Design and mechanical properties of glass fiber reinforced polypropylene polymer composite cable-anchor component

-

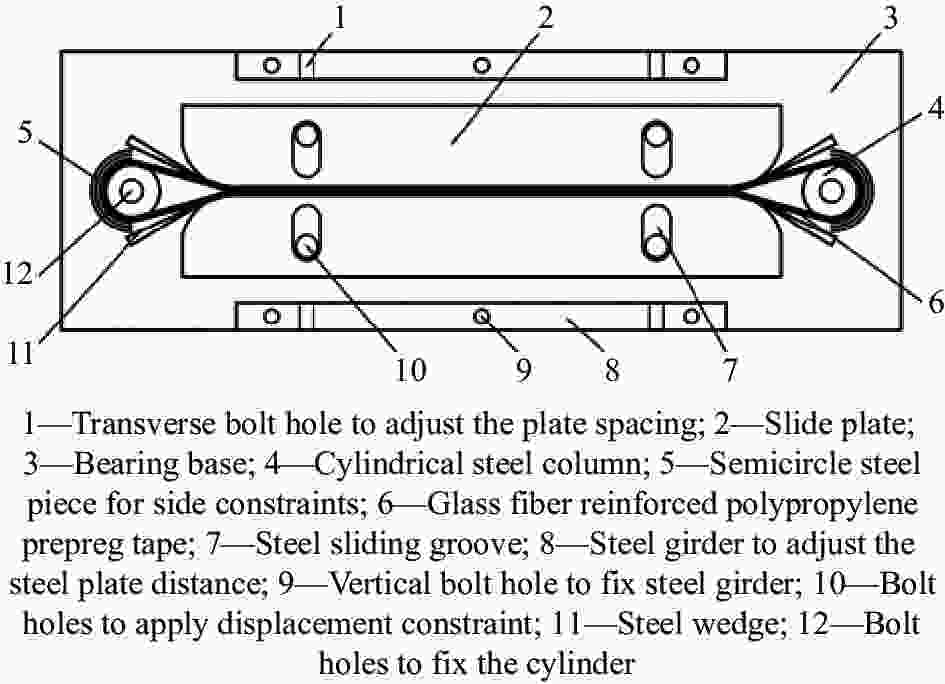

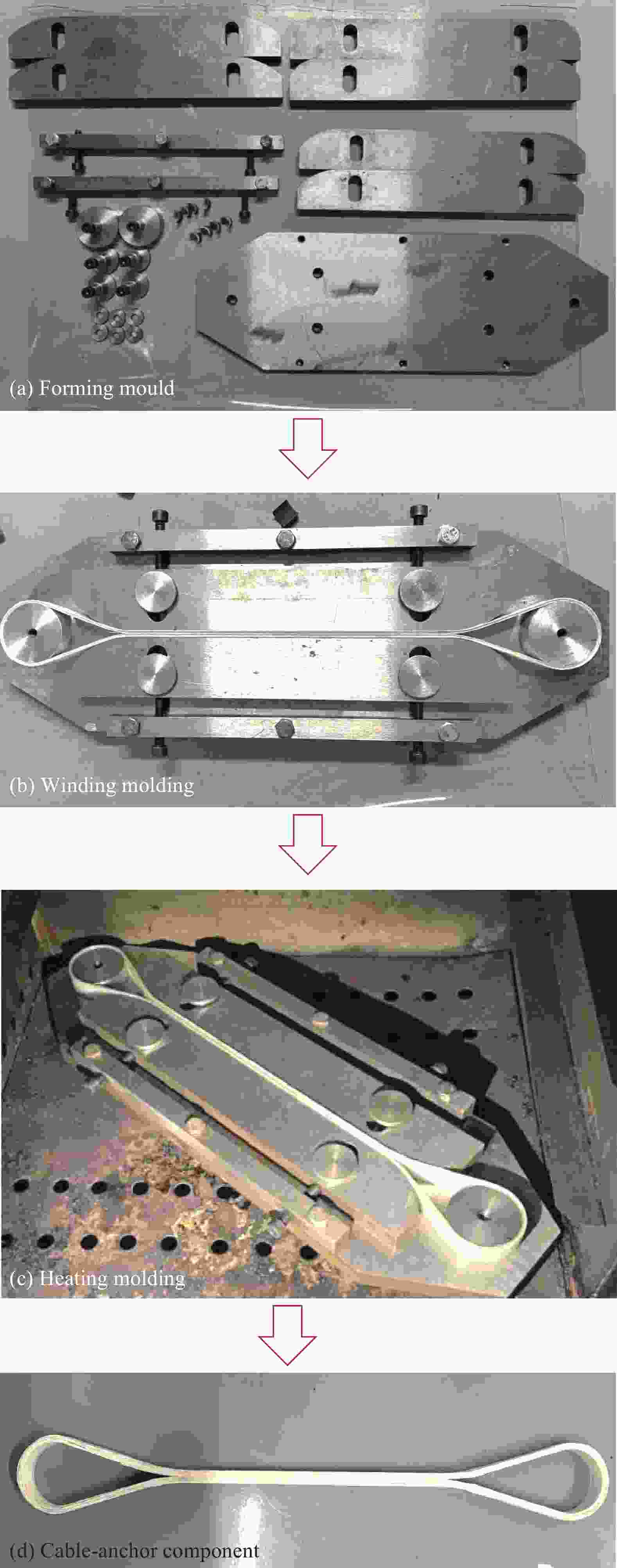

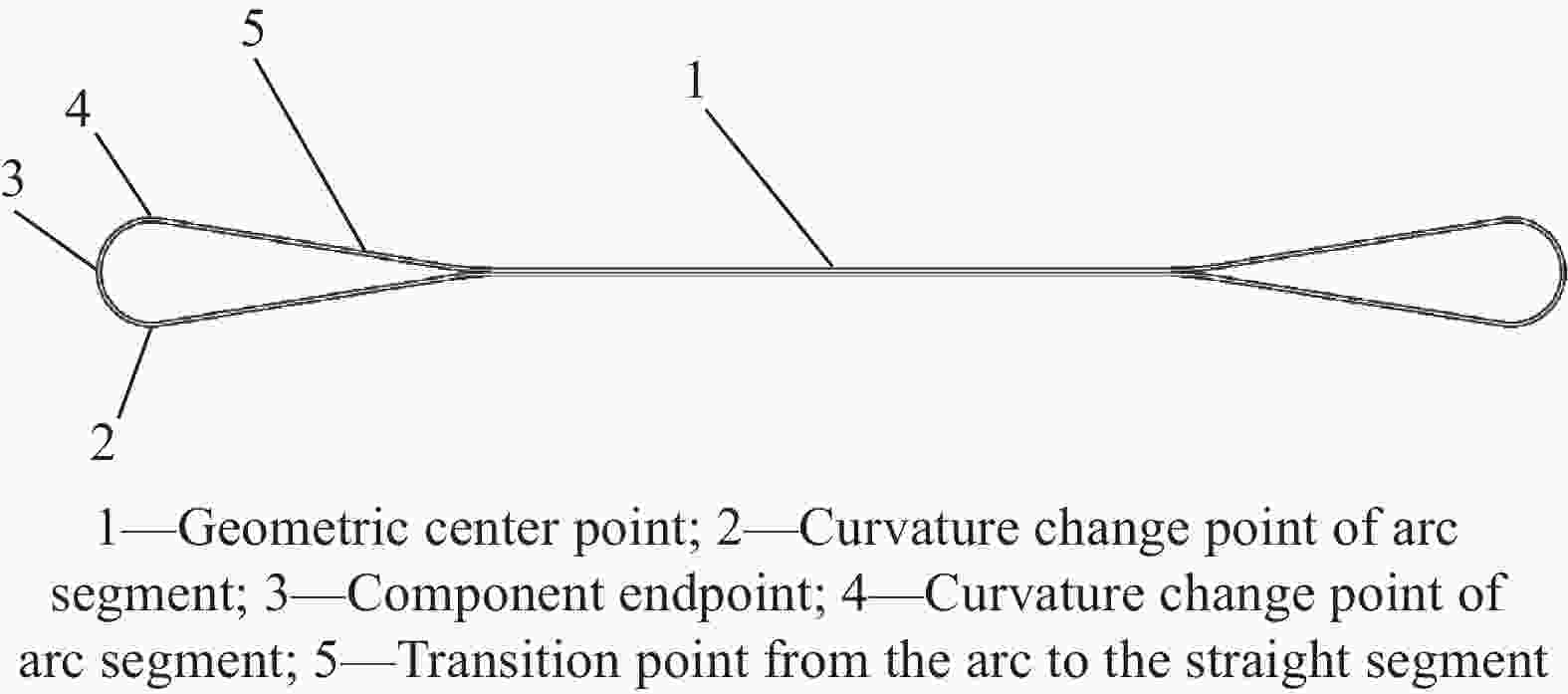

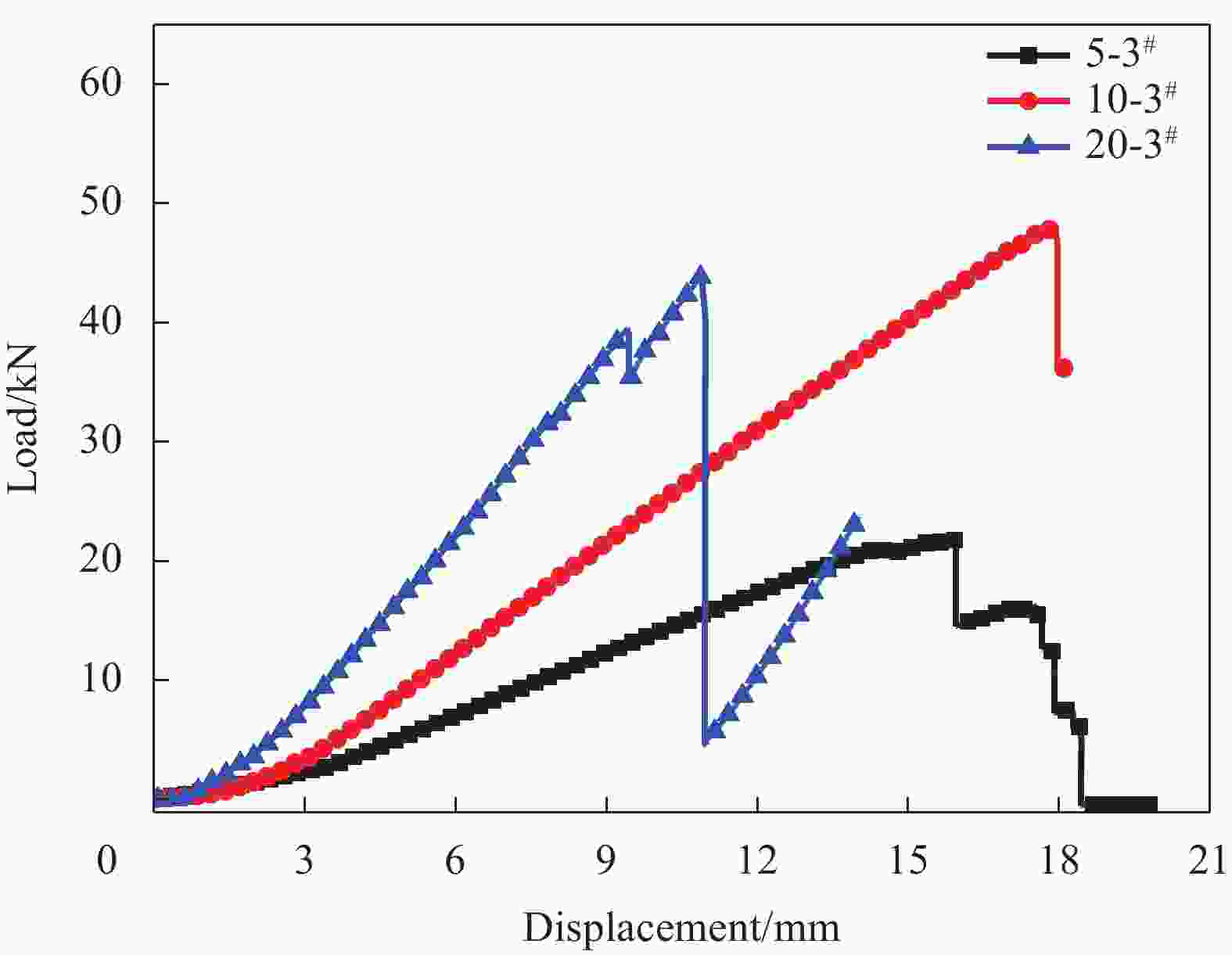

摘要: 桥梁拉索及预应力混凝土结构用纤维增强复合材料的可靠锚固是需要解决的关键难题。热塑性聚丙烯树脂具有优异的断裂韧性、耐湿热/抗疲劳性能及加工成型方便和可回收利用等优点,根据其加热熔化冷却成型原理,本文采用玻璃纤维增强聚丙烯预浸带制备了一种尺寸稳定、性能优异、具有自锁结构的复合材料索锚构件。采用拉伸测试及有限元模拟研究预浸带层数与圆弧段角度对索锚结构极限承载力、应力分布及破坏模式的影响。研究发现,索锚构件的极限承载力随圆弧段角度增加而降低,随缠绕层增加先增加后下降。有限元模拟与实验结果吻合性较好,验证了缠绕10层预浸带,圆弧段角度为13.5°的索锚构件应力分布均匀并取得最高的拉伸强度。最后,通过总结与分析,论证了一体化新型索锚构件在桥梁拉索、地锚结构及预应力混凝土结构中的应用前景。Abstract: The reliable anchoring of fiber reinforced polymer composite used in bridge cable and prestressed concrete structures is the key problem to be solved. The thermoplastic polypropylene resin has the excellent fracture toughness, hygrothermal/fatigue resistances, convenient processing and recycling, etc. Based on the heating melting cooling molding principle of thermoplastic resin, a kind of composite cable-anchor with stable size, excellent performance and self-locking structure was prepared through adopting the glass fiber reinforced polypropylene prepreg tape. The effects of prepreg tape winding layer number and arc angle on the ultimate bearing capacity, stress distribution and failure mode of cable-anchor structure were studied by tensile test and finite element simulation. It is found that the ultimate bearing capacity of cable-anchor component decreases with the increase of the arc angle, and increases firstly and then decreases with the increase of the winding layer. The finite element simulation is in good agreement with the experimental results, which verifies that the stress distribution of cable-anchor component of 10-layer prepreg tape with the arc angle of 13.5° is uniform and the optimum tensile properties were obtained. Finally, by summarizing and analyzing, the application prospects of the new integrated cable-anchor components in bridge cable, ground anchor structure and prestressed concrete structure were demonstrated.

-

表 1 弧段角度对玻璃纤维增强聚丙烯树脂索锚构件拉伸性能的影响

Table 1. Effect of arc angle on tensile properties of glass fiber reinforced polypropylene cable-anchor component

Sample number Ultimate bearing capacity/kN Tensile strength/

MPaAnchorage efficiency/% 10-1# 36.05 400.6 76.4 10-2# 42.32 470.2 89.7 10-3# 49.65 551.7 105.3 Notes: 10-1# denotes that the number of winding layers of the prepreg tape is 10 layers, and the arc angle number is 1#, which is 21.8°. Other conditions are similar, 2# is 16.7°, 3# is 13.5°. 表 2 缠绕层数对玻璃纤维增强聚丙烯树脂索锚构件拉伸性能的影响

Table 2. Effect of winding layer number on tensile properties of glass fiber reinforced polypropylene cable-anchor component

Sample number Ultimate bearing capacity/kN Tensile strength/

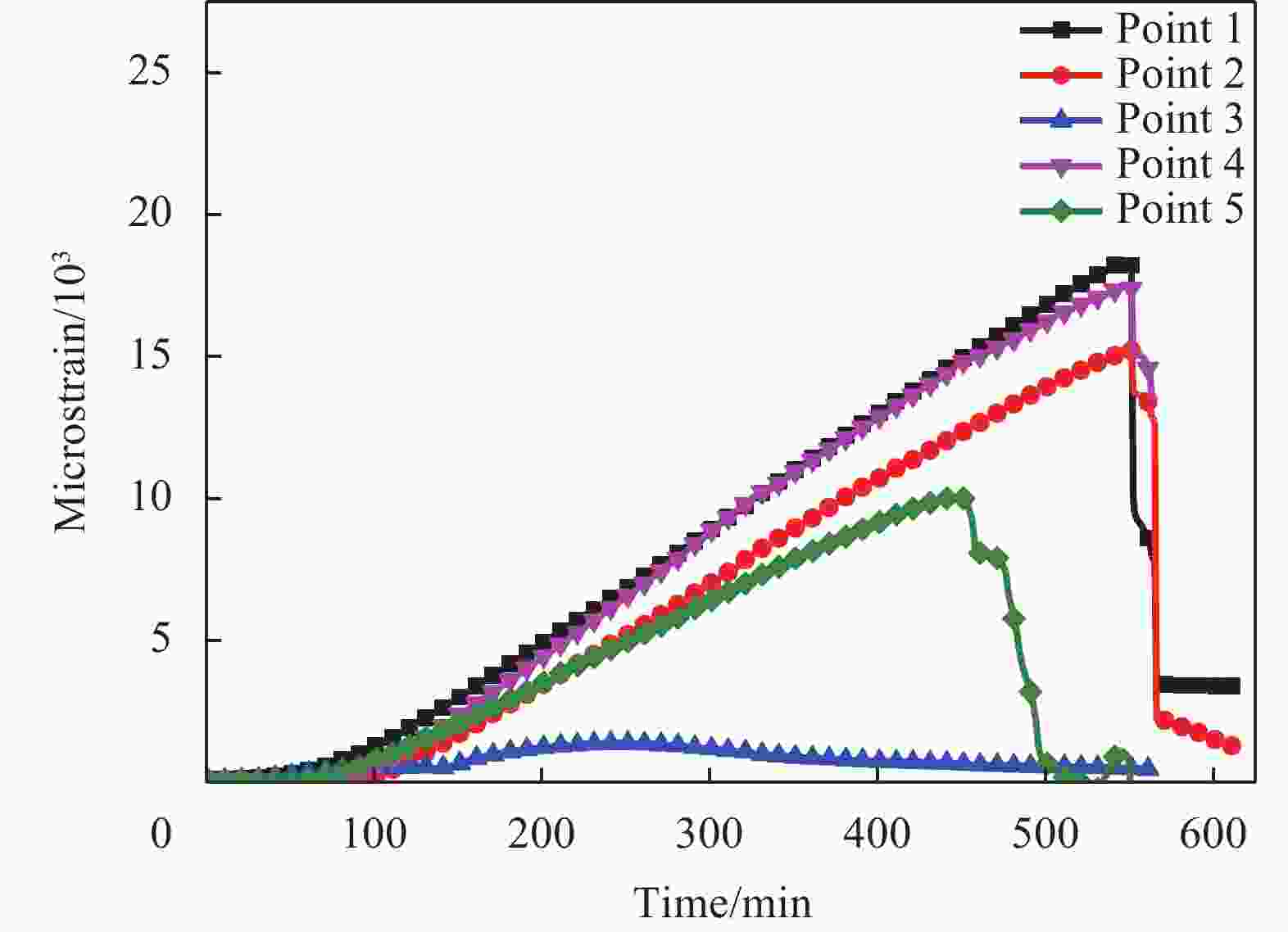

MPaAnchorage efficiency/% 5-3# 24.20 537.8 102.6 10-3# 49.65 551.7 105.3 20-3# 45.44 252.4 48.2 Notes: 5, 10 and 20 are the layers of prepreg tape, and 3# is 13.5°. 表 3 玻璃纤维增强聚丙烯树脂索锚构件不同监测位置的极限应变

Table 3. Ultimate strain of glass fiber reinforced polypropylene cable-anchor component at different monitoring positions

Position Maximum tensile

strain/10−6Strain ratio

to position 1/%1 18327 100.0 2 15237 83.1 3 1296 7.1 4 17403 95.0 5 9958 54.3 -

[1] 王晓军, 王家琦, 晋民杰, 等. 锈蚀疲劳耦合作用下的斜拉索钢绞线损伤分析[J]. 太原科技大学学报, 2019, 40(6):472-476. doi: 10.3969/j.issn.1673-2057.2019.06.010WANG Xiaojun, WANG Jiaqi, JIN Minjie, et al. Analysis of coupling injury caused by corrosion and fatigue of cable stayed cables[J]. Journal of Taiyuan University of Science and Technology,2019,40(6):472-476(in Chinese). doi: 10.3969/j.issn.1673-2057.2019.06.010 [2] MEIER U. Carbon fiber reinforced polymers: Modern materials in bridge engineering[J]. Structural Engineering International,1992,2(1):7-12. doi: 10.2749/101686692780617020 [3] XIAN G J, GUO R, LI C G, et al. Effects of rod size and fiber hybrid mode on the interface shear strength of carbon/glass fiber composite rods exposed to freezing-thawing and outdoor environments[J]. Journal of Materials Research and Technology,2021,14:2812-2831. doi: 10.1016/j.jmrt.2021.08.088 [4] PENG Z Q, WANG X, ZHOU J Y, et al. Reliability assessment of fiber-reinforced polymer cable-anchorage system[J]. Composite Structures,2021,273:114308. doi: 10.1016/j.compstruct.2021.114308 [5] 洪斌. 聚氨酯基CFRP拉挤板材的耐水碱盐性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.HONG Bin. Study of the resistance to water, alkali and salt solutions of pultruded polyurethane-based CFRP plates[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [6] WANG Z K, ZHAO X L, XIAN G J, et al. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars[J]. Corrosion Science,2018,138:200-218. doi: 10.1016/j.corsci.2018.04.002 [7] YANG Y Q, WANG X, WU Z S. Long-span cable-stayed bridge with hybrid arrangement of FRP cables[J]. Compo-site Structures,2020,237:111966. doi: 10.1016/j.compstruct.2020.111966 [8] 王常林. 碳纤维拉索及其锚固系统横向受力性能试验研究[D]. 长沙: 湖南大学, 2015.WANG Changlin. Experimental research on behavior of CFRP cable and anchorage subjecting to lateral force[D]. Changsha: Hunan University, 2015(in Chinese). [9] 韩娟, 刘伟庆, 方海. 纤维增强树脂基复合材料在土木基础设施领域中的应用[J]. 南京工业大学学报(自然科学版), 2020, 42(5):543-554.HAN Juan, LIU Weiqing, FANG Hai. Application of fiber-reinforced resin matrix composites in the civil infrastructure field[J]. Journal of Nanjing University of Technology (Natural Science Edition),2020,42(5):543-554(in Chinese). [10] 汪胜义. 碳纤维复合材料(CFRP)在桥梁工程中的应用及前景[J]. 重庆交通学院学报, 2005, 24(1):30-32, 41.WANG Shengyi. The application and future of carbon fiber reinforced polymer in bridge structure[J]. Journal of Chongqing Jiaotong University,2005,24(1):30-32, 41(in Chinese). [11] 孙杰, 孙峙华, 胡荣根. 碳纤维复合材料在桥梁工程中的应用及其前景[J]. 公路交通技术, 2004(1): 46-48, 60.SUN Jie, SUN Zhihua, HU Ronggen. Application of carbon fiber reinforced plastics (CFRP) to bridge engineering and prospects of CFRP[J]. Technology of Highway and Transport, 2004(1): 46-48, 60(in Chinese). [12] LIU Y, ZWINGMANN B, SCHLAICH M. Carbon fiber reinforced polymer for cable structures-A review[J]. Polymers,2015,7(10):2078-2099. doi: 10.3390/polym7101501 [13] 臧华, 刘钊, 吕志涛, 等. CFRP 筋用作斜拉桥拉索的研究与应用进展[J]. 公路交通科技, 2006, 23(10):70-74. doi: 10.3969/j.issn.1002-0268.2006.10.016ZANG Hua, LIU Zhao, LV Zhitao, et al. Research and application review on CFRP cables for cable-stayed bridges[J]. Journal of Highway and Transportation Research and Development,2006,23(10):70-74(in Chinese). doi: 10.3969/j.issn.1002-0268.2006.10.016 [14] 李代文. 连续玻璃纤维增强聚丙烯复合材料的制备及性能研究[D]. 杭州: 浙江理工大学, 2018.LI Daiwen. Preparation and performance of continuous glass fiber reinforced polypropylene composite[D]. Hangzhou: Zhejiang University of Technology, 2018(in Chinese). [15] FU S Y, LAUKE B, MAI Y W. Science and engineering of short fibre reinforced polymer composites[M]. Oxford: Woodhead Publishing, 2019. [16] 乔艳党. 连续玻璃纤维增强热塑性PVC层压板工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2009.QIAO Yandang. Study of lamination of the continuous glass fiber reinforced thermoplastic PVC[D]. Harbin: Harbin Institute of Technology, 2009(in Chinese). [17] COUSINS D S, SUZULI Y, MURRAY R, et al. Recycling glass fiber thermoplastic composites from wind turbine blades[J]. Journal of Cleaner Production,2019,209:1252-1263. doi: 10.1016/j.jclepro.2018.10.286 [18] CHILALI A, ZOUARI W, ASSARAR M, et al. Effect of water ageing on the load-unload cyclic behaviour of flax fibre-reinforced thermoplastic and thermosetting composites[J]. Composite Structures,2018,183:309-319. doi: 10.1016/j.compstruct.2017.03.077 [19] FUHRMANN G, STEINER M, FREITAG-WOLF S, et al. Resin bonding to three types of polyaryletherketones (PAEKs)-durability and influence of surface conditioning[J]. Dental Materials,2014,30:357-363. doi: 10.1016/j.dental.2013.12.008 [20] UTEKAR S, SURIYA V K, MORE N, et al. Comprehensive study of recycling of thermosetting polymer composites-driving force, challenges and methods[J]. Composites Part B: Engineering,2021,207:108596. doi: 10.1016/j.compositesb.2020.108596 [21] 李承高. 碳/玻璃纤维复合杆体的锚固及其耐久性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.LI Chenggao. Study on the anchorage and durability pro-perties of carbon/glass fiber composite rod[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [22] ZHOU J, WANG X, PENG Z, et al. Optimization of load transfer component for FRP cable anchor system[J]. Composite Structures,2022,282:115009. doi: 10.1016/j.compstruct.2021.115009 [23] LEES J M, WINISTORFER A U. Nonlaminated FRP strap elements for reinforced concrete, timber, and masonry applications[J]. Journal of Composites for Construction,2011,15(2):146-155. doi: 10.1061/(ASCE)CC.1943-5614.0000076 [24] AI P C, FENG P, LIN H W, et al. Novel self-anchored CFRP cable system: Concept and anchorage behavior[J]. Composite Structures,2021,263:113736. doi: 10.1016/j.compstruct.2021.113736 [25] American Society of Testing Materials. Standard test method for tensile properties of plastics: ASTM D638—2010[S]. West Conshohocken: American Society of Testing Materials, 2010. [26] 王振清, 雷红帅, 周博, 等. 基于内聚力模型的形状记忆合金短纤维增强树脂基复合材料的模拟分析[J]. 复合材料学报, 2012, 29(5):236-243.WANG Zhenqing, LEI Hongshuai, ZHOU Bo, et al. Simulation and analysis on short-cut shape memory alloy reinforced epoxy composite based on cohesive zone model[J]. Acta Materiae Compositae Sinica,2012,29(5):236-243(in Chinese). [27] YANG Y, FAHMY M F M, GUAN S, et al. Properties and applications of FRP cable on long-span cable-supported bridges: A review[J]. Composites Part B: Engineering,2020,190:107934. doi: 10.1016/j.compositesb.2020.107934 [28] 张强先, 赵华伟, 方园, 等. 悬索桥主缆钢丝腐蚀与防护的应用进展[J]. 南京工业大学学报(自然科学版), 2020, 42(3):278-283.ZHANG Qiangxian, ZHAO Huawei, FANG Yuan, et al. Application progress on corrosion and protection of main cable steel wire of suspension bridge[J]. Journal of Nanjing University of Technology (Natural Science Edition),2020,42(3):278-283(in Chinese). [29] WANG X, ZHOU J, DING L, et al. Static behavior of circumferential stress-releasing anchor for large-capacity FRP cable[J]. Journal of Bridge Engineering,2020,25(1):04019127. doi: 10.1061/(ASCE)BE.1943-5592.0001504 [30] ZHANG K, FANG Z, NANNI A, et al. Experimental study of a large-scale ground anchor system with FRP tendon and RPC grout medium[J]. Journal of Composites for Construction,2015,19(4):04014073. doi: 10.1061/(ASCE)CC.1943-5614.0000537 [31] ZHENG J J, DAI J G. Prediction of the nonlinear pull-out response of FRP ground anchors using an analytical transfer matrix method[J]. Engineering Structures,2014,81:377-385. doi: 10.1016/j.engstruct.2014.10.008 [32] KUERES S, WILL N, HEGGER J. Shear strength of prestressed FRP reinforced concrete beams with shear reinforcement[J]. Engineering Structures,2020,206:110088. doi: 10.1016/j.engstruct.2019.110088 [33] WANG H, MARINO E M, PAN P, et al. Experimental study of a novel precast prestressed reinforced concrete beam-to-column joint[J]. Engineering Structures,2018,156:68-81. doi: 10.1016/j.engstruct.2017.11.011 [34] 常鑫泉, 汪昕, 刘长源, 等. 预应力FRP板加固RC梁抗弯性能有限元模型可靠性评价[J]. 南京工业大学学报(自然科学版), 2021, 43(3):318-328.CHANG Xinquan, WANG Xin, LIU Changyuan, et al. Reliability evaluation of finite element model for flexural behavior of RC beams reinforced with prestressed FRP laminates[J]. Journal of Nanjing University of Technology (Natural Science Edition),2021,43(3):318-328(in Chinese). [35] HOSSEINI A, GHAFOORI E, MOTAVALLI M, et al. Prestressed unbonded reinforcement system with multiple CFRP plates for fatigue strengthening of steel members[J]. Polymers,2018,10(3):264. doi: 10.3390/polym10030264 [36] HOSSEINI A, GHAFOORI E, MOTAVALLI M, et al. Mode I fatigue crack arrest in tensile steel members using prestressed CFRP plates[J]. Composite Structures,2017,178:119-134. [37] FANG Z, ZHANG K, TU B. Experimental investigation of a bond-type anchorage system for multiple FRP tendons[J]. Engineering Structures,2013,57:364-373. doi: 10.1016/j.engstruct.2013.09.038 [38] 李承高, 郭瑞, 黄翔宇, 等. 碳纤维增强树脂复合材料(CFRP)拉挤板材的楔形挤压锚固机制[J]. 南京工业大学学报(自然科学版), 2021, 43(3):358-365.LI Chenggao, GUO Rui, HUANG Xiangyu, et al. Wedge-extrusion anchorage mechanism of pultruded CFRP plate[J]. Journal of Nanjing University of Technology (Natural Science Edition),2021,43(3):358-365(in Chinese). [39] LI C G, XIAN G J. Design optimization and experimental validation of a novel wedge-shaped bond anchorage system for prestressed CFRP plates[J]. Polymer Testing,2019,75:167-174. doi: 10.1016/j.polymertesting.2019.02.001 -

下载:

下载: