Mechanical properties of square concrete short columns strengthened by concrete canvas and CFRP strips under axial compression

-

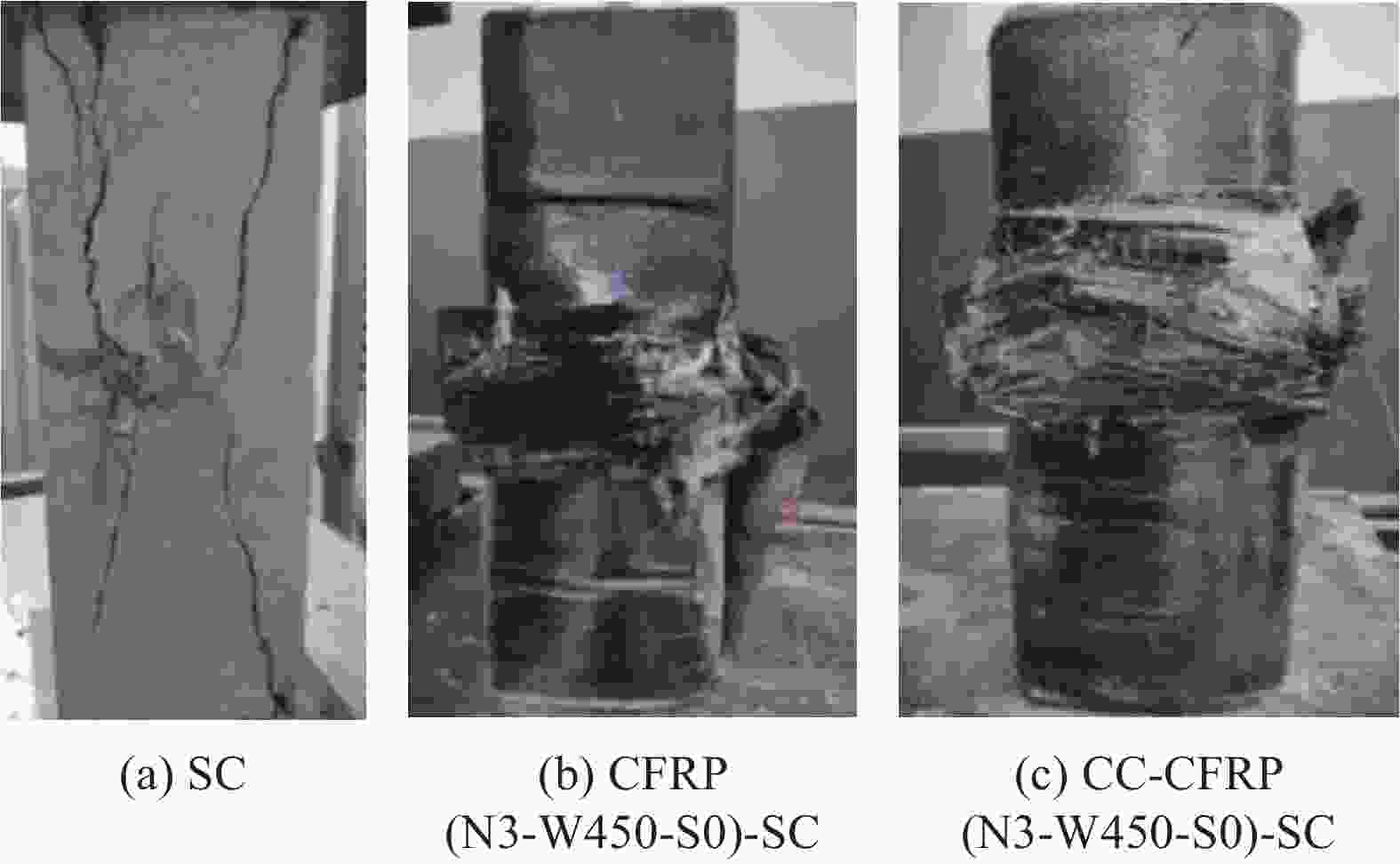

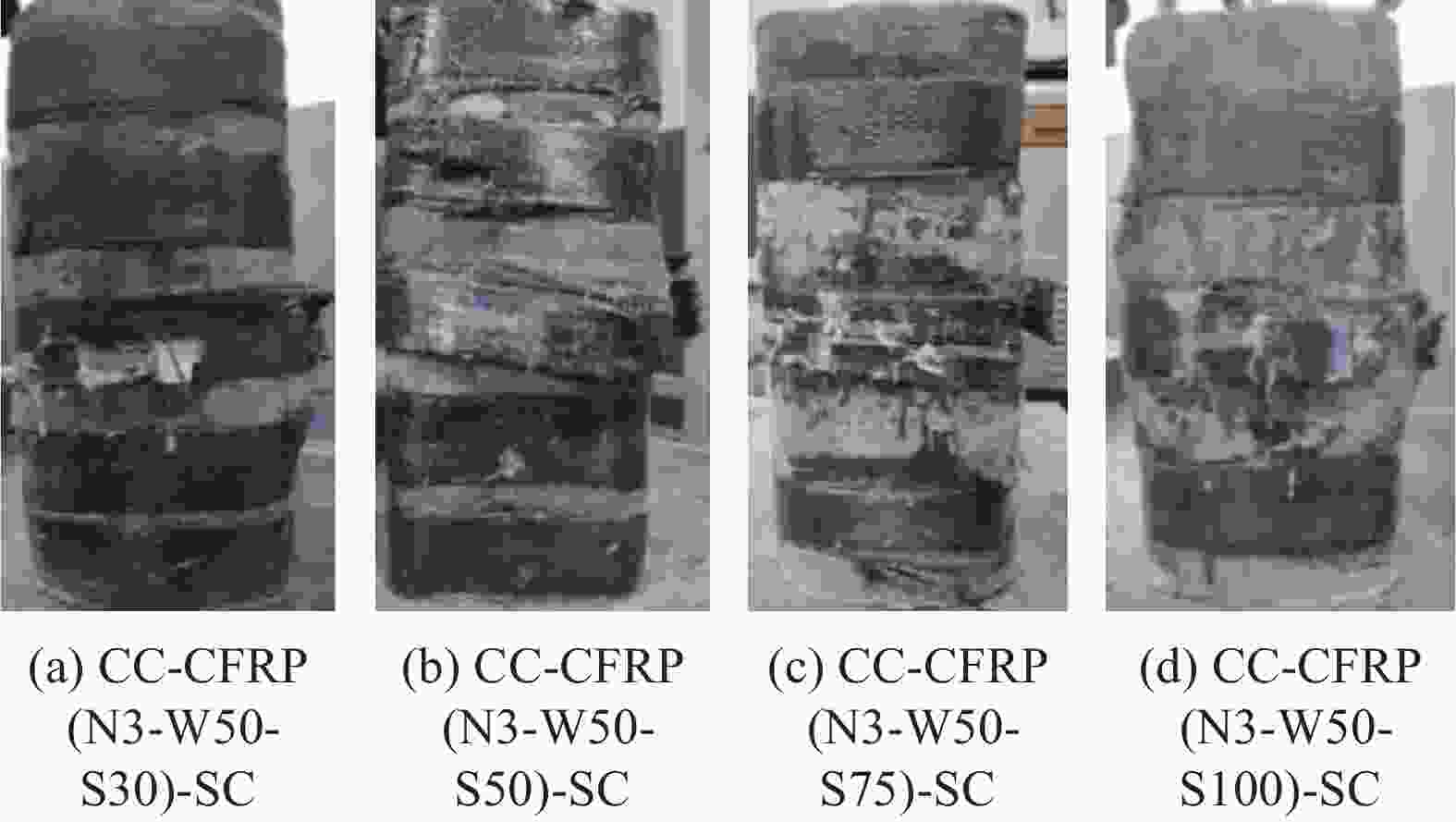

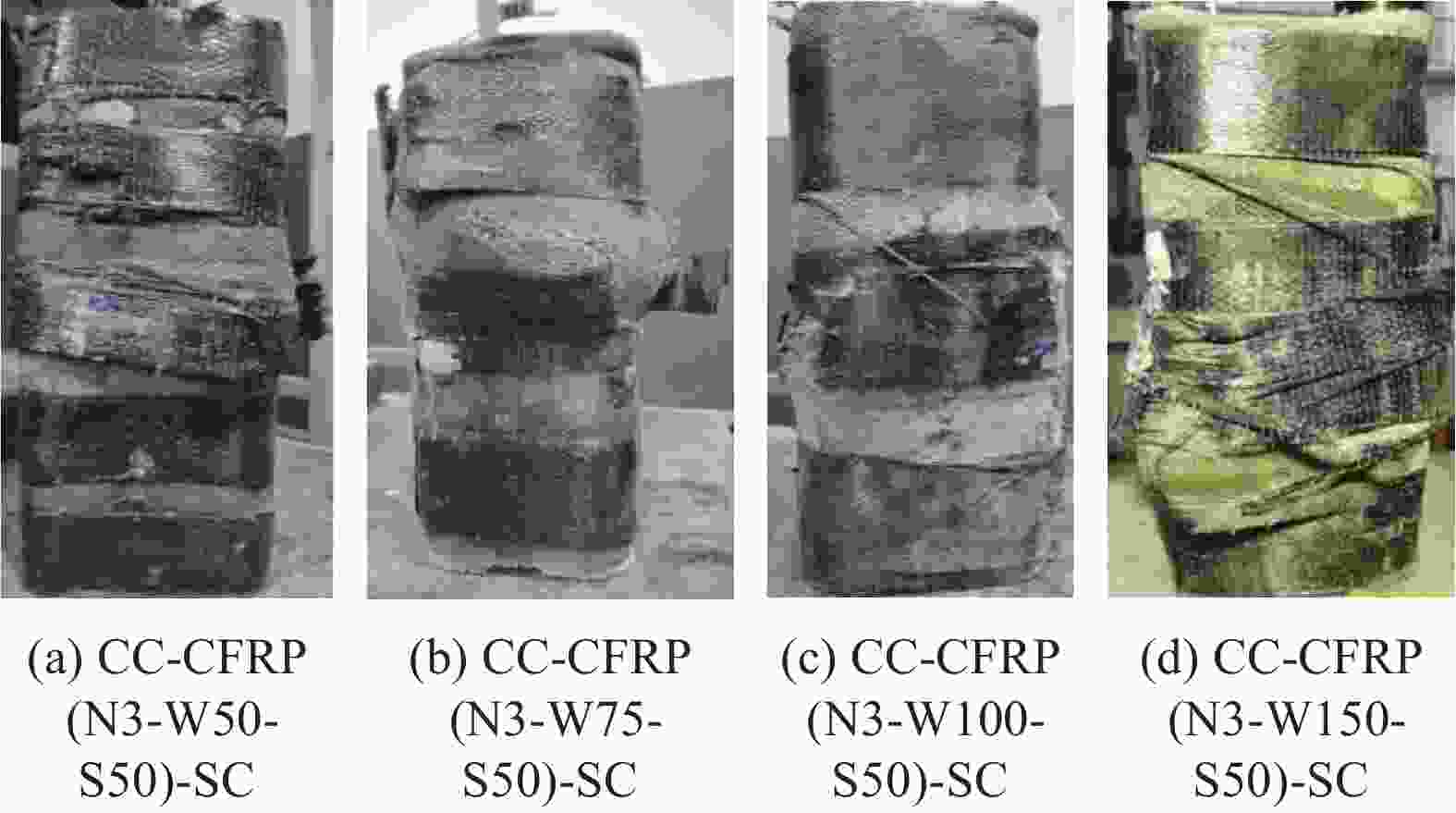

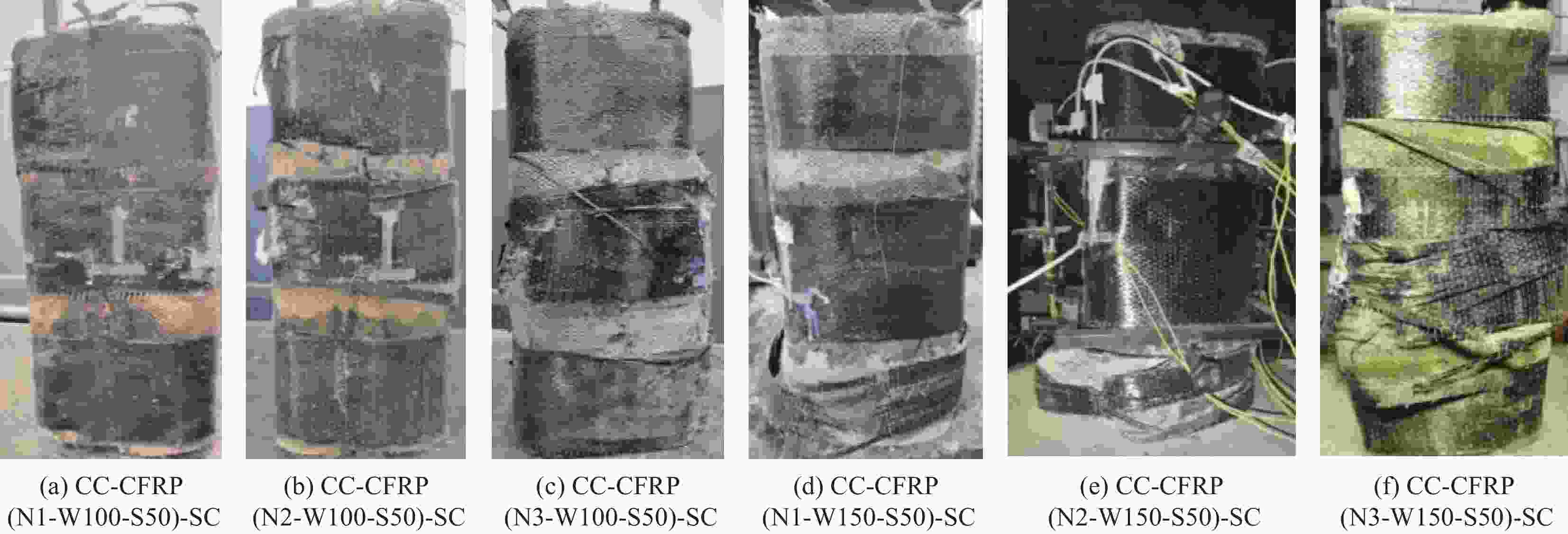

摘要: 通过混凝土帆布(CC)与碳纤维增强树脂复合材料(CFRP)条带联合加固混凝土方柱轴压试验,研究了纤维条带约束率、CFRP宽度与间距、层数对混凝土方柱轴压力学性能的影响,分析加固后混凝土方柱的破坏形态、承载力、耗能能力及变形能力。研究结果表明:CC的加入可以缓解角部应力集中,明显提高试件的变形能力,改善柱的破坏形态;条带宽度与间距对试件承载力和耗能能力的影响归结于纤维条带约束率,随着纤维条带约束率与CFRP层数的增加,试件的承载能力与耗能能力不断提高;当纤维条带约束率为0.5、宽度与间距为50 mm时,承载力与耗能能力最大。在试验研究的基础上,对有效约束面积变化进行理论分析,得出CC在联合加固中起到的作用,并建立联合加固混凝土方柱轴心受压承载力模型,通过误差分析可知,该模型具有较高的预测精度。

-

关键词:

- 混凝土帆布 /

- 碳纤维增强树脂复合材料 /

- 混凝土方柱 /

- 轴压试验 /

- 力学性能

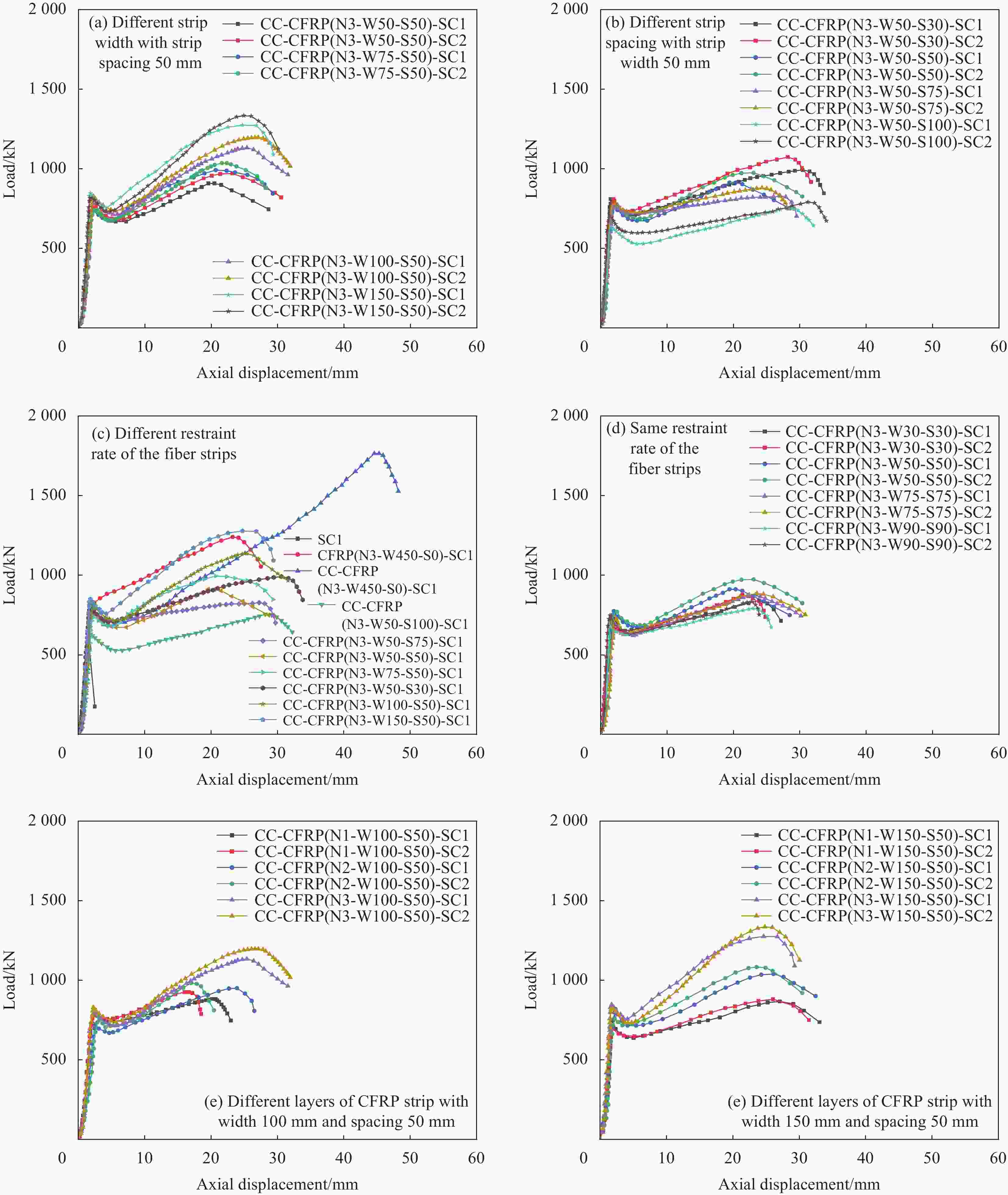

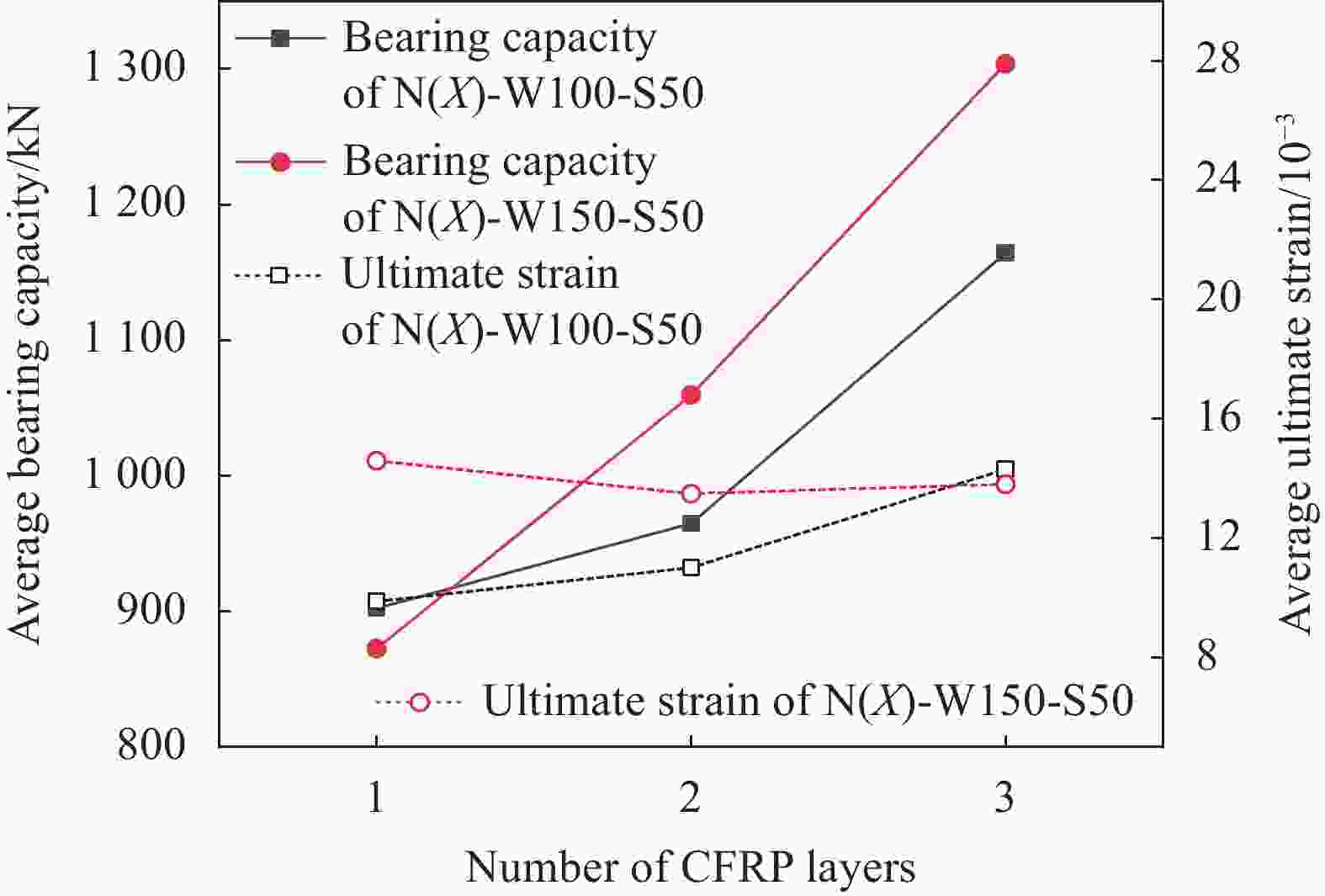

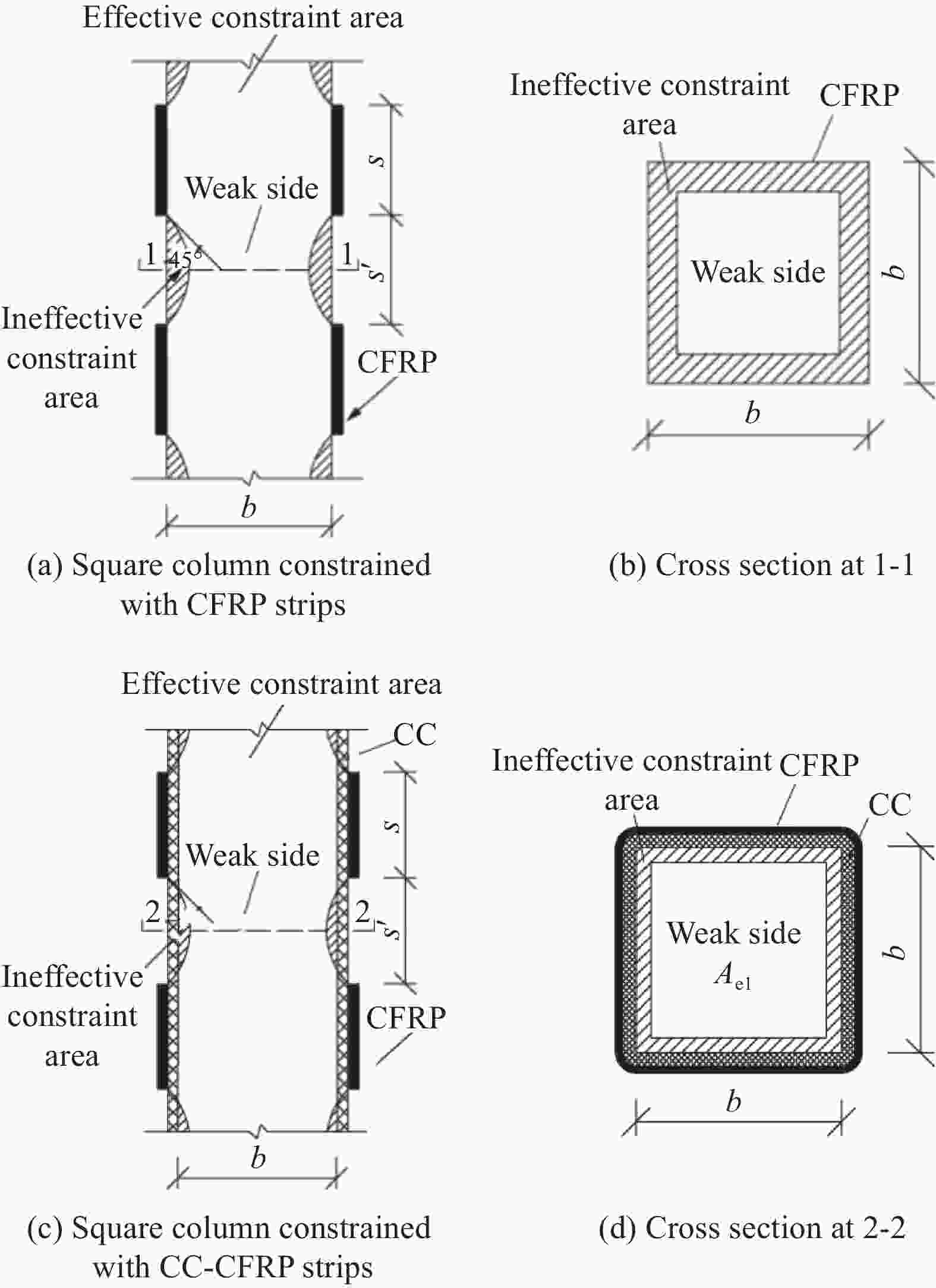

Abstract: Through the axial compression test of concrete square columns which strengthened by concrete canvas (CC) and carbon fiber reinforced polymer (CFRP) strips, the influences of restraint rate, width and spacing of CFRP, and number of layers on the mechanical property of the concrete square column were studied. The failure form, bearing capacity, energy consumption capacity and deformation capacity of the reinforced concrete square column were analyzed. The research results show that the addition of CC can alleviate the stress concentration at the corners, significantly increase the deformation ability of the specimen, and improve the failure form of the column. The influence of width and spacing of the strips on the bearing capacity and energy dissipation capacity of the specimen is attributed to the restraint rate of the fiber strips. With the increase of the strip restraint rate and the number of CFRP layers, the load-bearing capacity and energy consumption capacity of the specimens continue to increase. When the fiber restraint ratio is 0.5, the bearing capacity is the largest when the width and spacing are 50 mm. Based on the experimental research, a theoretical analysis of the effective constrained area change was carried out, and the role of CC in joint reinforcement was obtained, and the axial compression bearing capacity model was established. The error analysis shows that the model has high prediction accuracy. -

表 1 试件主要参数

Table 1. Main parameters of specimens

Number Strip width/mm Strip spacing/mm Restraint rate of the fiber strips Number of CFRP layers SC 0 0 0 0 CFRP(N3-W450-S0)-SC 450 0 1.00 3 CC-CFRP(N3-W450-S0)-SC 450 0 1.00 3 CC-CFRP(N3-W50-S100)-SC 50 100 0.33 3 CC-CFRP(N3-W50-S75)-SC 50 75 0.40 3 CC-CFRP(N3-W50-S50)-SC 50 50 0.50 3 CC-CFRP(N3-W75-S50)-SC 75 50 0.60 3 CC-CFRP(N3-W50-S30)-SC 50 30 0.625 3 CC-CFRP(N3-W100-S50)-SC 100 50 0.67 3 CC-CFRP(N3-W150-S50)-SC 150 50 0.75 3 CC-CFRP(N3-W30-S30)-SC 30 30 0.50 3 CC-CFRP(N3-W75-S75)-SC 75 75 0.50 3 CC-CFRP(N3-W90-S90)-SC 90 90 0.50 3 CC-CFRP(N1-W100-S50)-SC 100 50 0.67 1 CC-CFRP(N2-W100-S50)-SC 100 50 0.67 2 CC-CFRP(N1-W150-S50)-SC 150 50 0.75 1 CC-CFRP(N2-W150-S50)-SC 150 50 0.75 2 Notes: SC—Square column; First letter and number in parentheses—Number of CFRP layers; Second letter and number—Width of CFRP; Third letter and number—Spacing of CFRP. For example, CC-CFRP(N3-W50-S100)-SC—Strip width of concrete square columns strengthened by CC and CFRP is 50 mm, the spacing is 100 mm, and the number of CFRP is 3. 表 2 CFRP布力学性能参数

Table 2. Mechanical properties of CFRP

Model t/mm fu/MPa E/MPa εcu/% CFS-I-300 0.167 3548 2.33×105 1.62 Notes: t—Thickness of CFRP; fu—Tensile strength of CFRP; E— Elastic modulus of CFRP; εcu—Tensile elongation of CFRP at break. 表 3 CC力学性能参数

Table 3. Mechanical properties of CC

Type of CC fc/MPa ft/MPa ρ/(kg·m−3) Sulphoaluminate concrete canvas 30.10 2.77 1250 Notes: fc—Compressive strength of CC; ft—Tensile strength of CC; ρ—Bulk density of CC. 表 4 各组混凝土方柱试件实验结果

Table 4. Test results of concrete square column specimens

Number kf Nu/kN Nu,m/kN $ f{'_{{\text{cc}}}} $/

MPa$ f{'_{{\text{cc,m}}}} $

/

MPa$ \dfrac{{f{'_{{\text{cc,m}}}}}}{{f{'_{{\text{co,m}}}}}} $ $ {\varepsilon _{{\text{cc}}}} $/10−3 $ {\varepsilon _{{\text{cc,m}}}} $/

10−3$ \dfrac{{{\varepsilon _{{\text{cc,m}}}}}}{{{\varepsilon _{{\text{co,m}}}}}} $ EP/(kN·mm) EP,m/

(kN·mm)SC1 0.00 546.51 588.48 24.29 26.15 1.00 2.24 2.27 1.00 751.39 837.12 SC2 630.45 28.02 2.30 922.85 CFRP(N3-W450-S0)-SC1 1.00 1236.46 1250.00 54.95 55.56 2.12 12.08 11.67 5.14 27742.55 25913.95 CFRP(N3-W450-S0)-SC2 1263.54 56.16 11.26 24085.35 CC-CFRP(N3-W450-S0)-SC1 1.00 1761.01 1766.97 78.27 78.53 3.00 25.63 26.36 11.61 54182.75 57328.26 CC-CFRP(N3-W450-S0)-SC2 1772.93 78.80 27.09 60473.76 CC-CFRP(N3-W50-S100)-SC1 0.33 751.26 768.54 33.39 34.16 1.31 16.69 16.87 7.43 19748.52 21124.90 CC-CFRP(N3-W50-S100)-SC2 785.82 34.93 17.05 22501.28 CC-CFRP(N3-W50-S75)-SC1 0.40 824.21 849.92 36.63 37.77 1.44 12.94 12.87 5.66 21949.59 21900.44 CC-CFRP(N3-W50-S75)-SC2 875.63 38.92 12.80 21851.29 CC-CFRP(N3-W50-S50)-SC1 0.50 900.07 935.05 40.00 41.74 1.60 12.08 12.16 5.35 21639.50 23133.31 CC-CFRP(N3-W50-S50)-SC2 970.03 43.11 12.24 24627.11 CC-CFRP(N3-W75-S50)-SC1 0.60 991.58 1013.58 44.07 45.05 1.72 12.49 12.45 5.48 24302.41 24293.83 CC-CFRP(N3-W75-S50)-SC2 1035.58 46.03 12.41 24285.25 CC-CFRP(N3-W50-S30)-SC1 0.62 988.09 1028.60 43.92 45.72 1.75 15.68 15.32 6.74 28081.90 27915.97 CC-CFRP(N3-W50-S30)-SC2 1069.11 47.52 14.96 27750.04 CC-CFRP(N3-W100-S50)-SC1 0.67 1132.30 1164.27 50.32 51.75 1.98 13.99 14.31 6.30 28452.54 29344.17 CC-CFRP(N3-W100-S50)-SC2 1196.24 53.17 14.61 30235.79 CC-CFRP(N3-W150-S50)-SC1 0.75 1273.82 1303.78 56.61 57.95 2.22 13.72 13.81 6.08 30020.55 30327.93 CC-CFRP(N3-W150-S50)-SC2 1333.74 59.28 13.90 30635.30 CC-CFRP(N3-W30-S30)-SC1 0.50 835.77 853.99 37.15 37.96 1.45 13.02 12.50 5.51 19276.97 18605.32 CC-CFRP(N3-W30-S30)-SC2 872.21 38.76 11.98 17933.67 CC-CFRP(N3-W75-S75)-SC1 0.50 871.83 876.74 38.75 38.97 1.49 13.56 13.70 6.04 21794.27 22218.48 CC-CFRP(N3-W75-S75)-SC2 881.65 39.18 13.84 22642.69 CC-CFRP(N3-W90-S90)-SC1 0.50 787.42 808.83 35.00 35.95 1.37 12.67 12.59 5.55 17377.05 17003.90 CC-CFRP(N3-W90-S90)-SC2 830.24 36.90 12.51 16630.75 CC-CFRP(N1-W100-S50)-SC1 0.67 880.34 902.30 39.13 40.10 1.53 10.42 9.88 4.35 17467.47 15920.07 CC-CFRP(N1-W100-S50)-SC2 924.26 41.08 9.34 14372.67 CC-CFRP(N2-W100-S50)-SC1 0.67 948.76 964.87 42.17 42.88 1.64 11.65 11.01 4.85 20375.14 17920.45 CC-CFRP(N2-W100-S50)-SC2 980.98 43.60 10.37 15465.76 CC-CFRP(N1-W150-S50)-SC1 0.75 865.43 872.55 38.46 38.78 1.48 15.12 14.59 6.53 24092.08 23705.29 CC-CFRP(N1-W150-S50)-SC2 879.67 39.10 14.06 23318.50 CC-CFRP(N2-W150-S50)-SC1 0.75 1037.97 1059.67 46.13 47.10 1.80 13.79 13.49 5.94 27598.94 27131.26 CC-CFRP(N2-W150-S50)-SC2 1081.37 48.06 13.19 26663.58 Notes: kf—Fiber strip restraint rate; Nu—Peak load of each group of specimens; Nu,m—Average peak load of each group of specimens; f 'cc—Peak stress of each group of specimens; f 'cc,m—Average peak stress of each group of specimens; f 'co —Peak stress corresponding to the SC group of specimens; f 'co,m—Average peak stress corresponding to the SC group of specimens; εcc—Strain corresponding to f 'cc of each group of specimens; εcc,m—Average strain corresponding to f 'cc of each group of specimens; εco—Strain corresponding to f 'co of SC group of specimens; εco,m—Average strain corresponding to f 'co of SC group specimens; EP—Energy dissipation capacity; EP,m—Average energy dissipation capacity. -

[1] 张鑫, 李安起, 赵考重. 建筑结构鉴定与加固改造技术的进展[J]. 工程力学, 2011, 28(1):1-11, 25.ZHANG Xin, LI Anqi, ZHAO Kaozhong. Advances in assessment and retrofitting of building structures[J]. Engineering Mechanics,2011,28(1):1-11, 25(in Chinese). [2] 龚建伍. 建筑物变形监测及安全评价方法研究[D]. 武汉: 武汉大学, 2004.GONG Jianwu. Study on building deformation monitoring and safety evaluation method[D]. Wuhan: Wuhan University, 2004(in Chinese). [3] 牛建刚, 刘威亨. 酸雨侵蚀混凝土研究进展[J]. 灾害学, 2020, 35(4):147-150, 168. doi: 10.3969/j.issn.1000-811X.2020.04.027NIU Jiangang, LIU Weiheng. Research progress on acid rain erosion of concrete[J]. Journal of Catastrophology,2020,35(4):147-150, 168(in Chinese). doi: 10.3969/j.issn.1000-811X.2020.04.027 [4] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-36. doi: 10.3321/j.issn:1000-131X.2006.03.004YE Lieping, FENG Peng. Application and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-36(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [5] 薛伟辰, 李杰. 碳纤维材料在加固工程中的应用研究[J]. 四川建筑科学研究, 2001, 27(4):28-30. doi: 10.3969/j.issn.1008-1933.2001.04.009XUE Weichen, LI Jie. Studies on applications of CFRP in strengthening structures[J]. Sichuan Building Science,2001,27(4):28-30(in Chinese). doi: 10.3969/j.issn.1008-1933.2001.04.009 [6] 李趁趁, 于爱民, 高丹盈, 等. 侵蚀环境下FRP条带加固锈蚀钢筋混凝土圆柱轴心受压试验[J]. 复合材料学报, 2020, 37(8):2015-2028. doi: 10.13801/j.cnki.fhclxb.20200212.005LI Chenchen, YU Aimin, GAO Danying, et al. Experimental study on axial compression of corroded reinforced concrete columns strengthened with FRP strips under erosion environment[J]. Acta Materiae Compositae Sinica,2020,37(8):2015-2028(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200212.005 [7] TENG J G, LAM L. Behavior and modeling of fiber reinforced polymer-confined concrete[J]. Journal of Structural Engineering,2004,130(11):1713-1723. doi: 10.1061/(ASCE)0733-9445(2004)130:11(1713) [8] 刘涛. 碳纤维(CFRP)布加固混凝土矩形柱的性能研究[D]. 上海: 上海大学, 2006.LIU Tao. Research on the behavior of rectangular concrete columns strengthened with CFRP sheets[D]. Shanghai: Shanghai University, 2006(in Chinese). [9] 岳清瑞, 杨勇新. 纤维增强复合材料加固结构耐久性研究综述[J]. 建筑结构学报, 2009, 30(6):8-15. doi: 10.14006/j.jzjgxb.2009.06.002YUE Qingrui, YANG Yongxin. Introduction to durability of concrete strengthened with fiber reinforced polymers[J]. Journal of Building Structures,2009,30(6):8-15(in Chinese). doi: 10.14006/j.jzjgxb.2009.06.002 [10] KAFODYA I, XIAN G J, LI H. Durability study of pultruded CFRP plates immersed in water and seawater under sustained bending: Water uptake and effects on the mechanical properties[J]. Composites Part B: Engineering,2015,70:138-148. doi: 10.1016/j.compositesb.2014.10.034 [11] 张磊. 带角部增强的CFRP约束混凝土方柱抗压性能试验研究[D]. 长沙: 湖南大学, 2015.ZHANG Lei. Compressive performance study of square concrete columns confined by CFRP with corner reinforced[D]. Changsha: Hunan University, 2015(in Chinese). [12] 杨俊龙, 王吉忠, 卢世伟, 等. FRP非均匀约束海水海砂混凝土方柱轴压性能[J]. 复合材料学报, 2022, 39(6):2801-2809. doi: 10.13801/j.cnki.fhclxb.20210708.004YANG Junlong, WANG Jizhong, LU Shiwei, et al. Axial compressive behavior of FRP nonuniformly wrapped seawater sea-sand concrete in square columns[J]. Acta Materiae Compositae Sinica,2022,39(6):2801-2809(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210708.004 [13] 胡忠君, 宋雪娇. CFRP布条带约束混凝土圆柱承载力计算方法研究[J]. 混凝土, 2016(11):46-48. doi: 10.3969/j.issn.1002-3550.2016.11.013HU Zhongjun, SONG Xuejiao. Study on the calculation method of circle concrete column wrapped with CFRP cloth straps[J]. Concrete,2016(11):46-48(in Chinese). doi: 10.3969/j.issn.1002-3550.2016.11.013 [14] HAN F Y, CHEN H S, LI X Y, et al. Improvement of mechanical properties of concrete canvas by anhydrite-modified calcium sulfoaluminate cement[J]. Journal of Composite Materials,2016,50(14):1937-1950. doi: 10.1177/0021998315597743 [15] LI H, CHEN H S, LI X Y, et al. Design and construction application of concrete canvas for slope protection[J]. Powder Technology,2019,344:937-946. doi: 10.1016/j.powtec.2018.12.075 [16] 胡伟勋. 工业SO2环境混凝土帆布力学性能及耐久性能试验研究[D]. 包头: 内蒙古科技大学, 2016.HU Weixun. Experimental study on mechanical properties and durability of concrete canvas in the environment with industrial sulfur dioxide[D]. Baotou: Inner Mongolia University of Science and Technology, 2016(in Chinese). [17] 曹鹏. 混凝土帆布的力学性能及其复合管研究[D]. 苏州: 苏州科技大学, 2016.CAO Peng. Study on mechanical properties and composite tube of concrete canvas[D]. Suzhou: Suzhou University of Science and Technology, 2016(in Chinese). [18] 张方圆. 混凝土帆布配合比优化、FRP增强及抗侵彻性能研究[D]. 南京: 东南大学, 2016.ZHANG Fangyuan. Mixture proportion optimization, FRP reinforcement and ballistic performance of concrete canvas[D]. Nanjing: Southeast University, 2016(in Chinese). [19] NIU J G, XU W M, LI J J, et al. Influence of cross-sectional shape on the mechanical properties of concrete canvas and CFRP-reinforced columns[J]. Advance in Materials Science and Engineering,2021,2021(30):1-14. doi: 10.1155/2021/5541587 [20] 相泽辉, 牛建刚, 王梦雨, 等. 混凝土帆布和碳纤维布联合约束圆形截面混凝土短柱轴压性能研究[J]. 建筑结构学报, 2020, 41(S1):154-161. doi: 10.14006/j.jzjgxb.2020.S1.017XIANG Zehui, NIU Jian'gang, WANG Mengyu, et al. Experience study on axial behavior of RC circular columns confined with CC and CFRP[J]. Journal of Building Structures,2020,41(S1):154-161(in Chinese). doi: 10.14006/j.jzjgxb.2020.S1.017 [21] 牛建刚, 栾瑞林, 刘晓. 混凝土帆布与CFRP加固钢筋混凝土方柱受力性能试验研究[J]. 建筑结构学报, 2018, 39(S2):169-175. doi: 10.14006/j.jzjgxb.2018.S2.023NIU Jian'gang, LUAN Ruilin, LIU Xiao. Experimental study on mechanical properties of reinforced concrete square columns strengthened with CFRP[J]. Journal of Building Structures,2018,39(S2):169-175(in Chinese). doi: 10.14006/j.jzjgxb.2018.S2.023 [22] ACI Committee 440. Guide for the design and construction of externally bonded FRP systems for strengthening concrete structures: ACI 440. 2R—08[S]. Farmington Hills: American Concrete Institute, 2008. [23] 中华人民共和国住房与城乡建设部. 建筑砂浆基本性能试验方法标准: JGJ/T 70—2009 [S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of performance on building mortar: JGJ/T 70—2009[S]. Beijing: China Architecture & Building Press, 2009(in Chinese). [24] ZHANG F Y, CHEN H S, LI X Y, et al. Experimental study of the mechanical behavior of FRP-reinforced concrete canvas panels[J]. Composite Structures,2017,176:608-616. doi: 10.1016/j.compstruct.2017.05.072 [25] 中华人民共和国住房与城乡建设部. 混凝土结构试验方法标准: GB/T 50152—2012[S]. 北京: 中国建筑工业出版社, 2012.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of concrete structures: GB/T 50152—2012[S]. Beijing: China Architecture & Building Press, 2012(in Chinese). [26] NISTICO N, PALLINI F, ROUSAKIS T, et al. Peak strength and ultimate strain prediction for FRP confined square and circular concrete sections[J]. Composites Part B: Engineering,2014,67:543-554. doi: 10.1016/j.compositesb.2014.07.026 [27] 彭亚萍, 刘增夕, 马明. 条带式FRP约束混凝土方柱的轴 压承载力分析[J]. 武汉理工大学学报, 2010, 32(3):24-28.PENG Yaping, LIU Zengxi, MA Ming. Analysis of axial compressive bearing capacity of square concrete column confined with striped FRP[J]. Journal of Wuhan University of Technology,2010,32(3):24-28(in Chinese). [28] TRIANTAFILLOU T, MATTHYS S, AUDENAERT K, et al. Externally bonded FRP reinforcement for RC structures[M]. Lausanne: International Federation for Structural Concrete (Fib), 2001. [29] 卢亦焱, 史健勇, 赵国藩. 碳纤维布约束轴心受压混凝土方形柱承载力计算研究[J]. 工程力学, 2004, 21(4):22-27. doi: 10.3969/j.issn.1000-4750.2004.04.005LU Yiyan, SHI Jianyong, ZHAO Guofan. Experimental research on concrete columns strengthened with the combination of CFRP and angle steel[J]. Engineering Mechanics,2004,21(4):22-27(in Chinese). doi: 10.3969/j.issn.1000-4750.2004.04.005 [30] 李伟政. 二轴拉压应力全组合下混凝土强度及变形试验研究[D]. 北京: 清华大学, 1989.LI Weizheng. Experimental research on concrete strength and deformation under full combination of biaxial tension and compression stress[D]. Beijing: Tsinghua University, 1989(in Chinese). [31] TENG J G, HU Y M, YU T. Stress-strain model for concrete in FRP-confined steel tubular columns[J]. Engineering Structure,2013,49(2):156-167. doi: 10.1016/j.engstruct.2012.11.001 [32] HUANG L, GAO C, YAN L B, et al. Reliability assessment of confinement models of carbon fiber reinforced polymer-confined concrete[J]. Journal of Reinforced Plastics & Composites,2016,35(12):996-1026. doi: 10.1177/0731684416633899 [33] TOUTANJI H A. Stress-strain characteristics of concrete columns externally confined with advanced fiber composite sheets[J]. ACI Structural Journal,1999,96(3):397-404. -

下载:

下载: