From Traditional to Intelligent: Advances in Wood Color Treatment Technologies

-

摘要:

近年来,木材颜色处理技术取得了显著进展,多种方法共同推动了木材加工业的发展。漂白剂的使用提升了木材颜色的均匀性,为后续处理奠定了基础。真菌染色通过生物作用实现了颜色变化,天然染料则增强了木材的抗紫外线和防霉性能,延长了户外使用寿命。金属离子变色与木材成分反应,带来丰富的颜色变化,提升了装饰性。热处理改变木材结构,使颜色加深并提高了耐久性。在此基础上,智能算法尤其是机器学习技术,被应用于染色和热处理工艺,精准调整参数并预测效果,显著提升了生产效率和产品质量。这些技术集成推动了木材加工业向高效、环保和可持续方向发展。

Abstract:In recent years, significant progress has been made in wood color treatment technologies, with various methods collectively advancing the wood processing industry. The use of bleaching agents has improved the color uniformity of wood, laying a solid foundation for subsequent treatments. Fungal staining achieves color changes through biological processes, while natural dyes enhance the UV resistance and anti-mold properties of wood, extending its outdoor lifespan. Metal ion color changes, through reactions with wood components, bring rich color variations and enhance decorative appeal. Heat treatment alters the wood's structure, deepening its color and increasing durability. Building on these advancements, intelligent algorithms, particularly machine learning techniques, have been applied to staining and heat treatment processes, enabling precise parameter adjustments and outcome predictions, significantly boosting production efficiency and product quality. These integrated technologies are driving the wood processing industry toward greater efficiency, environmental sustainability, and long-term viability.

-

Keywords:

- Wood color /

- fungal staining /

- natural dyes /

- metal ion color change /

- heat treatment /

- machine learning

-

膜分离技术具有高能效、易操作、环境友好和占地面积小等优点,近年来在气体分离领域受到广泛关注[1-4]。传统气体分离膜多以聚合物膜为主,然而由于聚合物分离膜固有的选择性和渗透性的制约关系(Trade-off效应),使其性能很难再提升[5-6]。研究者发现将多孔材料与聚合物基体共混制成混合基质膜,通过结合两种材料的优点,能够同时提升膜的气体渗透性和选择性,从而突破聚合物膜的Trade-off效应[7-8]。因此,制备混合基质膜是改善膜气体分离性能的一种有效方法。

对于混合基质膜,填料和聚合物基体材料的选择尤为重要。聚酰亚胺由于其优异的热稳定性、良好的力学性能以及可加工性,已经在气体分离膜领域发展多年,是混合基质膜聚合物基体候选材料之一[9-11]。对于填料材料的选择,共价有机框架材料(COFs)是一种由有机单元通过共价键构成的多孔材料,由于其具有优异的稳定性,易功能化、永久空隙率以及高比表面积等优点,在气体分离领域展现出不俗的潜力[12]。由于COFs全有机的性质,使其能够均匀地分散在聚合物基质中,减少了混合基质膜中由于界面缺陷产生的非选择性孔[13-14]。然而,大部分COFs的孔径很难做到2 nm以下,相对于气体分子动力学直径(N2:0.36 nm;O2:0.35 nm;CO2:0.33 nm)还是较大,难以实现对气体的高效分离,从而降低了气体选择性[15-16]。因此,需要对COFs的孔径大小调控或引入一些功能性吸附位点进行改善。研究表明,引入氟原子能够有效改善COFs的孔径大小且能够提供与气体相互作用的吸附位点。Alahakoon等[17]通过使用含氟单体制备出两种氟化COFs,将氟化COFs与未氟化的相比,发现氟化COFs具有更大的比表面积、更小且更明确的孔径。Gao等[18]报道了3种具有—H、—Me和—F取代基的同构三维共价有机骨架,对比不含氟的COFs,氟化COFs具有更高的CO2亲和力,对CO2/N2有着更高的IAST选择性。Yang等[19]制备了一种氟化CTF,通过氟原子的强静电作用以及C—F键与CO2的偶极-四极作用,使其具有优异的CO2吸附能力。

基于上述讨论,本文合成出一种具有较小孔径、高比表面积的氟化共价有机框架材料(TpPa-CF3)。随后,以TpPa-CF3为填料,聚酰亚胺(6FDA-ODA)为基体,制备出不同负载量的TpPa-CF3/6FDA-ODA混合基质膜。表征了其结构和表面、截面的微观形貌,探究了其热性能、力学性能以及疏水性能,最后讨论了混合基质膜的气体渗透性以及在烟道气分离(CO2/N2)和空气分离(O2/N2)上的应用前景。

1. 实验材料及方法

1.1 原材料

4,4-二氨基二苯醚(ODA,98%)、4,4-(六氟异丙烯)二酞酸酐(6FDA,98%+)、2,4,6-三甲酰间苯三酚(Tp,98%)、2-三氟甲基-1,4-苯二胺(Pa-CF3,97%)、1,3,5-三甲基苯(99%+)、1,4-二氧六环(99%)均购自上海阿达玛斯试剂有限公司;乙酸(AR)、N,N-二甲基甲酰胺(DMF,AR)均购自西陇科学股份有限公司;间甲酚(m-Cresol,99%)、异喹啉(97%)均购自上海阿拉丁试剂有限公司;丙酮(Acetone,AR),成都市科隆化学品有限公司;工业酒精(95%),弘昊实验设备有限公司。

1.2 TpPa-CF3的合成

将Tp (63.0 mg,0.30 mmol)、Pa-CF3 (79.0 mg,0.45 mmol)、1,3,5-三甲基苯(1.5 mL)、1,4-二氧六环(1.5 mL)依次加入到Pyrex管(25 mL)中。为使混合物均匀分散,超声处理0.5 h,再加入3 mol/L乙酸溶液(0.5 mL)。随后,用液氮将Pyrex管骤冻抽出空气,再在室温下解冻,此操作循环3次。密闭封管,将Pyrex管在120℃下油浴3天。反应完毕后冷却至室温,过滤收集产物,先用DMF溶液搅拌洗涤3次,再通过索氏提取法进行提纯(提纯溶剂采用丙酮)。随后,收集产物,在真空烘箱中120℃下干燥12 h后,得到橘红色粉末样品TpPa-CF3。

1.3 聚酰亚胺(6FDA-ODA)的合成

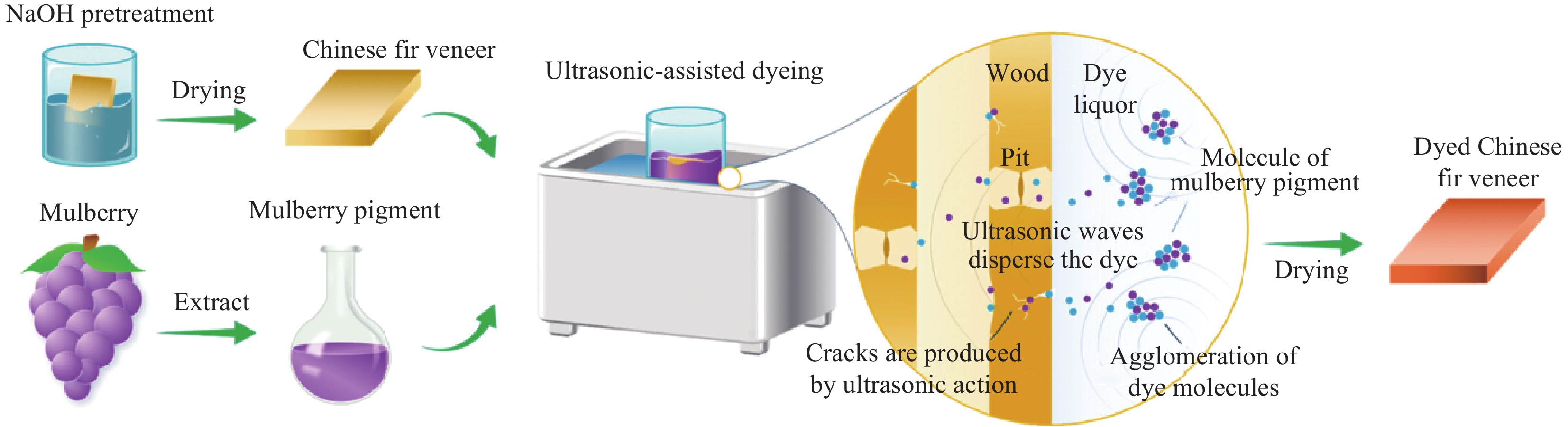

在N2氛围下,向装有机械搅拌、冷凝回流的150 mL三口烧瓶内依次加入ODA (2.00 g,9.99 mmol)、间甲酚(28 mL),待ODA完全溶解后再依次加入6FDA (4.44 g,9.99 mmol)、间甲酚(28 mL),随后将温度升到50℃待反应物完全溶解后,滴加5~6滴异喹啉后升温至80℃反应3 h,120℃反应3 h,180℃反应3 h,最后200℃反应12 h。反应结束冷却至室温后,将聚酰亚胺溶液缓慢倒入大量工业酒精中拉丝沉淀,过滤收集产物,在真空烘箱中150℃干燥8 h。随后,使用适量DMF重新溶解并进行二次沉淀以除去聚酰亚胺中残留杂质。

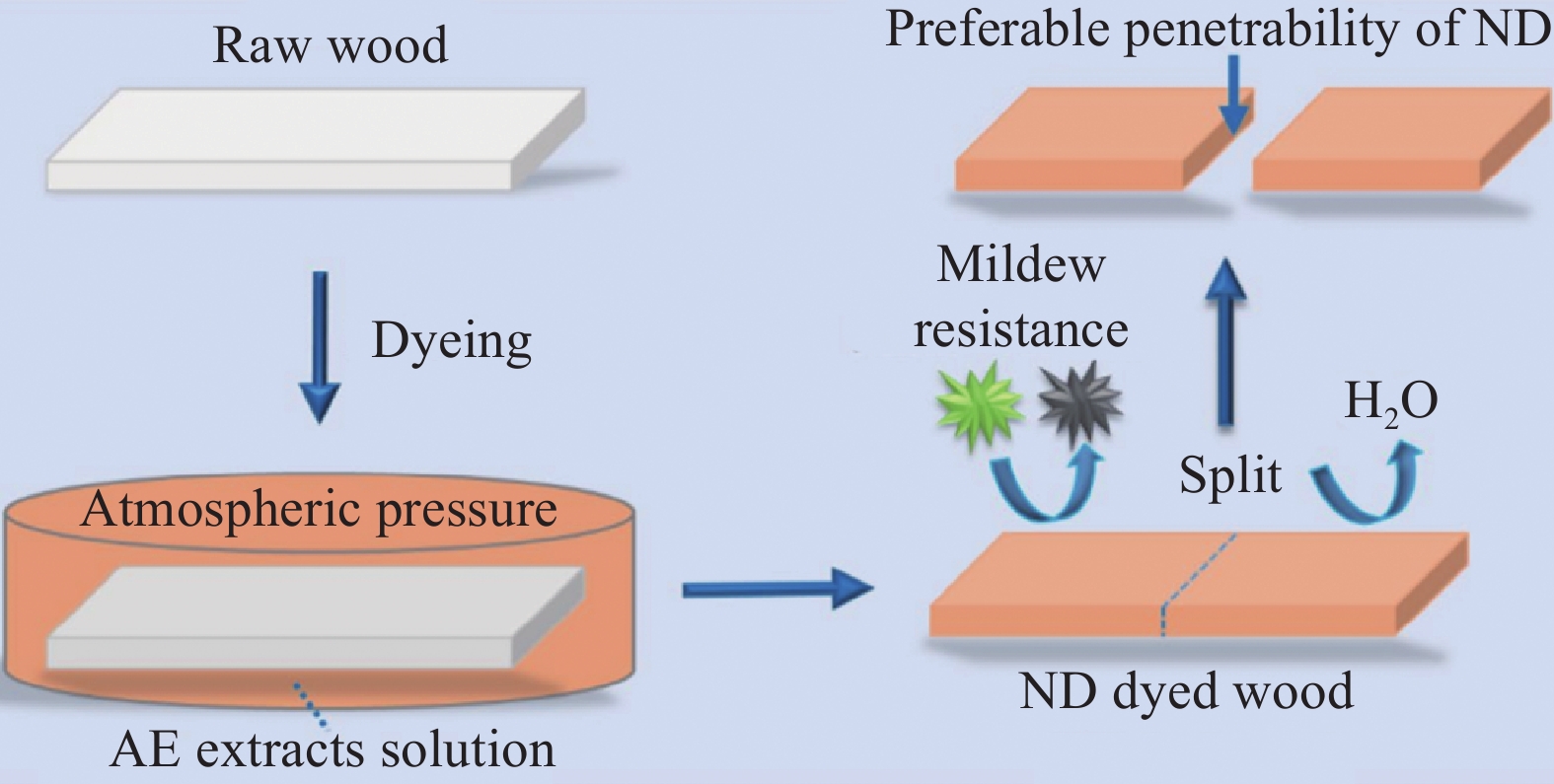

1.4 TpPa-CF3/6FDA-ODA混合基质膜的制备

取一定量的TpPa-CF3粉末分散在DMF (3 mL)中,使用细胞粉碎机,在300 W功率下超声0.5 h后再搅拌6 h,保证TpPa-CF3粉末在DMF溶液中分散均匀。同时,称取0.2 g 6FDA-ODA溶解在DMF (2 mL)中,用针式滤头(0.45 μm,尼龙)过滤除去杂质。随后,将TpPa-CF3的分散液滴加到6FDA-ODA溶液中搅拌12 h,确保TpPa-CF3和6FDA-ODA充分混合。最后,将混合溶液缓慢流延到光滑平整的玻璃板(5 cm×5 cm)上,在80℃下蒸发12 h除去溶剂,待冷却至室温后在温水中脱膜,最后在150℃的真空烘箱中干燥12 h以除去残留的溶剂分子。按以上步骤分别制备含量为0wt%、1wt%、3wt%、5wt%、7wt%的TpPa-CF3/6FDA-ODA混合基质膜。

1.5 表征测试

X射线衍射(XRD):采用荷兰帕纳科公司的X'Pert Pro型X射线衍射仪对制备的TpPa-CF3粉末与薄膜进行晶型及结构表征,扫描范围在3°~40°,扫描速度为2°/min。

傅里叶变换红外光谱(FTIR):采用美国尼高力公司的Nicolette 6700-NXR型傅里叶变换红外光谱仪分析TpPa-CF3和薄膜的化学键组成及官能团。对于粉末样品通过溴化钾压片的方式测试,对于薄膜样品通过制成厚度约为20 μm的薄膜直接测试。扫描范围为400~

4000 cm−1,扫描次数64次以上。固态核磁共振(ssNMR):通过德国布鲁克公司的Avance Neo 400 WB型固体核磁共振波谱仪测试TpPa-CF3的13C NMR,分析其化学键连接方式。所需样品压实后的体积应多于0.5 cm3。

X射线光电子能谱(XPS):采用美国热电公司的Escalab 250 Xi型X射线光电子能谱仪分析TpPa-CF3的化学元素及化学态。采用粉末压片的方式制样。

扫描电子显微镜(SEM):通过日本日立公司的SU 4800型扫描电子显微镜表征TpPa-CF3和薄膜表面、截面的微观形貌。对于粉末样品,用牙签将少量样品涂在导电胶上制样;对于薄膜样品,膜表面直接粘在导电胶上,膜断面通过液氮脆断选取平整截面制样。全部样品在测试前通过喷金处理提高样品导电性。

N2吸附-脱附测试:通过美国康塔公司的Autosorb IQ型比表面及孔隙度分析仪器表征TpPa-CF3的比表面积及孔径分布。采用BET (Brunauer-Emmett-Teller)法计算比表面积,密度泛函理论(DFT)计算孔径分布。

热重分析(TGA):通过德国耐驰公司的STA 449C型综合热分析仪测试TpPa-CF3和薄膜的热稳定性。在N2氛围下测试,升温速率为10℃/min,测试范围在50~800℃。

差示扫描量热分析(DSC):通过德国耐驰公司的DSC 214型差示扫描量热仪测试薄膜的玻璃化转变温度,在N2氛围下以10℃/min的速率升温,测试范围在30~350℃,所有结果均采用消除热历史后的二次升温曲线。

力学性能:通过美国美特斯公司的CMT2103型万能试验机来表征薄膜的力学性能。薄膜样品尺寸为50 mm×10 mm,拉伸载荷为5 kN,拉伸速率为2 mm/min,标距为20 mm。

水接触角测试:通过中国承德优特仪器有限公司JY-PHb型接触角分析仪测定薄膜的亲疏水性能。薄膜样品尺寸为20 mm×20 mm,测试次数至少3次。

气体渗透性测试:通过中国济南兰光公司的VAC-V1型气体渗透仪测试薄膜的气体渗透性能。测试方法为恒体积变压法,测试气体为高纯气体(CO2、O2、N2),测试条件为4 bar,35℃。测试过程如下,将厚度均匀的待测薄膜装入膜腔中,测试前将上下腔气压抽至20 Pa以下,随后下腔关闭,上腔通入待测纯气体形成压差。压差推动气体自上腔(高压侧)向下腔(低压侧)渗透,通过系统计算得到膜的气体渗透系数P。

2. 结果与讨论

2.1 TpPa-CF3的表征

通过粉末X射线衍射(PXRD)对合成的TpPa-CF3的晶体结构进行分析,图1(a)中2θ=4.79°处出现的强峰对应于COF的(100)晶面,其他峰也出现在2θ=7.81°、26.14°处,分别对应于(200)、(001)晶面,其中(001)晶面也是其π-π堆叠峰,通过布拉格方程计算得出其堆叠层间距为0.33 nm。将测试结果与模拟的晶体模型的衍射峰进行对比,结果表明二者衍射峰的位置与强度均匹配良好。TpPa-CF3在Pawley精修后得到的晶胞参数为a=

2.290351 nm,b=2.236760 nm,c=0.423813 nm,α=89.56415 ,β=89.73479 ,γ=120.51471 。实验结果与精修后的PXRD之间的残差值较小,Rwp=1.24%,Rp=0.91%。以上结果初步说明成功合成出了目标晶体结构,且具有良好的结晶性。为进一步说明TpPa-CF3成功合成,通过FTIR对TpPa-CF3以及其构筑单元测试,从图1(b)中可以看到,构筑单元2,4,6-三甲酰间苯三酚(Tp)在

2894 cm−1处醛基的CH=O特征峰和构筑单元2-三氟甲基-1,4-苯二胺(Pa-CF3)在3318 cm−1和3210 cm−1处的—NH2特征峰在产物TpPa-CF3中消失,表明醛胺缩合反应完全。在1282 cm−1处的C—N的特征吸收峰表明烯醇-酮异构的发生。因为框架是以酮的形式存在,结构中有强的分子内氢键及共轭作用,所以在1592 cm−1处的C=C的特征峰和1610 cm−1处的C=O特征峰合并呈肩状[20]。在1128 cm−1处出现了C—F的特征峰。13C固体NMR分析如图1(c)所示,图中显示化学位移在184.2×10−6和108.1×10−6处有两个较明显的信号峰,分别对应于烯醇-酮异构反应所形成的C=O键和C—N键上的C原子,123.6×10−6处归属于C—F上的C原子。其余在119.0×10−6、134.1×10−6和146.5×10−6处的信号峰则归属于芳香单元上的C原子。

FTIR和固体核磁分析结果证实TpPa-CF3的成功合成且以稳定的β-酮胺形式存在。

通过XPS测量TpPa-CF3的全谱和各个元素的光谱,由图2(a)的全谱可知TpPa-CF3是由C、N、O、F 4种元素组成的。图2(b)是C1s的高分辨率XPS光谱,其能够被卷积为4个峰,分别对应于TpPa-CF3中的C=C/C—C(284.8 eV)、C—N(286.2 eV)、C=O(288.9 eV)和C—F(292.9 eV)键,N1s的高分辨率XPS如图2(c)所示,其被卷积为2个峰,分别归属于N—C(400.2 eV)和N—H(403.9 eV)键,F1s的高分辨率XPS如图2(d)所示,其只有一个卷积峰归属于C—F(688.3 eV)。所有以上结果说明TpPa-CF3形成目标结构,由C1s和N1s证明该结构发生了烯醇-酮异构。

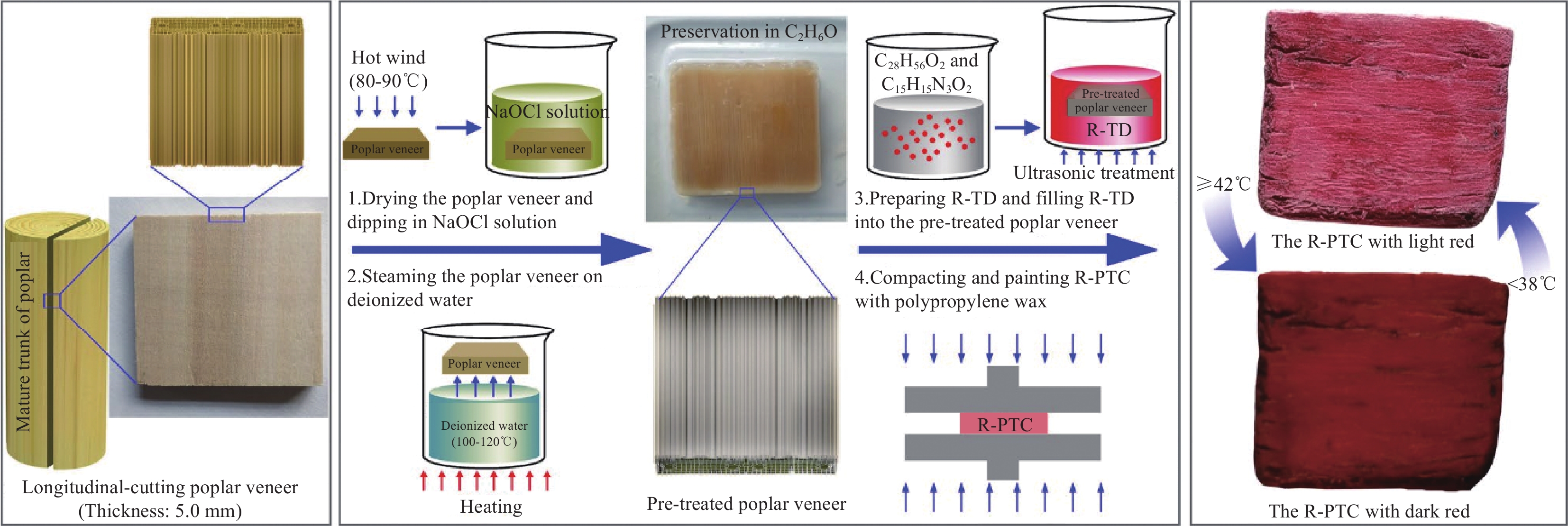

通过扫描电镜(SEM)观察TpPa-CF3的微观形貌。如图3(a)所示,TpPa-CF3具有均匀的微观形貌,呈现为“米粒”形颗粒堆积形成的团簇,每一颗“米粒”的尺寸在(100±30) nm。

为了解TpPa-CF3的多孔性,对其进行N2吸附-脱附测试。图3(b)中N2吸脱附曲线呈现出I型曲线特征,TpPa-CF3在相对压力较低的区域(p/p0<0.1),N2的吸附量快速增加,说明材料中存在丰富的微孔结构。通过计算分析得出TpPa-CF3具有较大的比表面积(791.83 m2·g−1),图3(c)显示TpPa-CF3具有较小的孔径(1.18 nm)。这归因于TpPa-CF3中氟原子的高电负性增强了框架中芳香环之间的相互作用力,这种相互作用力有助于COF形成较大的比表面积以及较小的孔径[17]。

通过热重分析TpPa-CF3的热性能。热重曲线如图3(d)所示,从图中看到热损失分为两个阶段,大约在400℃之前的损失可能为残留在孔道里的高沸点溶剂(DMF)的挥发。400℃后出现明显的质量损失,从DTG曲线上可以看到在416℃质量损失的速度最快,这主要归因于TpPa-CF3框架的分解。以上结果可以看出TpPa-CF3具有较好的热稳定性。

2.2 TpPa-CF3/6FDA-ODA混合基质膜的表征

通过XRD对膜结构表征,评价了填料对聚合物链排列的影响。从图4(a)中可以看到所有曲线在2θ=15°左右均出现典型的聚合物宽峰。通过布拉格方程计算,得到膜的分子链间距。纯6FDA-ODA膜的分子链间距为0.574 nm,随着填料TpPa-CF3负载量的增加,链间距呈现先增大后下降的趋势,7%TpPa-CF3/6FDA-ODA膜的链间距最小(0.566 nm)。分子链间距先增大主要是由于小负载量的掺入破坏了分子链的堆积,随着负载量的增大,填料与聚合物基质的相互作用逐渐增强,限制了分子链的迁移率,链间距减小有利于提高气体的选择性。同时,在TpPa-CF3/6FDA-ODA混合基质膜中没有观察到TpPa-CF3粉末的特征峰,这主要是由于在超声搅拌过程中COF填料的部分剥落[21]。

混合基质膜的FTIR图谱如图4(b)所示,所有膜都表现出6FDA-ODA的特征峰,包括C=O的对称(

1783 cm−1)和不对称拉伸(1733 cm−1)、C—N的拉伸振动(1378 cm−1)、C—O—C的拉伸振动(1157 cm−1)、C—F键的吸收峰(1110 cm−1),以及酰亚胺环的弯曲振动(721 cm−1),值得注意的是在1597 cm−1处的特征峰,随着填料的增加而增强,这主要归因于TpPa-CF3和6FDA-ODA中芳香环上的C=C的吸收峰重叠[22]。以上结果说明聚酰亚胺基体和填料之间具有良好的相容性,填料的加入并没有破坏聚酰亚胺的结构。为分析TpPa-CF3的加入对混合基质膜热稳定性的影响,对6FDA-ODA及TpPa-CF3/6FDA-ODA混合基质膜进行了热重测试。如图5(a)所示,混合基质膜的分解分为两个阶段,第一阶段是400℃左右TpPa-CF3框架的分解,第二阶段是500℃左右6FDA-ODA基体膜的分解,填料的加入对膜的热稳定性影响不大。所有混合基质膜都表现出高达500℃的良好热稳定性,远高于工业中膜的操作温度,表明这些膜具有良好的适用性。DSC曲线用于分析膜的玻璃化转变温度(Tg)。如图5(b)所示,6FDA-ODA膜的Tg出现在297.5℃。随着TpPa-CF3负载量的增加,TpPa-CF3/6FDA-ODA膜的Tg从297.5℃逐渐增加到302.1℃,说明TpPa-CF3与6FDA-ODA之间具有良好的界面相互作用,这有利于提升混合基质膜的气体选择性[23]。

膜表面、截面的扫描电镜表征能够反映出填料在膜内的分散情况。如图6(a1)~6(e1)所示,与表面光滑平整的纯膜相比,混合基质膜的表面随着填料负载量的增加逐渐变得粗糙,在负载量达到7wt%时可以看到膜表面出现不平整及大颗粒团聚的现象。图6(a2)~6(e2)为纯膜及其混合基质膜的截面扫描电镜图,纯膜的截面表现出均匀、致密的微观结构,在1wt%~5wt%混合基质膜的截面图中能够观察到随着负载量的增加其截面形貌逐渐变粗糙,同时在膜内能够观察到TpPa-CF3颗粒很好地被聚合物包裹且分散均匀。当填料负载量达到7wt%时膜内出现填料与聚合物基质相分离的现象,说明此时负载量已经达到聚合物基质所能承受的上限,5wt%为其最优负载量。

通过接触角测试仪分析纯膜及其混合基质膜的水接触角(θw)。如图7(a)和表1所示,6FDA-ODA膜的水接触角为79.9°,TpPa-CF3/6FDA-ODA混合基质膜的水接触角为81.4°~89.1°,呈现逐渐增大的趋势。这主要归因于TpPa-CF3框架中含有—CF3疏水基团,因此随着TpPa-CF3含量的增加相应负载量的混合基质膜水接触角也逐渐增加。提升膜的疏水性能有助于阻止水汽进入,提升其气体传输性能。

表 1 不同负载量下TpPa-CF3/6FDA-ODA混合基质膜的力学性能Table 1. Mechanical properties of TpPa-CF3/6FDA-ODA mixed matrix membranes at different loadingsTpPa-CF3 loadings/wt% Tensile strength/MPa Elongation at break/% Young's modulus/GPa θw/(°) 0 74.1 10.1 1.59 79.9 1 79.6 9.7 1.63 81.4 3 82.9 8.6 1.70 83.1 5 93.0 7.8 1.82 84.1 7 84.5 7.3 1.76 89.1 Note: θw—Water contact angle. 对混合基质膜进行拉伸实验以此来检验其力学性能。测试结果如图7(b)和表1所示。从表中可以看出,TpPa-CF3/6FDA-ODA混合基质膜的抗拉强度和杨氏模量随着TpPa-CF3负载量的增加呈现出先增加后下降的趋势,而断裂伸长率呈现逐渐下降的趋势。这主要归因于,在混合基质膜中TpPa-CF3与6FDA-ODA之间较好的相互作用力使得填料与聚合物之间具有良好的界面相容性,增强了膜的刚性。然而,当负载量达到7wt%时,抗拉强度和杨氏模量略微下降,这主要是过量的TpPa-CF3颗粒之间发生团聚,使得界面出现缺陷导致应力集中,降低了膜的力学性能[24]。

利用3种纯气体(CO2、O2、N2)渗透测试来评估不同负载量下TpPa-CF3/6FDA-ODA混合基质膜的渗透性及CO2/N2和O2/N2的理想选择性。结果如表2所示,每一种膜气体渗透系数的大小均与气体分子动力学直径呈反比,即膜的3种气体渗透系数大小排列为P(CO2)>P(O2)>P(N2),3种气体分子动力学直径大小排列为N2(0.36 nm)>O2(0.35 nm)>CO2(0.33 nm)。同6FDA-ODA膜相比所有混合基质膜的气体渗透性都有所提升。由图8(a)中可得,随着TpPa-CF3含量的增加,膜的气体渗透性呈现出先增大后下降的趋势,其中5%TpPa-CF3/6FDA-ODA膜气体渗透性能最佳,P(CO2)提升了149%,P(O2)提升了138%,P(N2)提升了98%。这主要归因于TpPa-CF3的高孔隙率提高了TpPa-CF3/6FDA-ODA膜的比表面积及固有孔隙率,为气体传输提供了快速通道。TpPa-CF3负载量到7wt%时,气体的渗透性明显下降,但仍然比6FDA-ODA膜高。这主要是由于负载量过大,造成TpPa-CF3在膜内团聚堵塞了气体传输的孔道。

表 2 6FDA-ODA及TpPa-CF3/6FDA-ODA混合基质膜的气体渗透系数P和理想选择性Table 2. Gas permeability coefficient P and ideal selectivity of 6FDA-ODA and TpPa-CF3/6FDA-ODA mixed matrix membranesMembrane Permeability/Barrer Ideal selectivity α CO2 O2 N2 α(CO2/N2) α(O2/N2) 6FDA-ODA 12.47 2.55 0.64 19.5 4.0 1%TpPa-CF3/6FDA-ODA 16.91 3.76 0.98 17.2 3.8 3%TpPa-CF3/6FDA-ODA 22.77 4.43 1.03 22.0 4.3 5%TpPa-CF3/6FDA-ODA 31.08 6.08 1.27 24.5 4.8 7%TpPa-CF3/6FDA-ODA 18.62 4.16 1.11 16.8 3.8 Notes: 1 Barrer=10−10 cm3(STP)·cm·cm−2·s−1·cmHg−1; Ideal selectivity α=P(A)/P(B), A and B are two different pure gases. TpPa-CF3/6FDA-ODA膜的气体选择性变化趋势和气体渗透性变化趋势不同,如图8(b)所示,CO2/N2和O2/N2均呈现出先下降后上升再下降的趋势,CO2/N2及O2/N2的理想选择性范围分别在16.8~24.4和3.8~4.8。其中,当TpPa-CF3负载量为5wt%时,混合基质膜的CO2/N2和O2/N2选择性最好,分别是6FDA-ODA膜的125%和119%。理想选择性的提高主要归因于两个方面:一个方面是CO2和O2的分子动力学直径要小于N2的分子动力学直径,从而CO2和O2分子倾向于优先通过。另一个方面,TpPa-CF3中富含大量对CO2具有亲和力的N、O和F等电负性原子,同时框架内还存在能与CO2发生偶极-四极相互作用的强极性C—F键,因此CO2/N2选择性相较于O2/N2的提升更明显[25]。然而,当负载量到7wt%时,混合基质膜的CO2/N2和O2/N2选择性大幅下降,略低于6FDA-ODA膜,这主要归因于当TpPa-CF3的负载量增加一定程度时,其在膜内发生团聚,并和聚合物基质产生部分相分离,产生一些非选择的孔,从而造成CO2/N2和O2/N2理想选择性的大幅下降。

对TpPa-CF3/6FDA-ODA混合基质膜进行72 h的连续气体渗透性测试,以验证膜的稳定性。如图8(c)所示,该膜在72 h的运行试验中P(CO2)下降了18%,CO2/N2的选择性下降了16%,总体表现出了良好的分离稳定性。

为了评估混合基质膜的气体分离性能,图9显示了不同负载量的TpPa-CF3/6FDA-ODA混合基质膜的气体分离性能与Robeson上限的对比。当负载量为5wt%时,其气体分离性能更靠近Robeson上限,气体的渗透性与选择性同步提升。说明适量的引入TpPa-CF3能够改善聚合物膜的气体分离性能。此外,表3显示了文献[26-30]中报道的混合基质膜气体分离性能与本工作的对比,TpPa-CF3/6FDA-ODA混合基质膜显示出适中的气体渗透性以及适中的气体选择性,说明TpPa-CF3/6FDA-ODA混合基质膜还有进一步提升的潜力。

表 3 文献中报道的混合基质膜气体分离性能与本工作的对比Table 3. Comparison of gas separation performance of mixed matrix membranes reported in the literature with the present workMembrane type P(CO2)/Barrer P(O2)/Barrer α(CO2/N2) α(O2/N2) Ref. TpPa-1-nc/Pebax 21 — 72 — [26] COFp-PVAm 270 — 86 — [27] TpBD@PBI-BuI 14.8 — 23 — [28] ZIF-7-I/(BPDA/6FDA-ODA) — 2.9 — 0.19 [29] PBI-PI-based carbon 293.5 93.1 8.3 2.6 [30] 5%TpPa-CF3/6FDA-ODA 31.08 6.08 24.4 4.8 This work Notes: TpPa-1-nc—; COFp—; TpBD—; BPDA—; Pebax—Poly(ether-block-amide); PVAm—Polyvinylamine; PBI-BuI—Tert-butylpolybenzimidazole; ZIF-7-I—Wide-pore ZIF-7; PBI—Polybenzimidazoles; PI—Polyimide. 3. 结 论

(1)采用溶剂热法合成了一种氟化共价有机框架材料(TpPa-CF3),其具有高比表面积(791.83 m2·g−1),较小且均一的孔径(1.18 nm)以及良好的热稳定性。

(2)采用共混法成功制备TpPa-CF3/聚酰亚胺(6FDA-ODA)混合基质膜。通过表征得出,所得膜具有良好的界面相容性以及较高的热稳定性(热分解温度在500℃左右)。水接触角的范围在81.4°~89.1°,且膜具有良好的力学性能,有利于膜在分离过程中的稳定性。

(3) TpPa-CF3的掺入提高了混合基质膜的气体渗透性,随着膜中TpPa-CF3负载量的增加,混合基质膜的气体渗透性呈现先减小后增大再减小的趋势。其中,5%TpPa-CF3/6FDA-ODA膜的气体分离性能最好,其CO2和O2的渗透性能分别提高了149%和138%,CO2/N2和O2/N2的分离性能分别是6FDA-ODA基体膜的125%和119%。

-

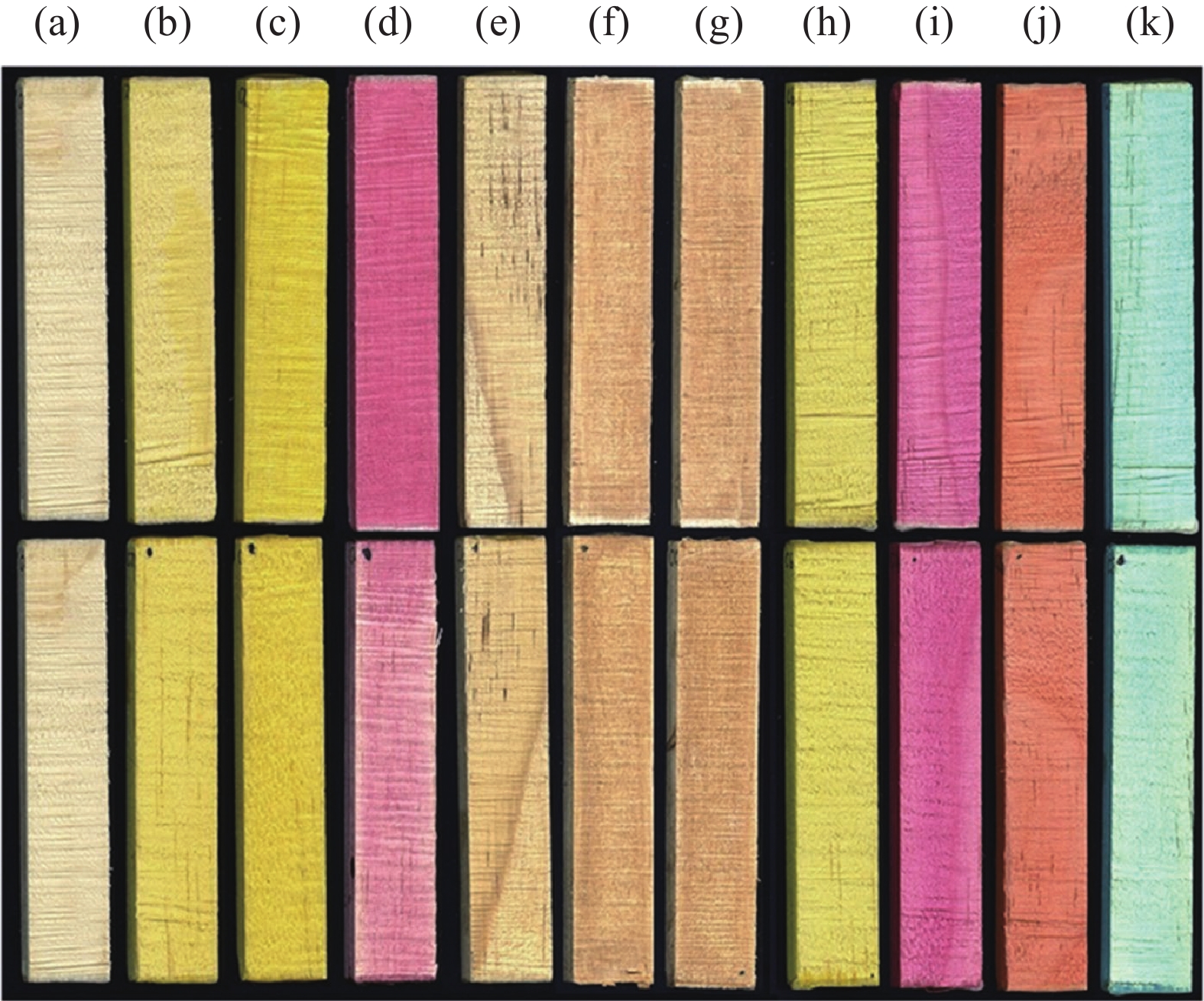

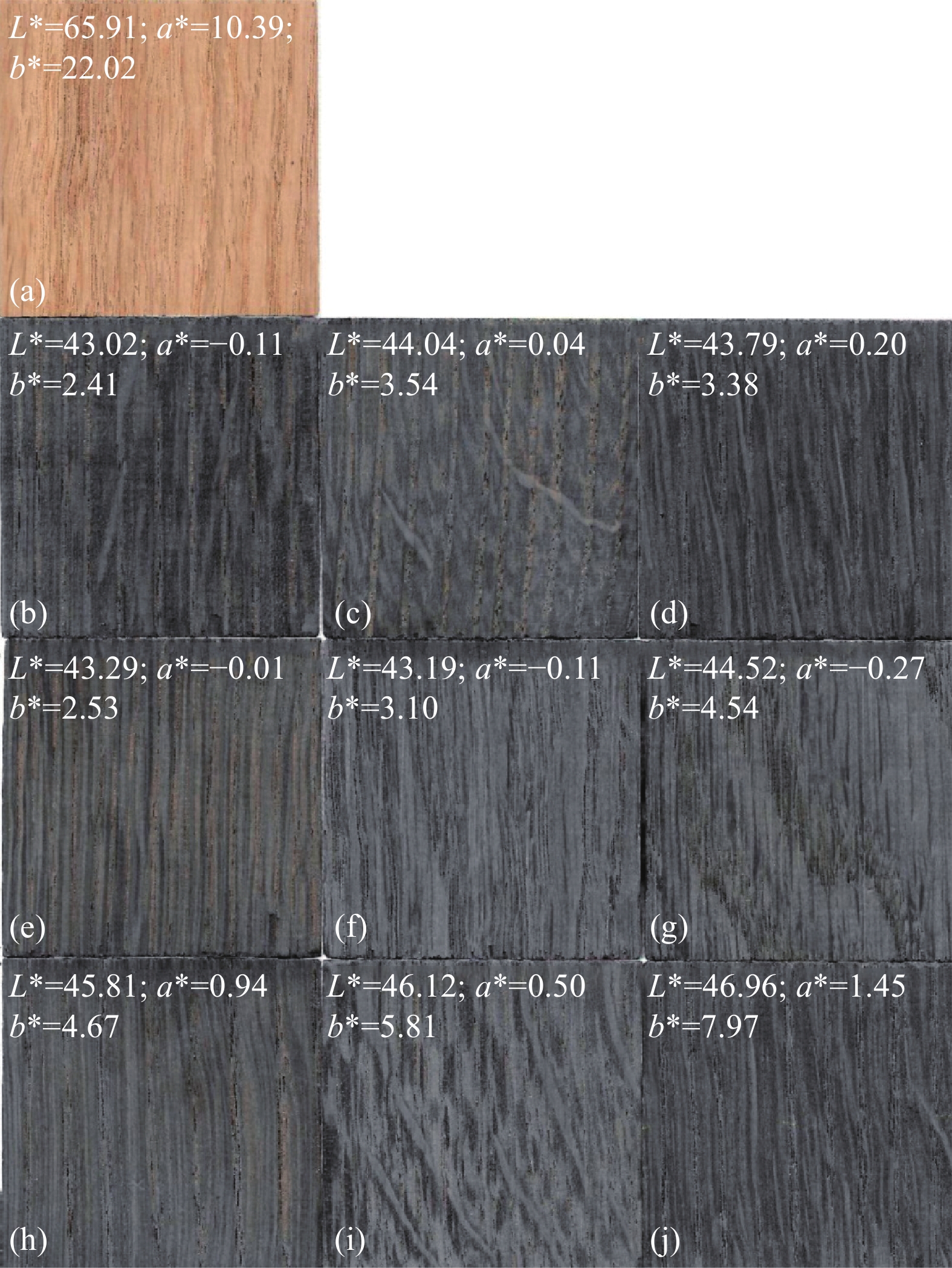

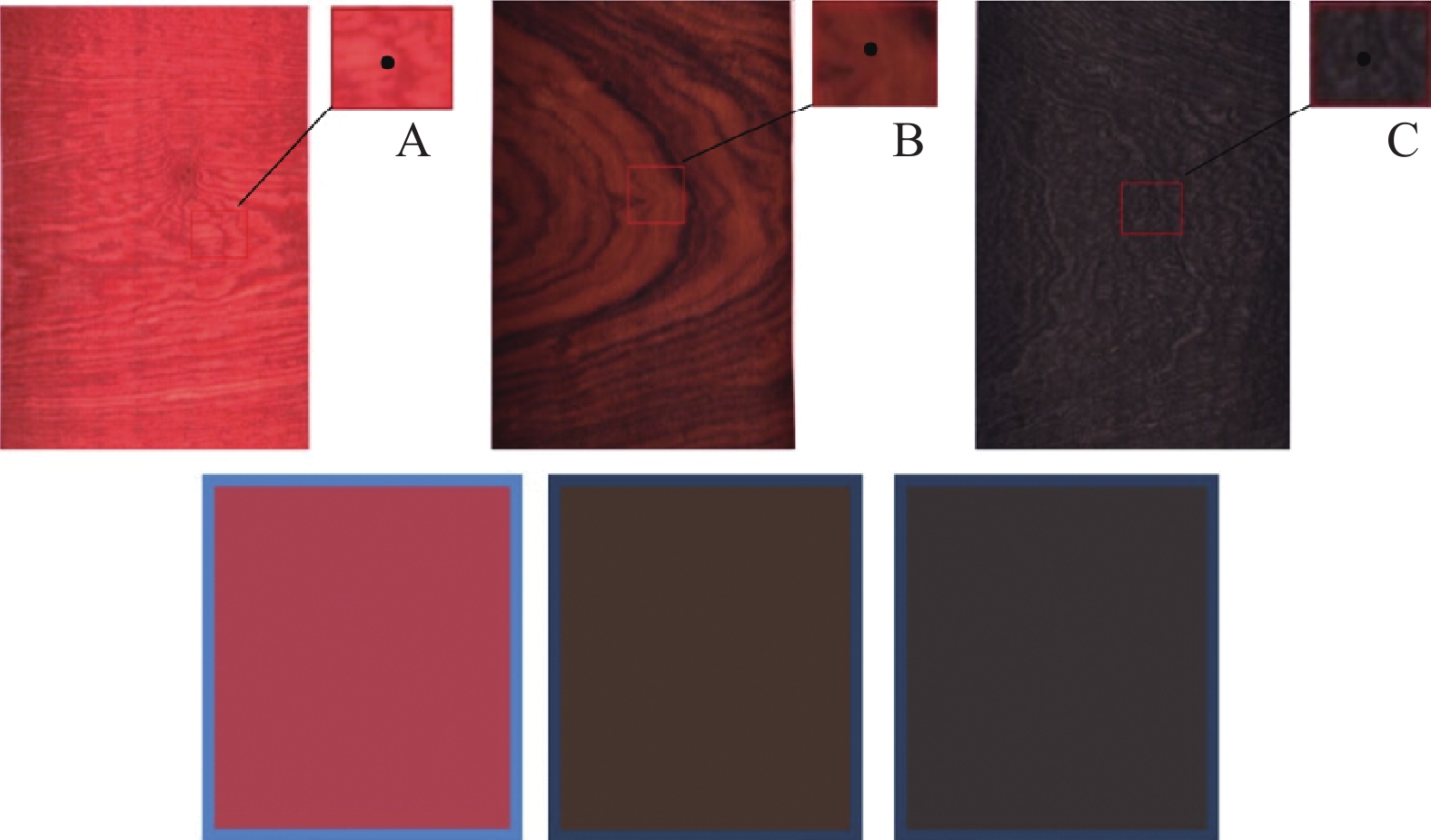

图 3 所选染色木块的扫描图像。(a)未处理。(b) Pergasol 黄。(c)果胶酶/Pergasol 黄。(d) Pergasol 红。(e)鞣酸。(f)果胶酶/鞣酸。(g)果胶酶/漆酶/鞣酸。(h) Procion 柠檬黄。(i)Procion 洋红。(j) Procion 鲜橙。(k) Procion 蓝绿。上排:未浸洗;下排:用水浸洗[18]。

Figure 3. Scanned images of selected dyed wood blocks. (A) Untreated. (B) Pergasol Yellow. (C) Pectinase/Pergasol Yellow. (D) Pergasol Red. (E) Tannin. (F) Pectinase/tannin. (G) Pectinase/ laccase/tannin. (H) Procion Lemon Yellow. (I) Procion Magenta. (J) Procion Brilliant Orange. (K) Procion Turquoise. Upper row: unleached; lower row: leached with water[18].

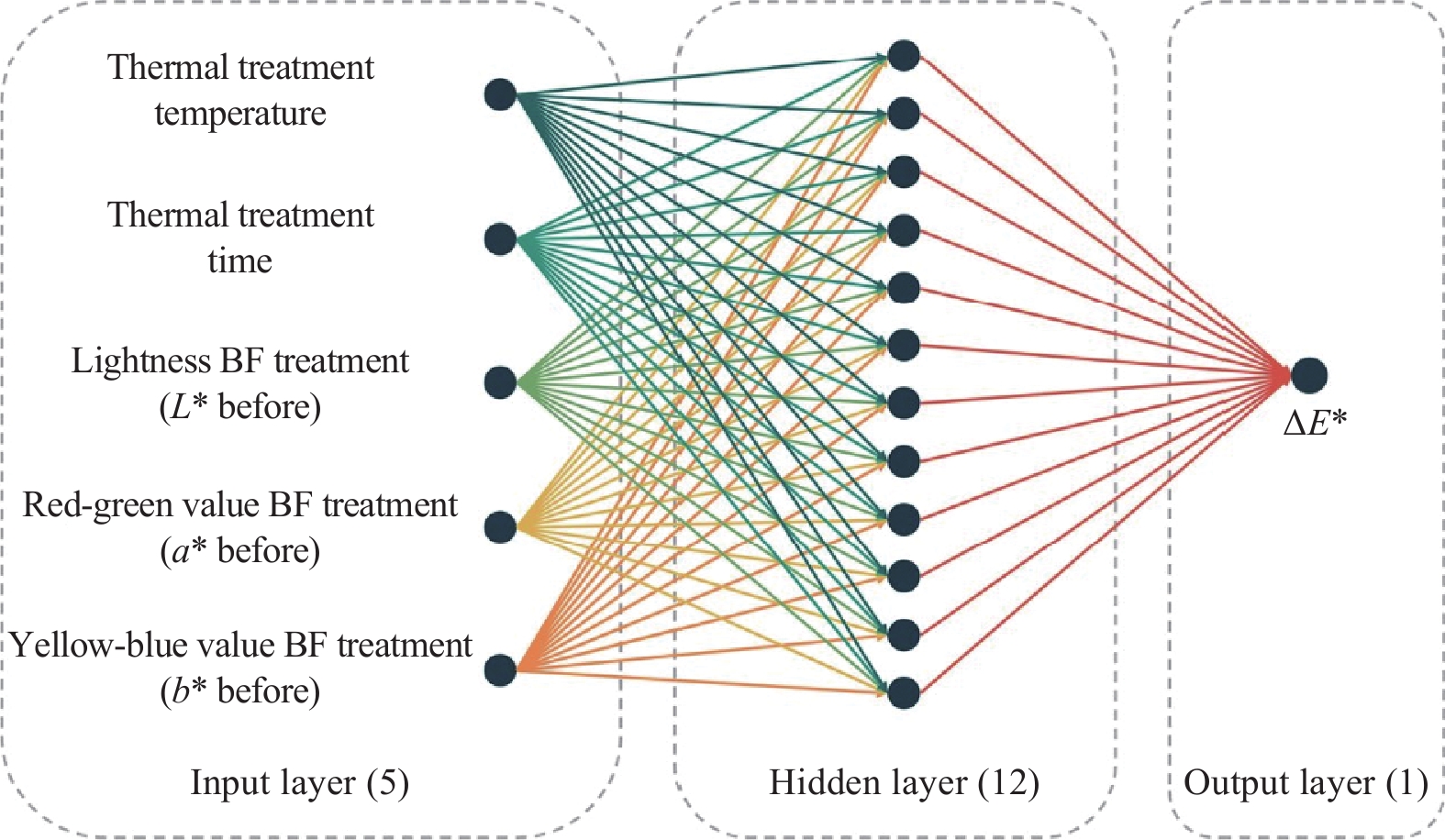

图 8 参考木材及用硫酸铁处理的木材图像:从左到右分别是施加10%、20%和30%溶液后的效果;从上到下分别是短时冷浴(2小时,20°C)、短时热浴(2小时,70°C)和长时冷浴(24小时,20°C)后的效果[28]。

Figure 8. Images of reference wood, and wood treated with iron sulphate: from left to right after 10 %, 20 % and 30 % solution was applied; from top to bottom: after short-term cold bath (2 h; 20℃), after short-term hot bath (2 h, 70℃), after long-term cold bath (24 h, 20℃)[28].

表 1 木材染色技术中色彩匹配和预测算法的最新进展。

Table 1 Recent Advances in Color Matching and Prediction Algorithms in Wood Dyeing Technologies.

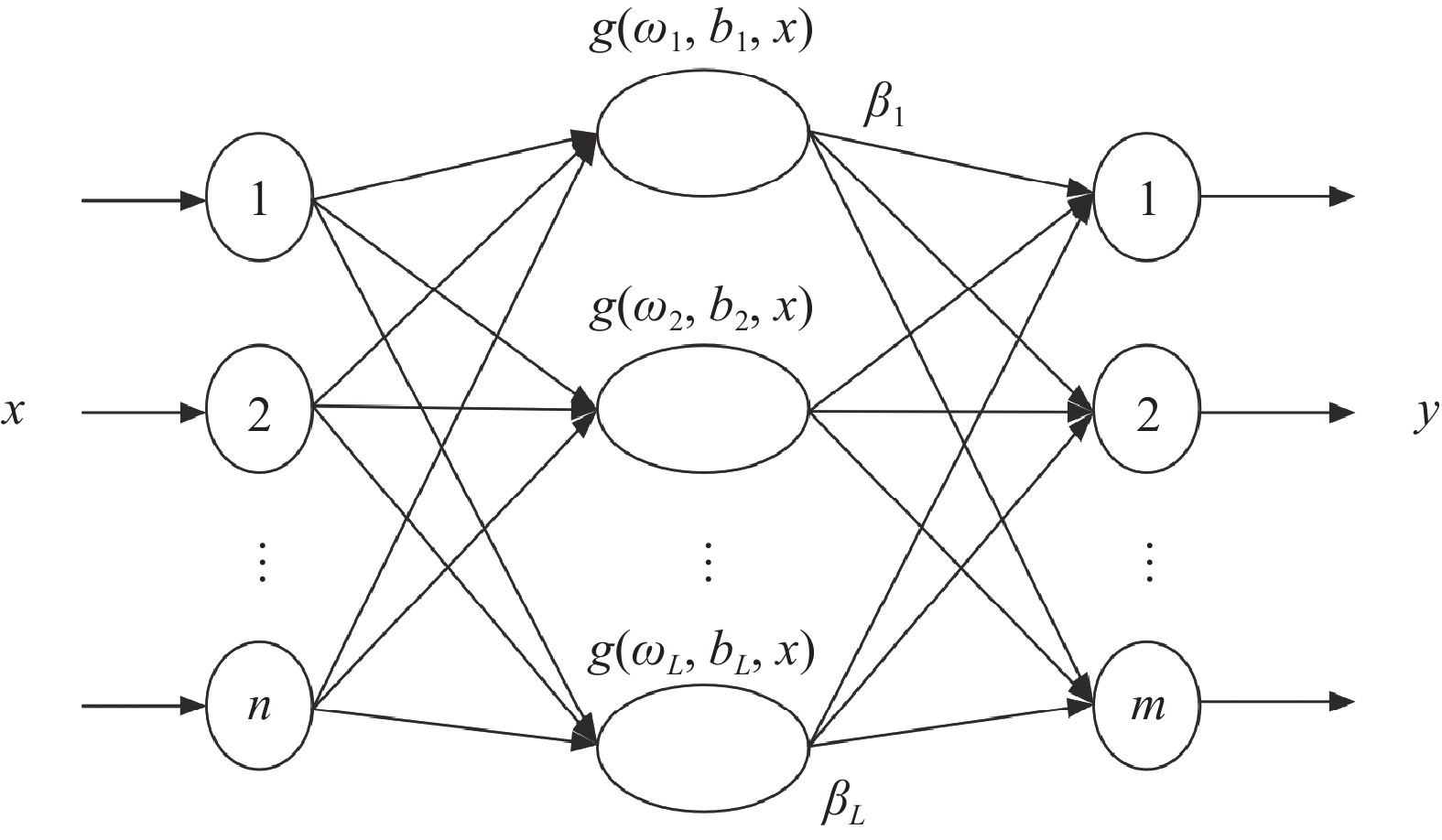

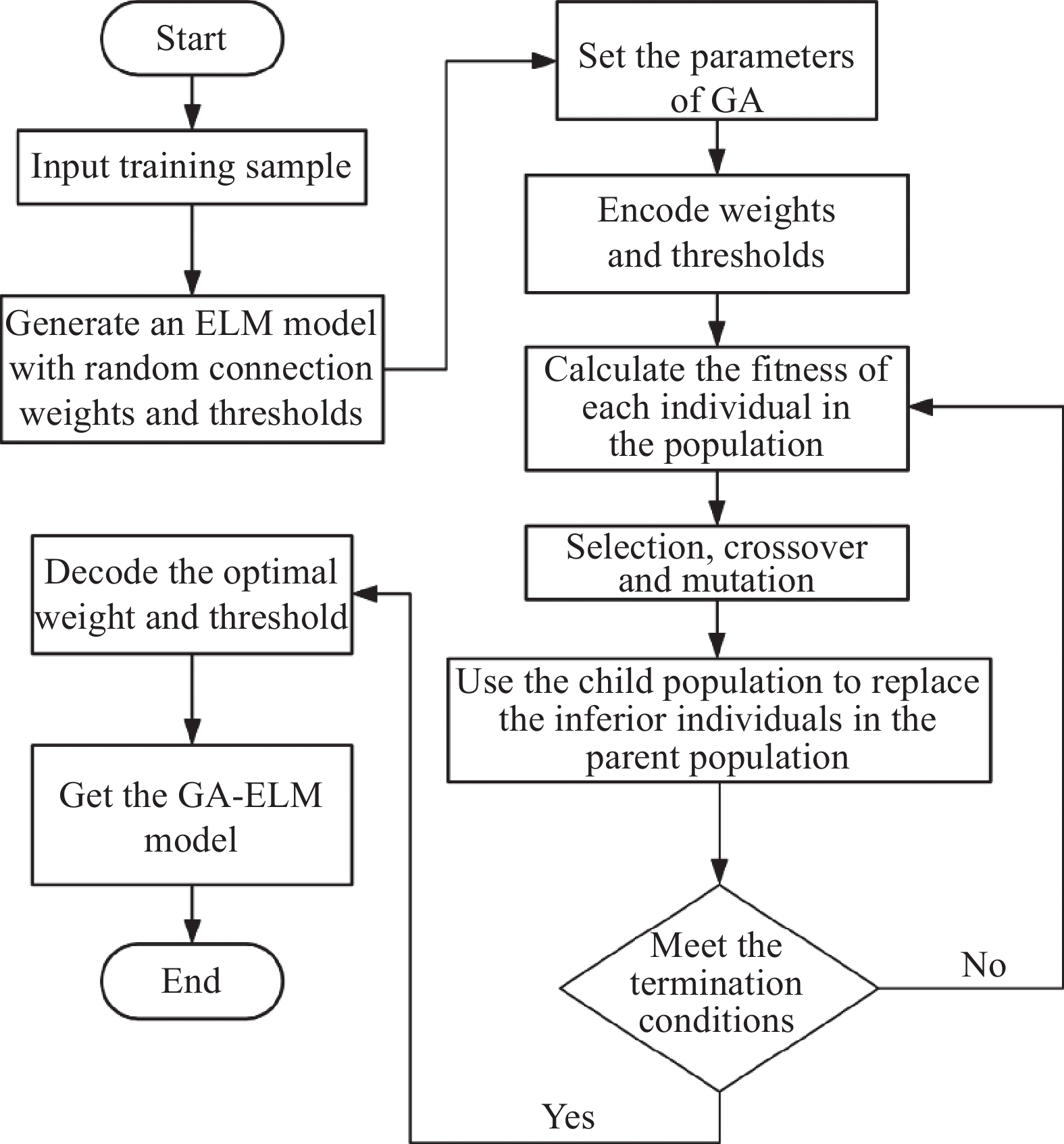

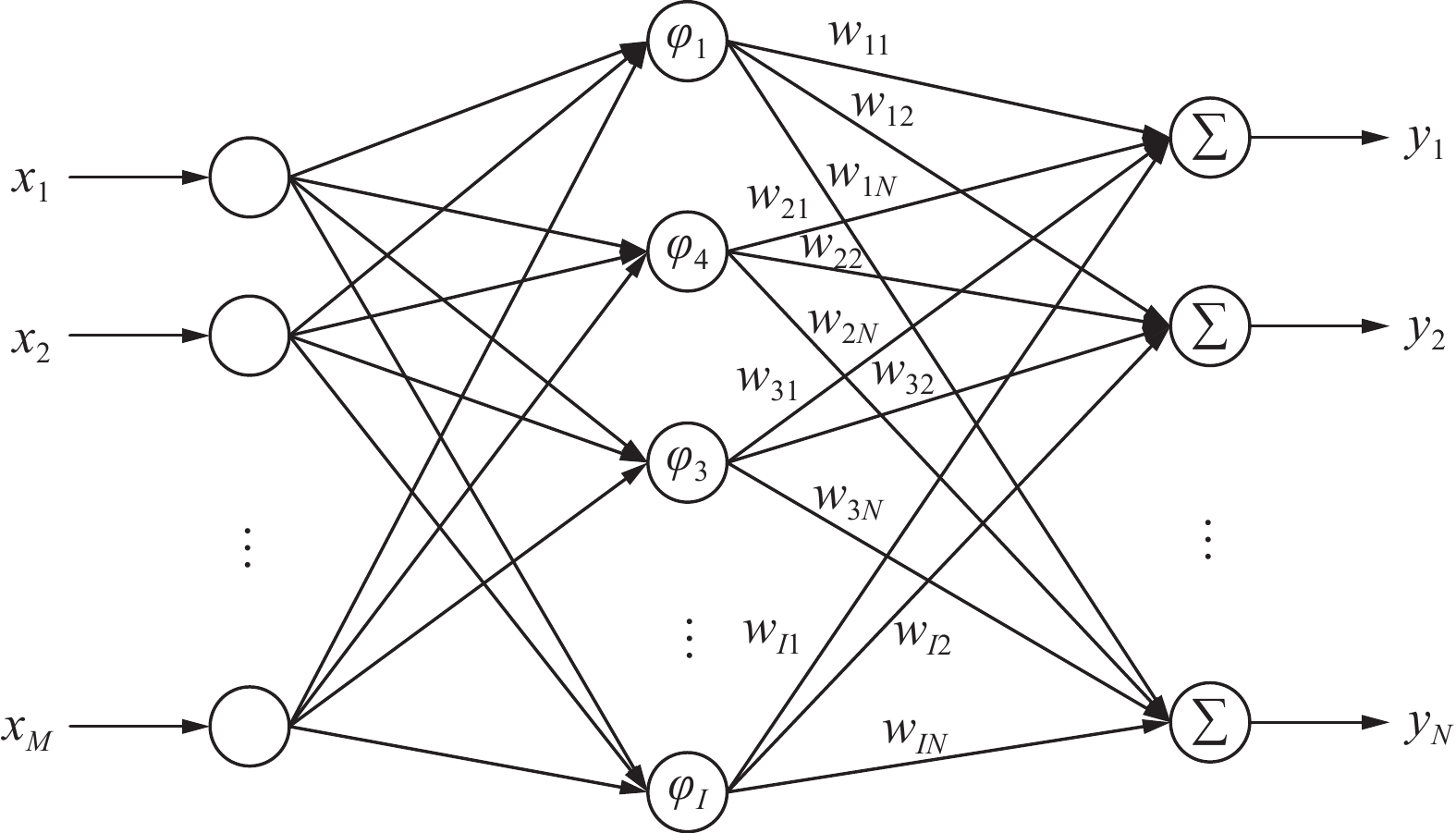

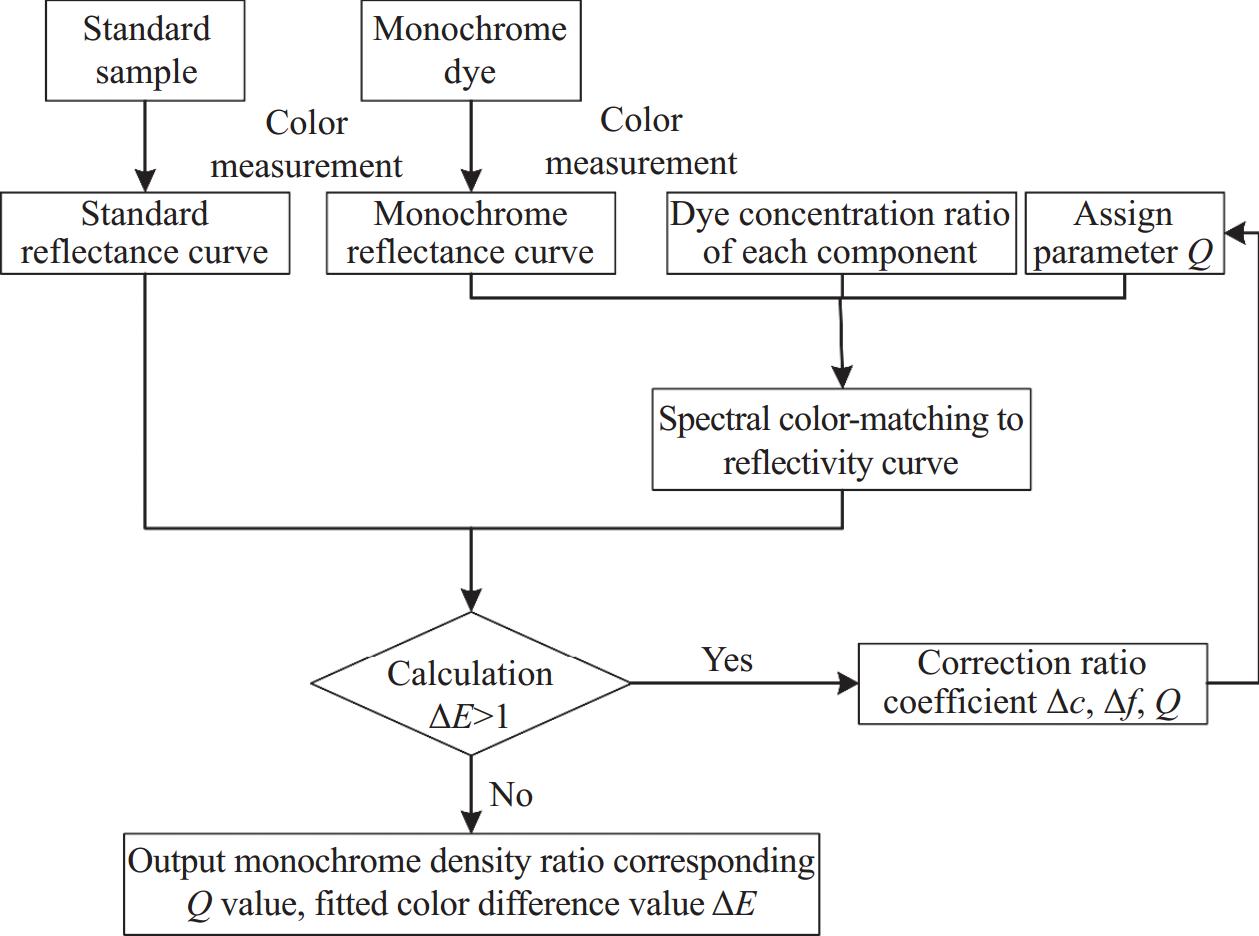

Researcher Algorithm Type Purpose Results and Advantages Reference Guan et al. Genetic Algorithm (GA) optimizing Extreme Learning Machine (ELM) Improve accuracy of dye formula prediction Average relative deviation reduced to 0.262, significant accuracy improvement, cost-effectiveness and resource efficiency enhanced [11] Guan et al. Particle Swarm Optimization (PSO) Improve accuracy and efficiency of computer color matching Average relative deviation of 0.643%, average fit color difference of 0.720, significantly improved color matching accuracy and efficiency [48] Guan et al. Enhanced Radial Basis Function (RBF) Network Increase convergence speed and approximation accuracy of neural networks Average relative error reduced from 1.55% to 0.62%, training epochs reduced to 50, improved speed and accuracy [49] Wu et al. Particle Swarm Optimization (PSO) Improve wood dyeing accuracy Optimized model has lower color difference values, improved color matching accuracy, suitable for furniture production and interior design [50] Apraiz et al. Kubelka-Munk Theory with Self-learning Algorithms Predict dye color of stained oak accurately Accurately predicts wood color under various dye proportions and application methods, evaluates effects of varnishing on final color appearance [51] Wei et al. Adaptive Differential Evolution (ADE) Optimize prediction of wood dye formulas Optimized model's color difference ΔE00 less than 3, significantly improved prediction accuracy and optimization efficiency [52] Guan et al. Particle Swarm Optimization (PSO) Improve color matching accuracy Average fit color difference reduced from 0.8202 to

0.7287 , significantly improved color matching accuracy[53] Guan et al. Wolf Algorithm Optimized Support Vector Regression (SVR) Increase accuracy and speed of wood dye color matching Relative formula deviation reduced to 0.177, optimized model superior to traditional models, demonstrated global optimization capability [54] 表 2 先进预测模型在木材热处理及他颜色处理技术中的应用分析。

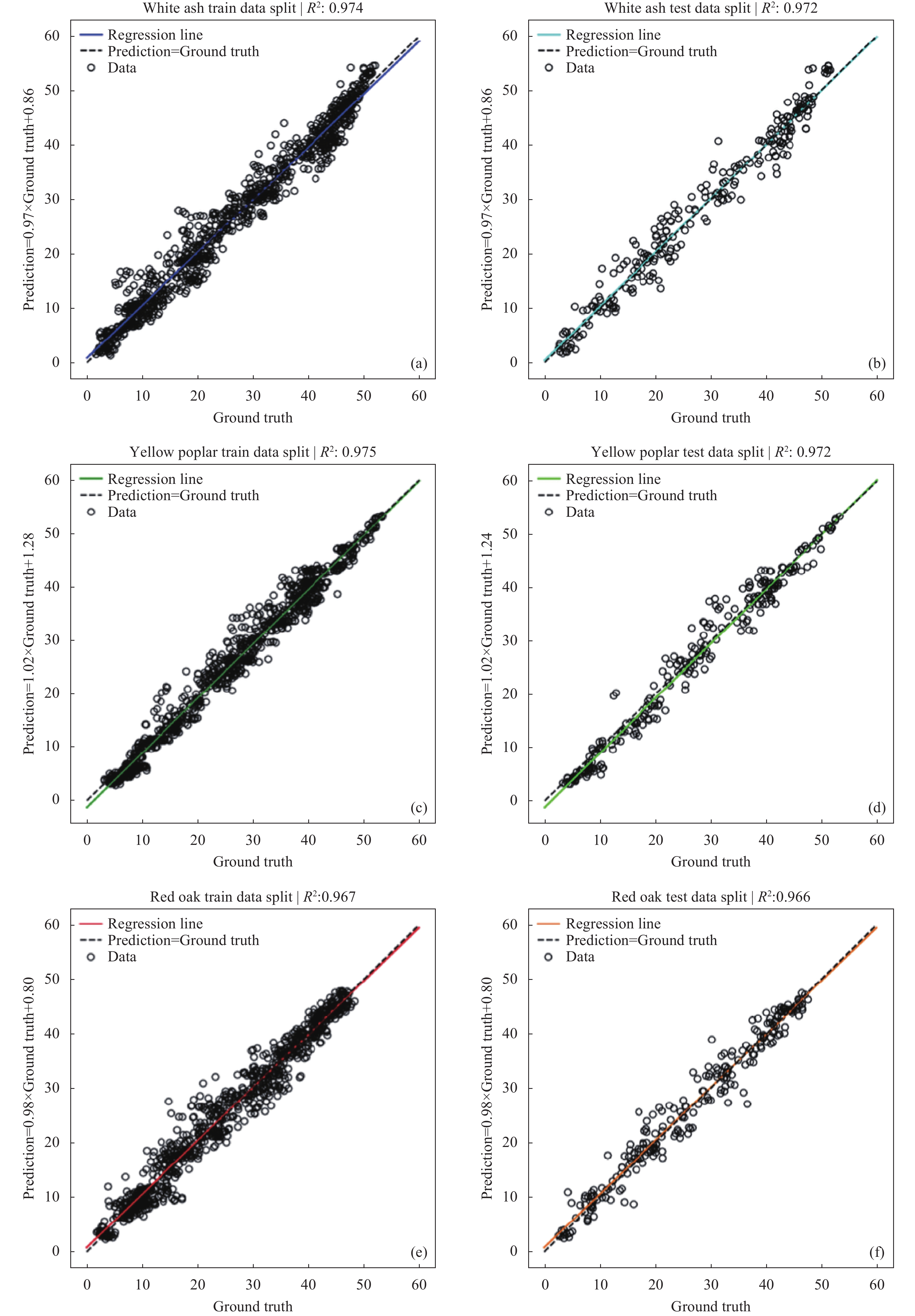

Table 2 Analysis of the Application of Advanced Prediction Models in Wood Heat Treatment and Other Color Processing Technologies.

Algorithm Type Research Objective Results and Advantages Reference Mo et al. Artificial Neural Networks (ANN) Predict color changes in wood High accuracy (R²>0.96), reduced time and resource usage [55] Kropat et al. Partial Least Squares Regression (PLSR) Predict visibility of chemically dyed wood Improved consistency, especially with iron acetate (R²_cv=0.92) [60] Nguyen et al. Artificial Neural Networks (ANN) Predict color changes in heat-treated and weather ed wood High accuracy (all datasets R²>0.92), reduced experimental costs [56] Van et al. Artificial Neural Networks (ANN) Predict color changes in heat-treated wood Extremely high predictive accuracy (R²>0.99), saves physical tests [57] Li et al. Improved Particle Swarm Optimization-Support Vector Machine (IPSO-SVM) Enhance prediction accuracy of color changes post heat treatment and weathering Significantly improved accuracy, reduced errors and variance [58] Li et al. Response Surface Methodology (RSM) Study the effect of CO2 laser on changing wood color Quantified relationship between laser settings and color results, showed chemical changes related to

color changes[59] -

[1] WANG H, ZHANG Y, LI H, et al. Research on the Impregnation Process and Mechanism of Silica Sol/Phenolic Resin Modified Poplar Wood[J]. Forests, 2023, 14(11): 2176. DOI: 10.3390/f14112176

[2] HE S, ZHAO X, WANG E Q, et al. Engineered Wood: Sustainable Technologies and Applications[J]. Annual Review of Materials Research, 2023, 53(1): 195-223. DOI: 10.1146/annurev-matsci-010622-105440

[3] WANG H, ZHANG Y, LI H, et al. Study on the Physico-Mechanical Properties and Mechanisms of Poplar Wood Co-Modified by Anoxic High-Temperature Heat Treatment and Impregnation with Silica Sol/Phenolic Resin[J]. Industrial Crops & Products, 2024, 221119312-119312.

[4] ZHANG, J. , YANG, L. , & LIU, H. (2021). Green and Efficient Processing of Wood with Supercritical CO2: A Review. Applied Sciences, 11, 3929.

[5] LU D, XIONG X, LU G, et al. Effects of NaOH/H2O2/Na2SiO3 Bleaching Pretreatment Method on Wood Dyeing Properties[J]. Coatings, 2023, 13(2): 233. DOI: 10.3390/coatings13020233

[6] LIU Y, YU Z, ZHANG Y, et al. Microbial Dyeing—Infection Behavior and Influence of Lasiodiplodia Theobromae in Poplar Veneer[J]. Dyes and Pigments, 2020, 173: 107988. DOI: 10.1016/j.dyepig.2019.107988

[7] ZHU T, SHENG J, CHEN J, et al. Staining of Wood Veneers with Anti-UV Property Using the Natural Dye Extracted from Dalbergia Cohinchinensis[J]. Journal of Cleaner Production, 2021, 284: 124770. DOI: 10.1016/j.jclepro.2020.124770

[8] DAGHER R, STEVANOVIC T, LANDRY V. Wood Color Modification with Iron Salts Aqueous Solutions: Effect on Wood Grain Contrast and Surface Roughness[J]. Holzforschung, 2023, 77(5): 356-367. DOI: 10.1515/hf-2022-0189

[9] GAŠPARÍK M, GAFF M, KAČÍK F, et al. Color and Chemical Changes in Teak (Tectona Grandis L. f. ) and Meranti (Shorea spp. ) Wood after Thermal Treatment[J]. BioResources, 2019, 14(2): 2667-2683. DOI: 10.15376/biores.14.2.2667-2683

[10] SHI Y, LYU W, WANG X, et al. Effect of Various Compounding Methods on Acid Red 18050-Melamine Modified Urea Formaldehyde Resin Compound as Wood Modifier[J]. BioResources, 2019, 14(4): 9100-9109. DOI: 10.15376/biores.14.4.9100-9109

[11] GUAN X, LI W, HUANG Q, et al. Intelligent Color Matching Model for Wood Dyeing Using Genetic Algorithm and Extreme Learning Machine[J]. Journal of Intelligent & Fuzzy Systems, 2022, 42(6): 4907-4917.

[12] AKKUŞ M, BUDAKÇI M. Determination of Color-Changing Effects of Bleaching Chemicals on Some Heat-Treated Woods[J]. Journal of Wood Science, 2020, 66: 1-14. DOI: 10.1186/s10086-020-1848-7

[13] ÇAKICIER N, ULAY G. Determination of Color Characteristics of Some Wood Species Treated with Bleaching Chemicals[J]. BioResources, 2023, 18(4): 7796. DOI: 10.15376/biores.18.4.7796-7804

[14] BALÇIK Ö B, ÖZDEMIR T. The Effect of Bleaching Agents on Color Change in Different Section Shapes in Beech And Fir Woods[J]. Kastamonu University Journal of Forestry Faculty, 23(2): 111-118.

[15] LIU Y, ZHANG Y, YU Z, et al. Microbial Dyes: Dyeing of Poplar Veneer with Melanin Secreted by Lasiodiplodia Theobromae Isolated from Wood[J]. Applied Microbiology and Biotechnology, 2020, 104: 3367-3377. DOI: 10.1007/s00253-020-10478-2

[16] VIDHOLDOVÁ Z, REINPRECHT L. The Colour of Tropical Woods Influenced by Brown Rot[J]. Forests, 2019, 10(4): 322. DOI: 10.3390/f10040322

[17] SONG T, CHENG F, SUN J. Stain Capacity of Three Fungi on Two Fast-Growing Wood[J]. Journal of Forestry Research, 2021, 32(1): 427-434. DOI: 10.1007/s11676-020-01103-z

[18] WIDSTEN P, CHITTENDEN C, WEST M, et al. Enzymatic Treatments for Improved Dyeing of Solid Wood[J]. Holzforschung, 2022, 76(6): 493-502. DOI: 10.1515/hf-2021-0230

[19] ZHU T, LIU S, REN K, et al. Colorability of Dyed Wood Veneer Using Natural Dye Extracted from Dalbergia Cochinchinensis with Different Organic Solvents[J]. BioResources, 2018, 13(4): 7197-7211.

[20] YUNIANTI A D, PANGESTU K T P. COLOR IMPROVEMENT OF PRETREATED GMELINA WOOD BY IMPREGNATION OF NATURAL DYES[J].

[21] RUI H, ROBINSON S C, VEGA GUTIERREZ P, et al. Spalting Colorants as Dyes for Wood Stabilizers[J]. Journal of Coatings Technology and Research, 2019, 16: 905-911. DOI: 10.1007/s11998-019-00203-8

[22] QI Y, ZHOU Z, LI J, et al. Study on the Dyeing Properties of Chinese Fir with Cinnamomum Camphor Pigment by Premordant Dyeing[J]. Wood Material Science & Engineering, 2024: 1-11.

[23] QI Y, ZHOU Z, XU R, et al. Research on the Dyeing Properties of Chinese Fir Using Ultrasonic-Assisted Mulberry Pigment Dyeing[J]. Forests, 2023, 14(9): 1832. DOI: 10.3390/f14091832

[24] ZHU T, REN K, SHENG J, et al. Natural Dye Extracted from Dalbergia Cochinchinensis Residue with Water Fastness, Mildew Resistance and Permeability Properties for Wood Staining[J]. Wood Science and Technology, 2022, 56(3): 969-988. DOI: 10.1007/s00226-022-01385-y

[25] BELDEAN E, TIMAR M C. Wood Colouring with Natural Dye Extracts. New Research and Perspectives[J]. Bulletin of the Transilvania University of Brasov. Series II: Forestry• Wood Industry• Agricultural Food Engineering, 2023: 81-92.

[26] DAGHER R, LANDRY V, STEVANOVIC T. Contribution to Understanding the Color Development on Wood Surfaces Treated with Iron Salts by a Combination of Analytical Methods[J]. Journal of Wood Chemistry and Technology, 2020, 40(4): 223-234. DOI: 10.1080/02773813.2020.1745845

[27] HUNDHAUSEN U, MAI C, SLABOHM M, et al. The Staining Effect of Iron (II) Sulfate on Nine Different Wooden Substrates[J]. Forests, 2020, 11(6): 658. DOI: 10.3390/f11060658

[28] JANKOWSKA A, KWIATKOWSKI A. Effectiveness of European Oak Wood Staining with Iron (II) Sulphate During Natural Weathering[J]. Maderas. Ciencia y Tecnología, 2022, 24.

[29] QI H, LI X, LIU M, et al. DISCOLORATION OF OAK VENEER INDUCED BY METAL IONS[J]. WOOD RESEARCH, 2023, 68(2): 224-240. DOI: 10.37763/wr.1336-4561/68.2.224240

[30] DAGHER R, STEVANOVIC T, RYAN D H, et al. A Note on Mössbauer Analysis of White Oak Surfaces Colored with Aqueous Iron Salt Solutions[J]. Journal of Wood Chemistry and Technology, 2022, 42(2): 83-90. DOI: 10.1080/02773813.2022.2033780

[31] 侯豪杰, 齐华春, 王宏兴, 等. Fe~(2+)、Cu~(2+)诱导工艺对柞木表板颜色变化规律的影响[J]. 东北林业大学学报, 2024, 52(1): 124-127. HOU Haojie, QI Huachun, WANG Hongxing, et al. Effect of Fe~(2+), Cu~(2+) Induced Processes on the Color Change Patterns of Oak Veneer[J]. Journal of Northeast Forestry University, 2024, 52(1): 124-127(in Chinese).

[32] SLABOJEVA G, SMIRIADKOVA M. Colour Stability of Surface Finishes on Thermally Modified Beech Wood[J]. Annals of Warsaw University of Life Sciences-SGGW. Forestry and Wood Technology, 2021, 114.

[33] WANG P, CHENG S, CAO S, et al. Evaluation of Color Changes, Wettability, and Moisture Sorption of Heat-Treated Blue-Stained Radiata Pine Lumber[J]. BioResources, 2022, 17(3): 4952. DOI: 10.15376/biores.17.3.4952-4961

[34] KAČÍK F, KUBOVSKÝ I, BOUČEK J, et al. Colour and Chemical Changes of Black Locust Wood During Heat Treatment[J]. Forests, 2022, 14(1): 73. DOI: 10.3390/f14010073

[35] DA SILVA E J, CREMONEZ V G, NISGOSKI S. Color Change and Thermogravimetric Analysis of Thermally Treated Eucalyptus Grandis Wood[J]. Revista Ciência da Madeira (Brazilian Journal of Wood Science), 2019, 10(1).

[36] DZURENDA L, DUDIAK M. Cross-Correlation of Color and Acidity of Wet Beech Wood in the Process of Thermal Treatment with Saturated Steam[J]. Wood Res, 2021, 66(1): 105-116. DOI: 10.37763/wr.1336-4561/66.1.105116

[37] BORŮVKA V, ŠEDIVKA P, NOVÁK D, et al. Haptic and Aesthetic Properties of Heat-Treated Modified Birch Wood[J]. Forests, 2021, 12(8): 1081. DOI: 10.3390/f12081081

[38] ZHANG P, GAO J, LIU F, et al. Study on the Discoloration Mechanism of Eucalyptus Wood During Thermal Treatment in Different Media[J]. Polymers, 2023, 15(7): 1599. DOI: 10.3390/polym15071599

[39] ZHANG P, WEI Y, LIU Y, et al. Heat-Induced Discoloration of Chromophore Structures in Eucalyptus Lignin[J]. Materials, 2018, 11(9): 1686. DOI: 10.3390/ma11091686

[40] VIDHOLDOVÁ Z, SLABEOJEVÁ G. Colour Stabilisation of Surface of Four Thermally Modified Woods with Saturated Water Vapour by Finishes[J]. Polymers, 2021, 13(19): 3373. DOI: 10.3390/polym13193373

[41] 王雪玉, 吕文华. 杉木增强-染色复合改性剂的制备工艺[J]. 东北林业大学学报, 2018, 46(4): 73-77. DOI: 10.3969/j.issn.1000-5382.2018.04.015 WANG Xueyu, LÜ Wenhua. Preparation Process of Fir Strengthening-Dyeing Composite Modifier[J]. Journal of Northeast Forestry University, 2018, 46(4): 73-77(in Chinese). DOI: 10.3969/j.issn.1000-5382.2018.04.015

[42] 蹇鸿洋, 王张恒, 孙德林, 等. 增强-染色复合改性松木的制备及性能研究[J]. 家具与室内装饰, 2022, 29(12): 50-53. JIAN Hongyang, WANG Zhangheng, SUN Delin, et al. Preparation and Performance Study of Strengthening-Dyeing Composite Modified Pine[J]. Furniture and Interior Decoration, 2022, 29(12): 50-53(in Chinese).

[43] JAXEL J, GUSENBAUER C, BÖHMDORFER S, et al. Improving Single-Step scCO2 Dyeing of Wood by DMSO-Induced Micro-Swelling[J]. The Journal of Supercritical Fluids, 2020, 165: 104978. DOI: 10.1016/j.supflu.2020.104978

[44] VIDHOLDOVÁ Z, SLABEOJEVÁ G. Colour Stabilisation of Surface of Four Thermally Modified Woods with Saturated Water Vapour by Finishes[J]. Polymers, 2021, 13(19): 3373. DOI: 10.3390/polym13193373

[45] ZOU W, LI Z, WANG Z, et al. Poplar-Based Thermochromic Composites That Change Colour at 38° C to 46° C[J]. Scientific Reports, 2021, 11(1): 16865. DOI: 10.1038/s41598-021-95274-2

[46] KANG Z, FENG N, LIU B, et al. Polyvinyl Alcohol/Propylene Glycol Facilitates Reversible Thermochromism of Passive Energy-Saving Flexible Wood Films at Low (Brightness) to High (Depth) Temperatures[J]. RSC Advances, 2023, 13(47): 33096-33106. DOI: 10.1039/D3RA06336D

[47] WU Y, ZHOU J, HUANG Q, et al. Study on the Properties of Partially Transparent Wood Under Different Delignification Processes[J]. Polymers, 2020, 12(3): 661. DOI: 10.3390/polym12030661

[48] 管雪梅, 黄靖一, 许宝成, 等. 基于粒子群优化Stearns-Noechel模型的全光谱木材配色算法研究[J]. 林产工业, 2022, 59(5): 20-26. GUAN Xuemei, HUANG Jingyi, XU Baocheng, et al. Study on Full-Spectrum Wood Color Matching Algorithm Based on Particle Swarm Optimization of Stearns-Noechel Model[J]. China Forest Products Industry, 2022, 59(5): 20-26(in Chinese).

[49] GUAN X, ZHU Y, SONG W. Application of RBF Neural Network Improved by Peak Density Function in Intelligent Color Matching of Wood Dyeing[J]. Chaos, Solitons & Fractals, 2016, 89: 485-490.

[50] WU M, GUAN X, LI W, et al. Color Spectra Algorithm of Hyperspectral Wood Dyeing Using Particle Swarm Optimization[J]. Wood Science and Technology, 2021, 55: 49-66. DOI: 10.1007/s00226-020-01233-x

[51] APRAIZ I I, DE LA OSA R A, ORTIZ D, et al. Industrial Research on Evolution and Prediction of Hardwood Color[J]. Applied Optics, 2020, 59(31): 9681-9689. DOI: 10.1364/AO.403565

[52] 魏艳秀, 管雪梅, 李文峰, 等. 基于ADE算法优化的木材单板染色全光谱配色模型研究[J]. 西南林业大学学报(自然科学), 2021, 41(2): 125-132. WEI Yanxiu, GUAN Xuemei, LI Wenfeng, et al. Study on Full-Spectrum Wood Veneer Dyeing Color Matching Model Optimized by ADE Algorithm[J]. Journal of Southwest Forestry University (Natural Science), 2021, 41(2): 125-132(in Chinese).

[53] 管雪梅, 吴马超, 李文峰, 等. 基于粒子群优化Friele模型木材染色配色算法研究[J]. 西北林学院学报, 2020, 35(6): 244-248. DOI: 10.3969/j.issn.1001-7461.2020.06.34 GUAN Xuemei, WU Machao, LI Wenfeng, et al. Study on Wood Dyeing Color Matching Algorithm Based on Particle Swarm Optimization of Friele Model[J]. Journal of Northwest Forestry University, 2020, 35(6): 244-248(in Chinese). DOI: 10.3969/j.issn.1001-7461.2020.06.34

[54] 管雪梅, 杨渠三, 吴言. 基于灰狼算法优化支持向量回归模型的木材染色配色算法研究[J]. 林产工业, 2023, 60(7): 27-33. GUAN Xuemei, YANG Qusan, WU Yan. Research on Wood Dyeing Color Matching Algorithm Based on Grey Wolf Optimizer and Support Vector Regression Model[J]. China Forest Products Industry, 2023, 60(7): 27-33(in Chinese).

[55] MO J, TAMBOLI D, HAVIAROVA E. Prediction of the Color Change of Surface Thermally Treated Wood by Artificial Neural Network[J]. European Journal of Wood and Wood Products, 2023, 81(5): 1135-1146. DOI: 10.1007/s00107-023-01969-w

[56] NGUYEN T T, VAN NGUYEN T H, JI X, et al. Prediction of the Color Change of Heat-Treated Wood During Artificial Weathering by Artificial Neural Network[J]. European Journal of Wood and Wood Products, 2019, 77: 1107-1116. DOI: 10.1007/s00107-019-01449-0

[57] VAN NGUYEN T H, NGUYEN T T, JI X, et al. Predicting Color Change in Wood During Heat Treatment Using an Artificial Neural Network Model[J]. BioResources, 2018, 13(3): 6250-6264. DOI: 10.15376/biores.13.3.6250-6264

[58] LI J, LI N, LI J, et al. Prediction of Thermally Modified Wood Color Change After Artificial Weathering Based on IPSO-SVM Model[J]. Forests, 2023, 14(5): 948. DOI: 10.3390/f14050948

[59] LI R, XU W, WANG X, et al. Modeling and Predicting of the Color Changes of Wood Surface During CO2 Laser Modification[J]. Journal of Cleaner Production, 2018, 183: 818-823. DOI: 10.1016/j.jclepro.2018.02.194

[60] KROPAT M, LALEICKE P F, ACOSTA J J. Towards Inline Prediction of Color Development for Wood Stained with Chemical Stains Using Near-Infrared Spectroscopy[J]. Forest Products Journal, 2022, 72(2): 130-139. DOI: 10.13073/FPJ-D-22-00021

-

目的

木材颜色处理技术在木材加工业中发挥着关键作用,既能提升木材的外观美感,又能增强其耐用性和功能性。随着环保意识的提升,如何在保持处理效果的同时实现环保和高效的木材处理成为业界的关注焦点。本文综述了主要的木材颜色处理技术,包括漂白、染色(天然染料和真菌染色)、金属离子变色、热处理,以及近年来引入的智能算法在木材处理工艺中的应用,探讨这些技术在优化工艺、提高资源利用效率和降低环境影响方面的潜力。

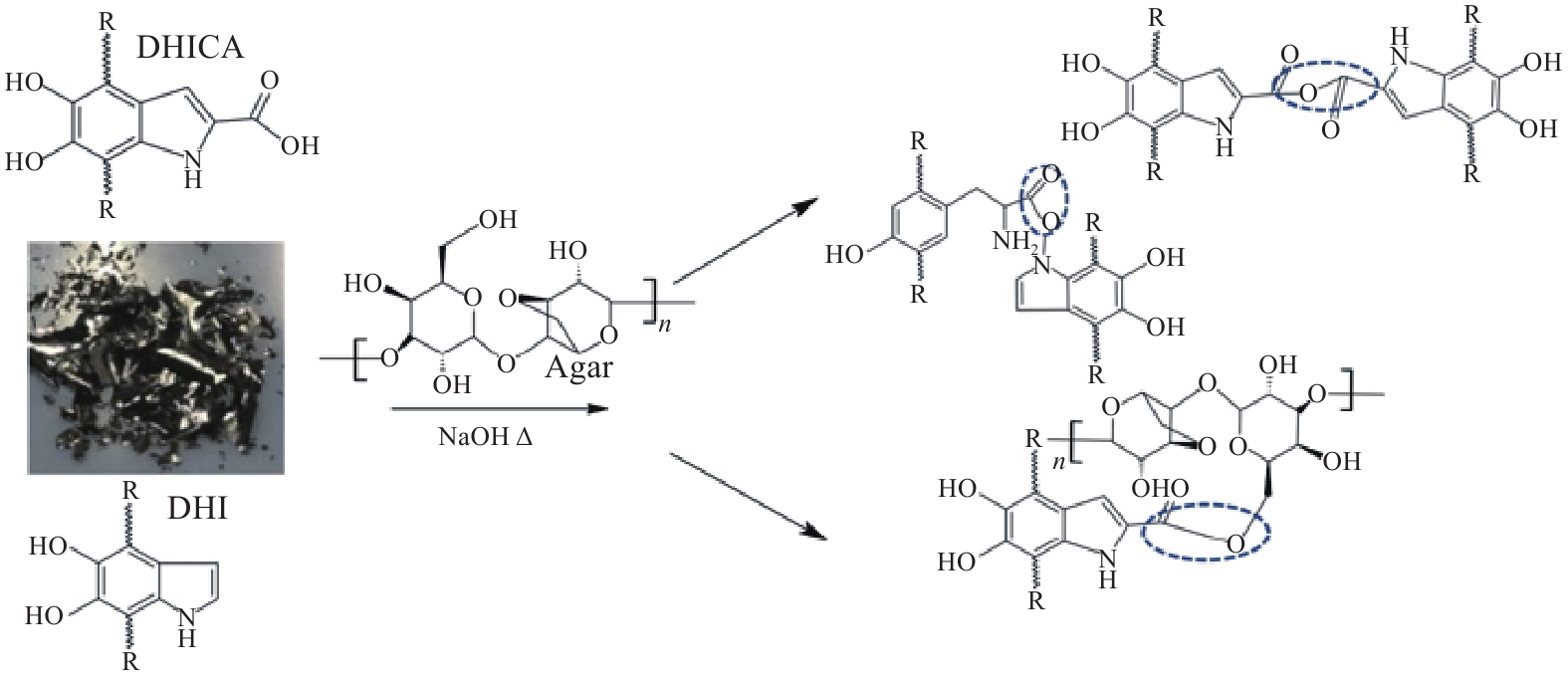

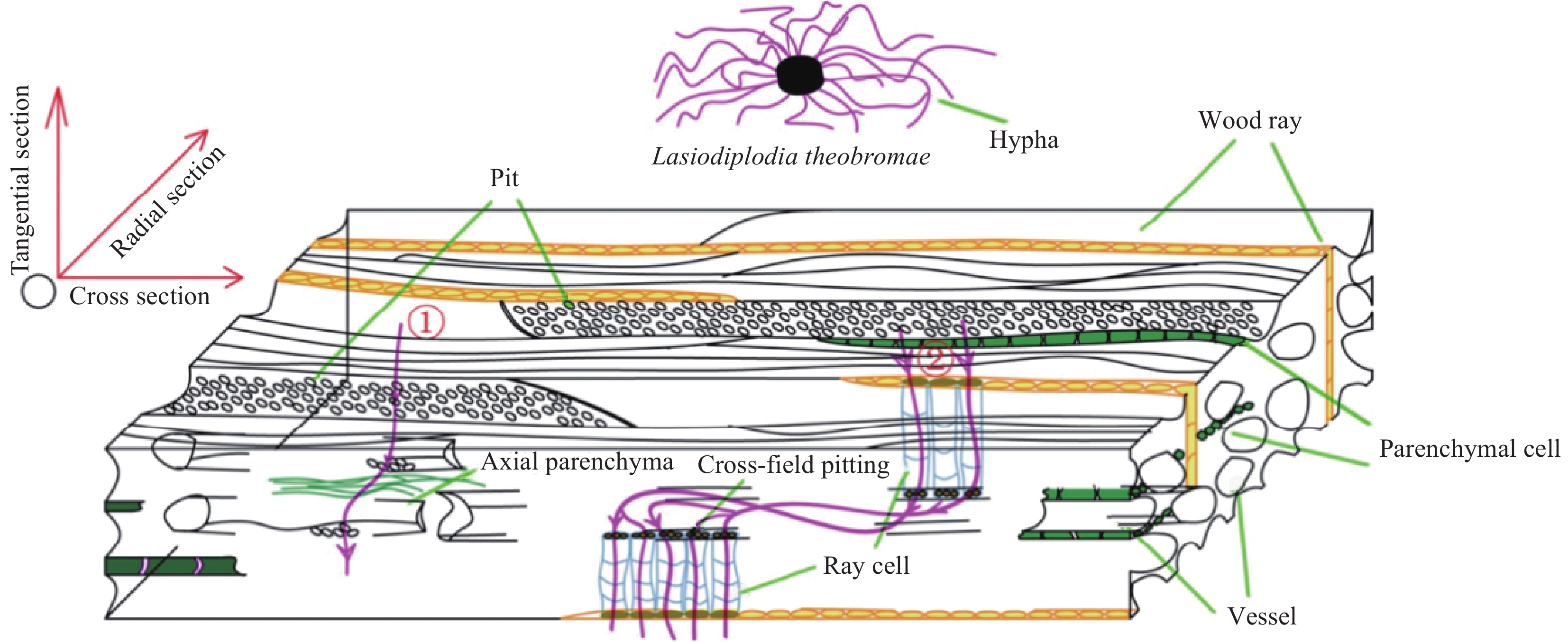

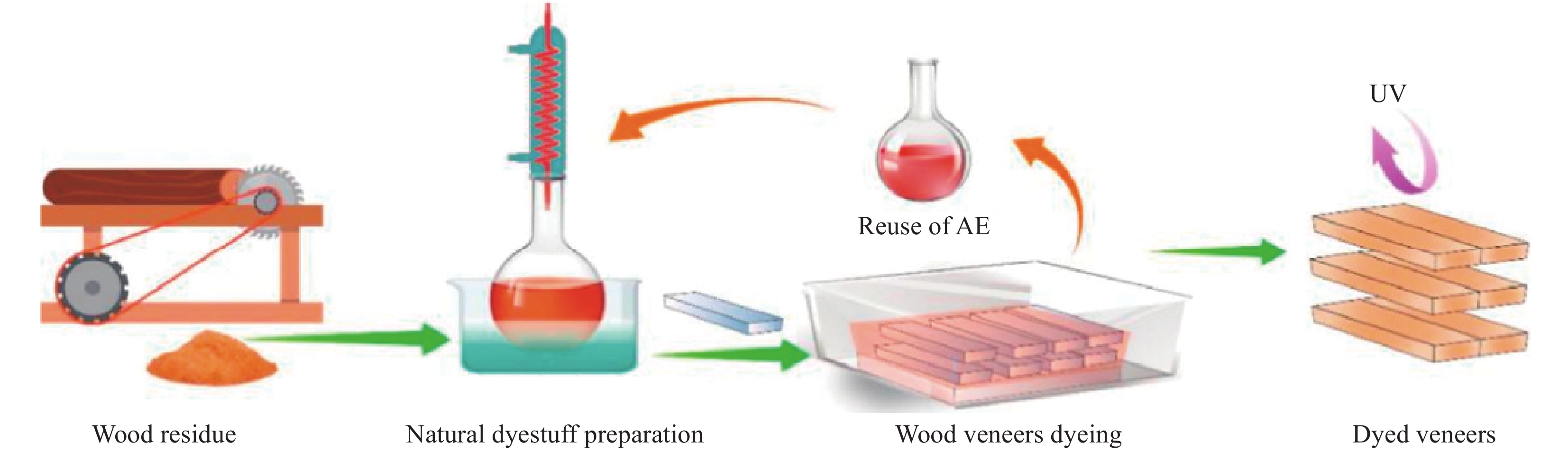

方法本文介绍了几种主要的木材颜色处理方法及其应用。漂白技术通过化学处理去除木材表面的天然色斑,使颜色更为均匀,为后续工艺打下基础。这一过程不仅改善了木材的视觉效果,还提高了其对后续染色处理的适应性。天然染料作为一种环保的染色方式,赋予木材丰富的色彩,并增强其抗紫外线性能,延长了木材的使用寿命。真菌染色则利用特定真菌的代谢产物,为木材提供一种生物友好的染色方案,同时在染色过程中也提升了木材的抗腐蚀性能。金属离子变色通过与木材中的化学成分反应,形成多样化的颜色效果,常用于高端家具和艺术品的制作,增强了木材的装饰性和市场竞争力。热处理技术通过高温处理,不仅使木材颜色加深,还提高了其稳定性和耐久性,使其更加适合在各种恶劣环境下使用。此外,智能算法的引入为木材颜色处理带来了新的优化机会。这些算法能够通过大量数据的学习和分析,精确优化处理工艺中的多个参数,从而提升处理效果的稳定性和一致性。遗传算法、粒子群优化算法和人工神经网络已经在染色配方优化、工艺参数调整和效果预测中展现出极大的潜力,推动了木材加工技术的智能化发展。

结果不同的木材颜色处理技术在改善木材外观和性能方面各具优势。漂白有效改善了木材的颜色一致性,提升了其美观度和后续加工的效果,但需控制化学药剂的环境影响。天然染料具有环保性和多样的颜色选择,为木材增添了自然之美,但其提取和应用成本较高,且颜色稳定性有限。真菌染色展示了良好的应用前景,能够在提升木材颜色的同时增强其抗腐蚀性能,这使其成为一种理想的环保染色方案。金属离子变色技术通过化学反应实现丰富的颜色变化,适用于高端产品,特别是在需要独特装饰效果的应用场景中。热处理技术通过高温作用显著改善了木材的物理性能,是一种不依赖化学添加剂的环保处理方法,尤其适合需要高耐久性和稳定性的木制品。然而,这些技术在资源利用效率和处理时间上仍存在优化空间。智能算法显著提升了木材颜色处理的效果和效率。遗传算法优化了染色配方,显著减少了工艺参数调整的时间和成本。粒子群优化算法在处理工艺中的表现突出,特别是在多参数协同优化方面显示出优势。人工神经网络通过精确的预测能力,有效减少了实验次数和资源浪费,推动了木材处理工艺的现代化和智能化。

结论本文综述了木材颜色处理技术的多样性及其在提升木材美观性和功能性方面的重要作用。尽管这些技术在资源利用效率和环保性方面仍有提升空间,但智能算法的应用为工艺优化提供了新的可能性。随着技术的发展和环保要求的提高,木材颜色处理技术将朝着更高效、环保和智能化的方向发展,为木材加工业的可持续发展提供强有力的支持。通过进一步优化工艺参数、减少资源消耗、降低环境影响,木材颜色处理技术将在未来木材加工业中发挥更加重要的作用,助力行业迈向更加可持续的未来。

下载:

下载: