Flexural toughness and damping property of recycled PET plastic aggregate mortar

-

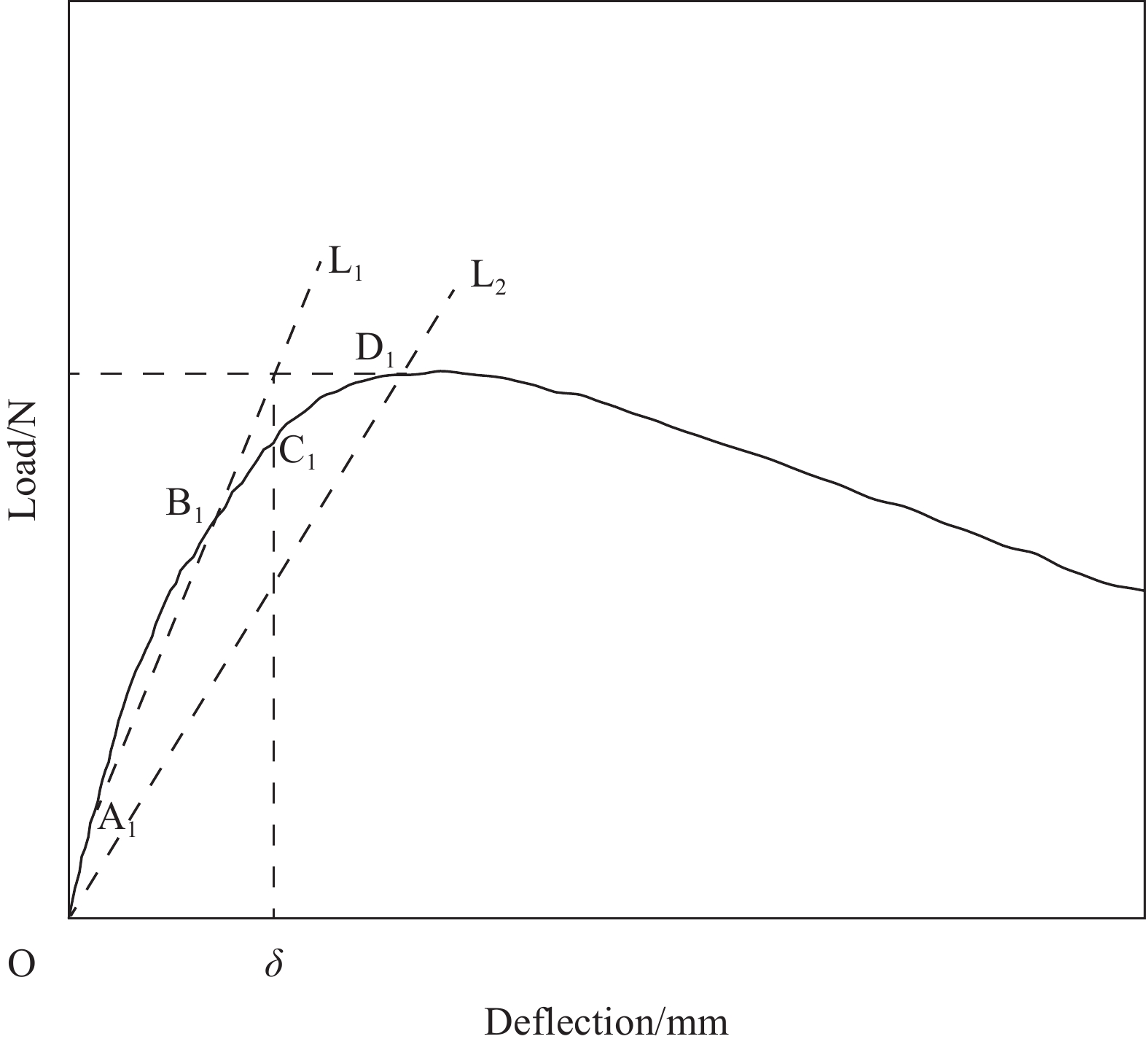

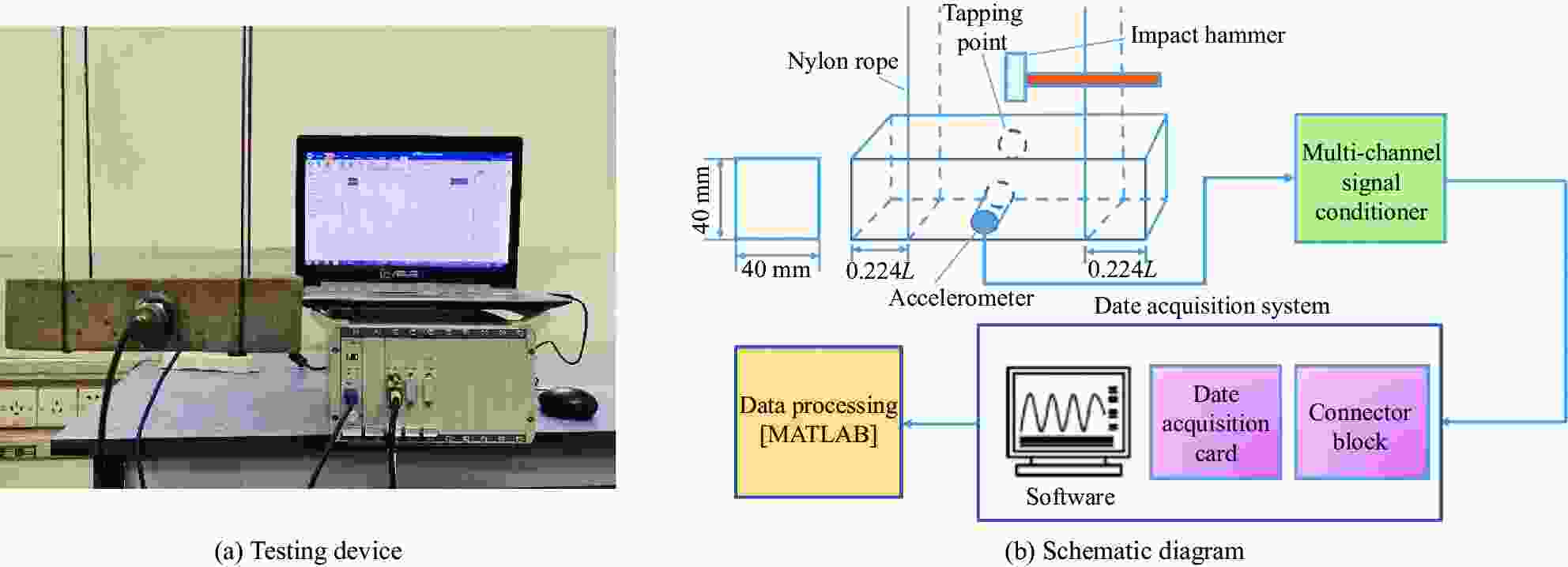

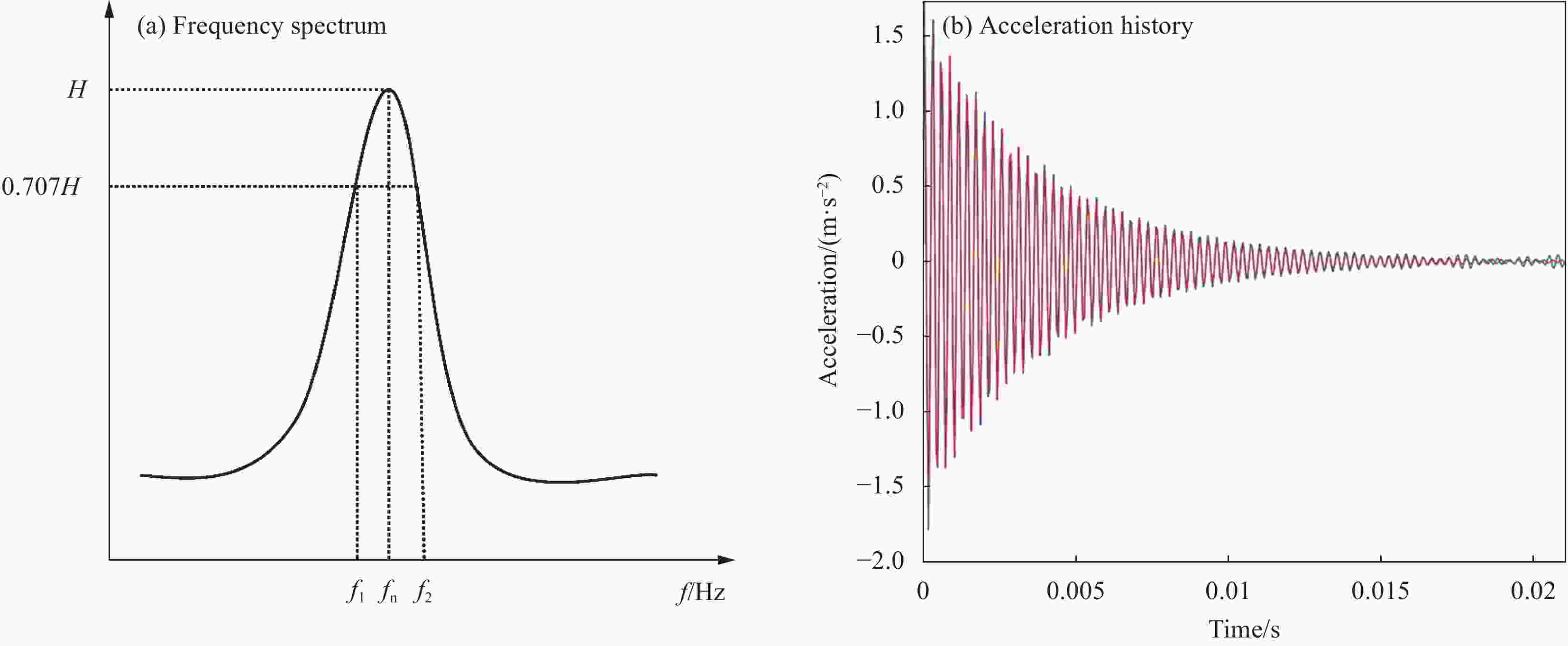

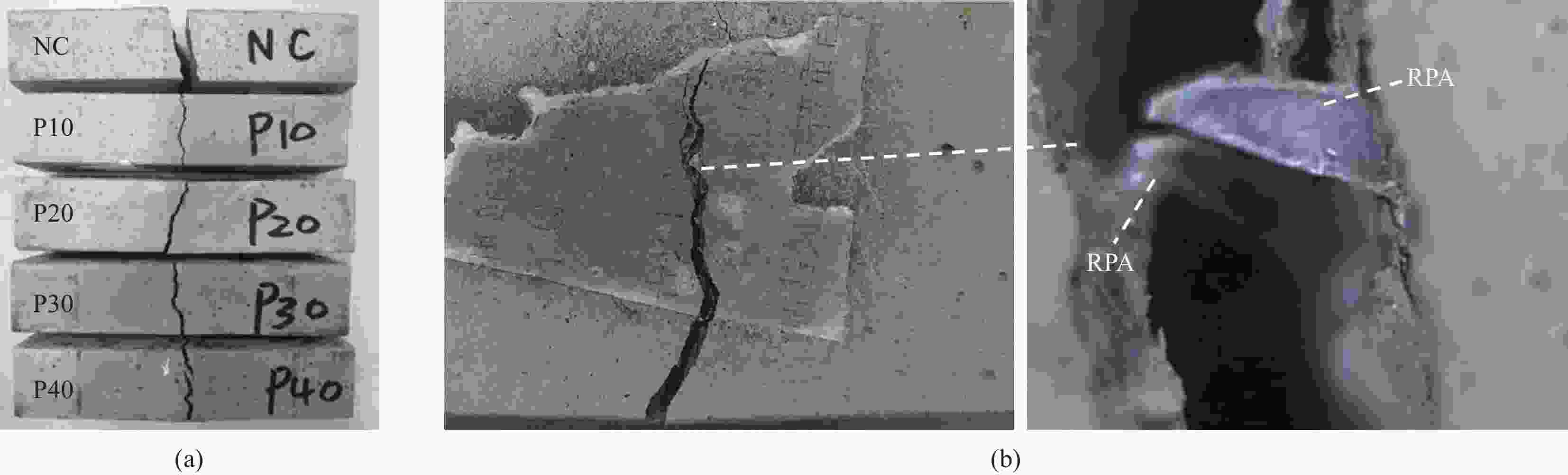

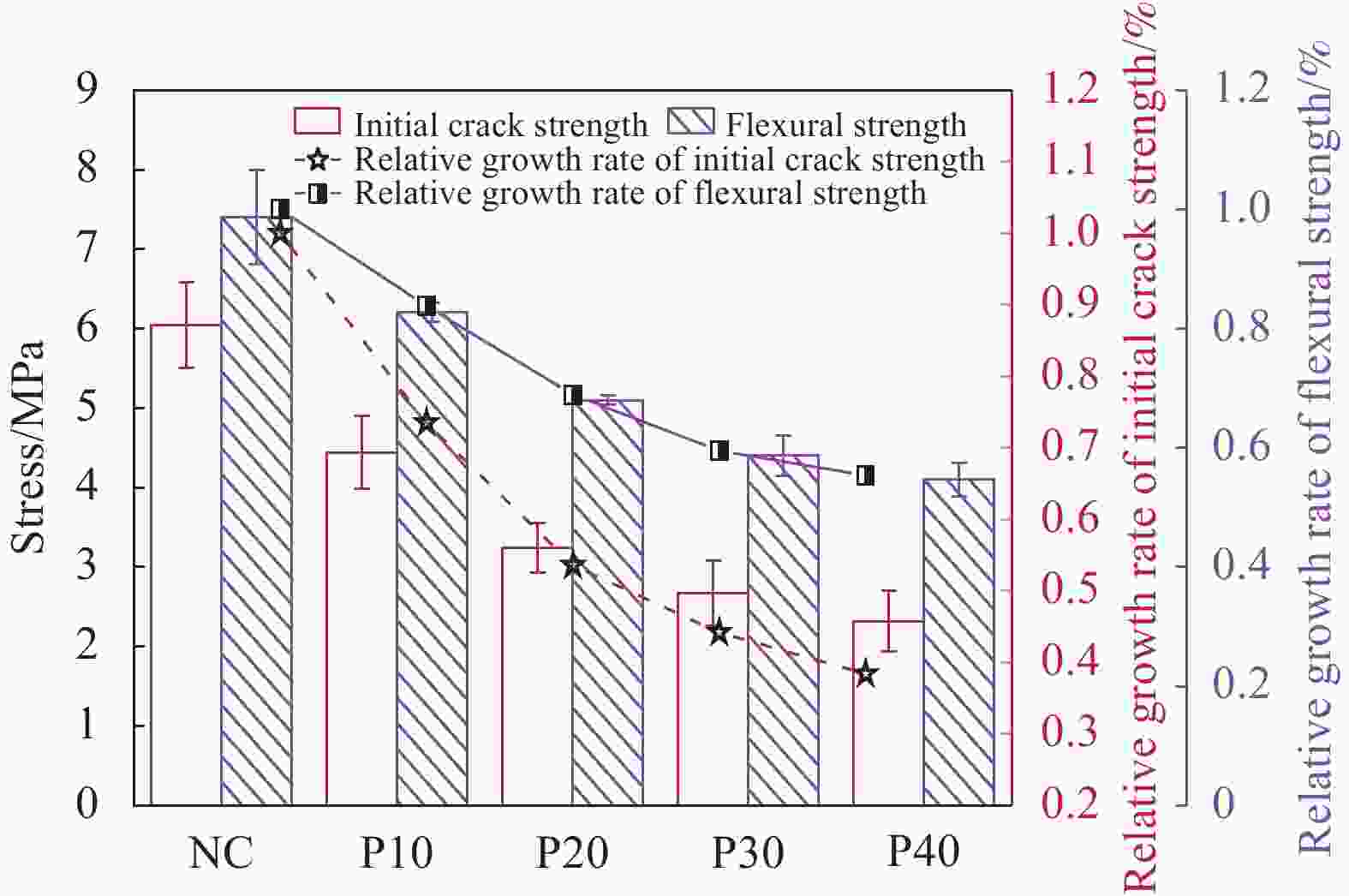

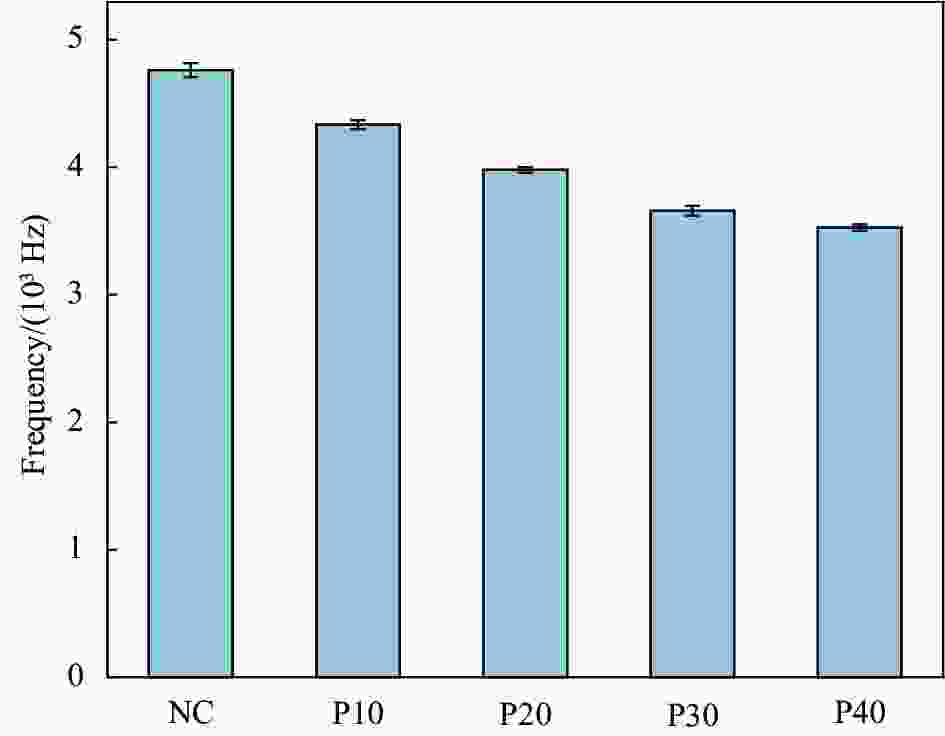

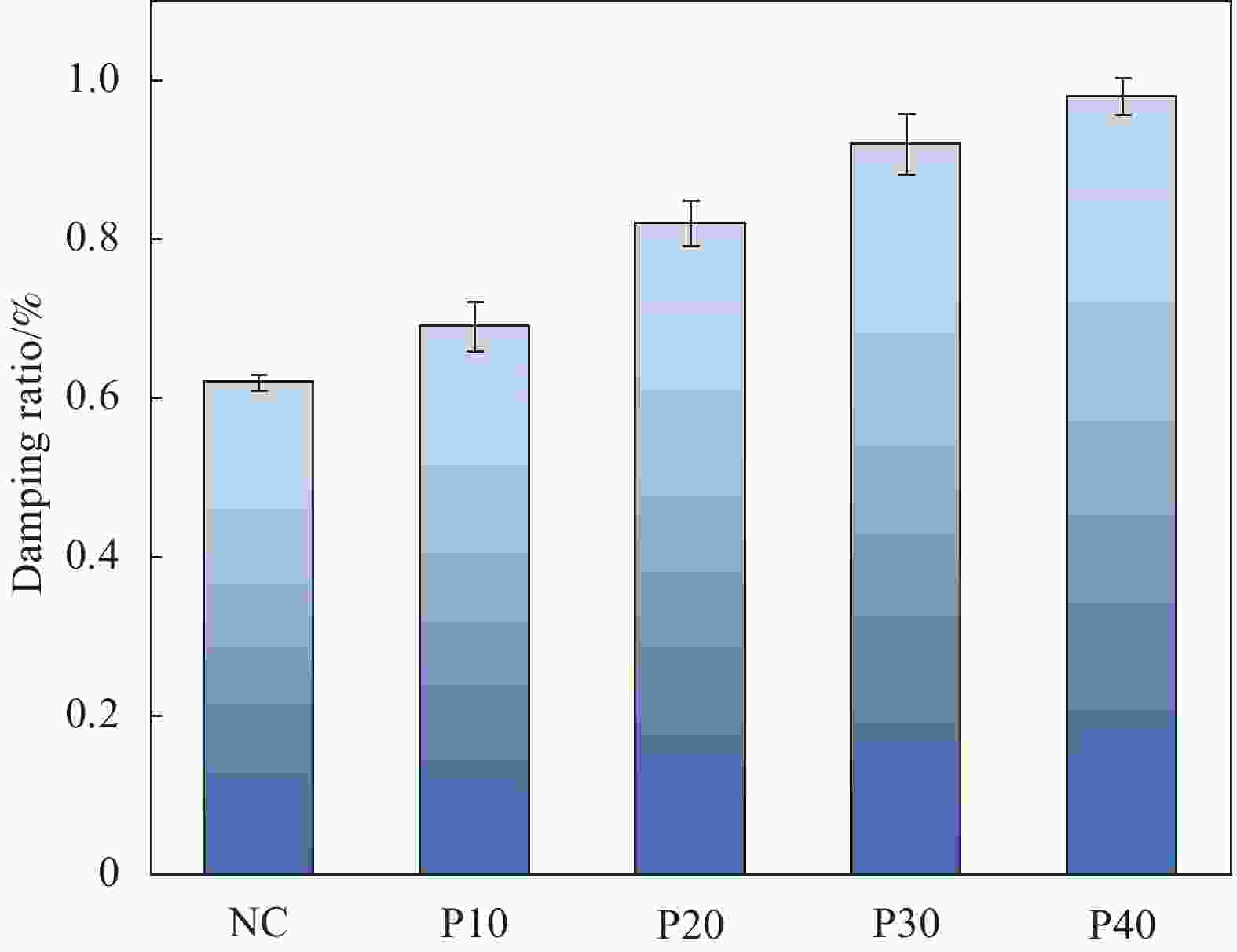

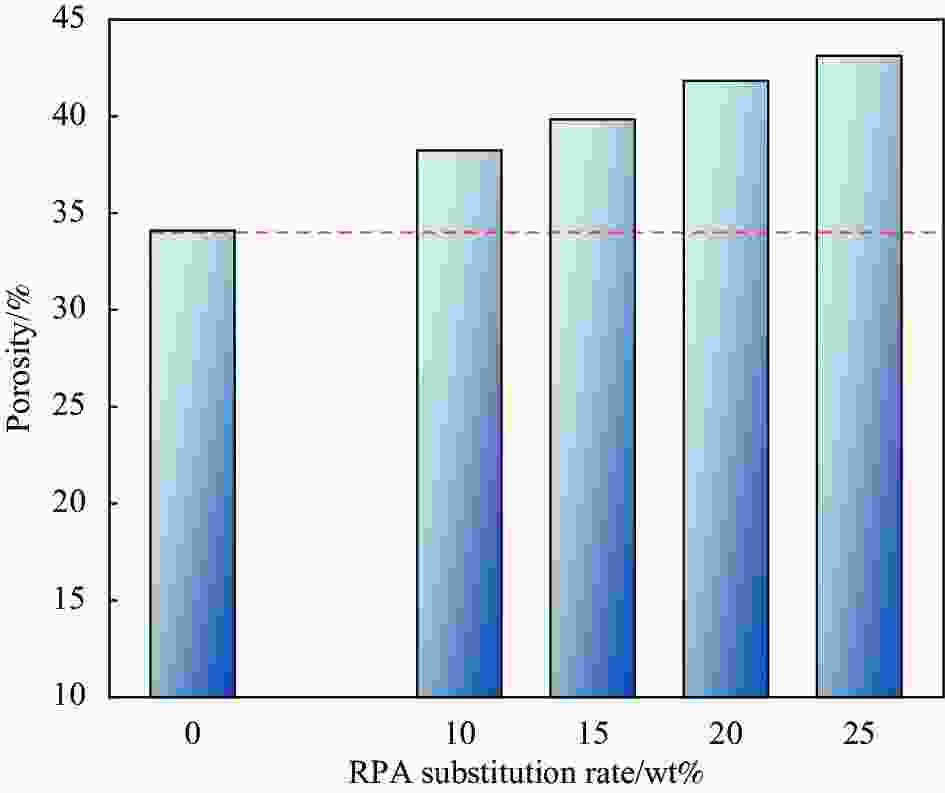

摘要: 为研究再生聚对苯二甲酸乙二醇酯(PET)塑料骨料砂浆(RPAM)的弯曲韧性及阻尼特性,利用废弃PET塑料制备再生PET塑料骨料(RPA),以RPA取代率为参变量,开展了RPAM三点弯曲加载试验和悬挂梁弯曲自由振动试验,分析了三点弯曲RPAM荷载-挠度全曲线与弯曲韧性、弯曲振动一阶阻尼比与频率随RPA取代率的演变规律,并通过SEM测试RPA界面特征,分析其阻尼机制。结果表明:随RPA取代率增加RPAM延性增加,荷载-挠度曲线上升段和下降段斜率逐渐降低,初裂强度和抗弯强度降低;RPA的掺入使得RPAM破坏更具延性,初裂挠度和峰值挠度均明显增大,韧性指数I5、I10 、I20分别比普通砂浆提高4.17倍、5.65倍、5.89倍,且RPAM的剩余强度随RPA取代率增加逐渐增大;随RPA取代率增加,RPAM一阶频率降低9.0%~25.9%,阻尼比增加11.3%~58.1%;RPA与水泥基体之间的界面过渡区(ITZ)微观结构疏松,ITZ界面滑移与摩擦作用及RPA的黏性增加了RPAM的阻尼耗能;RPA最佳用量为15.5vol%~17.2vol%。Abstract: In order to study the flexural toughness and damping characteristics of recycled polyethylene terephthalate (PET) plastic aggregate mortar (RPAM), the recycled PET plastic aggregate (RPA) was prepared from the wasted PET plastics. Taking RPA substitution rate as the variable, the three-point bending loading test and the suspension beam bending free vibration test on RPAM were carried out. The load-deflection curve, flexural toughness, first-order damping ratio and frequency of RPAM with different RPA substitution rates were analyzed. Besides, the damping mechanism of RPA interface was analyzed based on the SEM test. The results show that with the increase of RPA substitution rate, the ductility of RPAM increases, the slopes of loading branch and unloading branch of load-deflection curve gradually decrease, and the initial crack strength and flexural strength decrease. The addition of RPA makes the failure of RPAM more ductile, which increases the initial crack deflection and peak deflection significantly. The toughness indexes I5, I10 and I20 are 4.17, 5.65 and 5.89 times larger than that of ordinary mortar, respectively. The residual strength of RPAM increases gradually as the RPA substitution rate increasing. With the increase of RPA substitution rate, the first-order frequency of RPAM decreases by 9.0%-25.9%, while the damping ratio increases by 11.3%-58.1%. The micro structure of interface transition zone (ITZ) between RPA and cement matrix is loose. The slippage and friction of the ITZ and the viscosity of RPA increase the damping energy consumption of RPAM, and the recommended dosage of RPA is in the range of 15.5vol%-17.2vol%.

-

图 16 RPAM各性能指标与RPA取代率关系

Figure 16. Relationship between RPAM performance indexes and RPA substitution rate

σ—Peak stress of RPAM; σm—Maximum peak stress; f—Flexural strength of RPAM; fm—Maximum flexural strength; δ—Peak deflection of RPAM; δm—Maximum peak deflection; ζ—RPAM damping ratio of RPAM; ζm—Maximum damping ratio

表 1 水泥化学成分

Table 1. Chemical composition of cement

wt% NaO MgO Al2O3 SiO2 P2O5 K2O CaO Fe2O3 0.37 1.80 5.41 14.24 0.51 0.89 64.74 2.46 表 2 骨料基本性能

Table 2. Basic properties of aggregates

Aggregate type Water content/wt% Water absorption/wt% Apparent density/(kg·m−3) Modulus of elasticity/GPa Tensile strength/MPa River sand 1.0 1.2 2580 47.5 — RPA 0 0.2 1350 3.3 60 Note: RPA—Recycled PET plastic aggregate. 表 3 再生PET塑料骨料砂浆(RPAM)配合比

Table 3. Mixture proportion of recycled PET plastic aggregate mortar (RPAM)

Mixture PRA replacement ratio/vol% Material consumption/(kg·m−3) Cement Water Sand RPA Water reducer NC 0 731 300 1217.0 0.0 1.59 P10 10 731 300 1095.3 63.7 1.42 P20 20 731 300 973.6 127.4 1.45 P30 30 731 300 851.9 191.0 1.40 P40 40 731 300 730.2 254.7 1.27 Notes: NC—Mortar with RPA volume substitution ratio of 0vol%; P10, P20, P30 and P40—Mortars with RPA volume substitution ratio of 10vol%, 20vol%, 30vol% and 40vol%, respectively. 表 4 RPAM弯曲韧性

Table 4. Flexural toughness of RPAM

Mixture I5/% I10/% I20/% R5,10 R10,20 NC 1.49 1.49 1.49 0 0 P10 2.78 3.04 3.04 5.2 0 P20 4.58 5.59 5.59 20.2 0 P30 5.28 6.62 6.63 26.8 0.1 P40 6.21 8.42 8.77 44.2 3.5 Notes: I—Toughness index; I5, I10, I20—Corresponds to mid-span deflection 3δ, 5.5δ, 10δ; R—Residual strength. -

[1] GU L, OZBAKKALOGLU T. Use of recycled plastics in concrete: A critical review[J]. Waste Management,2016,51:19-42. doi: 10.1016/j.wasman.2016.03.005 [2] 张效林, 王汝敏, 王志彤, 等. 废旧塑料在复合材料领域中回用技术的研究进展[J]. 材料导报, 2011, 25(15):92-95.ZHANG Xiaolin, WANG Rumin, WANG Zhitong, et al. Research advances in the recycling technologies of waste plastics in composites field[J]. Materials Reports,2011,25(15):92-95(in Chinese). [3] 胡曙光, 王发洲. 轻集料混凝土[M]. 北京: 化学工业出版社, 2006: 26-28.HU Shuguang, WANG Fazhou. Lightweight aggregate concrete[M]. Beijing: Chemical Industry Press, 2006: 26-28(in Chinese). [4] 刘雨姗, 庞建勇, 姚韦靖. 页岩陶粒轻骨料混凝土高温后蠕变特性[J]. 建筑材料学报, 2021, 24(5):1096-1104. doi: 10.3969/j.issn.1007-9629.2021.05.027LIU Yushan, PANG Jianyong, YAO Weijing. Crrep behavior of shale ceramsite lightweight aggregate concrete exposed to high temperature[J]. Journal of Building Materials,2021,24(5):1096-1104(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.05.027 [5] SAIKIA N, BRITO J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review[J]. Construction and Building Materials,2012,34:385-401. doi: 10.1016/j.conbuildmat.2012.02.066 [6] BAHIJ S, OMARY S, FEUGEAS F, et al. Fresh and hardened properties of concrete containing different forms of plastic waste—A review[J]. Waste Management,2020,113:157-175. doi: 10.1016/j.wasman.2020.05.048 [7] ALQAHTANI F, ZAFAR I. Plastic-based sustainable synthe-tic aggregate in Green Lightweight concrete—A review[J]. Construction and Building Materials,2021,292:123321. doi: 10.1016/j.conbuildmat.2021.123321 [8] 陆俊, 鲍聪, 方刘基, 等. 再生PET塑料骨料对砂浆单轴受压性能的影响[J]. 混凝土与水泥制品, 2022(1):95-99.LU Jun, BAO Cong, FANG Liuji, et al. Effect of recycled PET plastic aggregate on uniaxial compression performance of mortar[J]. China Concrete and Cement Products,2022(1):95-99(in Chinese). [9] 刘锋, 黄海滨, 夏晓舟, 等. 再生塑料改性混凝土力学性能研究及数值模拟[J]. 建筑材料学报, 2011, 14(2):173-179. doi: 10.3969/j.issn.1007-9629.2011.02.006LIU Feng, HUANG Haibin, XIA Xiaozhou, et al. Mechanical test on modified concrete with recycled plastic particles and its numerical simulation[J]. Journal of Building Materials,2011,14(2):173-179(in Chinese). doi: 10.3969/j.issn.1007-9629.2011.02.006 [10] 陈海明, 朱云涛, 张东磊, 等. PP塑料粒径和掺量对砂浆物理力学性能的影响[J]. 塑料工业, 2019, 47(2):134-138, 169. doi: 10.3969/j.issn.1005-5770.2019.02.028CHEN Haiming, ZHU Yuntao, ZHANG Donglei, et al. Effect of particle size and dosage of PP plastic on physical and mechanical properties of mortar[J]. China Plastics Industry,2019,47(2):134-138, 169(in Chinese). doi: 10.3969/j.issn.1005-5770.2019.02.028 [11] 张海波, 尚海涛, 管学茂. 塑料骨料对水泥砂浆性能的影响[J]. 建筑材料学报, 2014, 17(6):1066-1069. doi: 10.3969/j.issn.1007-9629.2014.06.022ZHANG Haibo, SHANG Haitao, GUAN Xuemao. Effect of plastic aggregate on properties of cement mortar[J]. Journal of Building Materials,2014,17(6):1066-1069(in Chinese). doi: 10.3969/j.issn.1007-9629.2014.06.022 [12] YESILATA B, ISıKER Y, TURGUT P. Thermal insulation enhancement in concretes by adding waste PET and rubber pieces[J]. Construction and Building Materials,2009,23(5):1878-1882. doi: 10.1016/j.conbuildmat.2008.09.014 [13] 张海波, 师广岭, 尚海涛, 等. PVC塑料砂浆导热性研究[J]. 材料导报, 2015, 29(16):142-146.ZHANG Haibo, SHI Guangling, SHANG Haitao, et al. Study on thermal conductivity of PVC plastic mortar[J]. Materials Reports,2015,29(16):142-146(in Chinese). [14] WANG R, MEYER C. Performance of cement mortar made with recycled high impact polystyrene[J]. Cement and Concrete Composites,2012,34(9):975-981. doi: 10.1016/j.cemconcomp.2012.06.014 [15] 高丹盈, 赵亮平, 冯虎, 等. 钢纤维混凝土弯曲韧性及其评价方法[J]. 建筑材料学报, 2014, 17(5):783-789. doi: 10.3969/j.issn.1007-9629.2014.05.006GAO Danying, ZHAO Liangping, FENG Hu, et al. Flexural toughness and it's evaluation method of steel fiber reinforced concrete[J]. Journal of Building Materials,2014,17(5):783-789(in Chinese). doi: 10.3969/j.issn.1007-9629.2014.05.006 [16] 梁超锋, 何佳俊, 肖建庄, 等. 再生骨料混凝土梁的阻尼性能及其机理分析[J]. 同济大学学报(自然科学版), 2018, 46(6):737-743, 750.LIANG Chaofeng, HE Jiajun, XIAO Jianzhuang, et al. Damping property and mechanism of recycled aggregate concrete beams[J]. Journal of Tongji University (Natural Science),2018,46(6):737-743, 750(in Chinese). [17] 孙杰, 陈国珍, 吕康琪, 等. 橡胶地聚物混凝土力学性能及阻尼特性试验研究[J]. 复合材料学报, 2022, 39(11):5321-5332. doi: 10.13801/j.cnki.fhclxb.20211201.002SUN Jie, CHEN Guozhen, LYU Kangqi, et al. Experimental study on mechanical properties and damping characteristics of rubber geopolymer concrete[J]. Acta Materiae Compositae Sinica,2022,39(11):5321-5332(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211201.002 [18] ASTM. Standard test method for flexural toughness and first-crack strength of fiber-reinforced concrete (Using beam with third-point loading): ASTM C1018—1997[S]. West Conshohocken: ASTM, 1997. [19] MARZOUK O, DHEILLY R, QUENEUDEC M. Valorization of post-consumer waste plastic in cementitious concrete composites[J]. Waste Management,2007,27(2):310-318. doi: 10.1016/j.wasman.2006.03.012 [20] AZHDARPOUR A, NIKOUDEL M, TAHERI M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; a laboratory evaluation[J]. Construction and Building Materials,2016,109:55-62. doi: 10.1016/j.conbuildmat.2016.01.056 [21] 丁一宁, 董香军, 王岳华. 钢纤维混凝土弯曲韧性测试方法与评价标准[J]. 建筑材料学报, 2005, 8(6):660-664. doi: 10.3969/j.issn.1007-9629.2005.06.013DING Yining, DONG Xiangjun, WANG Yuehua. Testing methods and evaluating standards of flexural toughness for steel fiber reinforced concrete[J]. Journal of Building Materials,2005,8(6):660-664(in Chinese). doi: 10.3969/j.issn.1007-9629.2005.06.013 [22] 史占崇, 苏庆田, 邵长宇, 等. 粗骨料UHPC的基本力学性能及弯曲韧性评价方法[J]. 土木工程学报, 2020, 53(12):86-97. doi: 10.15951/j.tmgcxb.2020.12.009SHI Zhanchong, SU Qingtian, SHAO Changyu, et al. Basic mechanical behavior and flexural toughness evaluation method of coarse aggregate UHPC[J]. China Civil Engineering Journal,2020,53(12):86-97(in Chinese). doi: 10.15951/j.tmgcxb.2020.12.009 [23] 陈维灯, 韩冬冬, 钟世云. 丁苯乳液和超高分子质量聚乙烯纤维对砂浆抗弯性能的影响[J]. 新型建筑材料, 2017, 44(2):94-98. doi: 10.3969/j.issn.1001-702X.2017.02.022CHEN Weideng, HAN Dongdong, ZHONG Shiyun. Influences of SBR latex and UHMW-PE fiber on bending properties of mortar[J]. New Building Materials,2017,44(2):94-98(in Chinese). doi: 10.3969/j.issn.1001-702X.2017.02.022 [24] YAN L, JENKINS C, PENDLETON R. Polyolefin fiber-reinforced concrete composites: Part I. Damping and frequency characteristics[J]. Cement and Concrete Research,2000,30(3):391-401. doi: 10.1016/S0008-8846(99)00267-7 [25] 田耀刚. 高强混凝土阻尼功能设计及其性能研究[D]. 武汉: 武汉理工大学, 2008.TIAN Yaogang. Research on design and performance of damping and high strength concrete[D]. Wuhan: Wuhan University of Technology, 2008(in Chinese). [26] 应怀樵, 刘进明, 沈松. 半功率带宽法与INV阻尼计法求阻尼比的研究[J]. 噪声与振动控制, 2006, 26(2):4-6. doi: 10.3969/j.issn.1006-1355.2006.02.002YING Huaiqiao, LIU Jinming, SHEN Song. Half-power bandwidth method and INV damping ration solver study[J]. Noise and Vibration Control,2006,26(2):4-6(in Chinese). doi: 10.3969/j.issn.1006-1355.2006.02.002 [27] XIAO J, LIU Q, WU Y. Numerical and experimental studies on fracture process of recycled concrete[J]. Fatigue & Fracture of Engineering Materials & Structures,2012,35(8):801-808. [28] XIAO J, SCHNEIDER H, DÖNNECKE C, et al. Wedge splitting test on fracture behaviour of ultra high strength concrete[J]. Construction and Building Materials,2004,18(6):359-365. doi: 10.1016/j.conbuildmat.2004.04.016 [29] REIS J, CAMEIRO E. Evaluation of PET waste aggregates in polymer mortars[J]. Construction and Building Materials,2012,27(1):107-111. doi: 10.1016/j.conbuildmat.2011.08.020 [30] REIS J, CHIANELLI-JUNIOR R, CARDOSO J, et al. Effect of recycled PET in the fracture mechanics of polymer mortar[J]. Construction and Building Materials,2011,25(6):2799-2804. doi: 10.1016/j.conbuildmat.2010.12.056 [31] KAUR G, PAVIA S. Physical properties and microstructure of plastic aggregate mortars made with acrylonitrile-butadiene-styrene (ABS), polycarbonate (PC), polyoxymethylene (POM) and ABS/PC blend waste[J]. Journal of Building Engineering,2020,31:101341. doi: 10.1016/j.jobe.2020.101341 [32] 曾振海, 李传习, 柯璐, 等. 玄武岩/聚丙烯腈混杂纤维混凝土力学性能及最优纤维掺量研究[J]. 铁道科学与工程学报, 2020, 17(10):2549-2557. doi: 10.19713/j.cnki.43-1423/u.t20200451ZENG Zhenhai, LI Chuanxi, KE Lu, et al. Study on mechanical properties and optimum fiber content for basalt/polyacrylonitrile hybrid fiber reinforced concrete[J]. Journal of Railway Science and Engineering,2020,17(10):2549-2557(in Chinese). doi: 10.19713/j.cnki.43-1423/u.t20200451 [33] 江世永, 陶帅, 飞渭, 等. 高韧性纤维混凝土受弯性能试验研究[J]. 工业建筑, 2018, 48(6):111-118. doi: 10.13204/j.gyjz201806021JIANG Shiyong, TAO Shuai, FEI Wei, et al. Experimental research on flexural behavior of engineered cementitious composite[J]. Industrial Construction,2018,48(6):111-118(in Chinese). doi: 10.13204/j.gyjz201806021 [34] AATTACHE A, SOLTANI R, MAHI A. Investigations for properties improvement of recycled PE polymer particles-reinforced mortars for repair practice[J]. Construction and Building Materials,2017,146:603-614. doi: 10.1016/j.conbuildmat.2017.04.110 [35] LEE Z, PAUL S, KONG S, et al. Modification of waste aggregate PET for improving the concrete properties[J]. Advances in Civil Engineering,2019,2019:6942052. [36] 谈亚文, 杨哲, 李丹, 等. 硫酸盐腐蚀对混杂纤维混凝土弯曲韧性的影响研究[J]. 硅酸盐通报, 2017, 36(8):2756-2762. doi: 10.16552/j.cnki.issn1001-1625.2017.08.041TAN Yawen, YANG Zhe, LI Dan, et al. Effect of sulfate corrosion on flexural toughness of hybrid fiber reinforced concrete[J]. Bulletin of the Chinese Ceramic Society,2017,36(8):2756-2762(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2017.08.041 [37] SAFI B, SAIDI M, ABOUTALEB D, et al. The use of plastic waste as fine aggregate in the self-compacting mortars: Effect on physical and mechanical properties[J]. Construction and Building Materials,2013,43:436-442. doi: 10.1016/j.conbuildmat.2013.02.049 [38] 朱星曈, 耿欧, 朱思远. 废轮胎橡胶混凝土界面过渡区特征试验研究[J]. 硅酸盐通报, 2021, 40(2):573-578. doi: 10.16552/j.cnki.issn1001-1625.2021.02.026ZHU Xingtong, GENG Ou, ZHU Siyuan. Characteristics of interface transition zone of waste tire rubber concrete[J]. Bulletin of the Chinese Ceramic Society,2021,40(2):573-578(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2021.02.026 [39] MOHR B, BIERNACKI J, KURTIS K. Microstructural and chemical effects of wet/dry cycling on pulp fiber-cement composites[J]. Cement and Concrete Research,2006,36(7):1240-1251. doi: 10.1016/j.cemconres.2006.03.020 [40] IUCOLANO F, LIGUORI B, CAPUTO D, et al. Recycled plastic aggregate in mortars composition: Effect on physical and mechanical properties[J]. Materials & Design,2013,52:916-922. [41] AKÇAÖZOĞLU S, ATIS C, AKÇAÖZOĞLU K. An investigation on the use of shredded waste PET bottles as aggregate in lightweight concrete[J]. Waste Management,2010,30(2):285-290. doi: 10.1016/j.wasman.2009.09.033 [42] 刘铁军, 乔国富, 邹笃建. 纳米SiO2对混凝土材料阻尼性能的改良研究[J]. 功能材料, 2011, 42(7):1184-1188.LIU Tiejun, QIAO Guofu, ZOU Dujian. Improving the damping ability by the addition of nano-SiO2 to the concrete materials[J]. Journal of Functional Materials,2011,42(7):1184-1188(in Chinese). [43] LIANG C, XIAO J, WANG Y, et al. Relationship between internal viscous damping and stiffness of concrete material and structure[J]. Structural Concrete,2021,22(3):1410-1428. doi: 10.1002/suco.202000628 [44] LIANG C, XIAO J, WANG C, et al. Frequency-dependent damping properties of recycled aggregate concrete[J]. Journal of Materials in Civil Engineering,2021,33(7):4021160. doi: 10.1061/(ASCE)MT.1943-5533.0003742 [45] YAN L, JENKINS C, PENDLETON R. Polyolefin fiber-reinforced concrete composites: Part II. Damping and interface debonding[J]. Cement and Concrete Research,2000,30(3):403-410. doi: 10.1016/S0008-8846(99)00268-9 [46] CHI L, LU S, YAO Y. Damping additives used in cement-matrix composites: A review[J]. Composites Part B: Engineering,2019,164:26-36. doi: 10.1016/j.compositesb.2018.11.057 -

下载:

下载: