Preparation of mussel-inspired porous magnetic materials for application in immobilized lipase

-

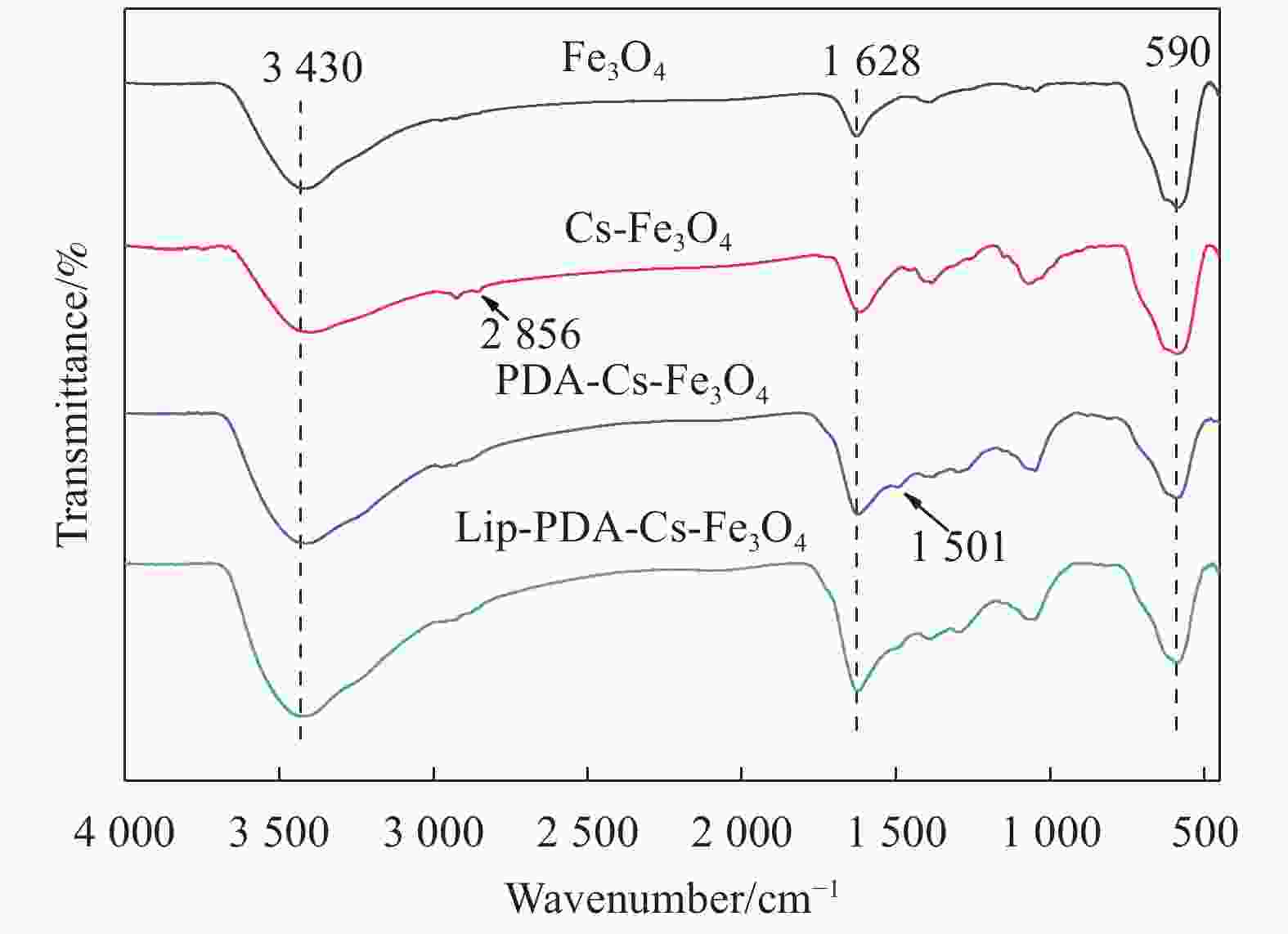

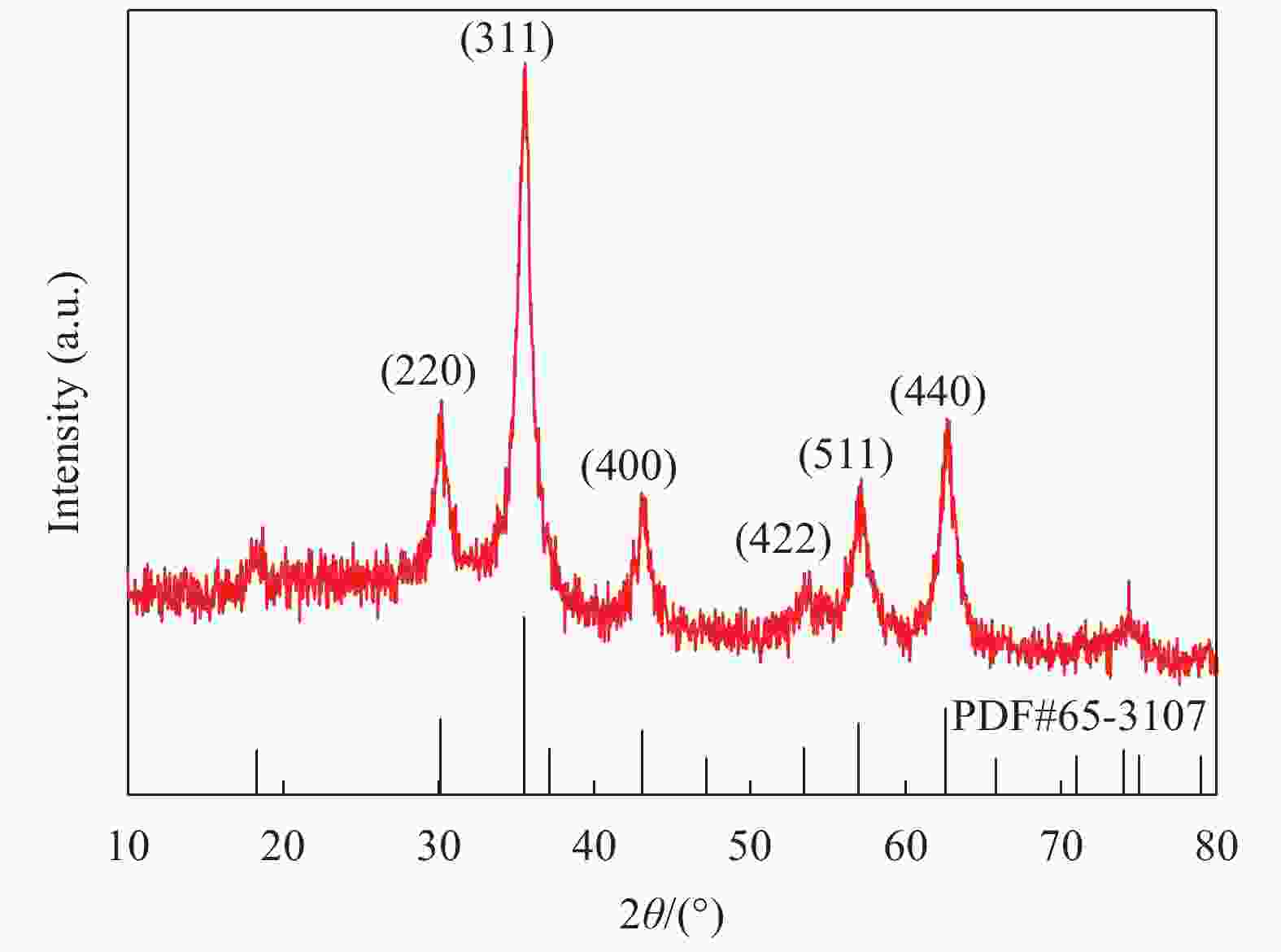

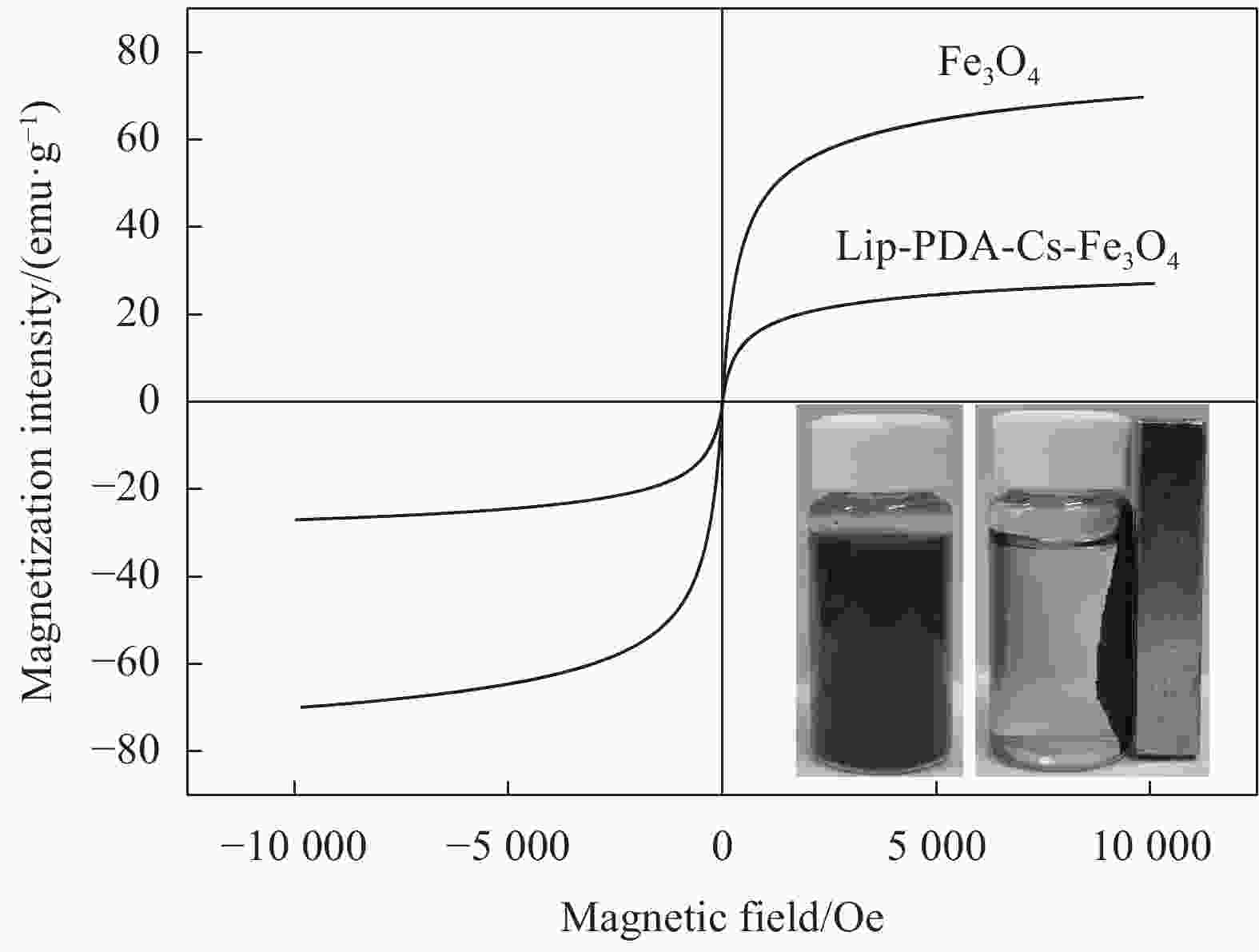

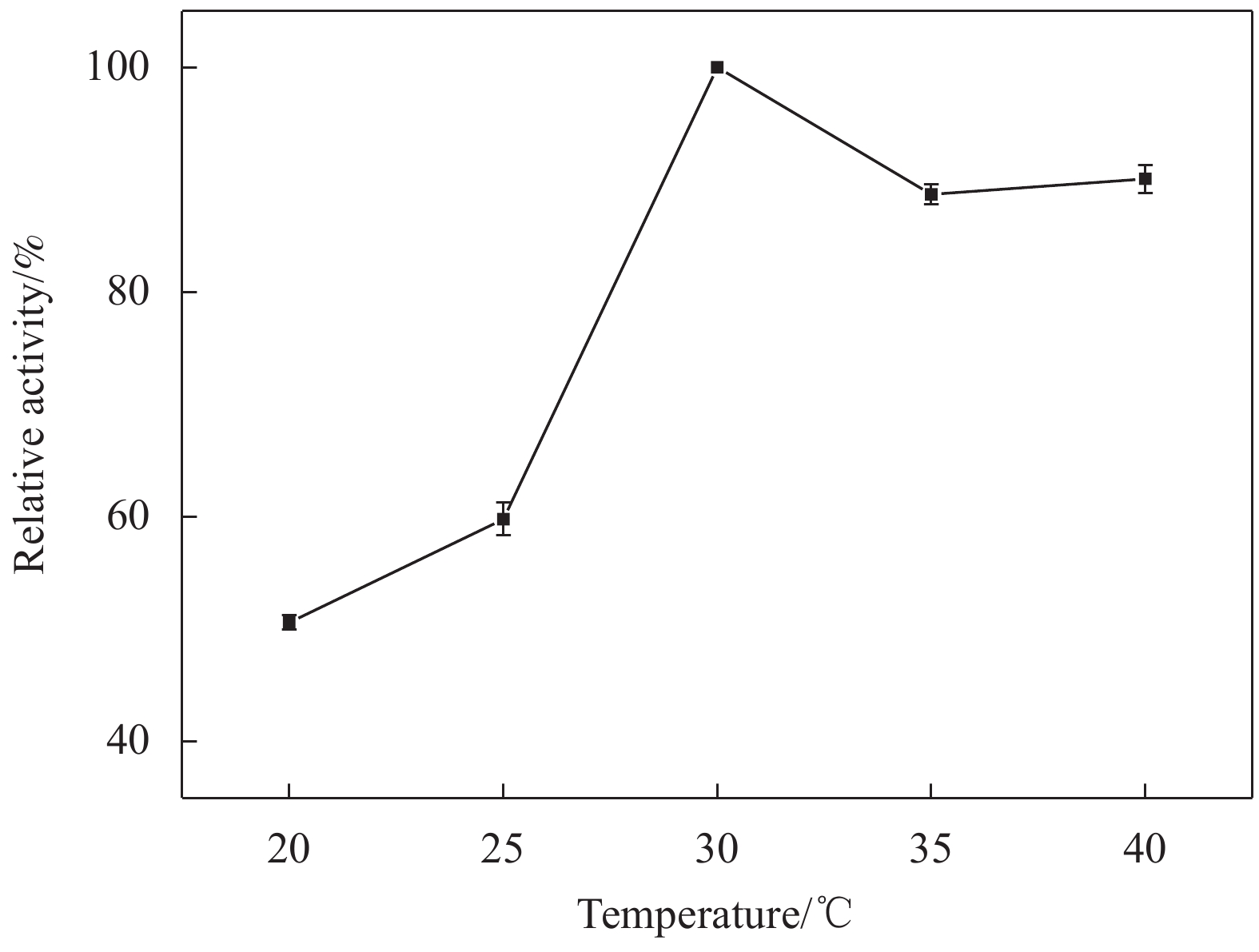

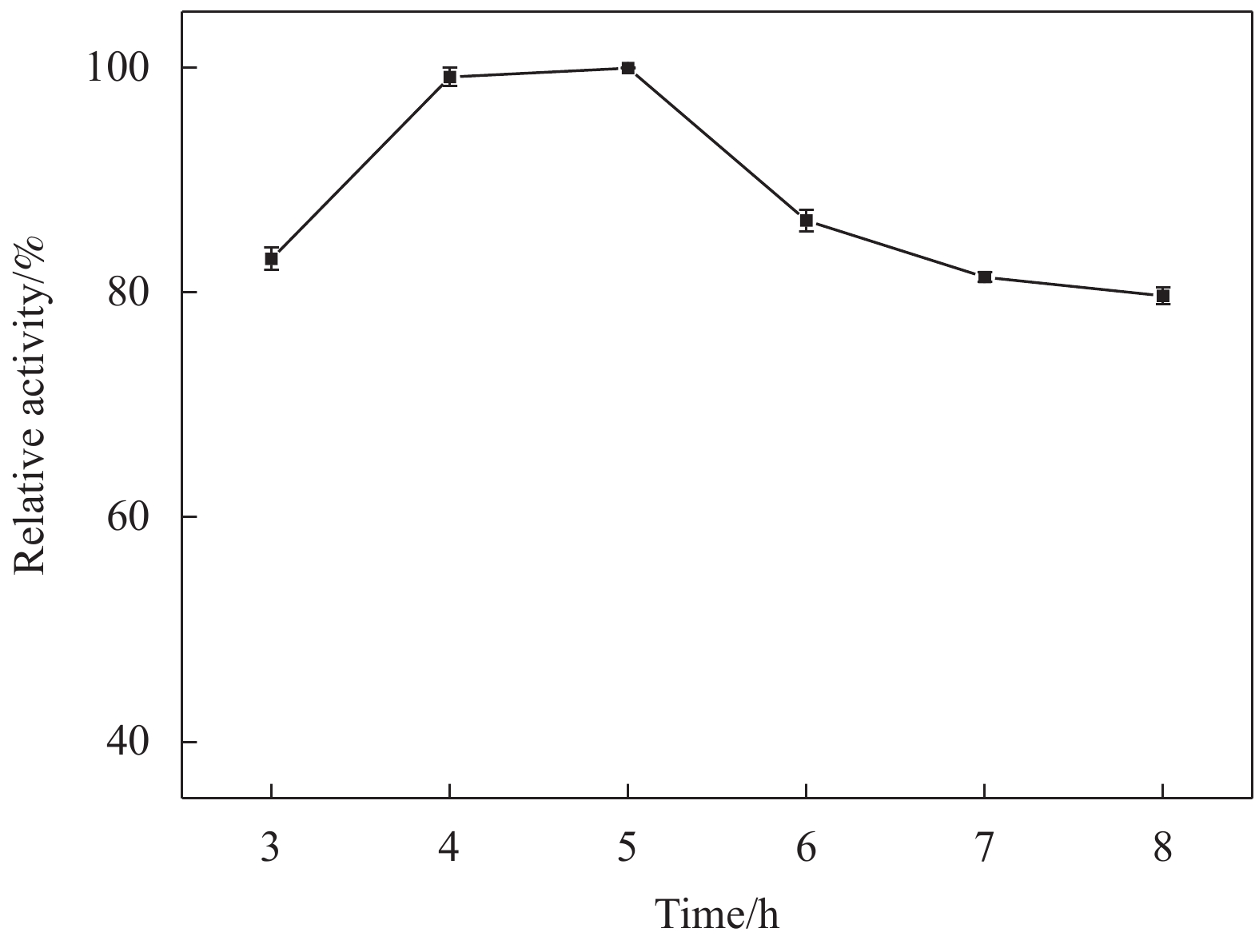

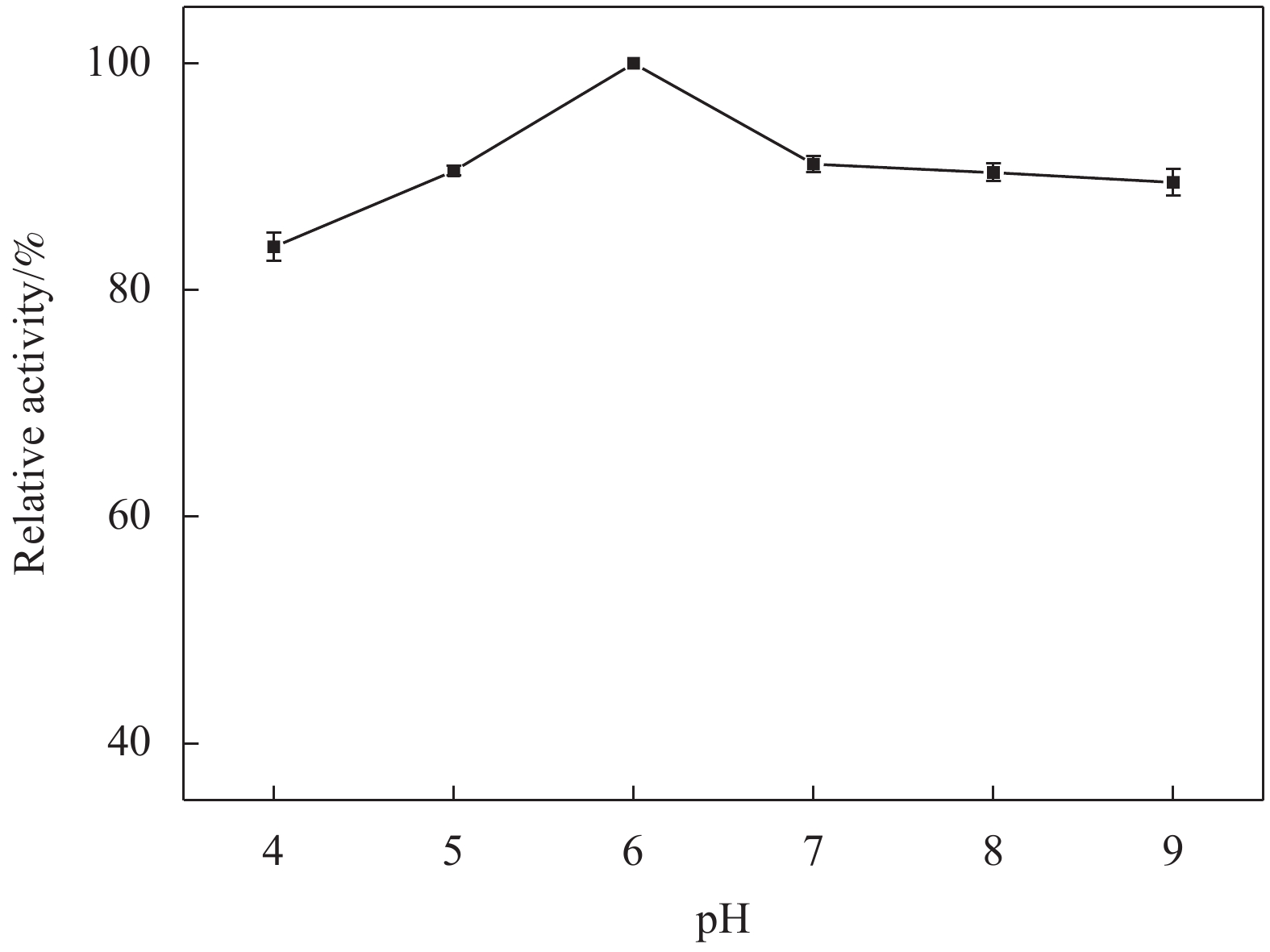

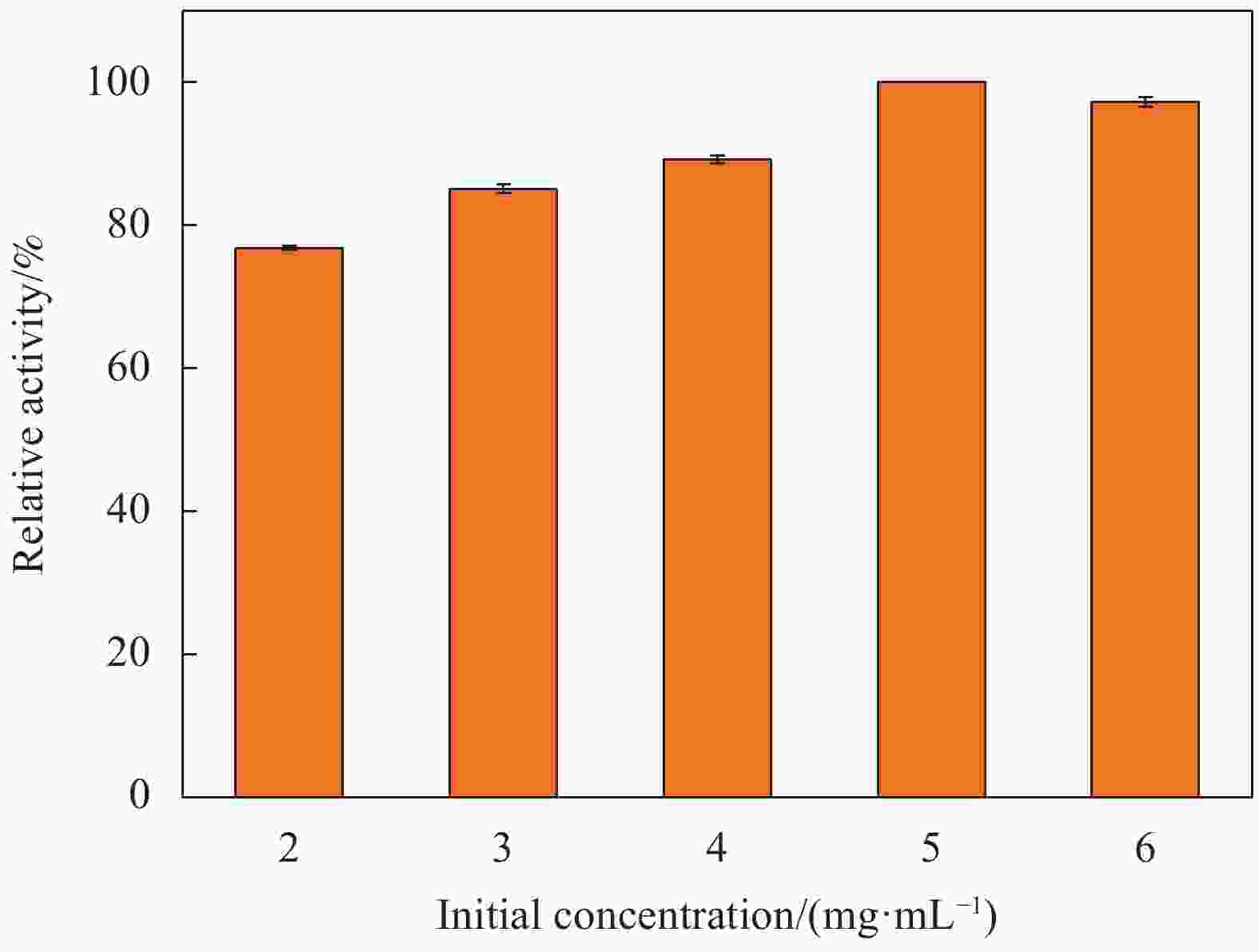

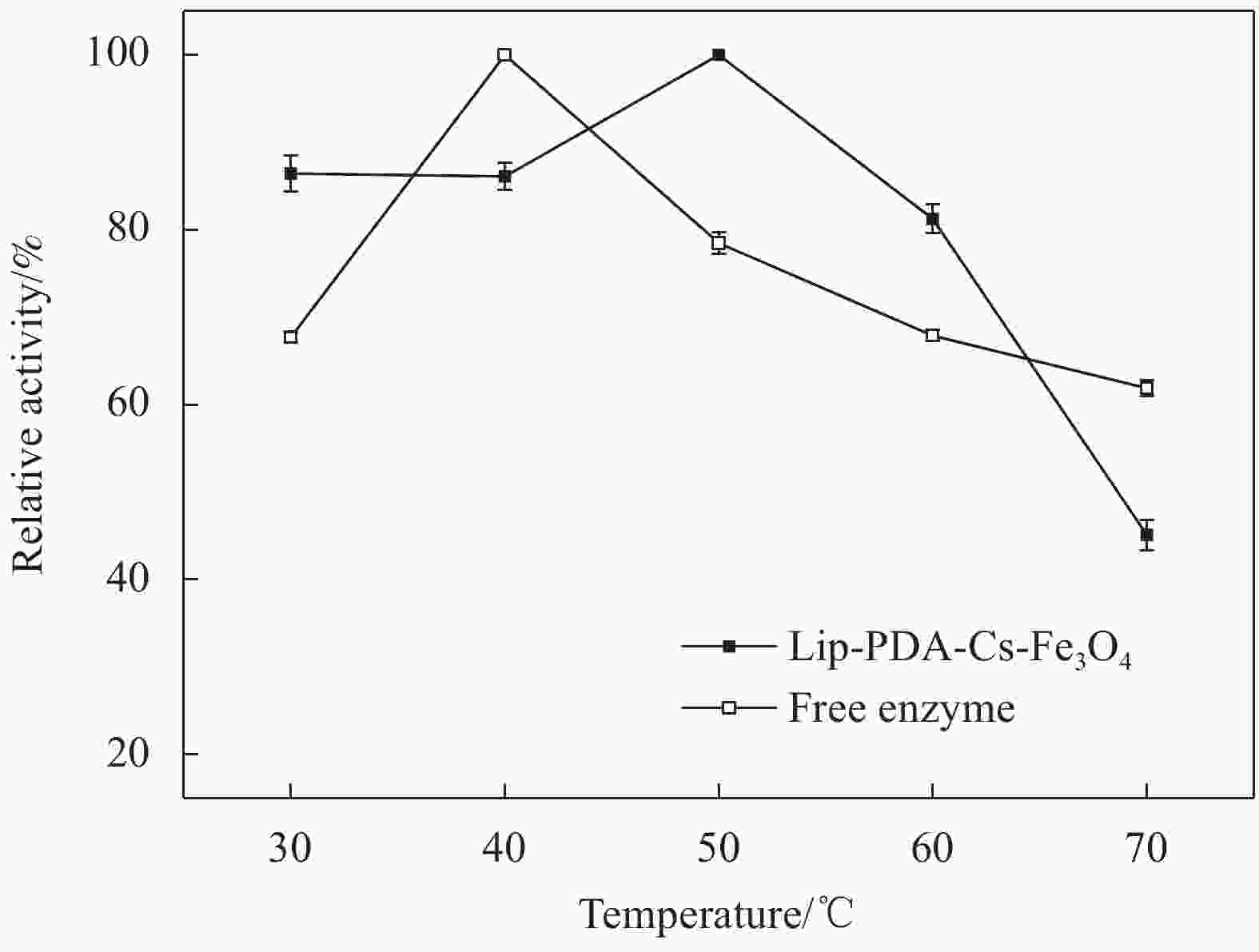

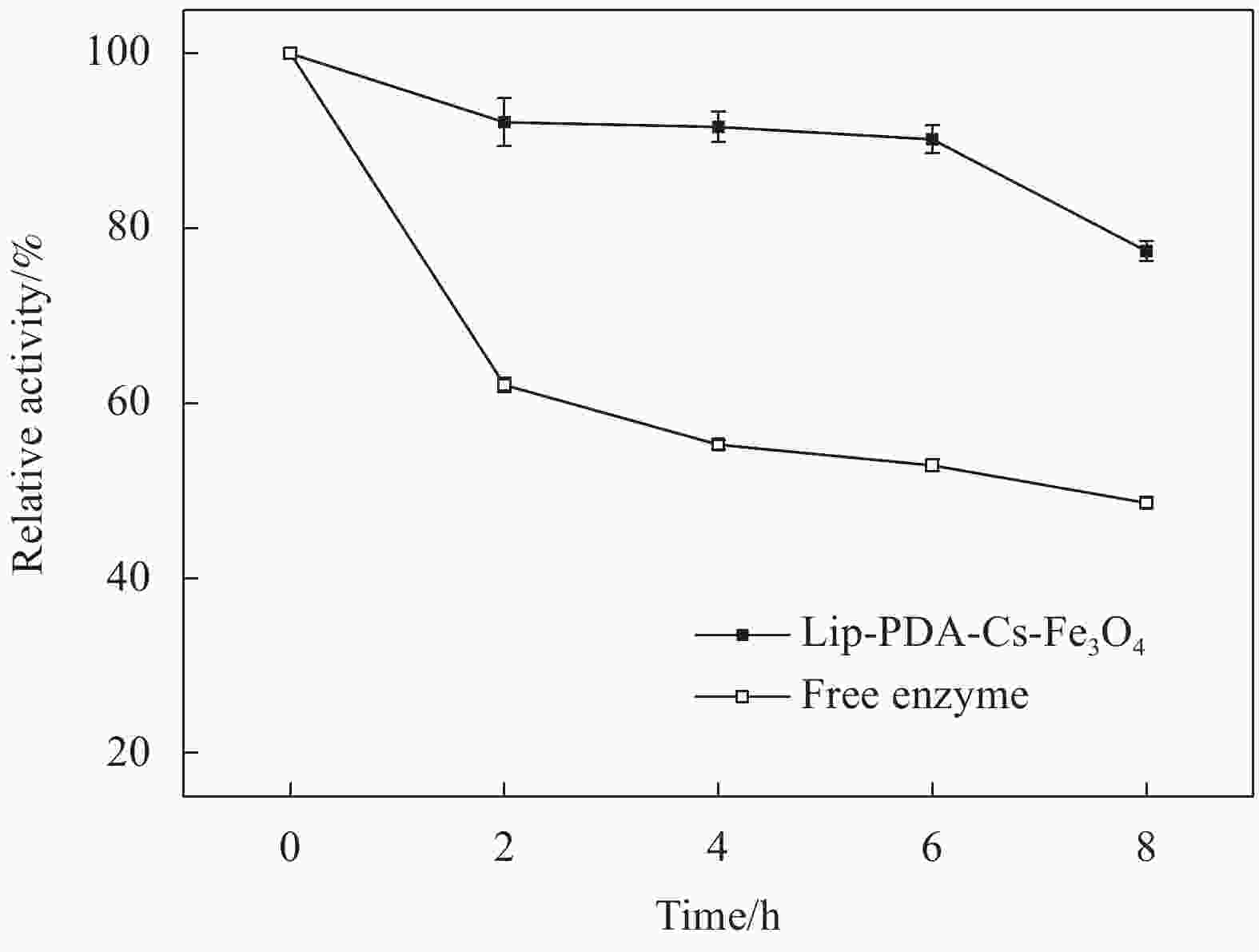

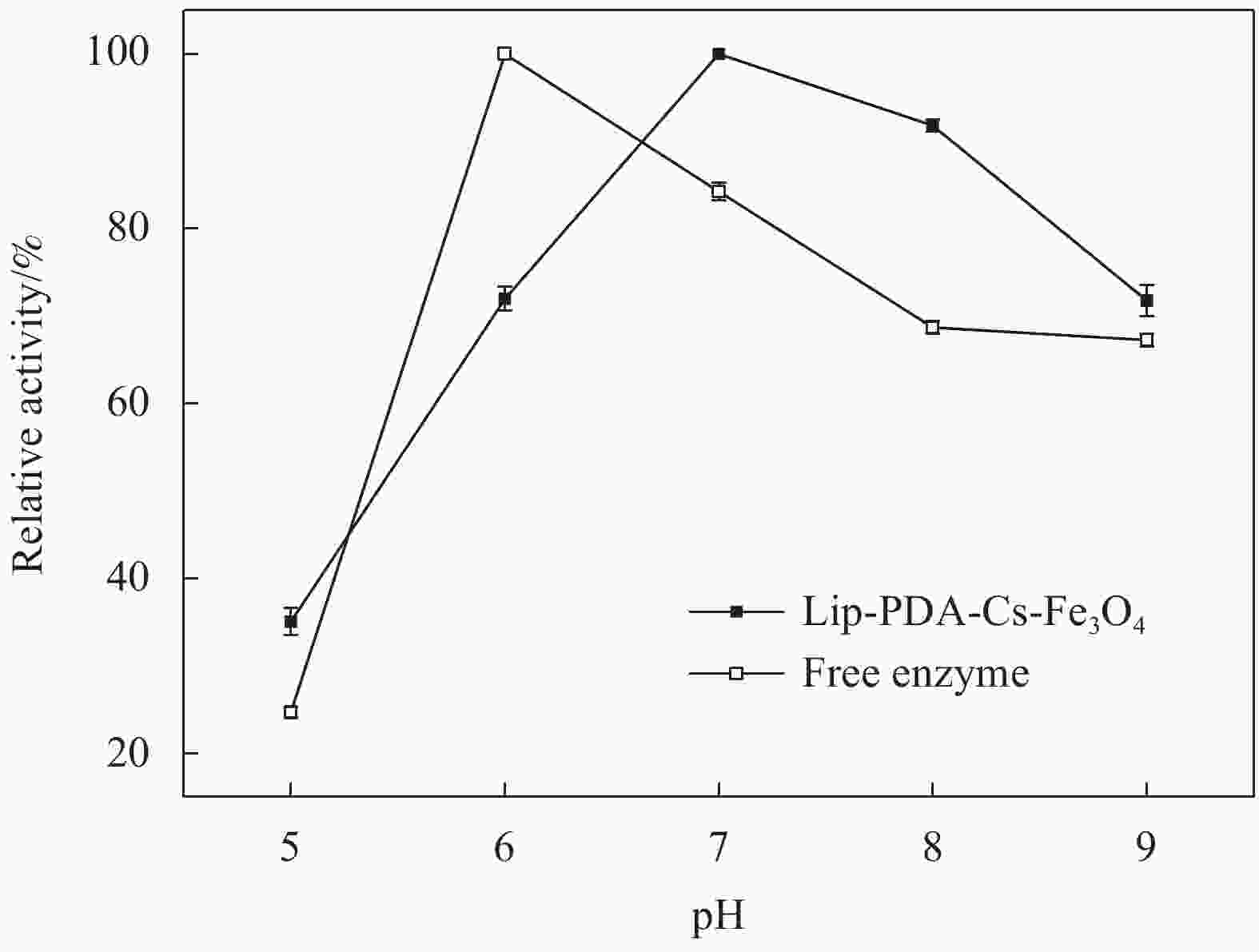

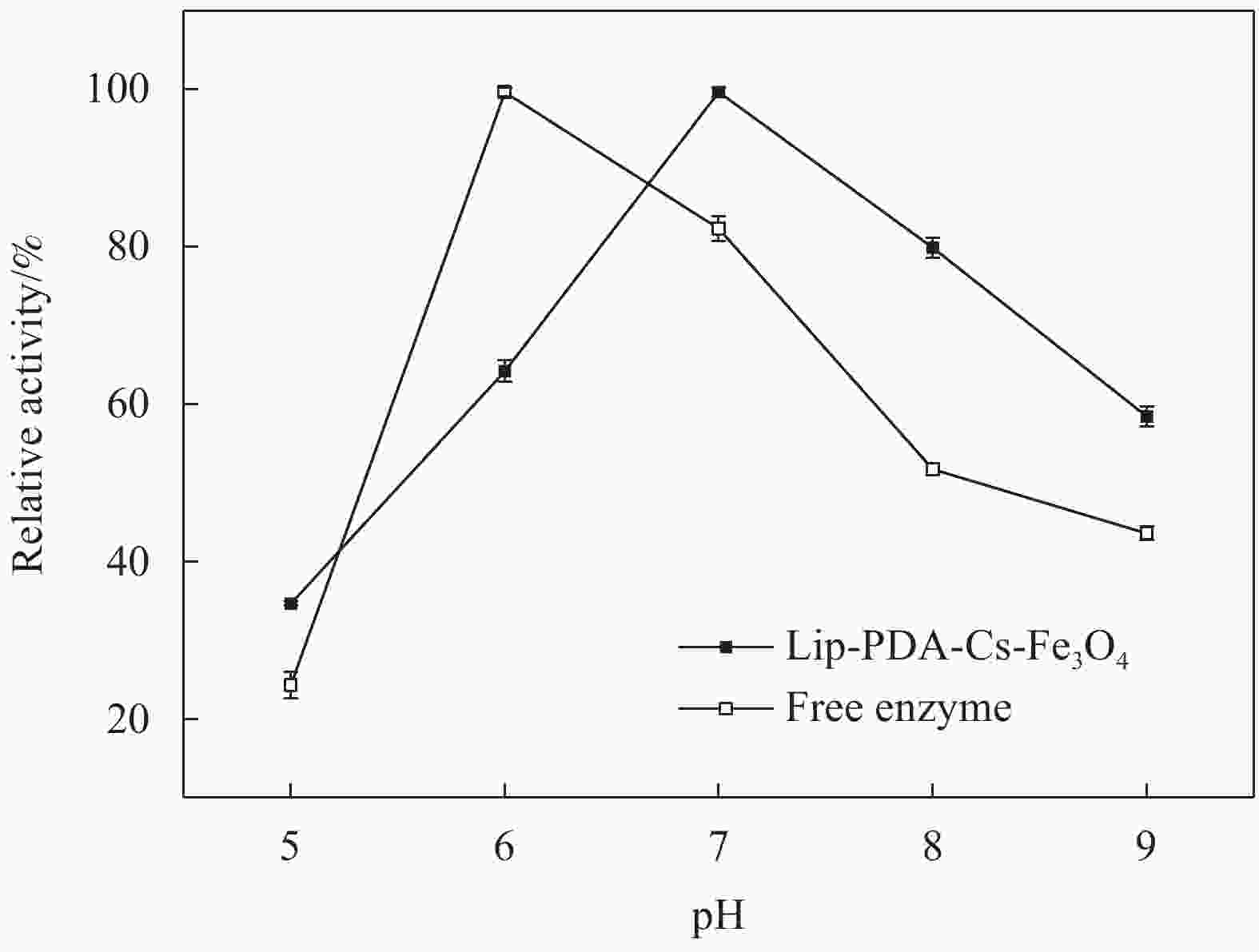

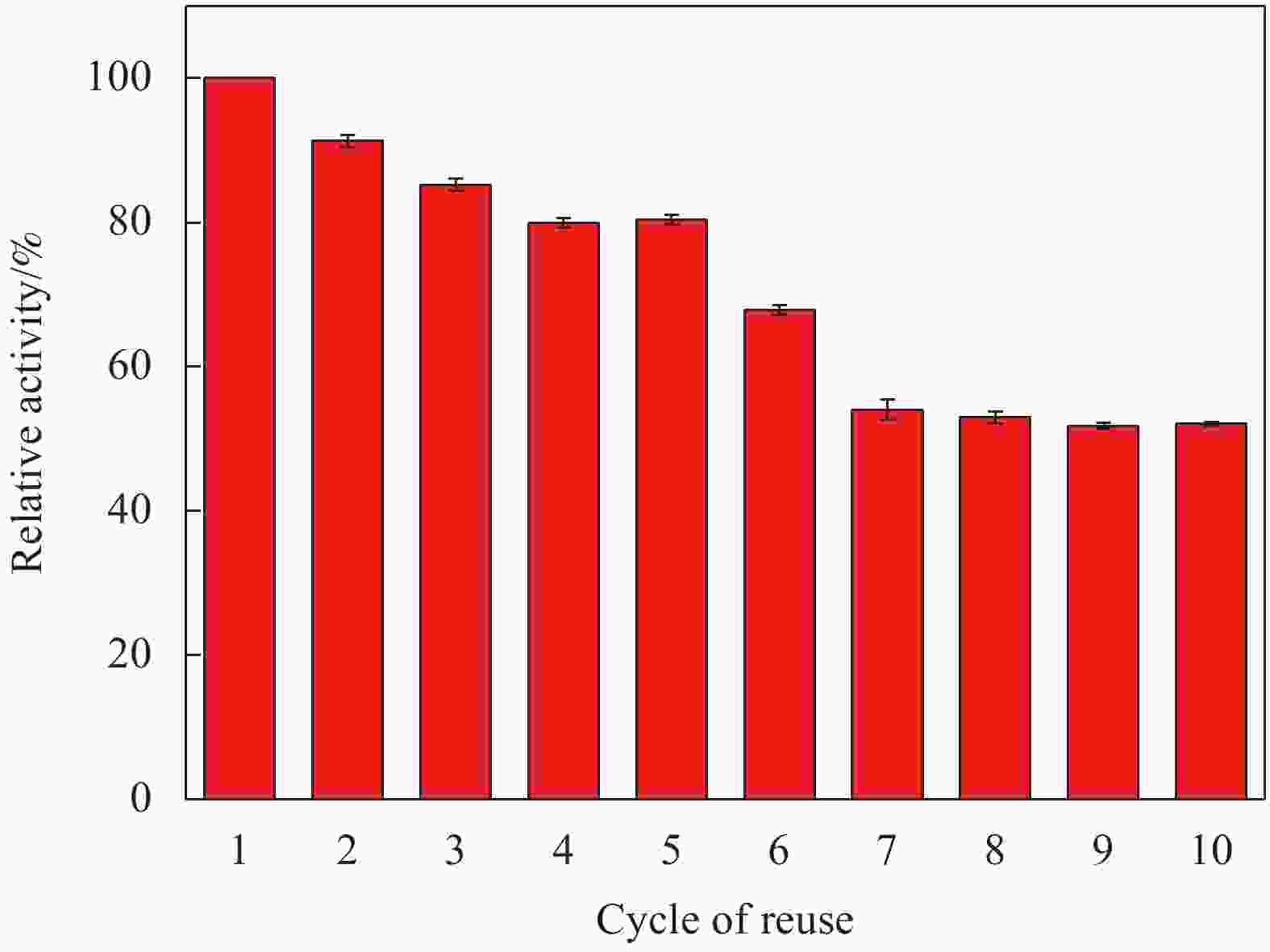

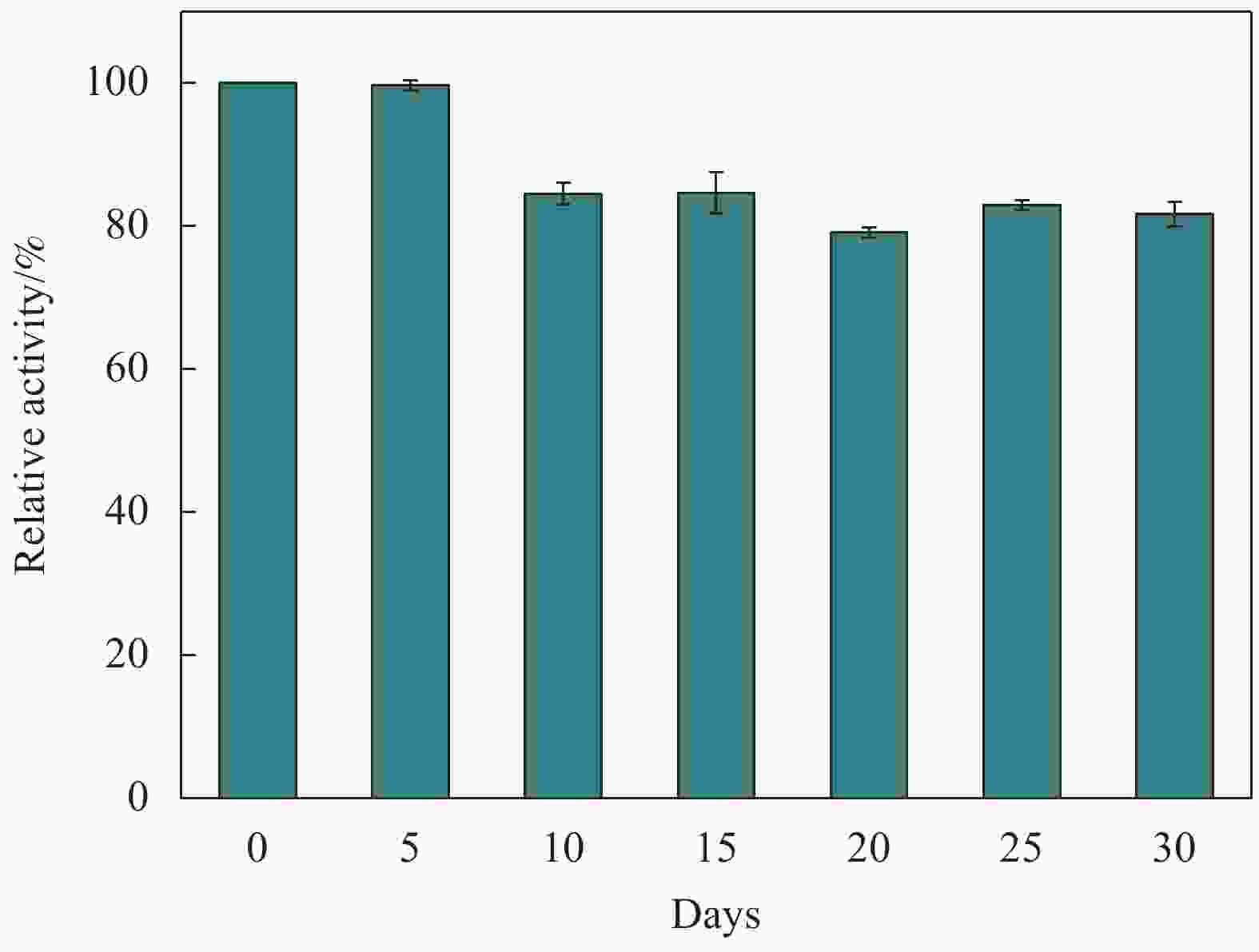

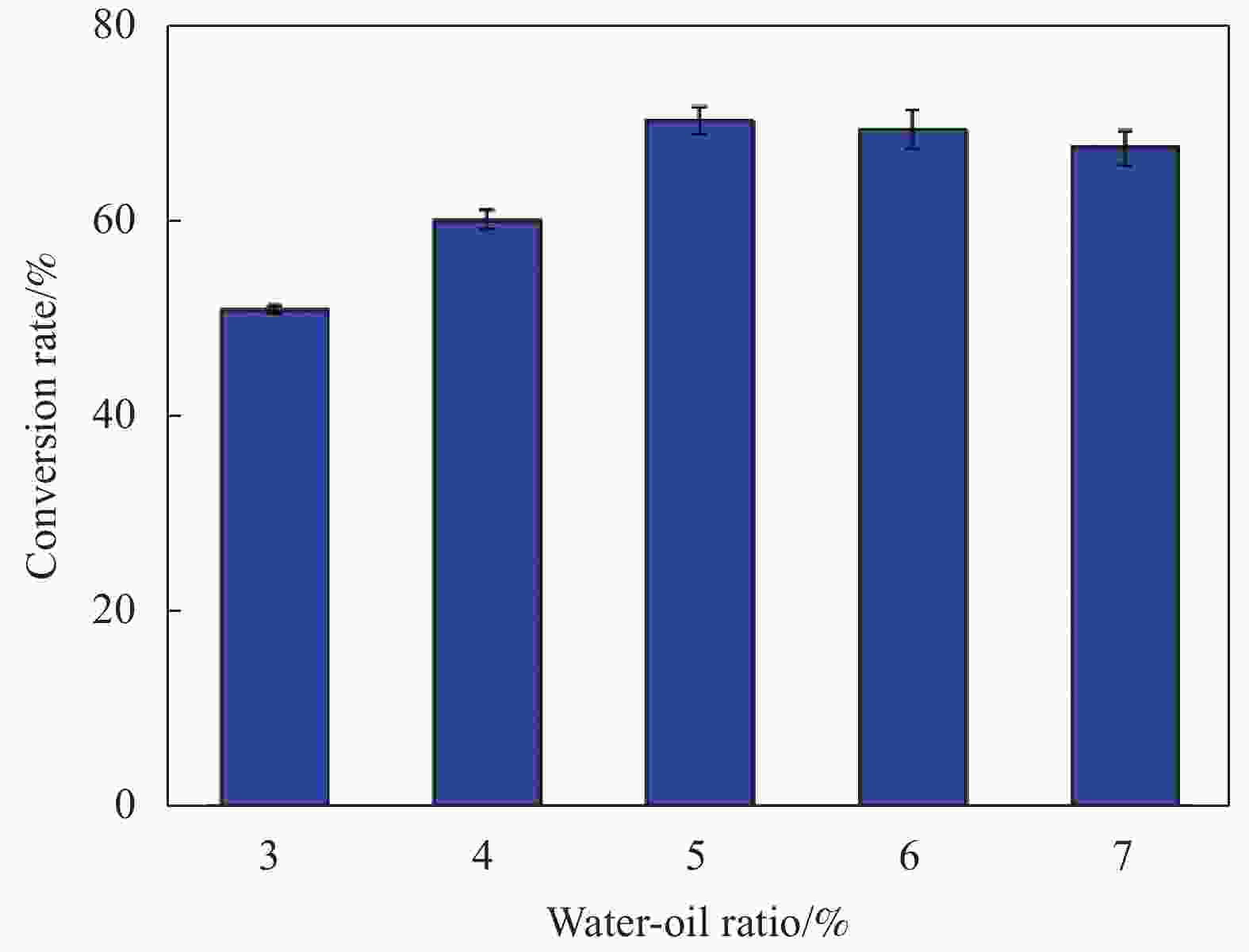

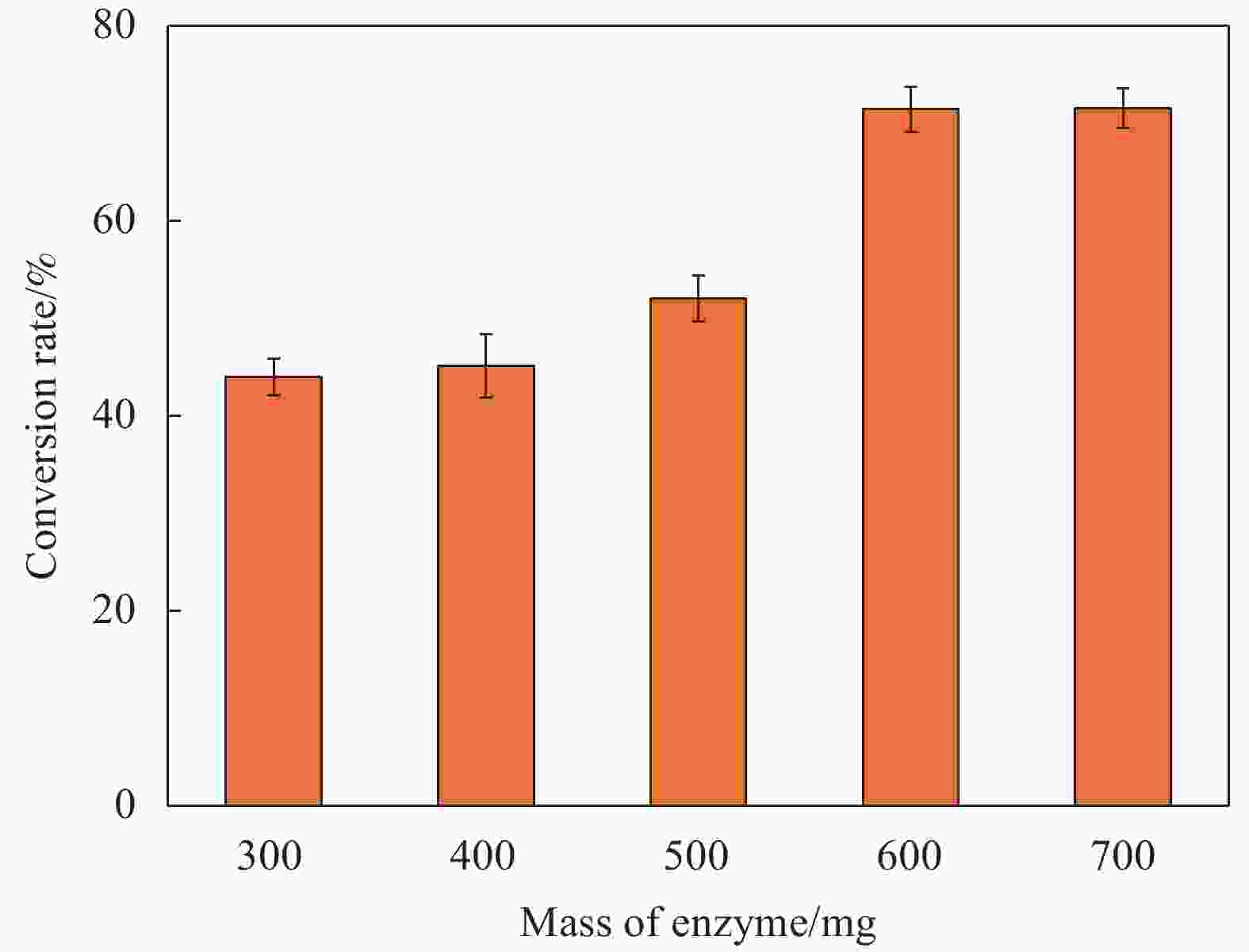

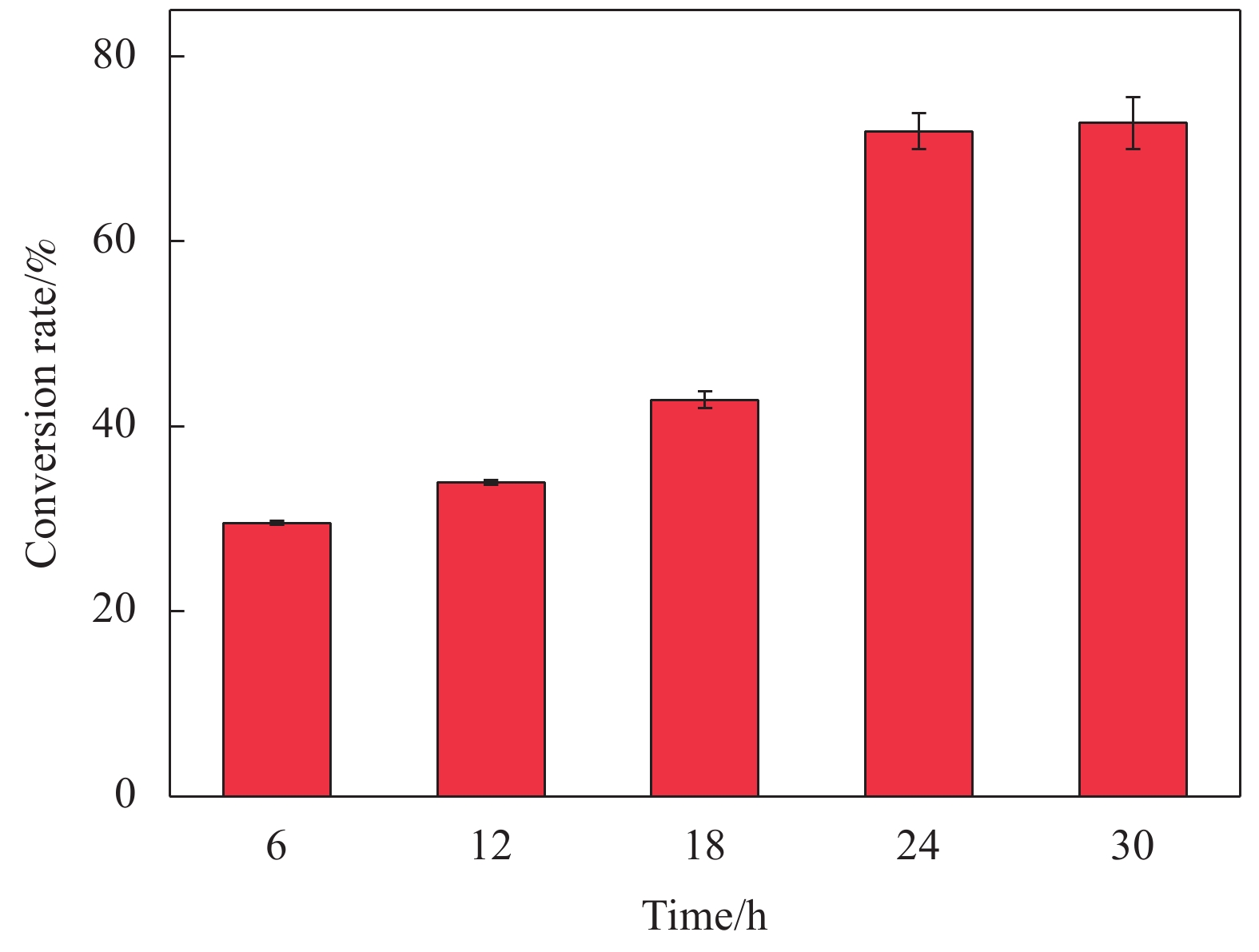

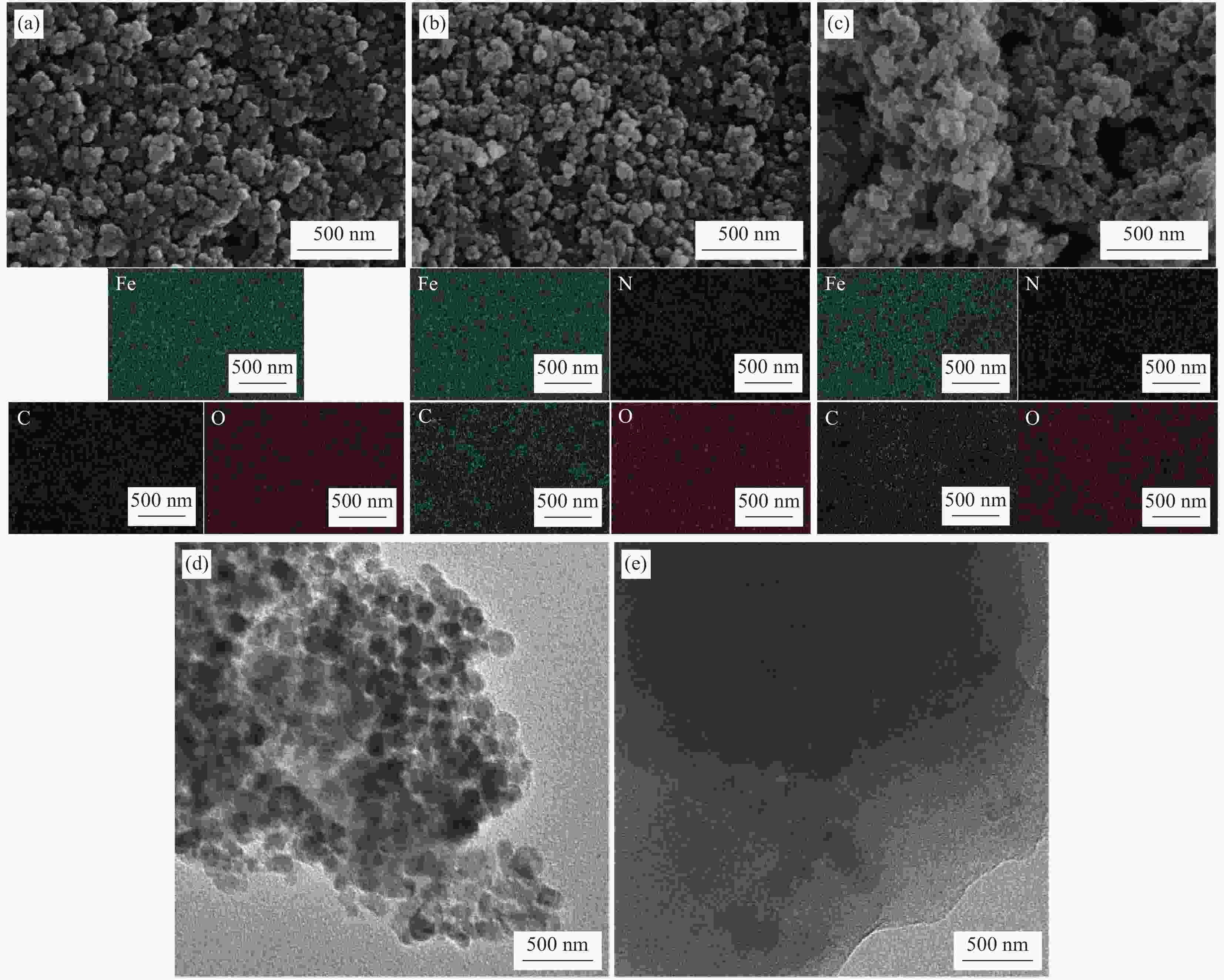

摘要: 本研究制备了一种以磁性壳聚糖为基材的多孔复合材料,通过在其表面涂覆聚多巴胺涂层替代传统的交联剂,用于脂肪酶的固定化研究。该材料具有优异的孔结构和较大的比表面积,孔容积可达0.6028 mL/g,比表面积可达106.8239 m2/g,经优化后固定化脂肪酶的酶活可达7392.91±121.22 U/g-载体。进一步探究了固定化酶的酶学性质,得到最佳反应温度为50 ℃,最佳反应pH为7.0,制备的固定化酶具有优异的热稳定性和pH稳定性,经过5次循环使用后,该固定化酶可以保持80%以上的初始酶活,经过10次循环使用后仍能保持52%的初始酶活。最后,将固定化酶应用于生物柴油转化并优化了相关工艺参数。Abstract: In this study, a porous composite material based on magnetic chitosan was prepared for lipase immobilization by applying a polydopamine coating on its surface instead of the traditional cross-linking agent. The material had excellent pore structure and large specific surface area, with a pore volume of 0.6028 mL/g and a specific surface area of 106.8239 m2/g, and the highest enzyme activity of the immobilized lipase could reach up to 7392.91±121.22 U/g-carrier. In addition, the enzymatic properties of the immobilized enzyme were investigated, and the optimal reaction temperature and pH were 50 ℃ and 7.0, respectively. Furthermore, the prepared immobilized enzyme exhibited good thermal and pH stabilities, and could maintain above 80% of the initial enzyme activity by the immobilized enzyme after five cycles of reuse, while 52% of the initial enzyme activity could be still maintained after ten cycles of reuse. Finally, the immobilized enzyme was applied in biodiesel conversion and the process was optimized.

-

Key words:

- Magnetic materials /

- Mussel-inspired /

- Lipase /

- Enzymatic properties /

- Biodiesel conversion

-

表 1 PDA-Cs-Fe3O4与Lip-PDA-Cs-Fe3O4的BET分析

Table 1. BET analysis of PDA-Cs-Fe3O4 and Lip-PDA-Cs-Fe3O4

Name Surface area/(m2·g−1) Pore volume/(mL·g−1) PDA-Cs-Fe3O4 106.8239 0.6028 Lip-PDA-Cs-Fe3O4 77.6027 0.4449 表 2 PDA-Cs-Fe3O4的孔径分析

Table 2. Pore size analysis of PDA-Cs-Fe3O4

Pore size/nm Pore volume/(mL·g−1) Percentage/% Micropore 0.35-2 0.0081 1.35 Mesopore 2-10 0.0589 9.84 10-50 0.2175 36.31 Macropore 50-120 0.3145 52.50 表 3 Lip-PDA-Cs-Fe3O4与其他研究中固定化酶热稳定性的比较

Table 3. Comparison of thermal stability of Lip-PDA-Cs-Fe3O4 with previous publications for immobilized lipase

Name Temperature/℃ Time/h Relative activity/% References PEG/PLA/CRL 50℃ 2 <70 [39] L-PHM3 4 <85 [40] PFL@EMMS 3 <80 [41] Lip-PDA-Cs-Fe3O4 6 90 This work Notes:Time is the duration of staying at 50℃; PEG is polyethylene glycol; PLA is polylactic acid; CRL is Candida rugosa lipase; L is Candida antarctica lipase; PHM is polyacrylamide hydrogel microspheres; 3 is the concentration of phosphate buffer solution of lipase immobilized on polyacrylamide hydrogel microspheres; PFL is Pseudomonas fluorescens lipase; EMMS is epoxy-functionalized macroporous and mesoporous SiO2. 表 4 Lip-PDA-Cs-Fe3O4与其他研究中固定化酶pH稳定性的比较

Table 4. Comparison of pH stability of Lip-PDA-Cs-Fe3O4 with previous publications for immobilized lipase

Name pH range References CRL-BSA-CELLAs 7.0-8.0 [44] PPL@COF 7.5-9.0 [45] Fe3O4-COOH@UiO-66-NH2@PPL 7.0-9.0 [46] Lip-PDA-Cs-Fe3O4 6.0-9.0 This work Notes:pH range is pH range in which the relative enzyme activity remains higher than 50%; CRL is Candida rugosa lipase; BSA is bovine albumin; CELLAs is cross-linked enzyme aggregates; PPL is porcine pancreatic lipase; COF is covalent organic framework; Fe3O4-COOH is carboxylic-functionalized magnetite; Uio-66-NH2 is zirconium aminobenzenedicarboxylate metal organic framework. -

[1] 刘书成, 鲁海龙, 张林尚, 等. 酶在油脂制取、精炼与改性中的应用[J]. 中国油脂, 2023, 48(12): 31-39.LIU Shucheng, LU Hailong, ZHANG Linshang, et al. Application of enzymes in oil production, refining, and modification[J]. China Oils and Fats, 2023, 48(12): 31-39(in Chinese). [2] 陈金行, 张逸, 张军涛, 等. 固定化脂肪酶的创制及其在乙酸肉桂酯无溶剂制备中的应用[J]. 生物技术通报, 2023, 39(9): 97-104.CHEN Jinxing, ZHANG Yi, ZHANG Juntao, et al. Preparation of immobilized lipase for the solvent-free synthesis of cinnamyl acetate[J]. Biotechnology Bulletin, 2023, 39(9): 97-104(in Chinese). [3] 张永民. 纤维素链霉菌AU-10源脂肪酶-一种可应用于洗涤剂配方的酶[J]. 中国洗涤用品工业, 2020, 7: 64-72.ZHANG Yongmin. Streptomyces cellulosus AU-10 source lipase-an enzyme that can be applied to detergent formulations[J]. China Cleaning Industry, 2020, 7: 64-72(in Chinese). [4] GAYATRIBEN B. P, PARITA R, TORAL S, et al. Lipolytic nocardiopsis for reduction of pollution load in textile industry effluent and SWISS model for structural study of lipase[J]. Bioresource Technology, 2021, 341: 125673. doi: 10.1016/j.biortech.2021.125673 [5] VERMA S, CHOUDHARY R N, KANADJE A P, et al. Diversifying arena of drug synthesis: in the realm of lipase mediated waves of biocatalysis[J]. Catalysts, 2021, 11(11): 1328. doi: 10.3390/catal11111328 [6] KUMAR A, VERMA V, DUBEY V K, et al. Industrial applications of fungal lipases: a review[J]. Frontiers in Microbiology, 2023, 14: 1142536. doi: 10.3389/fmicb.2023.1142536 [7] SAMUI A, CHOWDHURI A R, SAHU S K. Lipase immobilized metal-organic frameworks as remarkably biocatalyst for ester hydrolysis: a one step approach for lipase immobilization[J]. Chemistry Select, 2019, 4(13): 3745-3751. [8] RIBEIRO E S, FARIAS B S, JUNIOR T R S A C, et al. Chitosan-based nanofibers for enzyme immobilization[J]. International Journal of Biological Macromolecules, 2021, 183: 1959-1970. doi: 10.1016/j.ijbiomac.2021.05.214 [9] RODRIGUES R C, VIRGEN-ORTIZ J J, DOS S J C S, et al. Immobilization of lipases on hydrophobic supports: immobilization mechanism, advantages, problems, and solutions[J]. Biotechnology Advances, 2019, 37(5): 746-770. doi: 10.1016/j.biotechadv.2019.04.003 [10] 柳有财, 蔡俊. 羧基改性多孔磁性壳聚糖微球共固定化葡萄糖氧化酶与过氧化氢酶[J]. 功能材料, 2022, 53(2): 2146-2155.LIU Youcai, CAI Jun. Glucose oxidase and catalase co-immobilized by carboxyl modified porous magnetic chitosan microspheres[J]. Journal of Functional Materials, 2022, 53(2): 746-770(in Chinese). [11] 毛梦雷, 孟令玎, 高蕊, 等. 多孔框架材料固定化酶研究进展[J]. 化工进展, 2023, 42(5): 2516-2535.MAO Menglei, MENG Lingding, GAO Rui, et al. Research progress on enzyme immobilization on porous framework materials[J]. Chemical Industry and Engineering Progress, 2023, 42(5): 2516-2535(in Chinese). [12] 王曦琦, 刘梓钰, 梁晓云, 等. 聚多巴胺纳米材料及其在食品领域中的应用[J/OL]. 食品工业科技: 1-132024-02-04]. https: //doi. org/10.13386/j. issn1002-0306.2023050055. WANG Xiqi, LIU Ziyu, LIANG Xiaoyun, et al. Polydopamine nanomaterials and their applications in food field[J/OL]. Science and Technology of Food Industry: 1-13[2024-02-04].https://doi.org/10.13386/j.issn1002-0306.2023050055.(in Chinese). [13] ZHAO Y T, ZHANG K, ZENG J, et al. Immobilization on magnetic PVA/SA@Fe3O4 hydrogel beads enhances the activity and stability of neutral protease[J]. Enzyme and Microbial Technology, 2022, 157: 110017. doi: 10.1016/j.enzmictec.2022.110017 [14] AMIN R, KHORSHIDI A, BENSCH W, et al. Degradation of sesame oil phenolics using magnetic immobilized laccase[J]. Catalysis Letters, 2020, 150: 3086-3095. doi: 10.1007/s10562-020-03226-8 [15] 高丰琴, 王珊, 王云芳, 等. 磁性氧化石墨烯固定化氯过氧化物酶及其在奥酸性蓝45脱色中的应用[J]. 高等学校化学学报, 2018, 39(5): 904-910.GAO Fengqin, WANG Shan, WANG Yunfang, et al. Magnetic graphene oxide immobilized chloropperoxidase and its application in the decolorization of auroic acid blue 45[J]. Chemical Journal of Chinese Universities, 2018, 39(5): 904-910(in Chinese). [16] 胡艺凡, 李正军, 刘长霞. 基于磁性Fe3O4粒子的固定化过氧化氢酶的制备及催化性质研究[J]. 北京化工大学学报(自然科学版), 2023, 50(2): 53-62.HU Yifan, LI Zhengjun, LIU Changxia. Preparation and catalytic properties of catalase immobilized on magnetic Fe3O4 particles[J]. Journal of Beijing University of Chemical Technology (Natural Science), 2023, 50(2): 53-62(in Chinese). [17] 邵文泰. 液体脂肪酶催化地沟油制备生物柴油的工艺优化[D]. 烟台: 烟台大学, 2023.SHAO Wentai. Optimization of biodiesel from gutter oil catalyzed by liquid lipase[D]. Yantai: Yantai University, 2023(in Chinese). [18] 罗旭聪. 基于共价有机框架材料构建生物催化剂及性能研究[D]. 天津: 河北工业大学, 2020.LUO Xucong. Construction of biocatalyst based on covalent organic frame materials and the catalytic performance[D]. Tianjin: Hebei University of Technology, 2020(in Chinese). [19] SUO H, GAO Z, XU L, et al. Synthesis of functional ionic liquid modified magnetic chitosan nanoparticles for porcine pancreatic lipase immobilization[J]. Materials Science and Engineering:C, 2019, 96: 356-364. doi: 10.1016/j.msec.2018.11.041 [20] 王淑婧, 曾祥冰, 孙西同, 等. 贻贝仿生涂层修饰聚合物微球固定化脂肪酶的制备及应用[J]. 食品工业科技, 2024, 45(1): 108-117.WANG Shujing, ZENG Xiangbing, SUN Xitong, et al. Synthesis and application of lipase immobilized on mussel-inspired polymer microspheres[J]. Science and Technology of Food Industry, 2024, 45(1): 108-117(in Chinese). [21] YANG X, CHEN Y, YAO S, et al. Preparation of immobilized lipase on magnetic nanoparticles dialdehyde starch[J]. Carbohydrate Polymers, 2019, 218: 324-332. doi: 10.1016/j.carbpol.2019.05.012 [22] 包国庆, 吴纯鑫, 赵德明. 磁性Fe3O4纳米复合材料的制备及其对Pb(II)的吸附[J]. 复合材料学报, 2023, 40(1): 219-231.BAO Guoqing, WU Chunxin, ZHAO Deming. Preparation of magnetic Fe3O4 nanocomposites and their adsorption to Pb(II)[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 219-231(in Chinese). [23] BAI Y, WU W. The neutral protease immobilization: physical characterization of sodium alginate-chitosan gel beads[J]. Applied Biochemistry and Biotechnology, 2022, 194(5): 2269-2283. doi: 10.1007/s12010-021-03773-9 [24] QIN T, LIU L, CAO H, et al. Polydopamine modified cellulose nanocrystals(CNC) for efficient cellulase immobilization towards advanced bamboo fiber flexibility and tissue softness[J]. International Journal of Biological Macromolecules, 2023, 253(6): 126734. [25] 铁伟伟, 邱帅彪, 王红霞, 等. Fe3O4/BiOBr/Graphene磁性气凝胶的构筑与Cr(Ⅵ)污水净化[J/OL]. 复合材料学报: 1-112024-02-04]. https: //doi. org/10.13801 /j. cnki. fhclxb. 20230911.001. TIE Weiwei, QIU Shuaibiao, Wang Hongxia, et al. Construction of magnetic Fe3O4/BiOBr/Graphene aerogel and Cr(Ⅵ) wastewater purification[J/OL] Acta Materiae Compositae Sinica: 1-11[2024-02-04].https://doi.org/10.13801/j.cnki.fhclxb.20230911.001.(in Chinese). [26] 郭小华, 马剑琪. 磁性核壳结构Fe3O4@SiO2@TiO2-Au的制备及其光催化还原性能[J/OL]. 复合材料学报: 1-9[2024-02-04]. https: //doi. org/10.13801/j. cnki. fhclxb. 20240012.003.GUO Xiaohua, MA Jianqi. Fabrication of Magnetic Fe3O4@SiO2@TiO2-Au with core-shell structure and its photocatalytic reduction activity[J/OL] Acta Materiae Compositae Sinica: 1-9[2024-02-04].https://doi.org/10.13801/j.cnki.fhclxb.20240012.003.(in Chinese). [27] 梁艳莉, 马剑琪, 郭少波. CoFe2O4@PDA@Pt核壳型磁性复合材料的制备及催化性能[J]. 复合材料学报, 2021, 38(5): 1551-1557.LIANG Yanli, MA Jianqi, GUO Shaobo. Preparation and catalytic properties of CoFe2O4@PDA@Pt magnetic composite with core shell structure[J] Acta Materiae Compositae Sinica, 2021, 38(5): 1551-1557(in Chinese). [28] CHENG W, LI Y, LI X, et al. Preparation and characterization of PDA/SiO2 nanofilm constructed macroporous monolith and its application in lipase immobilization[J]. Journal of the Taiwan Institute of Chemical Engineers, 2019, 104: 351-359. doi: 10.1016/j.jtice.2019.09.013 [29] 闵丹, 彭川, 陈建, 等. 多孔纳米碳球的制备及其电化学性能研究[J]. 四川轻化工大学学报(自然科学版), 2020, 33(6): 6-11.MIN Dan, PENG Chuang, CHEN Jian, et al. Study on synthesis and electrochemical performance of porous carbon nano-spheres[J] Journal of Sichuan University of Science & Engineering(Natural Science Edition), 2020, 33(6): 6-11(in Chinese). [30] 李铃, 莫创荣, 邓冬祝, 等. La-Fe改性蛭石对水中磷酸盐的高效去除: 吸附行为及内在机制[J/OL]. 复合材料学报: 1-11[2024-02-04]. https: //doi. org/10.13801/ j. cnki. fhclxb. 20240022.003.LI Ling, MO Chuangrong, DENG Dongzhu, et al. Performance and mechanism of La-Fe modified vermiculite adsorbent for efficient phosphorus removal[J/OL]. Acta Materiae Compositae Sinica: 1-11[2024-02-04].https://doi.org/10.13801/ j.cnki.fhclxb.20 240022.003.(in Chinese). [31] 黄文涛, 邓呈逊, 吉宇尘, 等. 壳聚糖功能化磁性氧化石墨烯复合材料的制备及对甲基橙的吸附[J]. 复合材料学报, 2021, 38(4): 1262-1271.HUANG Wentao, DENG Chengxun, JI Yuchen, et al. Synthesis of chitosan functionalized magnetic graphene oxidecomposite and adsorption on methyl orange[J]. Acta Materiae Compositae Sinica, 2021, 38(4): 1262-1271(in Chinese). [32] YIN Y, FEI X, TIAN J, et al. Synthesis of lipase-hydrogel microspheres and their application in deacidification of high-acid rice bran oil[J]. New Journal of Chemistry, 2022, 46(44): 21287-21300. doi: 10.1039/D2NJ03761K [33] BI Y, WANG Z, ZHANG R, et al. Improved catalytic properties of Thermomyces lanuginosus lipase immobilized onto newly fabricated polydopamine-functionalized magnetic Fe3O4 nanoparticles[J]. Processes, 2020, 8(5): 629. doi: 10.3390/pr8050629 [34] GUO H, LEI B, YU J, et al. Immobilization of lipase by dialdehyde cellulose crosslinked magnetic nanoparticles[J]. International journal of biological macromolecules, 2021, 185: 287-296. doi: 10.1016/j.ijbiomac.2021.06.073 [35] 李薇, 石爱民, 焦博, 等. 乙酰化花生球蛋白载酶颗粒的制备及表征[J]. 生物技术进展, 2023, 13(5): 771-778.LI Wei, SHI Aimin, JIAO Bo, et al. Preparation technology and characterization of lipase immobilized with acetylated arachin nanoparticles[J]. Current Biotechnology, 2023, 13(5): 771-778(in Chinese). [36] 徐然, 韩生华, 王利刚. 硅胶吸附-交联脂肪酶的研究[J]. 山西大同大学学报(自然科学版), 2021, 37(3): 7-11.XU Ran, HAN Shenghua, WANG Ligang. Study on the immobilization of lipase on silica gel by adsorption and cross-linking method[J]. Shanxi Datong University Journal, 2021, 37(3): 7-11(in Chinese). [37] 韩本勇, 周志梅, 耿树香, 等. 改性核桃壳固定化脂肪酶研究[J]. 江苏农业科学, 2020, 48(2): 282-286.HAN Benyong, ZHOU Zhimei, GENG Shuxiang, et al. Study of modified walnut shell immobilized lipase[J]. Jiangsu Agricultural Sciences, 2020, 48(2): 282-286. [38] LYU J, LI Z, MEN J, et al. Covalent immobilization of Bacillus subtilis lipase A on Fe3O4 nanoparticles by aldehyde tag: an ideal immobilization with minimal chemical modification[J]. Process Biochemistry, 2019, 81: 63-69. doi: 10.1016/j.procbio.2019.03.017 [39] LI S, ZHAO S, HOU Y, et al. Polylactic acid (PLA) modified by polyethylene glycol (PEG) for the immobilization of lipase[J]. Applied Biochemistry and Biotechnology, 2020, 190: 982-996. doi: 10.1007/s12010-019-03134-7 [40] QIN Z, FENG N, Li Y, et al. Hydrogen-bonded lipase-hydrogel microspheres for esterification application[J]. Journal of Colloid and Interface Science, 2022, 606: 1229-1238. doi: 10.1016/j.jcis.2021.08.147 [41] 张辉. 整体型大孔-介孔SiO2的制备及在固定化脂肪酶中的应用[D]. 宁波: 宁波大学, 2020.ZHANG Hui. Preparation of monolithic macroporous-mesoporous SiO2 and their application in lipase immobilization[D]. Ningbo: Ningbo University, 2020(in Chinese). [42] WANG H, YUE W, ZHANG S, et al. Modification of silica xerogels with polydopamine for lipase B from Candida antarctica immobilization[J]. Catalysts, 2021, 11(12): 1463. doi: 10.3390/catal11121463 [43] ACıKGOZ-ERKAYA I, BAYRAMOGLU G, AKBULUT A, et al. Immobilization of Candida rugosa lipase on magnetic biosilica particles: hydrolysis and transesterification studies[J]. Biotechnology and Bioprocess Engineering, 2021, 26: 827-840. doi: 10.1007/s12257-020-0387-9 [44] 闫妍. 磁性交联脂肪酶聚集体的制备及其催化植物甾醇酯化的研究[D]. 镇江: 江苏大学, 2022.YAN Yan. Preparation of magnetic cross-linked lipase aggregates and its catalytic esterification of phytosterols[D]. Zhenjiang: Jiangsu University, 2022(in Chinese). [45] LIU X, WU J, YANG S, et al. Carboxy-functionalized covalent organic framework as a carrier for lipase immobilization and its application in inhibitors screening[J]. Applied Biochemistry and Biotechnology, 2023: 1-14. [46] XU J, CAO P, FAN Z, et al. Rapid screening of lipase inhibitors in scutellaria baicalensis by using porcine pancreatic lipase immobilized on magnetic core–shell metal–organic frameworks[J]. Molecules, 2022, 27(11): 3475. doi: 10.3390/molecules27113475 [47] 张 帆, 郑兰兰, 曹红, 等. 双重包埋激活脂肪酶内花凝胶微球的制备与表征[J]. 高等学校化学学报, 2023, 44(4): 108-116.ZHANG Fan, ZHENG Lanlan, CAO Hong, et al. Preparation and characterization of an inner flower gel microsphere double-embedded with the activated-lipase[J]. Chemical Journal of Chinese Universities, 2023, 44(4): 108-116(in Chinese). [48] JI X, LI Y, WANG S, et al. Lipase/tannic acid magnetic hydrogel microspheres and their continuous catalytic application[J]. New Journal of Chemistry, 2023, 47(39): 18163-18172. doi: 10.1039/D3NJ03268J [49] ASMAT S, ANWER A H, HUSAIN Q. Immobilization of lipase onto novel constructed polydopamine grafted multiwalled carbon nanotube impregnated with magnetic cobalt and its application in synthesis of fruit flavours[J]. International Journal of Biological Macromolecules, 2019, 140: 484-495. doi: 10.1016/j.ijbiomac.2019.08.086 [50] 陈进坤, 丁 浩, 龙苋魏, 等. 猪胰脂肪酶固定化及连续流催化拆分合成(S)-2-四氢糠酸[J]. 发酵科技通讯, 2023, 52(3): 131-137.CHEN Jinkun, DING Hao, LONG Xianwei, et al. Immobilization of porcine pancreatic lipase and synthesis of (S)-2-tetrahydrofuroic acid by continuous flow catalytic splitting[J]. Bulletin of Fermentation Science and Technology, 2023, 52(3): 131-137(in Chinese). [51] 孙周权. 多孔纤维素-壳聚糖微球载体的制备及其应用研究[D]. 上海: 东华大学, 2022.SUN Zhouquan. Preparation and application of porous cellulose-chitosan microsphere carrier[D]. Shanghai: Donghua University, 2022(in Chinese). [52] 张锋. 纳米纤维素基固载材料制备及固定漆酶性能研究[D]. 哈尔滨: 东北林业大学, 2022.ZHANG Feng. Preparation of nanocellulose-based immobilized materials and study on the performance of its immobilized laccase[D]. Haerbin: Northeast Forestry University, 2022(in Chinese). [53] NEZHAD M K, AGHAEI H. Tosylated cloisite as a new heterofunctional carrier for covalent immobilization of lipase and its utilization for production of biodiesel from waste frying oil[J]. Renewable Energy, 2021, 164: 876-888. doi: 10.1016/j.renene.2020.09.117 [54] 王舒舒, 王俞涵, 杨旭, 等. 磁性壳聚糖纳米复合材料固定化褶皱假丝酵母脂肪酶催化合成木质甾醇酯[J]. 精细化工, 2023, 40(1): 124-129.WANG Shushu, WANG Yuhan, YANG Xu, et al. Synthesis of lignosterol esters catalyzed by Candida rugosa lipase immobilized on magnetic nanocomposites[J]. Fine Chemicals, 2023, 40(1): 124-129(in Chinese). [55] 苏丽访, 王翠娥, 蔡再生, 等. 聚多巴胺改性自支撑碳纤维固定化酶研究[J]. 国际纺织导报, 2020, 48(8): 32-36+46.SU Lifang, WANG Cuie, CAI Zaisheng, et al. Study on immobilized enzyme of polydopamine modified self-supporting carbon fiber[J]. Melliand China, 2020, 48(8): 32-36+46(in Chinese). [56] 朱衡, 张继福, 张云, 等. 环氧交联剂和氨基载体固定化海洋假丝酵母脂肪酶[J]. 中国生物工程杂志, 2020, 40(5): 57-68.ZHU Heng, ZHANG Jifu, ZHANG Yun, et al. Immobilization of marine candida lipase using novel epoxy cross-linker and amino carrier[J] China Biotechnology, 2020, 40(5): 57-68(in Chinese). [57] BINHAYEEDING N, KLOMKLAO S, Prasertsan P, et al. Improvement of biodiesel production using waste cooking oil and applying single and mixed immobilised lipases on polyhydroxyalkanoate[J]. Renewable Energy, 2020, 162: 1819-1827. doi: 10.1016/j.renene.2020.10.009 [58] 苗长林, 吕鹏梅, 李志兵, 等. 生物质结渣固体碱催化剂制备生物柴油[J]. 太阳能学报, 2022, 43(2): 33-39.MIAO Changlin, LV Pengmei, LI Zhibing, et al. Preparation of biodiesel using biomass slagging as solid base catalyst[J]. Acta Energiae Solaris Sinica, 2022, 43(2): 33-39(in Chinese). [59] 黄振旭, 裴先茹, 李雨晴, 等. 大豆油制备生物柴油K2CO3/SiO2固体碱催化剂性能研究[J]. 山东化工, 2023, 52(6): 9-12.HUANG Zhenxu, PEI Xianru, LI Yuqing, et al. Performance study on the preparation of biodiesel K2CO3/SiO2 solid alkali catalyst from soybean oil[J]. Shandong Chemical Industry, 2023, 52(6): 9-12(in Chinese). [60] PALUZAR H. Production of high quality biodiesel from sunflower soapstock acid oil as novel feedstock: catalyzed by immobilized pancreatic lipase[J]. Journal of the American Oil Chemists' Society, 2023, 1-15. [61] FAN X, ZHANG P, TENG S, et al. Recent research on lipase immobilization with multipoint covalent treatment by glutaraldehyde[J]. Current Organic Chemistry, 2023, 27(4): 248-259. doi: 10.2174/1385272827666230417084200 [62] 毕艳红. 磁性纳米材料固定化脂肪酶及其催化性能研究[D]. 无锡: 江南大学, 2020.BI Yanhong. Preparation and the catalytic performance of lipase immoblized on magnetic nanoparticles[D]. Wuxi: Jiangnan University, 2020(in Chinese). [63] MULINARI J, AMBROSI A, DE MELLO INNOCENTINI M D, et al. Lipase immobilization on alumina membranes using a traditional and a nature-inspired method for active degradation of oil fouling[J]. Separation and Purification Technology, 2022, 287: 120527. doi: 10.1016/j.seppur.2022.120527 -

点击查看大图

点击查看大图

计量

- 文章访问数: 75

- HTML全文浏览量: 46

- 被引次数: 0

下载:

下载: