Advances in carbon fiber-based solar powered interfacial water evaporation devices

-

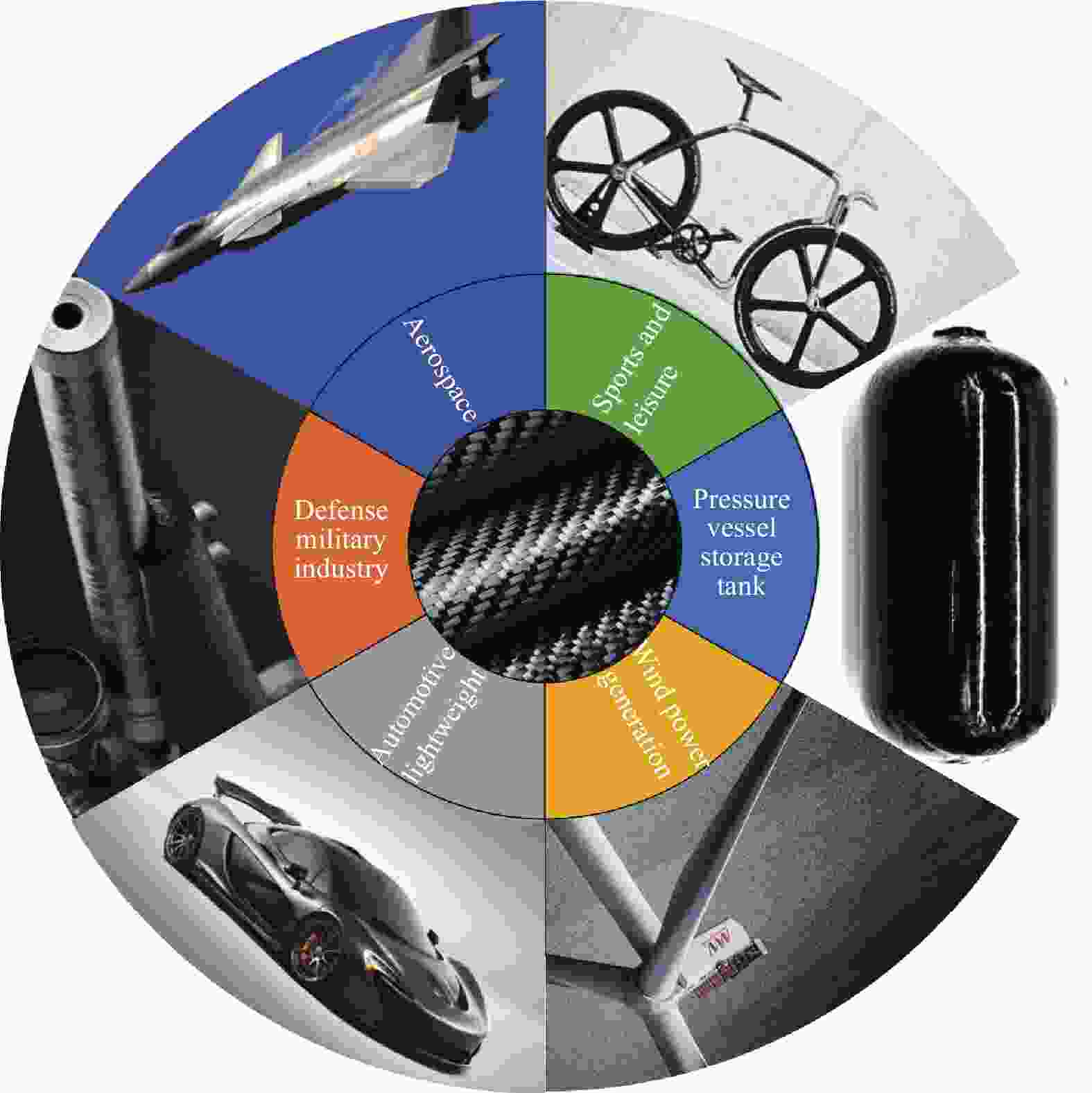

摘要: 碳纤维是三大高性能纤维之一,具有较强的光热以及电热转化性能,可以高效的将太阳光和电能转化为热能。目前对于碳纤维的应用还大部分基于低密度、高强高模的优势特性上,为了促进碳纤维在界面水蒸发的应用,本文从碳纤维光热及光电耦合两个方面来综述目前碳纤维在界面水蒸发的研究进展,针对碳纤维光滑致密的表面结构以及低表面能等缺点,总结其解决方法,以及在水通道、仿生结构、多级结构、掺杂其他光热材料和回收碳纤维的应用几个方面来讨论碳纤维界面蒸发器的发展,并对将来碳纤维在界面蒸发中的应用提出展望。Abstract: Carbon fiber is a high-performance material known for its strong photothermal and electrothermal conversion properties, enabling efficient conversion of sunlight and electrical energy into thermal energy. Despite its current utilization primarily based on its low density, high strength, and modulus, this paper reviews the ongoing research on enhancing the application of carbon fiber in interfacial water evaporation. The review focuses on two key aspects: carbon fiber's photothermal properties and optoelectronic coupling. It addresses the challenges posed by carbon fiber's smooth, dense surface and low surface energy, proposing various solutions. Furthermore, it explores advancements in developing carbon fiber interfacial evaporators through strategies such as bionic structures, multi-stage designs, incorporation of other photothermal materials, and carbon fiber recycling. Finally, the paper outlines future prospects for leveraging carbon fibers in interfacial evaporation applications.

-

图 4 碳纤维表面改性示意图(a)原始碳纤维(b)和(c)水热处理改性的碳纤维(d)来源于葡萄糖的不溶性互键芳香族两亲性大分子[50]

Figure 4. Schematic diagram of surface modification of carbon fibers (a) original carbon fibers (b) and (c) carbon fibers modified by hydrothermal treatment (d) insoluble aromatic amphiphilic macromolecules derived from glucose [50]

表 1 不同碳纤维基太阳能蒸发器对比

Table 1. Comparison of different carbon fiber based solar evaporators

处理方法 蒸发速率 蒸发效率 水传输通道 类型 是否焦

耳加热电压

大小参考

文献通过对改性碳纤维进行表面蚀刻,然后通过三层碳纤维织物,两层非织造布和一层隔热层组成太阳能蒸发器 3.39 kg·m−2·h−1 93.41~96.69% 涤纶和棉混纺的非织造布输送水 光热 否 —— [48] 受荷叶的启发,设计可调水供应的3 D碳纤维棉基锥体蒸发器 3.27 kg·m−2·h−1 194.40% 棉棒输送水 光热 否 —— [11] 通过原位生长将碳纳米管长在碳纤维上 1.40 kg·m−2·h−1 —— 直接置于水面 光热 否 —— [53] 由疏水性聚偏氟乙烯(PVDF)/多壁碳纳米管(MWCNTs)层和具有亲水性三维梯度结构的聚多巴胺(PDA)改性

CF/PPS纤维基板组成的自浮太阳能蒸发膜1.24 kg·m−2·h−1 79.20% PDA改性CF/PPS亲水性纤维输送水 光热 否 —— [54] 采用PDA对具有良好光吸收性的疏水性工业级碳膜(CFM)进行表面改性,用于建造无盐分积累的高效悬挂式蒸发器 1.79 kg·m−2·h−1 92.60% 改性碳纤维织物 光热 否 —— [55] 通过编织法制备碳纤维/天丝复合编织纱(CBY),并制备成驱蚊香状织物 1.84 kg·m−2·h−1光热;2.97 kg·m−2·h−1光电协同 88% 亲水性天丝纤维输

送水光电协同 是 3 V [65] 制备沸石-壳聚糖-TiO2@PPy气凝胶(ZCTP),并利用碳纤维加热丝电驱动 1.66 kg·m−2·h−1光热;11.7 kg·m−2·h−1光电协同 —— 气凝胶内部垂直排列多孔结构输送水 光电协同 是 5 V [63] 使用疏水性碳纤维布 (CC) 涂有金属有机

框架 (MOF) 衍生的超亲水碳膜,并弯曲成

拱形结构3.21 kg·m−2·h−1光热;5.5 kg·m−2·h−1光电协同 —— 亲水性碳膜输送水 光电协同 是 5 V [66] -

[1] GAO S W, DONG X L, HUANG J Y, et al. Bioinspired soot-deposited janus fabrics for sustainable solar steam generation with salt-rejection[J]. Global Challenges, 2019, 3(8): 1800117. doi: 10.1002/gch2.201800117 [2] LI G P, LU L. Modeling and performance analysis of a fully solar-powered stand-alone sweeping gas membrane distillation desalination system for island and coastal households[J]. Energy Conversion and Management, 2020, 205: 112375. doi: 10.1016/j.enconman.2019.112375 [3] MENG X Y, XU W L, LI Z H, et al. Coupling of hierarchical Al2O3/TiO2, nanofibers into 3D photothermal aerogels toward simultaneous water evaporation and purification[J]. Advanced Fiber Materials, 2020, 2(2): 93-104. doi: 10.1007/s42765-020-00029-9 [4] JANG H, CHOI J, LEE H, et al. Corrugated wood fabricated using laser-induced graphitization for salt-resistant solar steam generation[J]. ACS applied materials & interfaces, 2020, 12(27): 30320-30327. [5] HUANG C H, HUANG J X, CHIAO Y H, et al. Tailoring of a piezo-photo-thermal solar evaporator for simultaneous steam and power generation[J]. Advanced Functional Materials, 2021, 31(17): 2010422. doi: 10.1002/adfm.202010422 [6] XU K, WANG C, LI Z, et al. Salt mitigation strategies of solar-driven interfacial desalination[J]. Advanced Functional Materials, 2021, 31(8): 2007855. doi: 10.1002/adfm.202007855 [7] GENG Y, SUN W, YING P, et al. Bioinspired fractal design of waste biomass-derived solar-thermal materials for highly efficient solar evaporation[J]. Advanced Functional Materials, 2021, 31(3): 2007648. doi: 10.1002/adfm.202007648 [8] TUFA R A, CURCIO E, BRAUNS E, et al. Membrane distillation and reverse electrodialysis for near-zero liquid discharge and low energy seawater desalination[J]. Journal of Membrane Science, 2015, 496: 325-333. doi: 10.1016/j.memsci.2015.09.008 [9] DONG X Y, SI Y, CHEN C J, et al. Reed leaves inspired silica nanofibrous aerogels with parallel-arranged vessels for saltresistant solar desalination[J]. ACS Nano, 2021, 15(7): 12256-12266. doi: 10.1021/acsnano.1c04035 [10] BIAN Y, TANG K, TIAN L Y, et al. Sustainable solar evaporation while salt accumulation[J]. ACS Applied Materials & Interfaces, 2021, 13(4): 4935-4942. [11] BU Y M, ZHOU Y H, LEI W W, et al. A bioinspired 3D solar evaporator with balanced water supply and evaporation for highly efficient photothermal steam generation[J]. Journal of Materials Chemistry A, 2022, 10(6): 2856-2866. doi: 10.1039/D1TA09288J [12] LI T Z, XU X T, SHENG X R, et al. Solar-powered sustainable water production: state-of-the-art technologies for sunlight-energy-water nexus[J]. ACS Nano, 2021, 15(8): 12535-12566. doi: 10.1021/acsnano.1c01590 [13] ZHANG Y X, XIONG T, NANDAKUMAR D K, et al. Structure architecting for salt rejecting solar interfacial desalination to achieve high-performance evaporation with in situ energy generation[J]. Advanced Science, 2020, 7(9): 1903478. doi: 10.1002/advs.201903478 [14] LIU S, HUANG C L, LUO X, et al. Performance optimization of bi-layer solar steam generation system through tuning porosity of bottom layer[J]. Applied energy, 2019, 239: 504-513. doi: 10.1016/j.apenergy.2019.01.254 [15] BAI B L, YANG X H, TIAN R, et al. High-efficiency solar steam generation based on blue brick-graphene inverted cone evaporator[J]. Applied Thermal Engineering, 2019, 163: 114379. doi: 10.1016/j.applthermaleng.2019.114379 [16] ZHANG X C, WANG X N, WU W D, et al. Self-floating monodisperse microparticles with a nano-engineered surface composition and structure for highly efficient solar-driven water evaporation[J]. Journal of materials chemistry A, 2019, 7(12): 6963-6971. doi: 10.1039/C8TA12290C [17] FAN Y K, BAI W, MU P, et al. Conductively monolithic polypyrrole 3-D porous architecture with micron-sized channels as superior salt-resistant solar steam generators[J]. Solar Energy Materials and Solar Cells, 2020, 206: 110347. doi: 10.1016/j.solmat.2019.110347 [18] SHI Y, LI R Y, JIN Y, et al. A 3D photothermal structure toward improved energy efficiency in solar steam generation[J]. Joule, 2018, 2(6): 1171-1186. doi: 10.1016/j.joule.2018.03.013 [19] CHEN H, WU S L, WANG H L, et al. Photothermal devices for sustainable uses beyond desalination[J]. Advanced Energy and Sustainability Research, 2021, 2(3): 2000056. doi: 10.1002/aesr.202000056 [20] XIE Z J, DUO Y H, LIN Z T, et al. The rise of 2D photothermal materials beyond graphene for clean water production[J]. Advanced Science, 2020, 7(5): 1902236. doi: 10.1002/advs.201902236 [21] CAO S S, JIANG Q S, WU X H, et al. Advances in solar evaporator materials for freshwater generation[J]. Journal of Materials Chemistry A, 2019, 7(42): 24092-24123. doi: 10.1039/C9TA06034K [22] REN P, LI J, ZHANG X, et al. Highly efficient solar water evaporation of TiO2@ TiN hyperbranched nanowires-carbonized wood hierarchical photothermal conversion material[J]. Materials Today Energy, 2020, 18: 100546. doi: 10.1016/j.mtener.2020.100546 [23] ZHU R F, LIU M M, HOU Y Y, et al. Mussel-inspired photothermal synergetic system for clean water production using full-spectrum solar energy[J]. Chemical Engineering Journal, 2021, 423: 129099. doi: 10.1016/j.cej.2021.129099 [24] IRSHAD M S, ARSHAD N, WANG X B. Nanoenabled photothermal materials for clean water production[J]. Global Challenges, 2021, 5(1): 2000055. doi: 10.1002/gch2.202000055 [25] ZOU Y, YANG P, YANG L, et al. Boosting solar steam generation by photothermal enhanced polydopamine/wood composites[J]. Polymer, 2021, 217: 123464. doi: 10.1016/j.polymer.2021.123464 [26] GUO Y H, WU H, GUO S Y, et al. Tunable all-in-one bimodal porous membrane of ultrahigh molecular weight polyethylene for solar driven interfacial evaporation[J]. Separation and Purification Technology, 2022, 302: 122071. doi: 10.1016/j.seppur.2022.122071 [27] GAO M M, ZHU L L, PEH C K, et al. Solar absorber material and system designs for photothermal water vaporization towards clean water and energy production[J]. Energy & Environmental Science, 2019, 12(3): 841-864. [28] VÉLEZ-CORDERO J R, HERNANDEZ-CORDERO J. Heat generation and conduction in PDMS-carbon nanoparticle membranes irradiated with optical fibers[J]. International Journal of Thermal Sciences, 2015, 96: 12-22. doi: 10.1016/j.ijthermalsci.2015.04.009 [29] ZHOU Q X, LI H, LI D D, et al. A graphene assembled porous fiber-based Janus membrane for highly effective solar steam generation[J]. Journal of Colloid and Interface Science, 2021, 592: 77-86. doi: 10.1016/j.jcis.2021.02.045 [30] KIM M, YANG K, KIM Y S, et al. Laser-induced photothermal generation of flexible and salt-resistant monolithic bilayer membranes for efficient solar desalination[J]. Carbon, 2020, 164: 349-356. doi: 10.1016/j.carbon.2020.03.059 [31] JO S, LEE W, PARK J, et al. Wide-range direct detection of 25-hydroxyvitamin D3 using polyethylene-glycol-free gold nanorod based on LSPR aptasensor[J]. Biosensors and Bioelectronics, 2021, 181: 113118. doi: 10.1016/j.bios.2021.113118 [32] CHEN J X, YE Z Y, YANG F, et al. Plasmonic nanostructures for photothermal conversion[J]. Small Science, 2021, 1(2): 2000055. doi: 10.1002/smsc.202000055 [33] ZHU H W, GE J, ZHAO H Y, et al. Sponge-templating synthesis of sandwich-like reduced graphene oxide nanoplates with confined gold nanoparticles and their enhanced stability for solar evaporation[J]. Science China Materials, 2020, 63(10): 1957-1965. doi: 10.1007/s40843-020-1446-5 [34] SUN Z Y, WANG J J, WU Q L, et al. Plasmon based double-layer hydrogel device for a highly efficient solar vapor generation[J]. Advanced Functional Materials, 2019, 29(29): 1901312. doi: 10.1002/adfm.201901312 [35] CHAE H G, NEWCOMB B A, GULGUNJE P V, et al. High strength and high modulus carbon fibers[J]. Carbon, 2015, 93: 81-87. doi: 10.1016/j.carbon.2015.05.016 [36] WANG Z X, YANG H C, HE F, et al. Mussel-inspired surface engineering for water-remediation materials[J]. Matter, 2019, 1(1): 115-155. doi: 10.1016/j.matt.2019.05.002 [37] SUN H X, LI Y Z, LI J Y, et al. Facile preparation of a carbon-based hybrid film for efficient solar-driven interfacial water evaporation[J]. ACS Applied Materials & Interfaces, 2021, 13(28): 33427-33436. [38] WANG H Q, ZHANG C, ZHANG Z H, et al. Artificial trees inspired by monstera for highly efficient solar steam generation in both normal and weak light environments[J]. Advanced Functional Materials, 2020, 30(48): 2005513. doi: 10.1002/adfm.202005513 [39] XU Y, GUO Z Z, WANG J, et al. Harvesting solar energy by flowerlike carbon cloth nanocomposites for simultaneous generation of clean water and electricity[J]. ACS Applied Materials & Interfaces, 2021, 13(23): 27129-27139. [40] CAO P, ZHAO L M, ZHANG J W, et al. Gradient heating effect modulated by hydrophobic/hydrophilic carbon nanotube network structures for ultrafast solar steam generation[J]. ACS Applied Materials & Interfaces, 2021, 13(16): 19109-19116. [41] YANG D Z, ZHOU B, HAN G J, et al. Flexible transparent polypyrrole-decorated MXene-based film with excellent photothermal energy conversion performance[J]. ACS Applied Materials & Interfaces, 2021, 13(7): 8909-8918. [42] XIONG Z C, ZHU Y J, QIN D D, et al. Flexible salt-rejecting photothermal paper based on reduced graphene oxide and hydroxyapatite nanowires for high-efficiency solar energy-driven vapor generation and stable desalination[J]. ACS applied materials & interfaces, 2020, 12(29): 32556-32565. [43] ZHANG H T, LI L, JIANG B, et al. Highly thermally insulated and superhydrophilic corn straw for efficient solar vapor generation[J]. ACS applied materials & interfaces, 2020, 12(14): 16503-16511. [44] 陈根余, 陶能如, 李明全, 等. 碳纤维复合材料激光制孔技术研究进展[J]. 复合材料学报, 2022, 39(4): 1395-1410.CHEN Genyu, TAO Nengru R, LI Mingquan, et al. Research progress of laser drilling technology for carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica, 2022, 39(4): 1395-1410(in Chinese). [45] TAO P, NI G, SONG C, et al. Solar-driven interfacial evaporation[J]. Nature energy, 2018, 3(12): 1031-1041. doi: 10.1038/s41560-018-0260-7 [46] 刘强, 肖维新, 罗渊, 等. 高效海水淡化的太阳能界面蒸发器研究进展[J]. 太阳能学报, 2024, 45(3): 591-602.LIU Qiang, XIAO Weixin, LUO Yuan, et al. Research progress on solar interface evaporators for efficient seawater desalination[J]. Acta Energiae Solaris Sinica, 2024, 45(3): 591-602(in Chinese). [47] SHAHBAZI, M. A, GHALKHANI, M, MALEKI, H. Directional freeze- casting: a bioinspired method to assemble multifunctional aligned porous structures for advanced applications[J]. Advanced engineering materials, 2020, 22(7): 2000033. doi: 10.1002/adem.202000033 [48] TONG D D, SONG B. A high-efficient and ultra-strong interfacial solar evaporator based on carbon-fiber fabric for seawater and wastewater purification[J]. Desalination, 2022, 527: 115586. doi: 10.1016/j.desal.2022.115586 [49] 杜恒, 方剑, 葛灿, 等. 界面光热水蒸发用碳基纤维材料的研究进展[J]. 复合材料学报, 2023, 40(6): 3115-3124.DU Heng, FANG Jian, GE Can, et al. Research progress in carbon-based fibrous materials for interfacial photothermal steam generation[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3115-3124(in Chinese). [50] LI T T, FANG Q L, XI X F, et al. Ultra-robust carbon fibers for multi-media purification via solar-evaporation[J]. Journal of materials chemistry A, 2019, 7(2): 586-593. doi: 10.1039/C8TA08829B [51] ZHAO G M, CHEN Y L, PAN L Q, et al. Plant-inspired design from carbon fiber toward high-performance salt-resistant solar interfacial evaporation[J]. Solar Energy, 2022, 233: 134-141. doi: 10.1016/j.solener.2022.01.025 [52] JI M W, LIU H C, CHENG M S, et al. Plasmonic Metal Nanoparticle Loading to Enhance the Photothermal Conversion of Carbon Fibers[J]. The Journal of Physical Chemistry C, 2022, 126(5): 2454-2462. doi: 10.1021/acs.jpcc.1c10792 [53] LIU H C, HUANG G C, WANG R, et al. Carbon Nanotubes Grown on the Carbon Fibers to Enhance the Photothermal Conversion toward Solar-Driven Applications[J]. ACS Applied Materials & Interfaces, 2022, 14(28): 32404-32411. [54] WU M Y, WANG Z X, YAO S J, et al. A self-floating photothermal evaporator with 3D gradient water channel for highly efficient solar seawater desalination[J]. Reactive and Functional Polymers, 2023, 185: 105529. doi: 10.1016/j.reactfunctpolym.2023.105529 [55] CHONG W M, MENG R R, LIU Z X, et al. Superhydrophilic Polydopamine-Modifed Carbon-Fiber Membrane with Rapid Seawater-Transferring Ability for Constructing Efficient Hanging-Model Evaporator[J]. Advanced Fiber Materials, 2023, 5(3): 1063-1075. doi: 10.1007/s42765-023-00276-6 [56] WU C M, CHENG C T, TESSEMA A A, et al. Staple carbon fabric/polyurethane Janus membranes for photothermal conversion and interfacial steam generation[J]. Journal of Polymer Research, 2023, 30(6): 196. doi: 10.1007/s10965-023-03594-w [57] WAN J M, XU J, ZHU S Y, et al. Flexible biomimetic materials with excellent photothermal performance and superhydrophobicity[J]. Journal of Colloid and Interface Science, 2023, 629: 581-590. doi: 10.1016/j.jcis.2022.09.108 [58] 王业文, 董洁, 孙润军, 等. 碳纤维电加热元件最新研究进展[J]. 高科技纤维与应用, 2023, 18-25.WANG Yewen, DONG Jie, SUN Runjun, et al. The latest research progress on carbon fiber electric heating elements[J]. Hi- Tech Fiber and Application, 2023, 18-25. (in Chinese) [59] 韩朝锋, 薛有松, 张东生, 等. 碳纤维复合材料电导特性和力电耦合行为研究进展[J]. 复合材料学报, 2023, 40(6): 3136-3152.HAN Chaofeng, XUE Yousong, ZHANG Dongsheng, et al. Research progress on electrical property and electromechanical coupling behaviors of carbon fiber composites[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3136-3152(in Chinese). [60] 杨小平, 荣浩鸣, 沈曾民. 碳纤维面状发热材料的性能研究[J]. 高科技纤维与应用, 2000, 25(3): 39-42.YANG Xiaoping, RONG Haoming, SHEN Zengmin. Study on the properties of carbon fiber facial heating material[J]. Hi-Tech Fiber and Application, 2000, 25(3): 39-42(in Chinese). [61] LI Q Q, YING Y F, TAO Y L, et al. Assemblable carbon fiber/metal–organic framework monoliths for energy-efficient atmospheric water harvesting[J]. Industrial & engineering chemistry research, 2022, 61(3): 1344-1354. [62] LEE J S, HOANG V T, KWEON J H, et al. Multifunctional Ni-plated carbon fiber reinforced thermoplastic composite with excellent electrothermal and superhydrophobic properties using MWCNTs and SiO2/Ag microspheres[J]. Composites Part A: Applied Science and Manufacturing, 2023, 171: 107585. doi: 10.1016/j.compositesa.2023.107585 [63] ZHAO S J, ZHANG X, WEI G, et al. All-weather photothermal-electrothermal integrated system for efficient solar steam generation[J]. Chemical Engineering Journal, 2023, 458: 141520. doi: 10.1016/j.cej.2023.141520 [64] HUANG J, HE Y R, HU Y W, et al. Coupled photothermal and joule-heating process for stable and efficient interfacial evaporation[J]. Solar Energy Materials and Solar Cells, 2019, 203: 110156. doi: 10.1016/j.solmat.2019.110156 [65] XU D, GE C, CHEN Z, et al. Composite Braided Fabric Coupled with Photothermal and Electrothermal Processes for Stable and Continuous All-Day Desalination[J]. ACS Applied Materials & Interfaces, 2022, 14(46): 52087-52095. [66] WANG C B, XU K Y, SHI G L, et al. Water Skin Effect and Arched Double-Sided Evaporation for Boosting All-Weather High Salinity Desalination[J]. Advanced Energy Materials, 2023, 13(21): 2300134. doi: 10.1002/aenm.202300134 -

点击查看大图

点击查看大图

计量

- 文章访问数: 40

- HTML全文浏览量: 45

- 被引次数: 0

下载:

下载: