Preparation process, compression and shear behavior of carbon/carbon honeycomb

-

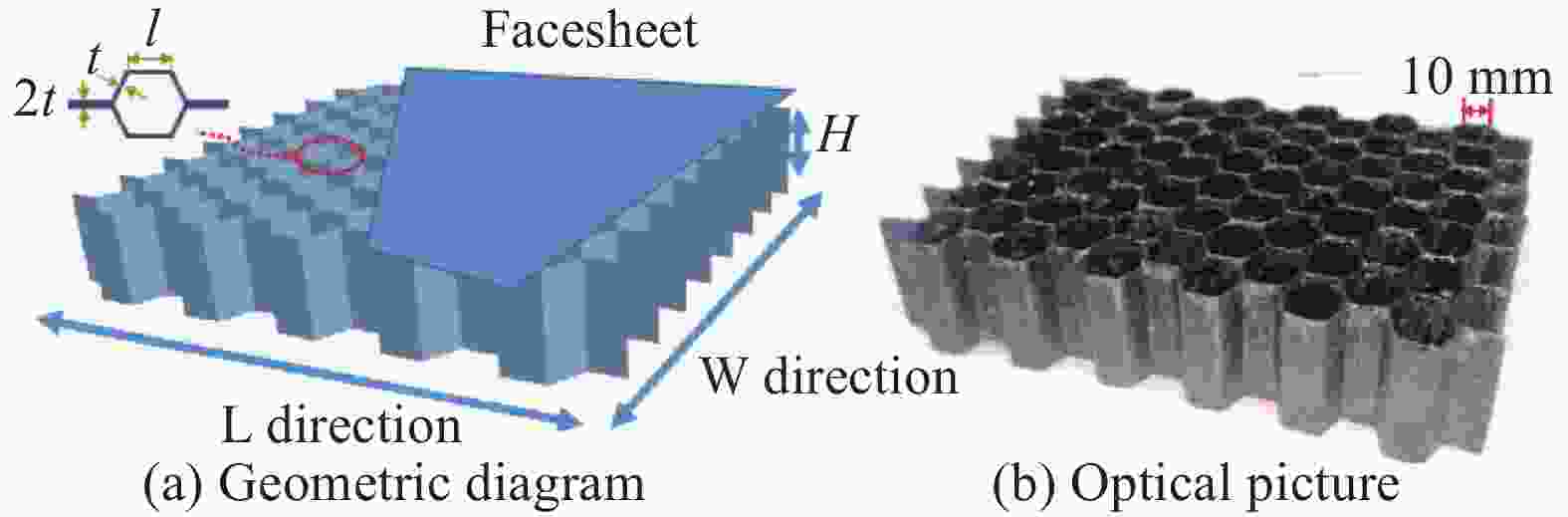

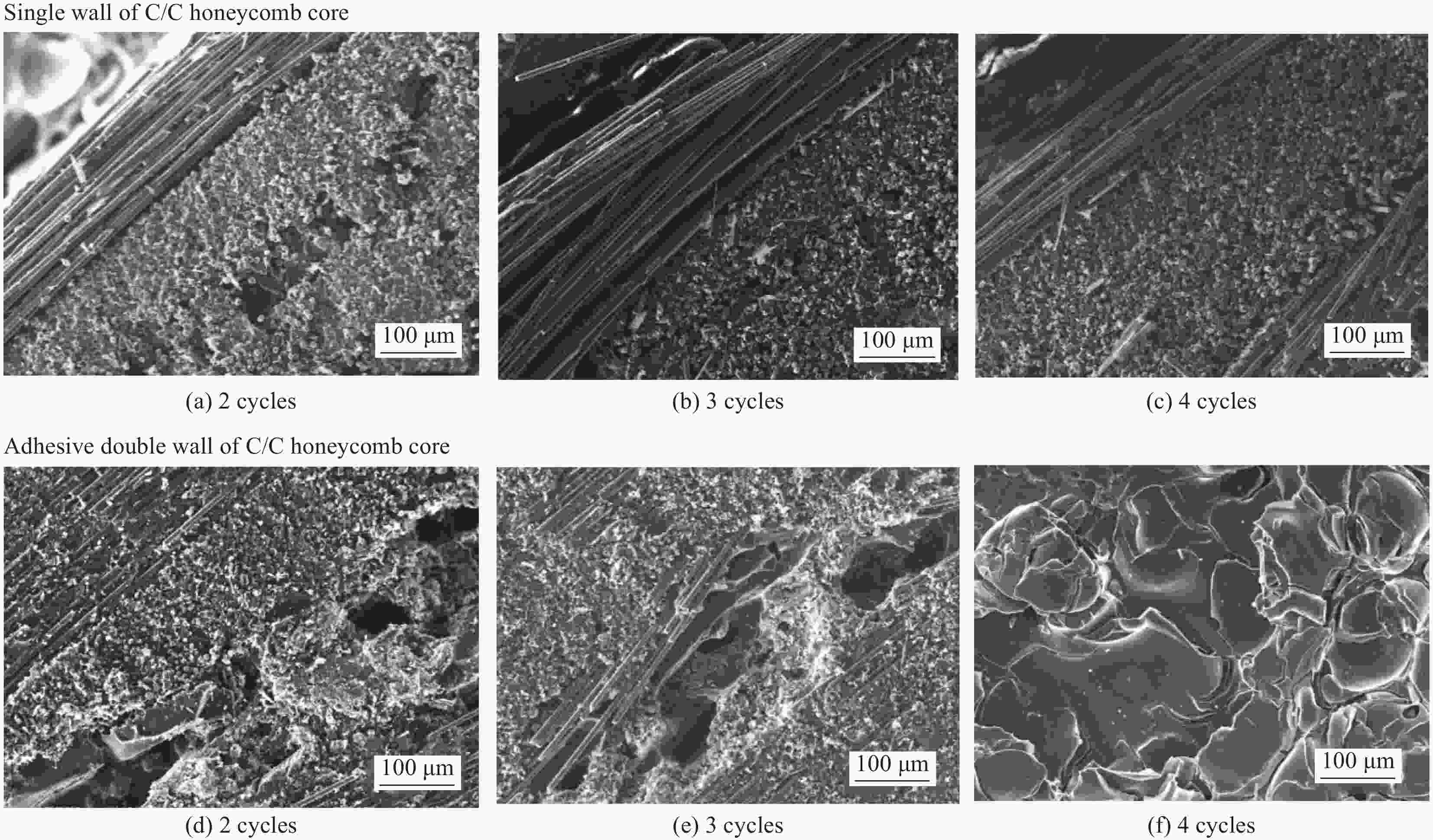

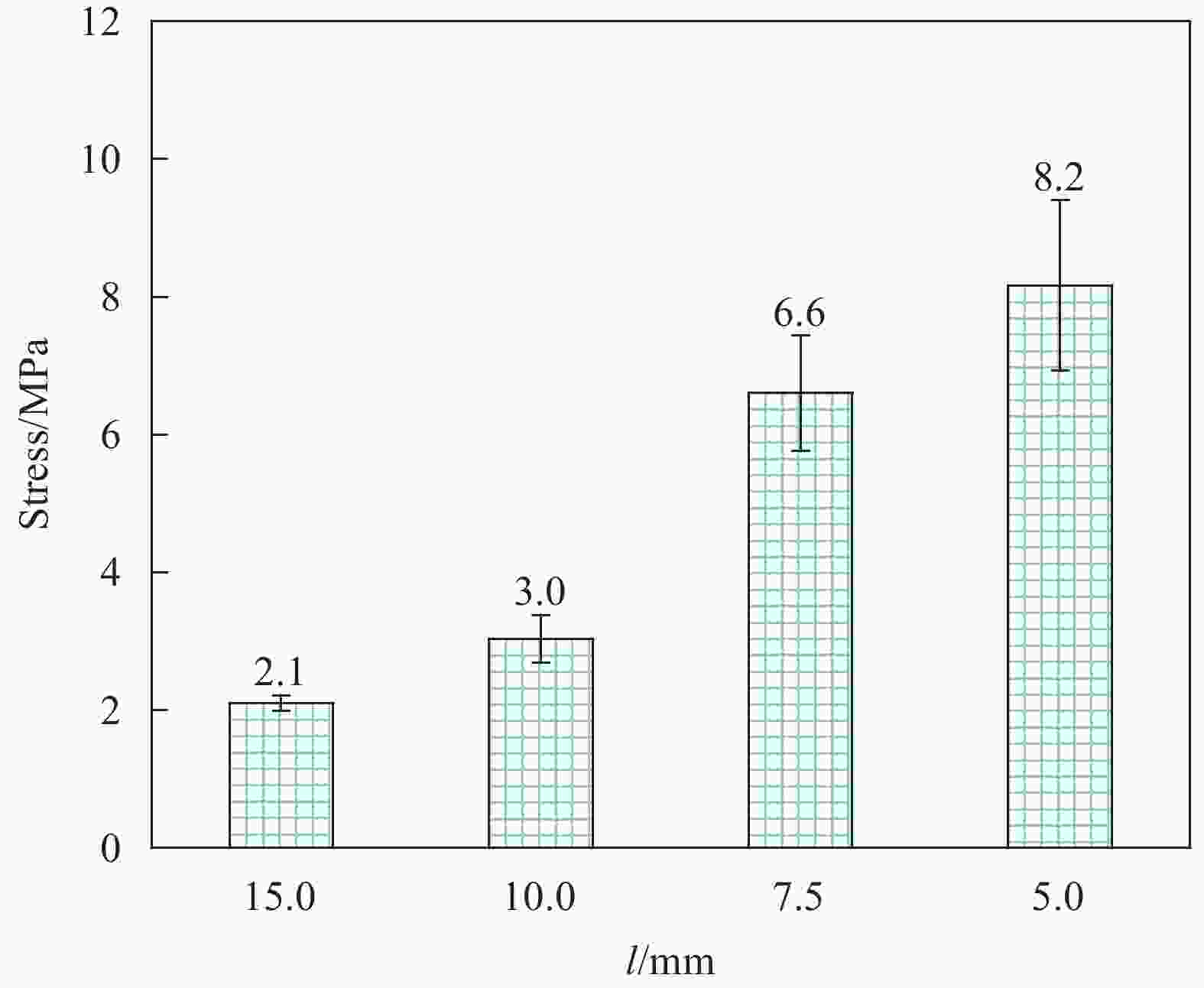

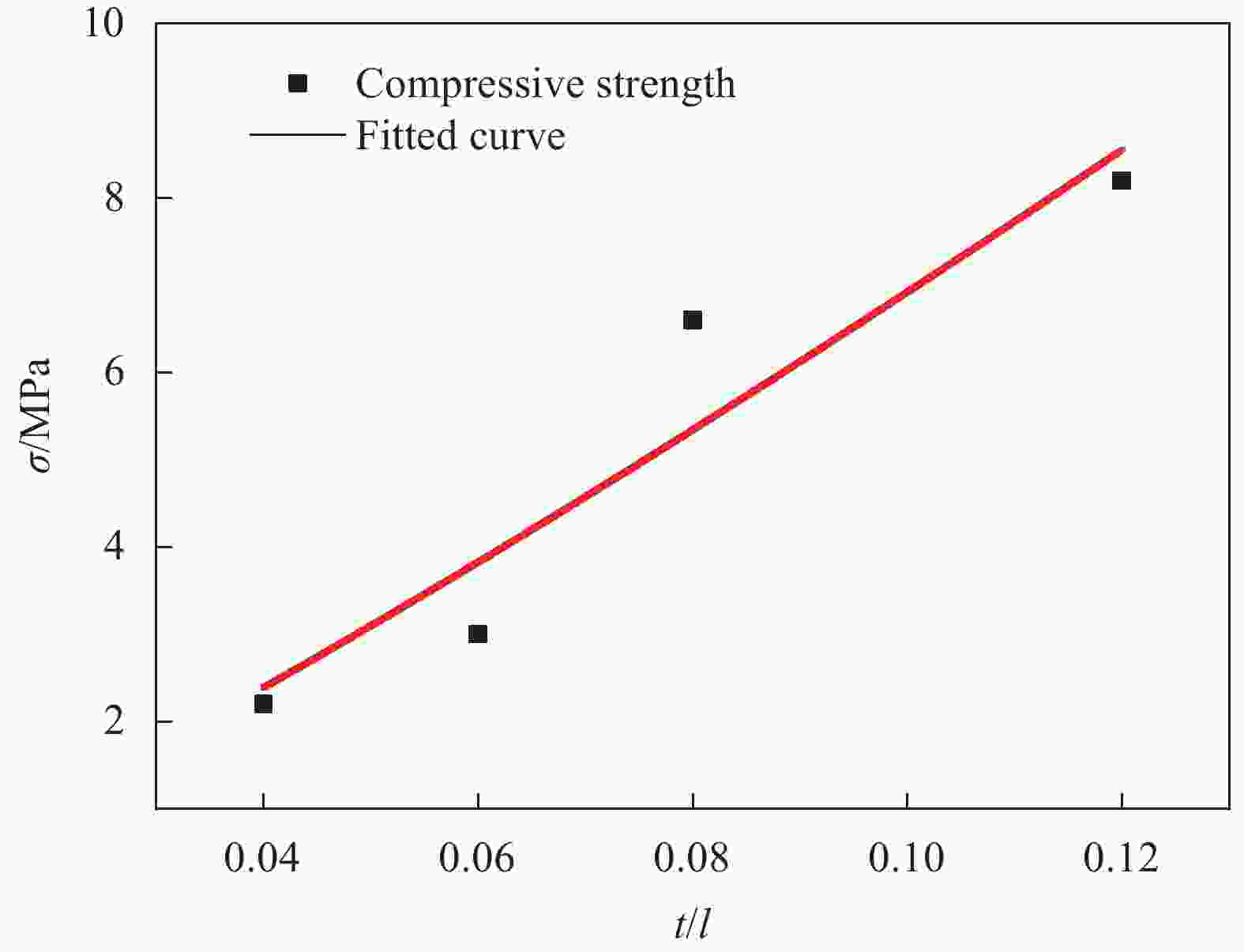

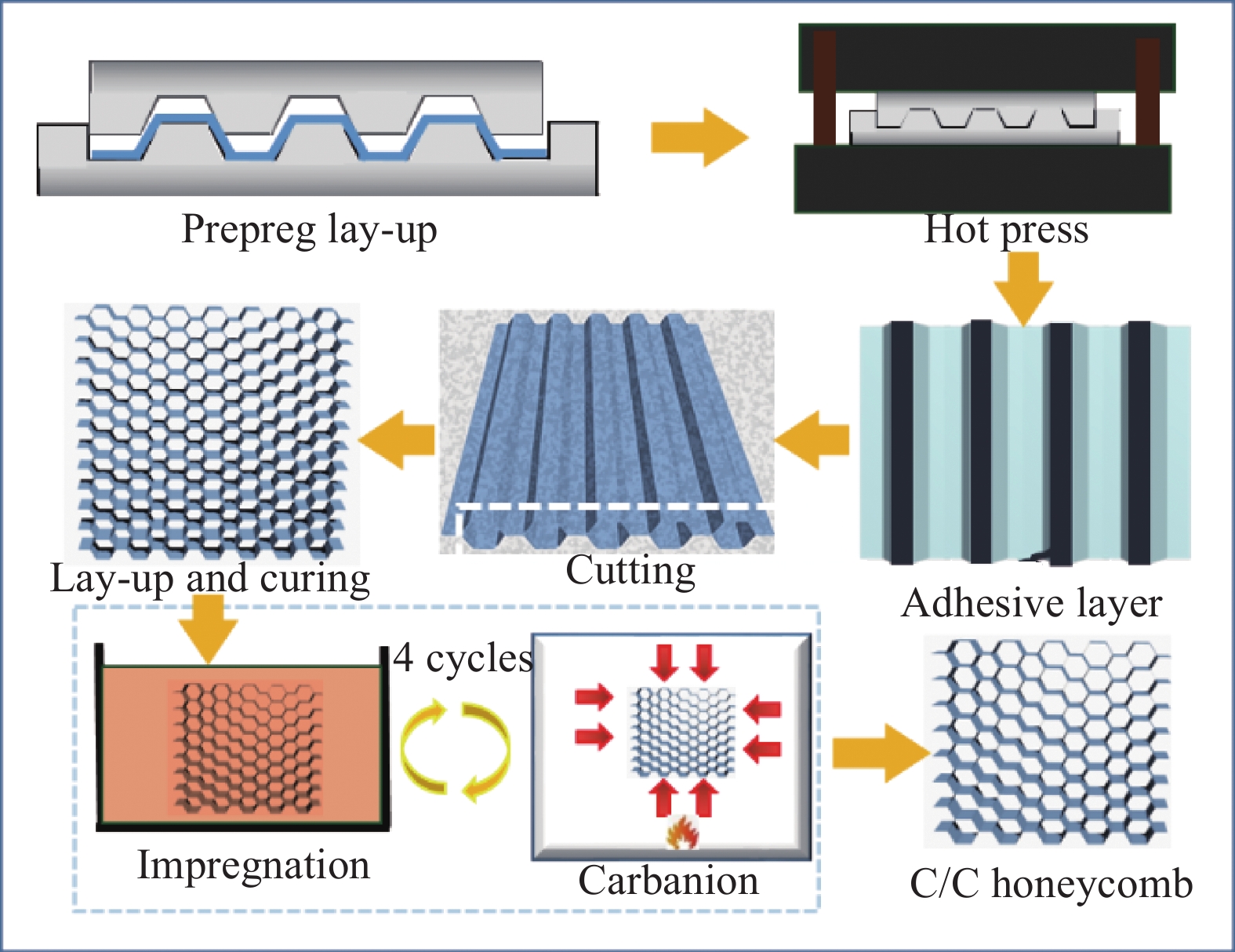

摘要: 为了满足高分辨率航天器承载平台对尺寸稳定性、轻量化和高承载空间结构的多重需求,采用热压成型和树脂浸渍-碳化组合工艺制备了4种不同规格的碳/碳(C/C)蜂窝。以碳纤维预浸料为原料,通过热压工艺成型波纹片,用无机胶粘剂粘合片材形成蜂窝,经过浸渍-碳化工艺成型C/C蜂窝。对不同规格C/C蜂窝在不同加载方式下的力学行为进行了研究。结果表明,采用所提出组合工艺制备的C/C蜂窝未发生节点脱粘。边长5 mm蜂窝的压缩强度为8.2 MPa。在面外压缩、L向与W向剪切载荷下,C/C蜂窝的主要失效模式是双层壁脱粘分层。C/C蜂窝结构具有较高的抗压强度和良好可设计性,可能满足未来轻质高强航天器承载平台结构要求。Abstract: To meet the multiple requirements of dimensional stability, light weight, and high load-bearing capacity for the high resolution spacecraft bearing platform, four different sizes of carbon/carbon (C/C) honeycomb were prepared by the combination of hot pressing and resin impregnation-carbonization processes. Carbon fiber prepreg was used as the raw material to form corrugated sheets by hot pressing, and inorganic adhesive was used to bond the corrugated sheets to form the honeycomb. C/C honeycomb was formed by the impregnation-carbonization process. The mechanical behaviors of different sizes of C/C honeycomb under different load modes were investigated. The results show that the C/C honeycombs prepared by the proposed combined process do not experience nodal debonding, and the compressive strength of the 5 mm edge length honeycomb is 8.2 MPa. The main failure mode of C/C honeycomb is double wall debonding delamination under out-of-plane compression, L and W direction shear process loads. The C/C honeycombs show high compressive strength and good designability and may meet the requirements of future lightweight and high strength spacecraft bearing platforms.

-

图 5 不同边长碳/碳蜂窝面外压缩应力-应变曲线与破坏过程:((a), (b)) 5 mm;((c), (d)) 7.5 mm;((e), (f)) 10 mm;((g), (h)) 15 mm

Figure 5. Out-of-plane compression stress-strain curves and failure progress of C/C honeycomb core specimens with different cell side length: ((a), (b)) 5 mm; ((c), (d)) 7.5 mm; ((e), (f)) 10 mm; ((g), (h)) 15 mm

表 1 不同几何规格蜂窝芯子规格参数

Table 1. Different test specimens of different cell length

l/mm Test item Density

ρ/(g·cm−3)Relative

density ρ*/%15 Compression 0.13 4.6 10 Compression,

shear0.18 6.9 7.5 Compression 0.26 9.2 5 Compression 0.36 13.8 Note: l—Cell side length of honeycomb core. 表 2 碳/碳蜂窝结构面外压缩性能和破坏模式

Table 2. Failure modes of the different C/C honeycomb structure specimens under various loadings

l/mm Test item Specimens type Modulus/MPa Strength/MPa Failure mode 10 Compression Sandwich panel 159 5.1 Wall delamination Honeycomb 168 3.0 15 Compression Honeycomb 161 2.1 7.5 Compression Honeycomb 243 6.6 Core crushing 5 Compression Honeycomb 274 8.2 Wall delamination 表 3 边长10 mm碳/碳蜂窝剪切性能和破坏模式

Table 3. Failure modes of the different C/C honeycomb structure specimens under various loadings

l/mm Test item Modulus

/MPaStrength/MPa Failure mode 10 L shear 60 1.3 Core debonding W shear 64 0.9 Wall delamination -

[1] KASSAPOGLOU C. Design and analysis of composite structures: With applications to aerospace structures[M]. 2th ed. New Jersey: John Wiley & Sons Inc, 2013: 275-307. [2] TOOR Z S. Space applications of composite materials[J]. Journal of Space Technology,2018,8(1):65-70. [3] BAILLY B, CORNU J L, CAPDEPUY B, et al. Dimensionally stable structures[C]//BURKE W R. Spacecraft Structures: Materials and Mechanical Engineering. European Space Agency, 1996: 361-369. [4] LI F, RUAN P, LI T, et al. Application of carbon-carbon composite for load-carrying cylinder in lunar optical telescope[C]//JEFFERY J. Puschell. International Symposium on Photoelectronic Detection and Imaging 2011: Space Exploration Technologies and Applications. SPIE, 2011: 443-451. [5] KRUMWEIDE D E, WONACOTT G D, WOIDA P M, et al. Carbon-carbon mirrors for exoatmospheric and space applications[C]//GOODMAN B. Optical Materials and Structures Technologies III. SPIE, 2007, 6666: 134-141. [6] YAO S G, XIAO X L, XU P, et al. The impact performance of honeycomb-filled structures under eccentric loading for subway vehicles[J]. Thin-Walled Structures, 2018, 123: 360-370. [7] WANG J F, SHI C Y, YANG N, et al. Strength, stiffness, and panel peeling strength of carbon fiber-reinforced compo-site sandwich structures with aluminum honeycomb cores for vehicle body[J]. Composite Structures, 2018, 184: 1189-1196. [8] STOCCHI A, COLABELLA L, CISILINO A, et al. Manufacturing and testing of a sandwich panel honeycomb core reinforced with natural-fiber fabrics[J]. Materials & Design,2014,55:394-403. doi: 10.1016/j.matdes.2013.09.054 [9] ALIA R A, AL-ALI O, KUMAR S, et al. The energy-absorbing characteristics of carbon fiber-reinforced epoxy honeycomb structures[J]. Journal of Composite Materials,2019,53(9):1145-1157. doi: 10.1177/0021998318796161 [10] HAN D, TSAI S W. Interlocked composite grids design and manufacturing[J]. Journal of Composite Materials, 2003, 37(4): 287-316. [11] WEI X Y, LI D F, XIONG J. Fabrication and mechanical behaviors of an all-composite sandwich structure with a hexagon honeycomb core based on the tailor-folding approach[J]. Composites Science and Technology,2019,184:107878. doi: 10.1016/j.compscitech.2019.107878 [12] NEJE G, BEHERA B K. Failure analysis of 3D woven spacer sandwich composites with woven cross-links and face sheet thickening under compressive and flexural loading[J]. Journal of Composite Materials,2021,55(24):3471-3481. doi: 10.1177/00219983211018733 [13] RAJKUMAR S. Strength and stiffness characteristics of A3003 aluminum honeycomb core sandwich panels[J]. Materials Today: Proceedings,2021,37:1140-1145. doi: 10.1016/j.matpr.2020.06.348 [14] 辛亚军, 孙帅, 杨硕, 等. 铝蜂窝夹芯板面外剪切性能试验研究与数值模拟[J]. 复合材料学报, 2022, 39(12):6119-6129. doi: 10.13801/j.cnki.fhclxb.20211125.002XIN Yajun, SUN Shuai, YANG Shuo, et al. Experiment and numerical simulation of out-plane shear performance of aluminum honeycomb sandwich panel[J]. Acta Materiae Compositae Sinica,2022,39(12):6119-6129(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211125.002 [15] KONG C W, NAM G W, JANG Y S, et al. Experimental strength of composite sandwich panels with cores made of aluminum honeycomb and foam[J]. Advanced Composite Materials, 2014, 23(1): 43-52. [16] LIU Y E, LIU W, GAO W C, et al. Mechanical responses of a composite sandwich structure with Nomex honeycomb core[J]. Journal of Reinforced Plastics and Composites,2019,38(13):601-615. doi: 10.1177/0731684419836492 [17] AYANOGLU M O, TAUHIDUZZAMAN M, CARLSSON L A. In-plane compression modulus and strength of Nomex honeycomb cores[J]. Journal of Sandwich Structures & Materials,2022,24(1):627-642. [18] PEHLIVAN L, BAYKASOĞLU C. An experimental study on the compressive response of CFRP honeycombs with various cell configurations[J]. Composites Part B: Engineering,2019,162:653-661. doi: 10.1016/j.compositesb.2019.01.044 [19] 吴楠, 郝旭峰, 史耀辉, 等. 高精度碳纤维增强树脂复合材料夹层天线面板热变形影响参数仿真与实验[J]. 复合材料学报, 2020, 37(7):1619-1628. doi: 10.13801/j.cnki.fhclxb.20191107.002WU Nan, HAO Xufeng, SHI Yaohui, et al. Simulation and experiment on thermal deformation influence parameters of high accuracy carbon fiber reinforced plastic sandwiched antenna panels[J]. Acta Materiae Compositae Sinica,2020,37(7):1619-1628(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191107.002 [20] PANIN F, LUTZ-NIVET M, LEMAIRE H. Development of carbon-carbon sandwich panels[J]. European Space Agency,2003,540:81-86. [21] LUTZ M, COMILLON L, VITUPIER Y, et al. Evaluation of ultra stable carbon/carbon sandwich structures joined with ceramic cement[C]//KHAYRUTDINOV A. Preeedings of the 61st International Astronautically Congress (IAC), Prague, 2010, 10: 1-4. [22] SALVO M, CASALEGNO V, VITUPIER Y, et al. Study of joining of carbon/carbon composites for ultra stable structures[J]. Journal of the European Ceramic Society,2010,30(7):1751-1759. [23] 刘宇峰, 张中伟, 许正辉, 等. 空间高稳定碳/碳蜂窝夹层结构制备及性能[J]. 宇航学报, 2020, 41(8):1067-1075. doi: 10.3873/j.issn.1000-1328.2020.08.010LIU Yufeng, ZHANG Zhongwei, XU Zhenghui, et al. Preparation and properties of carbon/carbon honeycomb sandwich panels for space ultra-stable structures[J]. Journal of Astronautics,2020,41(8):1067-1075(in Chinese). doi: 10.3873/j.issn.1000-1328.2020.08.010 [24] 王中钢. 轻质蜂窝结构力学[M]. 北京: 科学出版社, 2019.WANG Zhonggang. Mechanics of lightweight honeycomb structures[M]. Beijing: Science Press, 2019(in Chinese). [25] 中国国家标准化管理委员会. 夹层结构或芯子平压性能测试方法: GB/T 1453—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for flatwise compression properties of sandwich constructions or cores: GB/T 1453—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [26] 中国国家标准化管理委员会. 夹层结构或芯子剪切性能测试方法: GB/T 1455—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for shear properties of sandwich constructions or cores: GB/T 1455—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [27] 刘玥. 蜂窝复合材料夹芯结构承载特性及渐进损伤失效研究 [D]. 哈尔滨: 哈尔滨工业大学, 2020.LIU Yue. Bearing characteristics and progressive failure behavior of honeycomb composite sandwich structures[D]. Harbin: Harbin Institute of Technology, 2020(in Chinese). [28] 王俊, 樊喜刚. 轻质蜂窝结构压缩性能的测试[J]. 理化检验(物理分册), 2014, 50(4):261-265, 272.WANG Jun, FAN Xigang. Compression properties testing of lightweight honeycomb structure[J]. Physical Testing and Chemical Analysis (Part A: Physical Testing),2014,50(4):261-265, 272(in Chinese). [29] 周祝林, 杨云娣. 蜂窝芯子密度及平压强度的理论分析和试验比较[J]. 上海硅酸盐, 1995(1):15-23.ZHOU Zhulin, YANG Yundi. Theoretical analysis and experimental comparison of honeycomb core density and flat compressive strength[J]. Shanghai Silicate,1995(1):15-23(in Chinese). -

下载:

下载: