Thermal/mechanical properties of incompletely cured carbon fiber/vinyl ester composites after hydrothermal aging

-

摘要:

碳纤维/乙烯基酯树脂复合材料(CF/VE)因其轻质高强和耐腐蚀等特点被逐渐应用于大厚度、大尺度的舰船结构件,由于尺寸和制造装备的限制,舰船用大厚度复合材料装备后的固化往往不充分。为了解不完全固化的CF/VE在水热环境下的耐久性,分析了树脂的表面形貌变化和水解机制,研究了树脂及其复合材料的动态热力学性能和高温下的力学性能。液相色谱-质谱联用和FTIR的结果表明树脂分子链中的酯键发生了强水解;由于树脂发生由表及里的强水解反应和渗透开裂,导致质量增长率在达到最大值后下降,

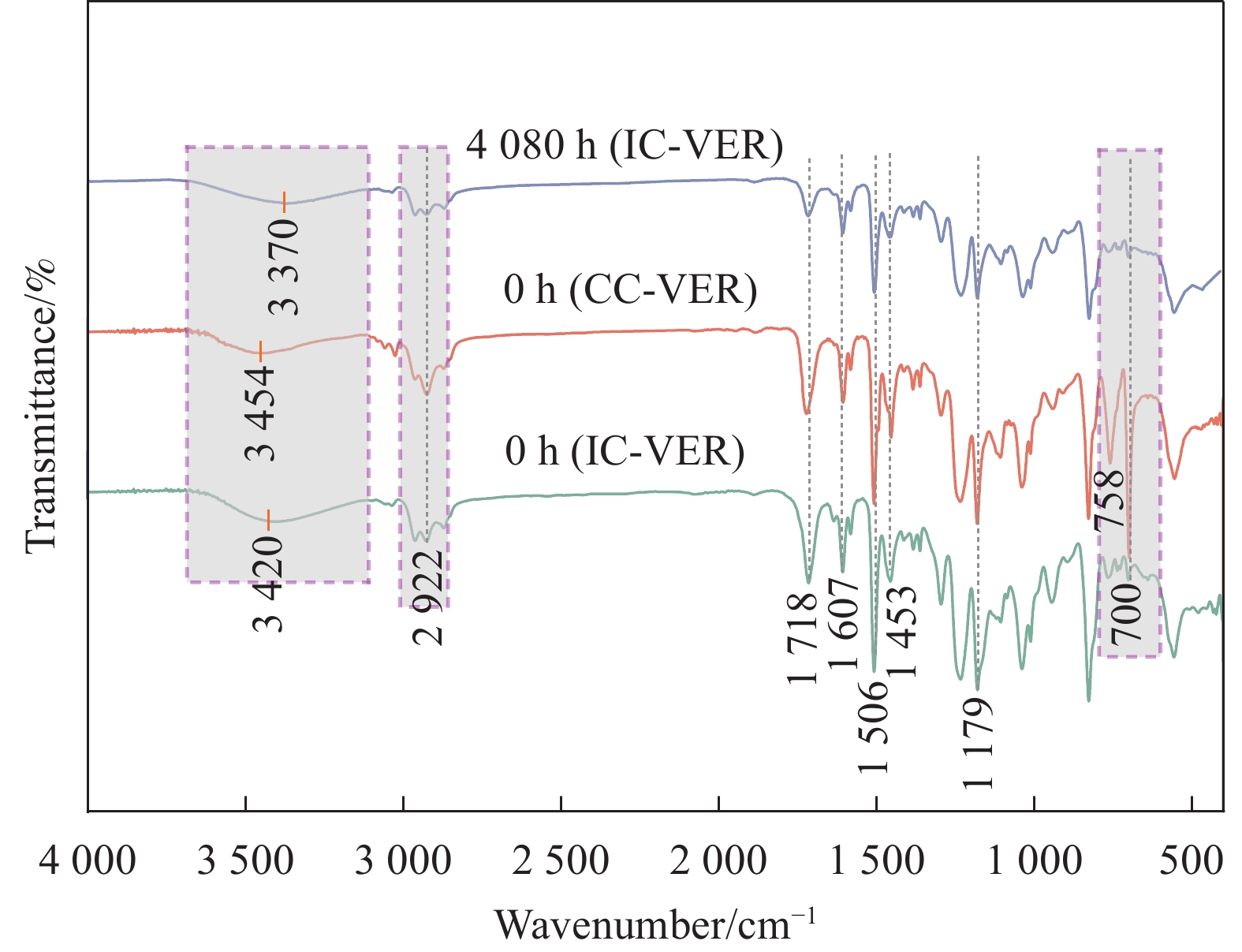

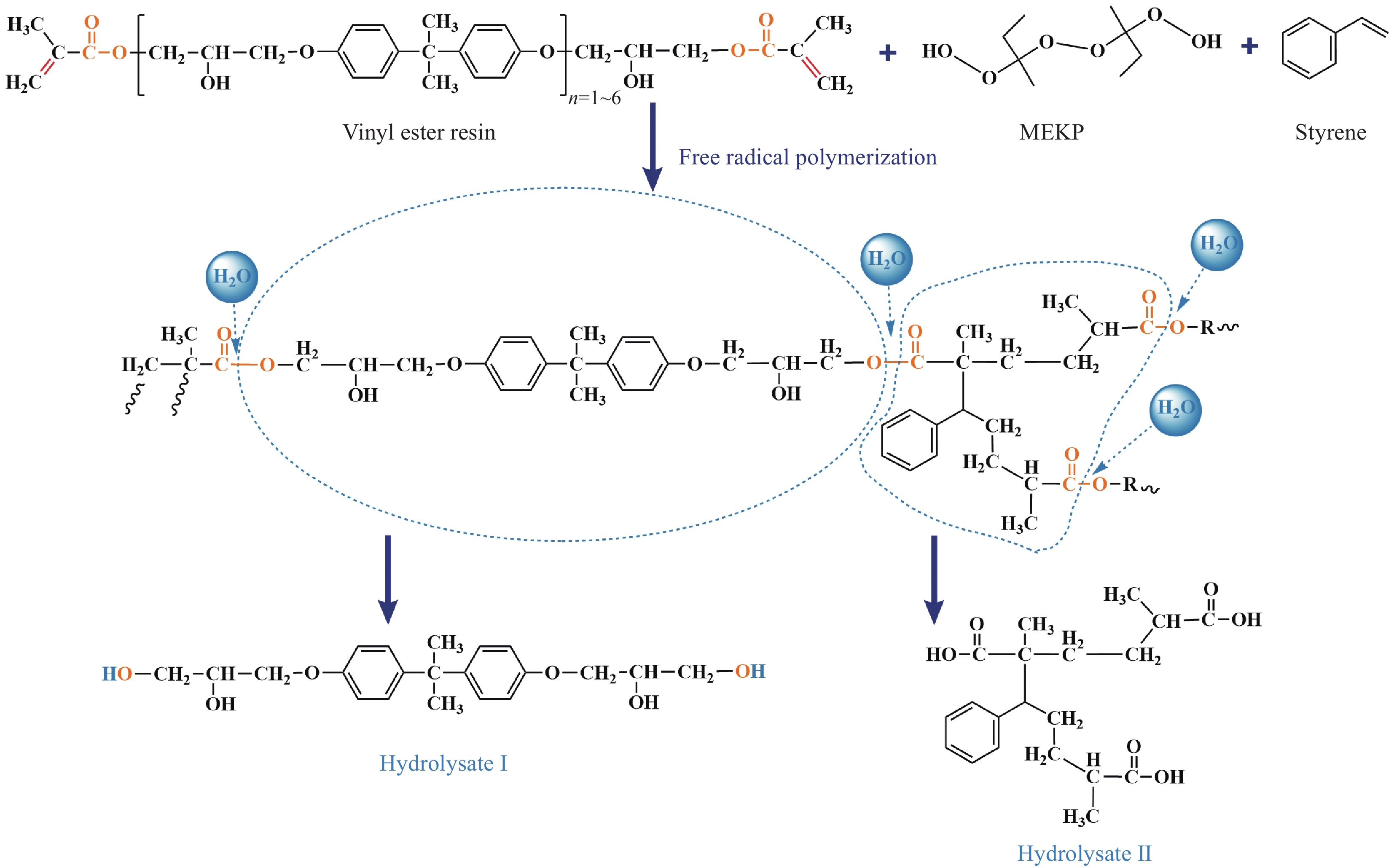

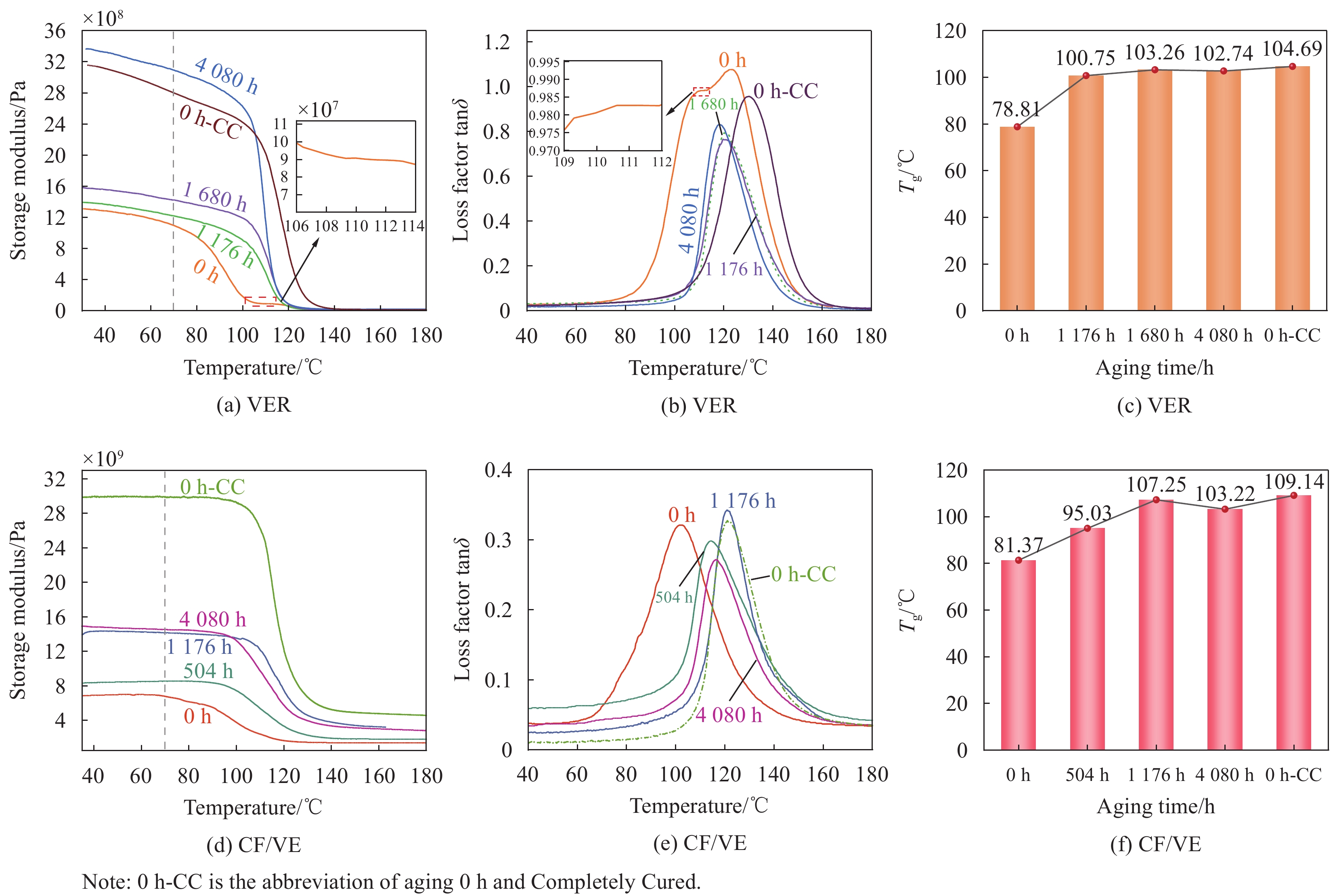

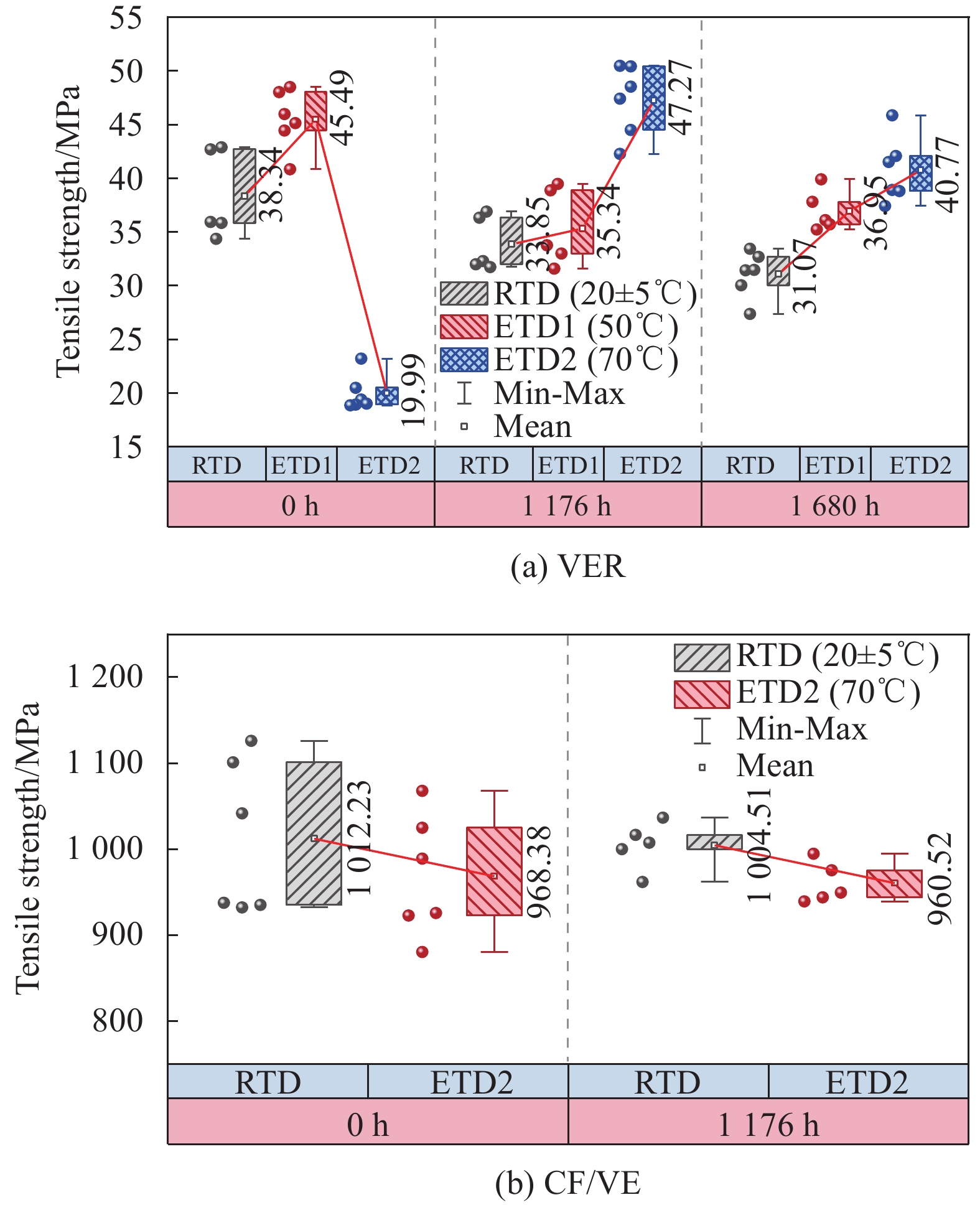

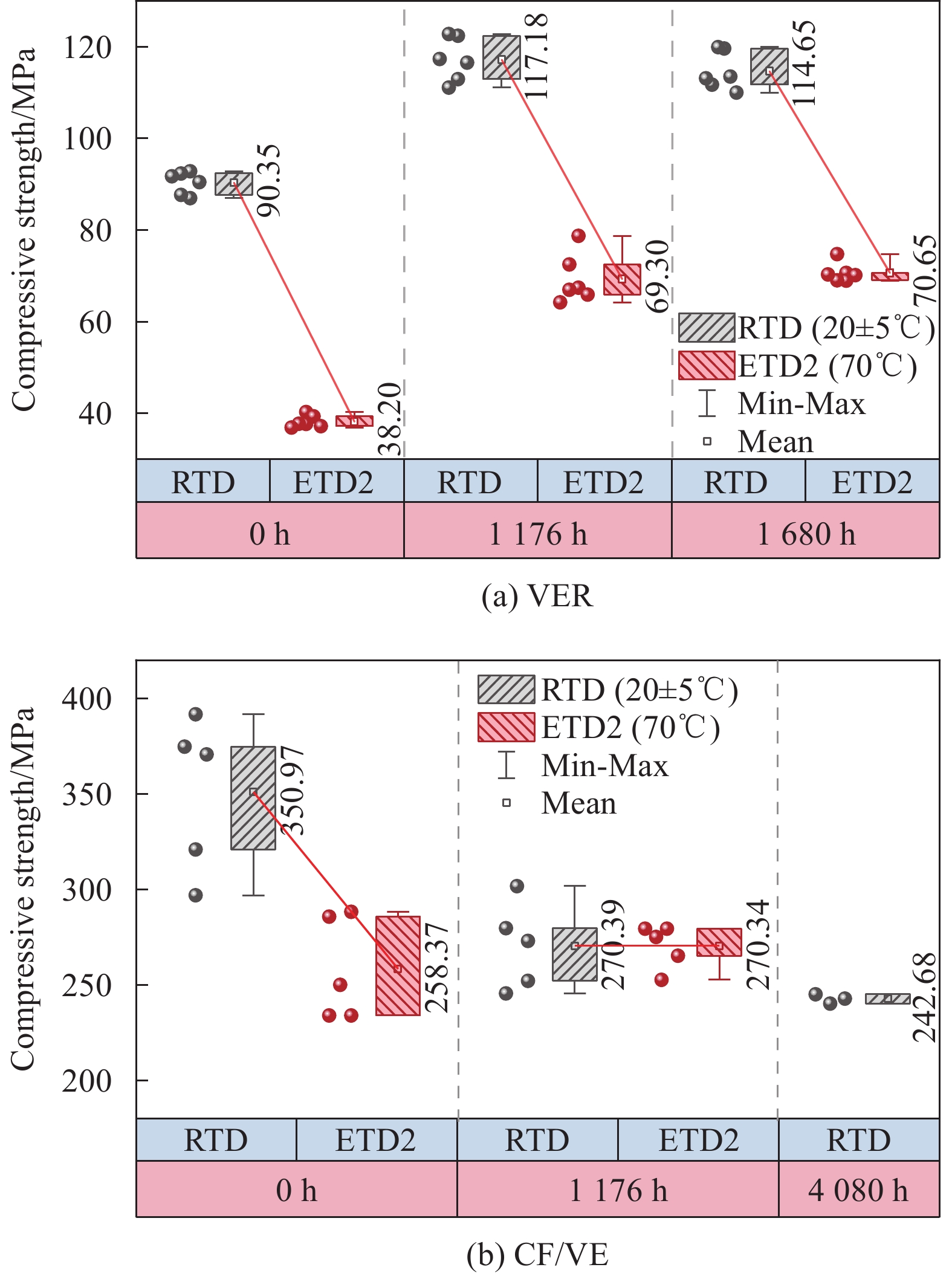

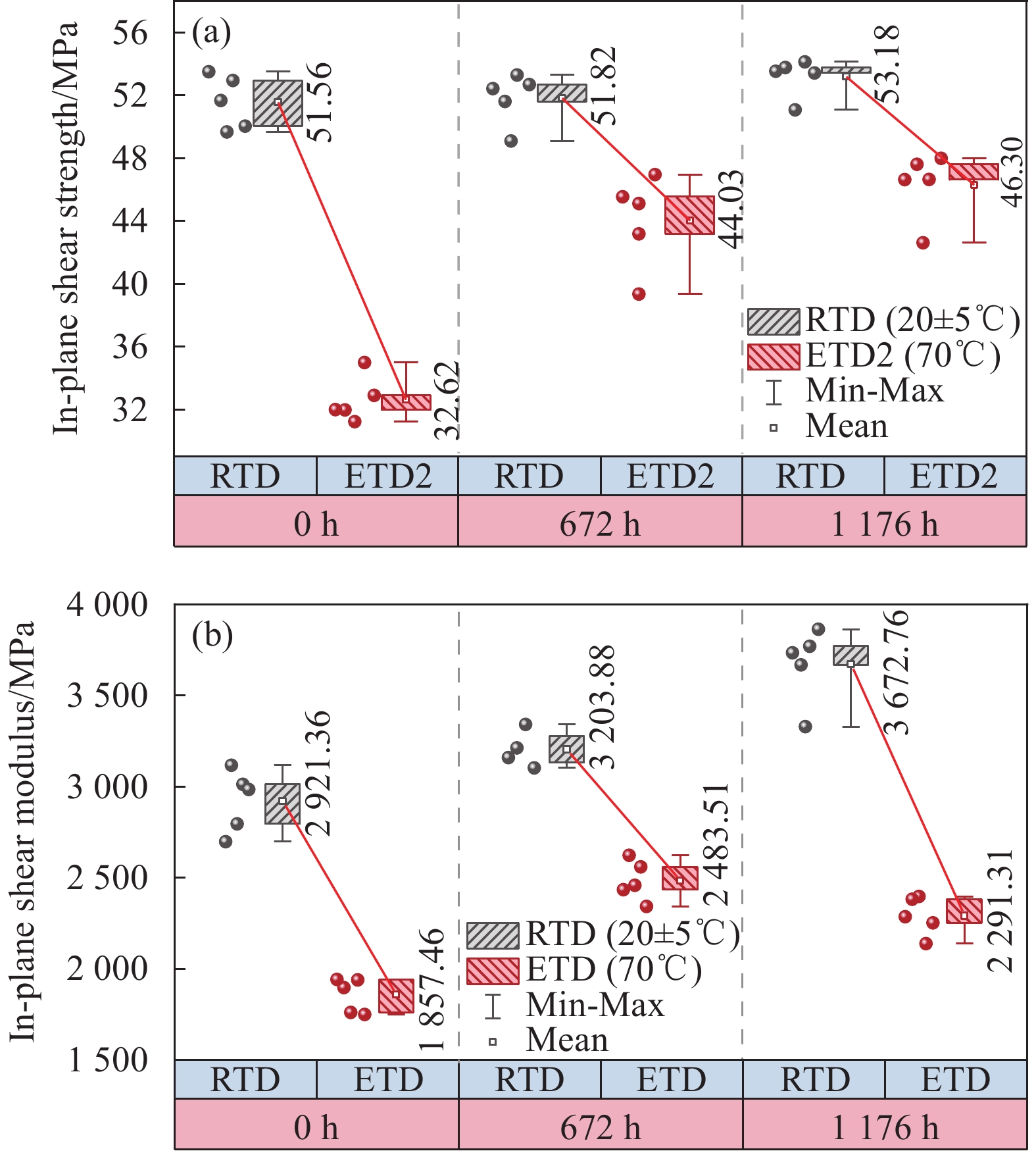

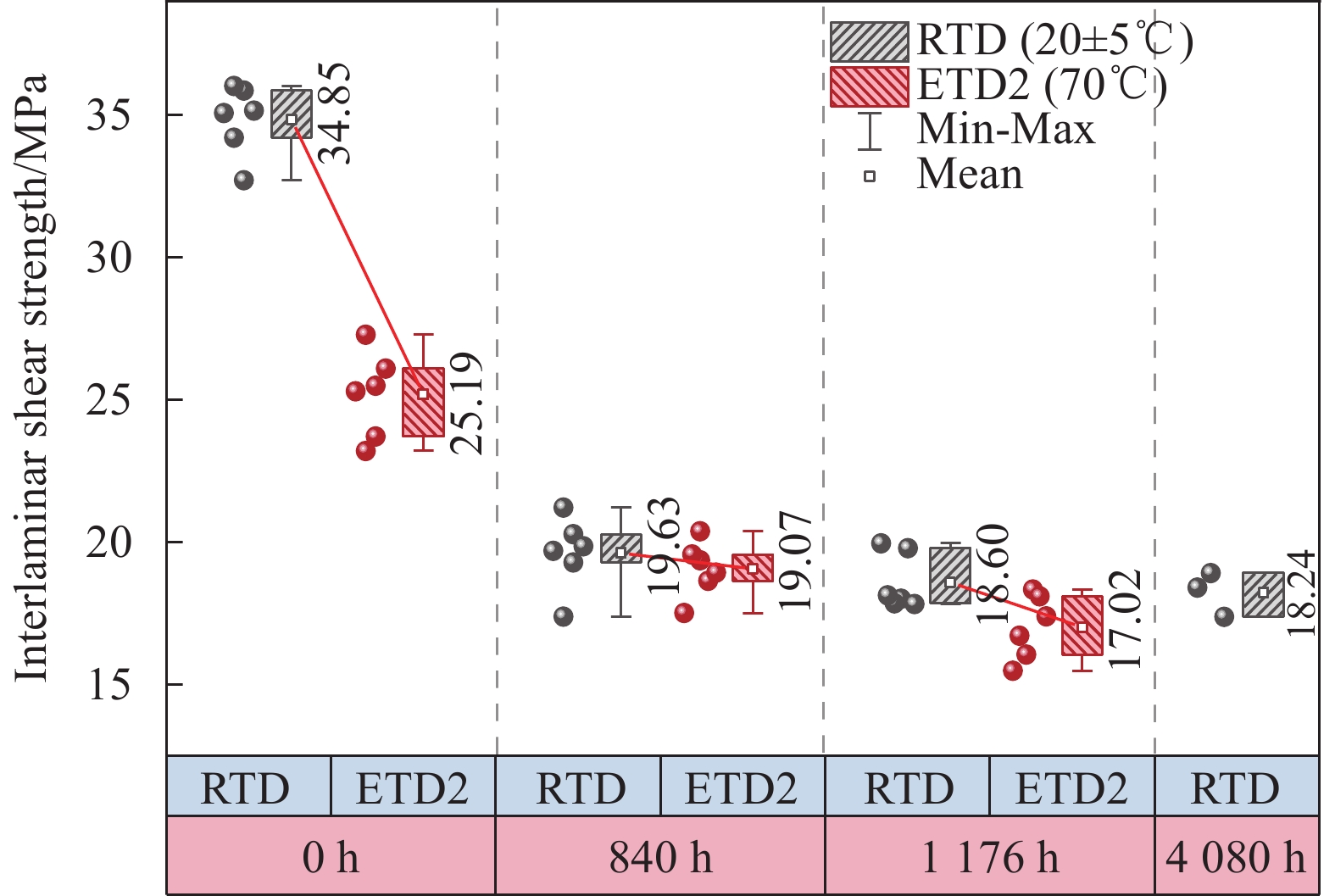

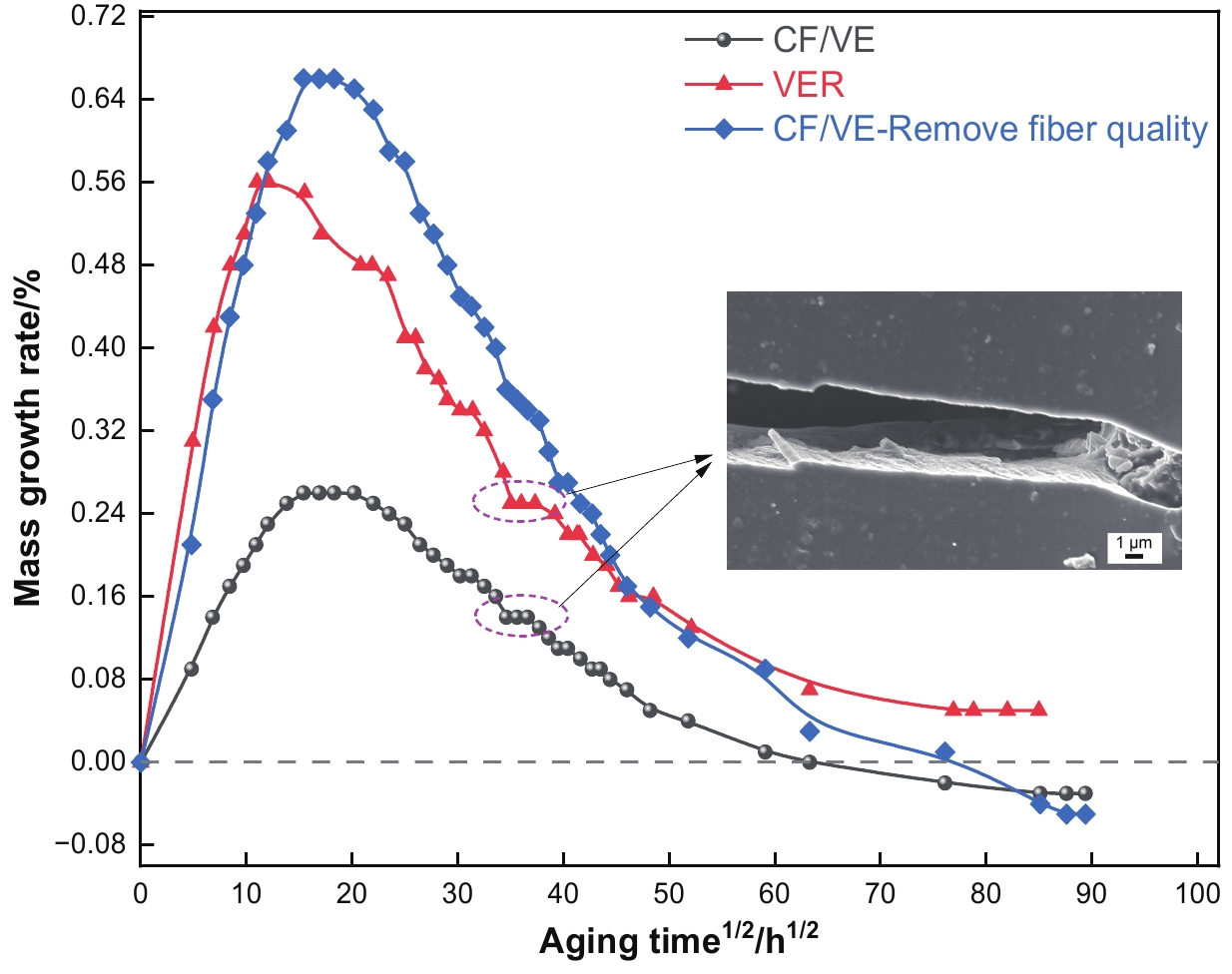

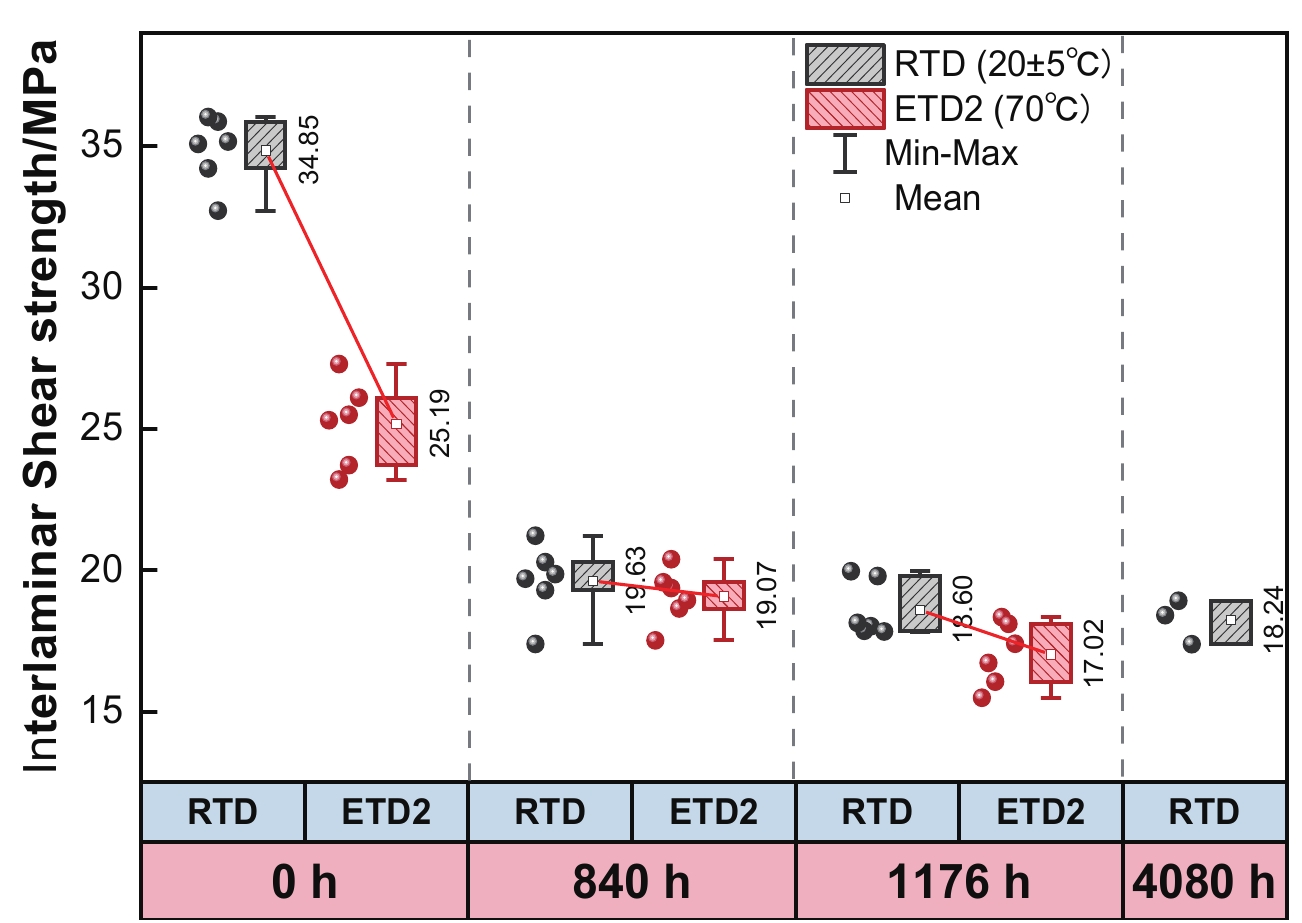

4000 h后CF/VE质量低于初始值。动态热力学数据表明:树脂及CF/VE的储能模量和玻璃化转变温度(Tg)在水热老化前期上升,且热膨胀系数降低,老化后期Tg有所恢复。室温环境下CF/VE的压缩、层间剪切强度在水热老化短期内显著下降,1176 h分别降低23.0%,46.6%,之后性能退化速率减缓,4080 h时分别降低30.9%、47.7%。老化后,树脂在70℃下的拉伸、压缩强度上升;CF/VE在70℃下的压缩、面内剪切强度上升。Abstract:Carbon fiber/vinyl ester resin composite (CF/VE) was gradually applied to large-thickness and large-scale ship structural parts due to its light weight, high strength and corrosion resistance. Due to the limitation of size and manufacturing equipment, the curing of large-thickness composite materials used in ships was often insufficient. In order to understand the durability of incompletely cured CF/VE in hydrothermal environment, the surface morphology change and hydrolysis mechanism of the resin were analyzed, the dynamic mechanical properties and mechanical properties at high temperature of resin and its composites were studied. The results of liquid chromatography-mass spectrometry and FTIR show that the ester bond in the resin molecular chain is strongly hydrolyzed; due to the strong hydrolysis reaction and osmotic cracking of the resin from the surface to the inside, the mass growth rate decreases after reaching the maximum value, and the CF/VE mass is lower than the initial value after

4000 h. The dynamic thermodynamic data shows that the storage modulus and glass transition temperature (Tg) of the resin and CF/VE increase in the early stage of hydrothermal aging, and the thermal expansion coefficient decreases, and the Tg recovers in the later stage of aging. The compressive and interlaminar shear strength of CF/VE at room temperature decreases significantly in the short term of hydrothermal aging, which decreases by 23.0% and 46.6% respectively at1176 h, and then the performance degradation rate slows down, which decreases by 30.9% and 47.7% respectively at4080 h. After aging, the tensile and compressive strength of the resin at 70°C increases; and the compressive and in-plane shear strength of CF/VE at 70°C increase.-

Keywords:

- CFRP /

- Vinyl ester resin /

- Incompletely cured /

- Hydrothermal aging /

- Mechanical properties

-

3D机织复合材料具有优异的抗分层、抗冲击、耐疲劳性能及复杂构件近净成型等优点,在航空航天、海洋船舶、军事、建筑、车辆工程和体育等领域得到了广泛应用[1-2]。近年来,人们对大尺寸、复杂外形的3D机织复合材料提出了更多的应用需求[3-4]。

预制体的纤维结构对复合材料的力学性能有着决定性的影响,在大尺寸、异形复合材料结构件的制备过程中,预制体往往发生复杂的外形转换,其中弯曲变形是一种常见的变形模式[5-7]。研究表明,预制体的弯曲性能对变形过程中褶皱缺陷的形成、演化及最终形态有着决定性影响。弯曲性能是影响预制体适形性能和复合材料力学性能的重要因素[8-10]。

实验是研究预制体力学性能的最直接手段。目前预制体弯曲性能的测试方法主要包括Peirce悬臂弯曲、Kawabata弯曲及三点弯曲[11]。在Peirce悬臂弯曲测试中,预制体在自身重力作用下发生弯曲,并接触到特定倾角的斜面,通过测量悬臂长度计算弯曲刚度[12-13]。Bilbao等[14]设计了一种利用光学技术测量织物弯曲变形的悬臂梁实验方法,测试装置由两个模块组成:机械模块能够在自身质量下将样品置于悬臂结构中,也可以在样品的自由边缘添加质量,达到更大的曲率;光学模块可以拍摄弯曲试样的形状,通过图像处理计算试样的弯曲曲率。传统悬臂梁试验中预制体由于载荷分布不均有可能出现扭转现象。针对这一问题,Dangora等[15]采用垂直悬臂梁法对预制体进行了弯曲测试,该方法将预制体竖直悬挂,通过绑在自由端的绳子施加载荷,使用数码相机记录试样的位移并计算弯曲曲率。悬臂弯曲试样容易制备、实验操作简单,但高厚度预制体很难在自身重力作用下发生较大的弯曲变形,需要额外施加一定的载荷,容易造成较大误差[16]。Kawabata弯曲实验将试样夹持在特定的夹具中,通过旋转夹具实现试样的弯曲变形。Kawabata弯曲方法能够实现试样的往复弯曲-展平变形,获取试样的弯矩-曲率曲线,表征织物的非线性弯曲变形行为[17]。Ropers等[18]和Sachs等[19]在Kawabata弯曲法的基础上开发了一种基于流变仪的测试方法,可以实现摆动式旋转加载,这种加载方式同样能够确保试样发生纯弯曲变形。目前的Kawabata弯曲实验往往适用于较小尺寸的试样,难以保障大尺寸、高厚度试样变形时曲率的均匀性。预制体的三点弯曲测试方法借鉴了复合材料的测试标准,该方法简单易操作,主要适用于具有较大厚度和弯曲刚度的预制体[20]。Charmetant等[21]、Liang等[22]、Boisse等[23]和Margossian等[24]使用三点弯曲法对3D碳纤维层层角联锁预制体的弯曲行为进行了测试,通过光学图像记录弯曲变形前后预制体厚度的变化、计算试样的曲率。结果表明,由于纱线的抗拉刚度较大,预制体弯曲变形主要由横向剪切引起,原本与试样表面垂直的法线在变形之后不再与表面垂直。

目前的预制体弯曲实验主要关注试样的宏观力学响应,包括弯曲变形过程中的载荷、挠度和曲率等,对预制体内部各纱线系统的微细观变形机制仍然缺乏系统性的研究。本文采用三点弯曲实验研究了碳纤维3D机织预制体的弯曲行为。引入临界弯曲能量表征预制体的弯曲变形性能,通过Micro-CT技术观测试样弯曲变形前、后的内部纱线形态,分析预制体的弯曲变形机制,建立经纱密度和纬纱密度与弯曲性能的量化关系,为预制体工艺设计提供理论指导。

1. 试验材料及方法

1.1 原材料

按照3种经纱密度(5.0根/cm、8.0根/cm、10.0根/cm)和3种纬纱密度(2.5根/cm、3.0根/cm、3.5根/cm)制备了9件碳纤维3D机织预制体样件。所有样件的经纱和纬纱均由T800-24 K碳纤维纱线组成,预制体交织方式为一三斜纹层层角联锁结构,如图1所示。预制体内部纬纱呈伸直状态,经纱呈屈曲状态,经、纬纱互相垂直,经纱将纬纱捆绑连接起来。预制体试样的具体参数如表1所示,试样编号中的J表示经纱密度、W表示纬纱密度。例如“J5W2.5”表示该试样经纱密度5根/cm,纬纱密度2.5根/cm。试样设计厚度为5 mm,该厚度指的是该试样被压缩至纤维体积含量55vol%时的厚度,实际上织物在纺织成形后(未受压力的状态下)的实际厚度往往会略高于设计厚度。

表 1 3D机织预制体结构参数Table 1. Structure parameters of 3D woven preformsSample Number of warp layer Number of weft layer Apparent thickness/mm Weaving point density/cm−2 J5W2.5 7 8 6.31 21.88 J5W3.0 6 7 5.89 22.50 J5W3.5 6 7 6.19 26.25 J8W2.5 5 6 6.78 25.00 J8W3.0 5 6 6.60 30.00 J8W3.5 4 5 5.97 28.00 J10W2.5 4 5 6.71 25.00 J10W3.0 4 5 7.00 30.00 J10W3.5 4 5 6.73 35.00 1.2 三点弯曲测试

采用电动裁切机(GD-H690)对预制体进行裁剪。参考标准GB/T 33621—2017[25](三维编织物及其树脂基复合材料弯曲性能试验方法),在岛津实验机(AGS-J1KN)上开展预制体样件的三点弯测试。预制体样件的跨距与厚度之比为8∶1,样件尺寸为100 mm×30 mm×5 mm。将预制体试样放置在三点弯曲支座上,保证左右对称,通过支座上的标尺调节至适当跨距,设定压头加载速率5 mm/min,测试过程中记录载荷-挠度数据。

1.3 Micro-CT测试

为了研究预制体的弯曲变形机制,通过Micro-CT技术获得样件弯曲变形前、后的内部纤维结构。参考三点弯曲夹具的尺寸设计了一种弯曲控形工装,如图2所示。将预制体试样放入控形工装中,通过调节压头位置可以实现不同程度的弯曲变形,锁紧螺栓使弯曲变形得以“固定”。扫描测试时将预制体试样连同控形工装一起放入Micro-CT扫描设备的观测腔室中。本文采用卡尔蔡司Xradia 510 Versa设备开展Micro-CT测试,X射线源的起始能量设置为80 kV/7 W,曝光时间为1 s,图像分辨率为25 μm。

2. 三点弯曲测试结果及分析

2.1 3D机织预制体宏观力学响应

三点弯曲实验过程中,预制体样件的弯曲变形如图3所示。随着弯曲挠度的增大,试样两端逐渐翘起,变形后的预制体试样呈“V”字形。当弯曲挠度达到10 mm左右时,试样与支座之间开始发生显著滑移。三点弯曲载荷下预制体试样的变形曲率并不均匀,靠近压头的位置曲率较大,两端位置曲率很小,几乎呈平直状态。

图4显示了不同结构参数的预制体弯曲载荷-挠度曲线。不同试样的载荷-挠度曲线变化趋势大致相同,曲线均表现出显著的非线性特征,当挠度达到10 mm左右时,弯曲载荷基本达到峰值,弯曲挠度继续增加时,弯曲载荷不再增加,随着试样与支座之间发生滑移,弯曲载荷逐渐下降,直到试样脱离支座。

![]() 图 4 3D机织预制体三点弯曲试样载荷-挠度曲线:((a)~(c)) 经纱密度5根/cm、8根/cm、10根/cm;((d)~(f)) 纬纱密度2.5根/cm、3.0根/cm、3.5根/cmFigure 4. Load-deflection curves of three-point bending samples of 3D woven preform: ((a)-(c)) Warp densities of 5 ends/cm, 8 ends/cm and 10 ends/cm; ((d)-(f)) Weft densities of 2.5 picks/cm, 3.0 picks/cm and 3.5 picks/cm

图 4 3D机织预制体三点弯曲试样载荷-挠度曲线:((a)~(c)) 经纱密度5根/cm、8根/cm、10根/cm;((d)~(f)) 纬纱密度2.5根/cm、3.0根/cm、3.5根/cmFigure 4. Load-deflection curves of three-point bending samples of 3D woven preform: ((a)-(c)) Warp densities of 5 ends/cm, 8 ends/cm and 10 ends/cm; ((d)-(f)) Weft densities of 2.5 picks/cm, 3.0 picks/cm and 3.5 picks/cm当试样经纱密度相同时,纬纱密度越大,弯曲载荷的峰值越大;同样地,当试样纬纱密度相同时,经纱密度越大,弯曲载荷的峰值也越大。这说明3D机织预制体的弯曲性能与试样内部的组织点密度(dw,单位体积内组织点的数量)密切相关,组织点密度越大,试样越不容易发生弯曲变形。

2.2 3D机织预制体临界弯曲能量

织物预制体是一种柔性材料,当弯曲挠度超过某一临界弯曲挠度值dc (dc约为10 mm)时,试样与三点弯曲支座开始发生滑移,随着弯曲挠度的继续增加,试样逐渐脱离支座。因此,本文认为试样弯曲挠度小于dc时为稳定弯曲状态。当弯曲挠度为dc时,载荷值为Fc、载荷累积做功为Ec (对应图5曲线下方的面积)。将Ec定义为试样的临界弯曲能量,表征其抗弯曲性能。

![]() 图 5 3D机织预制体三点弯曲试样临界弯曲能量Figure 5. Critical bending energy of three-point bending sample of 3D woven preformEi—Bending energy under a certain bending deflection; F—Bending load; Fc—Critical bending load value; Fi—Bending load value under a certain bending deflection; d—Bending deflection; dc—Critical bending deflection value; Δd—Unit bending deflection value

图 5 3D机织预制体三点弯曲试样临界弯曲能量Figure 5. Critical bending energy of three-point bending sample of 3D woven preformEi—Bending energy under a certain bending deflection; F—Bending load; Fc—Critical bending load value; Fi—Bending load value under a certain bending deflection; d—Bending deflection; dc—Critical bending deflection value; Δd—Unit bending deflection value将曲线覆盖区域分为n个宽Δd的狭长矩形,第i个矩形的高度为Fi,则临界弯曲能量Ec可由下式计算:

Ec=∑Ei=∑FiΔd (1) 预制体的弯曲性能与其组织点密度dw有关,dw由下式计算:

dw=dwarpdweftnwarpN (2) 其中:

dwarp 为经纱密度;dweft 为纬纱密度;nwarp 为经纱层数,N=4表示一根经纱上两个相邻组织点跨越的纬纱数量。不同预制体样件的组织点密度如表1中所示。图6给出了预制体临界弯曲能量Ec与组织点密度dw的关联关系。结果显示,Ec随着dw的增加而增大,二者大致呈线性关系。预制体组织点密度越大,纱线排布越紧密、彼此之间的相互约束力越强,因此弯曲变形时所需的临界弯曲能量越大。2.3 3D机织预制体经纱屈曲度变化

碳纤维3D机织预制体发生宏观弯曲变形后,其内部微细观结构也发生了显著变化。本文对典型结构的预制体试样(J5W3.0)开展了变形前、后的Micro-CT扫描测试。弯曲变形前,预制体内部的纱线排布比较规则:纬纱沿厚度方向排布成列,各纬纱列基本呈竖直状态;经纱与纬纱相互交织,一根经纱将上下相邻的两层纬纱连锁起来,各层经纱的路径基本一致。

弯曲变形后,经纱的屈曲形态会发生显著变化。引入经纱屈曲度

Bwarp 来表征变形前后经纱屈曲形态的变化:Bwarp=Lwarp−LbaseLbase (3) 其中:

Lwarp 为经纱实际长度(图7实线长度);Lbase 为基准线长度(图7虚线长度)。弯曲变形前,Lbase 是纱线两端的直线间距。弯曲变形后,基准线随着试样变形为弧线,Lbase 为图7(b)所示的弧线长度,该弧线是连接上下两层纬纱各中心点的样条曲线。预制体弯曲变形前、后,其内部各层经纱的路径分别如图8(a)和图8(b)所示,其中L1~L6表示第1层~第6层经纱。弯曲变形后,预制体样件表层经纱受压、底层经纱受拉,因此不同位置处的经纱屈曲度发生了变化。预制体样件在变形前、后的经纱屈曲度如图8(c)所示。未变形前各层经纱长度基本相同,屈曲度均为0.025。弯曲变形后,底层经纱(L1~L2)在拉伸载荷下伸直,屈曲度降低;中间层经纱(L3~L4)的屈曲度与变形前相比变化不大;表层经纱(L5~L6)在压缩载荷下屈曲度进一步提高。由底层至表层,经纱的屈曲度明显增大,L6经纱的屈曲度比L1经纱提高了98.3%。

弯曲变形会引起表层经纱的局部屈曲现象,如图9所示。这些位置的经纱没有其他纱线的约束,处于自由状态,受到纵向压缩时容易产生横向膨胀,即“负泊松”效应。L1经纱的局部屈曲使试样表面产生褶皱。试样内部的经纱在弯曲变形时的屈曲度较低,而且与周围纱线相接触,处于受约束状态,一般不会产生屈曲现象。

2.4 3D机织预制体纬纱列偏转角度

弯曲变形前,纬纱列的排布呈竖直状态,穿过纬纱列的直线与试样表面大致垂直。弯曲变形后,纬纱列的排布仍然保持为直线,但不再与试样表面垂直。可见,高厚度的碳纤维3D机织预制体的弯曲行为不符合Kirchhoff薄板弯曲理论,预制体弯曲过程中发生了层间剪切变形,即纬纱和经纱之间发生了层间滑移。为了量化分析预制体试样的层间剪切变形,本文基于Micro-CT扫描图像统计了8列纬纱(C1~C8)的偏转角度,如图10(a)所示。其中,织物表面路径是沿着试样上表面轮廓线进行设定的,在压头附近,试样与压头紧密贴合,此处的轮廓线曲率与压头曲率一致。纬纱列偏转角度为预制体初始法向和纬纱列方向之间的夹角。初始法向为经过表层纬纱形心且垂直于织物表面路径的直线(图10(a)点虚线);纬纱列方向为连接表层和底层纬纱形心的直线(图10(a)虚线)。统计结果如图10(b)所示:压头左右两侧纬纱列的偏转角度大致对称分布;靠近压头的纬纱列偏转角较小,远离压头的纬纱列偏转角较大;随着与压头距离的增大,纬纱列偏转角度表现出先增大后减小的趋势,最大偏转角度为26.85°。

3. 结 论

研究了碳纤维3D机织预制体结构参数对其弯曲性能的影响,基于Micro-CT技术分析了弯曲变形前后预制体内部细观结构的变化,得出以下结论:

(1) 碳纤维3D机织预制体的弯曲载荷-挠度曲线表现出显著的非线性特征,经、纬密较大时,预制体结构紧密,不容易发生弯曲变形;

(2) 预制体样件在三点弯曲测试中挠度小于10 mm时为稳定弯曲变形,临界弯曲能量随着组织点密度的增加线性增大;

(3) 碳纤维3D机织预制体的弯曲变形由经纱屈曲度变化、局部压缩屈曲和经纬纱层间滑移等微细观变形构成;

(4) 预制体发生弯曲变形后,其内部的微细观变形并不均匀,不同位置的纤维结构差异较大,会导致最终复合材料力学性能的离散性。

-

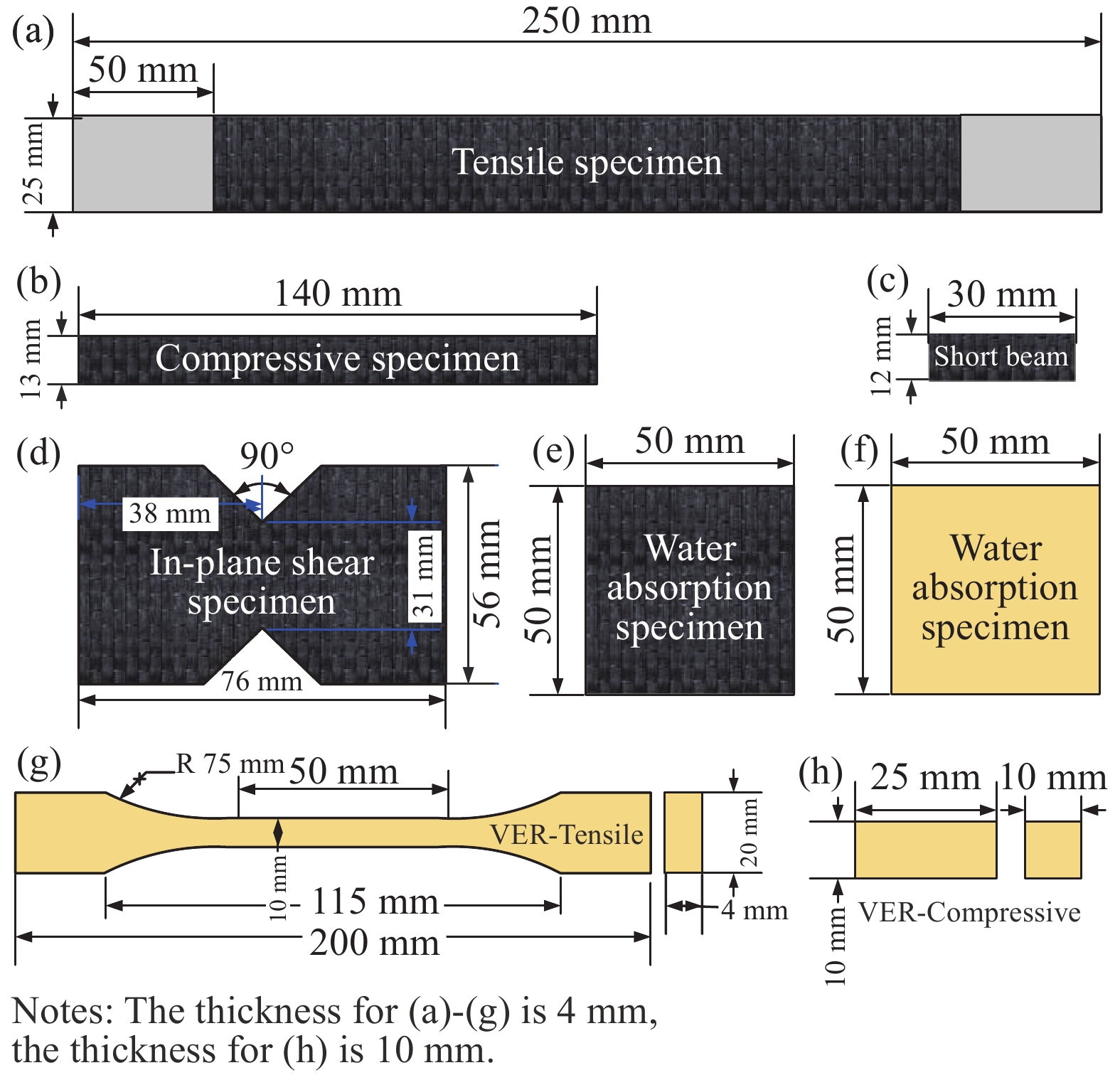

图 1 标准试样示意图:(a)-(e)分别为碳纤维/乙烯基酯树脂复合材料(CF/VE)的拉伸、压缩、层间剪切、面内剪切和吸水性实验的标准试样图;(f)-(h)分别为乙烯基酯树脂(VER)吸水、拉伸和压缩实验的标准试样图

Figure 1. Standard sample schematic diagram: (a)-(e) is the standard sample diagrams of carbon fiber/vinyl ester resin composite (CF/VE) tensile, compression, interlaminar shear, in-plane shear and water absorption test, respectively; (f)-(h) is the standard sample diagrams of vinyl ester resin (VER) water absorption, tensile and compression tests, respectively

图 7 VER及CF/VE动态热力学性能: (a-c)分别为VER的储能模量、损耗因子(tanδ)和玻璃化转变温度(Tg);(d-f)分别为CF/VE的储能模量、损耗因子(tanδ)和玻璃化转变温度(Tg)

Figure 7. Dynamic thermodynamic properties of VER and CF/VE: (a-c) is the Storage modulus, Loss factor (tanδ) and Glass transition temperature (Tg) of VER, respectively; (d-f) is the Storage modulus, Loss factor (tanδ) and Glass transition temperature (Tg) of CF/VE, respectively

表 1 力学性能测试标准

Table 1 Mechanical properties test standard

表 2 力学性能测试环境

Table 2 Mechanical properties test environment

Test environment Temperature/℃ Full name RTD 20±5℃ Room Temperature Dry state ETD1 50℃ Elevated Temperature Dry state 1 ETD2 70℃ Elevated Temperature Dry state 2 表 3 不同水热老化时间后VER及CF/VE的热膨胀系数

Table 3 The thermal expansion coefficient of VER and CF/VE after different hydrothermal aging time

Material Aging time/h Thermal expansion coefficient m.CTE/(10−6·K−1) CF/VE 0 7.32 504 4.43 1176 3.97 VER 0 81.98 1176 81.58 1680 75.47 -

[1] 童浩, 袁昱超, 唐文勇. 新型船用复合材料夹芯夹筋厚板损伤行为分析[J]. 中国舰船研究, 2024: 1-10. TONG Hao, YUAN Yichao, TANG Wenyong. Analysis of damage behavior of new marine composite sandwich reinforced thick plate[J]. China Ship Research, 2024: 1-10. (in Chinese)

[2] YANG L, XIA H, XU Z, et al. Influence of surface modification of carbon fiber based on magnetron sputtering technology on mechanical properties of carbon fiber composites[J]. Materials Research Express, 2020, 7(10): 105602. DOI: 10.1088/2053-1591/abbc90

[3] HE W, LI X, LI P, et al. Experimental Investigation on Hygroscopic Aging of Glass Fiber Reinforced Vinylester Resin Composites[J]. Polymers, 2022, 14(18): 3828. DOI: 10.3390/polym14183828

[4] 张裕恒, 丁安心. 湿热环境下碳纤维增强乙烯基树脂复合材料长期力学性能[J]. 复合材料学报, 2023, 40(3): 1406-1416. ZHANG Yuheng, DING Anxin. Long-term mechanical properties of carbon fiber reinforced vinyl resin composites in hygrothermal environment[J]. Journal of Composites, 2023, 40(3): 1406-1416(in Chinese).

[5] SANG L, WANG Y, WANG C, et al. Moisture diffusion and damage characteristics of carbon fabric reinforced polyamide 6 laminates under hydrothermal aging[J]. Composites Part A: Applied Science and Manufacturing, 2019, 123: 242-252. DOI: 10.1016/j.compositesa.2019.05.023

[6] 魏建辉. 吸湿老化后碳纤维增强乙烯基脂树脂复合材料高低温力学性能[J]. 复合材料学报, 2023, 40(6): 3279-3290. WEI Jianhui. High and low temperature mechanical properties of carbon fiber reinforced vinyl resin composites after moisture aging[J]. Journal of Composites, 2023, 40(6): 3279-3290(in Chinese).

[7] GAO J, LI X, WEI J, et al. Hygrothermal behavior of carbon fiber fabric reinforced vinylester resin composite structures[J]. Applied Composite Materials, 2024.

[8] 杜永, 马玉娥. 湿热环境下纤维增强树脂基复合材料疲劳性能研究进展[J]. 复合材料学报, 2022, 39(2): 431-445. DU Yong, MA Y E. Research progress on fatigue properties of fiber reinforced resin matrix composites in hygrothermal environment[J]. Journal of Composites, 2022, 39(2): 431-445(in Chinese).

[9] ZHANG X, WANG Y, WAN B, et al. Effect of specimen thicknesses on water absorption and flexural strength of CFRP laminates subjected to water or alkaline solution immersion[J]. Construction and Building Materials, 2019, 208: 314-325. DOI: 10.1016/j.conbuildmat.2019.03.009

[10] WANG D, SUN Y, DUAN J, et al. Hygrothermal Effect on GF/VE and GF/UP Composites: Durability Performance and Laboratory Assessment[J]. POLYMERS, 2024, 16(5).

[11] FEYZA S E, SINEM E, MAHSA S, et al. Effects of meso- and micro-scale defects on hygrothermal aging behavior of glass fiber reinforced composites[J]. Polymer Composites, 2022, 43(11): 8396-8408. DOI: 10.1002/pc.27011

[12] 樊俊铃, 马国庆, 焦婷, 等. 温度和湿度对碳纤维增强复合材料老化影响研究综述[J]. 航空科学技术, 2023, 34(9): 1-13. FAN Junling, MA Guoqing, JIAOTing, et al. Review of the effects of temperature and humidity on the aging of carbon fiber reinforced composites[J]. Aeronautical Science and Technology, 2023, 34(9): 1-13(in Chinese).

[13] 李佳楠, 项赫. 高性能纤维增强树脂基复合材料湿热老化研究进展[J]. 2024, 52(1): 1-7. LI JiaNan, XIANG He. Research progress on hygrothermal aging of high performance fiber reinforced resin matrix composites[J]. 2024, 52 (1): 1-7. (in Chinese)

[14] 李习习, 王涛, 侯锐钢. 玻璃纤维/乙烯基酯树脂复合材料的热老化机理[J]. 热固性树脂, 2020, 35(1): 49-53. LI Xixi, WANG Tao, HOU Yuegang. Thermal aging mechanism of glass fiber / vinyl ester resin composites[J]. Thermosetting resins, 2020, 35(1): 49-53(in Chinese).

[15] 王登霞, 谢可勇, 刘俊聪, 等. 树脂基复合材料模拟海洋环境长期老化及失效行为[J]. 装备环境工程, 2023, 20(6): 64-74. WANG Dengxia, XIE Keyong, LIU Juncong, et al. Long-term aging and failure behavior of resin matrix composites in simulated marine environment[J]. Equipment environmental engineering, 2023, 20(6): 64-74(in Chinese).

[16] GUO F L, HUANG P, LI Y Q, et al. Multiscale modeling of mechanical behaviors of carbon fiber reinforced epoxy composites subjected to hygrothermal aging[J]. Composite Structures, 2021, 256: 113098. DOI: 10.1016/j.compstruct.2020.113098

[17] LI D sen, DANG M guang, JIANG L. Elevated temperature effect on tension fatigue behavior and failure mechanism of carbon/epoxy 3D angle-interlock woven composites[J]. Composite Structures, 2021, 268: 113897. DOI: 10.1016/j.compstruct.2021.113897

[18] CÉSAR DOS SANTOS J, ÁVILA DE OLIVEIRA L, PANZERA T H, et al. Ageing of autoclaved epoxy/flax composites: Effects on water absorption, porosity and flexural behaviour[J]. Composites Part B: Engineering, 2020, 202: 108380. DOI: 10.1016/j.compositesb.2020.108380

[19] LE GUEN-GEFFROY A, DAVIES P, LE GAC P Y, et al. Influence of seawater ageing on fracture of carbon fiber reinforced epoxy composites for ocean engineering[J]. Oceans, 2020, 1(4): 198-214. DOI: 10.3390/oceans1040015

[20] 曹银龙, 于桢琪, 冯鹏, 等. 纤维增强环氧/乙烯基树脂复合材料性能优化与劣化机制研究进展[J]. 复合材料学报, 2024, 41(3): 1179-1191. CAO Yinlong, YU Zhenqi, FEN Peng, et al. Research progress on performance optimization and degradation mechanism of fiber reinforced epoxy / vinyl resin composites[J]. Journal of Composites, 2024, 41(3): 1179-1191(in Chinese).

[21] WU C, MENG B C, TAM L ho, et al. Yellowing mechanisms of epoxy and vinyl ester resins under thermal, UV and natural aging conditions and protection methods[J]. Polymer Testing, 2022, 114: 107708. DOI: 10.1016/j.polymertesting.2022.107708

[22] ASTM Standards. Standard test moisture absorption properties and equilibrium conditioning of polymer matrix compo-site materials: D5229M-14[S]. West Conshohocken, PA: ASTM International, 2014.

[23] ASTM Standards. Standard test method for water absorption of plas-tics: D570M-98(2018)[S]. West Conshohocken, PA: ASTM International, 2018.

[24] 中国建筑材料联合会. 纤维增强塑料树脂不可溶分含量试验方法: GB/T 2576—2005[S]. 北京: 中国标准出版社, 2005. China Building Materials Federation. Test method for insoluble content of fiber reinforced plastic resin. GB/T 2576-2005 [S]. Beijing: China Standard Press, 2005. (in Chinese)

[25] 沈艳, 鲁泳, 刘舒霆, 等. 飞机复合材料构件固化度在线监测方法[J]. 航空制造技术, 2021, 64(11): 76-85. SHEN Yan, LU Yong, LIU Shuting, et al. On-line monitoring method for curing degree of aircraft composite components[J]. Aeronautical manufacturing technology, 2021, 64(11): 76-85(in Chinese).

[26] ZHANG X, BITARAF V, WEI S, et al. Vinyl ester resin: Rheological behaviors, curing kinetics, thermomechanical, and tensile properties[J]. AIChE Journal, 2014, 60(1): 266-274. DOI: 10.1002/aic.14277

[27] ASTM Standards. Standard test method for tensile properties of polymer matrix composite materials: D3039M-17[S]. West Conshohocken, PA: ASTM International, 2017.

[28] ASTM Standards. Standard test method for compressive properties of polymer matrix composite materials using a com-bined loading compression (CLC) test fix-ture: D6641M-23[S]. West Conshohocken, PA: ASTM International, 2023.

[29] ASTM Standards. Test method for shear properties of composite materi-als by V-notched rail shear method: D7078M-12[S]. West Conshohocken, PA: ASTM International, 2012.

[30] ASTM Standards. Standard test method for short-beam strength of pol-ymer matrix composite materials and their lami-nates: D2344M-16[S]. West Conshohocken, PA: ASTM International, 2016.

[31] 中国建筑材料联合会. 树脂浇铸体性能试验方法: GB/T 2567-2021[S]. 北京: 中国标准出版社, 2021. China Building Materials Federation. Performance test methods for resin castings: GB/T 2567-2021 [S]. Beijing : China Standard Press, 2021. (in Chinese)

[32] 张裕恒. 碳纤维增强乙烯基酯树脂复合材料湿热老化实验研究[D]. 武汉理工大学, 2022. ZHANG YUheng. Experimental study on hygrothermal aging of carbon fiber reinforced vinyl ester resin composites [D]. Wuhan University of Technology, 2022. (in Chinese)

[33] 董保锋. 环氧乙烯基酯树脂的改性及其复合材料性能研究[D]. 哈尔滨工业大学, 2021. DONG Baofeng. Modification of epoxy vinyl ester resin and properties of its composites [D]. Harbin University of Technology, 2021. (in Chinese)

[34] KARBHARI V M, ZHANG S. E-glass/vinylester composites in aqueous environments – I: Experimental results[J]. Applied Composite Materials, 2003, 10(1): 19-48. DOI: 10.1023/A:1021153315780

[35] GAUTIER L, MORTAIGNE B, BELLENGER V, et al. Osmotic cracking nucleation in hydrothermal-aged polyester matrix[J]. Polymer, 2000, 41(7): 2481-2490. DOI: 10.1016/S0032-3861(99)00383-3

[36] 樊慧娟, 王晶, 张惠. 动态热机械分析在高分子聚合物及复合材料中的应用[J]. 化学与黏合, 2017, 39(2): 132-134. FAN Huijuan, WANG Jing, ZHANG Hui. Applications of Dynamic Thermomechanical Analysis in Polymers and Composites[J]. Chemistry and Adhesion, 2017, 39(2): 132-134(in Chinese).

[37] TOMASZEWSKA J, STERZYŃSKI T, WOŹNIAK-BRASZAK A, et al. Review of recent developments of glass transition in PVC nanocomposites[J]. Polymers, 2021, 13(24): 4336. DOI: 10.3390/polym13244336

[38] Dynamic mechanical analysis (DMA) of epoxy carbon-fibre prepregs partially cured in a discontinued autoclave analogue process[J]. Polymer Testing, 2015, 41: 140-148.

[39] WANG Y, ZHU W, WAN B, et al. Hygrothermal ageing behavior and mechanism of carbon nanofibers modified flax fiber-reinforced epoxy laminates[J]. Composites Part A: Applied Science and Manufacturing, 2021, 140: 106142. DOI: 10.1016/j.compositesa.2020.106142

-

期刊类型引用(2)

1. 朱琬清,谢军波,吴兰芳,陈利,杨林,刘静妍. 3D机织预制体准纤维尺度建模方法. 复合材料学报. 2024(03): 1528-1538 .  本站查看

本站查看

2. 蔣永亮,马文锁,马振宇,许泳豪,朱梦蝶. 低捻纱三维角联锁机织预制体的不稳定结构变形模型. 棉纺织技术. 2024(12): 38-44 .  百度学术

百度学术

其他类型引用(1)

-

目的

碳纤维/乙烯基酯树脂复合材料(CF/VE)因其轻质高强和耐腐蚀等特点被逐渐应用于大厚度、大尺度的舰船结构件,由于尺寸和制造装备的限制,实际环境制造的结构件不进行后固化处理,复合材料结构中树脂基体往往固化不完全。本文研究了未完全固化的乙烯基酯树脂(VER)及其碳纤维复合材料在水热环境下的耐久性,分析了树脂的表面形貌变化和水解机制,研究了VER及CF/VE的动态热力学性能和含高温下的力学性能。

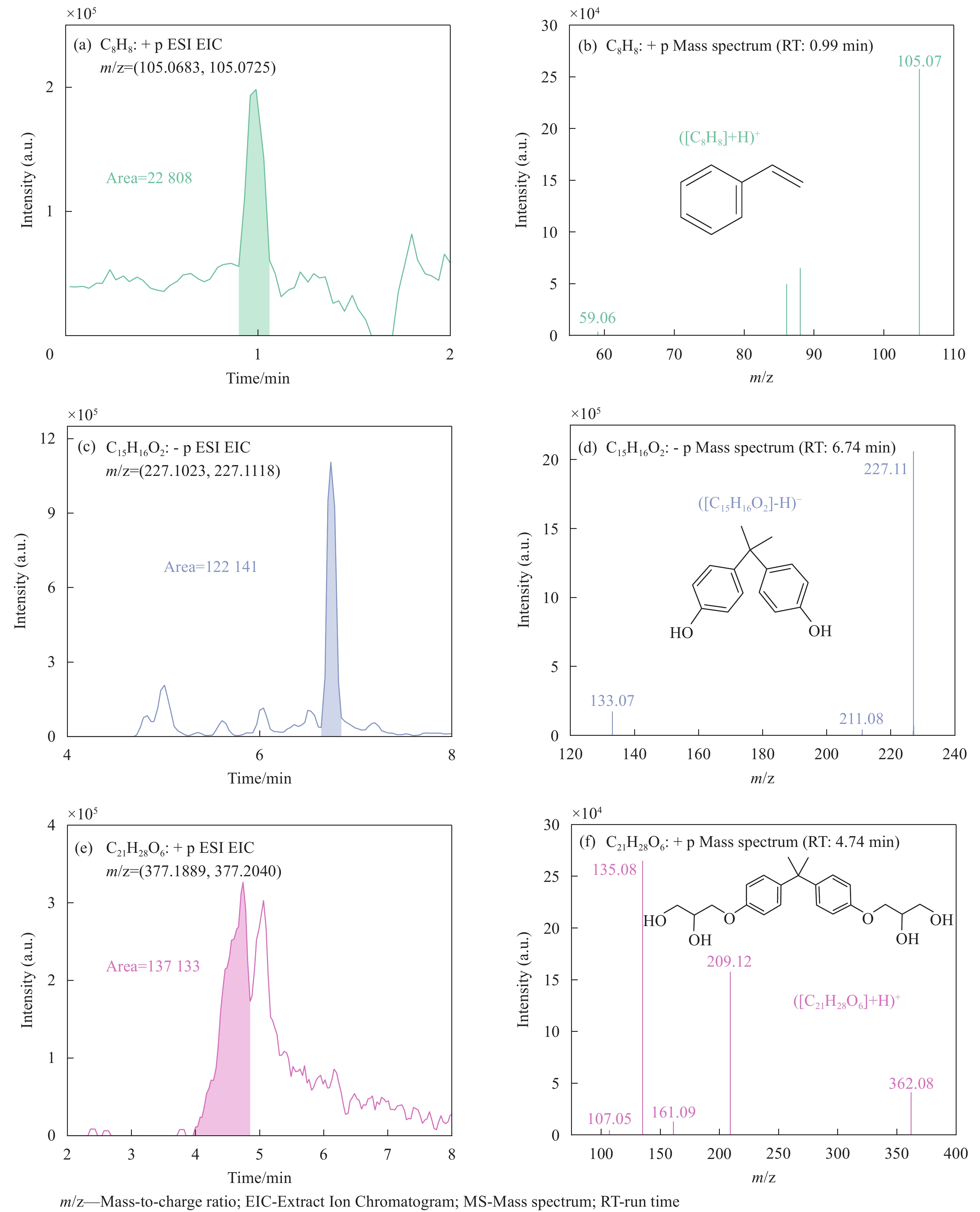

方法利用液相色谱-质谱联用(LC-MS)对树脂浸出液进行定性分析,利用傅里叶红外光谱仪(FTIR)对水热老化前后的树脂表面进行结构分析,利用称重法记录VER及CF/VE的质量变化,利用动态热机械分析仪(DMA)测定不同老化时间后试样的储能模量和玻璃化转变温度(),利用电子热膨胀仪测定试样的面内热膨胀系数,利用万能试验机测试试样在不同老化时间和温度下的力学性能变化,利用场发射扫描电子显微镜(SEM)对试样表面和断裂面进行形貌分析。

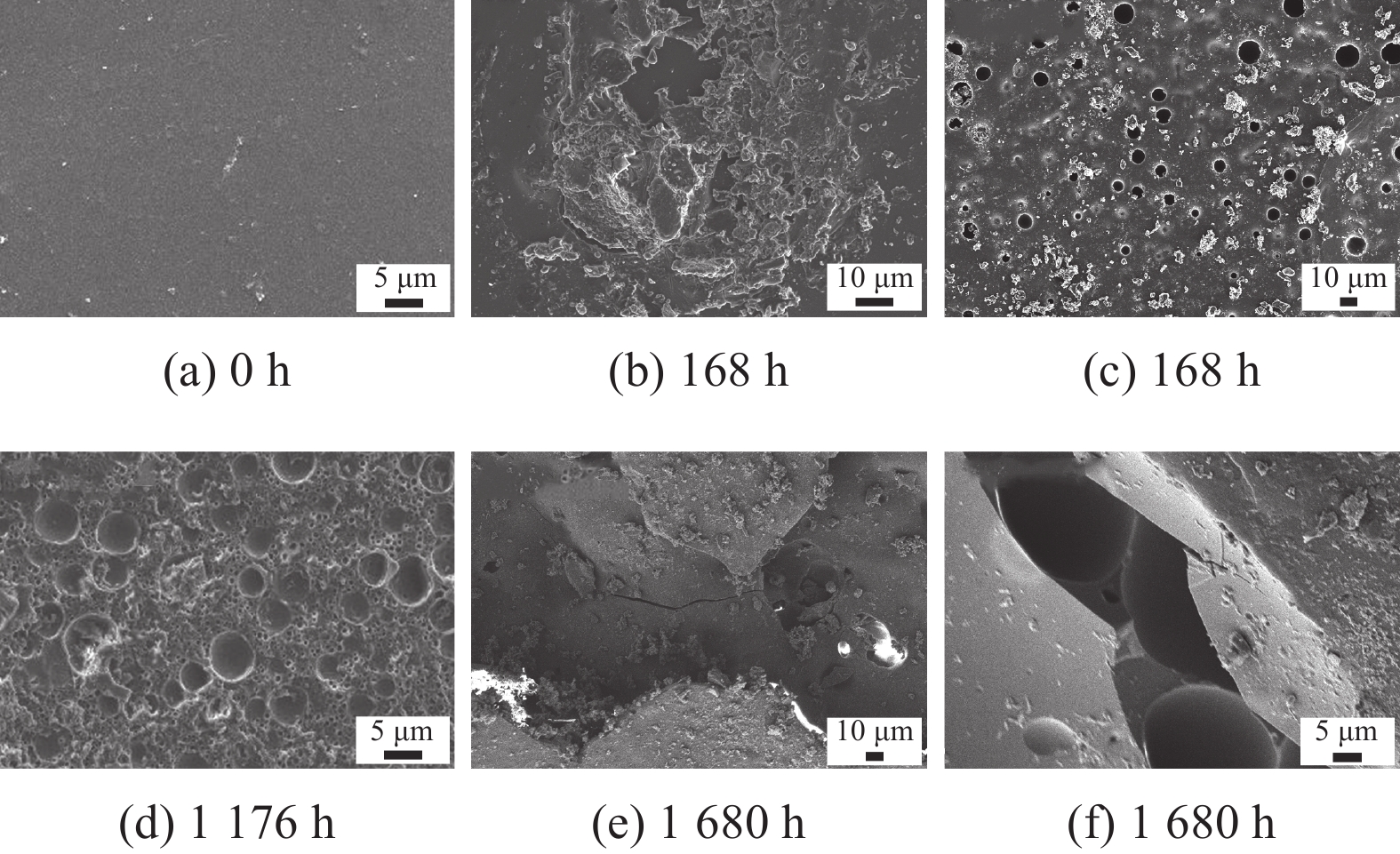

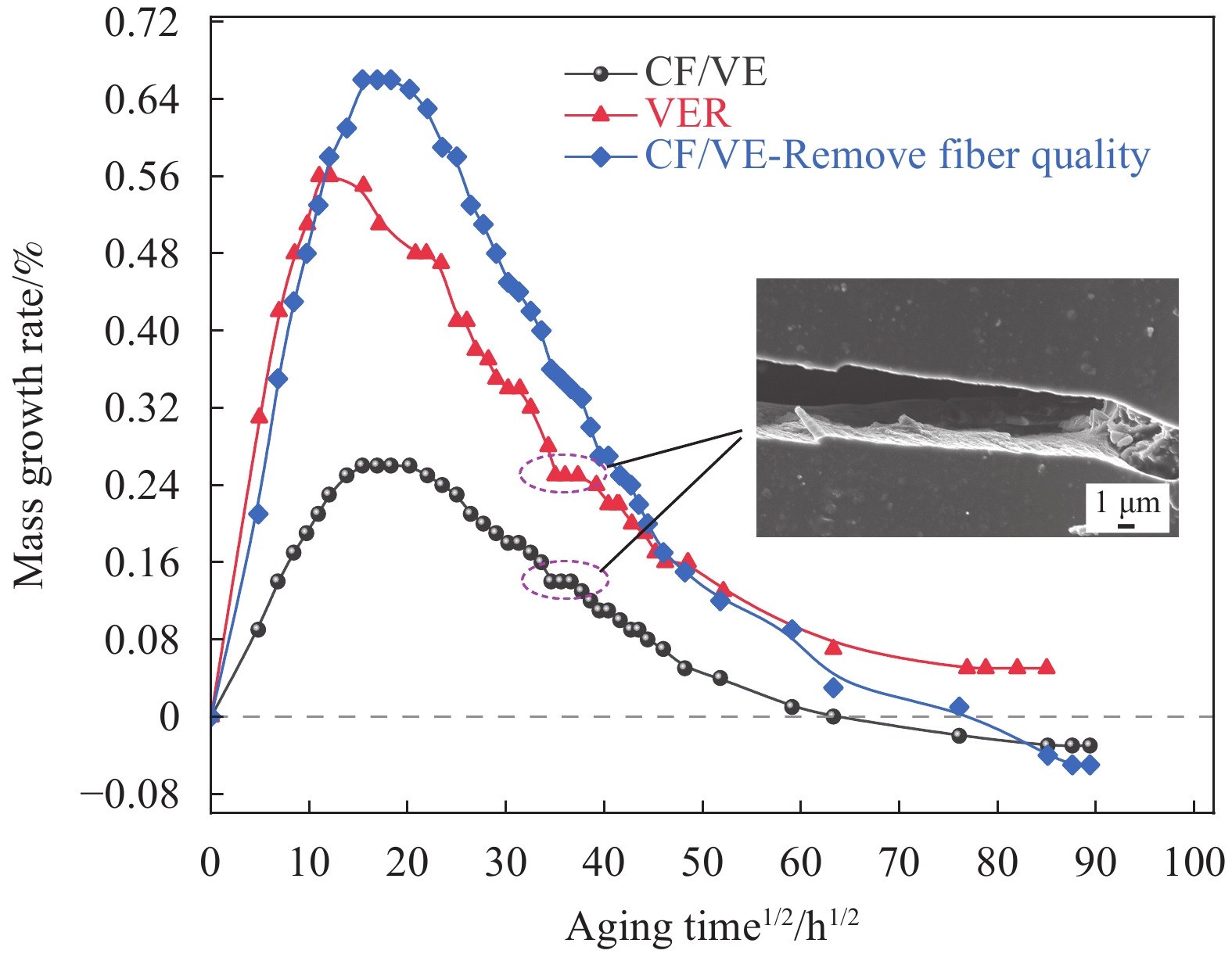

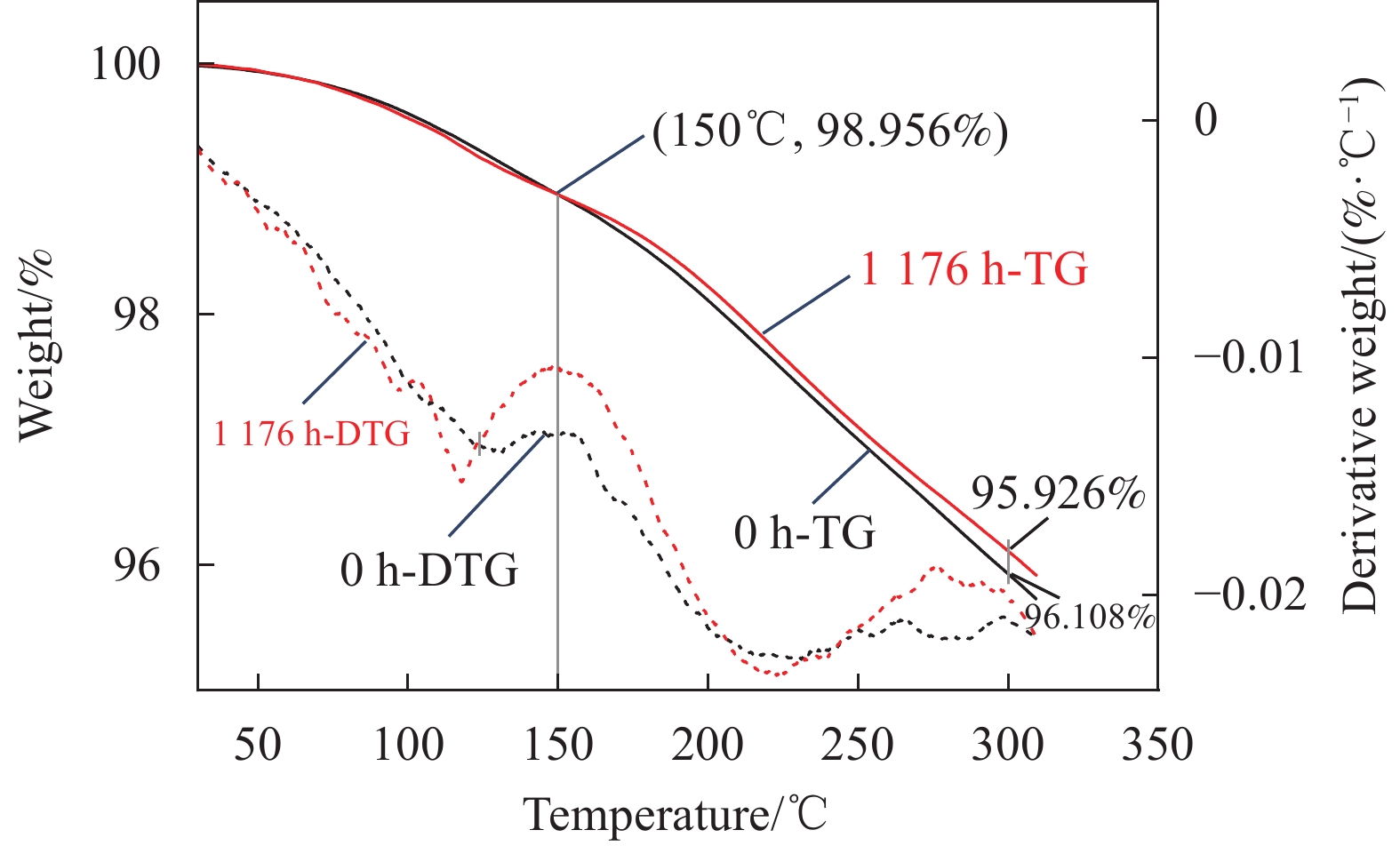

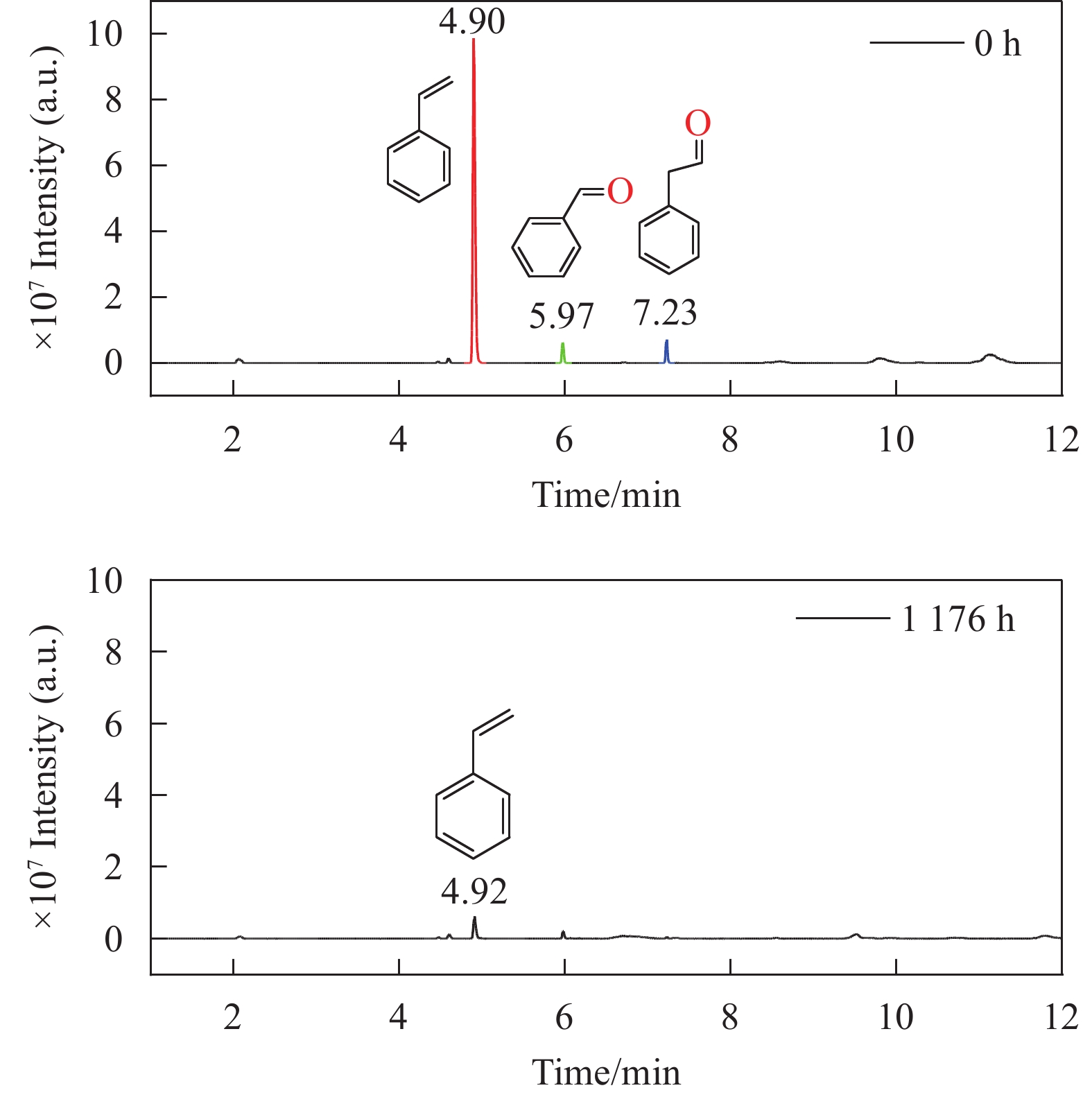

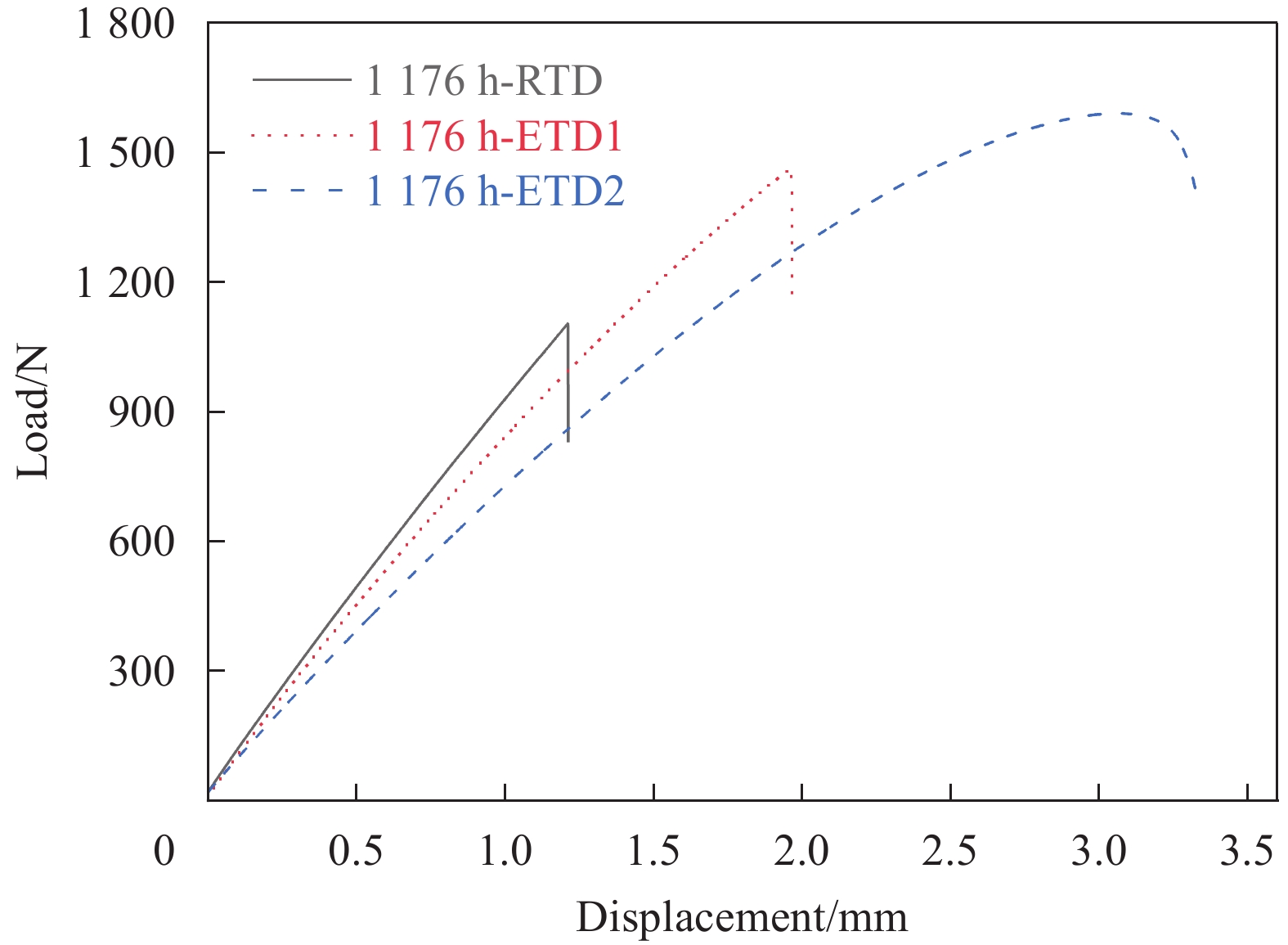

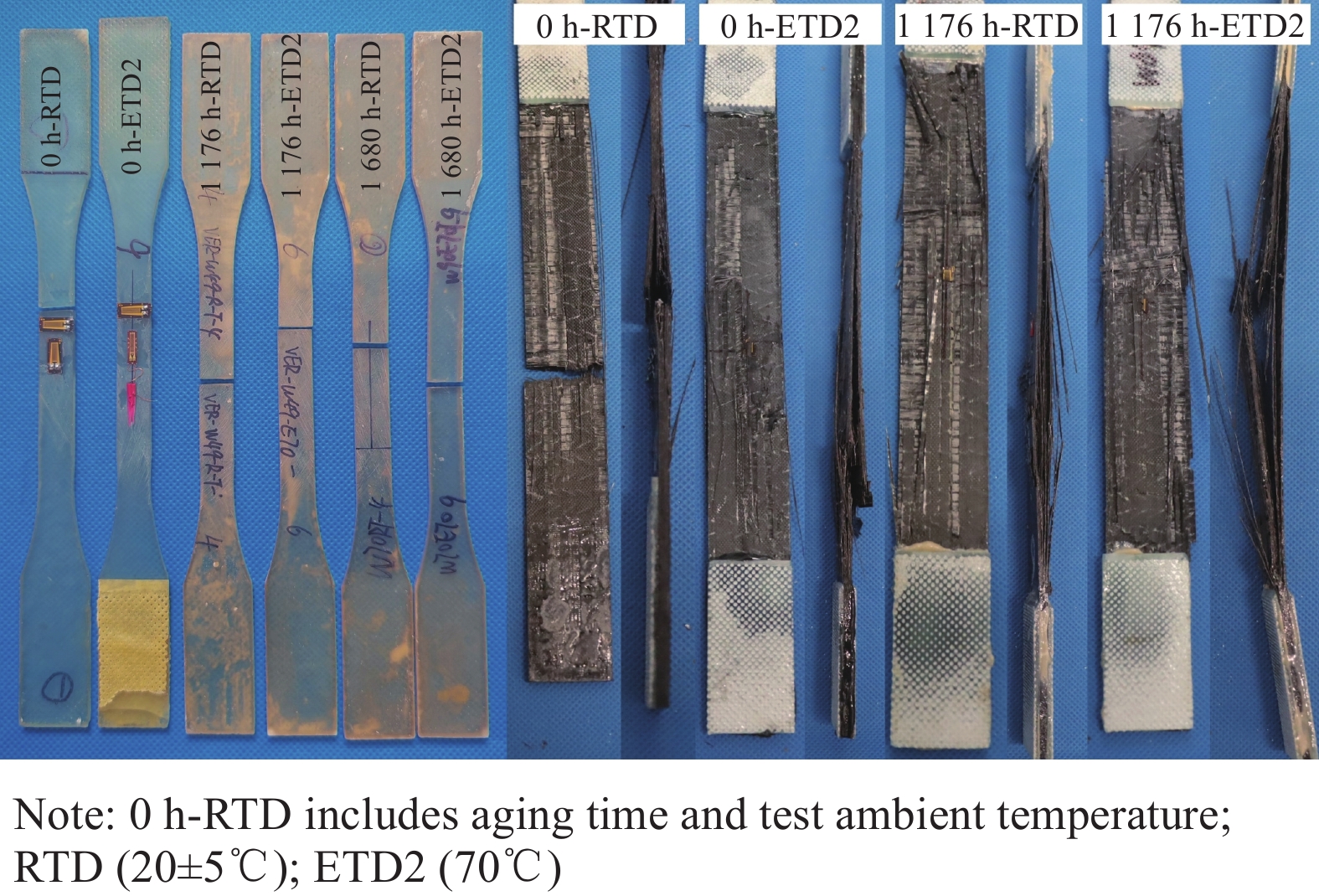

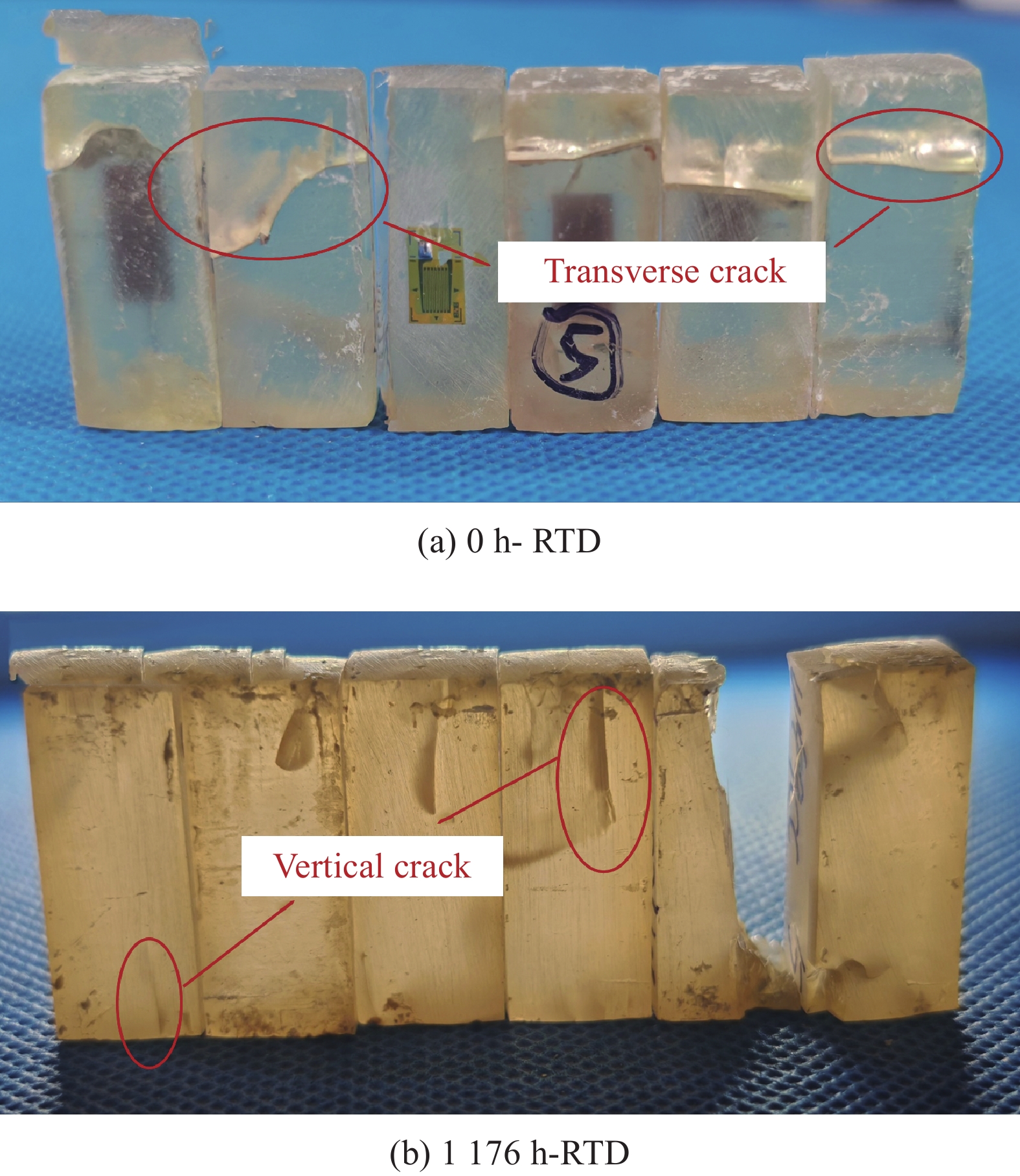

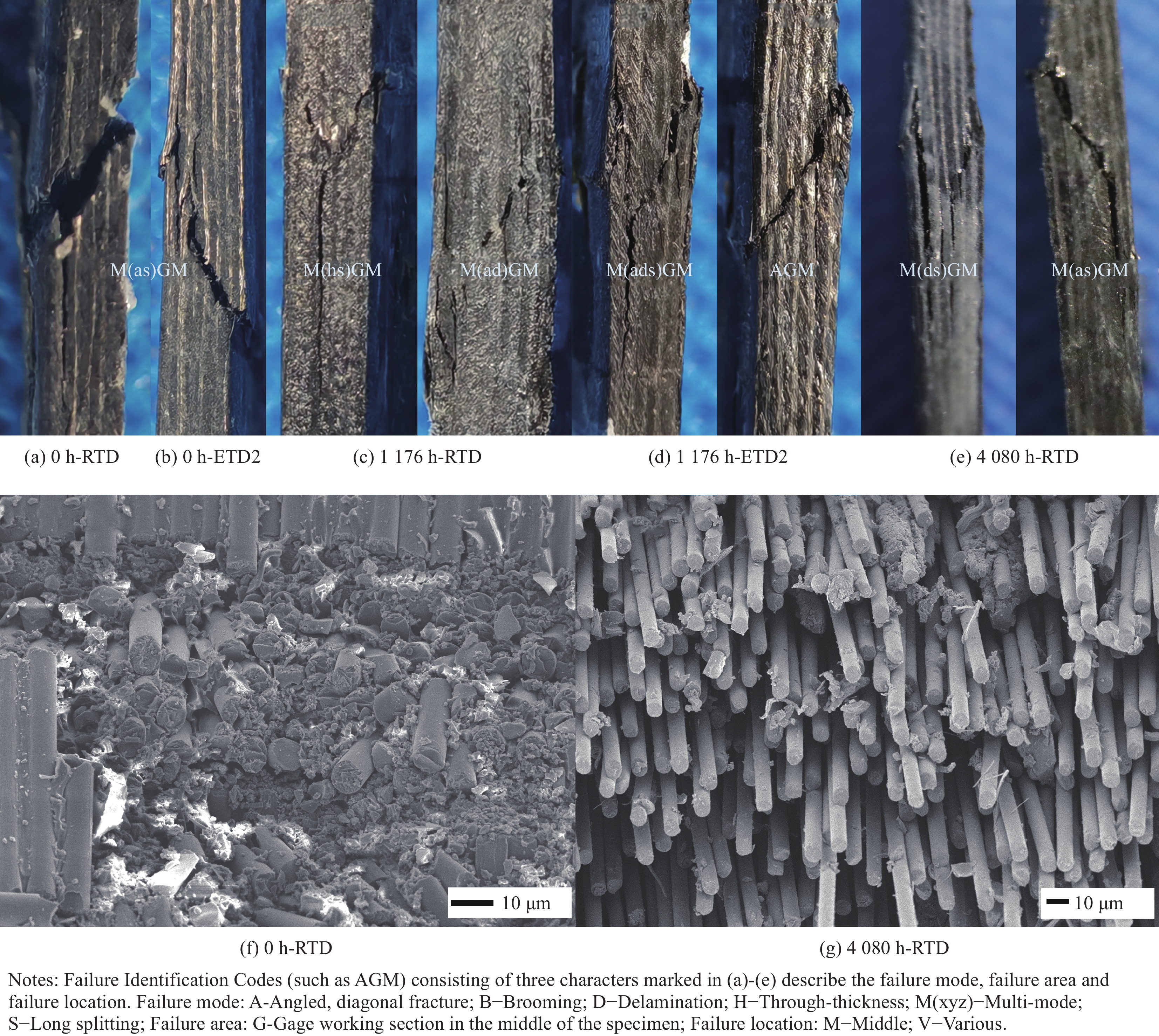

结果①LC-MS和FTIR的结果表明树脂分子链中的酯键发生了强烈的水解反应,树脂表面产生致密微孔、孔隙和微裂纹。②树脂在老化120 h时达到最大质量增长率0.56%,CF/VE在老化240 h时达到最大质量增长率0.26%,随后两者均呈下降趋势,4000 h后CF/VE质量低于初始值。③DMA结果表明,水热老化1176 h后,树脂和CF/VE的分别提高了21.94℃、25.88℃,两者储能模量明显升高;未老化时两者热膨胀系数差值为74.66×10/k,老化1176 h后,差值进一步扩大至77.61×10/k。④水热老化1176 h后,未完全固化CF/VE在室温环境下的压缩、层间剪切强度分别降低23.0%、46.6%,拉伸强度只降低了0.8%,面内剪切强度提升了3.1%。水热老化后,树脂在70℃下的拉伸、压缩强度相较于未老化时上升,CF/VE在70℃下的压缩、面内剪切强度相较于未老化时上升。⑤70℃下树脂拉伸、压缩强度相较于室温分别降低47.9%、57.7%;70℃下CF/VE压缩、面内/层间剪切强度相较于室温分别降低26.4%、36.7%、27.7%。

结论本文研究了水热老化前后未完全固化VER及CF/VE的热学/力学性能,结果表明:水热老化过程中,由于树脂发生由表及里的强水解反应和渗透开裂现象,大量有机溶质迁移到介质中,导致材料质量增长率在达到最大值后而下降。由于树脂基体发生后固化反应,两者的热学性能明显提高:储能模量和在水热老化前期上升,且热膨胀系数降低,材料的相对刚性增加;老化后期由于水的塑化作用导致有所恢复。水解导致树脂产生微裂纹、孔洞等缺陷;树脂对纤维的包覆性降低,复合材料层内纤维/树脂黏结性能和层间结合性能减弱,导致CF/VE的压缩、层间剪切强度在水热老化短期内显著下降。由于树脂基体的热稳定性和相对刚性增加,VER及CF/VE在70℃下的部分力学性能增加。

-

碳纤维/乙烯基酯树脂复合材料(CF/VE)具有轻质、高比强度和耐腐蚀等特点,被逐渐应用于舰船设备的大厚度结构件,由于尺寸和模具等因素,实际环境制造的结构件不进行后固化处理,装备时的固化往往不完全。然而目前对不完全固化CF/VE体系在水热环境下的老化报道较少,相关树脂基体及其复合材料的性能变化数据不足,对不完全固化复合材料结构件的耐久性认识不充分。

本文通过制备碳纤维/乙烯基酯复合材料和纯树脂基体,在未进行后固化处理的情况下对试样进行水热老化研究。液相色谱-质谱联用和FTIR的结果表明树脂分子链中的酯键发生了强水解;由于树脂发生由表及里的强水解反应和渗透开裂现象,导致质量增长率在达到最大值后下降,4000 h后复合材料质量低于初始值。树脂中发生后固化反应,树脂及CF/VE的储能模量和Tg在老化初期上升、热膨胀系数降低,老化后期由于水的塑化作用使Tg有所恢复;通过热重-气相色谱/质谱联用(TGA-GC/MS),进一步验证了树脂在水热老化后的热稳定性增加,热质量损失及热氧化产物含量减少;树脂中初始残留的苯乙烯除了流失于介质中和参与后固化反应外,仍有微量未被消耗而继续残留于基体中。通过高温性能测试发现水热环境导致树脂在70℃高温下的拉伸、压缩强度相较于未老化时上升,CF/VE在70℃下的部分力学性能也得到提升。但在水热老化短期时间内,CF/VE的压缩、层间剪切强度显著下降,1176 h室温环境下分别降低23.0%,46.6%,之后性能退化速率减缓,4080 h时分别降低30.9%、47.7%。压缩和层间剪切试样破坏形式的变化表明未完全固化体系层间界面受水热老化影响较大。

纯树脂基体及CF/VE的质量变化曲线

不同水热老化时间及测试温度下CF/VE层间剪切强度

下载:

下载: