Numerical simulation of the ablation process in phenolic resin impregnated quartz fiber composites

-

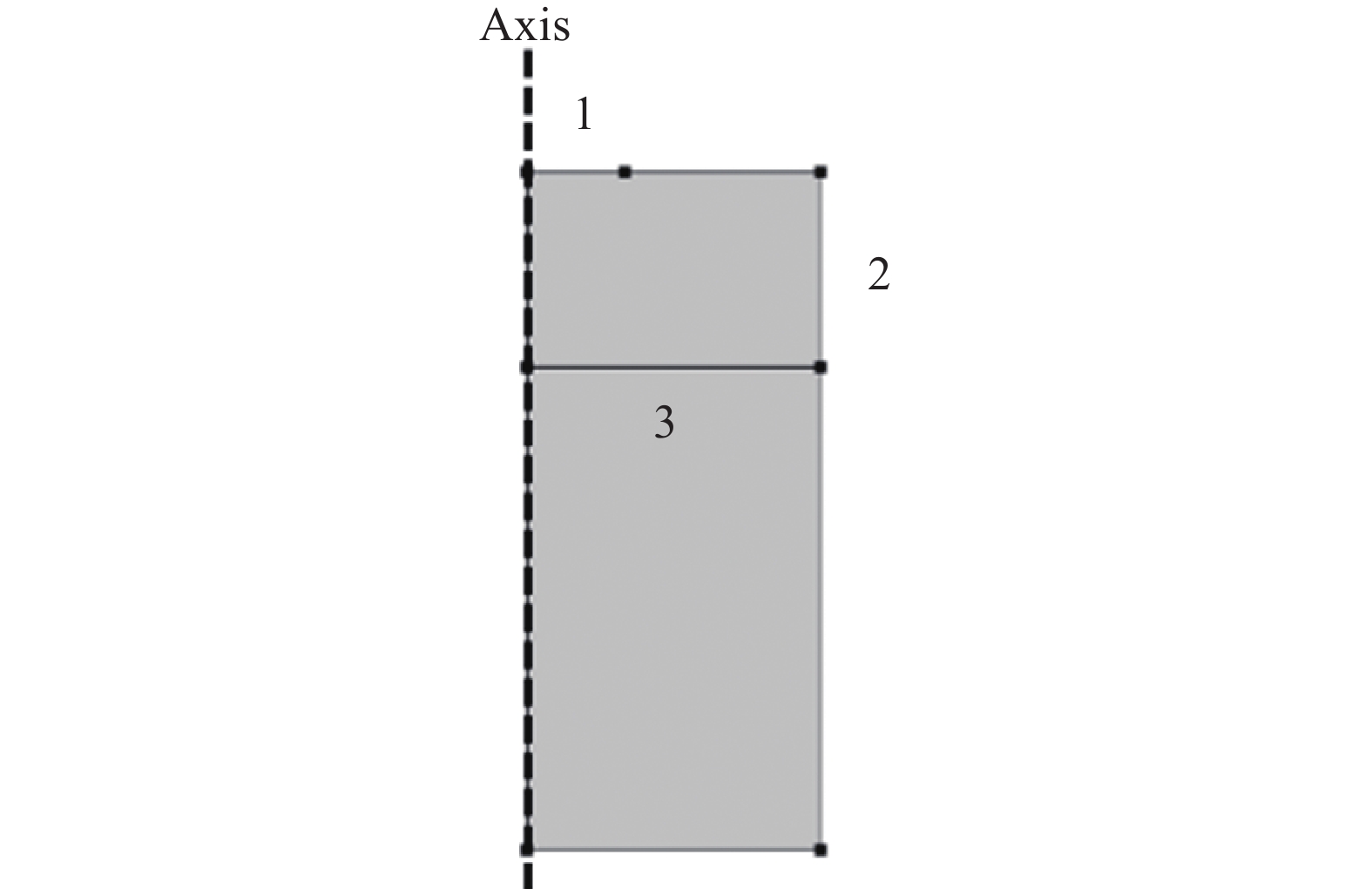

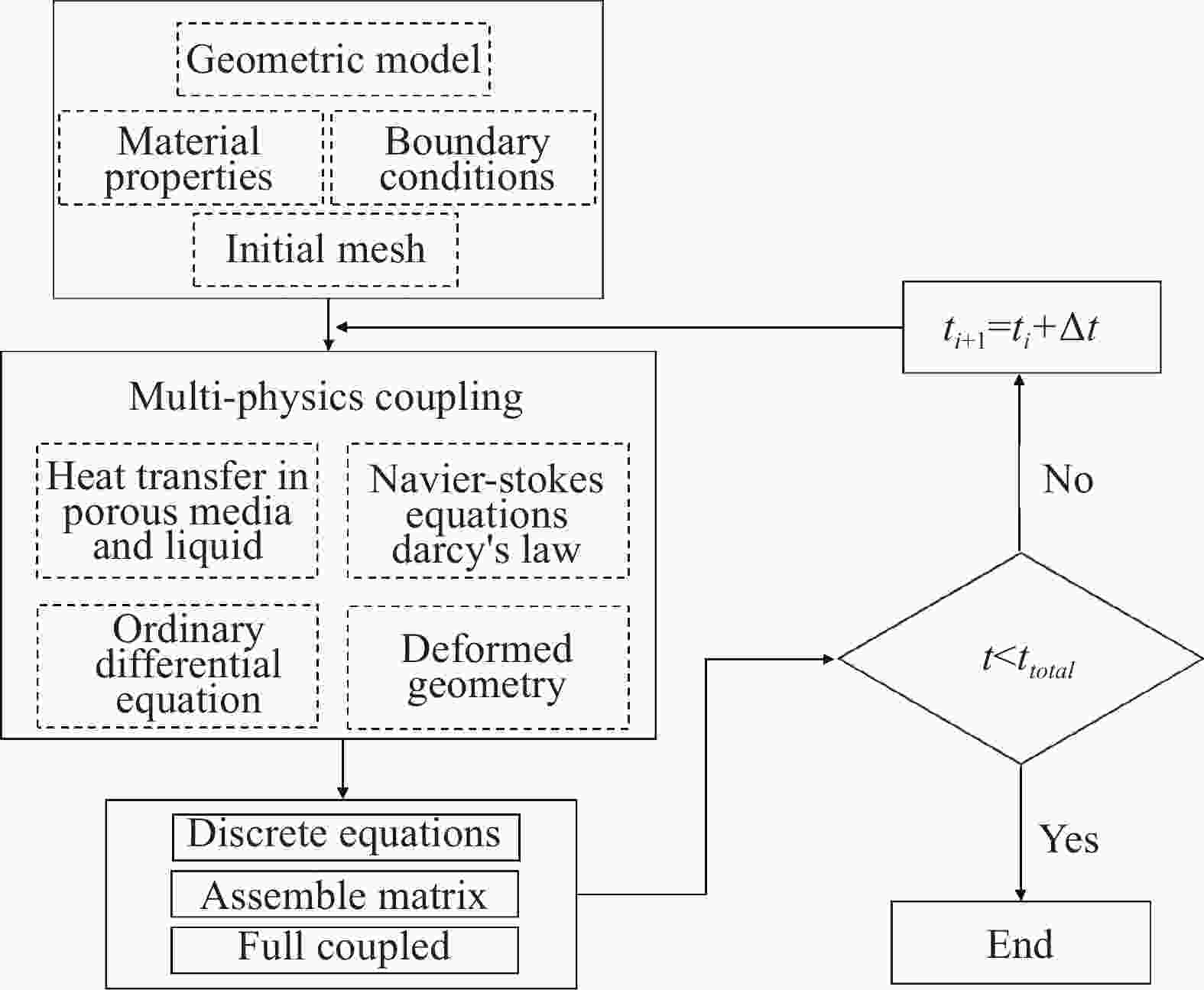

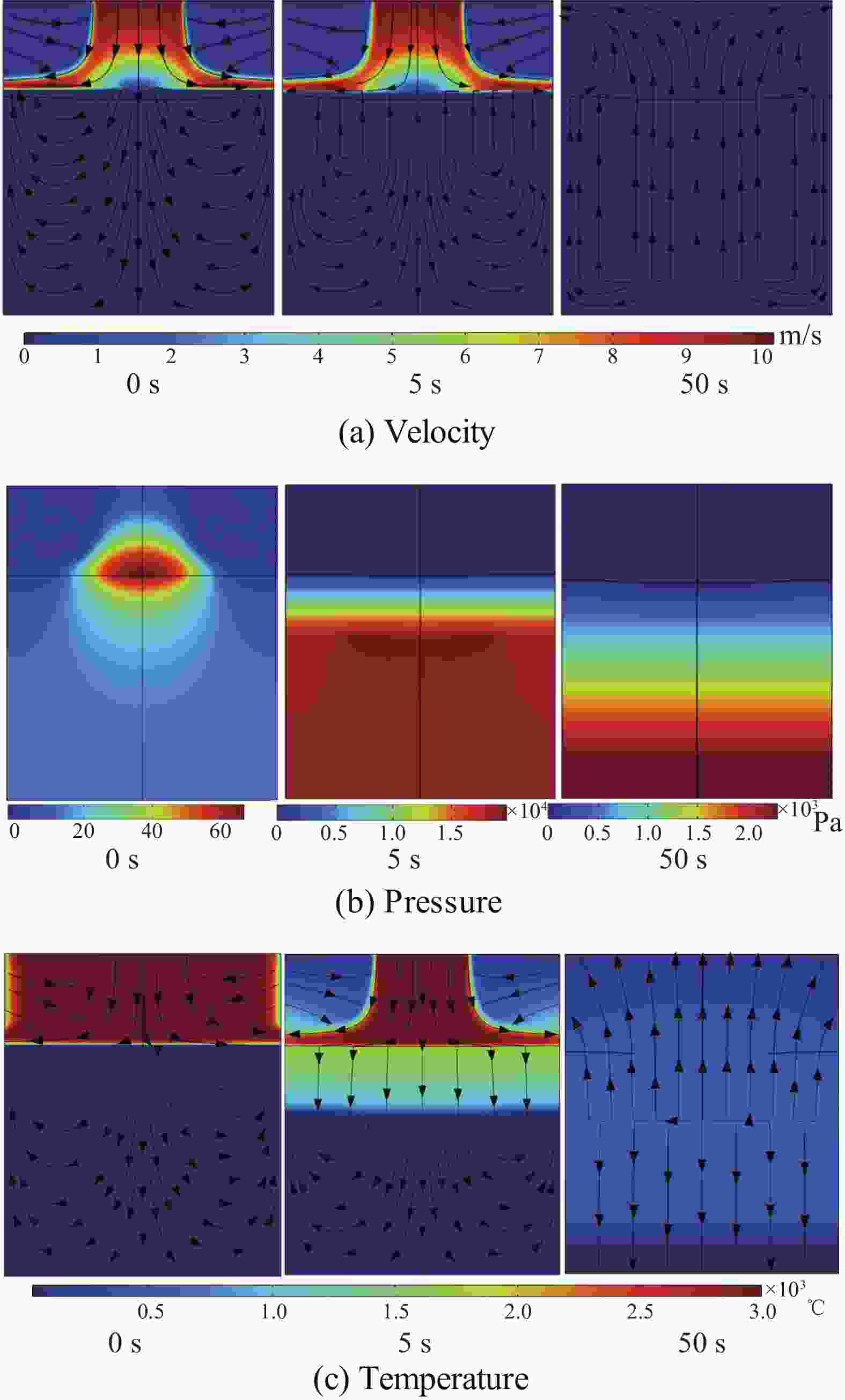

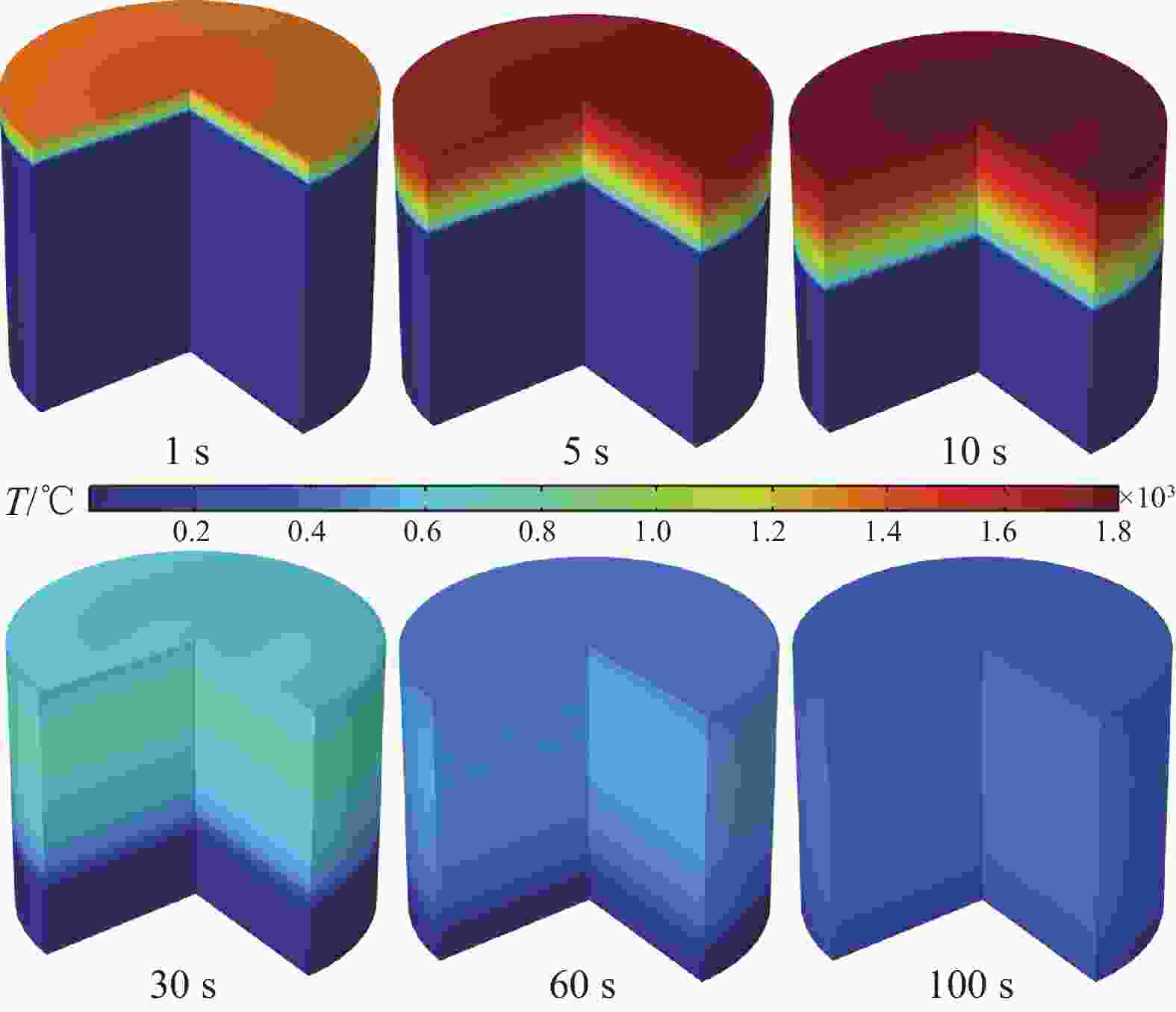

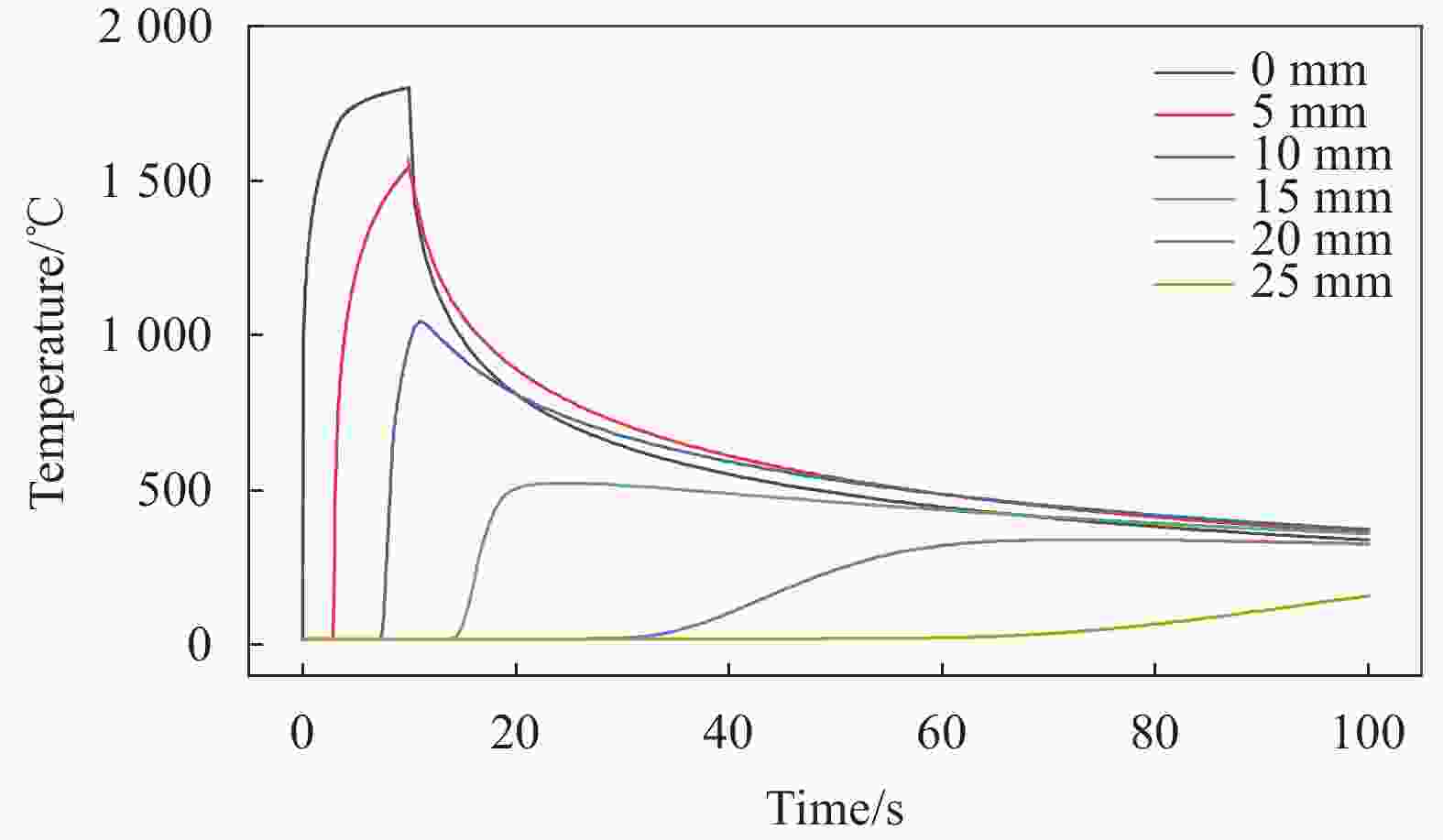

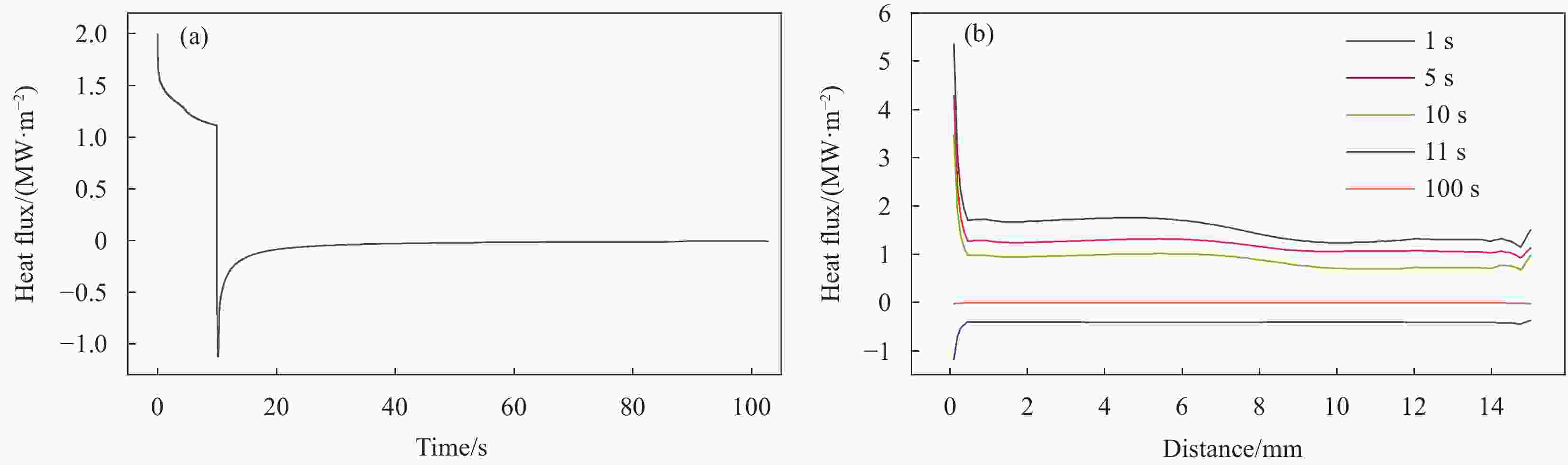

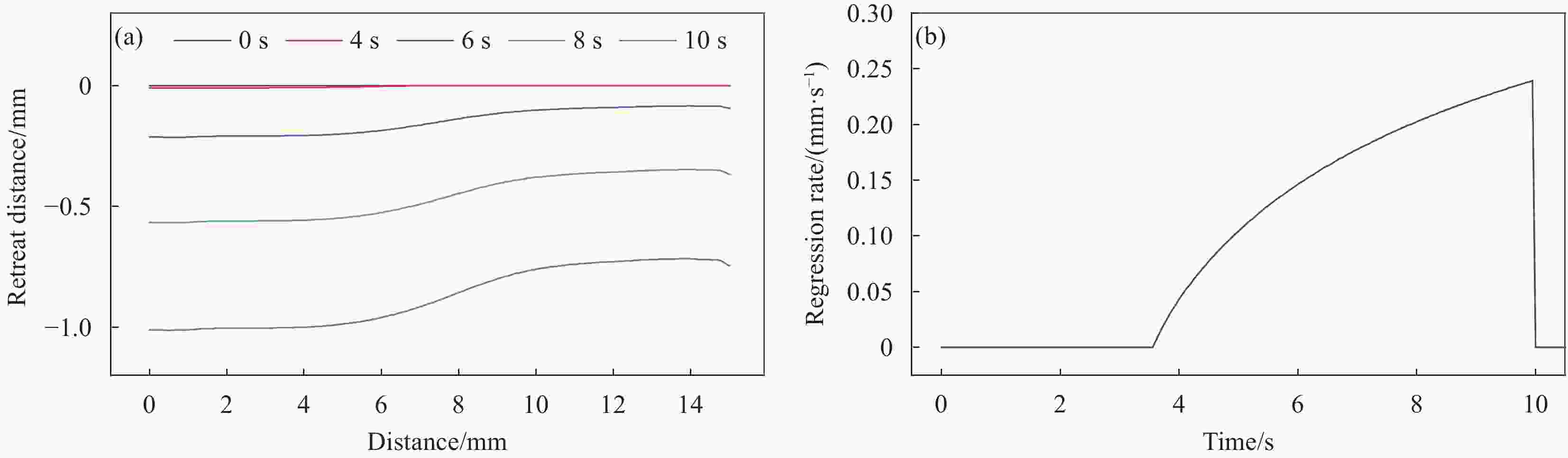

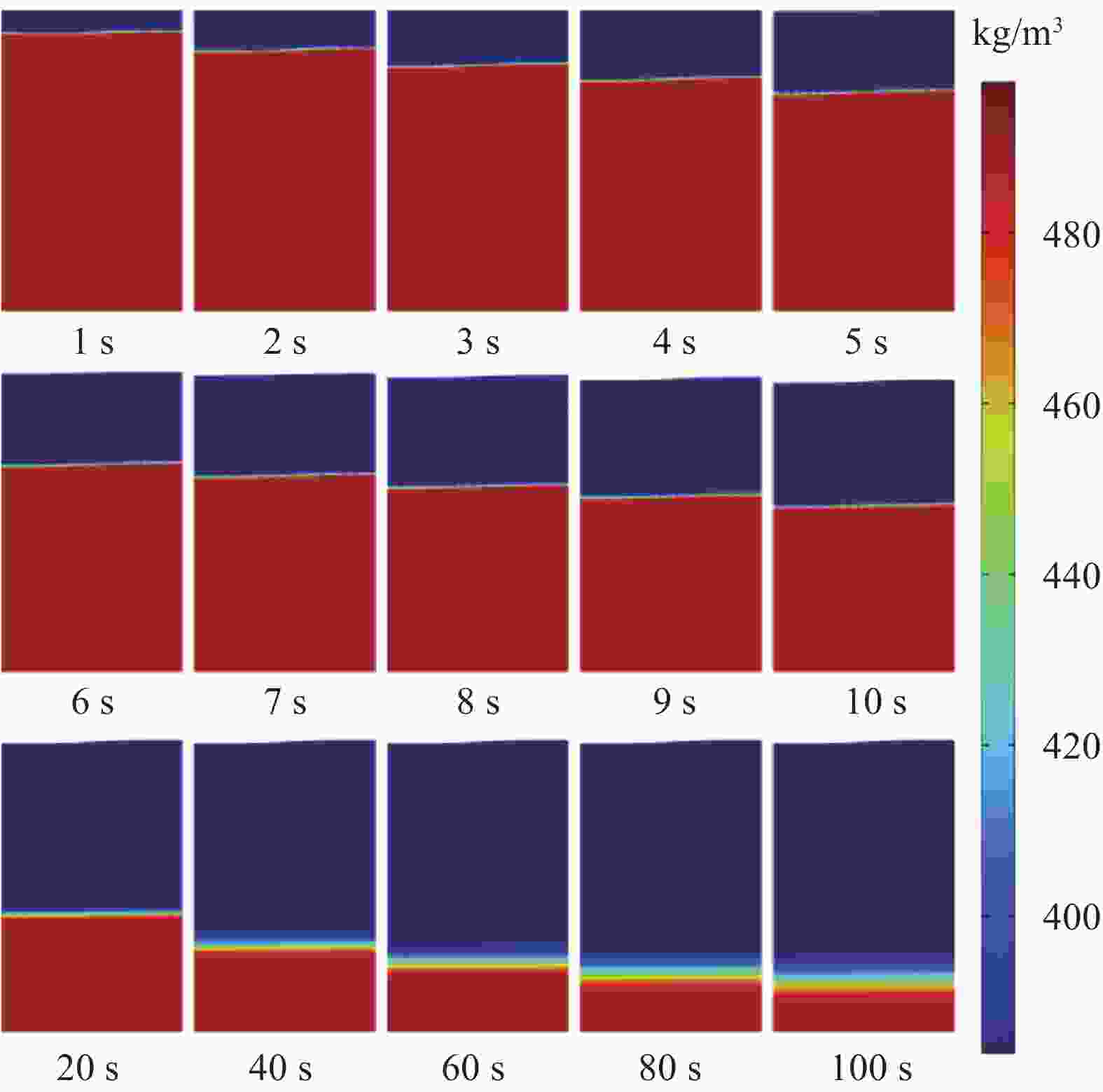

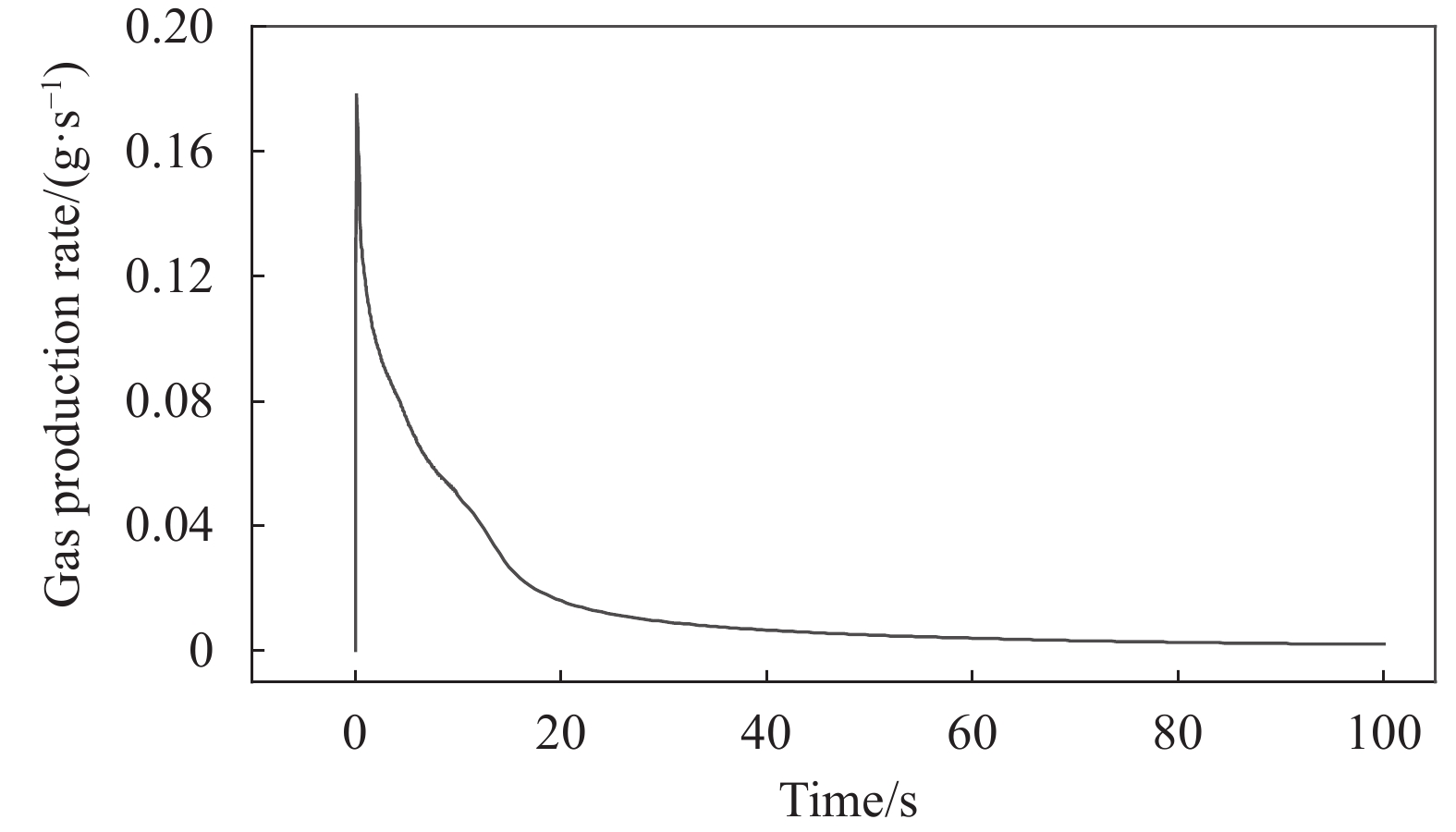

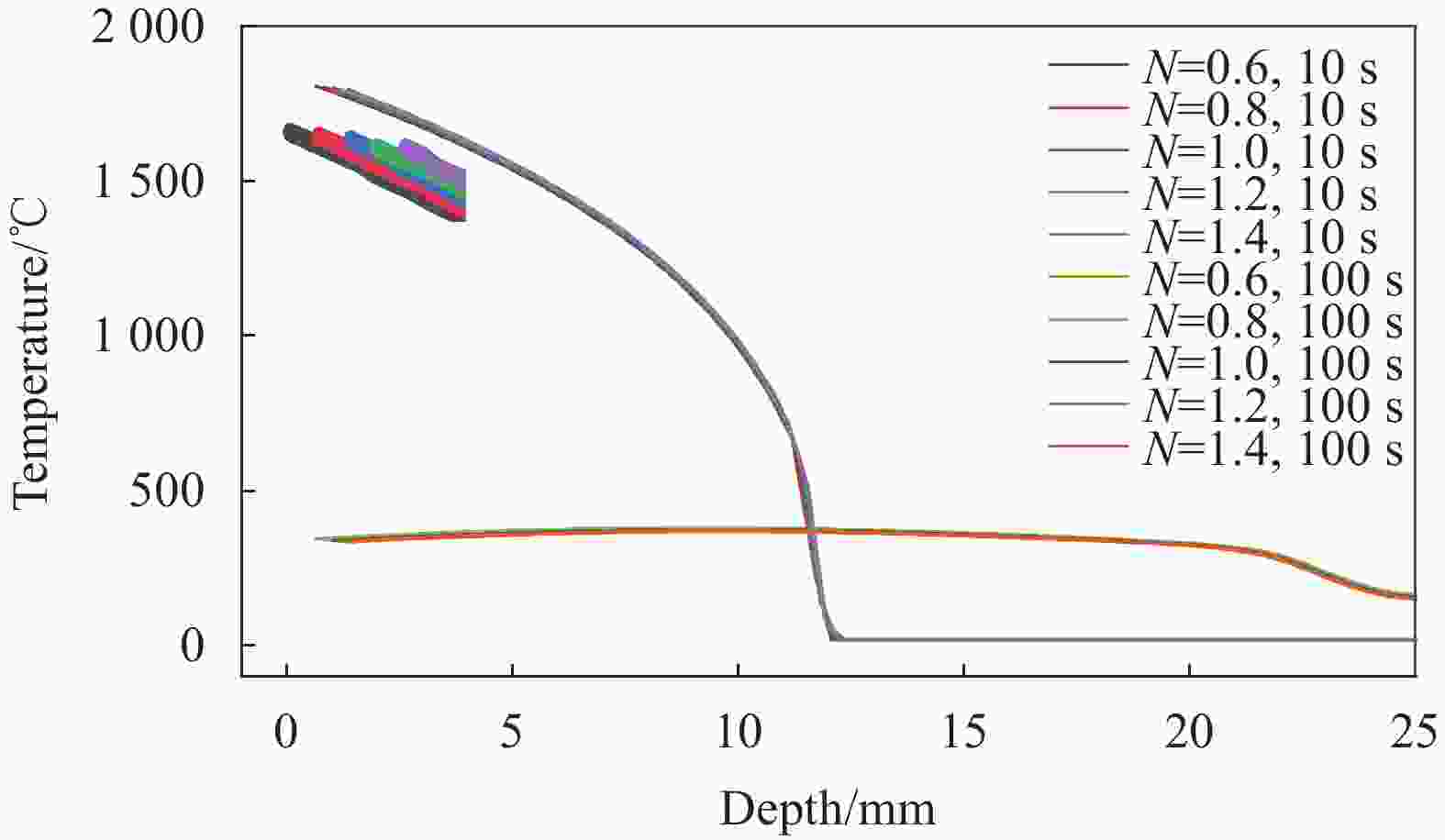

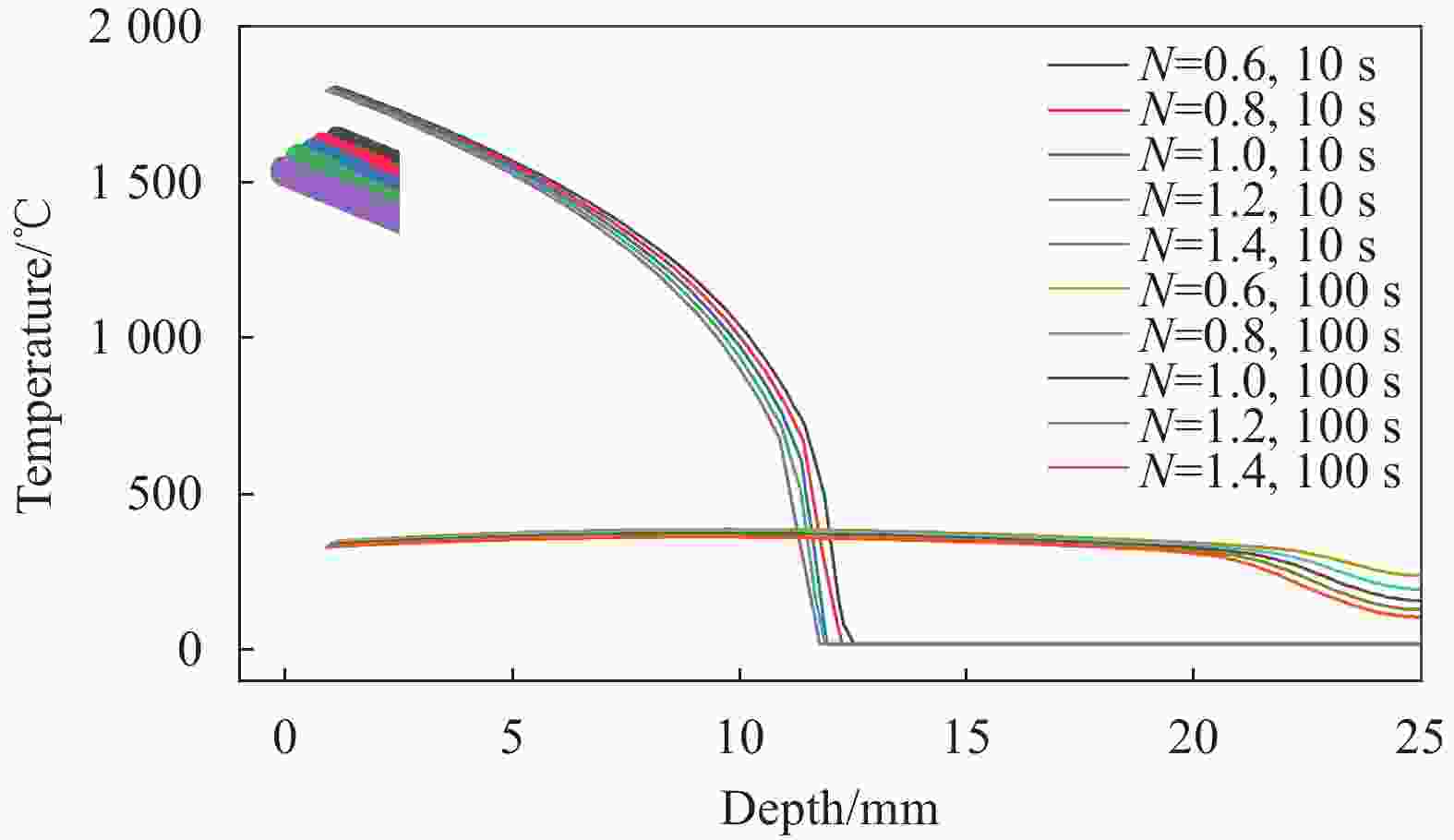

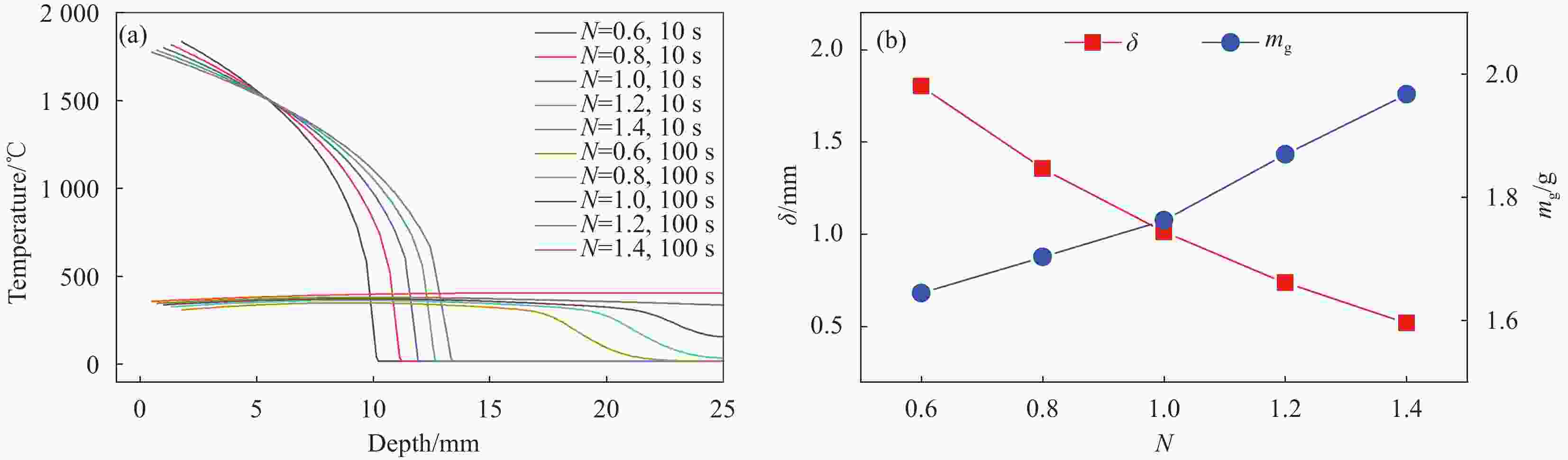

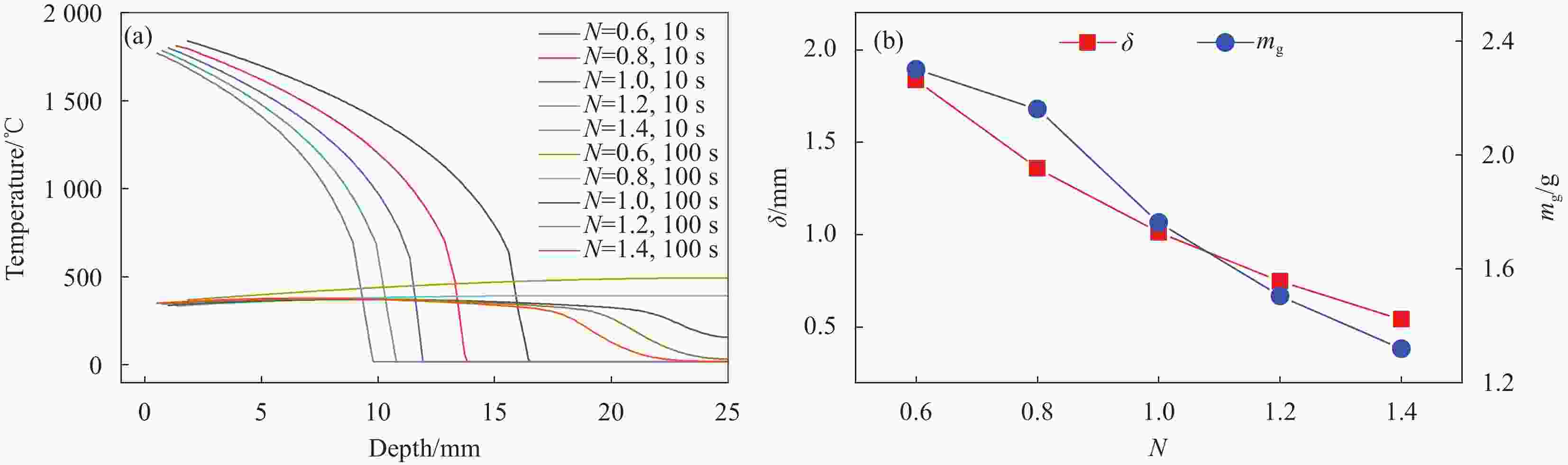

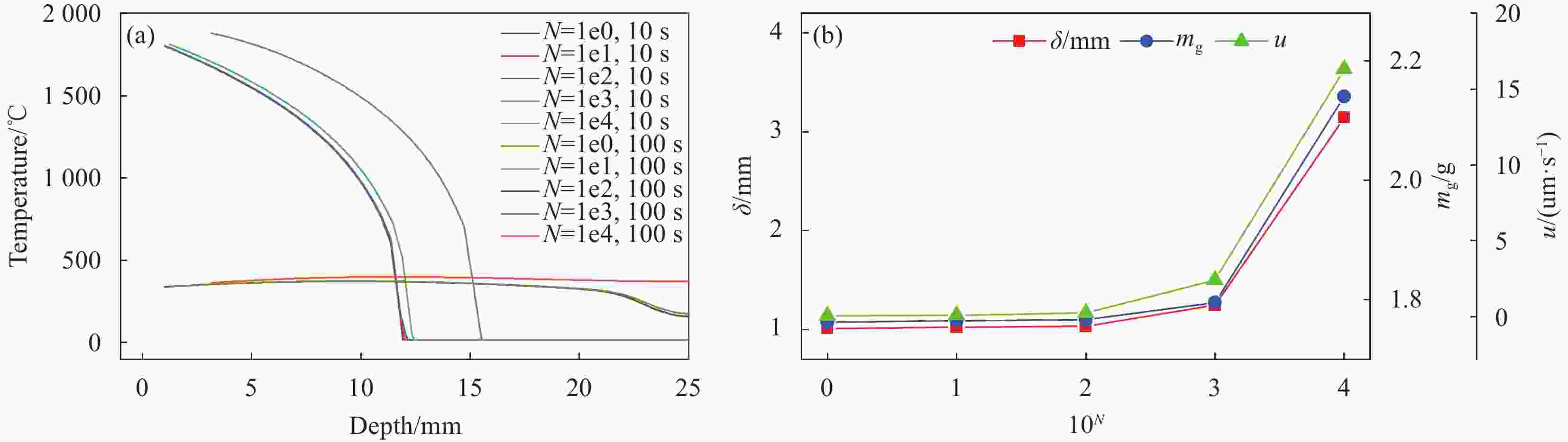

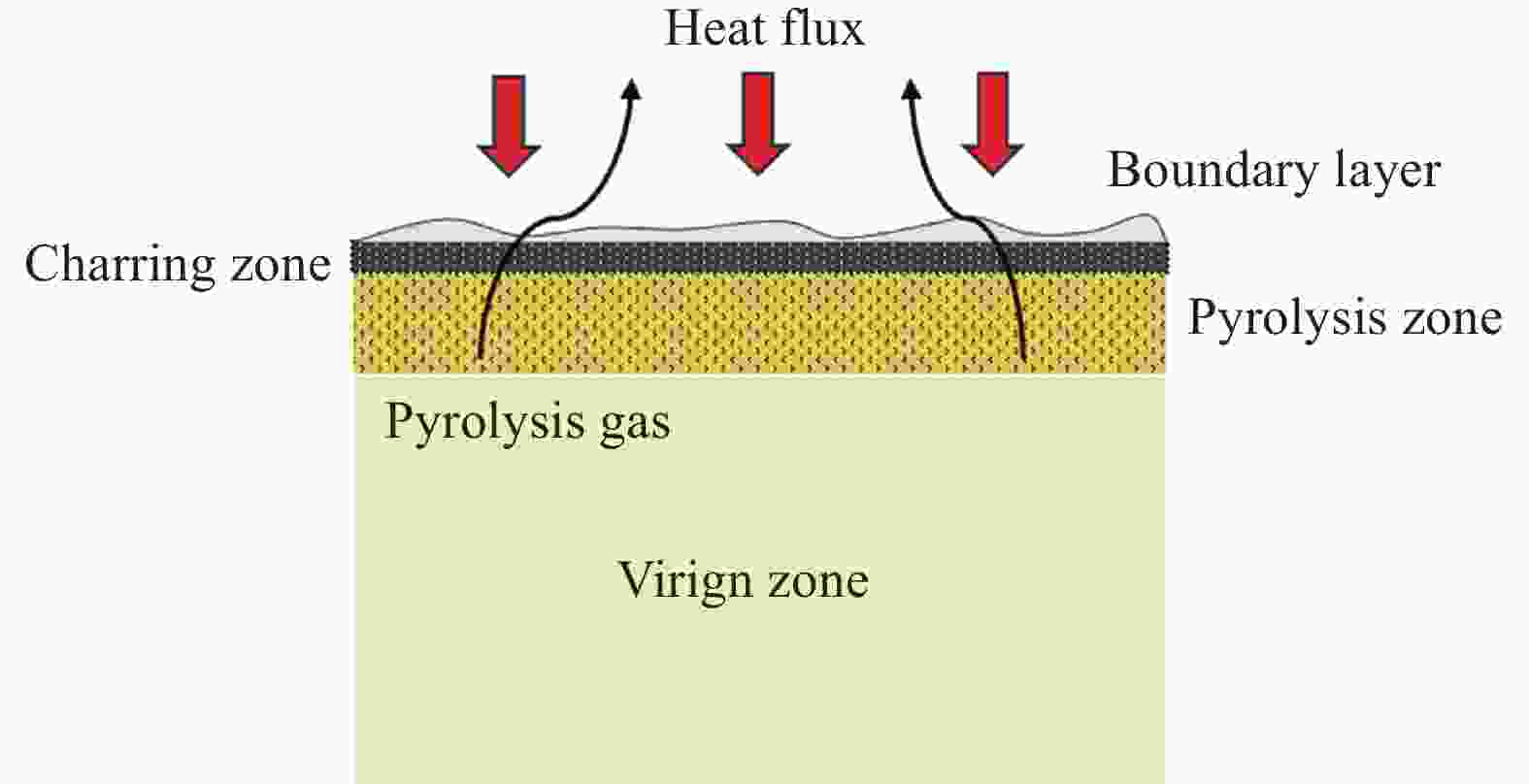

摘要: 针对酚醛树脂浸渍石英纤维复合材料(PISF)烧蚀热响应过程受热边界难处理的问题,建立了PISF的三维流-热-烧蚀多场耦合模型,预测了高温环境下材料受热过程和散热过程的瞬态温度分布,模拟了体积烧蚀和表面烧蚀过程,分析了各项参数对PISF传热的影响。结果表明:随着受热时间的增长,材料表面温度逐渐升高,流入表面的热流迅速减少。受热面中心点处受到的热流最大,约3.6 s后开始发生烧蚀,烧蚀最为明显。材料表面受热后迅速分解,产气速率迅速达到峰值,后期由于表面热阻效应,产气速率逐渐降低。一定条件下,提高导热系数会降低烧蚀后退速率和提高产气速率,背温升高,不利于材料隔热;提高热容会降低烧蚀后退速率和产气速率,背温降低,有利于材料隔热;显著提高渗透率会增强流体流动传热,提高烧蚀后退速率和产气速率,背温升高,不利于材料隔热。研究结果可以提高对PISF烧蚀热响应过程的认识,并为热防护材料的优化设计提供参考。Abstract: To address the challenge of handling the thermal boundary conditions in thermal response process of phenolic resin impregnated quartz fiber composites (PISF), a three-dimensional fluid-heat-ablation multi-field coupled model was established. The transient temperature distribution of the material during heating and heat dissipation under high-temperature environment was predicted, and the volume and surface ablation processes were simulated. The influence of various parameters on the heat transfer process of PISF was analyzed. The results indicate that with the increase of time, the surface temperature of the material gradually increases, and the heat flux entering the model decreases. The center point of the heated surface experiences the maximum heat flux and exhibits the most significant ablation. Ablation begins at about 3.6 s. After the material surface being heated, it rapidly decomposes, leading to a peak in gas production rate. Subsequently, due to the surface thermal resistance effect, the gas production rate gradually decreases. Under certain conditions, increasing the thermal conductivity will reduce the ablation regression rate and increase gas production rate, resulting in a higher back temperature, which is unfavorable to thermal insulation of the material. Increasing the specific heat will reduce the ablation regression rate and gas production rate, resulting in a lower back temperature, which is beneficial to thermal insulation of the material. Significantly increasing the permeability will enhance fluid flow heat transfer, increase the ablation regression rate and gas generation rate, resulting in a higher back temperature, which is unfavorable to thermal insulation of the material. The research results contribute to a better understanding of the pyrolysis thermal response process of PISF and provide reference for the optimization design of thermal protection materials.

-

Key words:

- ablation material /

- thermal response /

- volume ablation /

- surface ablation /

- numerical simulation

-

表 1 酚醛树脂浸渍石英纤维复合材料参数

Table 1. Parameters of phenolic resin impregnated quartz fiber composites

Property Value Ref. Density of virgin material $ {\rho }_{\mathrm{s}} $/(kg·m−3) 1553 * Density of product $ {\rho }_{\mathrm{c}} $/(kg·m−3) 1920 * Porosity of virgin material $ \mathrm{ \varepsilon } $ 0.68 * Porosity of product $ \varepsilon $ 0.8 * Activation energy $ {E}_{\mathrm{a}} $/(J·mol−1) 7.88×104 [8] Reaction rate constant $ {A}_{0} $/(kg·m−3·s−1) 1.94×105 [8] Order of reaction n 1 [8] Permeability of virgin material $ {K}_{\mathrm{s}} $/m2 6.18×10−18 [8] Permeability of product $ {K}_{\mathrm{c}} $/m2 4.85×10−15 [8] Specific heat of virgin material $ {c}_{\mathrm{p}\mathrm{s}} $/(J·(kg·K)−1) 783.55+0.976T [21] Specific heat of product $ {c}_{\mathrm{p}\mathrm{c}} $/(J·(kg·K)−1) 672.52+0.76T [21] Thermal conductivity of virgin material $ {k}_{\mathrm{v}} $/(W·(m·K)−1) 0.72+2.76×10−4T [21] Thermal conductivity of product $ {k}_{\mathrm{c}} $/(W·(m·K)−1) 0.32+4.25×10−3T−8.43×10−6T2+5.32×

10−9T3[21] Heat of decomposition $ \Delta {h}_{\mathrm{t}\mathrm{r}\mathrm{e}} $/(kJ·kg−1) −418.7 [21] reaction enthalpy $ \Delta {H}_{\mathrm{P}} $/(kJ·kg−1) 615 [21] Enthalpy of ablation Hv/(kJ·kg−1) −12686 [9] Note: *—Measured value. -

[1] MEURISSE J, LACHAUD J, PANERAI F, et al. Multidimensional material response simulations of a full-scale tiled ablative heatshield[J]. Aerospace science and technology, 2018, 76(MAY): 497-511. [2] RIVIER M, LACHAUD J, CONGEDO P M. Ablative thermal protection system under uncertainties including pyrolysis gas composition[J]. Aerospace Science and Technology, 2019, 84: 1059-1069. doi: 10.1016/j.ast.2018.11.048 [3] NIU B, SHEN H, LI T, et al. 2.5 D quartz fabric reinforced nanoporous phenolic composites with weakened heat transfer and optimized mechanical properties[J]. Composites Science and Technology, 2022, 230: 109726. doi: 10.1016/j.compscitech.2022.109726 [4] WILLARD J M. Low-Density Resin-Based Ablative Heat Protection Materials[J]. Science Insights, 2022, 40(6): 541-544. doi: 10.15354/si.22.re063 [5] PAGLIA L, TIRILLÒ J, MARRA F, et al. Carbon-phenolic ablative materials for re-entry space vehicles: plasma wind tunnel test and finite element modeling[J]. Materials & Design, 2016, 90: 1170-1180. [6] LI W, LIANG J, GE J. Novel designs of charring composites based on pore structure control and evaluation of their thermal protection performance[J]. International Journal of Heat and Mass Transfer, 2019, 129: 59-73. doi: 10.1016/j.ijheatmasstransfer.2018.09.094 [7] WENG H, MARTIN A. Multidimensional modeling of pyrolysis gas transport inside charring ablative materials[J]. Journal of Thermphysics and Heat Transfer, 2014, 28(4): 583-597. doi: 10.2514/1.T4434 [8] SHI S, LI L, LIANG J, et al. Surface and volumetric ablation behaviors of SiFRP composites at high heating rates for thermal protection applications[J]. International Journal of Heat and Mass Transfer, 2016, 102: 1190-1198. doi: 10.1016/j.ijheatmasstransfer.2016.06.085 [9] SHI S, LIANG J, LIN G, et al. High temperature thermomechanical behavior of silica-phenolic composite exposed to heat flux environments[J]. Composites science and technology, 2013, 87: 204-209. doi: 10.1016/j.compscitech.2013.08.012 [10] FERGUSON J C, PANERAI F, LACHAUD J, et al. Modeling the oxidation of low-density carbon fiber material based on micro-tomography[J]. Carbon, 2016, 96(2): 57-65. [11] CHEN Y K, MILOS F S. Multidimensional finite volume fully implicit ablation and thermal response code[J]. Journal of Spacecraft and Rockets, 2018, 55(4): 914-927. doi: 10.2514/1.A34184 [12] 张拜, 李旭东. 三维编织碳/酚醛复合材料高温热响应的数值计算[J]. 航空材料学报, 2019, 39(2): 75-83. doi: 10.11868/j.issn.1005-5053.2018.000074ZHANG Bai, LI Xudong. Numerical calculation of high temperature thermal response of 3D braided carbon/phenolic composite[J]. Journal of aeronautical materials, 2019, 39(2): 75-83(in Chinese). doi: 10.11868/j.issn.1005-5053.2018.000074 [13] 张拜, 李旭东. 碳/酚醛防热复合材料烧蚀行为的数值模拟[J]. 复合材料学报, 2018, 35(10): 2786-2792.ZHANG Bai, LI Xudong. Numerical simulation of ablation behavior of carbon/phenolic thermal protection system composite[J]. Acta Materiae Compositae Sinica, 2018, 35(10): 2786-2792(in Chinese). [14] WANG Y, RISCH T K, KOO J H. Assessment of a one-dimensional finite element charring ablation material response model for phenolic-impregnated carbon ablator[J]. Aerospace Science and Technology, 2019, 91: 301-309. doi: 10.1016/j.ast.2019.05.039 [15] TATAR M. Two-dimensional study of charring ablative materials using finite volume method[J]. International Journal of Thermal Sciences, 2021, 159: 106642. doi: 10.1016/j.ijthermalsci.2020.106642 [16] WANG P, ZHOU X, LI L, et al. Modeling and validation of ablative thermal response combined with microscopic heat transfer for porous ablative materials[J]. Thermal Science and Engineering Progress, 2024, 47: 102256. doi: 10.1016/j.tsep.2023.102256 [17] VIGNOLES G L, TURCHI A, BIANCHI D, et al. Ablative and catalytic behavior of carbon-based porous thermal protection materials in nitrogen plasmas[J]. Carbon, 2018, 134: 376-390. doi: 10.1016/j.carbon.2018.03.087 [18] LI W, HUANG H, XU X, et al. A new mechanism of surface ablation of charring materials for a vehicle during reentry[J]. Applied Thermal Engineering, 2016, 106: 838-849. doi: 10.1016/j.applthermaleng.2016.06.055 [19] LI X, HOU W, HAN B, et al. Thermal response during volumetric ablation of carbon fiber composites under a high intensity continuous laser irradiation[J]. Surfaces and Interfaces, 2021, 23: 101032. doi: 10.1016/j.surfin.2021.101032 [20] YANG J, ZHANG T, CAI J, et al. Investigating the pyrolysis mechanisms of three archetypal ablative resins through pyrolysis experiments and ReaxFF MD simulations[J]. Materials Today Communications, 2023, 36: 106683. doi: 10.1016/j.mtcomm.2023.106683 [21] 时圣波. 高硅氧/酚醛复合材料的烧蚀机理及热—力学性能研究[D]. 哈尔滨工业大学, 2013.SHI Shengbo. Ablation mechanism and thermo-mechanical behavior of silica/phenolic composites[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [22] GUO J, HUANG H, XU X. Protective effect of pyrolysis gases combustion against surface ablation under different Mach numbers[J]. Acta Astronautica, 2020, 166: 209-217. doi: 10.1016/j.actaastro.2019.10.032 [23] 李玮洁. 变密度炭化复合材料的热防护模型及其数值模拟[D]. 北京交通大学, 2017.LI Weijie. Thermal protection models and numerical simulation for variable density charring materials[D]. Beijing: Beijing Jiaotong University, 2017(in Chinese). [24] LIU S, AHMADI-SENICHAULT A, LEVET C, et al. Experimental investigation on the validity of the local thermal equilibrium assumption in ablative-material response models[J]. Aerospace Science and Technology, 2023, 141: 108516. doi: 10.1016/j.ast.2023.108516 [25] DING C, LIU X, XIE F, et al. Heat transfer and pyrolysis gas flow characteristics of light-weight ablative thermal protection system in the blunt body[J]. International Journal of Thermal Sciences, 2023, 186: 108122. doi: 10.1016/j.ijthermalsci.2022.108122 [26] XU Y, YE H, ZHANG L, et al. Investigation on the effective thermal conductivity of carbonized high silica/phenolic ablative material[J]. International Journal of Heat and Mass Transfer, 2017, 115: 597-603. doi: 10.1016/j.ijheatmasstransfer.2017.08.073 [27] FAN W, LI J, ZHENG Y, et al. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites[J]. Polymer degradation and stability, 2016, 123: 162-169. doi: 10.1016/j.polymdegradstab.2015.11.016 -

点击查看大图

点击查看大图

计量

- 文章访问数: 76

- HTML全文浏览量: 50

- 被引次数: 0

下载:

下载: