| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion[J]. Nature Materials, 2016, 15(8): 804-809. doi: 10.1038/nmat4687

|

| [2] |

张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展[J]. 航空制造技术, 2003, (1): 24-32. doi: 10.3969/j.issn.1671-833X.2003.01.009ZHANG Litong, CHENG Laifei, XU Yong-dong. Progress in research work of new CMC-SiC[J]. Aerospace Manufacturing Technology, 2003, (1): 24-32 (in Chinese). doi: 10.3969/j.issn.1671-833X.2003.01.009

|

| [3] |

冯志海, 李俊宁, 田跃龙, 等. 航天先进复合材料研究进展[J]. 复合材料学报, 2022, 39(9): 4187-4195.FENG Zhihai, LI Junning, TIAN Yuelong, et al. Research progress of advanced composite materials for aerospace applications[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4187-4195(in Chinese).

|

| [4] |

KRENKEL W, BERNDT F. C/C–SiC composites for space applications and advanced friction systems[J]. Materials Science and Engineering:A, 2005, 412(1): 177-81.

|

| [5] |

杨成鹏, 矫桂琼, 王波, 等. 2D-C/SiC复合材料的拉伸损伤研究[J]. 航空材料学报, 2010, 30(6): 87-92.YANG Chengpeng, JIE Guiqiong, WANG Bo, et al. Tensile damage behavior of 2D-C/SiC composite[J]. Journal of aerospace materi-als, 2010, 30(6): 87-92(in Chinese).

|

| [6] |

常岩军, 矫桂琼, 陶永强, 等. 2.5D-C/SiC复合材料的拉伸损伤研究[J]. 无机材料学报, 2008, (3): 509-14.CHANG Yanjun, JIE Guiqiong, TAO Yongqiang, et al. Damage behavior of 2.5-C/SiC composite under tensile loading[J]. Journal of Inorganic Materials, 2008, (3): 509-14(in Chinese).

|

| [7] |

ZHANG D, HAYHURST D R. Stress–strain and fracture behaviour of 0°/90° and plain weave ceramic matrix composites from tow multi-axial properties[J]. International Journal of Solids and Structures, 2010, 47(21): 2958-69. doi: 10.1016/j.ijsolstr.2010.06.023

|

| [8] |

RAO M P, PANTIUK M, CHARALAMBIDES P G. Modeling the geometry of satin weave fabric composites[J]. Journal of Composite Materials, 2008, 43(1): 19-56.

|

| [9] |

ZHANG D, HAYHURST D R. Prediction of stress–strain and fracture behaviour of an 8-Harness satin weave ceramic matrix composite[J]. International Journal of Solids and Struc-tures, 2014, 51(21): 3762-75.

|

| [10] |

RAJAN V P, SHAW J H, ROSSOL M N, et al. An elastic–plastic constitutive model for ceram-ic composite laminates[J]. Composites Part A:Applied Science and Manufacturing, 2014, 66: 44-57. doi: 10.1016/j.compositesa.2014.06.013

|

| [11] |

杨强, 解维华, 孟松鹤, 等. 复合材料多尺度分析方法与典型元件拉伸损伤模拟[J]. 复合材料学报, 2015, 32(3): 617-624.YANG Qiang, XIE Weihua, MENG Songhe, et al. Multi-scale analysis method of composites and damage simulation of typical component under tensile load[J]. Acta Materiae Compositae Sinica, 2015, 32(3): 617-624(in Chinese).

|

| [12] |

BALE H, BLACKLOCK M, BEGLEY M R, et al. Characterizing three-dimensional textile ceramic composites using synchrotron X B-ray micro-computed-Tomography[J]. Journal of the American Ceramic Society, 2012, 95(1): 392-402. doi: 10.1111/j.1551-2916.2011.04802.x

|

| [13] |

BALE H A, HABOUB A, MACDOWELL A A, et al. Real-time quantitative imaging of failure events in materials under load at temperatures above 1, 600 °C[J]. Nature Materials, 2013, 12(1): 40-6. doi: 10.1038/nmat3497

|

| [14] |

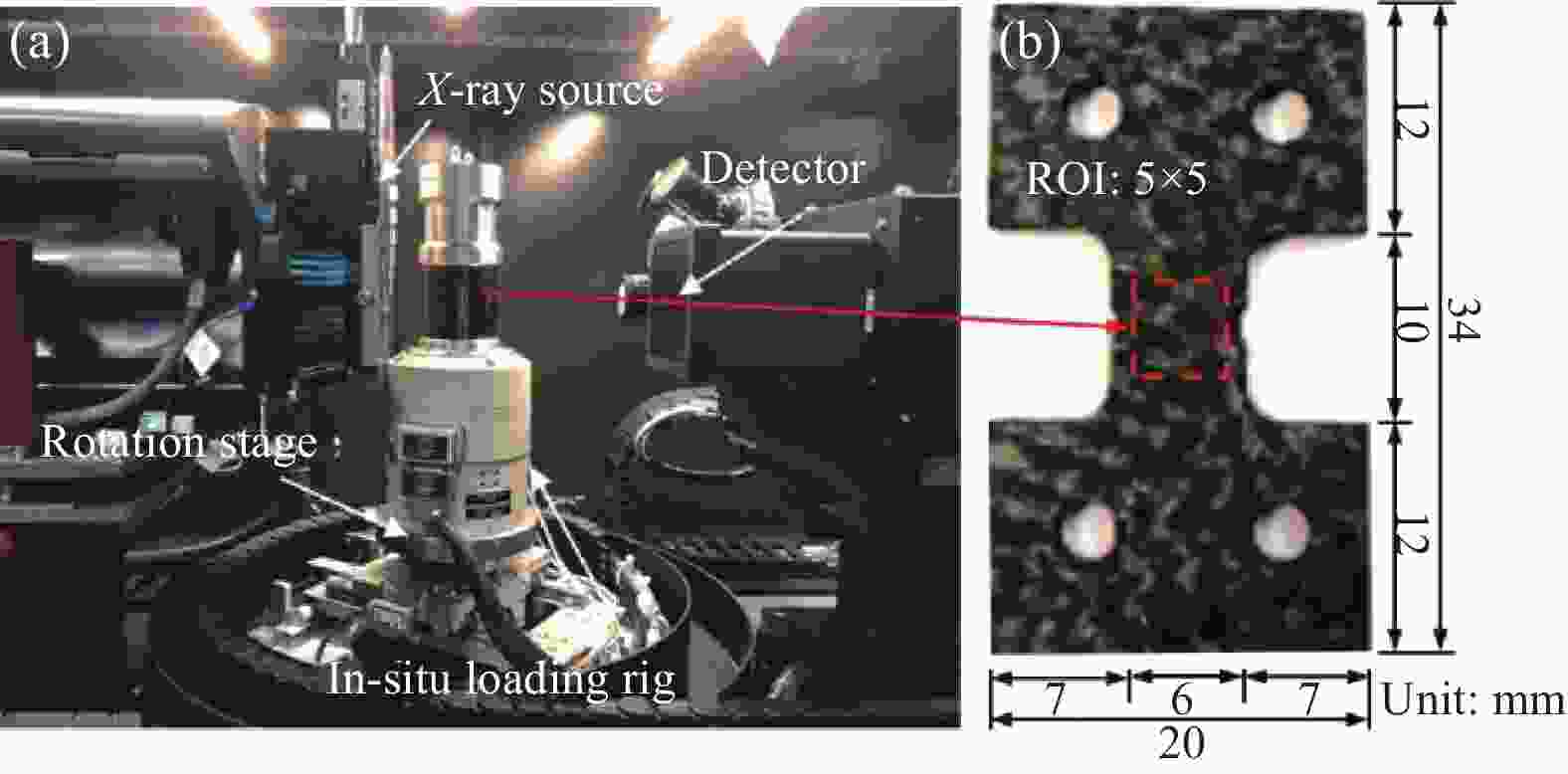

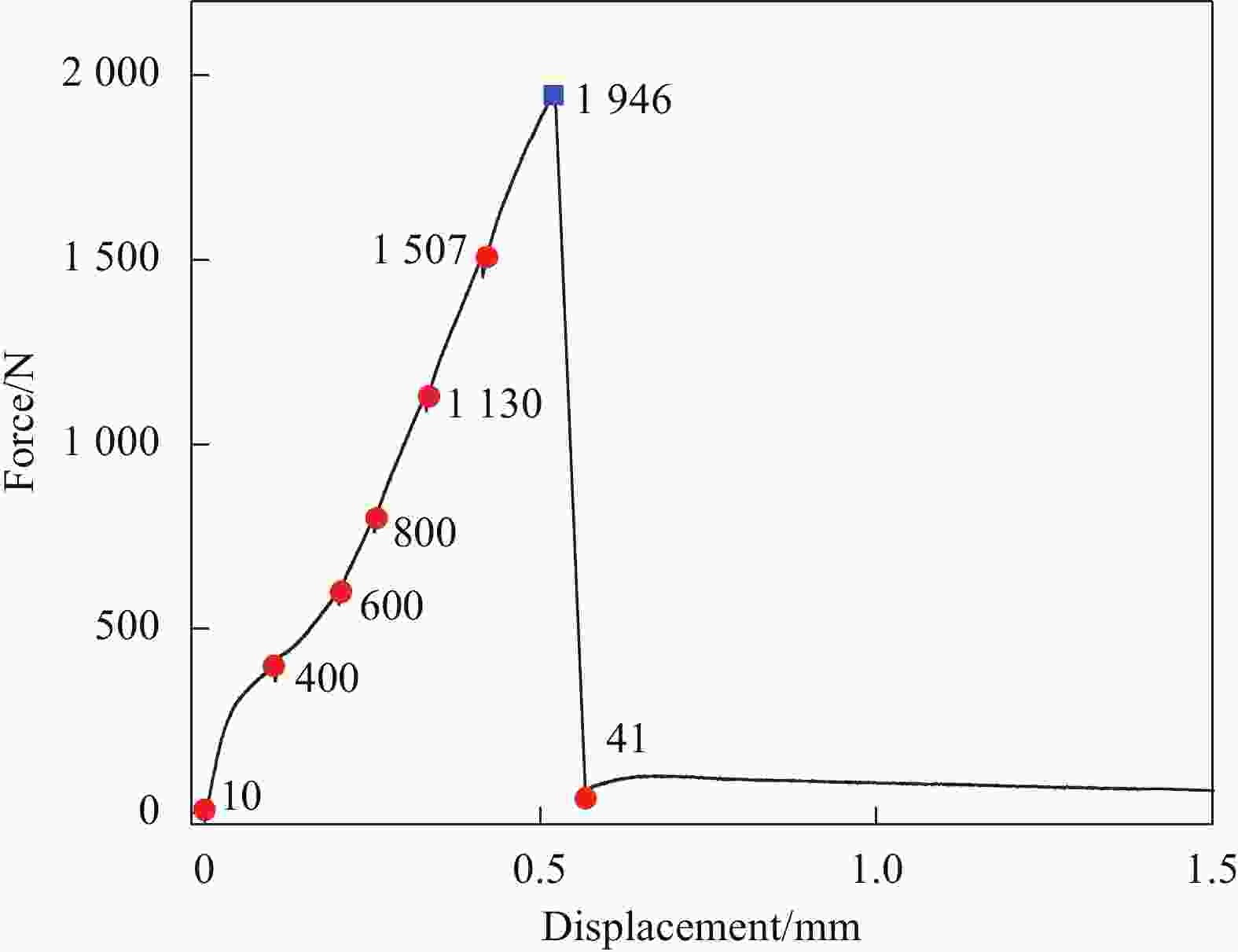

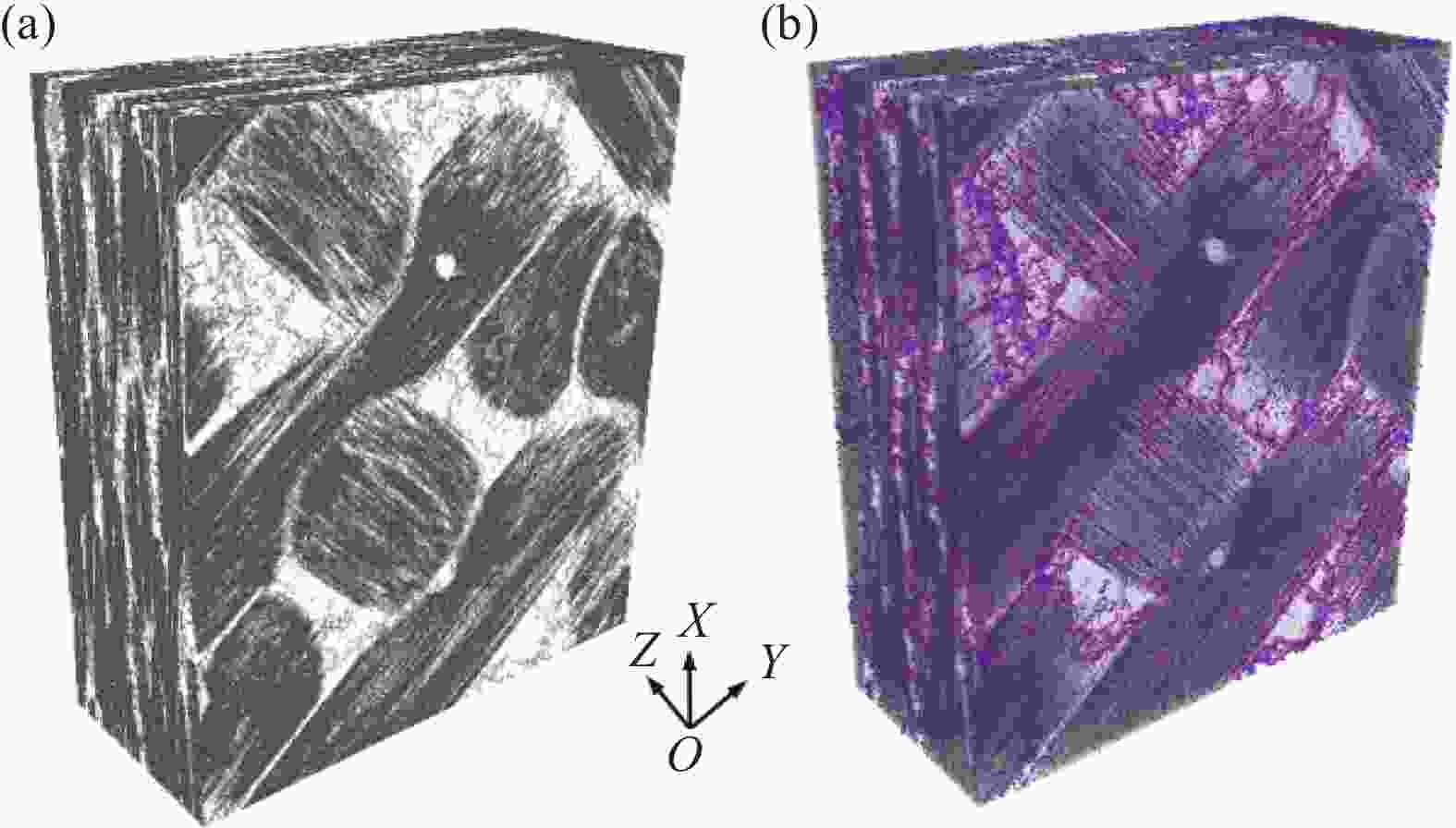

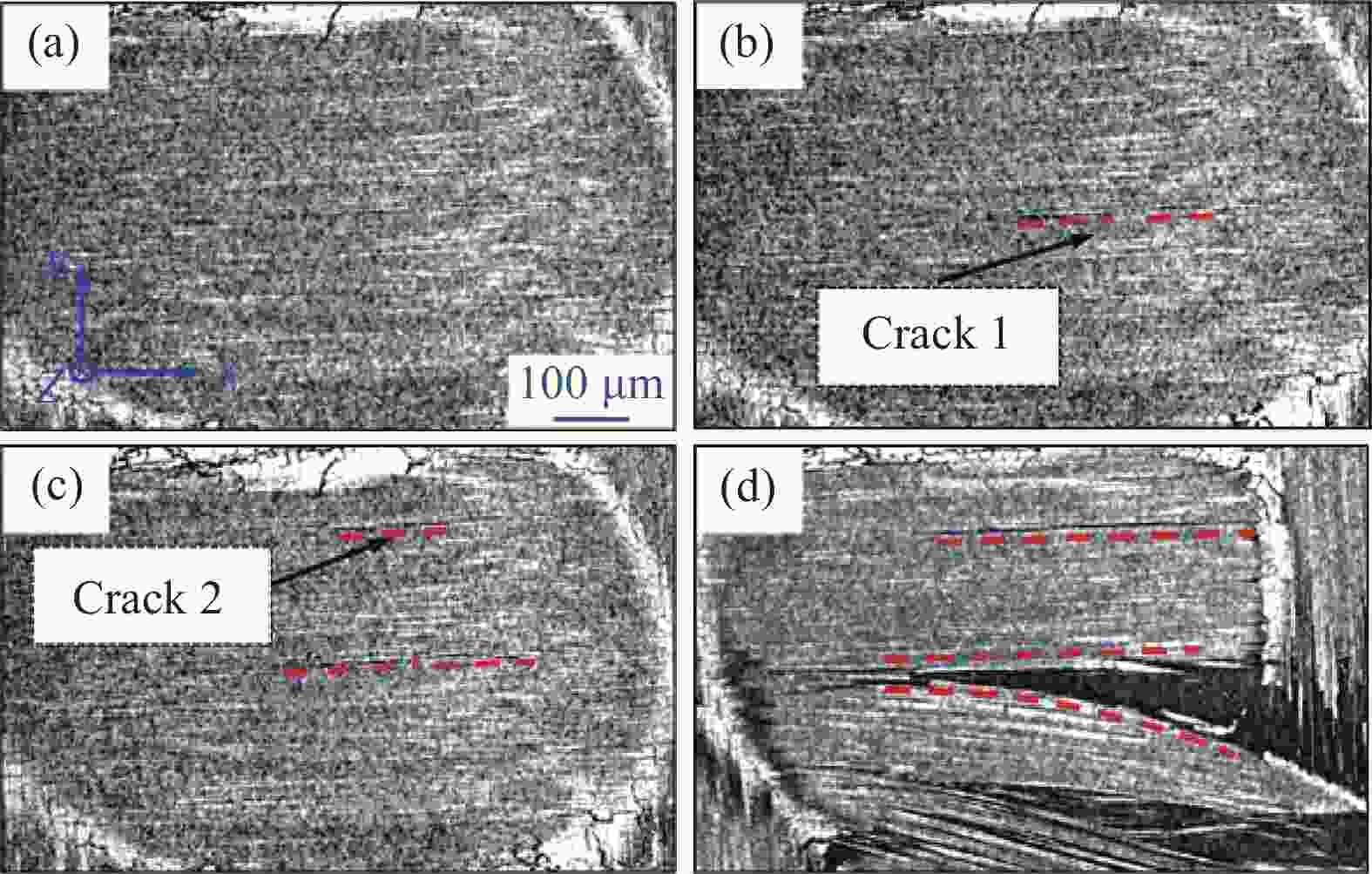

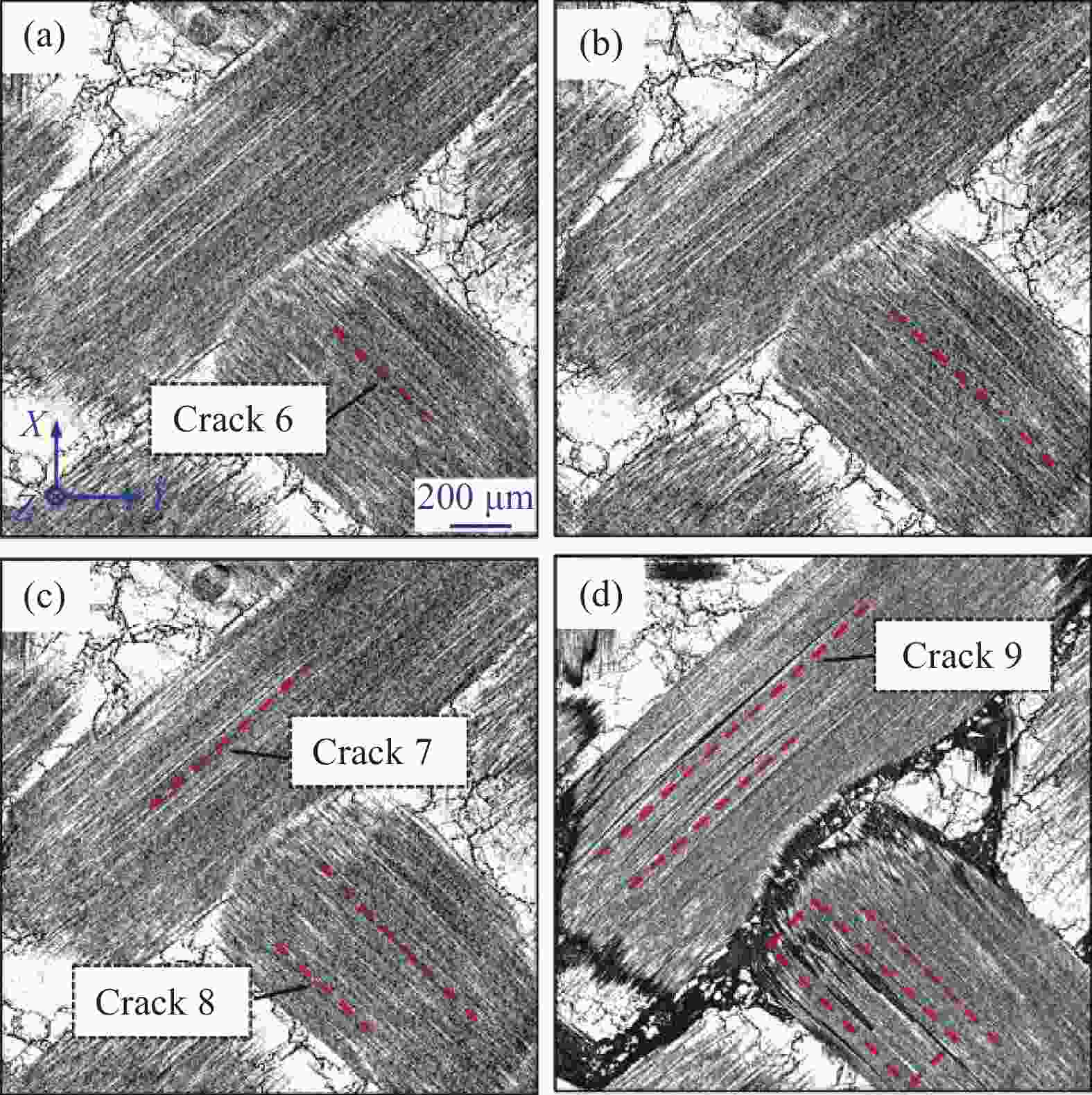

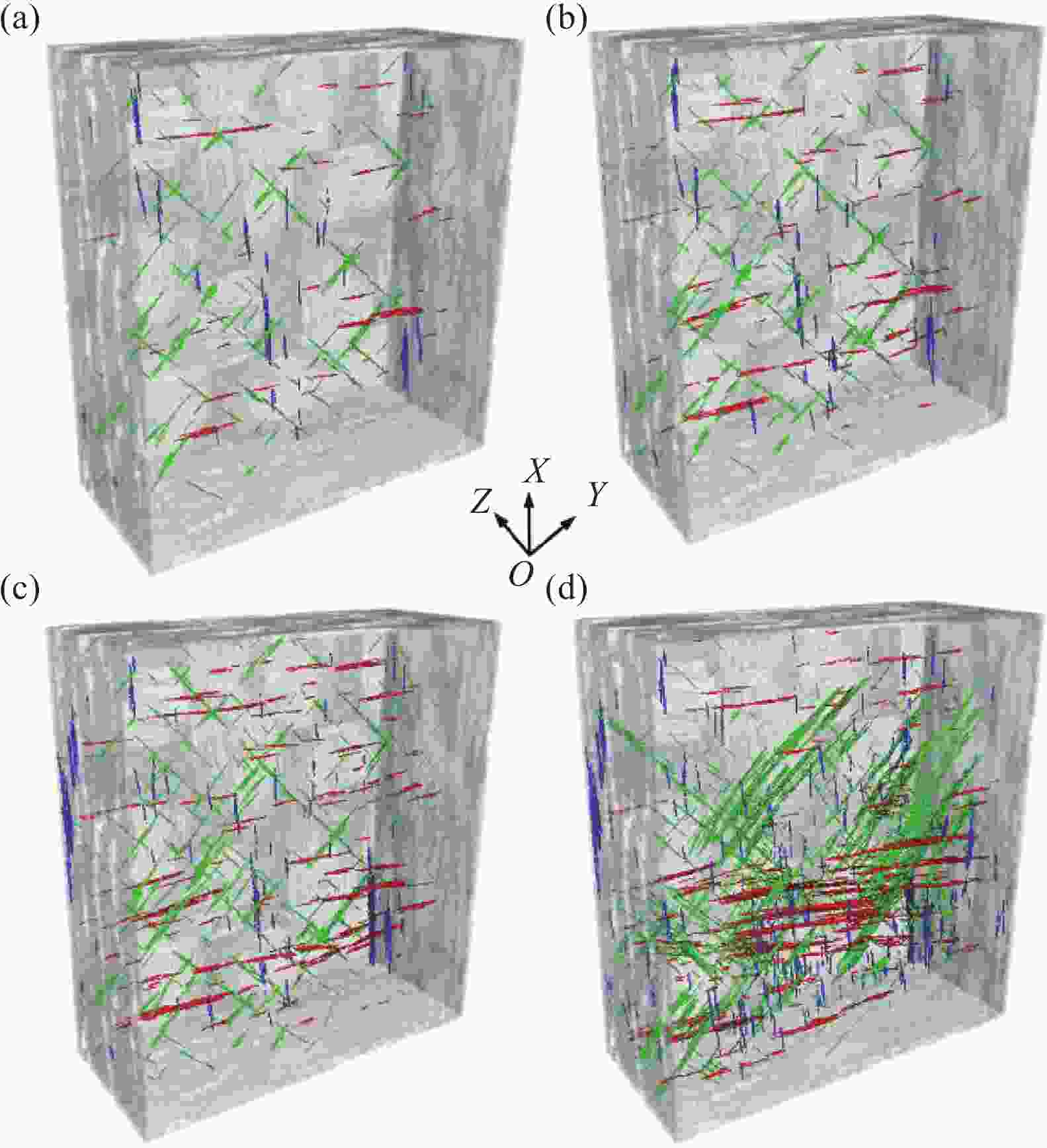

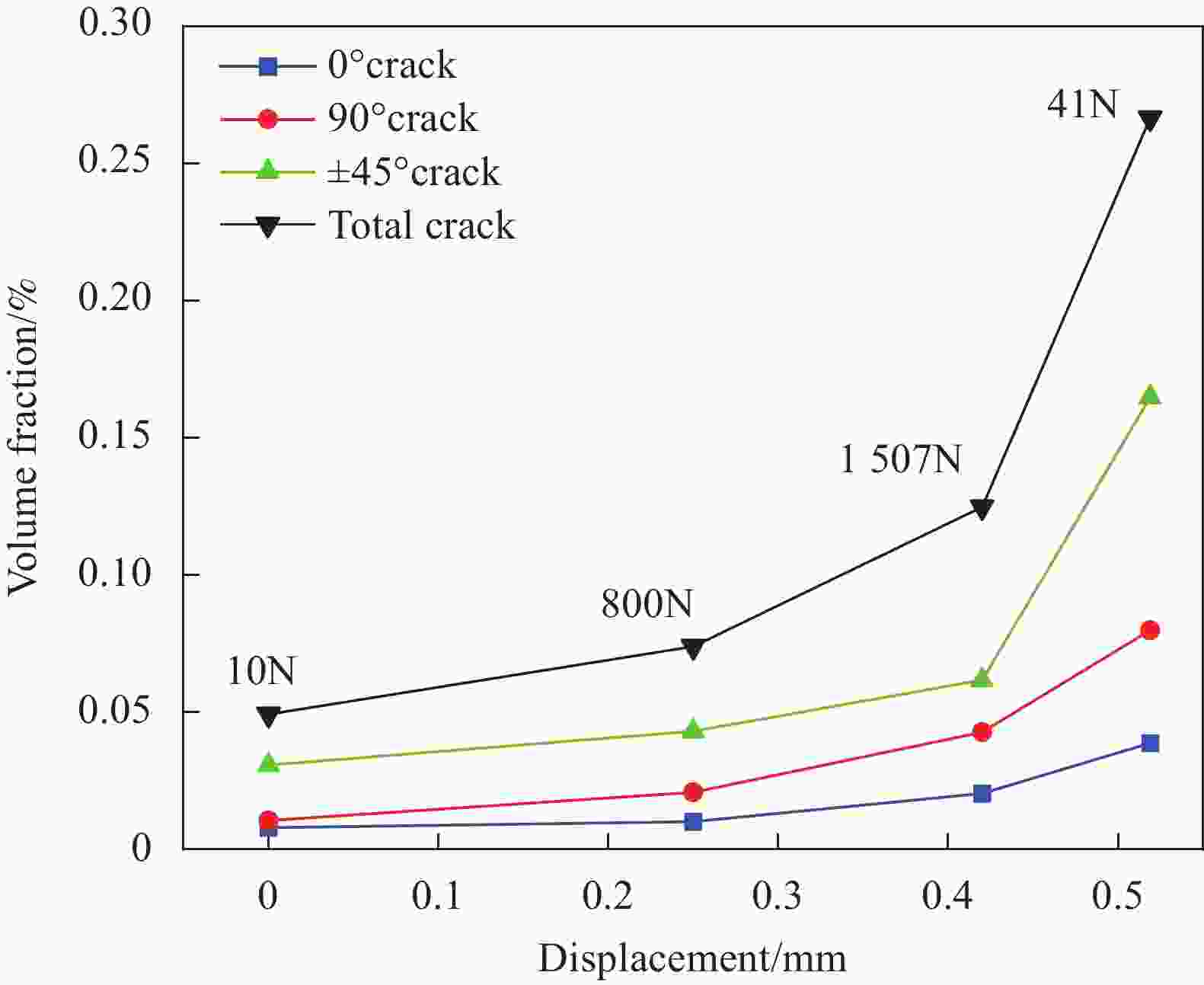

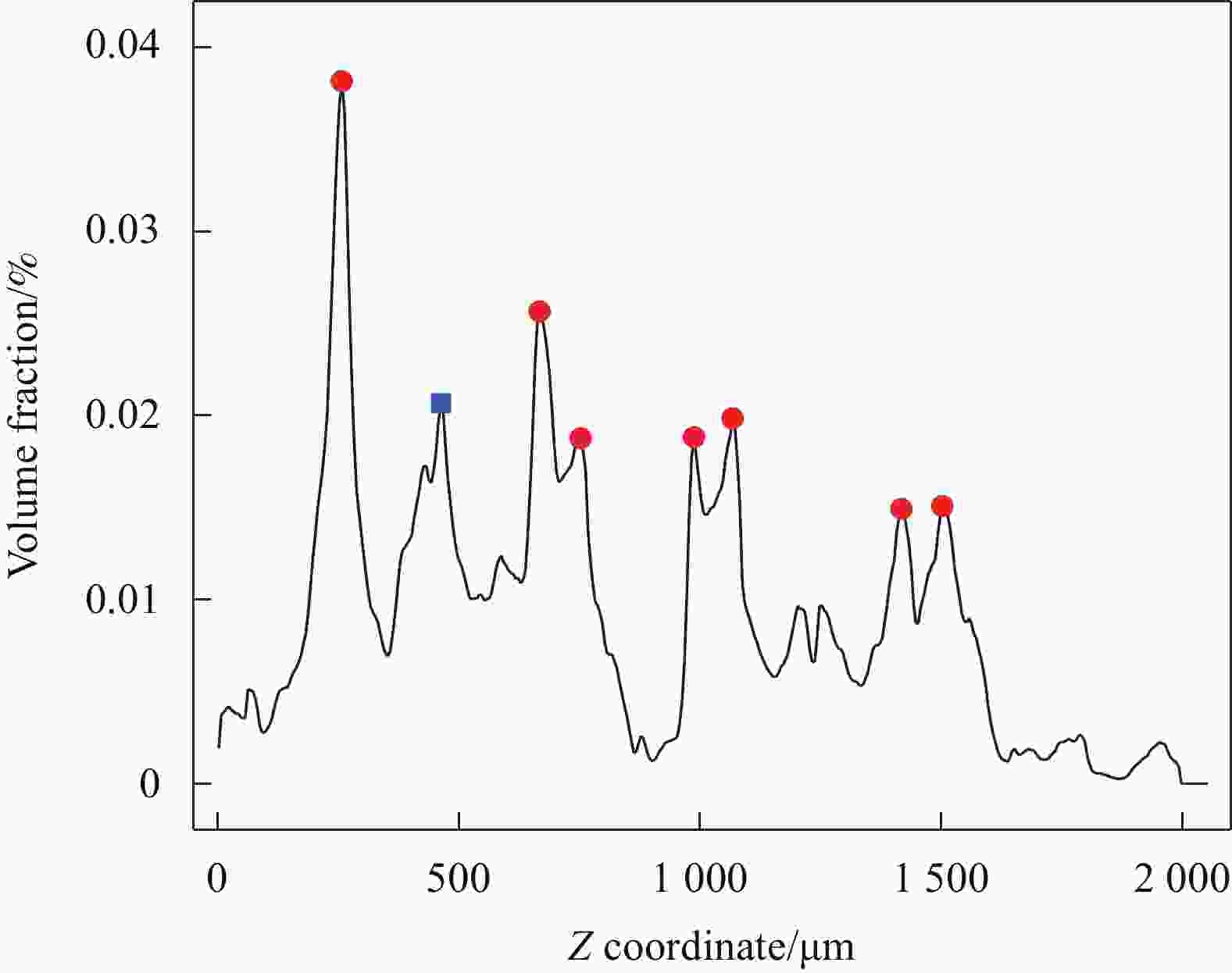

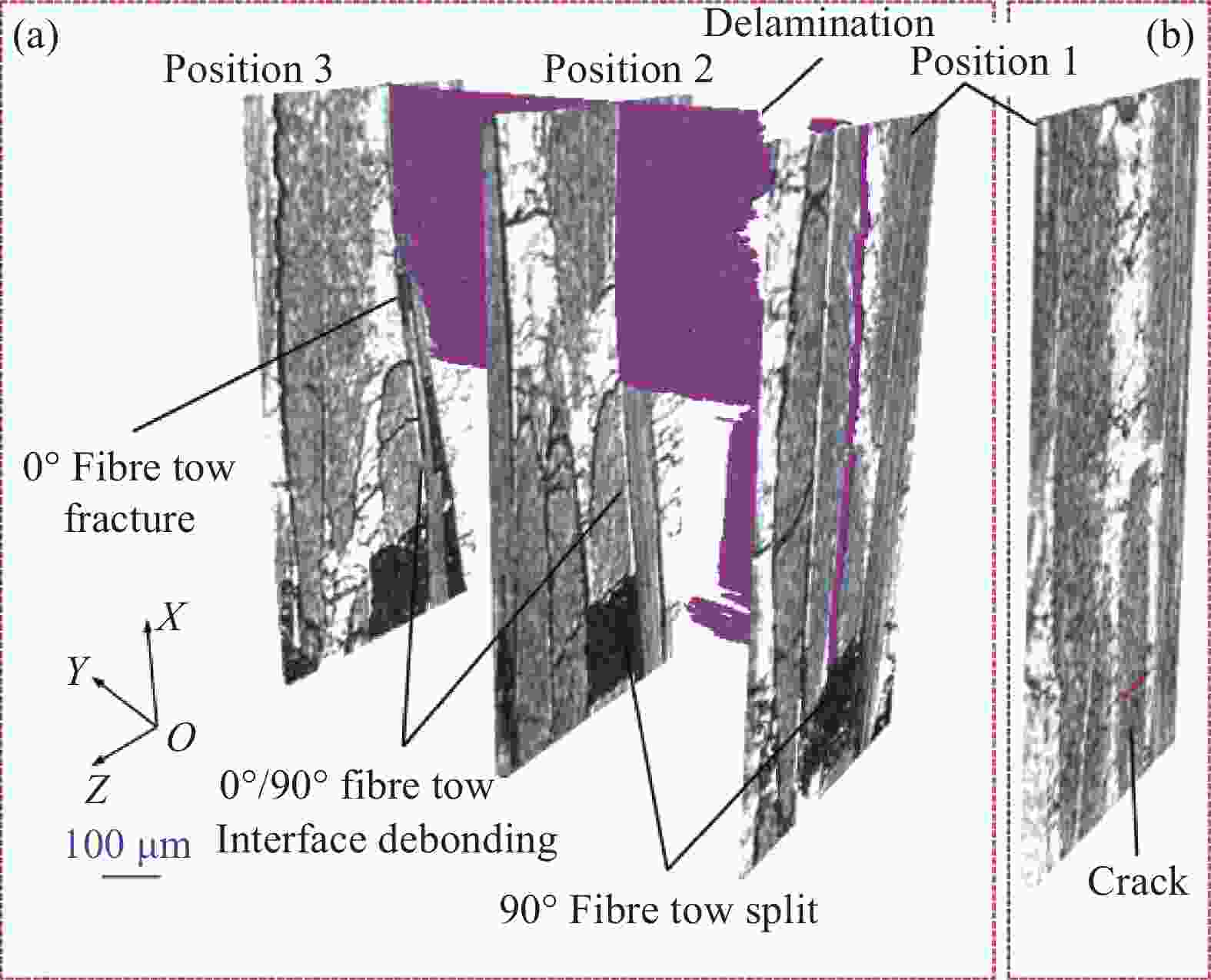

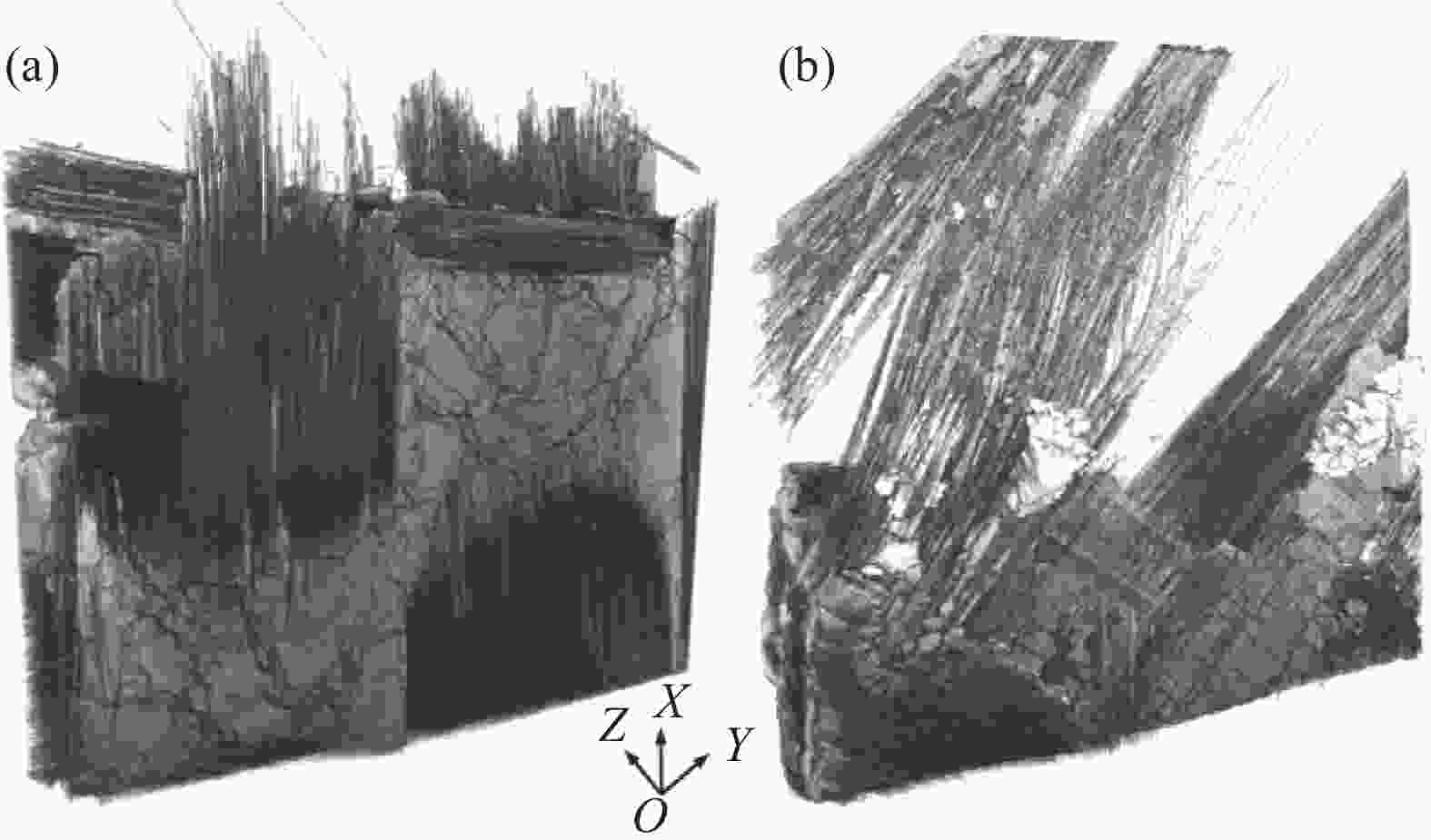

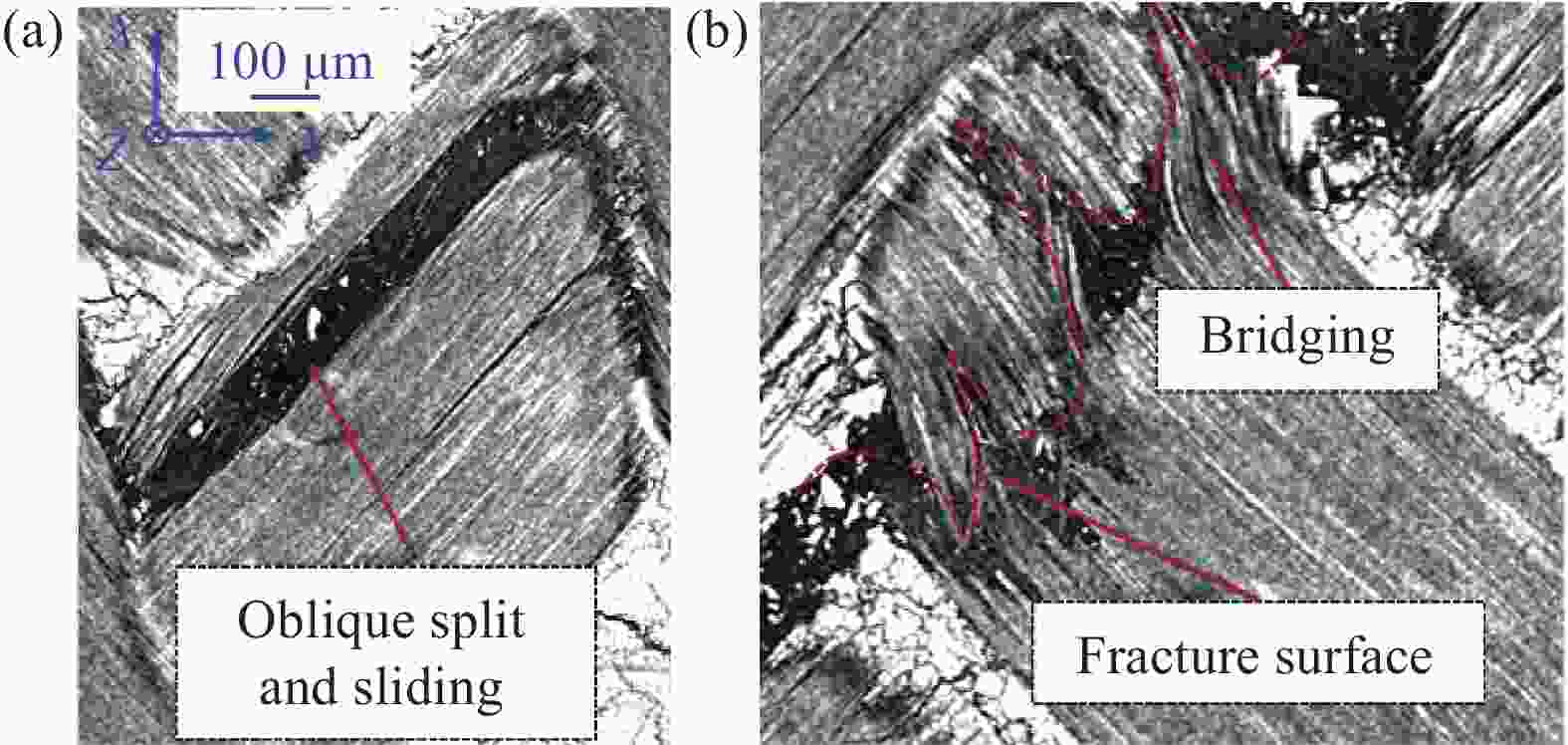

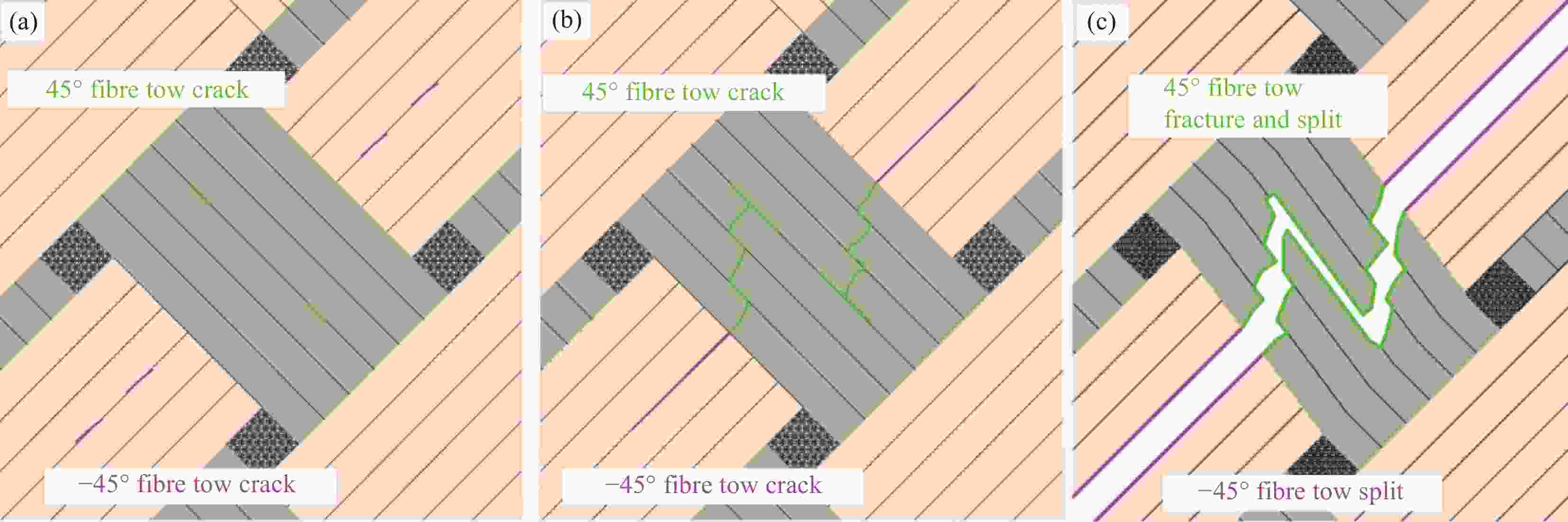

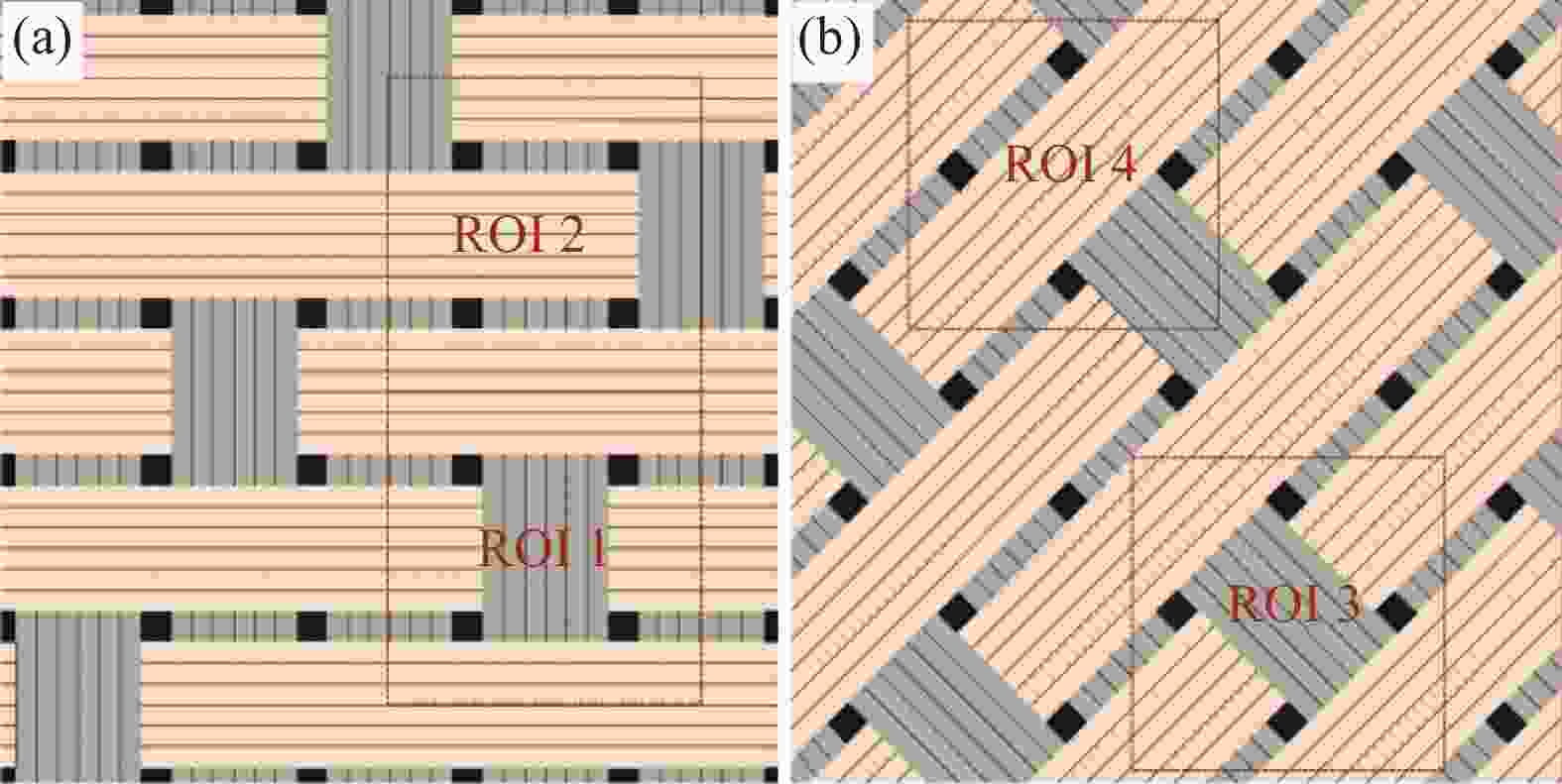

刘海龙, 张大旭, 祁荷音, 等. 基于X射线CT原位试验的平纹SiC/SiC复合材料拉伸损伤演化[J]. 上海交通大学学报, 2020, 54(10): 1074-83.LIU. Hailong, ZHANG Daxu, QI Huoyin, et al. Tensile damage evolution of plain weave SiC/SiC composites based on in-situ X-Ray CT tests[J]. Journal of Shanghai Jiao Tong Univer-sity, 2020, 54(10): 1074-83(in Chinese).

|

| [15] |

CHEN Y-S, SHI Y, CHATEAU C, et al. In situ X-ray tomography characterisation of 3D de-formation of C/C-SiC composites loaded under tension[J]. Composites Part A:Applied Science and Manufacturing, 2021, 145: 106390. doi: 10.1016/j.compositesa.2021.106390

|

| [16] |

AI S, SONG W, CHEN Y. Stress field and damage evolution in C/SiC woven composites: Image-based finite element analysis and in situ X-ray computed tomography tests[J]. Journal of the European Ceramic Society, 2021, 41(4): 2323-34. doi: 10.1016/j.jeurceramsoc.2020.12.026

|

| [17] |

WANG L, YUAN K, LUAN X, et al. 3D char-acterizations of pores and damages in C/SiC composites by using X-Ray computed tomography[J]. Applied Composite Materials, 2019, 26(2): 493-505. doi: 10.1007/s10443-018-9712-2

|

| [18] |

WANG L, ZHANG W, LI H, et al. 3D in-situ characterizations of damage evolution in C/SiC composite under monotonic tensile loading by using X-Ray computed tomography[J]. Applied Composite Materials, 2020, 27(3): 119-30. doi: 10.1007/s10443-020-09796-5

|

| [19] |

NIU G, ZHU R, LEI H, et al. Internal damage evolution investigation of C/SiC composites us-ing in-situ tensile X-ray computed tomography testing and digital volume correlation at 1000℃[J]. Composites Part A:Applied Science and Manufacturing, 2022, 163: 107247. doi: 10.1016/j.compositesa.2022.107247

|

| [20] |

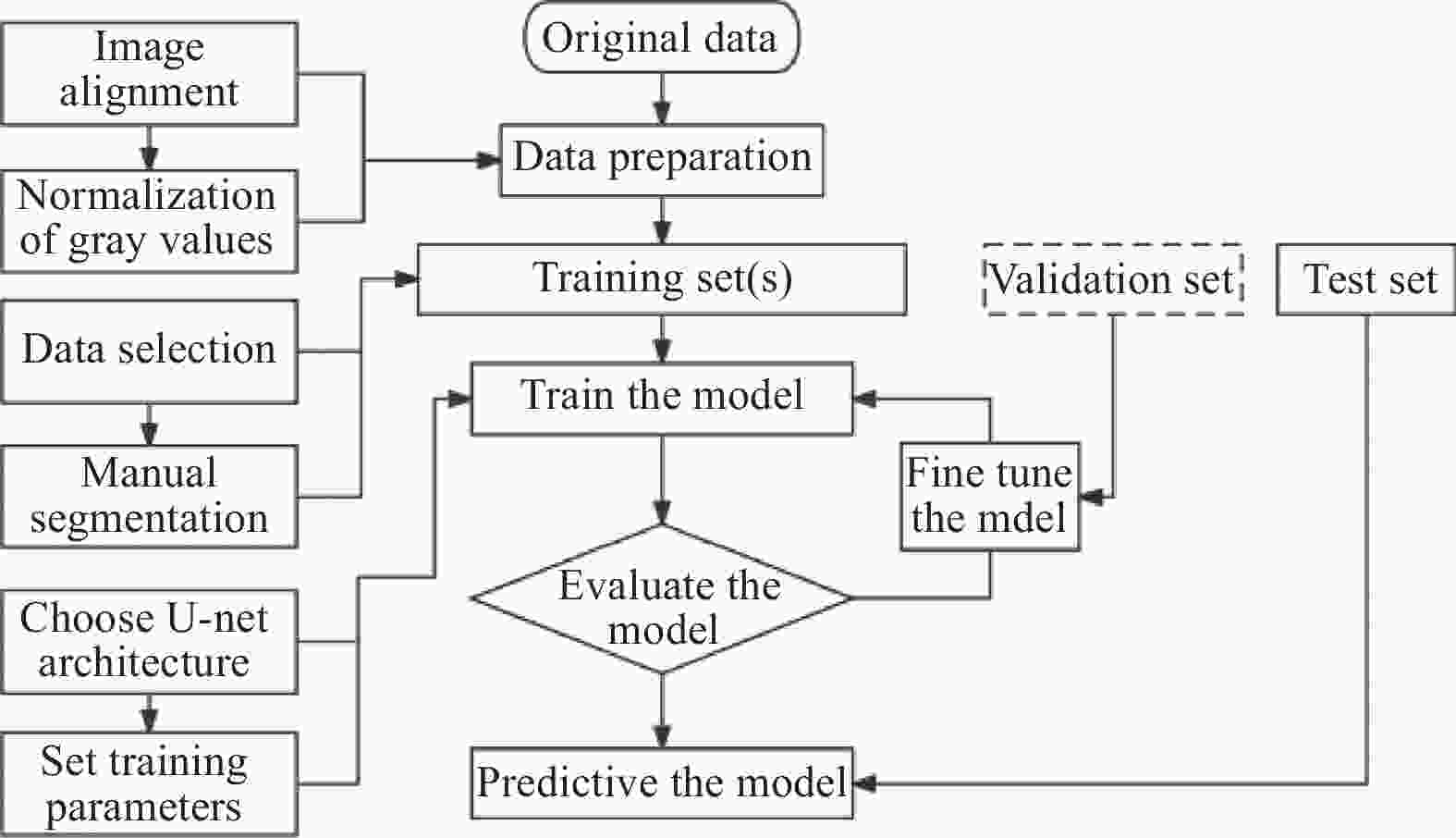

DU Y, ZHANG D, WANG L, et al. Damage mechanism characterisation of plain weave ce-ramic matrix composites under in-plane shear using in-situ X-ray micro-CT and deep-learning-based image segmentation[J]. Journal of the European Ceramic Society, 2024, 44(1): 142-53. doi: 10.1016/j.jeurceramsoc.2023.09.022

|

| [21] |

ZHANG D, LIU Y, LIU H, et al. Characterisa-tion of damage evolution in plain weave SiC/SiC composites using in situ X-ray micro-computed tomography[J]. Composite Structures, 2021, 275: 114447. doi: 10.1016/j.compstruct.2021.114447

|

| [22] |

KHAN A, KO D-K, LIM S C, et al. Structural vibration-based classification and prediction of delamination in smart composite laminates us-ing deep learning neural network[J]. Compo-sites Part B:Engineering, 2019, 161: 586-94. doi: 10.1016/j.compositesb.2018.12.118

|

| [23] |

SINCHUK Y, KIBLEUR P, AELTERMAN J, et al. Variational and deep learning segmentation of very-low-contrast X-ray computed tomography images of carbon/epoxy woven composites[J]. Materials, 2020, 13(4): 936. doi: 10.3390/ma13040936

|

| [24] |

SUN R, GUO L, LI Z, et al. A novel approach to assessing yarn/matrix (or yarn/yarn) in situ interfacial strength in 3D woven composites[J]. Composites Science and Technology, 2021, 213: 108893. doi: 10.1016/j.compscitech.2021.108893

|

| [25] |

王波, 吴亚波, 郭洪宝, 等. 2D-C/SiC 复合材料偏轴拉伸力学行为研究[J]. 材料工程, 2017, 45(07): 91-6.WANG Bo, WU Yabo, GUO Hongbao, et al. Investigation on off-axis tensile mechanical behaviors of 2D-C/SiC composites[J]. Journal of Materials Engineering, 2017, 45(7): 91-96(in Chinese).

|

点击查看大图

点击查看大图

下载:

下载: