机打磨抛光后贴上标签。在粘贴CFRP板之前用丙酮溶液擦拭抛光的钢板表面,确保干燥无尘后将4~5颗小钢珠均匀放置在抛光钢板表面,小钢珠的直径为0.5 mm和1 mm,以得到两种不同的胶层厚度。CFRP板粘贴之前用粗砂纸打磨至露出表面树脂即可,不可过度打磨而造成CFRP板的内部纤维的损伤。将被粘贴CFRP板的另一面画线确保其粘结长度,之后用棉球蘸丙酮溶液将打磨面擦拭干净,晾置干燥。随后将Araldite-2015 A胶与B胶按质量1∶1混合并快速搅拌,随后将胶均匀涂抹在CFRP上,粘结CFRP与钢板,用力挤压使得胶结剂外溢,排除气泡。最后将两块钢板压于CFRP上,将其置于汇泰生产的H-S-1000L可程式恒温恒湿箱下养护7 d后[1, 27],将钢板的另一面重复上述粘结步骤,再次置于恒温恒湿箱养护7 d待其完全固化。试验开始之前,将待观察应变的一侧CFRP板用砂纸打磨,然后喷白色哑光漆,待其干燥后,粘贴专用的散斑纸以造成像素颜色对比,以供相机采集需要。试件具体制作步骤如图2(a)所示。

1.3 试验加载装置及程序

试验加载均在美特斯生产的MTS322型疲劳试验机上进行,试验机最大拉力500 kN,静载精度不低于示值的±0.5%,加载过程通过位移控制,速率为0.2 mm/min,试验机采集频率为100 Hz。试验过程中应用合肥中科君达视界技术股份有限公司生产的双目3D-DIC非接触应变测量系统,用来记录加载过程中CFRP板的应变分布变化,加载前用LED灯作辅助光源,防止光线不均匀变化对图像的影响。之后,用标定板对试件标定,确定CFRP板上的散斑点的位置与软件中对应点位置的关系。加载结束后,使用3D-DIC软件计算CFRP表面应变数据。相机采集频率设定为1 Hz,与MTS系统同时采集。加载现场如图2(b)所示。

2. 试验结果与分析

2.1 破坏模式

试验中出现的破坏模式包括CFRP层离、CFRP断裂、胶层失效、钢-胶失效4种破坏模式,各典型破坏模式下的破坏形态图见图3所示。汇总各个试件的破坏模式及极限荷载见表2所示。

静载加载初期所有试件随着位移增大,荷载近似呈线性增加,加载初期均无异象,粘结界面呈良好的线弹性。荷载增大到一定数值时,试件会发出“砰、啪、滋”声,局部破坏均从加载段开始,之后逐步向自由端扩展。荷载达到极限荷载时,发出“崩”一声,有时伴有胶体碎屑飞出,荷载骤降,加载结束。

A组中,当胶层厚度相同时,随着L的增大,其峰值荷载也随之增大;当L=40或60 mm时,峰值荷载有A-40-0.5-30>A-40-1-30,A-60-0.5-30>A-60-1-30;当L=80或100 mm时,峰值荷载有A-80-0.5-30<A-80-1-30,A-100-0.5-30<A-100-1-30,这一规律与王海涛等[28]关于结构胶类型与CFRP板-钢界面粘结性能的影响类似。他们发现Araldite-2015胶在低温环境下,尽管其极限强度和弹性模量较低,但由于变形能力较强,因此在承载能力上表现更加优异。这种规律体现了在低温下胶层厚度对粘结界面荷载承受能力的复杂影响。与A-40-0.5-30相比,A-40-1-30胶层较厚会导致胶层固化不均匀或存在内部应力,尤其是在低温环境下,胶层固化速度较慢,使得胶层粘结强度不足,导致试件的极限荷载降低,相对于其他A组试件,其粘结长度较短,限制了试件的粘结面积,进而影响了极限荷载。综合来看,Araldite-2015作为一种环氧树脂胶,在低温下其粘结性能会受到影响,包括粘结强度和胶层的柔韧性。低温会使胶层变得更加脆性,难以承受加载过程中的剪切应力,从而加快了钢-胶界面的剥离。B组中L=40 mm的试件峰值荷载相对于其他粘结长度的试件偏低;在相同的粘结长度下,胶层厚度与湿度的增加对B组峰值荷载的提升不明显,相对于C组,B组试件峰值荷载的变化相对稳定。分析其原因是高湿度(如B组和C组的90%)导致胶层吸水和软化,从而影响粘结性能,增加CFRP层离(图3(a))和钢-胶界面的失效(图3(d))。C组在60℃的高温下,胶粘剂的固化反应加速,然而,高温也引起胶层和CFRP的热膨胀,两者热膨胀系数存在显著差异,导致固化后的内应力增加,影响结构的整体性能和失效模式。

2.2 CFRP-钢板荷载位移曲线

各试件的荷载-位移曲线见图4和图5。所有试件的荷载-位移曲线的起始部分均表现为近似线性上升,这表明在初始荷载作用下,试件的位移与荷载大致呈正比,显示出材料的线弹性。此阶段,胶层与CFRP及钢板之间的粘结性能良好。随着荷载的继续增加,曲线开始出现非线性,即位移增加的速率大于荷载增加的速率,这是由于材料接近极限强度,内部开始产生塑性变形或微裂纹等损伤现象。每条曲线在达到最高点即峰值荷载后,构件荷载承载能力急剧降低。此时,CFRP层与胶层可能发生了剥离,或CFRP层内部出现了裂纹或分层现象,导致整个粘结系统被破坏。

A组中不同试件的峰值荷载有明显的差异。从图4(a)可以看出,粘结长度增加(例如从A-40-0.5-30到A-100-0.5-30)会导致峰值荷载的提高,这表明更长的粘结长度有助于提高结构的承载能力。胶层厚度也对峰值荷载有影响。在同一粘结长度下,A-40-0.5-30比A-40-1-30峰值荷载更大。在B组中(图4(b)~4(d)),对于粘结长度和温湿度条件相同的试件,胶层厚度为0.5 mm的试件通常比1 mm的有更高的峰值荷载。这是由于较薄的胶层提供了更均匀的应力分布和更好的应力传递。在C组中(图5),峰值荷载随着粘结长度的增加而增加的趋势在C组试件中同样存在,但并非严格线性。类似图5中所有曲线在超过峰值荷载后突然下降到某一值,然后缓缓上升形成一个平台段。其产生的原因有:(1) 在CFRP材料内部发生层间分层,这种损伤进展相对缓慢,因此在曲线上呈现为一个平台段;(2) 胶层在经历初始的弹性变形后,可能进入塑性变形阶段,即使在某些纤维或胶层失效后,残余的材料仍能承担一定的荷载;(3) 当荷载超过粘结界面的最大承载能力时,CFRP层与胶层或胶层与钢板之间开始发生剥离。剥离初始是突然的,导致荷载的快速下降。但剥离扩展需要一定的能量,这可能导致荷载下降后出现平台段。

与−10℃相比,在25℃和60℃下,峰值荷载通常会提高,这是由于温度的提高有利于胶粘剂的固化。在高温环境下,李传习等[6]发现,高温会导致接头承载力下降,但他们使用的高强度胶粘剂显示出良好的高温性能,证明了在CFRP-钢界面性能中温度与胶层厚度间复杂的相互作用。然而,本文中过高的温度(C组的60℃)会导致胶层过度软化,引起粘结性能的降低。在低湿度环境下(A组和B组的30%湿度),峰值荷载较高,说明干燥条件有利于粘结强度的维持。高湿度条件(如C组的90%湿度)会显著降低峰值荷载,湿度的增加导致胶粘剂吸水性能降低。温度和湿度对峰值荷载的影响显著,适宜的温度可以提高峰值荷载,而不适宜的高温或高湿度则导致峰值荷载降低。C组数据显示,相同粘结长度与胶层的试件峰值荷载有如下关系,60%>30%>90%。例如,C-40-0.5-60>C-40-0.5-30>C-40-0.5-90,C-40-1-60>C-40-1-30>C-40-1-90,C组除C-100-0.5-X,其他试件都符合该规律。表明在高温高湿条件下,粘结剂的性能显著下降。相对湿度为30%时,粘结长度的增加并不总是导致峰值荷载增加,这与粘结长度增加引入的应力集中和材料性能在长粘结面上的不均匀分布有关。从荷载位移曲线结合破坏模式来看,当相对湿度为30%与90%时,养护试件温度应该优选25℃;当相对湿度为60%时,养护试件温度优选60℃。

3. 粘结破坏机制

3.1 CFRP应变分布

图6为试件A-100-0.5-30在不同荷载下的应变云图。3D-DIC技术的应用有效地捕捉了不同荷载下应变分布的演化。最初,应变主要集中在加载端,呈现出高应变梯度。随着荷载的增加,应变影响区域逐渐向自由端扩散,表明剪应力界面的影响区逐渐增大。3D-DIC技术的优势在于能够提供全场的、非接触式的应变分布数据,允许对材料表面的应变状态进行连续动态监测。这不仅有助于揭示荷载与应变分布范围之间的关联性,还使得对材料在实际工况下的行为有更深入的了解,特别是在捕捉局部应变和应力集中现象方面,3D-DIC显示出了其不可替代的分析优势。

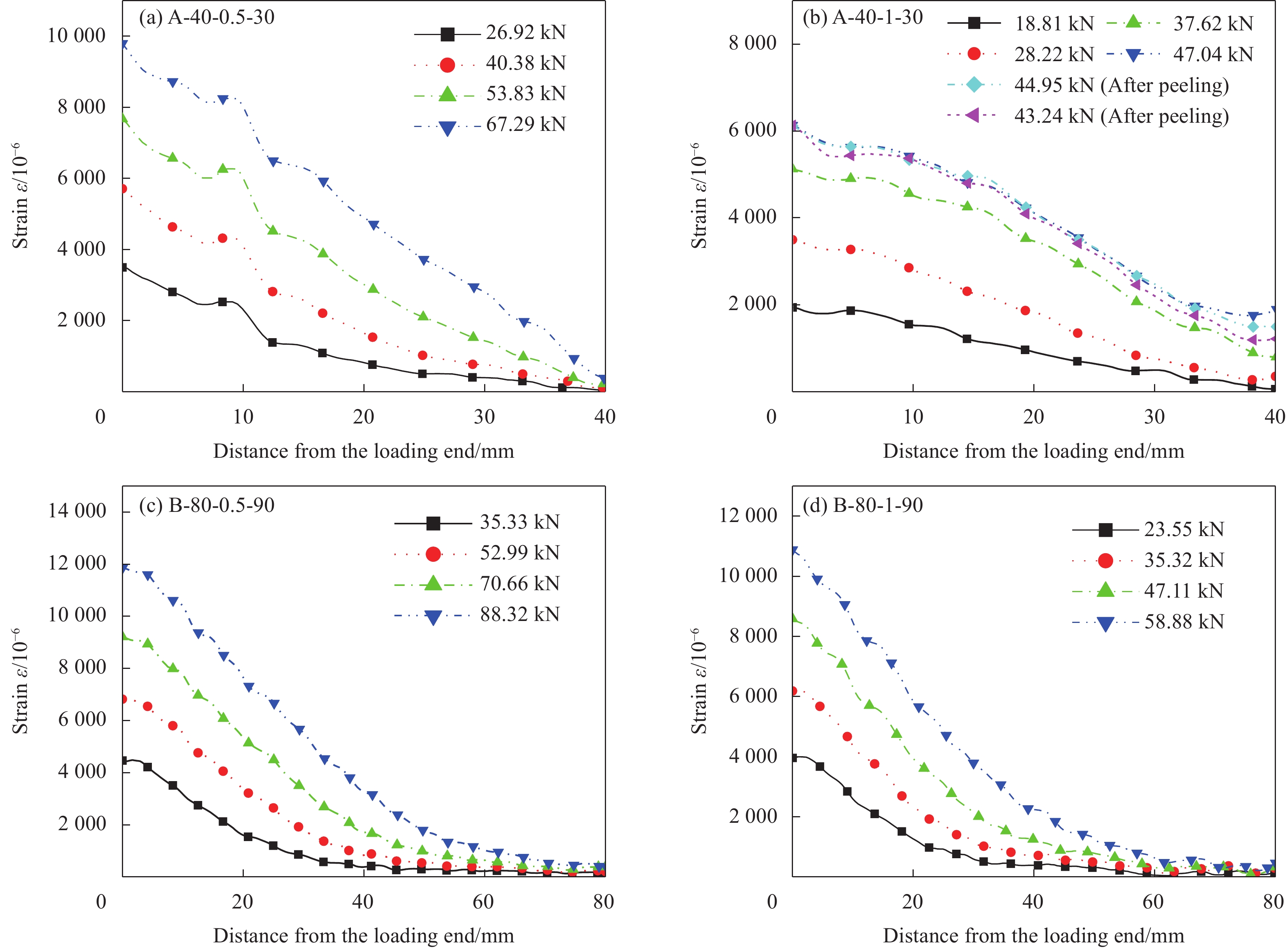

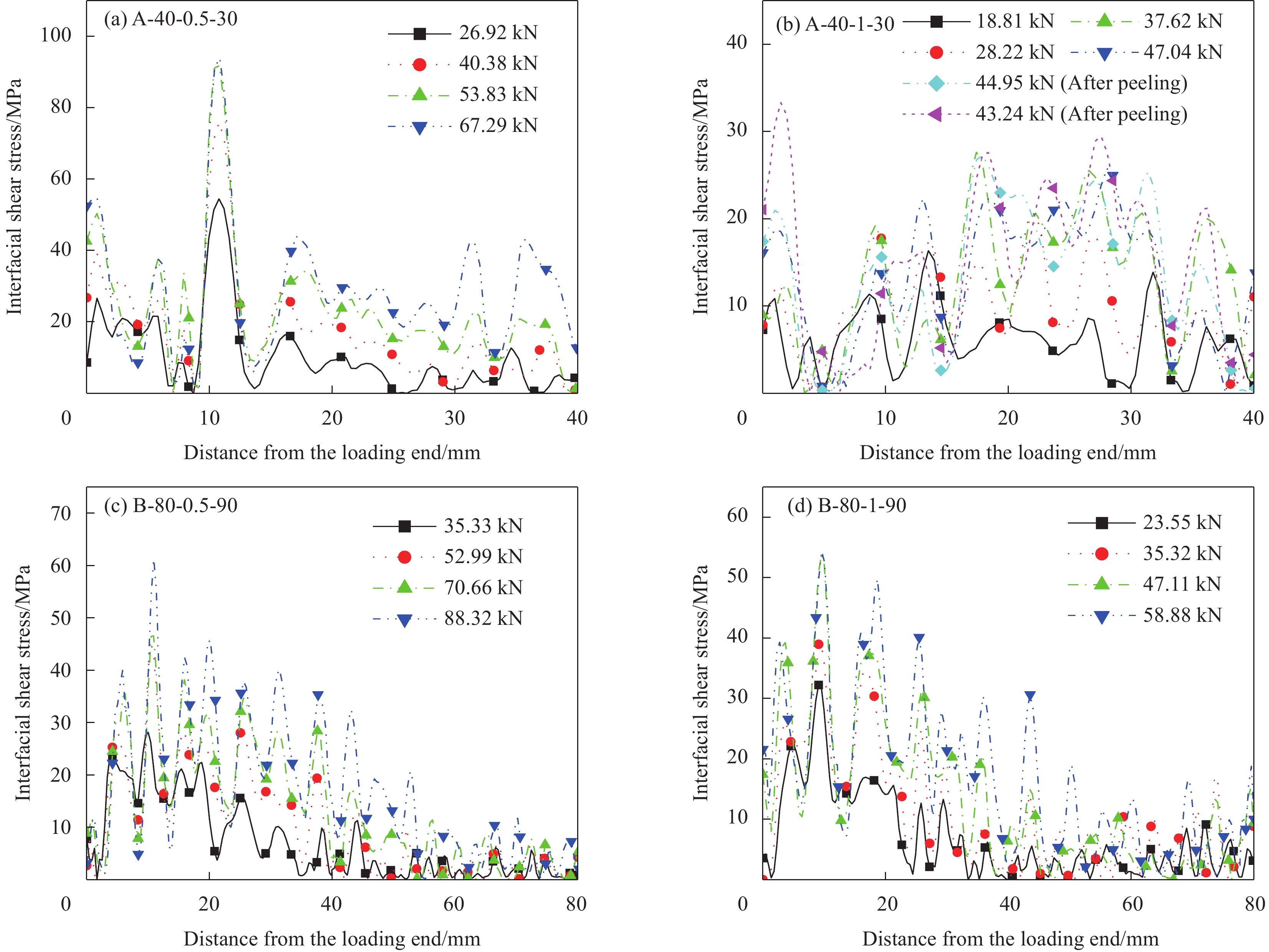

根据3D-DIC的分析数据,可获得每个试件拉伸时CFRP的轴向应变数据,图7为A、B组中几个典型的应变分布曲线。以峰值荷载Pu 为依据,依次绘出0.4Pu、0.6Pu、0.8Pu、Pu的应变分布曲线。本次试验的56个试件中,有4个存在应变软化阶段,分别为A-40-1-30、C-60-1-60、C-100-0.5-30、C-100-1-30。其中图7(b)中A-40-1-30的44.95 kN与43.24 kN分别对应图5(d)中(剥离段)的a、b两点。4个试件的a、b点对应图5(d),所有a、b点荷载-位移曲线坐标值见表3。由于环境噪声、空气扰动等因素,3D-DIC得到的数据具有一定的波动性。观察图7得知,在初始加载阶段,轴向应变主要在加载端附近高度集中,且最大应变随着施加荷载的提升而增加。一旦荷载达到特定值,界面剥离的迹象便显现,随后最大应变趋于稳定并在一定区间内波动。

表 3 具有应变软化段的CFRP-钢板a、b坐标值Table 3. Coordinate values of a and b of CFRP-steel plate with strain softening segmentSpecimen number Coordinate of point a Coordinate of point b A-40-1-30 ( 0.84297 ,44.94704 )( 0.92412 ,43.24049 )C-60-1-60 ( 1.42238 ,93.85569 )( 1.50692 ,91.73733 )C-100-0.5-30 ( 1.13675 ,70.70329 )( 1.22985 ,75.8377 )C-100-1-30 ( 1.02044 ,64.24918 )( 1.19141 ,64.22222 )3.2 CFRP-钢界面剪应力分布

CFRP-钢界面粘结滑移本构可归结为剪应力和滑移之间的关系。分析CFRP-钢界面错动剪应力时,需提出以下假设[1]:(1) CFRP的弯曲效应不予考虑;(2) 将钢板假定为理想刚体,其在试验中保持形态不变;(3) CFRP复合材料沿其厚度方向的轴向应变认为是均匀的;(4) 忽视由界面产生的正应力影响。应用3D-DIC测得的CFRP表面应变数据进行差分与积分处理,可以推算出界面剪应力与相对滑移公式。本次试验算法参考文献[29]算得出界面剪应力,其表达式如下式所示:

τ(x)=|Eftfdε(x)dx| (1) 其中:Ef为CFRP板的弹性模量;tf为CFRP板的厚度;ε(x)为距加载端x处的CFRP板轴向应变。

距离加载端x处的相对滑移s(x)通常可由CFRP板应变积分如下式所示:

s(x)=∫Lxε(x)dx (2) 其中,L为CFRP板的粘结长度。

图8为3.1节中提到的对应的剪应力分布曲线,其他试件采用同样的处理方式。在加载初期,界面剪应力的最大值位于加载端附近,并向自由端方向递减,剪应力集中在加载端的一个较小区域内。随着荷载的逐步增加,加载端的剪应力达到峰值,之后剪应力的峰值逐渐迁移离加载端。在此之后,尽管界面剪应力的分布形态保持相对稳定,其峰值及影响范围却持续向远离加载端的方向扩散。在图8可观察到,越长的粘结长度导致剪应力分布的范围越大。较长的粘结区域会使剪应力峰值从加载端向非加载端扩散的区域更宽,这样可以在更大的表面积上分散应力。较厚的胶层导致剪应力分布曲线更加波动,这是由于应力通过更厚的介质传播时,内部的应力集中和分散机制更为复杂。

3.3 CFRP-钢板粘结-滑移曲线

粘结-滑移曲线描述界面剪应力和滑移值之间的关系,即粘结界面的本构关系。参考文献[29],平滑处理不仅能有效降低由于实验误差、设备噪声或操作不当引起的数据波动,使得曲线更加光滑,减少异常值对曲线整体趋势的干扰,而且能更清楚地展示粘结-滑移曲线的关键特征,如极限荷载点、滑移起始点等,有助于精确识别和解释这些关键特性。因此本次试验数据采用Origin软件中的Savitzky-Golay方法对3D-DIC应变数据进行平滑处理,然后将平滑后的数据利用式(1)与式(2),可以得到不同载荷作用下粘结界面的剪切应力值与相对滑移。将这两种数据结合,就能够绘出粘结界面的粘结-滑移曲线(图9)。本次试验的56个试件的粘结滑移曲线均符合文献[29-30]中的三线型模型。

图9展示了3.1节中试件CFRP-钢粘结界面的典型粘结-滑移曲线。结果表明,尽管各试样在不同的温度、湿度、粘结长度、胶层厚度作用下,粘结-滑移反应表现出一定程度的分散性,但它们遵循着相似的发展趋势:首先是剪应力随滑移增加而提高的上升阶段;其次是剪应力随滑移增加而稳定的平台阶段;最后是剪应力随滑移增加而减少,直到降为零的下降阶段。参考文献[30],粘结-滑移三线性模型如图9(c)所示。其界面剪应力和相对滑移的关系如下式所示:

τ={τmaxss1, 0⩽ (3) 其中:τmax为最大界面剪应力;s1为最大剪应力对应的相对滑移值;s2为剪应力平台终止时对应的相对滑移值;sf为界面最大相对滑移。

根据拟合得到的粘结-滑移本构曲线,可得到粘结-滑移本构参数s1、s2、sf、τmax。其中,界面断裂能Gf也是表征界面性能的一个重要参量,其为粘结-滑移曲线所包围的面积。56个试件的粘结-滑移三线性模型参数与峰值荷载对比见表2和图10(a)~10(h)。

有效粘结长度表示界面承担的荷载能够达到最大值所需要的CFRP最小粘贴长度。对于具有三折线粘结-滑移模型的界面,其有效粘结长度可利用文献[29]中公式计算得到,但本试验通过利用上述公式得到的数据结果与预期存在显著偏差。这种偏差可能由多种因素引起,包括模型的适用性限制、实验条件的不稳定性或数据收集的误差等。因此,本文对有效粘结长度的讨论通过对试件出现b类破坏模式(CFRP断裂)来描述。出现该破坏模式的试件有B-80-0.5-30、B-80-1-30、B-100-1-30、B-80-1-60、B-60-0.5-90、B-80-1-90、C-100-0.5-60、C-100-1-60、C-100-1-90。因A组未出现b类破坏,故在该养护环境下有效粘结长度Le>100 mm。B组中出现6个b类破坏模式粘结长度为80 mm,故其Le≤80 mm且接近80 mm,C组中出现3个b类破坏模式粘结长度为100 mm,故其Le≤100 mm。因此,3种温度下有效粘结长度关系有{L_{\text{e}}}^{\text{A}}{\text{ > }}{L_{\text{e}}}^{\text{C}}{\text{ > }}{L_{\text{e}}}^{\text{B}}。

由参数表2与图10(a)~10(g)可看出,不同的粘结长度、胶层厚度、温度和湿度对τmax、s1、s2、sf以及Gf有明显的影响。温度的升高使得τmax降低,这是由于胶层在较高温度下变得更柔软,减弱了其抵抗滑移的能力。较高的温度条件下,sf增加,说明热环境影响了材料的延展性和粘结性。高湿度条件下τmax有所降低,这与湿气影响胶层材料性质有关,降低了其粘结能力。高湿度导致sf的增加,这是由于材料在湿润条件下更易于发生位移。较长的粘结长度通常会导致τmax降低,这是由于应力沿更长区域分布,减少了单位面积上的载荷。粘结长度的增加导致sf增加,这表明滑移在更长的粘结区域内发生。在相同条件下,胶层厚度为0.5 mm时通常有更高的τmax,表明胶层较薄有利于应力的更均匀分布和传递。胶层厚度为1 mm的试件,s1、s2、sf的数值相对更大,这是由于较厚胶层在固化和承载过程中存在更大的形变空间。在较低温度或较高湿度条件下Gf降低,这是由于胶层在这些条件下粘结强度降低,能量吸收能力减弱。在适宜的温湿度下,Gf一般较高,说明粘结状态更佳,能够吸收更多的能量。总体来说,粘结长度的增加趋向于增加sf和Gf,增加胶层厚度通常导致更大的s1和s2,而温度和湿度的提高则减少了τmax并增加了sf。这些规律表明,粘结性能受环境条件、胶层结构及粘结界面特性的共同影响,优化这些参数对于提升CFRP-钢板结构的粘结性能至关重要。

为了更便于分析温湿度对粘结-滑移的各种参数的影响,将A、B、C三组中,相同湿度下的所有试件的参数取其平均值,数据详见表4,以下讨论的参数均为平均值。当温度从−10℃升至25℃(A-30至B-30)时,τmax由20.47 MPa上升至27.05 MPa,增加了32.1%。这是因为温度的升高使得粘结剂的柔韧性增加,所以提高了材料的粘结强度。s1和s2的变化,分别增加了100%和36.4%,表明温度的升高导致了粘结界面的摩擦特性改变。而sf略有下降,减少了7.9%,反映出材料在更高温度下展现出较小的塑性变形。Gf上升29.0%则表明破坏过程中能量释放率的增加,这是由于温度升高导致的材料断裂模式从韧性断裂向脆性断裂的转变。当温度升高至60℃(B-30至C-30),τmax的提升减缓为5.1%,而s1和s2的增加幅度更为显著,分别为113.6%和33.4%。sf略有减少,降低了3.1%,而Gf的上升幅度为8.9%,这说明在更高的温度下,材料的热膨胀影响了粘结层的性能,导致了材料内部应力的分布变化。当湿度从30%升至60%,在25℃ (B-30至B-60)的温度下,τmax增加了3.4%,这表明在适中湿度条件下,材料由于水分的吸收而显示出更好的粘结性能。s1下降2.9%和s2显著增加32.2%,是由于湿度增加引起的粘结剂性质变化,导致了摩擦阻力的改变。sf的降低0.4%表明在该湿度范围内,材料的延展性受到的影响不大。Gf的增长16.2%反映了在高湿度环境下材料可能需要更多的能量才能引起破坏。

表 4 CFRP-钢板各类养护环境下的粘结-滑移参数平均值Table 4. Average values of bond-slip parameters of CFRP-steel plate under various maintenance environmentsMaintenance environment {\overline \tau _{{\text{max}}}}{\text{/mm}} {\overline s _{\text{1}}}{\text{/mm}} {\overline s _{\text{2}}}{\text{/mm}} {\overline s _{\text{f}}}{\text{/mm}} {\overline G _{\text{f}}}{\text{/(N}} \cdot {\text{m}}{{\text{m}}^{{\text{ - 1}}}}{\text{)}} A-30 20.47 0.02 0.11 0.38 4.61 B-30 27.05 0.04 0.15 0.35 5.94 C-30 28.43 0.08 0.19 0.34 6.47 B-60 27.97 0.04 0.19 0.34 6.91 C-60 28.42 0.06 0.22 0.38 7.47 B-90 29.91 0.05 0.18 0.34 7.03 C-90 14.94 0.02 0.15 0.27 2.94 Notes: A-30 represents Group A's curing temperature of −10℃ with a relative humidity of 30%; {\overline \tau _{{\text{max}}}} —The average value of the maximum shear stress of all specimens under the same temperature and humidity conditions; {\overline s _{\text{1}}} —The average value of the slip at max stress of all specimens under the same temperature and humidity conditions; {\overline s _{\text{2}}} —The average value of the slip at plateau end of all specimens under the same temperature and humidity conditions; {\overline s _{\text{f}}} —The average value of the max interface slip of all specimens under the same temperature and humidity conditions; {\overline G _{\text{f}}} —The average value of the fracture energy of all specimens under the same temperature and humidity conditions. 在60℃的条件下,湿度从30%增至60% (C-30至C-60),τmax基本保持不变,但s1、s2和sf的增加分别为15.7%、10.6%和13.6%,Gf的上升15.5%。这表明在高温下,湿度对材料的塑性变形能力和能量吸收能力有显著影响。湿度升至90%,在25℃ (B-60至B-90)的温度下,τmax继续上升6.9%。s1、s2的变化分别为24.8%的增加和4.4%的降低。sf略微降低2.4%,Gf几乎没有变化。在60℃ (C-60至C-90)下,τmax大幅下降47.5%,s1、s2、sf的下降幅度更为显著,分别为71.4%、28.9%和29.8%,Gf降低60.6%。这表明在高温高湿的条件下,由于水汽的高渗透性和热应力的累积效应,复合材料的粘结性能严重受损。

综上所述,温度和湿度联合作用对复合材料的性能有着显著且复杂的影响。温度升高通常能够提升τmax,但也导致塑性变形能力的降低。湿度的适度增加在某些条件下可以提高τmax,但过高的湿度则会导致材料性能下降,尤其是在高温条件下。因此,在复合材料的设计与应用中,必须充分考虑材料的养护环境并预测在实际工作中的性能变化,以确保结构的可靠性和安全性。

4. 结 论

基于双剪实验对碳纤维增强聚合物(CFRP)-钢界面的静载拉伸界面粘结性能进行了研究。探讨了CFRP-钢粘结界面在不同温湿度养护环境、粘结长度和胶层厚度情况下的粘结-滑移性能,重点讨论了温湿度养护环境对剪切滑移破坏的性能影响。基于3D-DIC采集技术,应用平滑法计算得到界面剪切-滑移关系,通过进一步拟合得到了相应的本构模型参数。主要结论如下:

(1) −10℃养护环境下,胶层脆性增加导致粘结性能下降,破坏模式为钢-胶失效;25℃下,破坏模式呈现多样化(CFRP层离、CFRP断裂、胶层失效、钢-胶失效),显示出粘结剂在载荷传递中的有效性;60℃下,高温导致粘结剂软化,主要破坏模式为a、b类,减少了不利的钢-胶界面失效风险;

(2) 双剪试件的峰值荷载与胶合剂胶层厚度、粘结长度和养护温湿度等相关,同等条件下较薄的胶层厚度(0.5 mm)展现出较高的峰值荷载;低温条件下峰值荷载较低,温度提高有利于提升峰值荷载,但高温高湿时由于水汽的高渗透性和温度应力的累积效应导致峰值荷载大幅度降低;随着粘结长度的增加峰值荷载提升,3种温度下有效粘结长度关系有{L_{\text{e}}^{\text{A}}}{\text{ > }}{L_{\text{e}}^{\text{C}}}{\text{ > }}{L_{\text{e}}^{\text{B}}};

(3) 同30%湿度条件下,温度从−10℃升至25℃时,最大界面剪应力τmax提升32.1%,表明温度升高会增强粘结剂的柔韧性和粘结性能,同时界面的摩擦特性改变,剪切滑移s1和s2分别增加了100%和36.4%,而界面最大相对滑移sf下降7.9%。在60℃时,τmax提升5.1%,但剪切滑移提升显著,说明高温条件下,热膨胀和内部应力分布对粘结层性能有显著影响;

(4) 在25℃环境下,湿度从30%增至60%时,τmax提升3.4%,说明适中湿度养护有利于改善粘结性能。湿度提升易导致粘结剂性能改变,剪切滑移s1略减而s2显著增加说明界面摩擦阻力的改变。在60℃环境下,湿度的增加会影响材料的塑性变形和能量吸收能力,尽管τmax保持不变,但剪切滑移和界面断裂能的增加揭示了湿度对材料性能的影响。尤其湿度升至90%时,粘结性能显著下降,τmax大幅减少,表明高温高湿环境下水汽的渗透和温度应力的累积会削弱粘结性能。

-

表 1 材料力学性能

Table 1 Material properties

Material Tensile

strength/

MPaYield

strength/

MPaShear

strength/

MPaTensile

modulus/

MPaElasticity

modulus/

GPaBending

strength/

MPaBending

modulus/

MPaInterlayer shear

strength/GPaPoisson’s

ratioElongation of

fractureSteel plate 455 345 – – 206 – – – 0.3 – Adhesive 31 – 23 1600 1.6 43 1800 – – 4.2% CFRP plate 2050 – – – 117 1710 117000 76.6 – – Notes: The adhesive parameter indicators were cured for 16 h at 40℃ and tested at 23℃; CFRP—Carbon fiber reinforced polymer. 表 2 CFRP-钢板试件及试验结果

Table 2 CFRP-steel plate specimens and test results

Specimen number Ultimate load/kN Failure mode τmax/MPa s1/mm s2/mm sf/mm Gf/(N·mm−1) A-40-0.5-30 67.29 d 30.13 0.0139 0.1093 0.2065 4.5489 A-60-0.5-30 74.35 d+c 23.93 0.0154 0.0442 0.3298 4.2893 A-80-0.5-30 69.52 d 18.38 0.0180 0.0720 0.4220 4.3752 A-100-0.5-30 76.11 d 14.02 0.0271 0.2158 0.5061 4.8704 A-40-1-30 47.04 c 19.06 0.0216 0.0537 0.1588 1.8191 A-60-1-30 72.34 d 23.87 0.0057 0.1324 0.3116 5.2311 A-80-1-30 72.44 d 18.50 0.0207 0.2262 0.4757 6.3012 A-100-1-30 81.08 d 15.86 0.0257 0.0459 0.6624 5.4115 B-40-0.5-30 59.56 c 32.65 0.0219 0.1121 0.1533 3.9750 B-60-0.5-30 84.09 d 22.07 0.0159 0.2394 0.3866 6.7324 B-80-0.5-30 86.50 b 30.64 0.0273 0.0770 0.5250 8.8029 B-100-0.5-30 85.40 a 33.98 0.0404 0.1163 0.2516 5.5646 B-40-1-30 71.93 d 26.74 0.0070 0.0300 0.2026 3.0164 B-60-1-30 73.38 d 22.37 0.0491 0.0953 0.2866 3.7215 B-80-1-30 87.98 b 23.03 0.0292 0.3653 0.4954 9.5767 B-100-1-30 57.21 b 24.95 0.1078 0.1351 0.4667 6.1613 B-40-0.5-60 57.12 d 27.92 0.0081 0.0501 0.2337 3.8495 B-60-0.5-60 84.45 a 30.47 0.0259 0.2859 0.4528 10.8612 B-80-0.5-60 65.77 b 34.35 0.0857 0.1773 0.3018 6.7566 B-100-0.5-60 80.90 a 29.64 0.0943 0.1865 0.4257 7.6737 B-40-1-60 52.96 d 27.69 0.0030 0.1004 0.1912 3.9953 B-60-1-60 64.99 c 25.12 0.0017 0.2172 0.3255 6.7948 B-80-1-60 85.35 a+b 23.23 0.0074 0.3458 0.4834 9.5441 B-100-1-60 66.94 a 25.35 0.0639 0.1783 0.3427 5.7938 B-40-0.5-90 62.78 c 37.98 0.0057 0.0710 0.2870 6.6892 B-60-0.5-90 63.00 b+d 30.63 0.0128 0.1979 0.3512 8.2143 B-80-0.5-90 88.32 a 27.33 0.0569 0.2586 0.3678 7.7814 B-100-0.5-90 81.84 b 36.33 0.0971 0.1761 0.4318 9.2786 B-40-1-90 65.98 d 28.58 0.0087 0.1280 0.2168 4.8008 B-60-1-90 79.41 d 20.66 0.0136 0.2150 0.3070 5.2518 B-80-1-90 58.88 a+b+d 29.42 0.0779 0.1786 0.2869 5.7010 B-100-1-90 81.63 a 28.37 0.0895 0.2477 0.4425 8.5191 C-40-0.5-30 68.81 a+c+d 31.16 0.0105 0.1313 0.2109 5.1678 C-60-0.5-30 77.71 a+c 34.25 0.0602 0.2017 0.3410 8.2637 C-80-0.5-30 68.80 a+d 33.73 0.1037 0.1691 0.3123 6.3685 C-100-0.5-30 78.83 a+d 26.69 0.1521 0.2635 0.4790 7.8810 C-40-1-30 63.82 a+c+d 29.84 0.0989 0.1398 0.2459 4.2798 C-60-1-30 85.15 a 31.29 0.0328 0.2751 0.4459 10.7671 C-80-1-30 71.38 a+d 22.53 0.0741 0.1995 0.3641 5.5140 C-100-1-30 67.91 d 17.92 0.0833 0.1780 0.2939 3.4820 C-40-0.5-60 69.81 a+c 24.23 0.0613 0.1075 0.1917 2.8820 C-60-0.5-60 81.95 a 27.03 0.0777 0.2885 0.3990 8.2411 C-80-0.5-60 93.97 b 26.10 0.0804 0.3073 0.4559 8.9127 C-100-0.5-60 73.67 a+b 32.20 0.0896 0.1911 0.3407 7.1183 C-40-1-60 73.90 a+c 33.70 0.0077 0.0247 0.2588 4.6481 C-60-1-60 94.26 a 32.89 0.0182 0.2193 0.4691 11.0239 C-80-1-60 88.98 a 23.23 0.0482 0.3268 0.5113 9.1776 C-100-1-60 83.96 a+b 28.01 0.1358 0.2581 0.4303 7.7389 C-40-0.5-90 50.65 d 14.61 0.0224 0.0809 0.1257 1.3463 C-60-0.5-90 44.04 d 12.26 0.0019 0.1080 0.1563 1.6087 C-80-0.5-90 41.31 d 14.82 0.0094 0.0316 0.1627 1.3706 C-100-0.5-90 70.26 a+d 10.47 0.0235 0.2705 0.3916 3.3420 C-40-1-90 58.59 c+d 23.65 0.0204 0.1056 0.1973 3.3410 C-60-1-90 52.88 d 11.96 0.0051 0.0799 0.2413 1.8898 C-80-1-90 39.81 c+d 15.00 0.0140 0.3404 0.5040 6.2288 C-100-1-90 63.81 b+d 16.74 0.0517 0.2081 0.3681 4.3897 Notes:A-40-0.5-30—Group A (−10℃), 40 mm bonding, 0.5 mm adhesive, 30% RH; τmax—Max shear stress; s1—Slip at max stress; s2—Slip at plateau end; sf—Max interface slip; Gf—Fracture energy; a—CFRP delamination; b—CFRP fracture; c—Adhesive failure; d—Steel-adhesive failure; Group A's humidity was ~30% due to curing chamber limitations. 表 3 具有应变软化段的CFRP-钢板a、b坐标值

Table 3 Coordinate values of a and b of CFRP-steel plate with strain softening segment

Specimen number Coordinate of point a Coordinate of point b A-40-1-30 ( 0.84297 ,44.94704 )( 0.92412 ,43.24049 )C-60-1-60 ( 1.42238 ,93.85569 )( 1.50692 ,91.73733 )C-100-0.5-30 ( 1.13675 ,70.70329 )( 1.22985 ,75.8377 )C-100-1-30 ( 1.02044 ,64.24918 )( 1.19141 ,64.22222 )表 4 CFRP-钢板各类养护环境下的粘结-滑移参数平均值

Table 4 Average values of bond-slip parameters of CFRP-steel plate under various maintenance environments

Maintenance environment {\overline \tau _{{\text{max}}}}{\text{/mm}} {\overline s _{\text{1}}}{\text{/mm}} {\overline s _{\text{2}}}{\text{/mm}} {\overline s _{\text{f}}}{\text{/mm}} {\overline G _{\text{f}}}{\text{/(N}} \cdot {\text{m}}{{\text{m}}^{{\text{ - 1}}}}{\text{)}} A-30 20.47 0.02 0.11 0.38 4.61 B-30 27.05 0.04 0.15 0.35 5.94 C-30 28.43 0.08 0.19 0.34 6.47 B-60 27.97 0.04 0.19 0.34 6.91 C-60 28.42 0.06 0.22 0.38 7.47 B-90 29.91 0.05 0.18 0.34 7.03 C-90 14.94 0.02 0.15 0.27 2.94 Notes: A-30 represents Group A's curing temperature of −10℃ with a relative humidity of 30%; {\overline \tau _{{\text{max}}}} —The average value of the maximum shear stress of all specimens under the same temperature and humidity conditions; {\overline s _{\text{1}}} —The average value of the slip at max stress of all specimens under the same temperature and humidity conditions; {\overline s _{\text{2}}} —The average value of the slip at plateau end of all specimens under the same temperature and humidity conditions; {\overline s _{\text{f}}} —The average value of the max interface slip of all specimens under the same temperature and humidity conditions; {\overline G _{\text{f}}} —The average value of the fracture energy of all specimens under the same temperature and humidity conditions. -

[1] 李腾, 宁志华, 吴嘉瑜. CFRP加固钢板的粘结界面剥离破坏[J]. 复合材料学报, 2021, 38(12): 4090-4105. LI Teng, NING Zhihua, WU Jiayu. Interfacial debonding failure of CFRP-strengthened steel structures[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4090-4105(in Chinese).

[2] WU C, ZHAO X L, CHIU W K, et al. Effect of fatigue loading on the bond behaviour between UHM CFRP plates and steel plates[J]. Composites Part B: Engineering, 2013, 50: 344-353. DOI: 10.1016/j.compositesb.2013.02.040

[3] WANG H T, WU G, JIANG J B. Fatigue behavior of cracked steel plates strengthened with different CFRP systems and configurations[J]. Journal of Composites for Construction, 2016, 20(3): 04015078. DOI: 10.1061/(ASCE)CC.1943-5614.0000647

[4] GRAMMATIKOS S A, JONES R G, EVERNDEN M, et al. Thermal cycling effects on the durability of a pultruded GFRP material for off-shore civil engineering structures[J]. Composite Structures, 2016, 153: 297-310. DOI: 10.1016/j.compstruct.2016.05.085

[5] WANG Y, ZHENG Y, LI J, et al. Experimental study on tensile behaviour of steel plates with centre hole strengthened by CFRP plates under marine environment[J]. International Journal of Adhesion and Adhesives, 2018, 84: 18-26.

[6] 李传习, 罗南海. 高温对CFRP板/钢界面力学性能的影响[J]. 交通科学与工程, 2019, 35(4): 34-39. DOI: 10.3969/j.issn.1674-599X.2019.04.006 LI Chuanxi, LUO Nanhai. Effect of high temperature on the mechanical properties of CFRP plate/steel interface[J]. Journal of Transportation Science and Engineering, 2019, 35(4): 34-39(in Chinese). DOI: 10.3969/j.issn.1674-599X.2019.04.006

[7] SOUSA J M, CORREIA J R, CABRAL-FONSECA S. Some permanent effects of hygrothermal and outdoor ageing on a structural polyurethane adhesive used in civil engineering applications[J]. International Journal of Adhesion and Adhesives, 2018, 84: 406-419. DOI: 10.1016/j.ijadhadh.2018.04.010

[8] 李传习, 李游, 高有为, 等. 纳米SiO2掺量对胶粘CFRP板-钢搭接界面黏结性能的影响[J]. 复合材料学报, 2020, 37(10): 2619-2635. LI Chuanxi, LI You, GAO Youwei, et al. Effect of nano SiO2 content on the bonding performance of adhesive CFRP plate-steel lap interface[J]. Acta Materiae Compositae Sinica, 2020, 37(10): 2619-2635(in Chinese).

[9] 李传习, 柯璐, 陈卓异, 等. CFRP-钢界面粘结性能试验与数值模拟[J]. 复合材料学报, 2018, 35(12): 3534-3547. LI Chuanxi, KE Lu, CHEN Zhuoyi, et al. Experimental and numerical simulation of bonding performance of CFRP-steel interface[J]. Acta Materiae Compositae Sinica, 2018, 35(12): 3534-3547(in Chinese).

[10] HE J, XIAN G. Debonding of CFRP-to-steel joints with CFRP delamination[J]. Composite Structures, 2016, 153: 12-20. DOI: 10.1016/j.compstruct.2016.05.100

[11] AL-SHAWAF A, AL-MAHAIDI R, ZHAO X L. Effect of elevated temperature on bond behaviour of high modulus CFRP/steel double-strap joints[J]. Australian Journal of Structural Engineering, 2009, 10(1): 63-74. DOI: 10.1080/13287982.2009.11465033

[12] 朱德举, 姚明侠, 张怀安, 等. 动态拉伸荷载下温度对CFRP/钢板单搭接剪切接头力学性能的影响[J]. 土木工程学报, 2016, 49(8): 28-35. ZHU Deju, YAO Mingxia, ZHANG Huai'an, et al. Effect of temperature on mechanical properties of CFRP/steel plate single lap shear joint under dynamic tensile load[J]. China Civil Engineering Journal, 2016, 49(8): 28-35(in Chinese).

[13] NGUYEN T C, BAI Y, ZHAO X L, et al. Durability of steel/CFRP double strap joints exposed to sea water, cyclic temperature and humidity[J]. Composite Structures, 2012, 94(5): 1834-1845. DOI: 10.1016/j.compstruct.2012.01.004

[14] 李传习, 司睹英胡, 高有为. 极端湿热环境对CFRP/钢界面性能的影响[J]. 建筑材料学报, 2024, 27(8): 757-763. LI Chuanxi, SI Duyinghu, GAO Youwei. Influence of extreme humid and hot environment on the interface properties of CFRP/steel[J]. Journal of Building Materials, 2024, 27(8): 757-763(in Chinese).

[15] DAWOOD M, RIZKALLA S. Environmental durability of a CFRP system for strengthening steel structures[J]. Construction and Building Materials, 2010, 24(9): 1682-1689. DOI: 10.1016/j.conbuildmat.2010.02.023

[16] 罗南海. 胶膜连接CFRP板/钢界面力学性能试验研究[D]. 长沙: 长沙理工大学, 2019. LUO Nanhai. Experimental study on mechanical properties of adhesive film bonded CFRP plate/steel interface[D]. Changsha: Changsha University of Science & Technology, 2019(in Chinese).

[17] HESHMATI M, HAGHANI R, AI-EMRANI M. Effects of moisture on the long-term performance of adhesively bonded FRP/steel joints used in bridges[J]. Composites Part B: Engineering, 2016, 92: 447-462. DOI: 10.1016/j.compositesb.2016.02.021

[18] YU T, FERNANDO D, TENG J G, et al. Experimental study on CFRP-to-steel bonded interfaces[J]. Composites Part B: Engineering, 2012, 43(5): 2279-2289. DOI: 10.1016/j.compositesb.2012.01.024

[19] 吴江, 柯倩倩, 祝雯, 等. 基于三维数字图像相关法的混凝土硫酸盐侵蚀膨胀研究[J]. 广州建筑, 2022, 50(6): 45-48. WU Jiang, KE Qianqian, ZHU Wen, et al. Study on sulfate attack expansion of concrete based on three dimensional digital image correlation method[J]. Guangzhou Architecture, 2022, 50(6): 45-48(in Chinese).

[20] 魏康, 员方, 董志强, 等. 基于标志点的多相机数字图像相关方法精度分析及土木工程中的应用[J]. 东南大学学报(自然科学版), 2021, 51(2): 219-226. DOI: 10.3969/j.issn.1001-0505.2021.02.005 WEI Kang, YUAN Fang, DONG Zhiqiang, et al. Accuracy analysis of multicamera digital image correlation method based on landmarks and its application in civil engineering[J]. Journal of Southeast University (Natural Science Edition), 2021, 51(2): 219-226(in Chinese). DOI: 10.3969/j.issn.1001-0505.2021.02.005

[21] 范杰, 朱星, 胡桔维, 等. 基于3D-DIC的砂岩裂纹扩展及损伤监测试验研究[J]. 岩土力学, 2022, 43(4): 1009-1019. FAN Jie, ZHU Xing, HU Juwei, et al. Experimental study on crack propagation and damage monitoring of sandstone based on 3D-DIC[J]. Rock and Soil Mechanics, 2022, 43(4): 1009-1019(in Chinese).

[22] TANG J, CHEN X, DAI F, et al. Experimental investigation of fracture damage of notched granite beams under cyclic loading using DIC and AE techniques[J]. Fatigue Fracture of Engineering Materials Structures, 2020, 43(7): 1583-1596.

[23] 祁彪. CFRP-钢界面改性及冻融环境作用下耐久性能研究[D]. 郑州: 郑州大学, 2022. QI Biao. Study on the durability performance of CFRP-steel interface modification and freeze-thaw environment[D]. Zhengzhou: Zhengzhou University, 2022(in Chinese).

[24] 朱海洋. 双向拉伸载荷下CFRP试验件设计、制造与试验研究[D]. 大连: 大连理工大学, 2022. ZHU Haiyang. Design, manufacturing, and experimental study of CFRP specimens under biaxial tensile load [D]. Dalian: Dalian University of Technology, 2022(in Chinese).

[25] 魏瑶瑶. 加速腐蚀环境下CFRP-钢界面疲劳性能研究[D]. 西安: 西安科技大学, 2020. WEI Yaoyao. Study on the fatigue performance of CFRP-steel interface under accelerated corrosion environment[D]. Xi'an: Xi'an University of Science and Technology, 2020(in Chinese).

[26] 岳清瑞, 杨勇新. 《碳纤维片材加固修复混凝土结构技术规程》(CECS146: 2003)介绍[J]. 建筑结构, 2003(6): 69-72. YUE Qingrui, YANG Yongxin. Introduction to the "Technical specification for strengthening and repairing concrete structures with carbon fiber sheet" (CECS146: 2003)[J]. Building Structure, 2003(6): 69-72(in Chinese).

[27] 杨怡, 黄炽辉, 吴作栋. 基于双剪实验的CFRP-钢板界面粘结性能研究[J]. 中山大学学报(自然科学版), 2021, 60(6): 62-70. YANG Yi, HUANG Chihui, WU Zuodong. Study on the bonding performance of CFRP-steel plate interface based on double shear test[J]. Journal of Sun Yat-sen University (Natural Science Edition), 2021, 60(6): 62-70(in Chinese).

[28] 王海涛, 吴刚, 庞育阳. 结构胶类型对CFRP板-钢界面粘结性能的影响[J]. 苏州科技大学学报(工程技术版), 2017, 30(4): 45-48. WANG Haitao, WU Gang, PANG Yuyang. Influence of adhesive types on the bonding performance of CFRP plate-steel interface[J]. Journal of Suzhou University of Science and Technology (Engineering and Technology Edition), 2017, 30(4): 45-48(in Chinese).

[29] 王海涛. CFRP板加固钢结构疲劳性能及其设计方法研究[D]. 南京: 东南大学, 2016. WANG Haitao. Research on the fatigue performance of steel structures reinforced with CFRP plates and its design method[D]. Nanjing: Southeast University, 2016(in Chinese).

[30] 庞育阳. 极端服役环境下CFRP-钢界面粘结性能研究[D]. 南京: 东南大学, 2019. PANG Yuyang. Study on the bonding performance of CFRP-steel interface under extreme service conditions[D]. Nanjing: Southeast University, 2019(in Chinese).

-

其他相关附件

-

目的

CFRP(碳纤维增强聚合物)与钢界面的粘结性能对于钢结构加固至关重要,直接影响加固效果。本研究旨在研究温度、湿度、粘结长度和胶层厚度等多种因素对CFRP-钢界面粘结性能的影响。为复杂环境条件下CFRP在钢结构加固中的应用提供理论支持和设计参考。

方法本文主要通过双剪试验,通过3D-DIC(数字图像相关)技术监测静载拉伸过程中CFRP板的轴向应变分布。研究CFRP-钢粘结界面在养护阶段对3类温度(-10℃、25℃、60℃)与3类相对湿度下(30%、60%、90%),探究4种粘结长度(40mm、60mm、80mm、100mm)、2种胶层厚度(0.5mm、1mm)对界面粘结-滑移、界面剪应力分布,峰值荷载及界面破坏模式等的影响。最终通过平滑法拟合得到考虑温湿度养护环境下,CFRP-钢界面三折线剪切-滑移本构关系。

结果同30%湿度条件下,温度从-10℃升至25℃时,τ提升32.1%,表明温度升高会增强粘结剂的柔韧性和粘结性能,同时界面的摩擦特性改变,剪切滑移s和s分别增加了100%和36.4%,而s下降7.9%。在60℃时,τ提升5.1%,但剪切滑移提升显著,说明高温条件下,热膨胀和内部应力分布对粘结层性能有显著影响。在25℃环境下,湿度从30%增至60%时,τ提升3.4%,说明适中湿度养护有利于改善粘结性能。湿度提升易导致粘结剂性能改变,剪切滑移s略减而s显著增加说明界面摩擦阻力的改变。在60℃环境下,湿度的增加会影响材料的塑性变形和能量吸收能力,尽管τ保持不变,但剪切滑移和界面断裂能的增加揭示了湿度对材料性能的影响。尤其湿度升至90%时,粘结性能显著下降,τ大幅减少,表明高温高湿环境下水汽的渗透和温度应力的累积会削弱粘结性能。

结论-10℃养护环境下,胶层脆性增加导致粘结性能下降,破坏模式为d类;25℃下,破坏模式呈现多样化(a-d类),显示出粘接剂在载荷传递中的有效性;60℃下,高温导致粘结剂软化,主要破坏模式为a、b类,减少了不利的钢-胶界面失效风险。双剪试件的峰值荷载与胶合剂胶层厚度、粘结长度和养护温湿度等相关,同等条件下较薄的胶层厚度(0.5mm)展现出较高的峰值荷载;低温条件下峰值荷载较低,温度提高有利于提升峰值荷载,但高温高湿时由于水汽的高渗透性和温度应力的累积效应导致峰值荷载大幅度降低;随着粘结长度的增加峰值荷载提升,三种温度下有效粘接长度关系有。研究结果强调,在碳纤维增强塑料钢结构的设计和应用中需要考虑这些环境因素,以确保最佳的性能和耐用性。

-

在钢结构加固中,CFRP与钢结构之间的界面粘结性能是关键基础,它直接影响到加固效果的显著性。本文针对这一问题,通过CFRP-钢双剪粘结试验和3D-DIC技术,综合考虑了温度、湿度、粘结长度和胶层厚度多因素对粘结性能的影响,对静载拉伸过程中的界面力学性能及破坏过程进行了全面分析。通过创新性的试验设计和精确的数据分析,揭示了温湿度对界面破坏模式的延展性和粘结性的影响,这些成果不仅提供了复杂环境下CFRP加固钢结构设计的理论依据,也为相关工程应用提供了重要参考。

试验采用了3D-DIC技术监测CFRP轴向应变分布,基于DIC数据,计算出相应的界面剪应力与相对滑移,通过平滑法简化的三折线剪切-滑移模型,较好地描述了CFRP-钢板界面的粘结-滑移关系,拓展了现有的理论模型。研究表明:养护阶段温度与湿度共同作用对粘结界面性能会产生显著影响。发现低温下胶层变脆,容易引起钢-胶界面失效。粘结长度和胶层厚度的变化对峰值荷载有直接影响,其中较薄胶层(0.5mm)能维持更高峰值荷载,显示了更好的应力传递和分布。温度和湿度对复合材料的性能有着显著且复杂的影响。从-10℃升至25℃时(A-30至B-30),τmax由20.47 MPa增至27.05 MPa,提升了32.1%,温度的升高增强了粘结剂的柔韧性,进而增加了材料的整体粘结强度;s1和s2分别增加了100%和36.4%,温度升高显著改变了粘结界面的摩擦特性;sf下降7.9%,反映了材料在较高温度下的较低塑性变形程度;Gf增加29.0%,温度升高导致的材料断裂模式从韧性向脆性的转变。温度升高至60℃(B-30至C-30),τmax增长率减缓至5.1%,s1和s2的增幅更为显著,分别为113.6%和33.4%,sf下降3.1%,Gf的增长8.9%,验证了高温对材料热膨胀及内部应力分布的显著影响。25℃(B-30至B-60)的环境中湿度从30%增至60%时,τmax提高了3.4%,在适中湿度下材料由于水分吸收而呈现更佳的粘结性能;s1下降2.9%,s2显著增长32.2%,表明湿度升高导致粘结剂性质的变化,进而改变了摩擦阻力;sf降低0.4%和Gf增长16.2%均反映了在该湿度范围内,材料的延展性及破坏所需能量的变化。在60℃条件下,湿度从30%增至60%(C-30至C-60)时,虽τmax基本不变,但s1、s2和sf的增加(分别为15.7%、10.6%和13.6%)以及Gf的提高(15.5%)揭示了高温下湿度对材料塑性变形能力和能量吸收能力的显著影响。在湿度升至90%时,特别是在60℃(C-60至C-90)环境下,τmax显著下降(47.5%),s1、s2、sf、Gf的下降更为显著(分别下降71.4%、28.9%、29.8%、60.6%),表明在高温高湿条件下,水汽的高渗透性和热应力的累积效应极大地削弱了复合材料的粘结性能。

研究表明,CFRP粘结加固钢结构时,养护环境的温湿度对粘结性能具有较大影响,通过本文的研究指明了在设计和施工中需要针对性的考虑养护环境条件。

A-40-0.5-30界面剪应力分布曲线

A-40-0.5-30拟合的剪切-滑移曲线

下载:

下载: