Design, preparation and properties of honeycomb 3D integral woven structure microwave absorbing composites

-

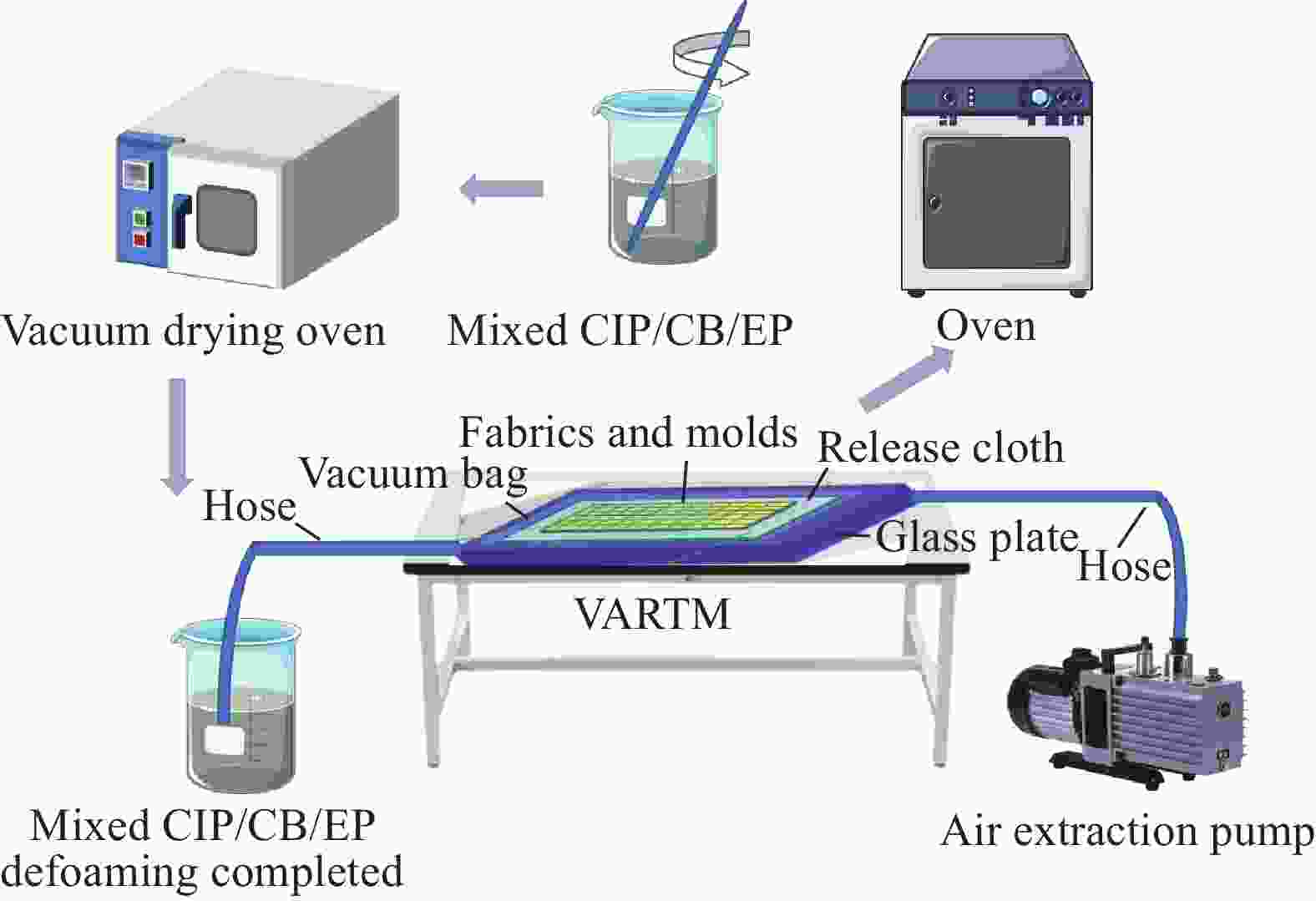

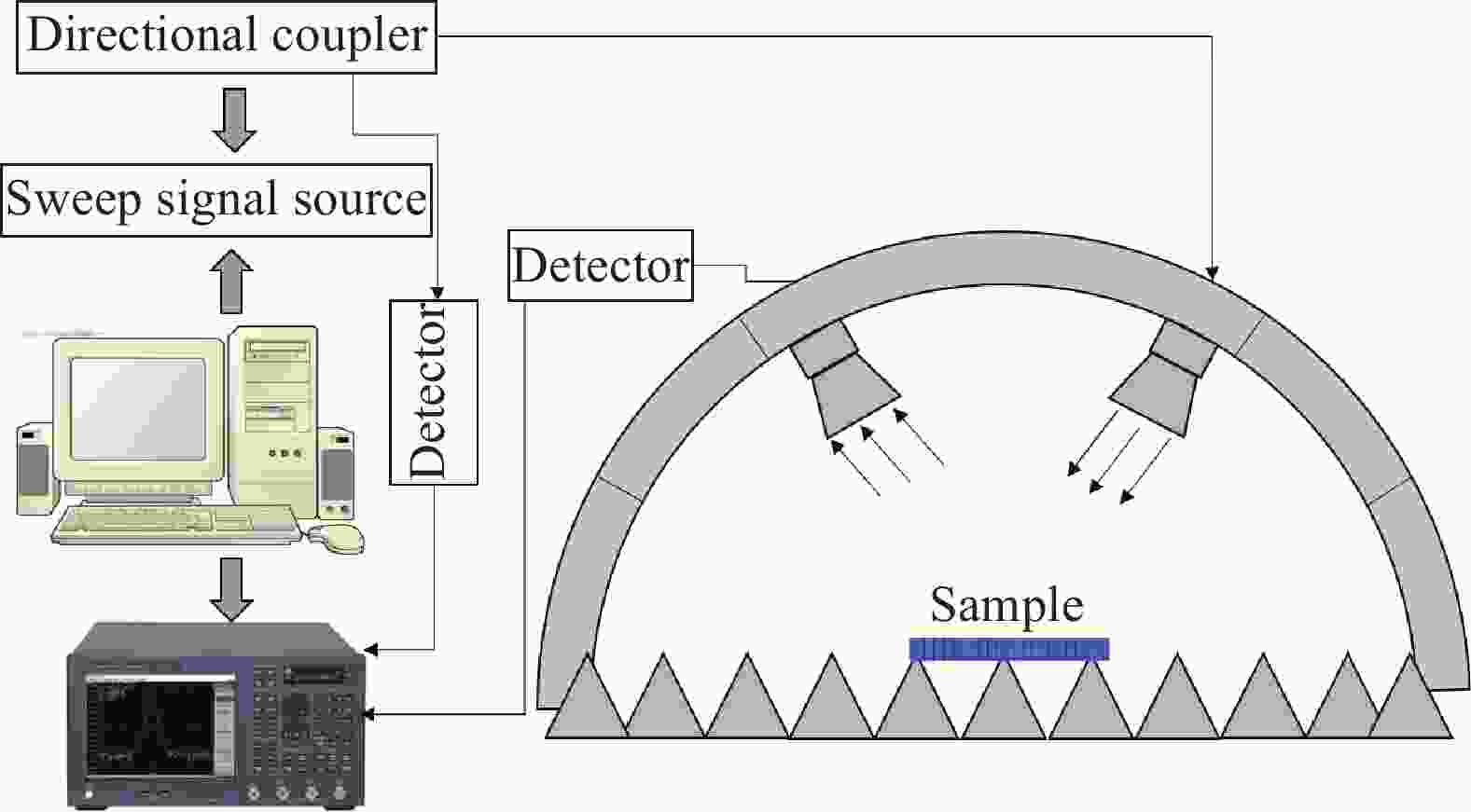

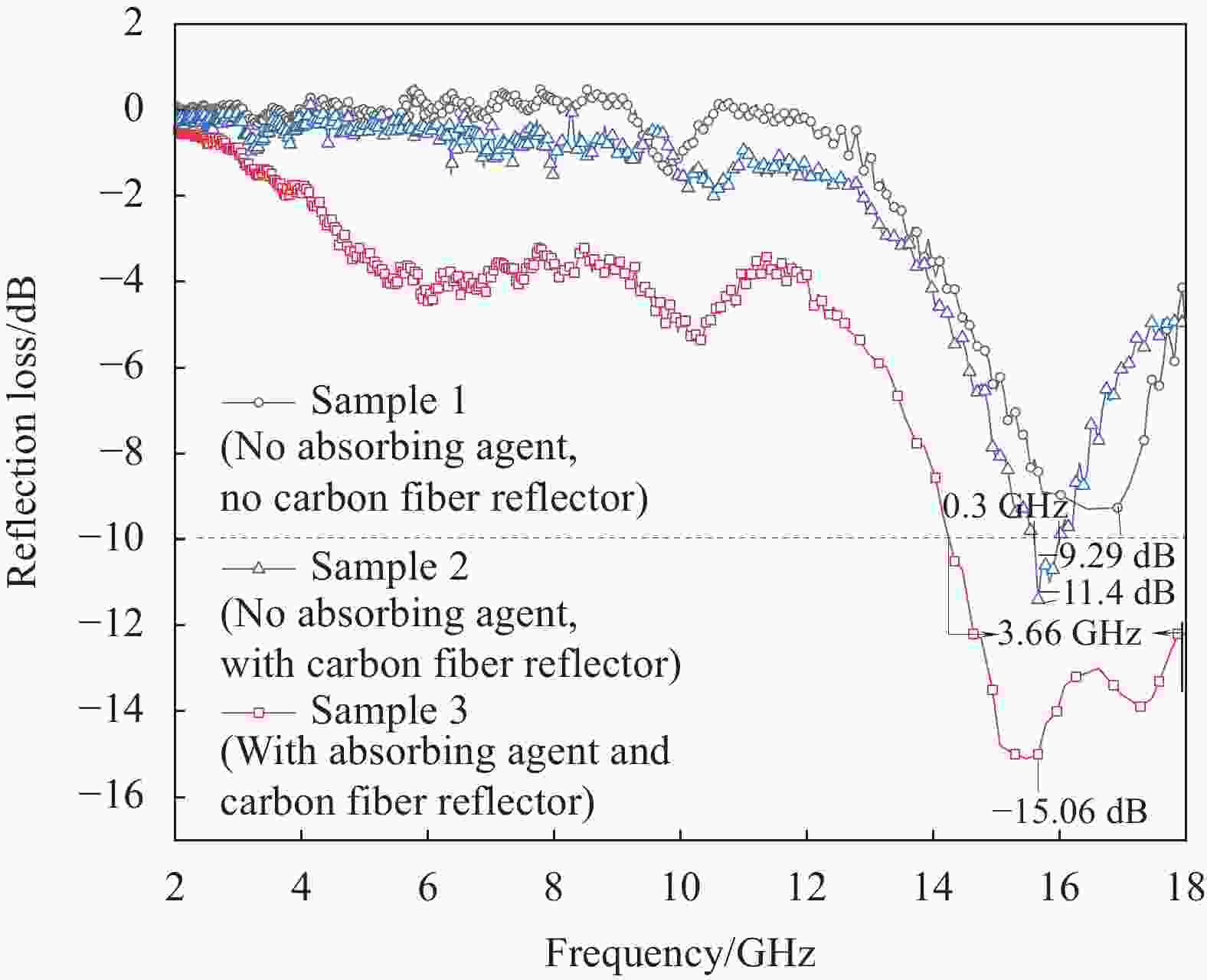

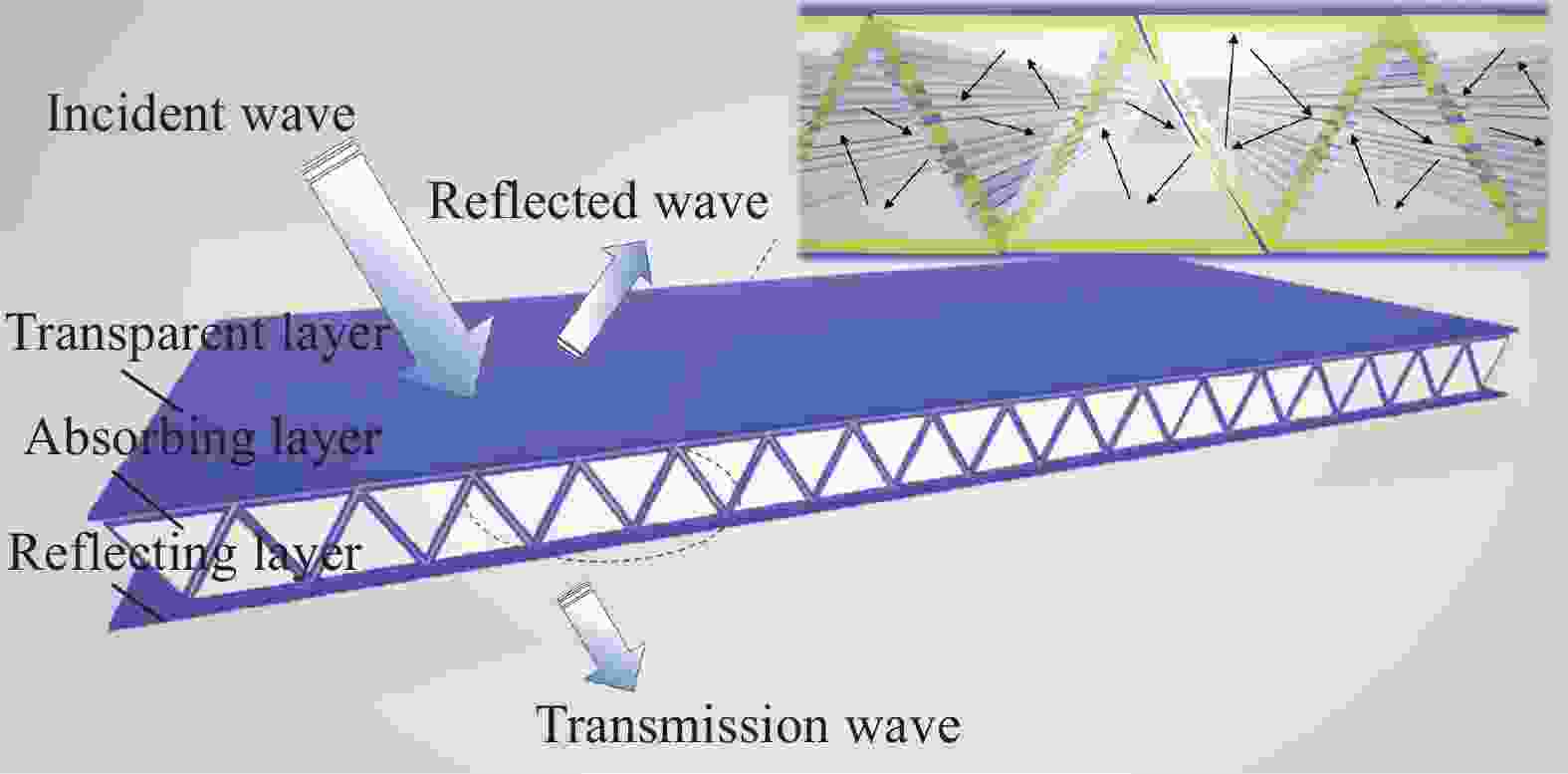

摘要: 为了解决蜂窝夹层结构材料的开裂和分层问题,以玄武岩纤维长丝纱和碳纤维长丝纱为原料,在普通织机上,经合理设计,织造了顶层为透波层、中间层为吸波层和底面为反射层的蜂窝状三维整体机织结构型吸波织物;其次,以蜂窝状三维整体机织结构型吸波织物为增强体,双酚A型环氧树脂为基体,羰基铁粉(CIP)和炭黑(CB)为吸波剂,采用真空辅助树脂传递模塑(VARTM)成型工艺,制备了不同结构参数的蜂窝状三维整体机织结构型吸波复合材料;最后,采用矢量网络分析仪和万能试验机分别对蜂窝状三维整体机织结构型吸波复合材料的吸波性能和力学性能进行研究。研究表明,其有良好的整体性能,兼具吸波和承载能力。Abstract: In order to solve the problems of cracking and delamination of honeycomb sandwich structure materials, basalt fiber filament yarn and carbon fiber filament yarn were used as raw materials, the honeycomb 3D integral woven structure microwave absorbing fabric was fabricated with the top layer as the wave transmitting layer, the middle layer as the wave absorbing layer and the bottom layer as the reflecting layer on the ordinary loom through reasonable design; Secondly, honeycomb 3D integral woven structure microwave absorbing composites with different structural parameters were prepared by vacuum assisted resin transfer molding (VARTM) process with honeycomb three-dimensional integral woven structure microwave absorbing fabric as reinforcement, bisphenol A epoxy resin as matrix, carbonyl iron powder (CIP) and carbon black (CB) as microwave absorbing agent; Finally, the microwave absorbing and mechanical properties of honeycomb 3D integral woven structure microwave absorbing composites were studied by vector network analyzer and universal testing machine. The research shows that it has good overall performance, both wave absorption and bearing integration.

-

Key words:

- honeycomb structure /

- 3D weaving /

- composite /

- microwave absorption performance /

- mechanical property

-

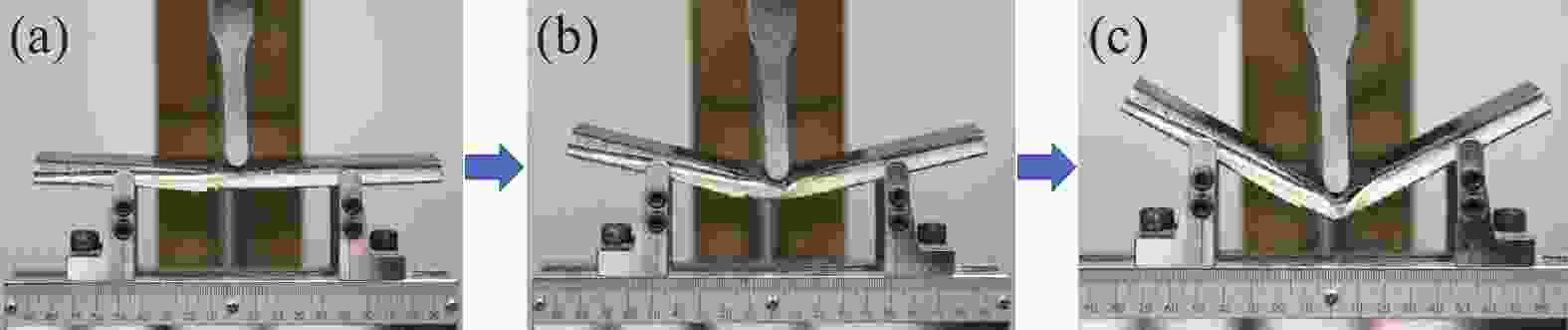

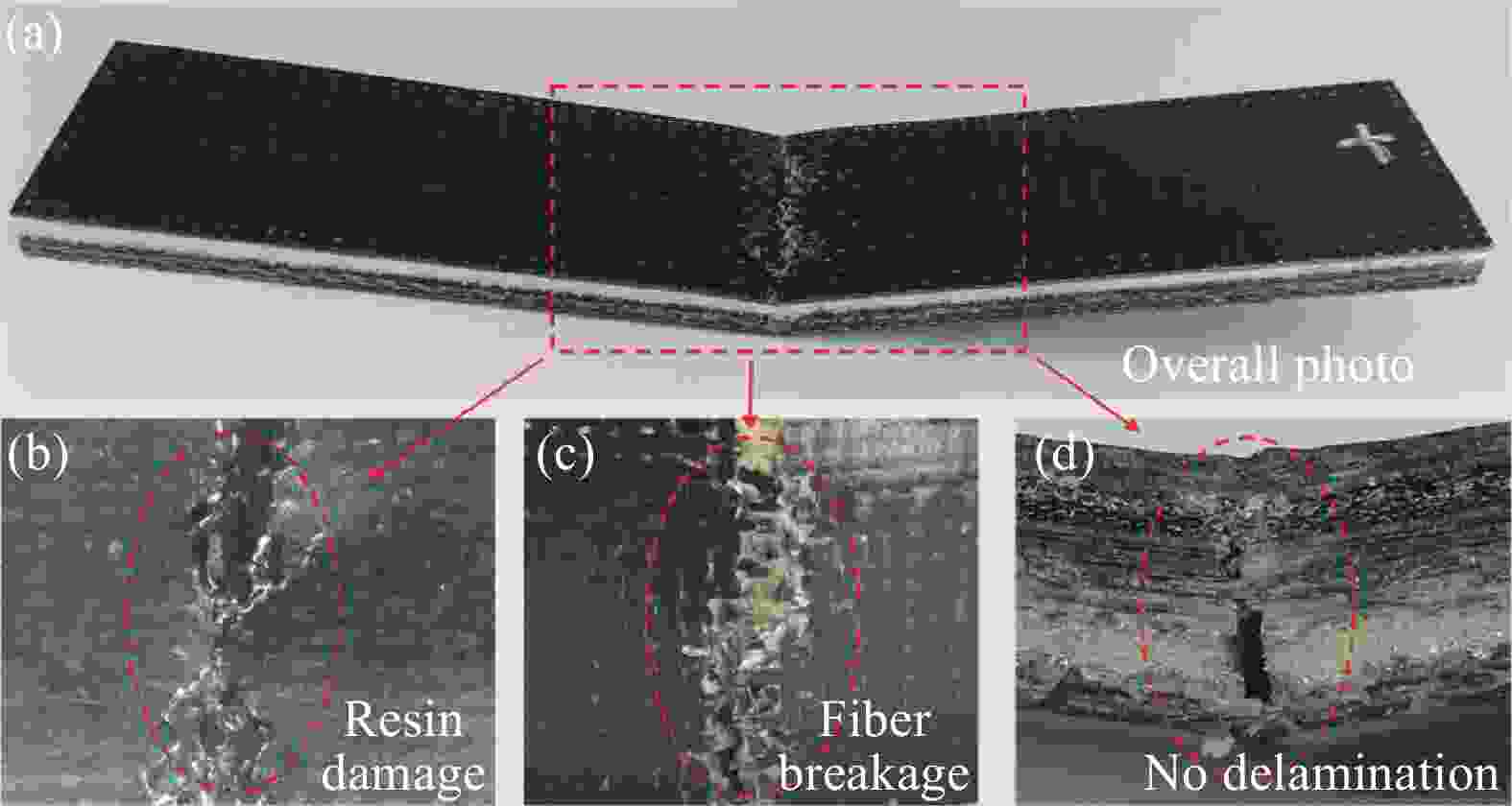

图 5 蜂窝状三维整体机织结构型复合材料实物图:(a) 无吸波剂无碳纤维反射层;(b) 无吸波剂有碳纤维反射层;(c) 有吸波剂有碳纤维反射层

Figure 5. Physical drawing of honeycomb 3D woven structure composite: (a) No absorbing agent, no carbon fiber reflection; (b) No absorbing agent, with carbon fiber reflection; (c) With absorbing agent and carbon fiber reflection

表 1 蜂窝状三维整体机织结构型吸波复合材料最大载荷对比

Table 1. Comparison of maximum load of honeycomb 3D integral woven structure microwave absorbing composites

Sample Maximum load/N Sample 1 (No absorbing agent,

no carbon fiber reflection)990.6 Sample 2 (No absorbing agent,

with carbon fiber reflection)1002.03 Sample 3 (With absorbing agent

and carbon fiber reflection)846.38 -

[1] 李善霖, 段华军, 汪鑫, 等. 镀镍碳纤维-碳纤维-玻璃纤维/乙烯基酯树脂导电复合材料的设计制备及其电磁性能[J]. 复合材料学报, 2018, 35(7):1709-1715.LI Shanlin, DUAN Huajun, WANG Xin, et al. Design, preparation and electromagnetic properties of nickel plated carbon fiber carbon fiber glass fiber/vinyl ester resin conductive composites[J]. Acta Materiae Compositae Sinica,2018,35(7):1709-1715(in Chinese). [2] SHAO T Q, MA H, WANG J, et al. High temperature absorbing coatings with excellent performance combined Al2O3 and TiC material[J]. Journal of the European Ceramic Society,2020,40(5):2013-2019. doi: 10.1016/j.jeurceramsoc.2020.01.036 [3] CHUH A, WONG W, LEE A. Electromagnetic wave absorption characteristics of single and double layer absorbers based on trimetallic [emailprotected] metalorganic framework incorporated with MWCNTs[J]. Synthetic Metals,2020,125(4):853-854. [4] LIU Y J, YANG Y F. A study on the electromagnetic properties of graphite/bismuth/bismuth oxide-coated composites[J]. Textile Research Journal,2021(12):1-13. [5] GI W J, YEONG H N, WON H C, et al. Electromagnetic-mechanical repair patch of radar-absorbing structure with electroless nickel-plated glass fabric damaged by lightning strike[J]. Journal of Composite Materials,2021,55(7):989-1002. doi: 10.1177/0021998320961558 [6] ZHAO S X, MA H, SHAO T Q, et al. Thermally stable ultra-thin and refractory microwave absorbing coating[J]. Ceramics International,2021,47(7):337-344. [7] HUANG L N, CHEN C G, LI Z J, et al. Challenges and future perspectives on microwave absorption based on two-dimensional materials and structures[J]. Nanotechnology,2020,31(16):16-32. [8] LI R, QING Y C, LI W, et al. The electromagnetic absorbing properties of plasma-sprayed TiC/Al2O3 coatings under oblique incident microwave irradiation[J]. Ceramics International,2021,47(16):22864-22868. doi: 10.1016/j.ceramint.2021.04.306 [9] ZHANG H Y, CHEN J Y, WANG Y, et al. Study on frequency selective/absorption/reflection multilayer composite flexible electromagnetic wave absorbing fabric[J]. Textile Research Journal,2021,91(15):16-27. [10] LONG L, XU J X, LUO H, et al. Dielectric response and electromagnetic wave absorption of novel macroporous short carbon fibers/mullite composites[J]. Journal of the American Ceramic Society,2020,103(12):11-23. [11] 李天舒, 王绍凯, 顾轶卓, 等. 碳纳米管膜层间改性碳纤维/双马来酰亚胺复合材料的结构调控及性能[J]. 复合材料学报, 2021, 38(6):1784-1794.LI Tianshu, WANG Shaokai, GU Yizhuo, et al. Structure regulation and properties of carbon fiber /bismaleimide composites modified by carbon nanotube films[J]. Acta Materiae Compositae Sinica,2021,38(6):1784-1794(in Chinese). [12] 张荣华, 史可宇, 李硕, 等. 平纹编织碳纤维增强树脂复合材料离散电导率建模方法[J]. 复合材料学报, 2020, 37(12):3119-3127.ZHANG Ronghua, SHI Keyu, LI Shuo, et al. Modeling method of discrete conductivity of plain woven carbon fiber reinforced resin composites[J]. Acta Materiae Compositae Sinica,2020,37(12):3119-3127(in Chinese). [13] JIAN H, DU Q R, MEN Q Q, et al. Structure-dependent electromagnetic wave absorbing properties of bowl-like and honeycomb TiO2/CNT composites[J]. Journal of Materials Science & Technology, 2022, 109(20): 105-113. [14] TITUS M, YOSHINOBU M, GODWILL M K, et al. Topological defects and unique stacking disorders in honeycomb layered oxide K2Ni2TeO6 nanomaterials: Implications for rechargeable batteries[J]. ACS Applied Nano Materials, 2021(4): 279-287. [15] XU F, ZHANG S Y, WANG G G, et al. Lightweight Low〧requency Sound〢bsorbing composites of graphene network reinforced by honeycomb structure[J]. Advanced Materials Interfaces,2021,8(16):183-191. [16] BYEONG S K, JEONG G W, CHOI W H, et al. Microwave-absorbing honeycomb core structure with nickel-coated glass fabric prepared by electroless plating[J]. Composite Structures,2021,256(5):113-148. [17] LIU Z X, ZHAO W K, YU G C, et al. Fabrication and mechanical behaviors of quartz fiber composite honeycomb with extremely low permittivity[J]. Composite Structures,2021,271(2):129-134. [18] ZHAO P, XU Y G, WEI F M, et al. Electromagnetic property of a novel gradient honeycomb composite fabricated by 3D forming[J]. Journal of Magnetism and Magnetic Materials,2020(493):165742-165753. [19] LI Z W, MA J X. Experimental study on mechanical properties of the sandwich composite structure reinforced by basalt fiber and nomex honeycomb[J]. Materials,2020,13(8):1870-1887. doi: 10.3390/ma13081870 [20] ANOSHKIN A, PISAREV P, ERMAKOV D. Influence of a delamination type defect on the operational life of a sound-absorbing structure with a honeycomb filler[J]. IOP Conference Series Materials Science and Engineering,2020,71(3):12012-12017. [21] GE J I, LEE W J, KIM S Y, et al. Electromagnetic damage tolerance for radar absorbing composite structures with impact damage[J]. Composites Science and Technology,2020,199(31):366-373. [22] 戴海军, 李嘉禄, 孙颖, 等. 纬编双轴向织物/环氧树脂电加热复合材料电热及层间剪切性能[J]. 复合材料学报, 2020, 37(8):1997-2004.DAI Haijun, LI Jialu, SUN Ying, et al. Electrothermal and interlaminar shear properties of weft knitted biaxial fabric/epoxy resin electrically heated composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1997-2004(in Chinese). [23] 樊威, 孟家光, 孙润军, 等. 混杂纤维增强结构隐身复合材料研究进展[J]. 纺织导报, 2017, 11(1):66-68.FAN Wei, MENG Jiaguang, SUN Ruijun, et al. Research progress of hybrid fiber reinforced structural stealth composites[J]. China Textile Leader,2017,11(1):66-68(in Chinese). [24] CHEN X G, LINDSAY T, WATER T, et al. An overview on fabrication of three-dimensional woven textile preforms for composites[J]. Textile Research Journal,2011,81(9):932-944. doi: 10.1177/0040517510392471 [25] 刘文迪, 吕丽华. 三维机织吸波复合材料的研究进展[J]. 棉纺织技术, 2020, 48(10):81-84. doi: 10.3969/j.issn.1001-7415.2020.10.019LIU Wendi, LYU Lihua. Research progress of three-dimensional woven microwave absorbing composites[J]. Cotton Textile Technology,2020,48(10):81-84(in Chinese). doi: 10.3969/j.issn.1001-7415.2020.10.019 [26] 国防科学技术工业委员会. 雷达吸波材料反射率测试方法: GJB 2038—94[S]. 北京: 中国标准出版社, 1994.Commission of Science, Technology and Industry for National Defense (COSTIND) commission. Methods for measurement of reflectivity of radar absorbing material: GJB 2038—94[S]. Beijing: China Standard Press, 1994(in Chinese). [27] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 塑料 弯曲性能的测定: GB/T 9341—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration. Plastics-Determination of flexural properties: GB/T 9341—2008[S]. Beijing: China Standard Press, 2008(in Chinese). [28] ZHANG M, WANG X X, LIU S Q, et al. Effects of face sheet structure on mechanical properties of 3D integrated woven spacer composites[J]. Fibers and Polymers,2020,21(7):1594-1604. doi: 10.1007/s12221-020-9908-6 [29] MA Z Y, ZHANG P Z, ZHU J X. Influence of fabric structure on the tensile and flexural properties of three-dimensional angle-interlock woven composites[J]. Journal of Industrial Textiles,2020,15(17):1-17. -

下载:

下载: