Impact compression performance of three-dimensional five directional glass fiber/epoxy resin braided composite circular tubes in low-temperature environment

-

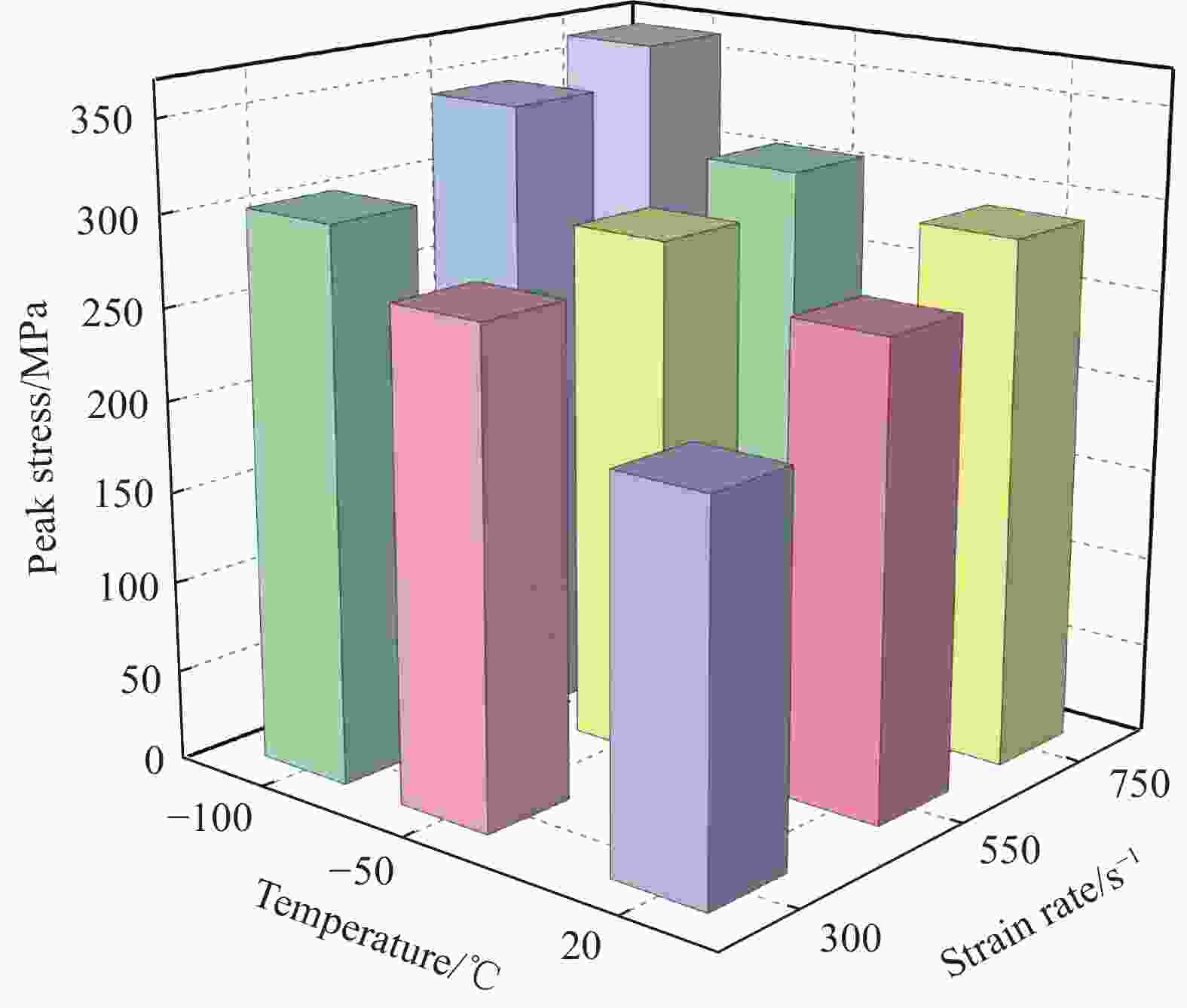

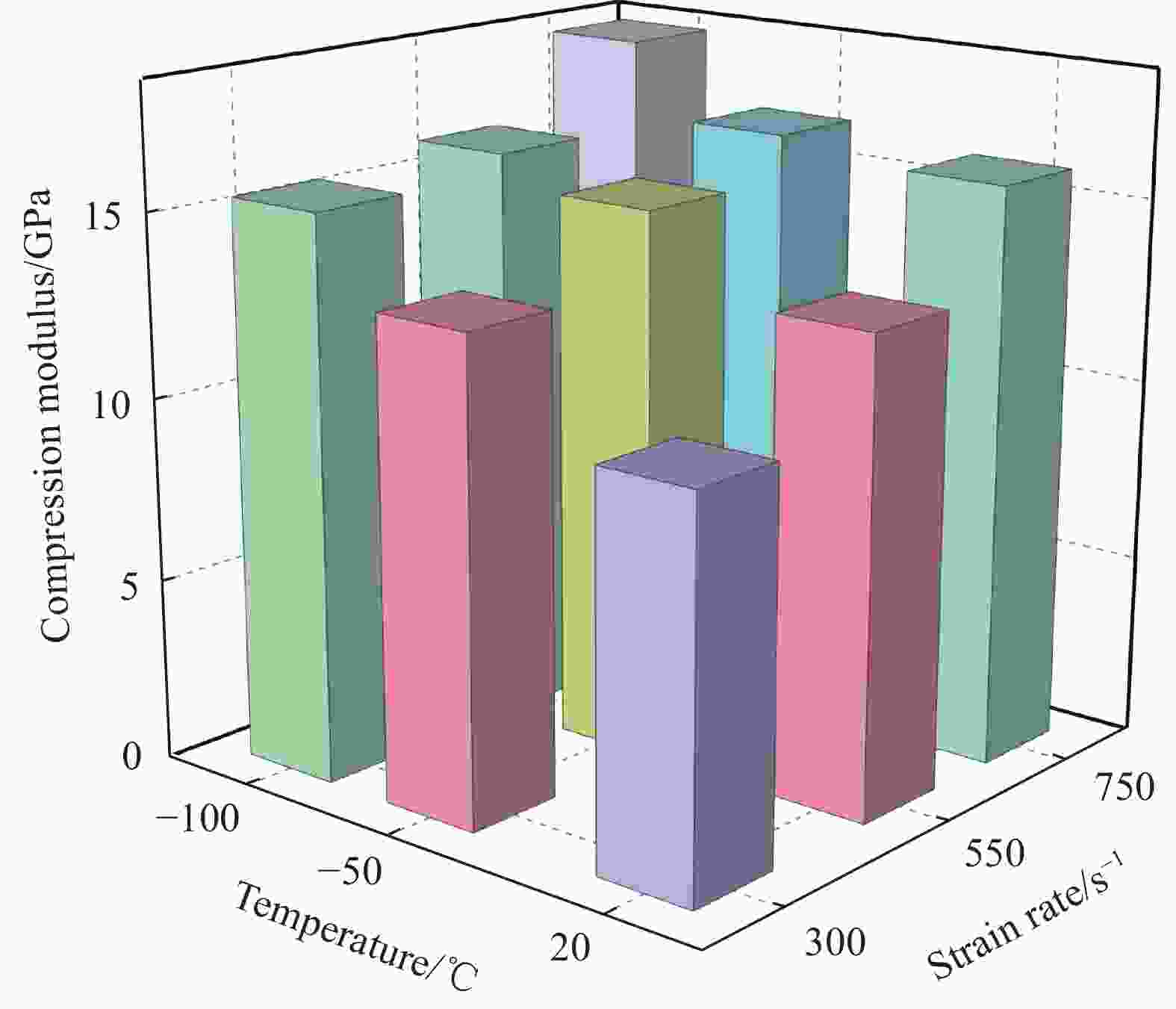

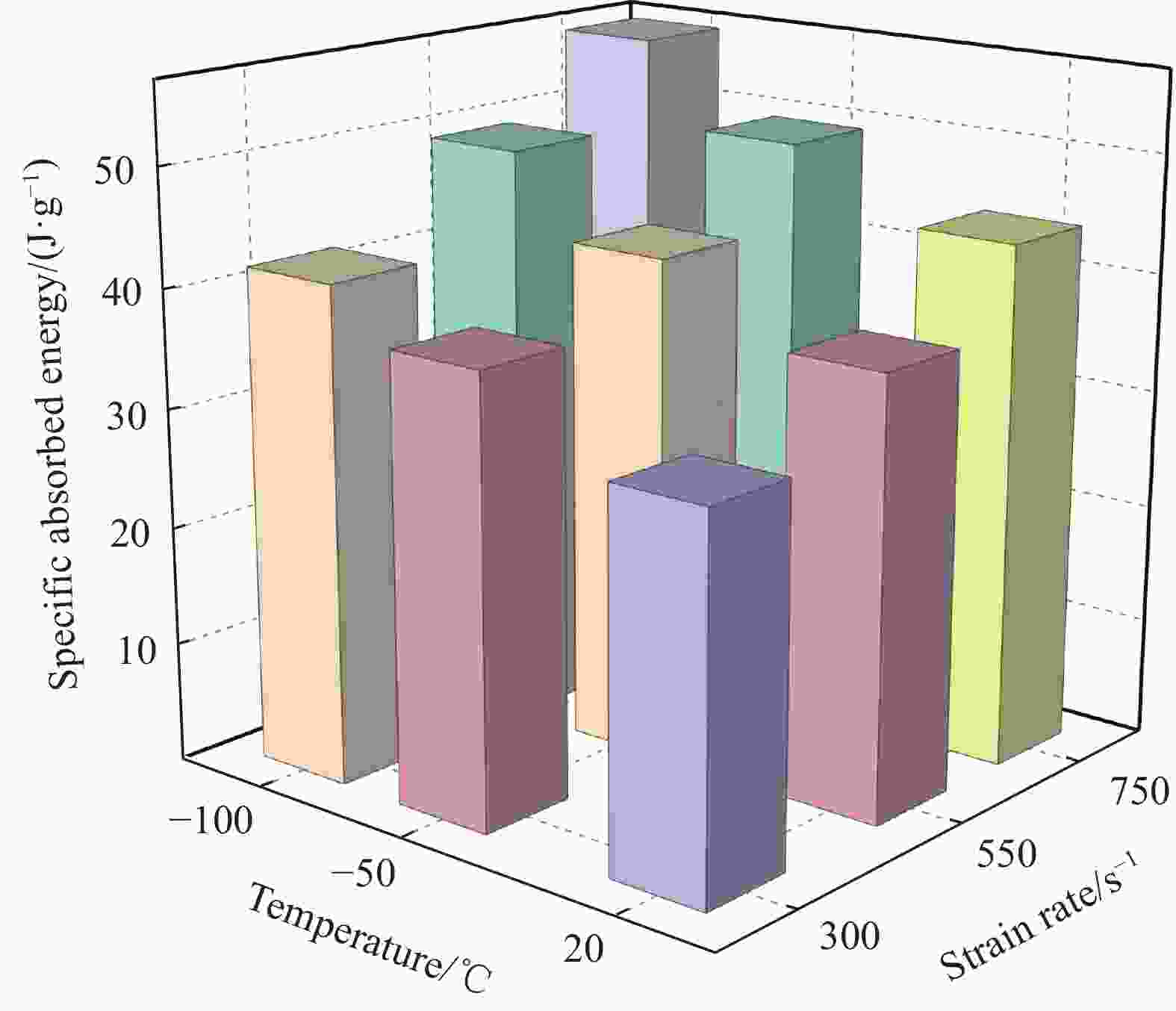

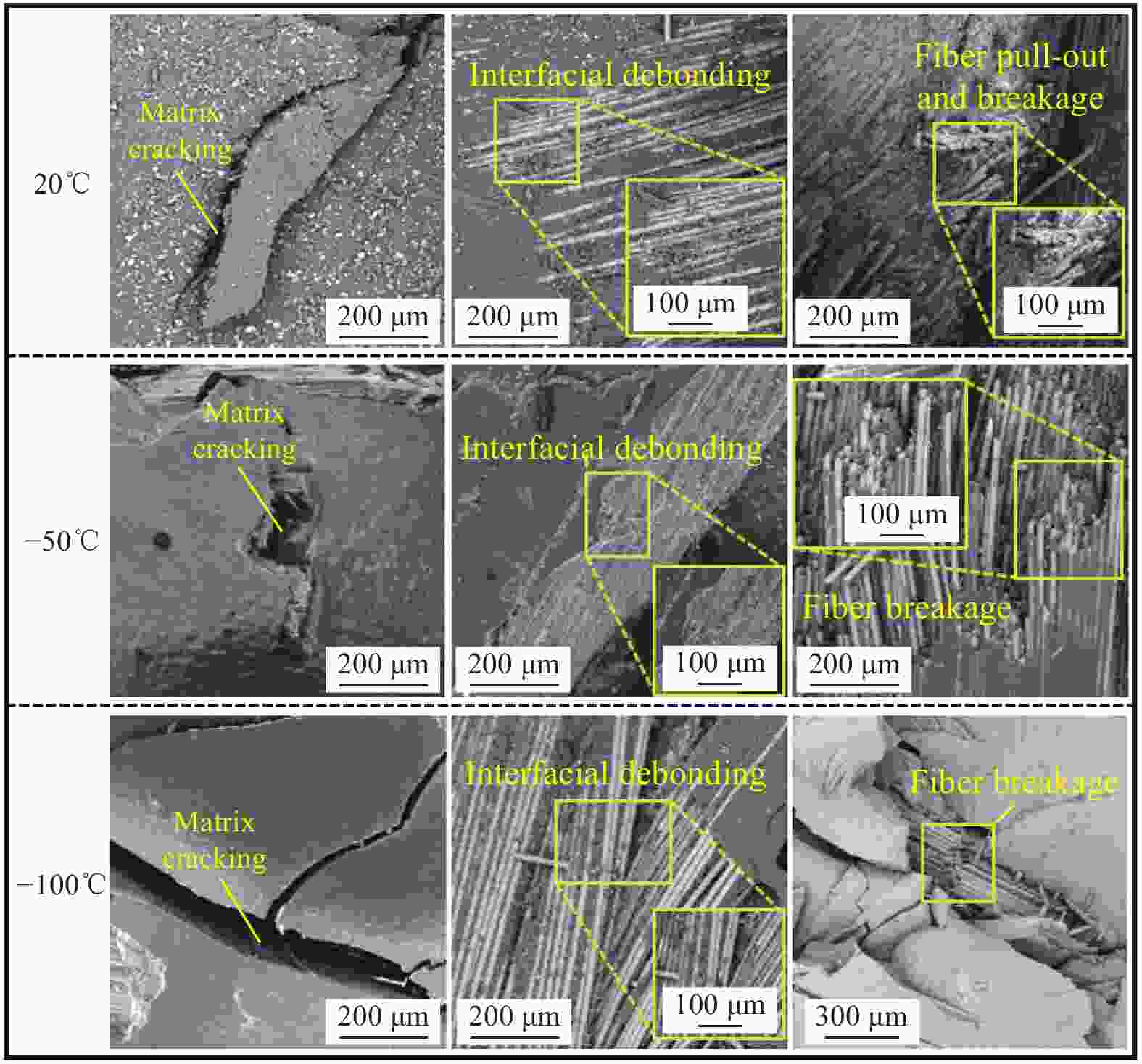

摘要: 通过三维编织成型技术与树脂传递模塑(RTM)工艺制备了三维五向玻璃纤维/环氧树脂编织复合材料圆管,分别在低温(−100℃、−50℃)和室温(20℃)条件下使用分离式Hopkinson压杆(SHPB)对三维五向编织复合材料圆管进行轴向冲击压缩性能测试,使用体式显微镜和SEM研究了温度和应变率对三维五向编织复合材料圆管轴向冲击压缩性能的影响。结果表明:温度和应变率对三维五向玻璃纤维/环氧树脂编织复合材料圆管轴向冲击压缩性能具有显著影响。低温度场下,三维五向编织复合材料圆管的轴向冲击压缩力学性能优于室温条件。随着应变率增加和温度降低,三维五向编织复合材料圆管的峰值应力、压缩模量与比吸收能均有不同程度的增加。低温度场下三维五向编织复合材料圆管轴向冲击压缩破坏特性为脆性断裂,纤维束断口较整齐,试样破坏及变形程度均随应变率的增加和温度的降低而更加严重,而在应变率较高和环境温度较低时试样仍保持较好的结构完整性。

-

关键词:

- 三维五向编织复合材料圆管 /

- 分离式Hopkinson压杆 /

- 冲击压缩性能 /

- 应变率 /

- 低温环境

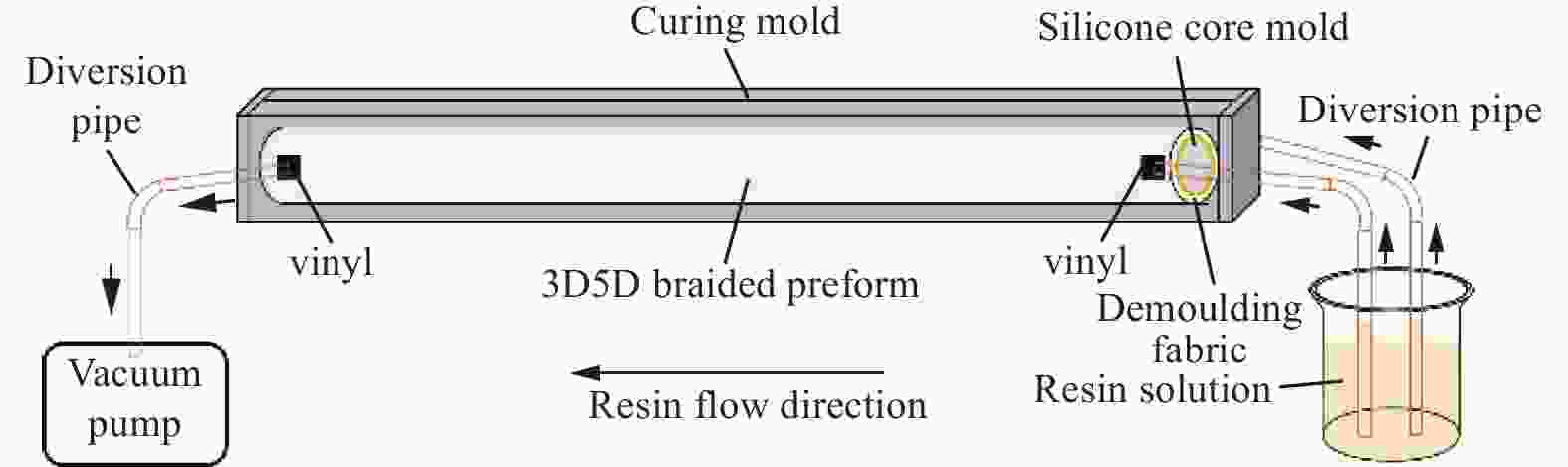

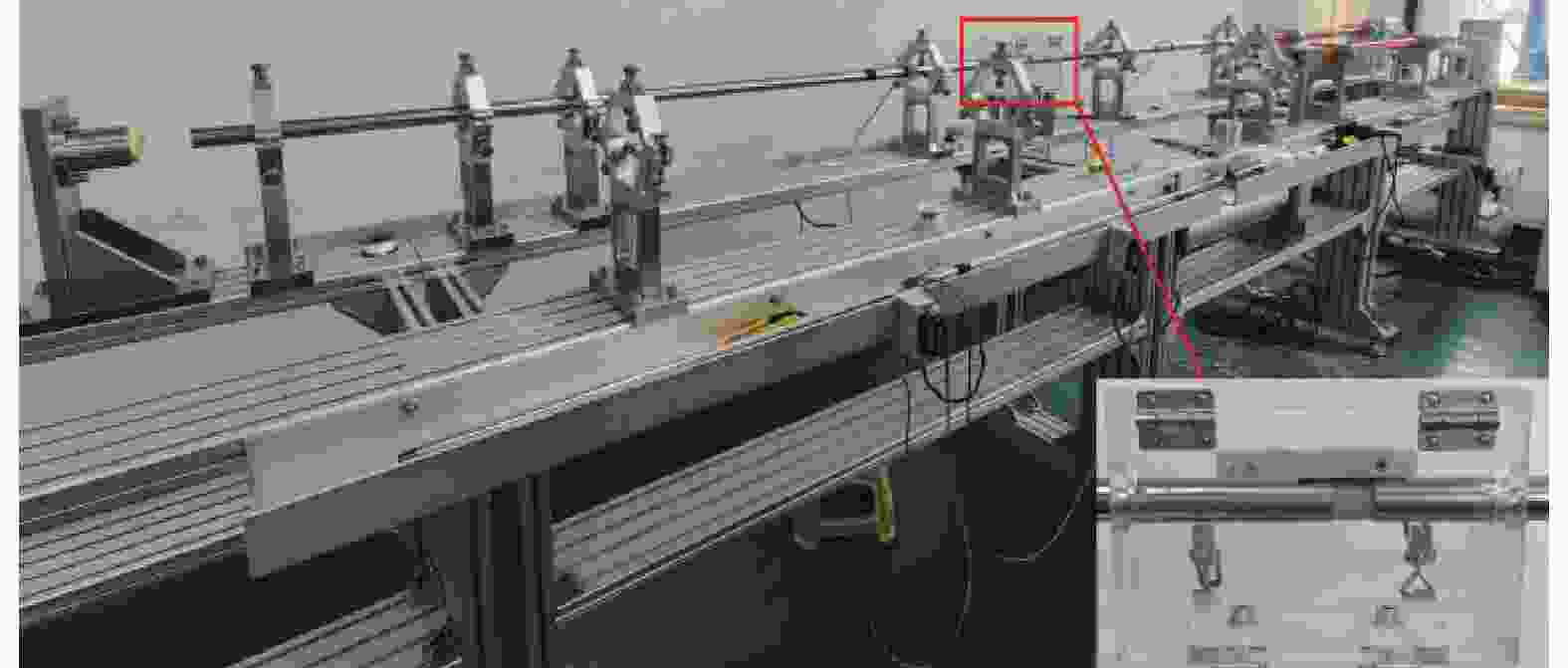

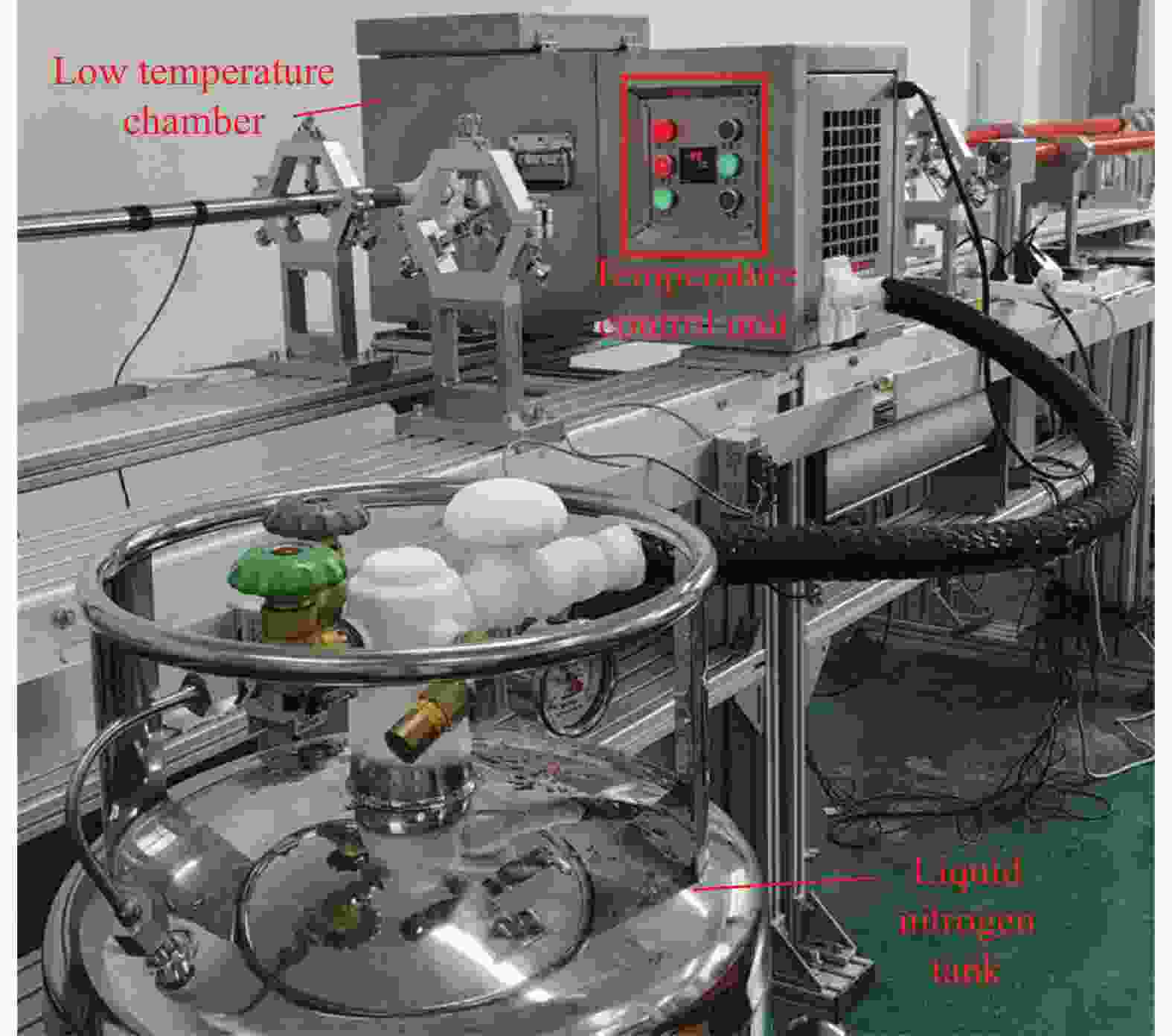

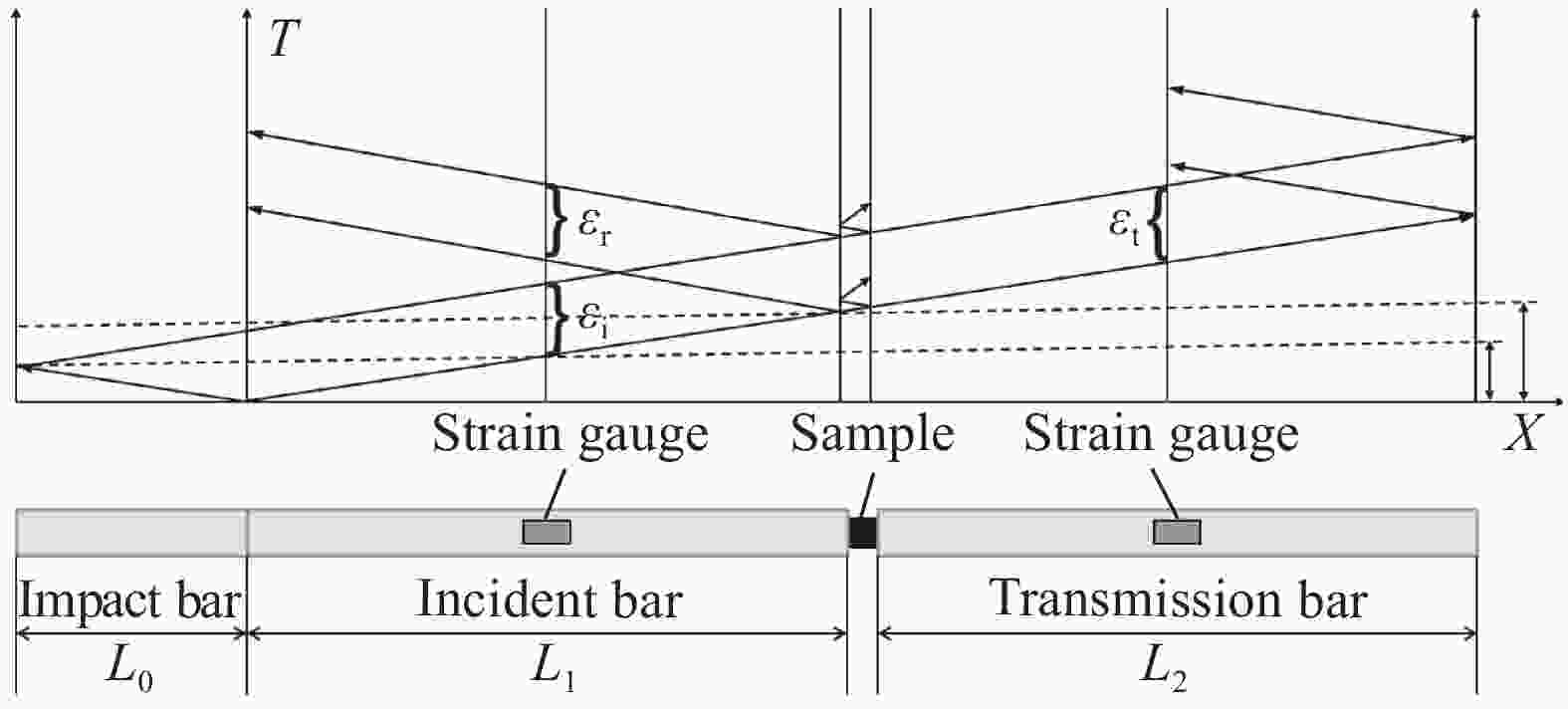

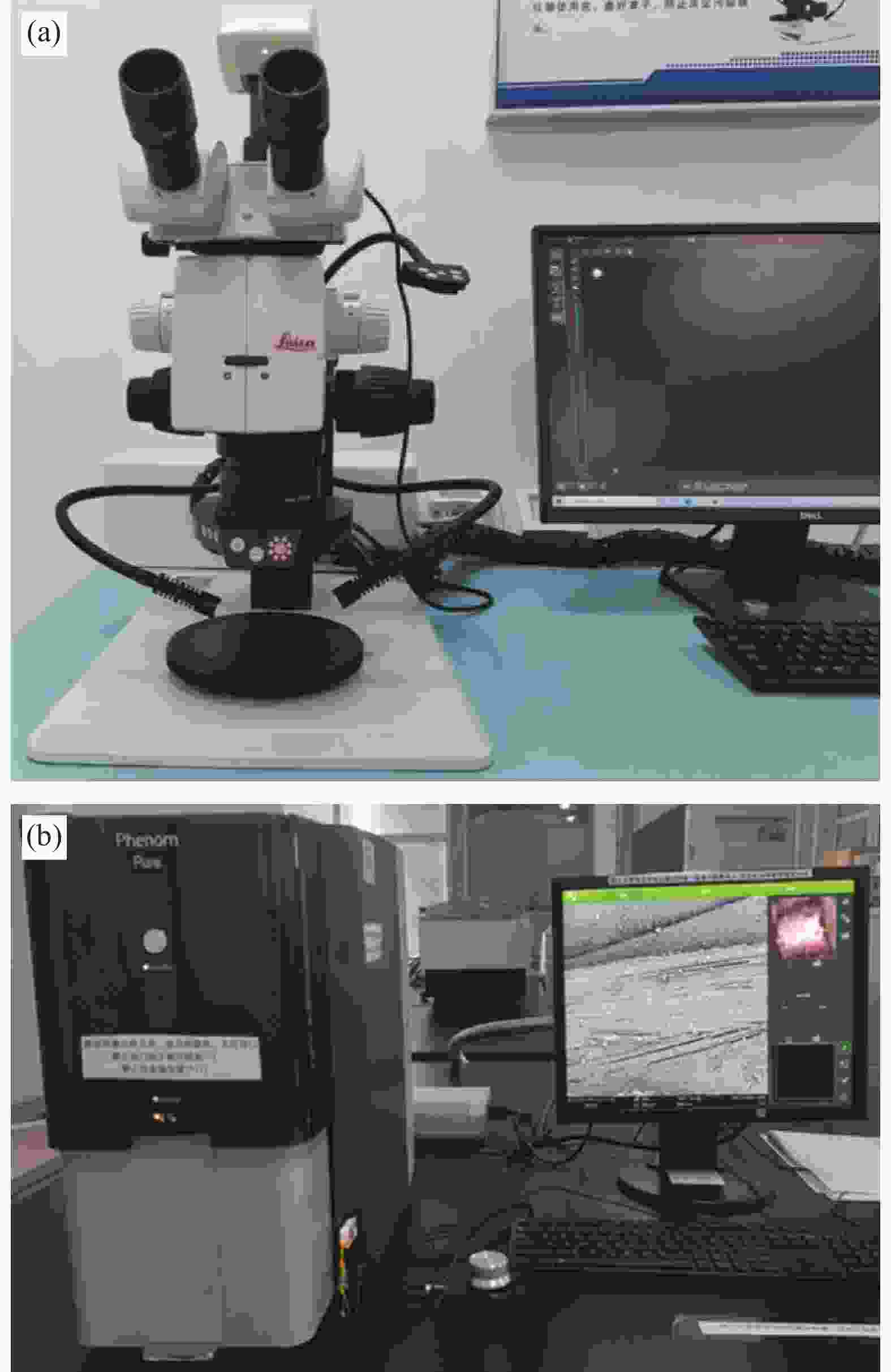

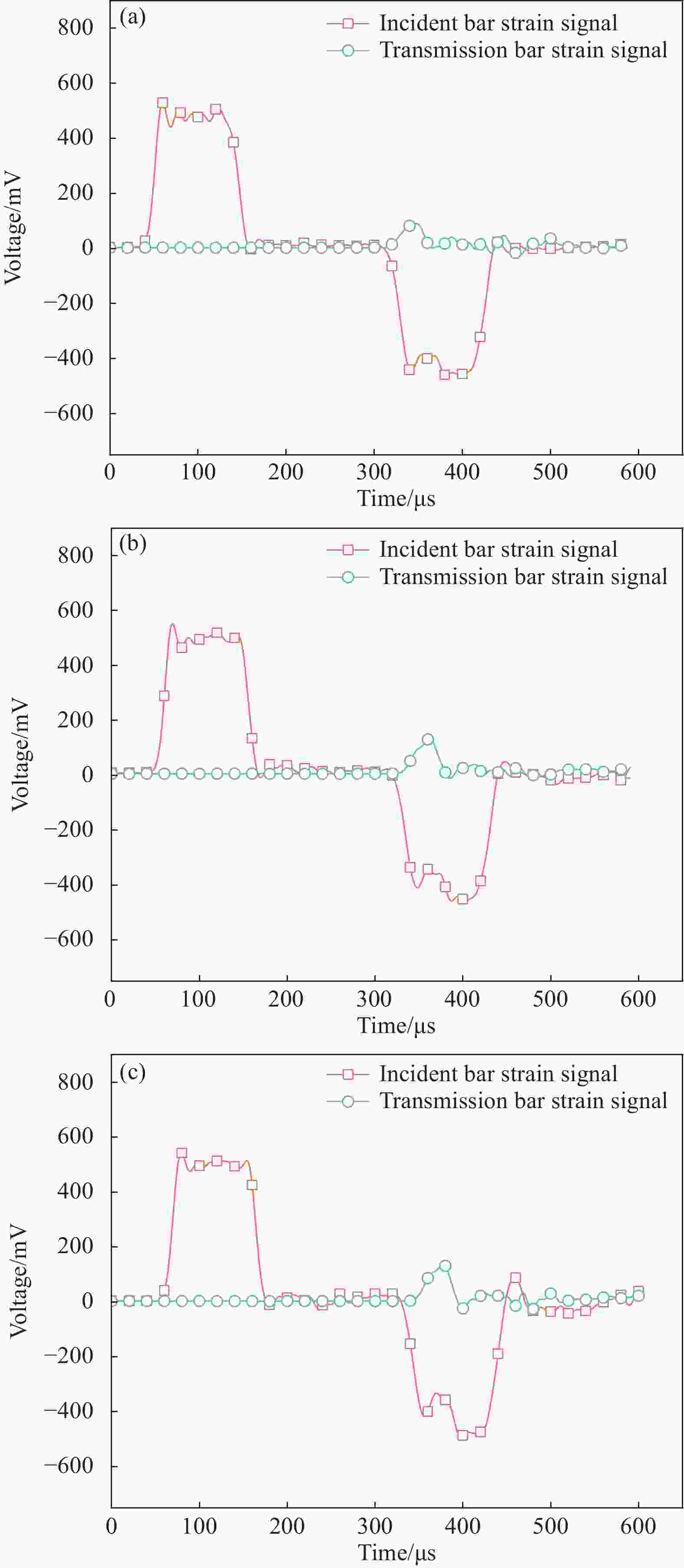

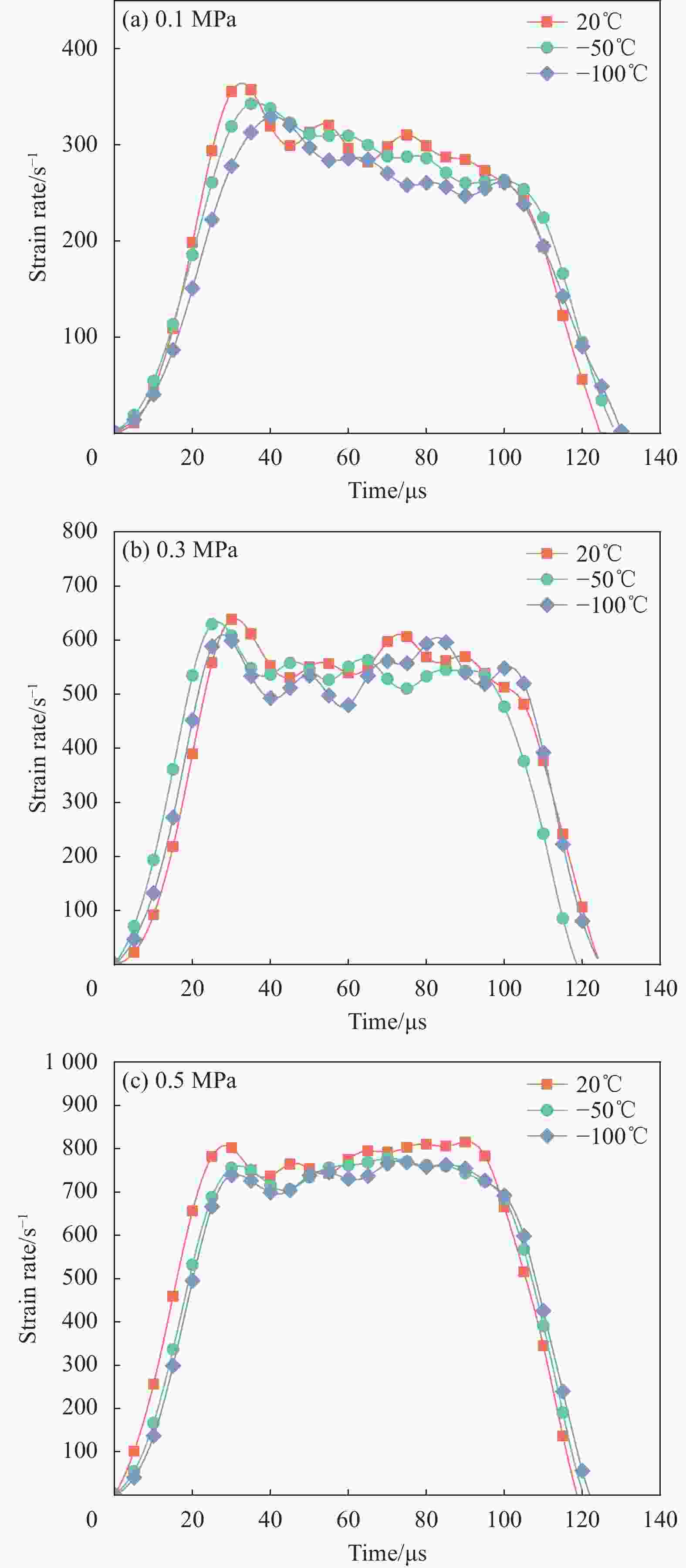

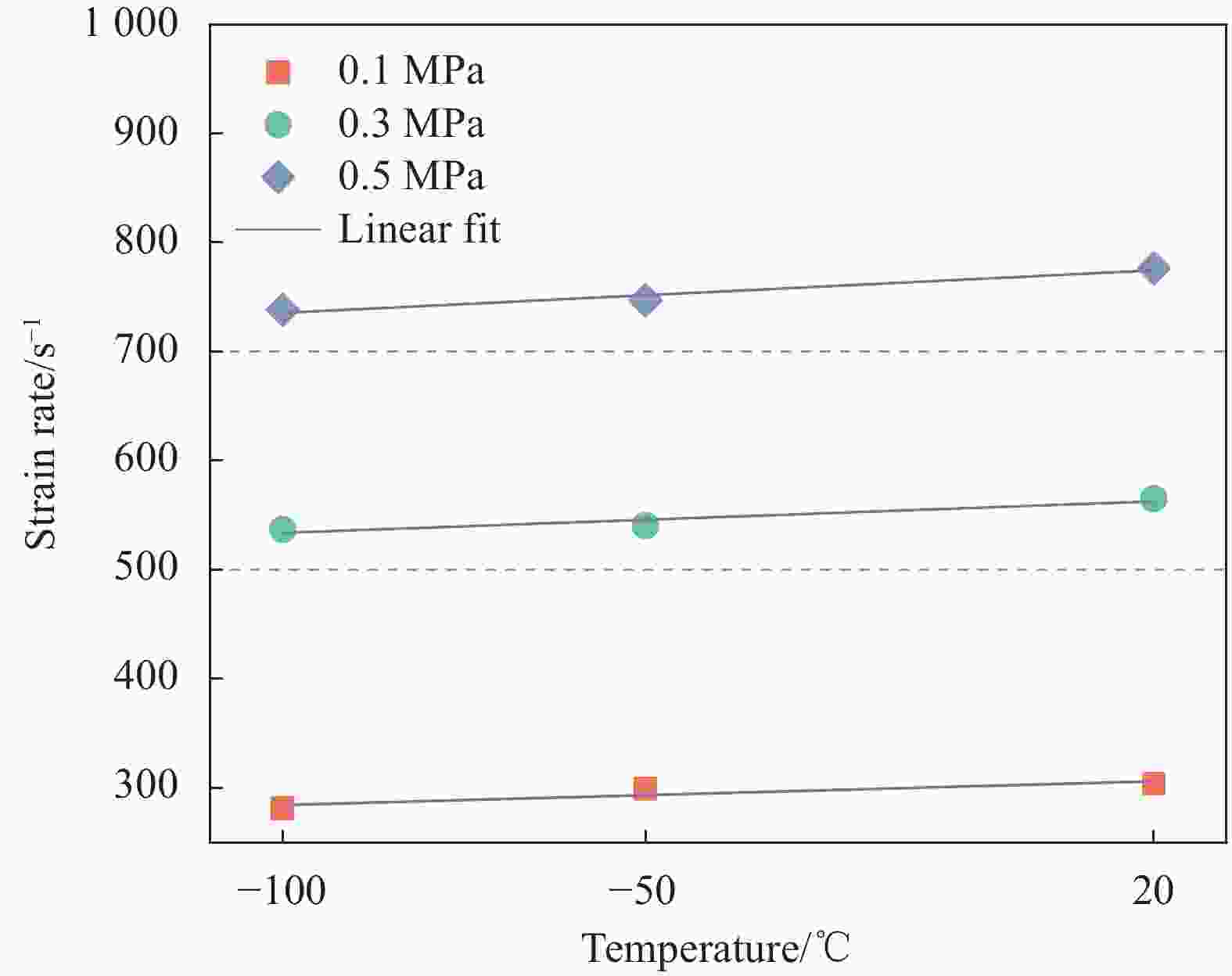

Abstract: Three-dimensional and five-directional (3D5D) glass fiber/epoxy resin braided composite circular tubes were fabricated by 3D braiding molding technology and resin transfer molding (RTM). Axial impact compression performance tests were conducted on the 3D5D braided composite circular tubes using the Split Hopkinson Pressure Bar (SHPB) at low temperatures (−100°C, −50°C) and room temperature (20°C). The effects of temperature and strain rate on the axial impact compression performance of 3D5D braided composite circular tubes were studied using the Stereomicroscope and SEM. The results show that temperature and strain rate have a significant effect on the axial impact compression performance of 3D5D glass fiber/epoxy resin braided composite circular tubes. Under the low-temperature field, the axial impact compression mechanical properties of 3D5D braided composite circular tubes are better than those at room temperature. With the increase of strain rate and the decrease of temperature, the peak stress, the compression modulus and the specific absorption energy of 3D5D braided composite circular tubes increase to varying degrees. In the low-temperature field, the axial impact compression failure characteristic of the material is brittle fracture and the fracture of the fiber bundle is relatively neat. The degrees of specimens’ failure and deformation become more severe with the increase of strain rate and the decrease of temperature. However, the 3D5D braided composite circular tubes maintain good structural integrity even at high strain rates and low temperatures. -

表 1 玻璃纤维性能参数

Table 1. Properties of glass fiber

Parameter σ/MPa E/GPa ρ/(g·cm−3) d/μm Value 2450 81.95 2.64 17 Notes: σ—Tensile strength; E—Tensile modulus; ρ—Density; d—Fiber diameter. 表 2 JC-02A型环氧树脂性能参数

Table 2. Properties of JC-02A epoxy resin

Parameter Viscosity/

(MPa·s)Epoxy value/

(mol·(100 g)−1)Density/

(g·cm−3)Value 1000 -3000 0.50-0.53 1.12-1.14 表 3 三维五向编织复合材料圆管试样规格

Table 3. Sample specification of 3D5D braided composite circular tubes

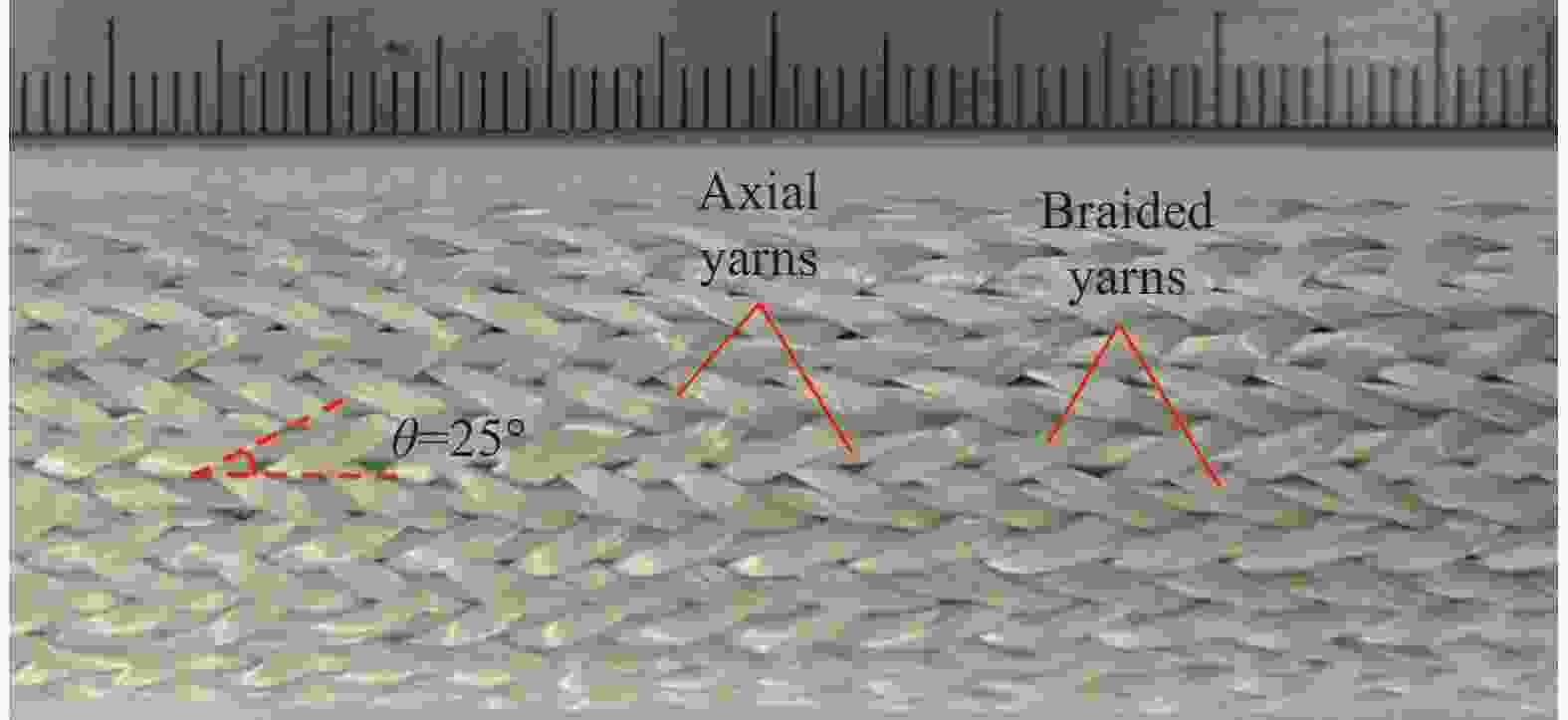

Braiding angle/(°) Outside diameter/mm Wall thickness/mm Fiber volume fraction/vol% 25 25.92 2.53 61.25 -

[1] ZHANG C, Curiel-Sosa J, BUI Q T. Meso-scale progressive damage modeling and life prediction of 3D braided composites under fatigue tension loading[J]. Composite Structures, 2018, 62-71. [2] GU Q J, QUAN Z Z, YU J Y, et al. Structural modeling and mechanical characterizing of three-dimensional four-step braided composites: A review[J]. Composite Structures, 2018, 119-128. [3] WU X Y, GU B H, SUN B Z. Comparisons of axial compression behaviors between four-directional and five-directional braided composite tubes under high strain rate loading[J]. Journal of Composite Materials, 2016, 50(28): 3905-3924. doi: 10.1177/0021998316628619 [4] LI D S, ZHAO C Q, GE T Q, et al. Experimental investigation on the compression properties and failure mechanism of 3D braided composites at room and liquid nitrogen temperature[J]. Composites Part B, 2014, 56: 647-659. doi: 10.1016/j.compositesb.2013.08.068 [5] 翟军军, 王露晨, 孔祥霞. 三维多向编织复合材料温度效应综述: 热传导、热膨胀性质和力学响应[J]. 复合材料学报, 2021, 38(8): 2459-2478.ZHAI Junjun, WANG Lunchen, KONG Xiangxia. A review on temperature effect of 3D multi-directional braided composites: Heat conduction, thermal expansion properties and mechanical response[J]. Acta Materiae Compositae Sinica, 2021, 38(8): 2459-2478(in Chinese). [6] WU X Y, SUN B Z, WANG B C, et al. X-ray microtomography analysis of the damage mechanisms in 3D circular braided carbon fiber/epoxy resin composite tubes under axial impact compression[J]. Composites Communications, 2023, 41. [7] LI Y D, YAN S B, YAN Y, et al. Modelling of the compressive behavior of 3D braided tubular composites by a novel unit cell[J]. Composite Structures, 2022, 287. [8] ZHANG Y Y, LI H M, GAO Y H, et al. Multi-scale modeling and elastic properties prediction of 3D four-directional tubular braided composites[J]. Composite Structures, 2022, 292. [9] LIU T, WU X Y, SUN B Z, et al. Investigations of defect effect on dynamic compressive failure of 3D circular braided composite tubes with numerical simulation method[J]. Thin-Walled Structures, 2021, 160. [10] PAN Z X, WU X Y, WU L W. Temperature rise caused by adiabatic shear failure in 3D braided composite tube subjected to axial impact compression[J]. Journal of Composite Materials, 2020, 54(10): 1305-1326. doi: 10.1177/0021998319877558 [11] ZHOU H L, HU D M, GU B H, et al. Transverse impact performance and finite element analysis of three dimensional braided composite tubes with different braiding layers[J]. Composite Structures, 2017, 345-359. [12] ZHOU H L, LI C, ZHANG L Q, et al. Micro-XCT analysis of damage mechanisms in 3D circular braided composite tubes under transverse impact[J]. Composites Science and Technology, 2018, 155: 91-99. doi: 10.1016/j.compscitech.2017.11.025 [13] WANG X P, CAI D A, Li C, et al. Failure analysis of three-dimensional braided composite tubes under torsional load: Experimental study[J]. Journal of Reinforced Plastics and Composites, 2017, 36(12): 878-888. doi: 10.1177/0731684417694255 [14] GIDEON R K, ZHOU H L, WU X Y, et al. Finite element analysis of 3D circular braided composites tube damage based on three unit cell models under axial compression loading[J]. International Journal of Damage Mechanics, 2016, 25(4): 574-607. doi: 10.1177/1056789515605568 [15] 张徐梁, 阳玉球, 阎建华, 等. 碳纤维-玻璃纤维混杂增强环氧树脂三维编织复合材料薄壁圆管压溃吸能特性与损伤机制[J]. 复合材料学报, 2021, 38(9): 2821-2828.ZHANG Xuliang, YANG Yuqiu, YAN Jianhua, et al. Crushing energy absorption characteristics and damage mechanism of carbon fiber-glass fiber hybrid reinforced epoxy 3D braided composite thin-walled circular tube[J]. Acta Materiae Compositae Sinica, 2021, 38(9): 2821-2828(in Chinese). [16] 谷元慧, 周红涛, 张典堂, 等. 碳纤维增强编织复合材料圆管的扭转力学性能及其损伤机制[J]. 纺织学报, 2022, 43(3): 95-102.GU Yuanhui, ZHOU Hongtao, ZHANG diantang, et al. Torsional mechanical properties and failure mechanism of braided carbon fiber reinforced composite tubes[J]. Journal of Textile Research, 2022, 43(3): 95-102(in Chinese). [17] 肖杰, 施涵, 余许多, 等. 碳纤维增强环氧树脂基复合材料轴管的低速冲击失效机制及剩余压缩性能[J]. 复合材料学报, 2021, 38(11): 3640-3651.XIAO Jie, SHI Han, YU Xuduo, et al. Failure mechanisms and residual compression performance of carbon fiber reinforced epoxy composite shaft tubes subjected to low velocity impact[J]. Acta Materiae Compositae Sinica, 2021, 38(11): 3640-3651(in Chinese). [18] 张辰, 饶云飞, 李倩倩, 等. 碳纤维-玻璃纤维混杂增强环氧树脂复合材料低速冲击性能及其模拟[J]. 复合材料学报, 2021, 38(1): 165-176.ZHANG Chen, RAO Yunfei, LI Qianqian, et al. Low-velocity impact behavior and numerical simulation of carbon fiber-glass fiber hybrid reinforced epoxy composites[J]. Acta Materiae Compositae Sinica, 2021, 38(1): 165-176(in Chinese). [19] 刘军, 刘奎, 宁博, 等. 三维编织复合材料T型梁的低温场弯曲性能[J]. 纺织学报, 2019, 40(12): 57-62.LIU Jun, LIU Kui, NING Bo, et al. Bending properties of three-dimensional braided composite T-beam at low temperature[J]. Journal of Textile Research, 2019, 40(12): 57-62(in Chinese). [20] ZHANG W, GU B H, SUN B Z. Transverse impact behaviors of 3D braided composites T-beam at elevated temperatures[J]. Journal of Composite Materials, 2016, 38(3): 187-93. [21] 王海楼, 曹淼, 孙宝忠, 等. 三维编织碳纤维/环氧树脂复合材料横向压缩性质的温度效应[J]. 复合材料学报, 2018, 35(3): 607-615.WANG Hailou, CAO Miao, SUN Baozhong, et al. Temperature effect on transverse compressive behaviors of 3D braided carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2018, 35(3): 607-615(in Chinese). [22] HAN W F, LI D S, JIANG L. Mechanical properties and failure mechanisms of 3D six-directional braided composites at elevated and liquid nitrogen temperatures[J]. Materials Letters-X, 2020, 6: 100035. doi: 10.1016/j.mlblux.2019.100035 [23] WANG H L, SUN B Z, GU B H. Finite element analyses on longitudinal compressive behaviors of 3D braided carbon /epoxy composite with different braided angles at low temperatures[J]. The Journal of The Textile Institute, 2019, 110(1): 37-49. doi: 10.1080/00405000.2018.1460038 [24] PAN Z X, GU B H, SUN B Z. Experimental investigation of high-strain rate properties of 3D braided composites material in cryogenic field[J]. Composites Part B-Engineering, 2015, 77: 379-390. doi: 10.1016/j.compositesb.2015.03.002 [25] DU X B, LI D S, LEI J, et al. Experimental study on the low-temperature compression performance of 3D five-directional braided composites applied to extreme environments[J]. Materials Letters, 2022, 324. [26] WU X Y, ZHANG Q, GU B H, et al. Influence of temperature and strain rate on the longitudinal compressive crashworthiness of 3D braided composite tubes and finite element analysis[J]. International Journal of Damage Mechanics, 2017, 26(7): 1003-1027. doi: 10.1177/1056789516648369 [27] 李紫伦, 杨安坤, 覃小红, 等. 三维编织玻璃纤维/环氧树脂复合材料薄壁管轴向压缩性能的温度效应[J]. 复合材料学报, 2023, 40(10): 5588-5600.LI Zilun, YANG Ankun, QIN Xiaohong, et al. Temperature effect on axial compressive properties of three-dimensional glass fiber/epoxy resin braided composite thin-walled tubes[J]. Acta Materiae Compositae Sinica, 2023, 40(10): 5588-5600(in Chinese). [28] 中国国家标准化管理委员会. 纤维增强塑料压缩性能试验方法: GB/T 1448—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastics composites-Determination of compressive properties: GB/T 1448—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [29] SUN B Z, LIU F, GU B H. Influence of the strain rate on the uniaxial tensile behavior of 4-step 3D braided composites[J]. Composites Part A, 2005, 36(11): 1477-1485. doi: 10.1016/j.compositesa.2005.03.012 [30] S M I, F L B, Garth P, et al. Toughening carbon fibre composites at cryogenic temperatures using low-thermal expansion nanoparticles[J]. Composites Part A, 2021, 150. [31] CHU X X, WU Z X, HUANG R J, et al. Mechanical and thermal expansion properties of glass fibers reinforced PEEK composites at cryogenic temperatures[J]. Cryogenics, 2010, 50(2): 84-88. doi: 10.1016/j.cryogenics.2009.12.003 -

点击查看大图

点击查看大图

计量

- 文章访问数: 50

- HTML全文浏览量: 32

- 被引次数: 0

下载:

下载: