Bond performance between surface modified bamboo scrimber bar and bamboo biochar mortar

-

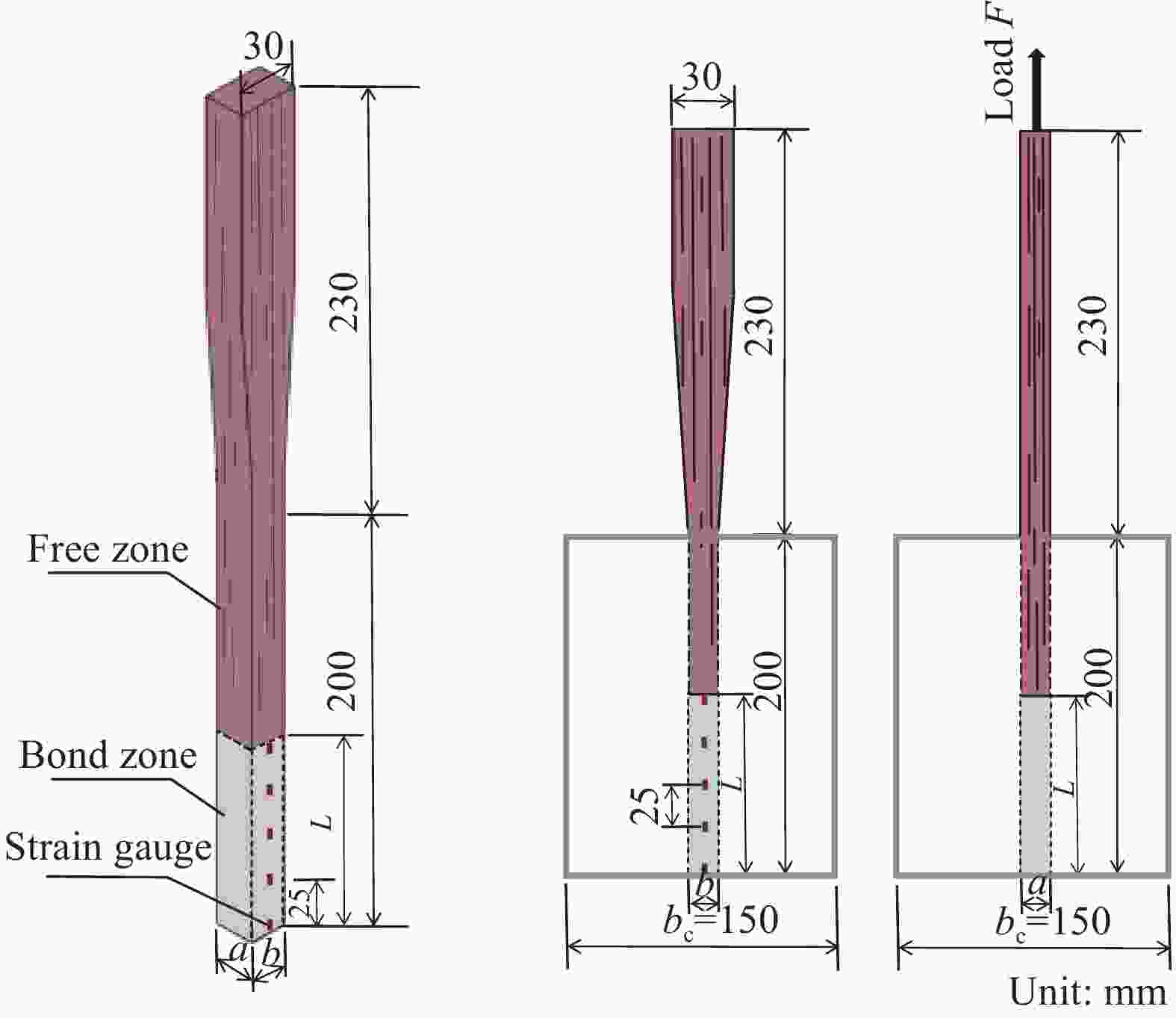

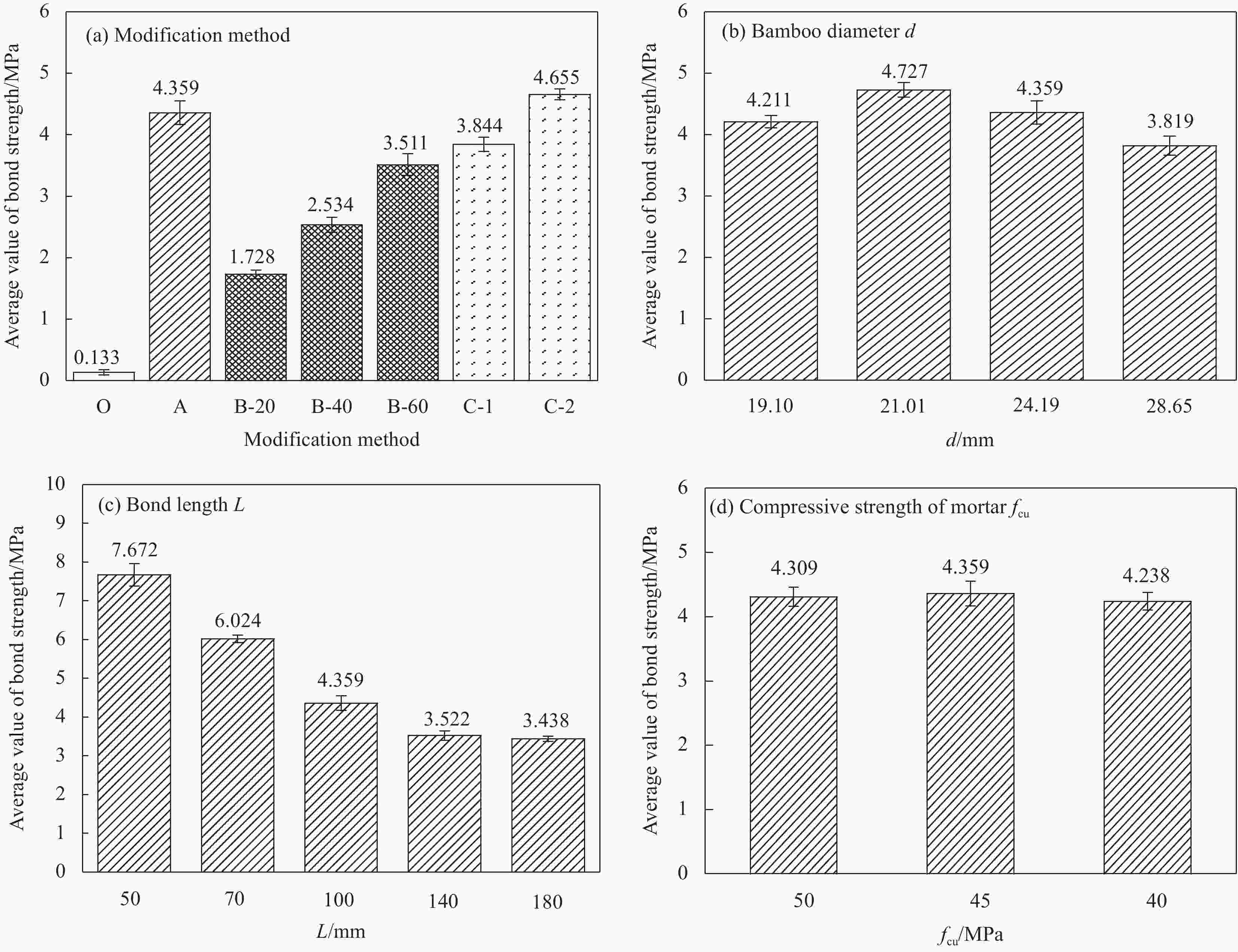

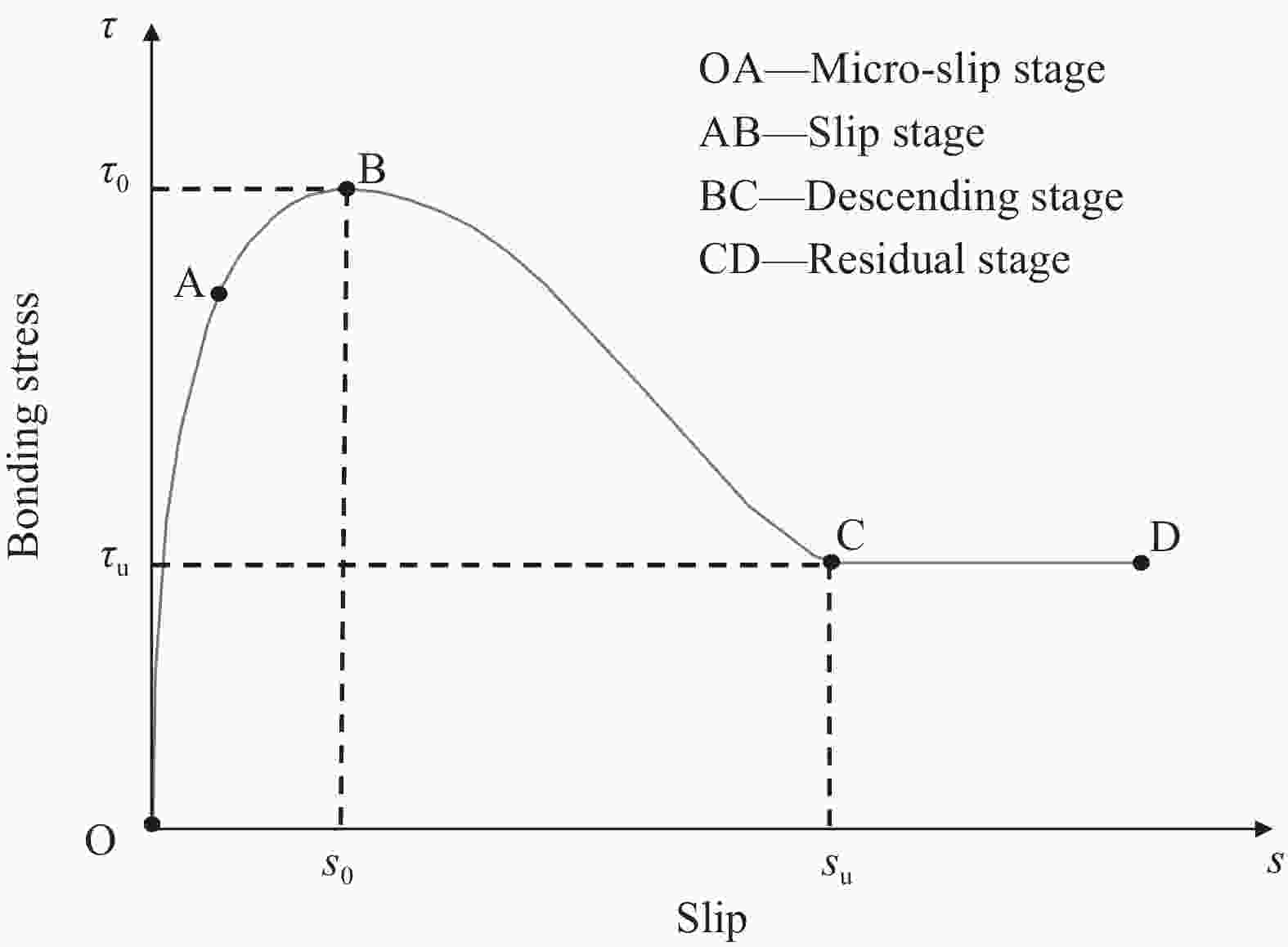

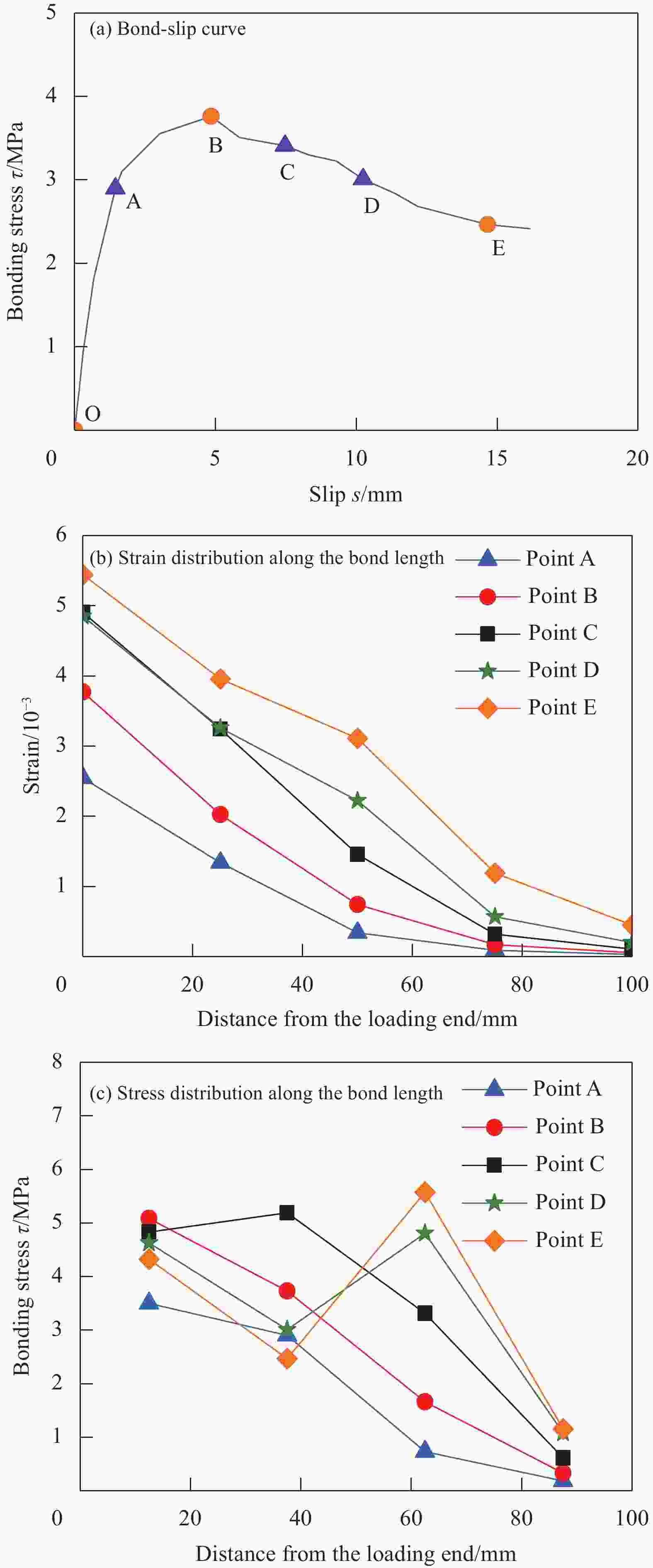

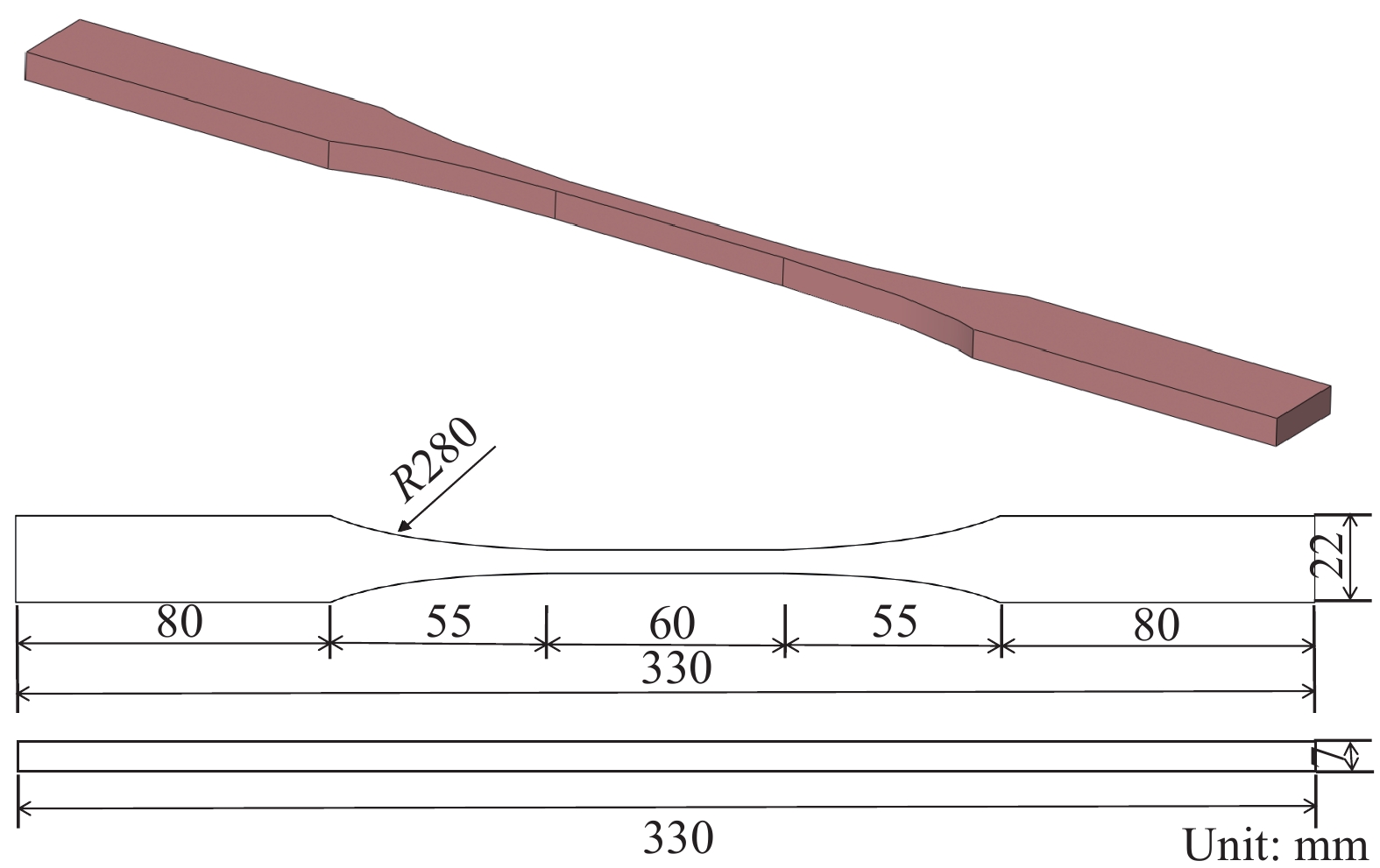

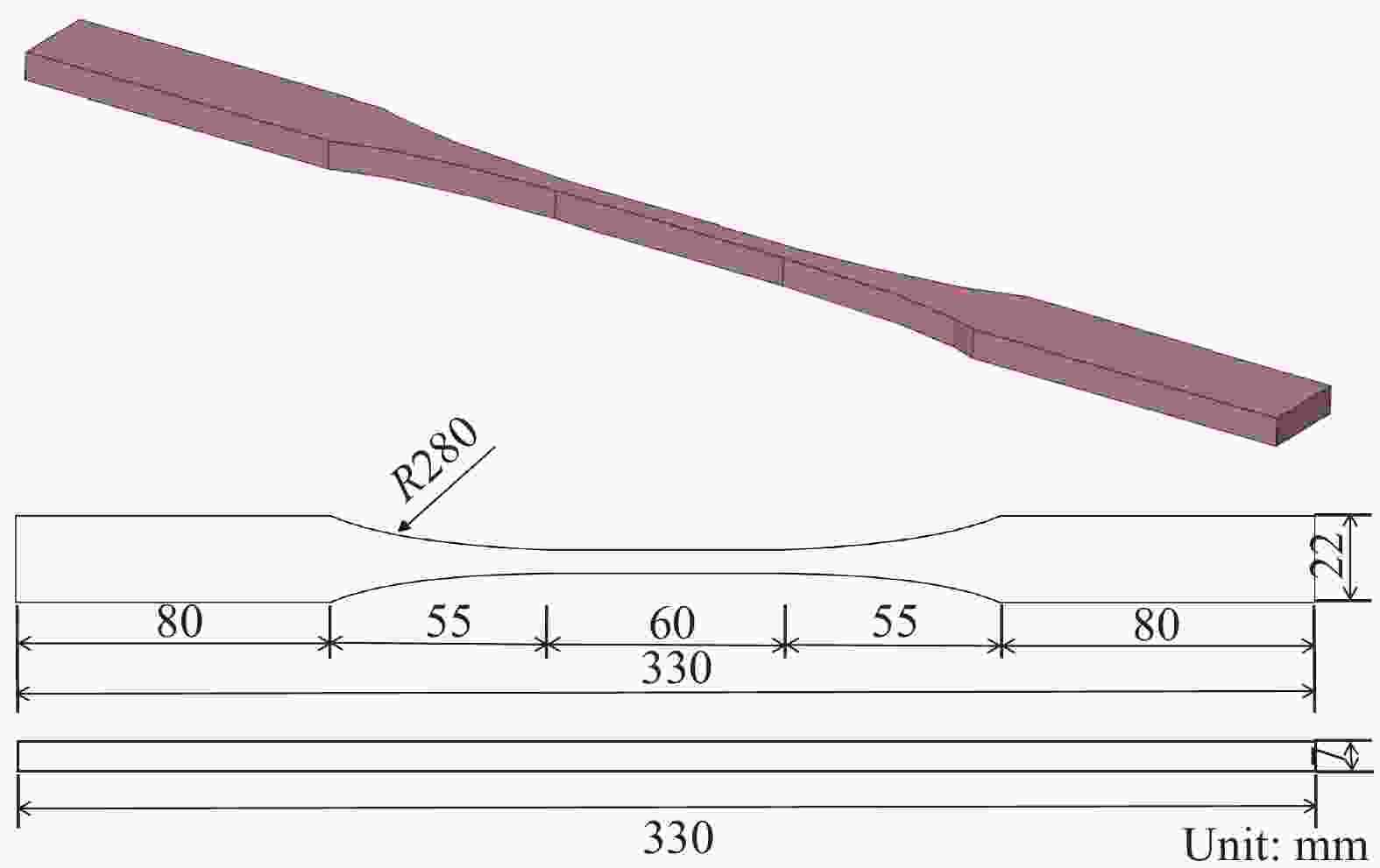

摘要: 为研究重组竹筋与竹炭砂浆的界面粘结性能,对共85个重组竹筋-竹炭砂浆试件进行中心拉拔试验,考虑了竹筋表面改性方法、等效直径、砂浆抗压强度、粘结长度等因素对界面粘结性能的影响。观察试件的粘结破坏形态,获取了各试件的粘结-滑移曲线、粘结强度和滑移量,分析了破坏机制,提出了界面粘结-滑移本构模型,得到了重组竹筋表面有效改性方法。结果表明:在不同初始条件下,拉拔试件存在3种破坏形态,分别为砂浆劈裂破坏、竹筋拉断破坏、竹筋拔出破坏,其中砂浆劈裂破坏最常见,破坏过程分为微滑移段、滑移段、下降段和残余段。竹筋表面经改性处理,其与砂浆界面粘结强度可提高13~46倍,界面粘结性能随竹筋粘结长度和等效直径的增大而降低,而砂浆强度对粘结性能的影响效果不显著。推荐使用粘砂和涂刷环氧砂浆两种方式对竹筋改性,在保证粘结性能的基础上,可改善养护过程中竹筋吸水膨胀导致与砂浆剥离,结构提前失效等问题。根据试验粘结-滑移曲线,得到经粘砂改性的重组竹筋-竹炭砂浆界面粘结-滑移本构模型,可准确预测重组竹筋与砂浆的界面粘结行为。经验证,该模型同样适用于试验中发生界面破坏的其他竹筋改性方法。Abstract: In order to study the bonding performance of bamboo scrimber bar-bamboo biochar mortar interface, pull-out tests were carried out on 85 bamboo scrimber bar-bamboo biochar mortar specimens. The effects of surface modification methods of bamboo bar, equivalent diameter of bamboo bar, compressive strength of mortar and bond lengths on the bond properties were also taken into consideration. The different bonding failure modes of the pull-out specimens were observed. The bond-slip curve, bonding strength and slippage were obtained. The failure mechanism was analyzed. A bond-slip constitutive model of bamboo scrimber bar-bamboo biochar mortar interface was established, and the effective surface modification method of bamboo scrimber bar was obtained. The results of the study show that there are three failure modes of the specimens under different initial conditions, including mortar splitting failure, bamboo bar tensile failure and bamboo bar pulled-out failure, among which mortar splitting failure is the most common. The failure process can be divided into micro-slip stage, slip stage, descending stage and residual stage. The bonding strength of the mortar interface can be increased by 13-46 times by modifying the surface of the bamboo bar. The interfacial bonding performance decreases with the increase of bonding length and equivalent diameter, and the effect of mortar strength on bonding strength is not obvious. It is recommended to modify the bamboo scrimber bar through the two methods of sticking sand and coating epoxy mortar. On the basis of ensuring bonding performance, it can improve the peeling of water absorption and expansion of bamboo bands during the maintenance process and the problem of the structure failing in advance. According to the experimental bond-slip curve, the bond-slip constitutive model of bamboo scrimber bar-bamboo biochar mortar treated by sticking sand was proposed. The bond-slip constitutive model can accurately predict the bond behavior between bamboo scrimber bar and mortar. After verification, the model is also applicable to the bonding interface destruction in the test under the other modification of bamboo.

-

表 1 竹炭砂浆配合比

Table 1. Mix proportion of bamboo biochar mortar

Water cement ratio Cement/(kg·m−3) Bamboo biochar/(kg·m−3) Water/(kg·m−3) Sand/(kg·m−3) fcu/MPa 0.45 549.45 5.55 250 1500 50 0.5 564.30 5.70 285 1500 45 0.58 500.94 5.06 300 1500 40 Note: fcu—Mortar pressure resistance intensity. 表 2 拉拔试件明细

Table 2. Details of pull-out specimens

Specimen

numberfcu/MPa L/mm a/mm b/mm d/mm Surface treatment method Failure pattern Average value of bond strength/

MPaA-0.5-50-360 45 50 20 18 24.19 Stick sand P 7.672 A-0.5-70-360 45 70 20 18 24.19 Stick sand P, S 6.024 A-0.5-100-360 45 100 20 18 24.19 Stick sand S 4.359 A-0.5-140-360 45 140 20 18 24.19 Stick sand S 3.522 A-0.5-180-360 45 180 20 18 24.19 Stick sand S 3.438 A-0.58-100-360 40 100 20 18 24.19 Stick sand S 4.238 A-0.45-100-360 50 100 20 18 24.19 Stick sand S 4.309 A-0.5-100-216 45 100 18 12 19.10 Stick sand F 4.211 A-0.5-100-270 45 100 18 15 21.01 Stick sand F 4.727 A-0.5-100-500 45 100 20 25 28.65 Stick sand S 3.819 B-0.5-100-360(20) 45 100 20 18 24.19 Nick P 1.728 B-0.5-100-360(40) 45 100 20 18 24.19 Nick F 2.534 B-0.5-100-360(60) 45 100 20 18 24.19 Nick F 3.511 C-0.5-100-360(1) 45 100 20 18 24.19 Coat epoxy mortar S 3.844 C-0.5-100-360(2) 45 100 20 18 24.19 Coat epoxy mortar S 4.655 O-0.5-100-360 45 100 20 18 24.19 Untreated P 0.133 O-0.5-180-360 45 180 20 18 24.19 Untreated P 0.150 Notes: A, B, C, O—Method of sticking sand, nicking, coating epoxy mortar and untreated bamboo scrimber surface modification methods; d—Equivalent diameter of bamboo scrimber bar; S—Spliting failure; P—Pulling-out failure; F represents the tensile failure. 表 3 竹筋膨胀率

Table 3. Expansion rate of bamboo scrimber bar

Specimen number a/mm a1/mm Wa/% b/mm b1/mm Wb/% A-0.5-50-360 20.01 20.33 1.60 18.02 18.32 1.66 A-0.5-100-360 20.03 20.32 1.45 18.06 18.33 1.50 A-0.5-180-360 19.96 20.14 0.90 18.10 18.25 0.83 A-0.58-100-360 20.00 20.36 1.80 18.03 18.45 2.33 A-0.45-100-360 20.06 20.21 0.75 18.03 18.23 1.11 A-0.5-100-500 20.05 20.35 1.50 24.98 25.42 1.76 B-0.5-100-360(20) 20.03 20.93 4.49 17.97 18.78 4.51 C-0.5-100-360(1) 19.99 20.17 0.90 18.00 18.22 1.22 O-0.5-100-360 20.00 20.76 4.30 18.01 18.72 3.94 Notes: a—Original thickness of bamboo scrimber bar; a1—Thickness of bamboo scrimber bar after 28 days of maintenance; Wa—Expansion rate of the thickness direction of the bamboo scrimber bar; b—Original width of bamboo scrimber bar; b1—Width of bamboo scrimber bar after 28 days of maintenance; Wb—Expansion rate of the width direction of the bamboo scrimber bar. 表 4 重组竹筋-竹炭砂浆试件粘结-滑移曲线拟合结果

Table 4. Bond-slip curves fitting results of bamboo scrimber bar-bamboo biochar mortar specimens

Specimen number Rising stage Descending stage α R2 n R2 A-0.5-70-360 0.366 0.880 2.206 0.991 A-0.5-100-360 0.332 0.954 1.969 0.994 A-0.5-140-360 0.397 0.931 2.091 0.976 A-0.5-180-360 0.239 0.960 1.999 0.975 A-0.58-100-360 0.428 0.976 1.937 0.988 A-0.45-100-360 0.432 0.982 1.744 0.958 A-0.5-100-500 0.499 0.947 2.330 0.941 Notes: α—Fitting coefficient of rising stage; R2—Correlation coefficient; n—Fitting coefficient of descending stage. -

[1] 李海涛, 宣一伟, 许斌, 等. 竹材在土木工程领域的应用[J]. 林业工程学报, 2020, 5(6):1-10.LI Haitao, XUAN Yiwei, XU Bin, et al. Bamboo application in civil engineering field[J]. Journal of Forestry Engineering,2020,5(6):1-10(in Chinese). [2] LIU K, JAYARAMAN D, SHI Y, et al. "Bamboo: A very sustainable construction material"-2021 international online seminar summary report[J]. Sustainable Structures,2022,2(1):000015. doi: 10.54113/j.sust.2022.000015 [3] CHOW H K. Bamboo as material for reinforced concrete[D]. Cambridge, Massachusetts: Massachusetts Institute of Technology, 1914. [4] 肖岩, 李佳. 现代竹结构的研究现状和展望[J]. 工业建筑, 2015, 45(4):1-6.XIAO Yan, LI Jia. The state of the art of modern bamboo structures[J]. Industrial Construction,2015,45(4):1-6(in Chinese). [5] MIMENDI L, LORENZO R, LI H. An innovative digital workflow to design, build and manage bamboo structures[J]. Sustainable Structures,2022,2(1):000011. doi: 10.54113/j.sust.2022.000011 [6] 邹立华, 钟坤禄, 谢吉鸿, 等. 改性竹筋混凝土受弯构件力学性能试验研究[J]. 土木建筑与环境工程, 2015, 37(5):33-40.ZOU Lihua, ZHONG Kunlu, XIE Jihong, et al. Experimental analysis of mechanical property of processed bamboo reinforced concrete flexural member[J]. Journal of Civil, Architectural and Environmental Engineering,2015,37(5):33-40(in Chinese). [7] LI Y, SHAN W, SHEN H, et al. Bending resistance of I-section bamboo-steel composite beams utilizing adhesive bonding[J]. Thin-Walled Structures,2015,89:17-24. doi: 10.1016/j.tws.2014.12.007 [8] BHONDE D, NAGARNAIK P B. Experimental investigation of bamboo reinforced concrete slab[J]. American Journal of Engineering Research,2014,3(1):128-131. [9] AZARGOHAR R, NANDA S, KOZINSKI J A, et al. Effects of temperature on the physicochemical characteristics of fast pyrolysis bio-chars derived from Canadian waste biomass[J]. Fuel,2014,125:90-100. doi: 10.1016/j.fuel.2014.01.083 [10] 刘明西, 刘承阳, 刘问, 等. 重组竹-混凝土界面粘结-滑移本构模型[J]. 复合材料学报, 2022, 39(5):2299-2307.LIU Mingxi, LIU Chengyang, LIU Wen, et al. Bond-slip constitutive model of bamboo scrimber-concrete interface[J]. Acta Materiae Compositae Sinica,2022,39(5):2299-2307(in Chinese). [11] HUANG D S, ZHOU A P, BIAN Y L. Experimental and analytical study on the nonlinear bending of parallel strand bamboo beams[J]. Construction and Building Materials,2013,44:585-592. doi: 10.1016/j.conbuildmat.2013.03.050 [12] HUANG D S, BIAN Y L, ZHOU A P, et al. Experimental study on stress-strain relationships and failure mechanisms of parallel strand bamboo made from phyllostachys[J]. Construction and Building Materials,2015,77:130-138. doi: 10.1016/j.conbuildmat.2014.12.012 [13] 谢鹏, 刘问, 胡雨村, 等. 重组竹横向准脆性断裂的断裂参数[J]. 复合材料学报, 2020, 37(6):1466-1475.XIE Peng, LIU Wen, HU Yucun, et al. Fracture parameters of bamboo scrimber's transverse quasi-brittle fracture[J]. Acta Materiae Compositae Sinica,2020,37(6):1466-1475(in Chinese). [14] LIU W, LI K, XU S. Utilizing bamboo biochar in cement mortar as a bio-modifier to improve the compressive strength and crack-resistance fracture ability[J]. Construction and Building Materials,2022,327:126917. doi: 10.1016/j.conbuildmat.2022.126917 [15] CARMI I, KRONFELD J, MOINESTER M. Sequestration of atmospheric carbon dioxide as inorganic carbon in the unsaturated zone under semi-arid forests[J]. CATENA,2019,173:93-98. doi: 10.1016/j.catena.2018.09.042 [16] RESTUCCIA L, FERRO G A. Promising low cost carbon-based materials to improve strength and toughness in cement composites[J]. Construction and Building Materials,2016,126:1034-1043. doi: 10.1016/j.conbuildmat.2016.09.101 [17] 中国国家标准化管理委员会. 木材顺纹抗拉强度试验方法: GB/T 1938—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People's Republic of China. Method of testing in tensile strength parallel to grain of wood: GB/T 1938—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [18] 中华人民共和国住房和城乡建设部. 砌筑砂浆配合比设计规程: JGJ/T 98—2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Specification for mix proportion design of masonry mortar: JGJ/T 98—2010[S]. Beijing: China Architecture Industry Press, 2010(in Chinese). [19] HARMON T G, KIM Y J, KARDOS J, et al. Bond of surface-mounted fiber-reinforced polymer reinforcement for concrete structures[J]. ACI Structural Journal,2003,100(5):557-564. [20] ACHILLIDES Z, PILAKOUTAS K. Bond behavior of fiber reinforced polymer bars under direct pullout conditions[J]. Journal of Composites for Construction,2004,8(2):173-181. doi: 10.1061/(ASCE)1090-0268(2004)8:2(173) [21] 周健. 竹筋陶粒混凝土粘结滑移性能研究[D]. 济南: 山东大学, 2015.ZHOU Jian. The experimental investigation and theoretical analysis of bond properties of ceramic reconstituted bamboo-rainforced concrete[D]. Ji'nan: Shandong Univercity, 2015(in Chinese). [22] 中国建筑科学研究院. 混凝土结构试验方法标准: GB/T 50152—2012[S]. 北京: 中国建筑工业出版社, 2012.China Academy of Building Research. Standard for test method of concrete structure: GB/T 50152—2012[S]. Beijing: China Architecture Industry Press, 2012(in Chinese). [23] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB 50010—2010[S]. Beijing: China Architecture Industry Press, 2010(in Chinese). [24] 许昆. 圆竹-轻质砂浆组合墙体力学性能的试验研究[D]. 西安: 西安建筑科技大学, 2014.XU Kun. Experimental study on mechanical properties of composite wall consisted of the bamboo and lightweight material[D]. Xi'an: Xi'an University of Architecture and Technology, 2014(in Chinese). [25] GHAVAMI K. Bamboo as reinforcement in structural concrete elements[J]. Cement and Concrete Composites,2005,27(6):637-649. doi: 10.1016/j.cemconcomp.2004.06.002 [26] DAI J G, UEDA T, SATO Y. Local bond stress slip relations for FRP sheets-concrete interfaces[C]. Singapore: World Scientific Publishing CO. Pte. LTD., 2003: 143-152. [27] ELIGEHAUSEN R, POPOV E P, BERTERO V V. Local bond stress-slip relationships of deformed bars under generalized excitations: Experimental results and analytical model[R]. Berkeley: Earthquake Engineering Research Center, University of California, 1983. [28] COSENZA E, MANFREDI G, REALFONZO R. Behavior and modeling of bond of FRP rebars to concrete[J]. Journal of Composites for Construction,1997,1(2):40-51. doi: 10.1061/(ASCE)1090-0268(1997)1:2(40) [29] 高丹盈, 朱海堂, 谢晶晶. 纤维增强塑料筋混凝土粘结滑移本构模型[J]. 工业建筑, 2003, 33(7):41-43. doi: 10.3321/j.issn:1000-8993.2003.07.011GAO Danying, ZHU Haitang, XIE Jingjing. The constitutive models for bond slip relation between FRP rebars and concrete[J]. Industrial Construction,2003,33(7):41-43(in Chinese). doi: 10.3321/j.issn:1000-8993.2003.07.011 -

下载:

下载: