Interlaminar toughening of carbon fiber/epoxy composites with graphene oxide-carbon nanotube composite film

-

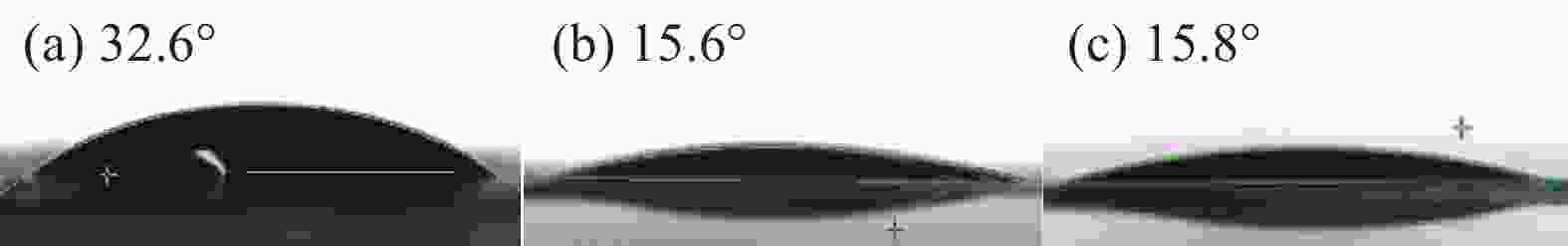

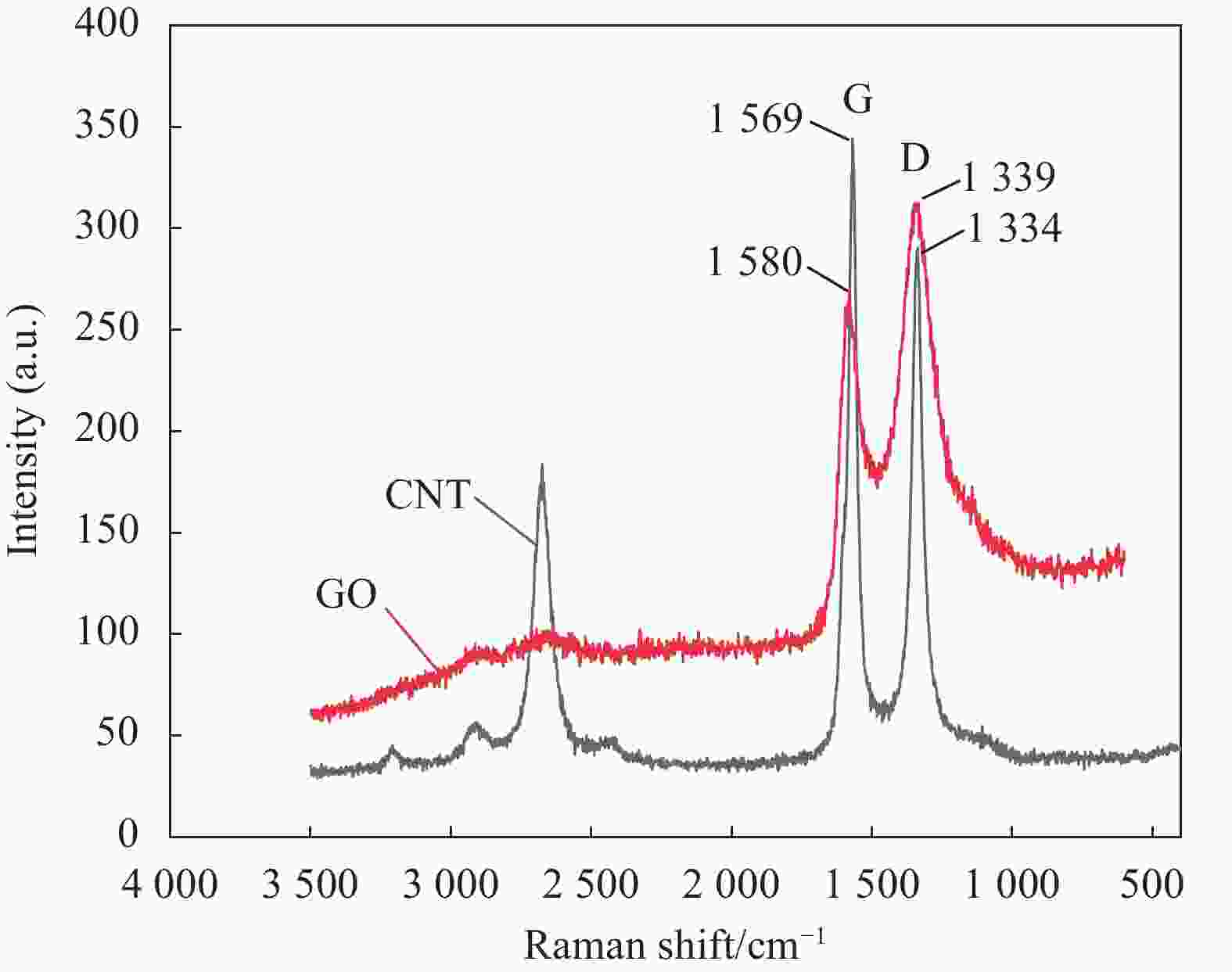

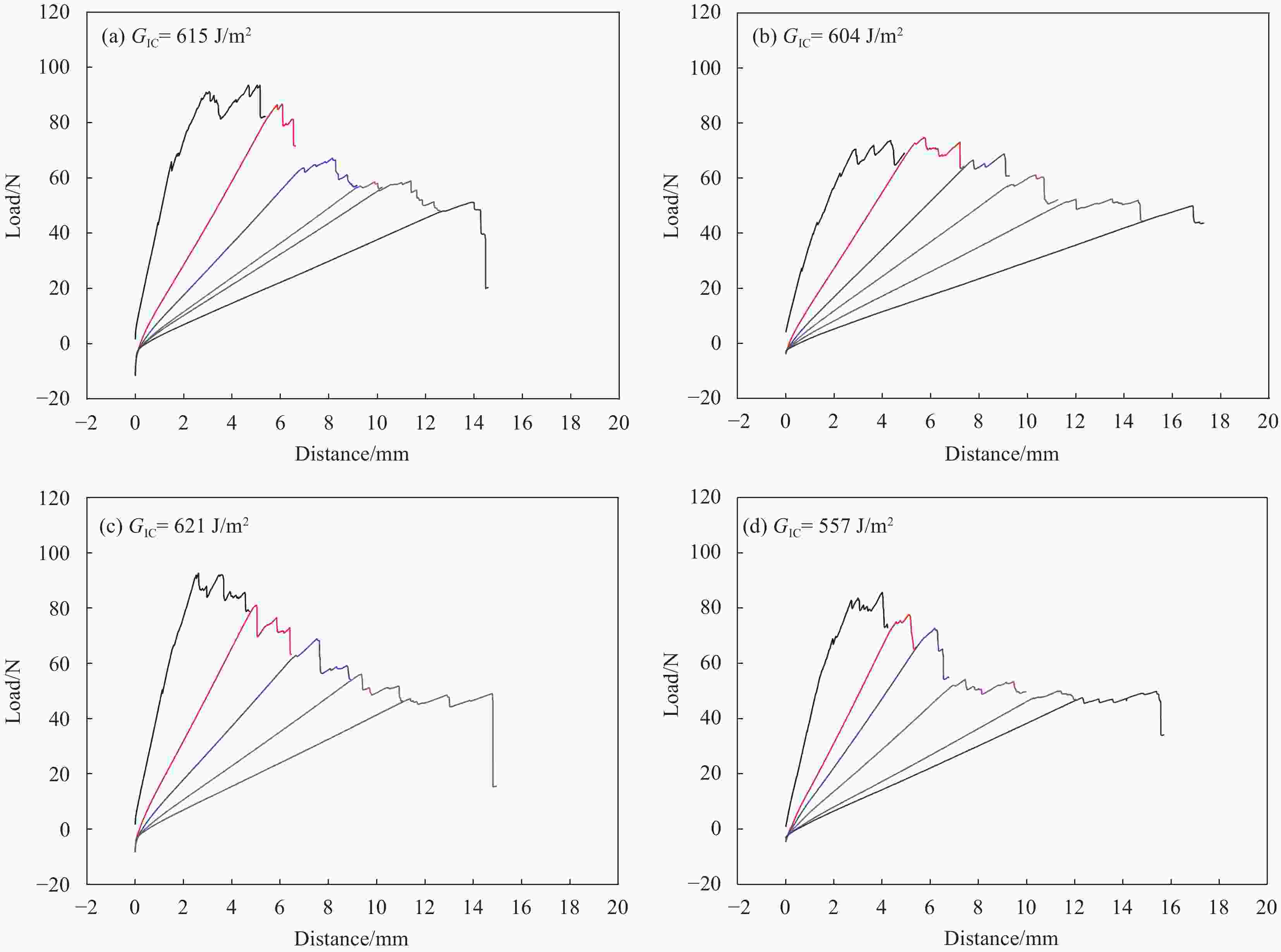

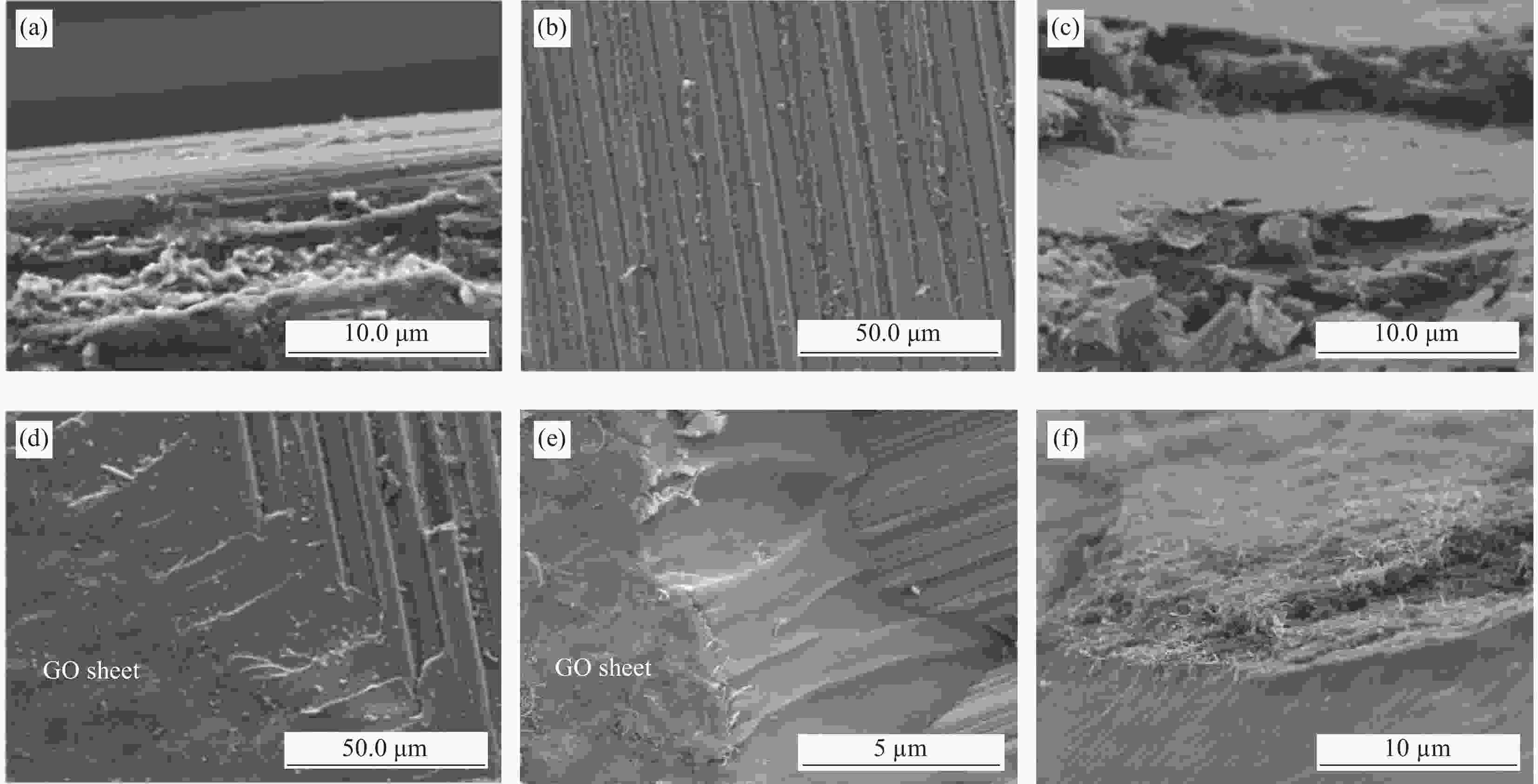

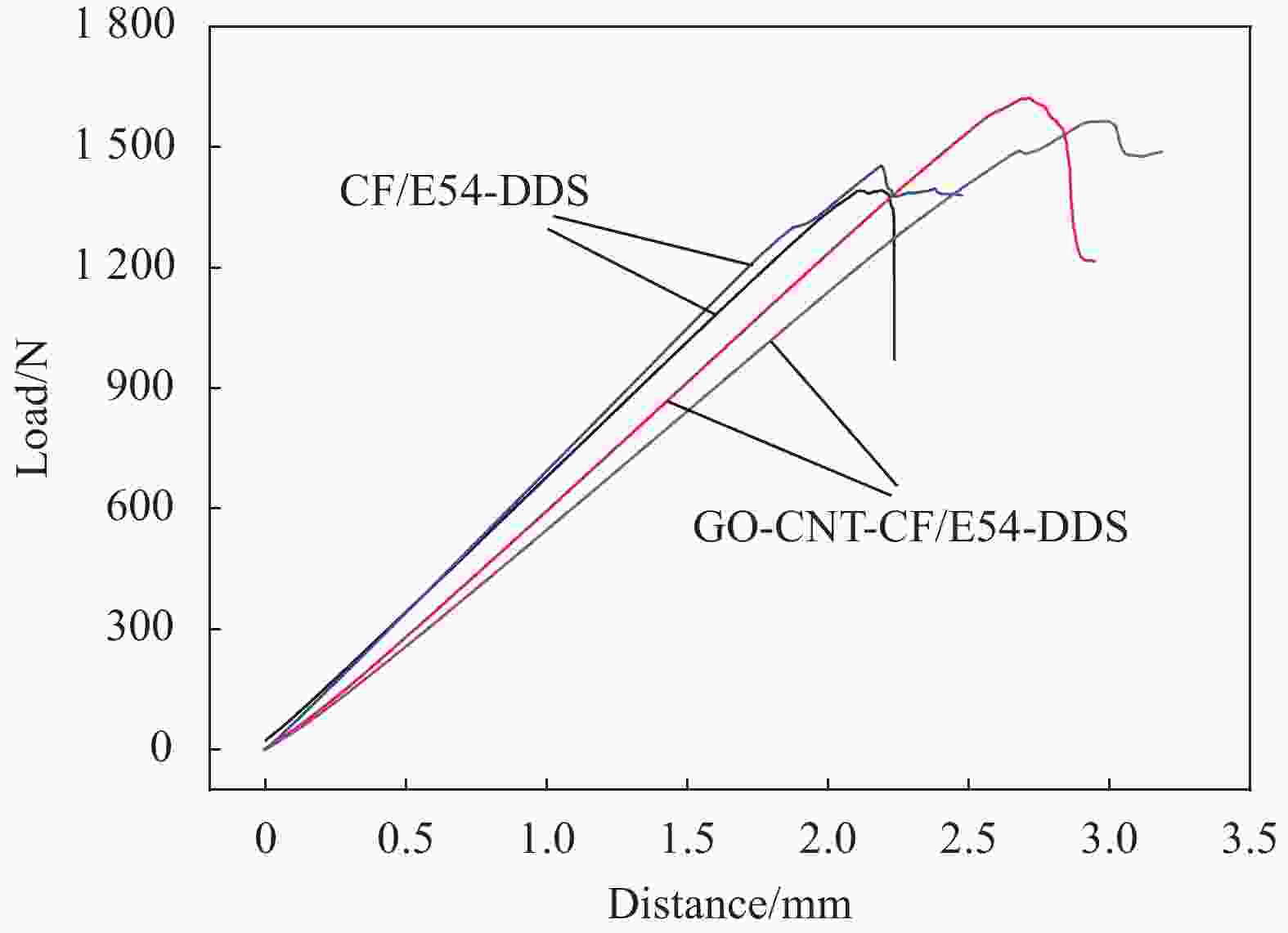

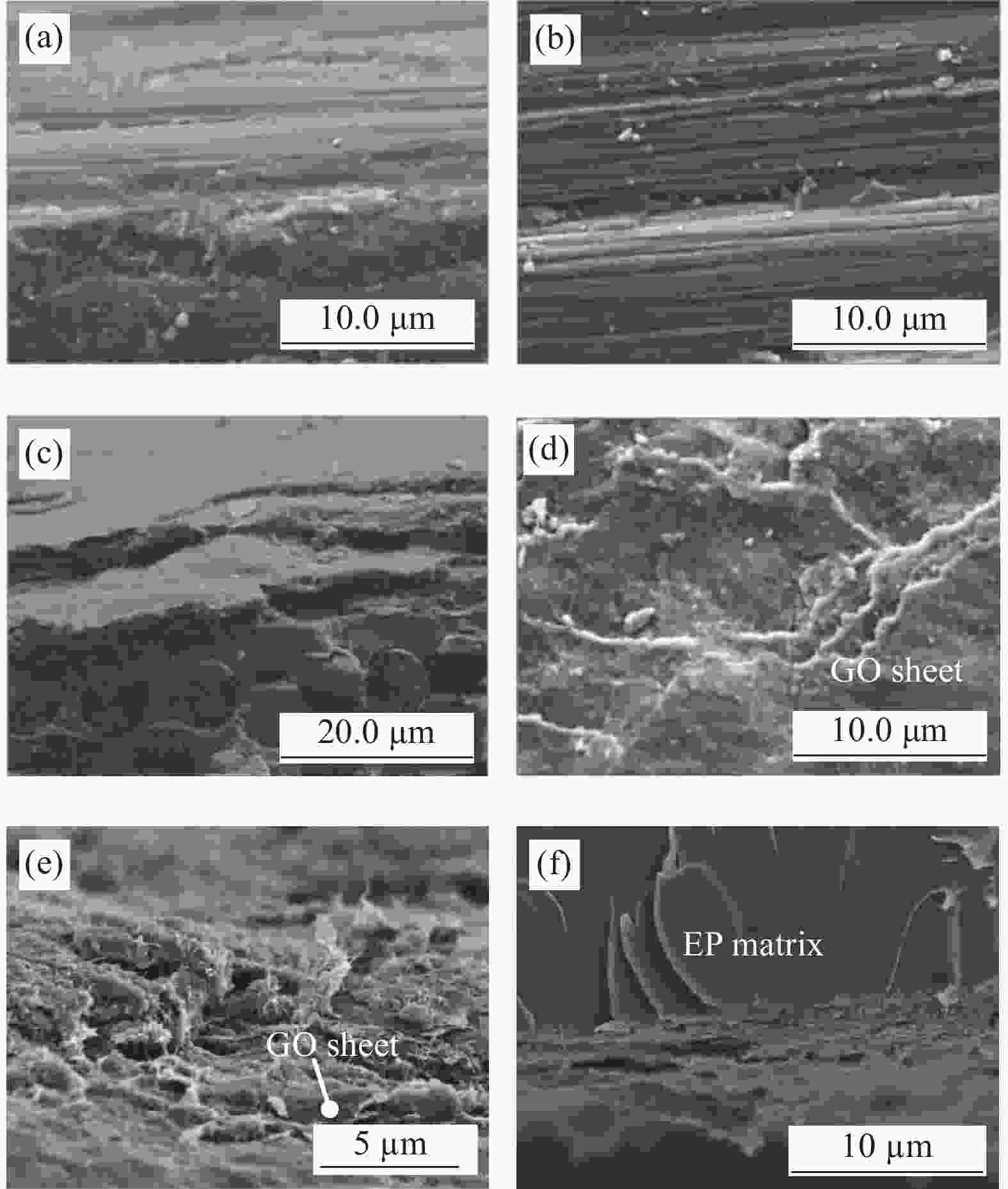

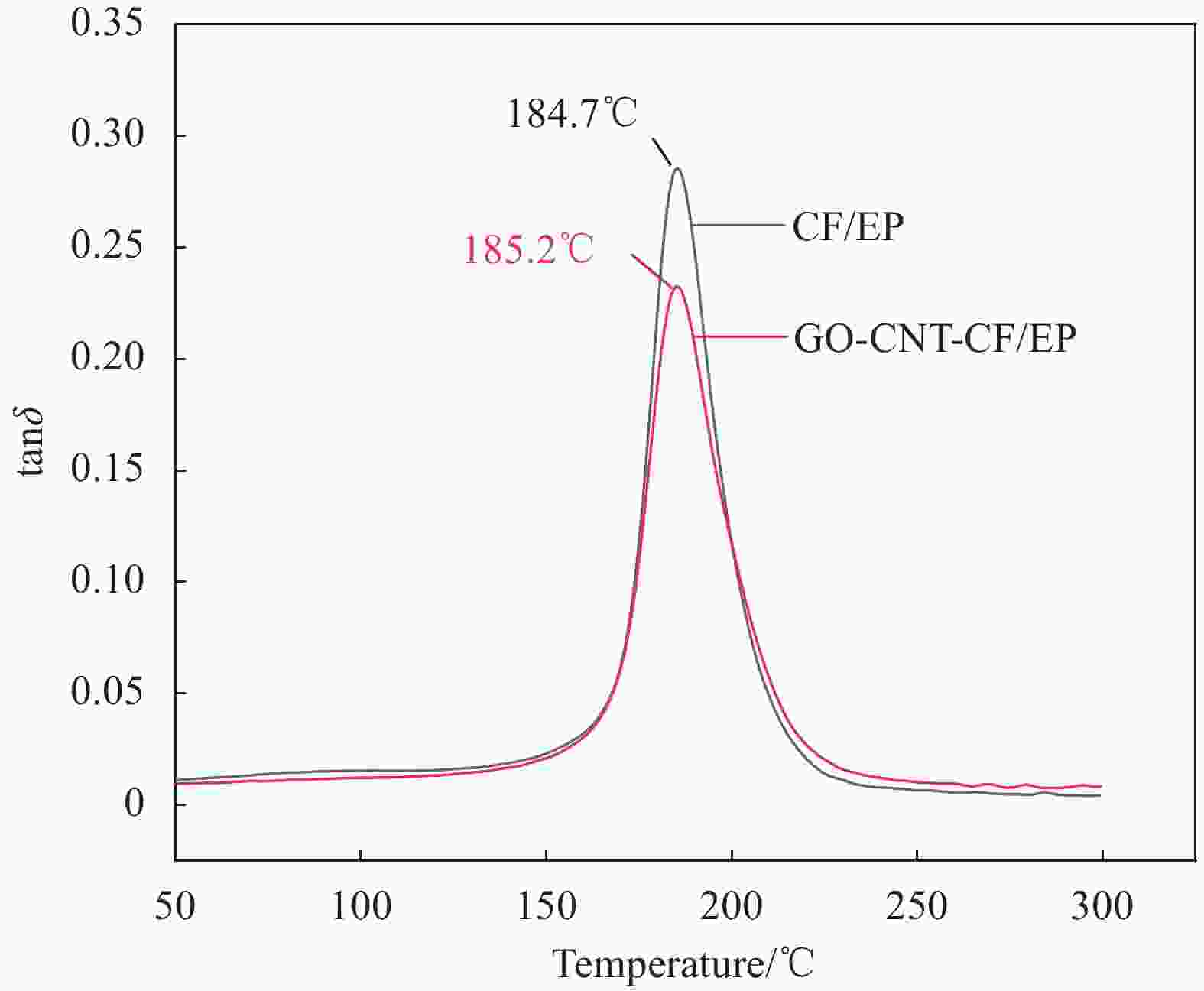

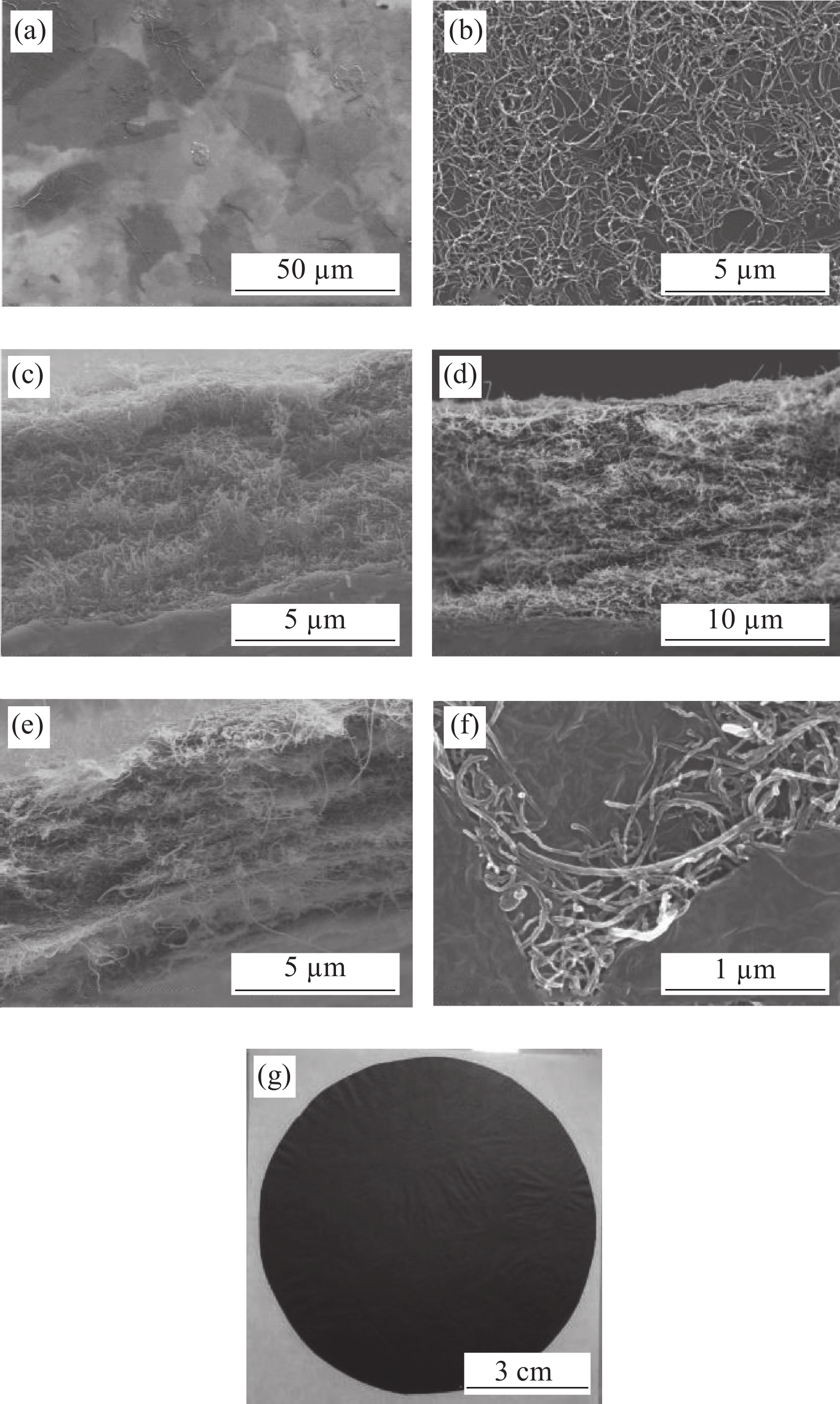

摘要: 碳纤维增强树脂基复合材料层合板结构的层间性能一直是材料的性能短板,本文利用氧化石墨烯(GO)和碳纳米管(CNT)设计制备了具有一定渗透性和树脂浸润性的复合膜,采用层间增韧方法,制备了GO-CNT复合膜改性碳纤维/环氧树脂(CF/EP)复合材料,通过张开型I型层间断裂韧性(GIC)与滑移型II型层间断裂韧性(GIIC)对GO-CNT-CF/EP复合材料的层间韧性进行了研究,并结合复合材料的破坏微观形貌和损伤/破坏特征分析了GO-CNT复合膜对复合材料的层间增韧效果及增韧机制。结果表明:GO与CNT质量比为3∶7时制备的复合膜具有良好的成膜工艺性和树脂浸润性,EP与GO-CNT复合膜的接触角远低于其与纯GO膜的接触角,并且GO与CNT结构中的羟基、羧基、环氧基等含氧基团增加了它们与EP的物理亲和性和化学作用,有利于复合材料层间GO-CNT/EP微区结构的强韧化。GO-CNT复合膜对复合材料的张开型层间断裂韧性GIC没有增强效果,甚至复合材料的GIC值还发生了轻微下降。而GO-CNT复合膜对复合材料的滑移型层间断裂韧性GIIC具有良好的改善作用。复合材料的GIIC从CF/EP复合材料的1 855 J/m2提高到GO-CNT-CF/EP复合材料的2720 J/m2,提高了47%。这归因于GO-CNT复合膜和树脂间形成的相互穿插交叠的网络结构抑制了滑移型破坏载荷导致的层间微裂纹的扩展。GO-CNT/EP复合材料具有和CF/EP基本相当的玻璃化转变温度。Abstract: The interlayer properties of carbon fiber reinforced resin matrix composites are always the weakness of composites. A composite film was designed and fabricated using graphene oxide (GO) and carbon nanotubes (CNT), which exhibited good permeability and resin wettability. A hybrid carbon fiber/epoxy (CF/EP) composite was prepared using the composite GO-CNT film by interlayer toughening method. The interlaminar toughness of the GO-CNT-CF/EP composites was investigated by open type interlaminar fracture toughness (GIC) and slip type interlaminar fracture toughness (GIIC). The interlayer toughening effect and toughening mechanism of the GO-CNT composite film on the GO-CN-CF/EP composites were analyzed based on the damage micro-morphology and damage/destruction characteristics of the composites. The results show that the composite GO-CNT film prepared with a mass ratio of GO to CNT of 3∶7 has good film-forming processability and resin wettability.The contact angle between EP and GO-CNT composite film is much lower than that between EP and pure GO film. Moreover, GO and oxygen-containing groups such as hydroxyl, carboxyl, and epoxy group in CNT increase their physical affinity and chemical interaction with EP, which is conducive to the toughening of GO-CNT/EP microzone structure between layers of composite materials. The GO-CNT composite film has no enhancement effect on the GIC of the composite. The GIC value of the GO-CNT-CF/EP composite even dropped slightly compared to the CF/EP composites. However, the GO-CNT composite film has a good effect on improving the GIIC of the GO-CNT-CF/EP composite. The GIIC of the composite increased from 1855 J/m2 for the CF/EP composite to 2720 J/m2 for the GO-CNT-CF/EP composite, which has an increase of 47%. This is attributed to the interpenetrating and overlapping network structure formed between the GO-CNT composite film and the resin, which inhibits the propagation of interlayer microcracks caused by slip-type loading. The glass transition temperature of GO-CNT/EP composites is similar to that of CF/EP composites.

-

Key words:

- graphene oxide /

- carbon nanotube /

- interlaminar toughening /

- carbon fiber /

- composites

-

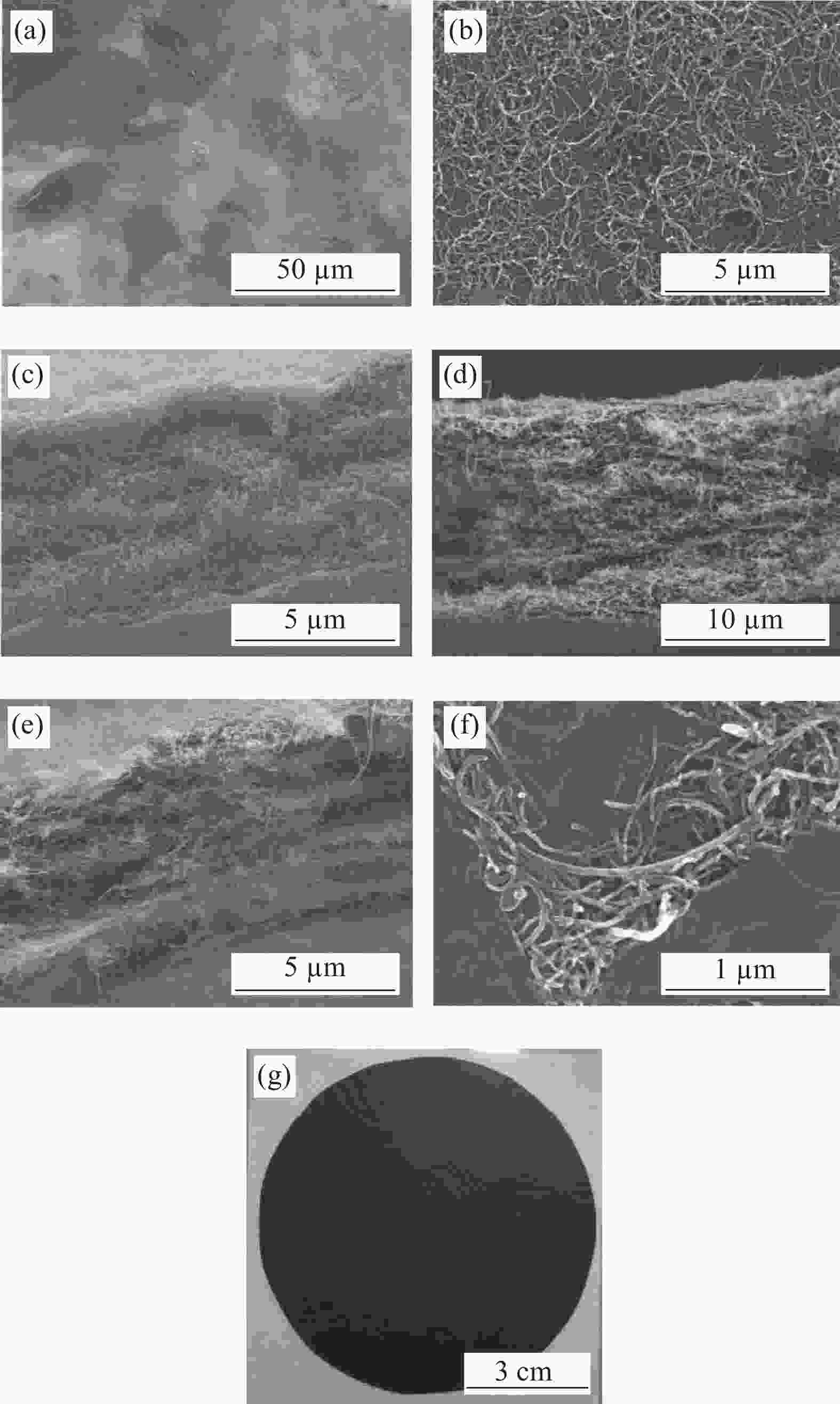

图 1 氧化石墨烯(GO) (a)、碳纳米管(CNT) (b)、GO-CNT复合膜SEM图像((c)~(f)) (其中,GO∶CNT质量比2∶8 (c)、3∶7 ((d), (f))、4∶6 (e))及GO∶CNT为3∶7的复合膜的宏观照片(g)

Figure 1. SEM images of graphene oxide (GO) (a), carbon nanotube (CNT) (b), GO-CNT composite film ((c)-(f)) (GO∶CNT mass ratio 2∶8 (c), 3∶7 ((d), (f)), 4∶6 (e)), and its macro photo of GO∶CNT mass ratio 3∶7 (g)

表 1 CF/EP和GO-CNT-CF/EP的GIIC测试结果

Table 1. GIIC testing results of CF/EP and GO-CNT-CF/EP composite

Sample Critical load/N Critical load distance/mm GIIC/

(J·m−2)CF/EP 1453.81 2.18 1 894 1392.66 2.19 1 815 GO-CNT-CF/EP 1565.57 3.00 2801 1622.18 2.73 2638 -

[1] BONACCORSO F, COLOMBO L, YU G H, et al. Graphene, related two-dimensional crystals, and hybrid systems for energy conversion and storage[J]. Science,2015,347(6217):1246501. doi: 10.1126/science.1246501 [2] LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. Science,2008,321(5887):385-388. doi: 10.1126/science.1157996 [3] MCCOY T M, TURPIN G, TEO B M, et al. Graphene oxide: A surfactant or particle[J]. Current Opinion in Colloid Interface Science,2019,39:98-109. doi: 10.1016/j.cocis.2019.01.010 [4] DIKIN D A, STANKOVICH S, ZIMNEY E J, et al. Preparation and characterization of graphene oxide paper[J]. Nature,2007,448(7152):457-460. doi: 10.1038/nature06016 [5] PATHAK A K, BORAH M, GUPTA A, et al. Improved mechanical properties of carbon fiber/graphene oxide-epoxy hybrid composites[J]. Composites Science and Technology,2016,135:28-38. doi: 10.1016/j.compscitech.2016.09.007 [6] MA Y Q, ZHAO Y T, LI F, et al. Influence of graphene oxide content on the morphology and properties of carbon fiber/epoxy composites[J]. Polymer Composites,2021,42(10):5574-5585. doi: 10.1002/pc.26248 [7] BHANUPRAKASH L, PARASURAM S, VARGHESE S, et al. Experimental investigation on graphene oxides coated carbon fibre/epoxy hybrid composites: Mechanical and electrical properties[J]. Composites Science and Technology,2019,179:134-144. doi: 10.1016/j.compscitech.2019.04.034 [8] ZHANG X Q, FAN X Y, YAN C, et al. Interfacial micro structure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials & Interfaces,2012,4(3):1543-1552. [9] GONG L Y, ZHANG F J, PENG X Q, et al. Improving the damping properties of carbon fiber reinforced polymer composites by interfacial sliding of oriented multilayer graphene oxide[J]. Composites Science and Technology,2022,224:109309. doi: 10.1016/j.compscitech.2022.109309 [10] ZENG L, LIU X Q, CHEN X G, et al. π-π interaction between carbon fibre and epoxy resin for interface improvement in composites[J]. Composites Part B: Engineering,2021,220:108983. doi: 10.1016/j.compositesb.2021.108983 [11] 胡晓兰, 周川, 代少伟, 等. 氧化石墨烯改性不同表面性质的碳纤维/环氧树脂复合材料的微观形貌与动态热力学性能[J]. 复合材料学报, 2020, 37(5):1070-1080. doi: 10.13801/j.cnki.fhclxb.20191021.001HU Xiaolan, ZHOU Chuan, DAI Shaowei, et al. Micro-structures and dynamic thermal mechanical properties of graphene oxide modified carbon fiber/epoxy composites with different fiber surface properties[J]. Acta Materiae Compositae Sinica,2020,37(5):1070-1080(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191021.001 [12] 代少伟, 李伟东, 邱虹, 等. 氧化石墨烯改性高温环氧树脂基碳纤维复合材料的热性能与力学性能[J]. 厦门大学学报(自然科学版), 2019, 58(3):324-332.DAI Shaowei, LI Weidong, QIU Hong, et al. Thermal and mechanical properties of graphene oxide modified high temperature epoxy resin based carbon fiber composites[J]. Journal of Xiamen University (Natural Science),2019,58(3):324-332(in Chinese). [13] KINLOCH L A, SUHR J, LOU J, et al. Composites with carbon nanotubes and graphene: An outlook[J]. Science,2018,362(6414):547-553. doi: 10.1126/science.aat7439 [14] OU Y F, GONZALEZ C, VILATELA J J. Interlaminar toughening in structural carbon fiber/epoxy composites interleaved with carbon nanotube veils[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105477. doi: 10.1016/j.compositesa.2019.105477 [15] OU Y F, GONZALEZ C, VILATELA J J. Under standing interlaminar toughening of unidirectional CFRP laminates with carbon nanotube veils[J]. Composites Part B: Engineering,2020,201:108372. doi: 10.1016/j.compositesb.2020.108372 [16] BAI Y X, YUE H J, WANG J, et al. Super-durable ultralong carbon nanotubes[J]. Science,2020,369(6507):1104-1106. doi: 10.1126/science.aay5220 [17] BEHABTU N, YOUNG C C, TSENTALOVICH D E, et al. Strong, light, multifunctional fibers of carbon nanotubes with ultrahigh conductivity[J]. Science,2013,339(6116):182-186. doi: 10.1126/science.1228061 [18] 闫民杰, 陈莉, 梁振江. 碳纳米管基体改性碳纤维增强环氧树脂基复合材料的性能研究[J]. 产业用纺织品, 2020, 38(8):34-39. doi: 10.3969/j.issn.1004-7093.2020.08.007YAN Minjie, CHEN Li, LIANG Zhenjiang. Study on properties of carbon nanotube matrix modified carbon fiber reinforced epoxy matrix composites[J]. Technical Textile,2020,38(8):34-39(in Chinese). doi: 10.3969/j.issn.1004-7093.2020.08.007 [19] 陈立军, 武凤琴, 张欣宇, 等. 环氧树脂/碳纤维复合材料的成型工艺与应用[J]. 工程塑料应用, 2007, 216(10):77-80. doi: 10.3969/j.issn.1001-3539.2007.10.020CHEN Lijun, WU Fengqin, ZHANG Xinyu, et al. Applications and molding techniques of EP/CF composite[J]. Engineering Plastics Application,2007,216(10):77-80(in Chinese). doi: 10.3969/j.issn.1001-3539.2007.10.020 [20] 吴良义. 先进复合材料的应用扩展: 航空、航天和民用航空先进复合材料应用技术和市场预测[J]. 化工新型材料, 2012, 40(1):4-9, 91. doi: 10.3969/j.issn.1006-3536.2012.01.002WU Liangyi. The application extend of advanced composite materials: Technology markets of ACM application in aeronautics and civil aviation[J]. New Chemical Materials,2012,40(1):4-9, 91(in Chinese). doi: 10.3969/j.issn.1006-3536.2012.01.002 [21] BHANUPRAKASH L, PARASURAM S, VARGHESE S, et al. Experimental investigation on graphene oxides coated carbon fibre/epoxy hybrid composites: Mechanical and electrical properties[J]. Composites Science and Technology,2019,79:134-144. [22] NING N, WANG M, ZHOU G, et al. Effect of polymer nanoparticle morphology on fracture toughness enhancement of carbon fiber reinforced epoxy composites[J]. Composites Part B: Engineering,2022,234:109749. doi: 10.1016/j.compositesb.2022.109749 [23] WANG W T, YU H N, POTTER K, et al. Effect of the characteristics of nylon microparticles on Mode-I interlaminar fracture toughness of carbon-fibre/epoxy composites[J]. Composites Part A: Applied Science and Manufacturing,2020,138:106073. doi: 10.1016/j.compositesa.2020.106073 [24] WANG C H, SIDHU K, YANG T, et al. Interlayer self-healing and toughening of carbon fibre/epoxy composites using copolymer films[J]. Composites Part A: Applied Science and Manufacturing,2012,43(3):512-518. doi: 10.1016/j.compositesa.2011.11.020 [25] 于妍妍, 张远, 高丽敏, 等. 基于碳纳米管薄膜的复合材料层间增韧[J]. 航空学报, 2019, 40(10):307-314.YU Yanyan, ZHANG Yuan, GAO Limin, et al. Toughness enhancement for interlaminar fracture composite based on carbon nanotube films[J]. Acta Aeronautica et Astronautica Sinica,2019,40(10):307-314(in Chinese). [26] 董慧民, 益小苏, 安学锋, 等. 纤维增强热固性聚合物复合材料层间增韧研究进展[J]. 复合材料学报, 2014, 31(2):273-285.DONG Huimin, YI Xiaosu, AN Xuefeng, et al. Development of interleaved fibre-reinforced thermoset polymer matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(2):273-285(in Chinese). [27] SHAO M Y, ZHOU G M, CHEN M D, et al. On mode I/II interlaminar fracture toughness of double-sided-loop 2D woven laminated composites[J]. Composite Structures,2022,286:115311. doi: 10.1016/j.compstruct.2022.115311 [28] GHAZALI H, YE L, ZHANG M Q, et al. Mode II interlaminar fracture toughness of CF/EP composite containing microencapsulated healing resins[J]. Composites Science and Technology,2017,142:275-285. doi: 10.1016/j.compscitech.2017.02.018 [29] ZHAO X R, CHEN W, HAN X, et al. Enhancement of interlaminar fracture toughness in textile-reinforced epoxy composites with polyamide 6/graphene oxide interlaminar toughening tackifier[J]. Composites Science and Technology,2020,191:108094. doi: 10.1016/j.compscitech.2020.108094 [30] 卢康逸, 张月义, 杨小平, 等. 碳纤维复合材料层间增强增韧技术研究进展[J]. 航空制造技术, 2020, 63(18):14-23.LU Kangyi, ZHANG Yueyi, YANG Xiaoping, et al. Research development of interlaminar reinforcing and toughening technique of carbon fiber composites[J]. Aeronautical Manufacturing Technology,2020,63(18):14-23(in Chinese). [31] 刘晓军, 战丽, 邹爱玲, 等. 纤维增强复合材料层间增韧技术研究进展[J]. 复合材料科学与工程, 2022, 336(1):117-128. doi: 10.19936/j.cnki.2096-8000.20220128.018LIU Xiaojun, ZHAN Li, ZOU Ailing, et al. Research progress on interlaminar toughening technology of fiber reinforced composites[J]. Composites Science and Engineering,2022,336(1):117-128(in Chinese). doi: 10.19936/j.cnki.2096-8000.20220128.018 [32] KOVTYUKHOVA N I, OLLIVIER P J, MARTIN B R, et al. Layer-by-layer assembly of ultrathin composite films from micron-sized graphite oxide sheets and polycations[J]. Chemistry of Materials,1999,11(3):771-778. doi: 10.1021/cm981085u [33] 中国航空工业总公司. 碳纤维复合材料层合板I型层间断裂韧性GIC试验方法: HB 7402—1996[S]. 北京: 中国标准出版社, 1996.Aviation Industry Corporation of China, Ltd.. GIC test method for type I interlaminar fracture toughness of carbon fiber composite laminates: HB 7402—1996[S]. Beijing: Standards Press of China, 1996(in Chinese). [34] 中国航空工业总公司. 碳纤维复合材料层合板II层间断裂韧性GIIC试验方法: HB 7403—1996[S]. 北京: 中国标准出版社, 1996.Aviation Industry Corporation of China, Ltd.. Test method for type II interlaminar fracture toughness GIIC of carbon fiber composite laminates: HB 7403—1996[S]. Beijing:Standards Press of China, 1996(in Chinese). [35] American Society for Testing and Materials. Standard test method for glass transition temperature (DMA Tg) of polymer matrix composites by dynamic mechanical analysis (DMA): ASTM D 7028—07e1[S]. Philadelphia: American Society for Testing and Materials International, 2007. [36] 刘刚, 胡晓兰, 张朋, 等. 碳纳米管膜层间改性碳纤维/环氧树脂复合材料[J]. 高分子学报, 2013(10):1334-1340.LIU Gang, HU Xiaolan, ZHANG Peng, et al. Carbon nanotube film interlayer toughened carbon fiber reinforced epoxy reisn hybrid composites[J]. Acta Polymerica Sinica,2013(10):1334-1340(in Chinese). [37] 张朋, 刘刚, 胡晓兰, 等. 结构化增韧层增韧RTM复合材料性能[J]. 复合材料学报, 2012, 29(4):1-9.ZHANG Peng, LIU Gang, HU Xiaolan, et al. Properties of toughened RTM composites by structural toughening layer[J]. Acta Materiae Compositae Sinica,2012,29(4):1-9(in Chinese). [38] LEE D W, DE LOS SANTOS V L, SEO J W, et al. The structure of graphite oxide: Investigation of its surface chemical groups[J]. Journal of Physical Chemistry B,2010,114(17):5723-5728. doi: 10.1021/jp1002275 [39] 李桂林. 环氧树脂与环氧涂料[M]. 北京: 化学工业出版社, 2003: 126-129.LI Guilin. Epoxy resin and epoxy coating[M]. Beijing: Chemical Industry Press, 2003: 126-129(in Chinese). [40] KHURANA P, NARULA A K, CHOUDHARY V. Curing and thermal behavior of diglycidyl ether of bisphenol A in the presence of a mixture of amines[J]. Journal of Applied Polymer Science,2003,90(7):1739-1747. doi: 10.1002/app.12662 [41] 孙曼灵. 环氧树脂应用原理与技术[M]. 北京: 机械工业出版社, 2002: 115-117.SUN Manling. Application principle and technology of epoxy resin[M]. Beijing: Machinery Industry Press, 2002: 115-117(in Chinese). [42] 李广宇, 李子东, 吉利, 等. 环氧胶黏剂与应用技术[M]. 北京: 化学工业出版社, 2007: 138-140.LI Guangyu, LI Zidong, JI Li, et al. Epoxy adhesive and application technology[M]. Beijing: Chemical Industry Press, 2007: 138-140(in Chinese). [43] 刘文军, 严建龙, 周川, 等. 氧化石墨烯改性碳纤维/环氧树脂复合材料的湿热性能及微观形貌[J]. 复合材料学报, 2021, 38(5):1416-1425.LIU Wenjun, YAN Jianlong, ZHOU Chuan, et al. Hygrothermal properties and micro morphology of graphene oxide modified carbon fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica,2021,38(5):1416-1425(in Chinese). -

下载:

下载: