Evolution on the microstructure and mechanical properties of the interface of crept SiCf/SiC at intermediate temperatures

-

摘要: 连续碳化硅纤维增强碳化硅复合材料(SiCf/SiC)在中温(500~

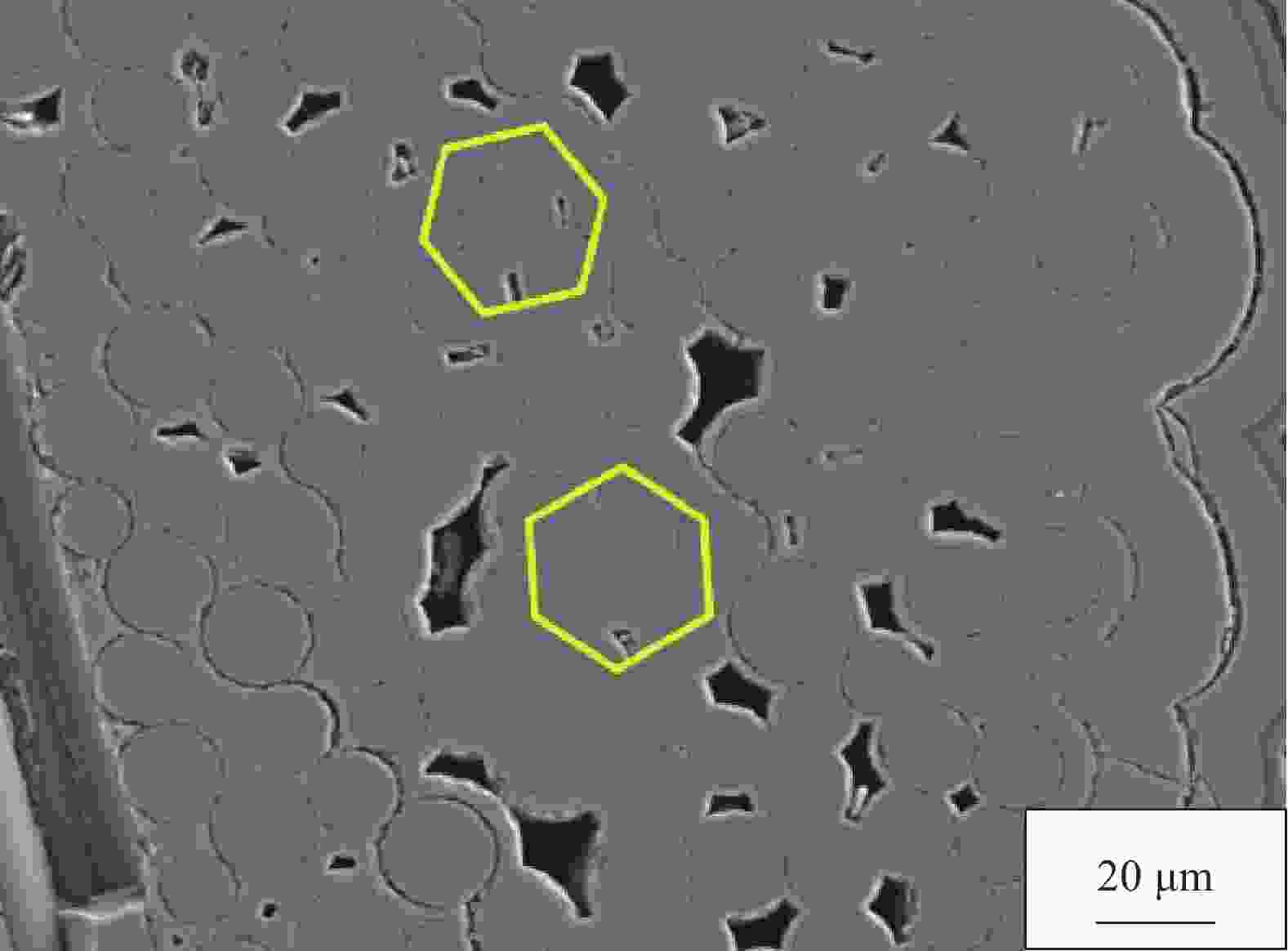

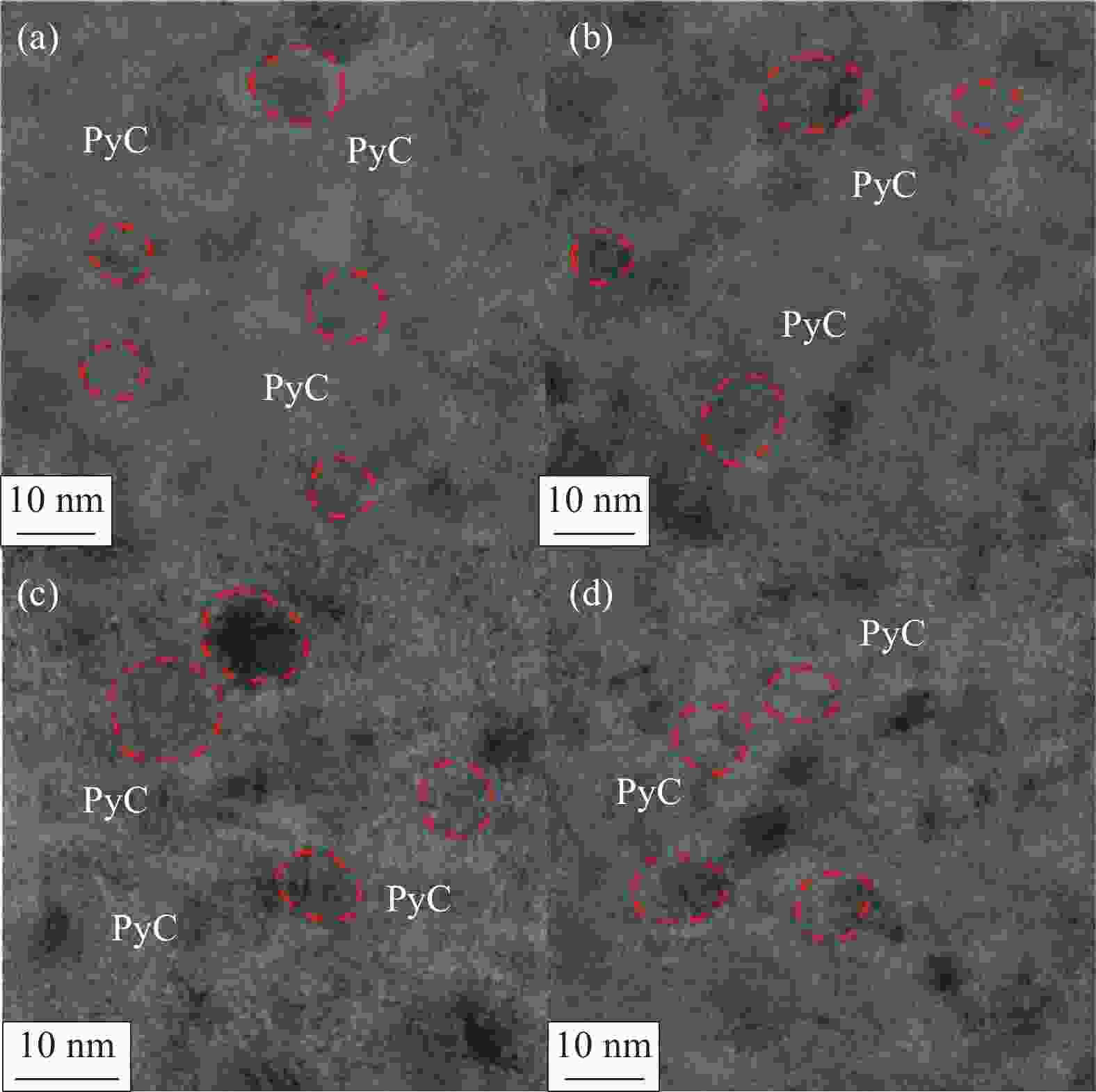

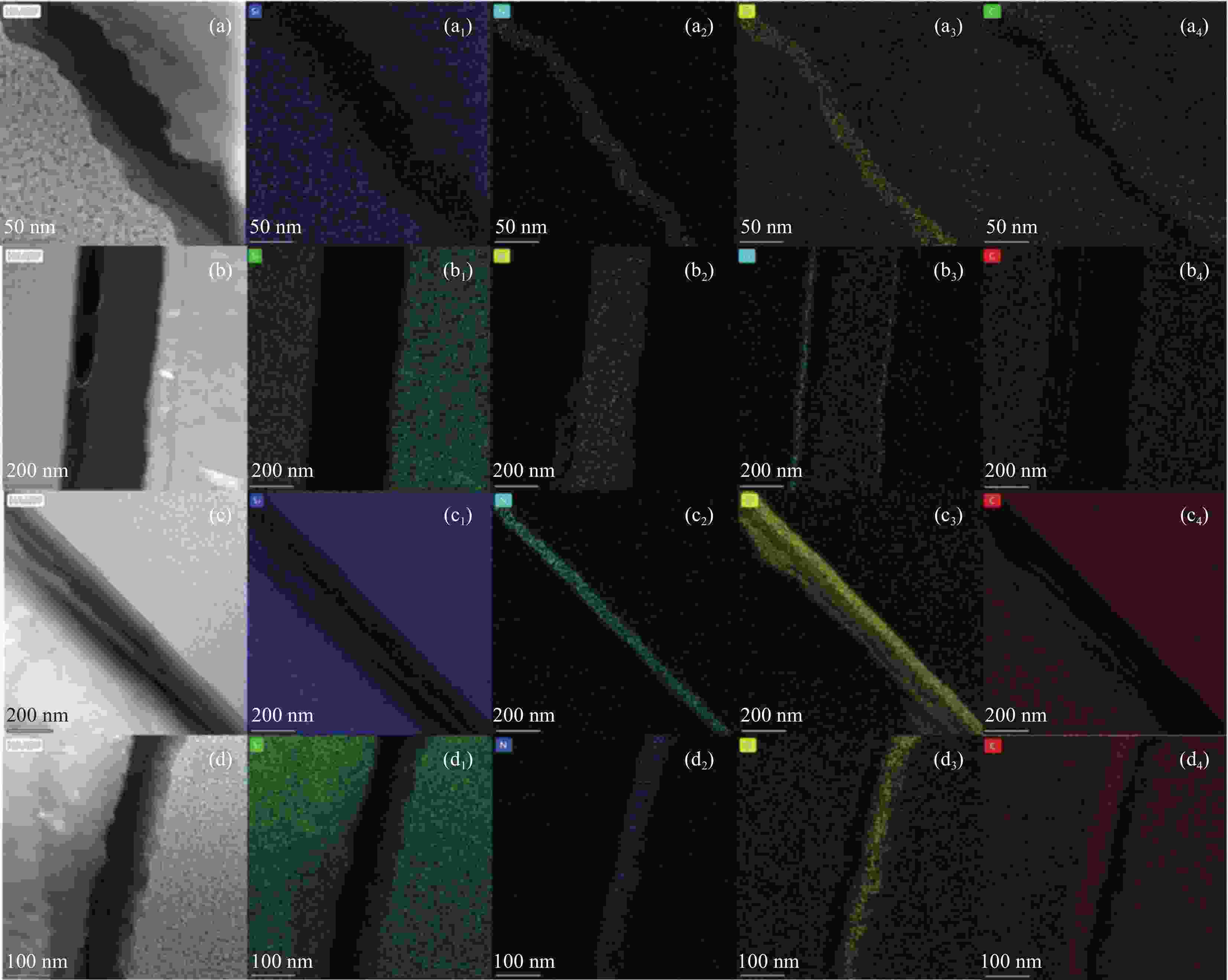

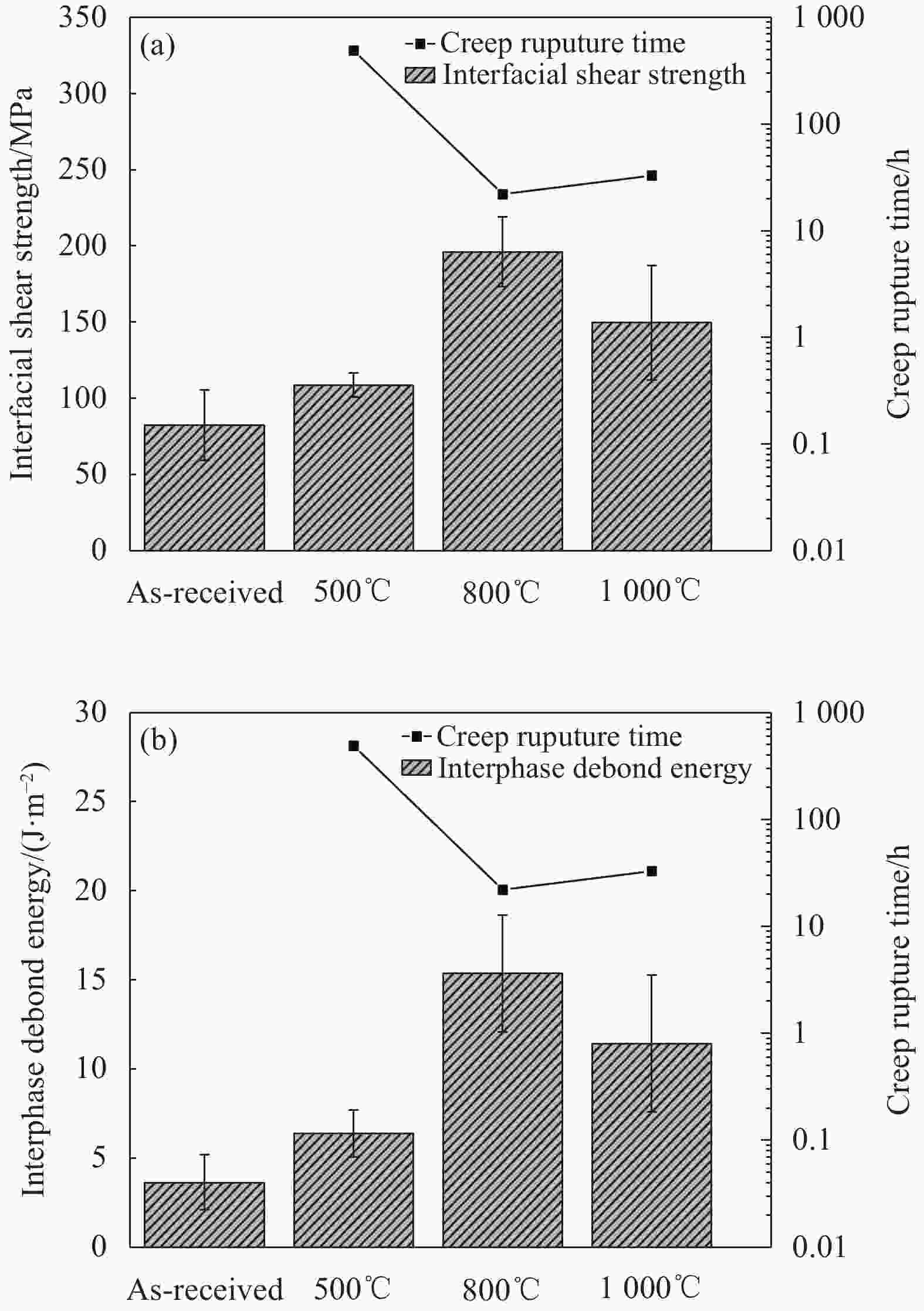

1000 ℃)范围内会发生蠕变断裂时间显著缩短的脆化现象,其机制主要与界面的微观结构和力学性能有关。为此,本文开展了国产二代平纹编织SiCf/SiC (2D-SiCf/SiC) 复合材料在中温范围的蠕变脆化失效机制研究。利用TEM分析了中温下不同蠕变条件后2D-SiCf/SiC的界面微观结构,进一步利用微纳力学测试技术表征界面力学性能。结果表明:纤维/界面侧在500 ℃下出现多孔隙的富碳层;800 ℃时,界面出现自发氧化,同时SiO2填充了部分BN界面因氧化消耗后产生的空隙。当温度进一步升高至1000 ℃后,氧元素主要分布于纤维/基体一侧。2D-SiCf/SiC的中温脆化机制与界面结合状态高度相关,蠕变断裂时间与界面结合的强弱呈现明显的反比关系,表明过强的界面结合不能发挥界面脱粘、纤维拔出等相关增韧机制,此时裂纹直接贯穿纤维,显著缩短其中温蠕变断裂时间。Abstract: The creep rupture time of continuous silicon carbide fiber reinforced silicon carbide composite (SiCf/SiC) is shortened at intermediate temperature (500~1000 ℃) inevitably, known as creep embrittlement. The mechanism primarily depends on the microstructure and the interfacial bonding state of the fiber/matrix interface. Therefore, present work investigated the creep embrittlement mechanisms of the domestic 2nd-generation plain woven SiCf/SiC (2D-SiCf/SiC) under intermediate temperature. The interfacial microstructure evolution and mechanical properties was characterized by transmission electron microscopy (TEM) and micro-mechanical testing techniques respectively. The results indicate that a carbon-rich layer with pores appear on the fiber/interface side at 500℃. Spontaneous oxidation of the interface occurs at 800℃, while a thin SiO2 layer fills the gap generated at the BN in- terface due to oxidation. When the temperature increases to1000 ℃, oxygen elements are mainly distributed on the fiber/matrix side. The intermediate temperature embrittlement mechanism of 2D-SiCf/SiC is closely associated with interface bonding state. The creep rupture time shows a clear inverse relationship with the interface bonding state, indicating that excessively strong interface bonding hinders related toughening mechanisms such as interface debonding and fiber pullout. Consequently, cracks directly penetrate the fiber, shortening the creep rupture time significantly.-

Key words:

- SiCf/SiC /

- intermediate temperature embrittlement /

- push-in /

- strong interfacial bonding /

- creep /

- failure mechanism

-

图 4 国产二代2D-SiCf/SiC复合材料蠕变前后界面区域的明场TEM像和元素分布(Si、N、O、C):(a)原始试样;(b) 500℃/120 MPa;(c) 800℃/120 MPa;(d)

1000 ℃/120 MPaFigure 4. Bright fields TEM images and element distribution of interfacial regions of the domestic 2nd-2D-SiCf/SiC before and after intermediate temperature creep (Si、N、O、C): (a) As-received; (b) 500℃/120 MPa; (c) 800℃/120 MPa; (d)

1000 ℃/120 MPa表 1 本文研究试样的相关信息

Table 1. Information about samples used in this study

Conditions Rupture

time/hCreep

Rate/s−1Creep

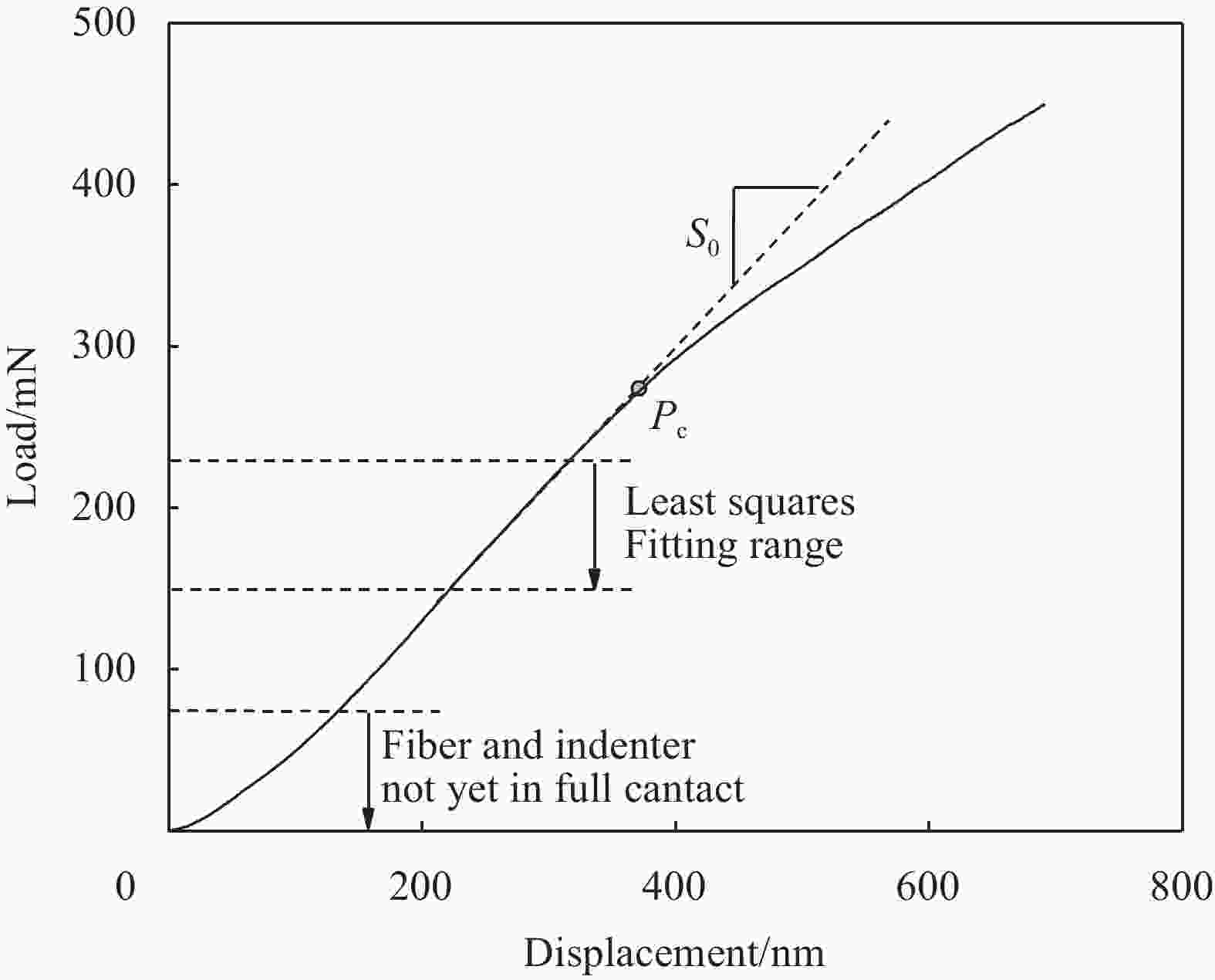

Strain/%500℃/120 MPa 490 7.1×10−10 0.37 800℃/120 MPa 22 5.4×10−9 0.19 1000 ℃/120 MPa33 1.7×10−8 0.39 表 2 基于纤维推入获得的国产二代2D-SiCf/SiC复合材料的界面力学性能

Table 2. The interfacial mechanical properties of domestic 2nd-2D-SiCf/SiC generated from push-in test

Conditions Pc/mN S0/(N·mm−1) IFSS/MPa Gi/(J·m−2) As-received 168±35 614±61 97±27 5.0±2.1 500℃/120 MPa 226±24 829±51 128±9 8.8±1.8 800℃/120 MPa 350±38 962±60 231±27 21.2±4.5 1000 ℃/120 MPa300±52 848±73 180±44 15.8±5.3 Notes:Pc is the critical load before interface debonding; S0 is the slope of the second stage; IFSS is the interfacial shear strength; Gi is the interphase debond energy. -

[1] 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨[J]. 复合材料学报, 2007, (2): 1-6. doi: 10.3321/j.issn:1000-3851.2007.02.001ZHANG Litong, CHENG Laifei. Discussion on strategies of sustainable development of conti nuous fiber reinforced ceramic matrix composites[J]. Acta Materiae Compositae Sinica, 2007, (2): 1-6 (in Chinese). doi: 10.3321/j.issn:1000-3851.2007.02.001 [2] 李世波, 徐永东, 张立同. 碳化硅纤维增强陶瓷基复合材料的研究进展[J]. 材料导报, 2001, (1): 45-49. doi: 10.3321/j.issn:1005-023X.2001.01.016LI Shibo, XU Yongdong, ZHANG Litong. Study on silicon carbide fibers reinforced ceramic-matrix composites[J]. Materials Review, 2001, (1): 45-49(in Chinese). doi: 10.3321/j.issn:1005-023X.2001.01.016 [3] 丁冬海, 周万城, 张标, 等. 连续SiC纤维增韧SiC基体复合材料研究进展[J]. 硅酸盐通报, 2011, 30(2): 356-361.DING Donghai, ZHOU Wancheng, ZAHNG Biao, et al. Research progress of SiC composite toughened with continuous SiCf[J]. Bulletion of the Chinese Ceramic Society, 2011, 30(2): 356-361(in Chinese). [4] POERSCHKEe D L, ROSSOL M N, ZOK F W. Intermediate temperature oxidative strength degradation of a SiC/SiNC omposite with a polymer-derived matrix[J]. Journal of the American Ceramic Society, 2017, 100(4): 1606-1617. doi: 10.1111/jace.14741 [5] DIAZ O G, MARQUARDT K, HARRIS S, et al. Degradation mechanisms of SiC/BN/SiC after low temperature humidity exposure[J]. Journal of the European Ceramic Society, 2020, 40(12): 3863-3874. doi: 10.1016/j.jeurceramsoc.2020.05.007 [6] MALL S. Effects of moisture on fatigue behavior of SiC/SiC composite at elevated temperature[J]. Materials Science and Engineering: A, 2005, 412(1-2): 165-170. doi: 10.1016/j.msea.2005.08.040 [7] FORIO P, LAVAIRE F, LAMON J. Delayed failure at intermediate temperatures (600°-700°C) in air in silicon carbide multifilament tows[J]. Journal of the American Ceramic Society, 2004, 87(5): 888-893. doi: 10.1111/j.1551-2916.2004.00888.x [8] HEREDIA F E, MCNULTY J C, ZOK F W, et al. Oxidation embrittlement probe for ceramic-matrix composites[J]. Journal of the American Ceramic Society, 1995, 78(8): 2097-2100. doi: 10.1111/j.1151-2916.1995.tb08621.x [9] LARA-CURZIO E. Stress rupture of Nicalon/SiC continuous fiber ceramic composites in air at 950°C[J]. Journal of the American Ceramic Society, 1997, 80(12): 3268-3272. doi: 10.1111/j.1151-2916.1997.tb03266.x [10] MORSCHER G N, HURST J, BREWER D. Intermediate temperature stress rupture of a woven Hi-Nicalon, BN-interphase, SiC-matrix composite in air[J]. Journal of the American Ceramic Society, 2000, 83(6): 1441-1449. doi: 10.1111/j.1151-2916.2000.tb01408.x [11] 朱思雨, 张巧君, 洪智亮, 等. 平纹编织SiCf/SiC复合材料的中温蠕变断裂时间及损伤机制[J]. 复合材料学报, 2023, 40(1): 464-471.ZHU Siyu, ZHANG Qiaojun, HONG Zhiliang, et al. Creep rupture time and damage mechanisms of a plain woven SiCf/SiC composite at intermediate temperature[J]. Acta Materiae Compositae Sinica, 2023, 40(1): 464-471(in Chinese). [12] JM MOLINA-ALDAREGUÍA, M RODRÍGUEZ, C GONZÁLEZ, et al. An experimental and numerical study of the influence of local effects on the application of the fibre push-in test[J]. Experimental Neurology, 2011, 91(7-9): 1293-1307. [13] RODRÍGUEZ M, MOLINA-ALDAREGUÍA J M, GONZÁLEZ C, et al. A methodology to measure the interface shear strength by means of the fiber push-in test[J]. Composites Science and Technology, 2012, 72(15): 1924-1932. doi: 10.1016/j.compscitech.2012.08.011 [14] 丁金雪. 基于push-in测试研究陶瓷基复合材料界面失效行为 [D]. 西安: 西北工业大学, 2020.DINg Jinxue. The interface failure behavior of ceramic matrix composites was studied based on push-in test. [D]. Xi’an: Northwestern Polytechnical University, 2020(in Chinese). [15] KHARRAT M, CHATEAUMINOIS A, CARPENTIER L, et al. On the interfacial behaviour of a glass/epoxy composite during a micro-indentation test: assessment of interfacial shear strength using reduced indentation curves[J]. Composites. Part A, Applied science and manufacturing, 1997, 28(1): 39-46. doi: 10.1016/S1359-835X(96)00092-9 [16] LIU Z L , YUE J L , FU Z Y , et al. Microstructure and mechanical performance of SiCf/BN/SiC mini-composites oxidized at elevated temperature from ambient temperature to 1500°C in air[J]. Journal of the European Ceramic Society, 2020, 40(8): 2821-2827 [17] BODET R, BOURRAT X, LAMON J, et al. Tensile creep behaviour of a silicon carbide-based fibre with a low oxygen content[J]. Journal of materials science, 1995, 30(3): 661-677. doi: 10.1007/BF00356326 [18] 王西, 王克杰, 柏辉, 等. 化学气相渗透2D-SiCf/SiC复合材料的蠕变性能及损伤机制[J]. 无机材料学报, 2020, 35(7): 817-821.WANG Xi, WANG Kejie, BAI Hui, et al. Creep Properties and Damage Mechanisms of 2D-SiCf/SiC Composites Prepared by CVI[J]. Journal of Inorganic Materials, 2020, 35(7): 817-821(in Chinese). [19] 荆开开, 管皞阳, 朱思雨, 等. Cansas-II SiCf/SiC复合材料的高温拉伸蠕变行为[J]. 无机材料学报, 2023, 38(2): 177-183. doi: 10.15541/jim20220441JING Kaikai, GUAN Haoyang, ZHU Siyu, et al. Tensile creep behavior of Cansas-II SiCf/SiC composites at high temperatures[J]. Journal of Inorganic Materials, 2023, 38(2): 177-183(in Chinese). doi: 10.15541/jim20220441 [20] MORSCHER G N. Tensile stress rupture of SiCf/SiCm minicomposites with carbon and boron nitride interphases at elevated temperatures in air[J]. Journal of the American Ceramic Society, 1997, 80(8): 2029-2042. doi: 10.1111/j.1151-2916.1997.tb03087.x [21] JACOBSON N S, MORSCHER G N, BRYANT t D R, et al. High-temperature oxidation of boron nitride: II, Boron nitride layers in composites[J]. Journal of the American Ceramic Society, 1999, 6(82): 1473-1482. [22] JACOBSON N S, MYERS D L. Active oxidation of SiC[J]. Oxidation of Metals, 2011, 75(1-2): 1-25. doi: 10.1007/s11085-010-9216-4 -

点击查看大图

点击查看大图

计量

- 文章访问数: 51

- HTML全文浏览量: 17

- 被引次数: 0

下载:

下载: