Tribological performance study of carbon fibre-carbon nanotube multiscale reinforced polytetrafluoroethylene composites

-

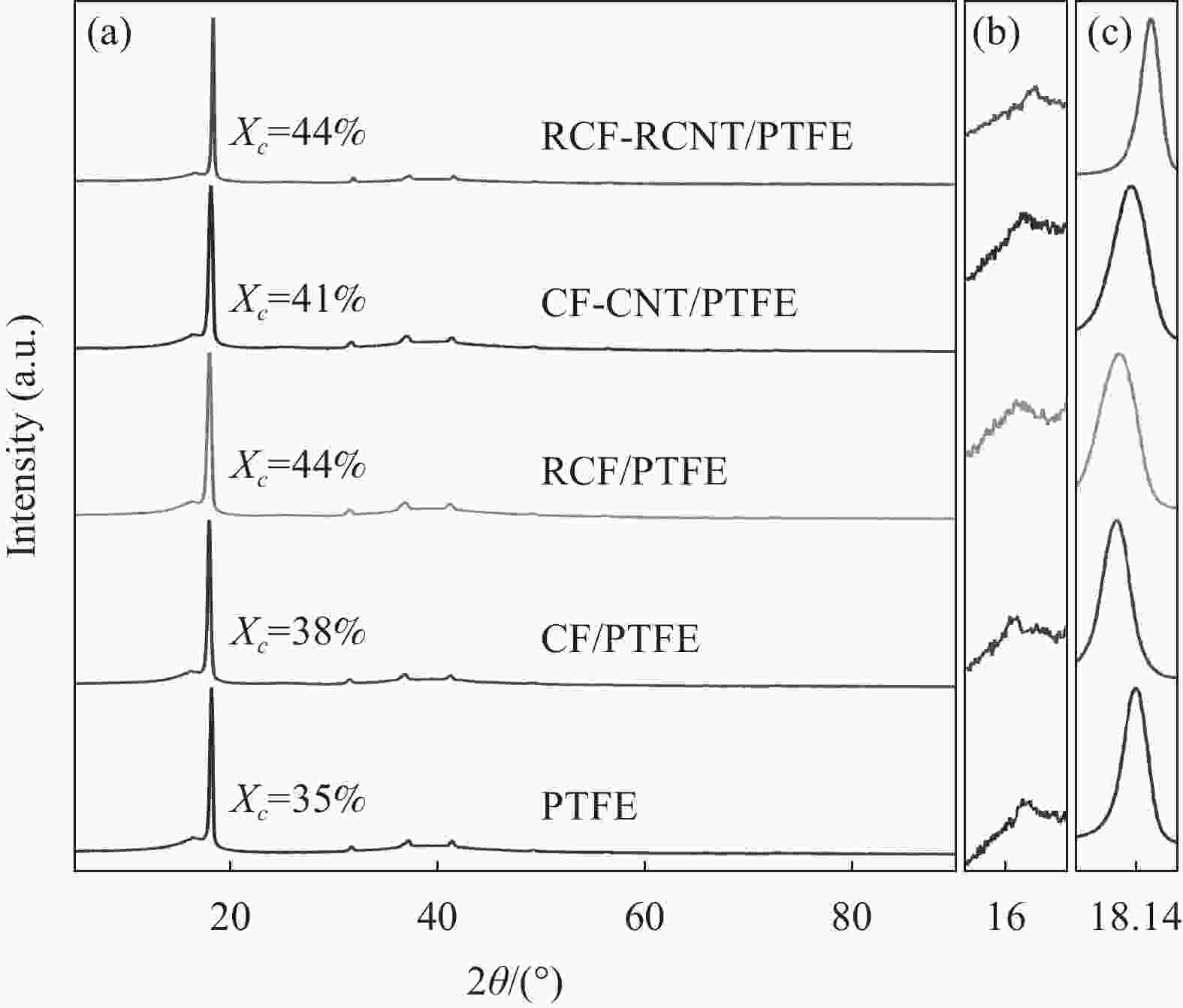

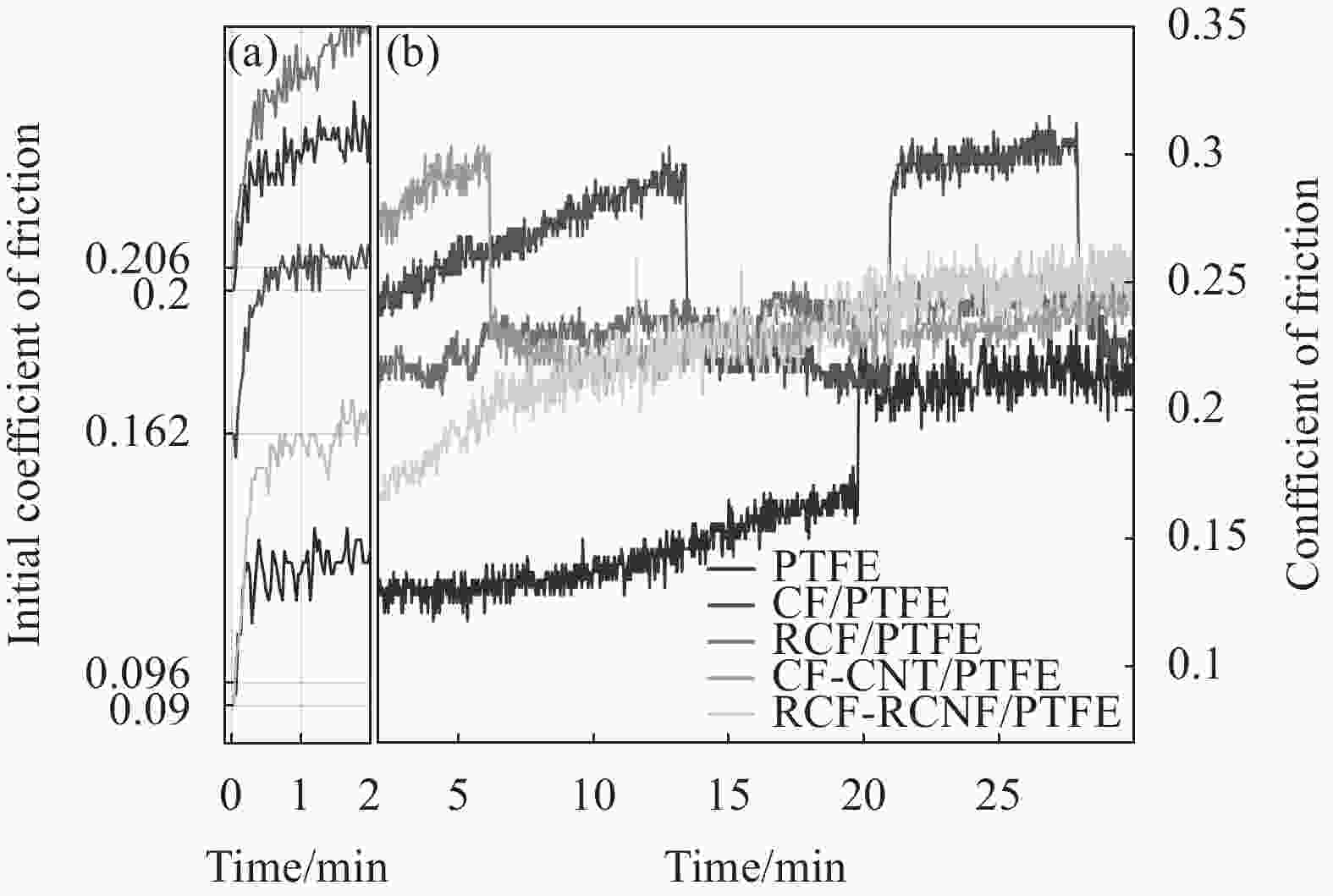

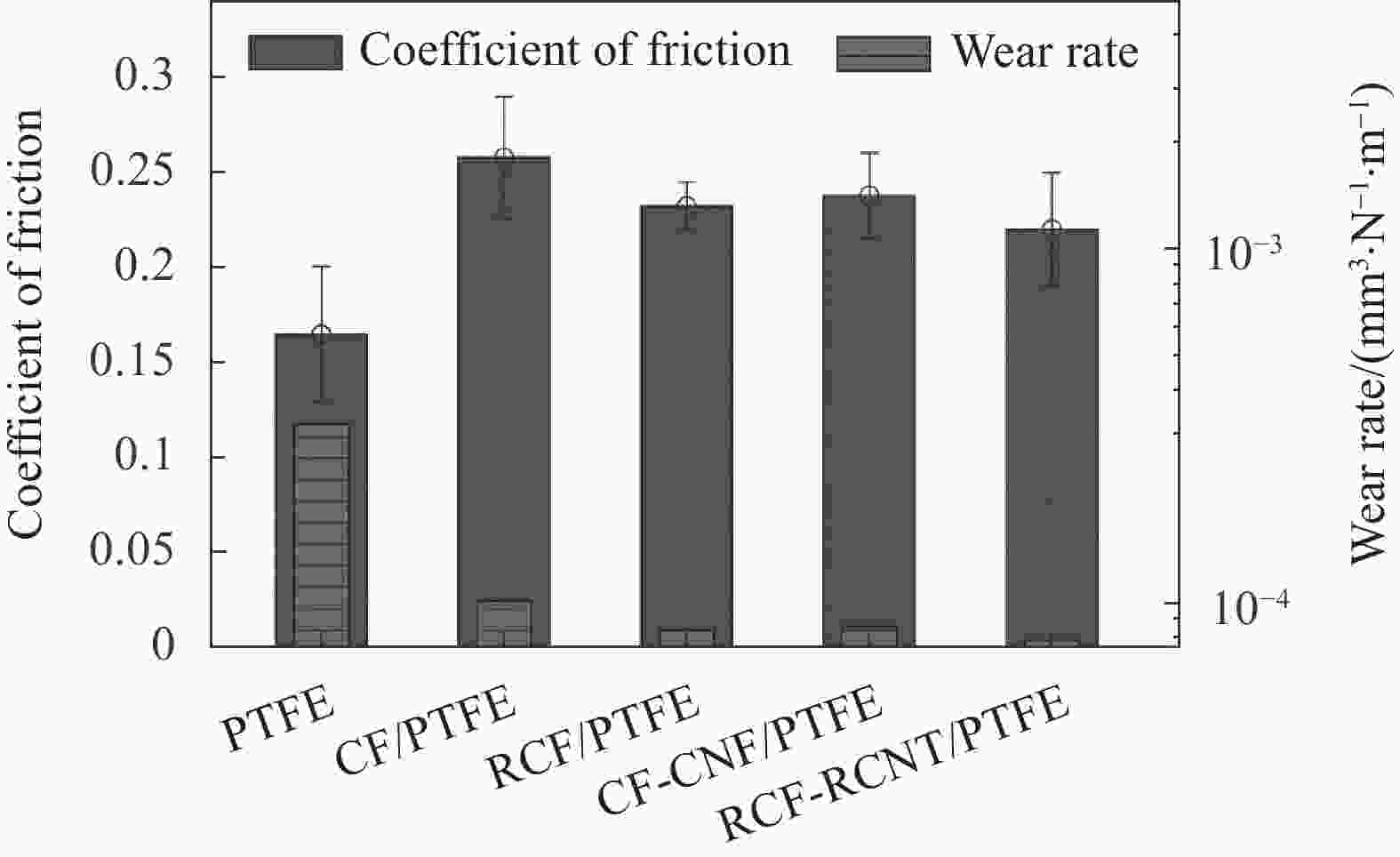

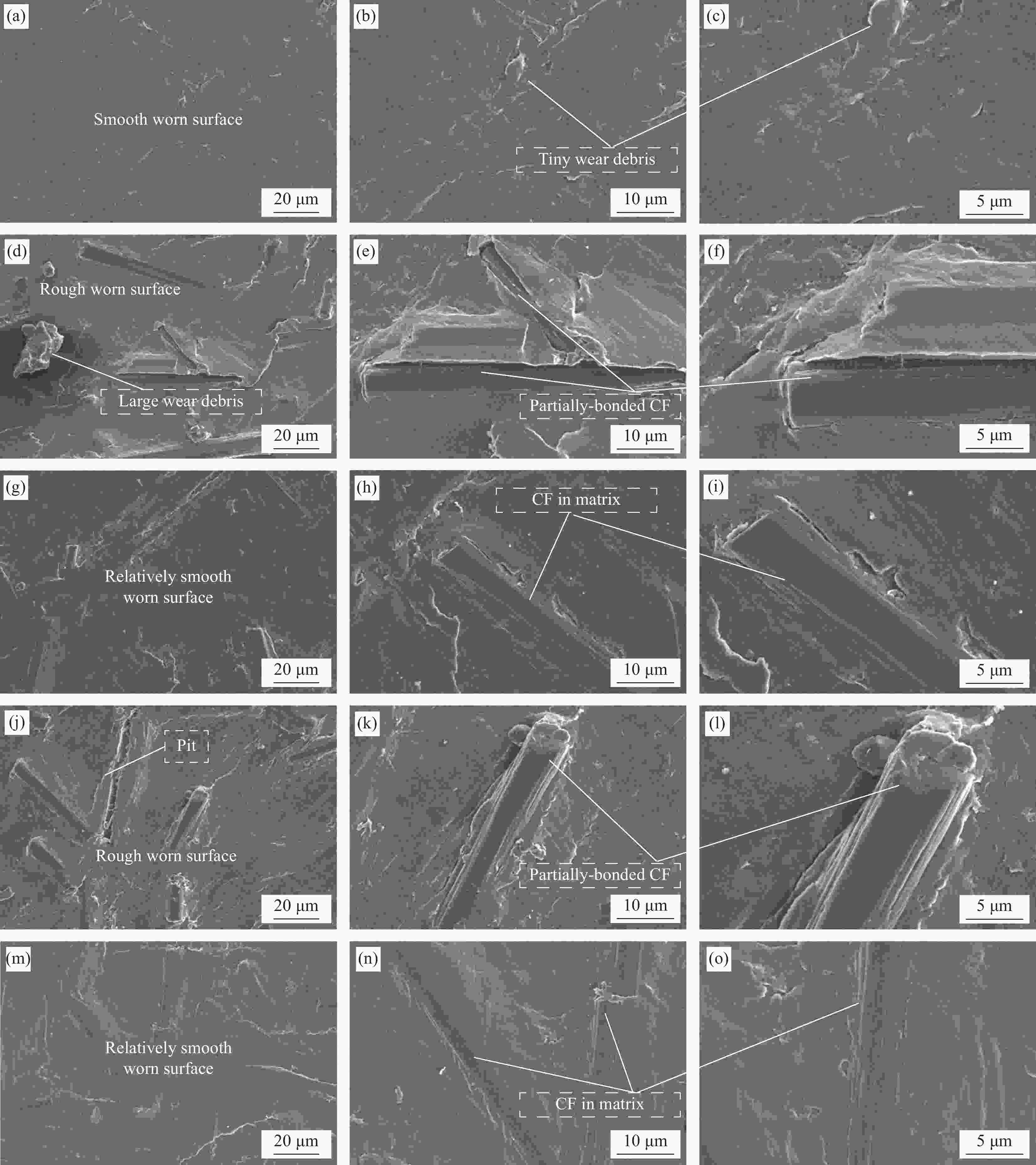

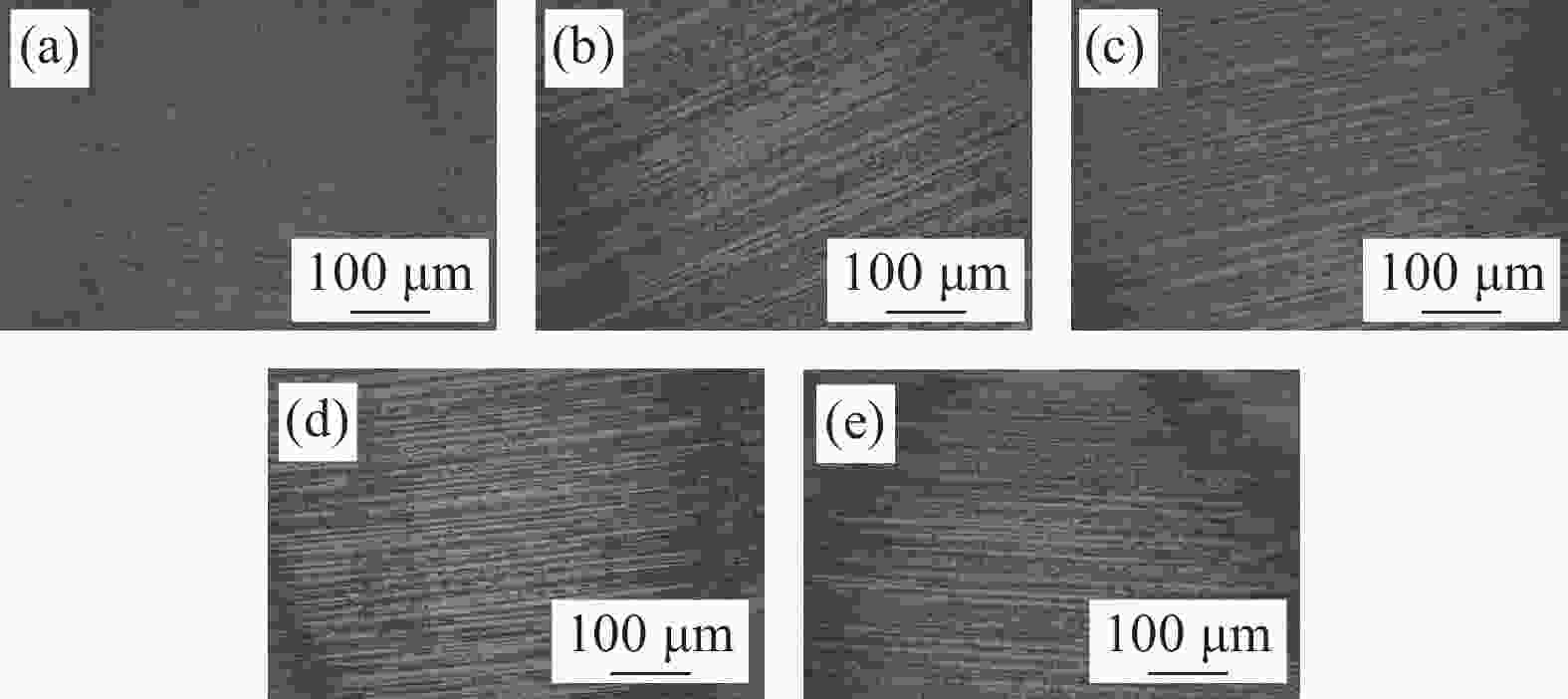

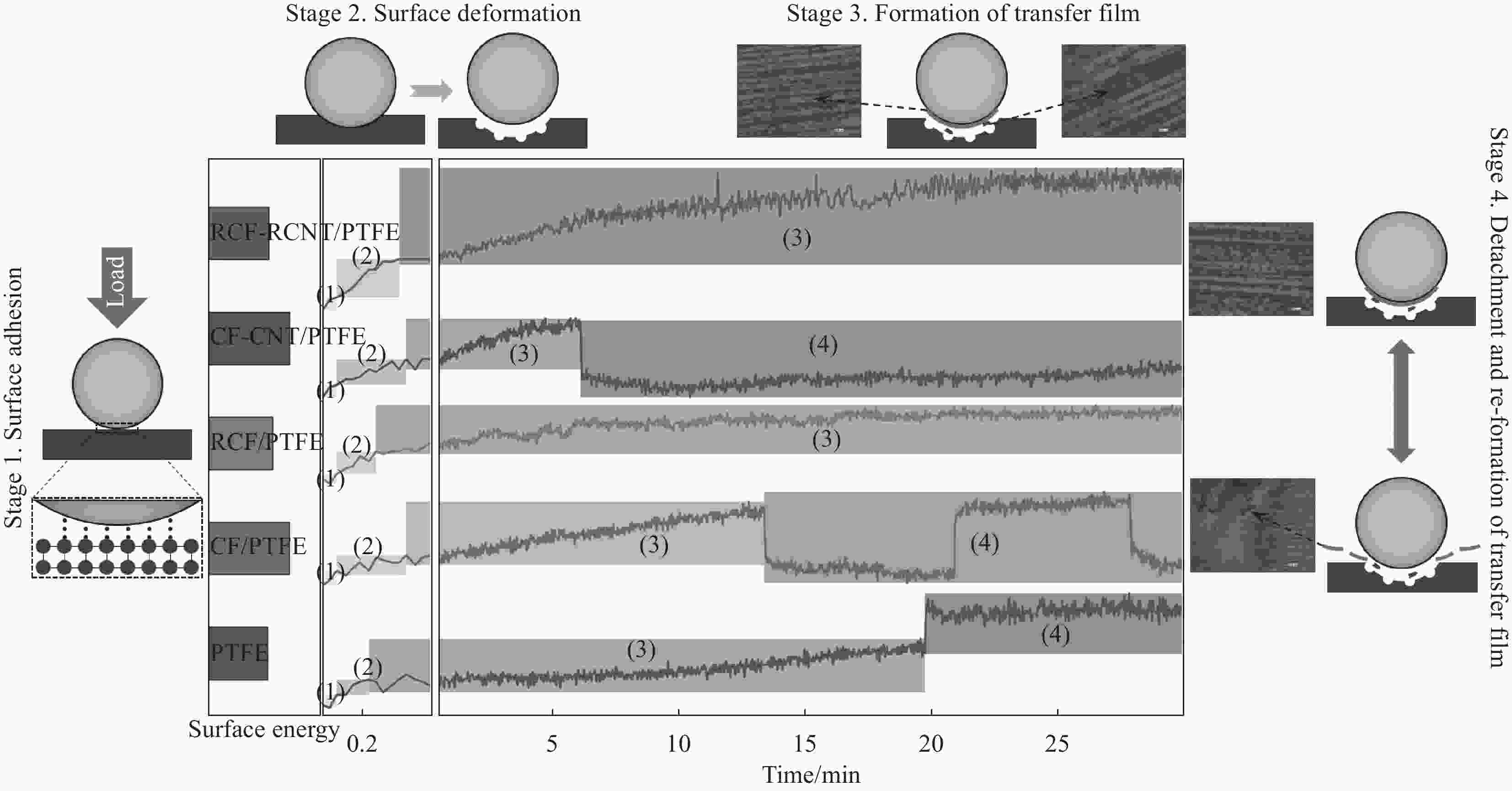

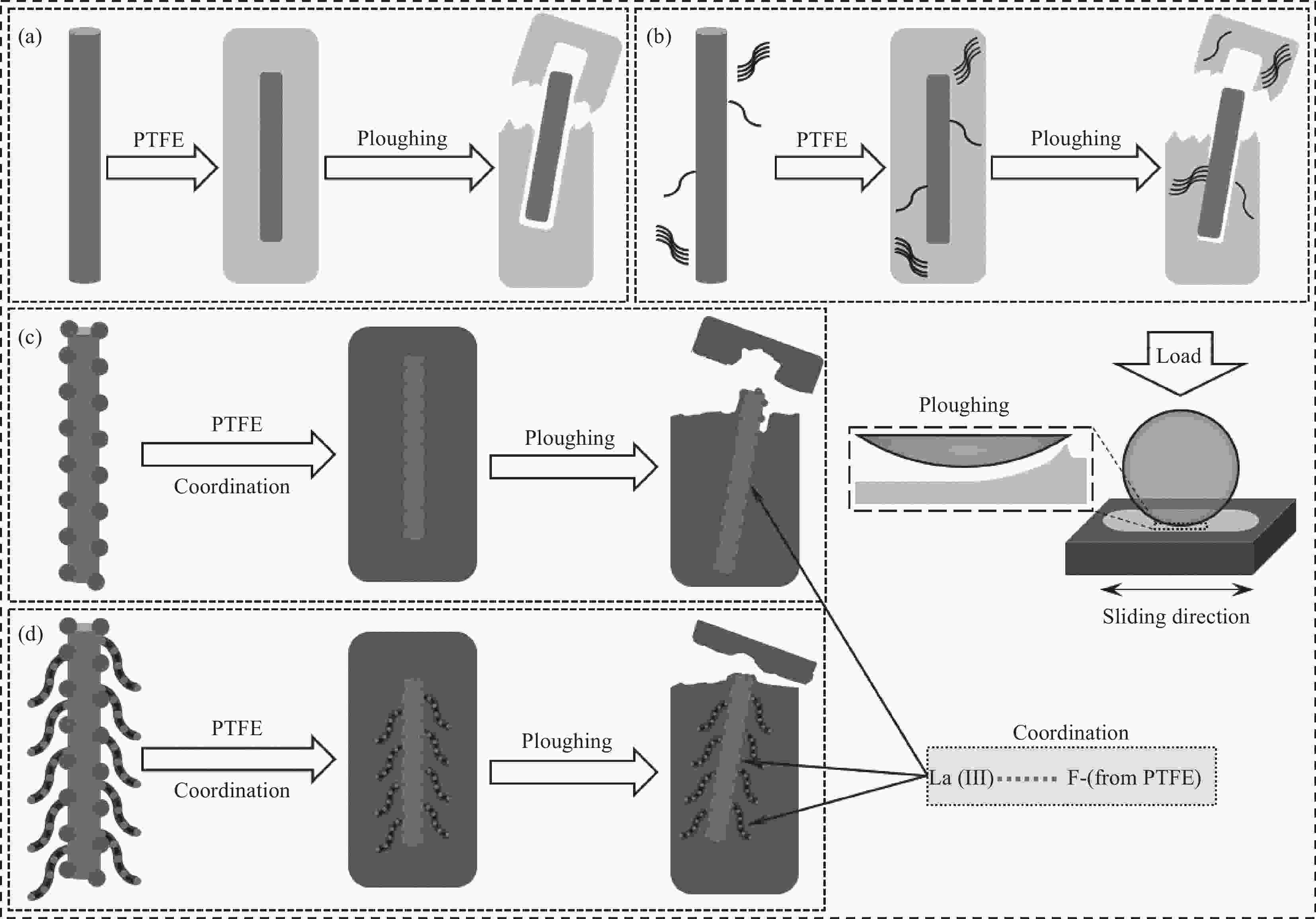

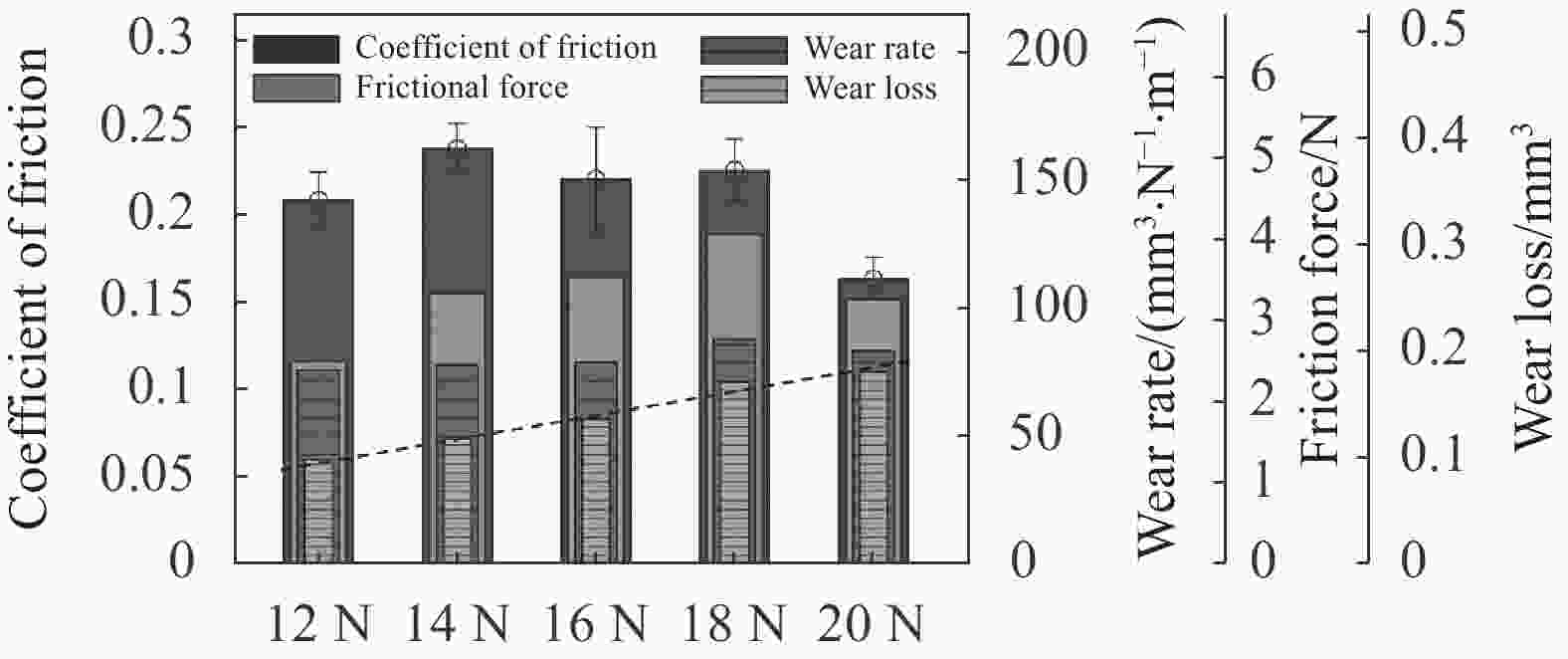

摘要: 针对传统化学法易损伤纤维、污染严重的缺点,采用稀土LaCl3表面处理方法合成碳纤维(Carbon Fibre, CF)-碳纳米管(Carbon Nanotube, CNT)微纳多尺度增强体,通过烧结工艺制备CF-CNT多尺度增强聚四氟乙烯(Polytetrafluoroethylene, PTFE)基复合材料。对增强体形貌、表面微晶结构以及复合材料硬度、晶体结构、浸润性等进行了表征,揭示了CF-CNT多尺度增强体对PTFE基复合材料结晶度、表面能的影响机制,在不同往复摩擦学试验参数下测试了复合材料的摩擦系数与磨损率,对摩擦过程各个阶段进行细致分析并提出了相应的摩擦磨损机制,结果表明:稀土LaCl3表面处理方法相对传统方法具有不损伤纤维、无毒害的工艺优势;多尺度增强PTFE基复合材料磨损率降低了75.3%,优于同类研究;CF-CNT多尺度增强复合材料较小的表面能降低了起始摩擦系数;多尺度结构及La(III)提高了CF-CNT增强体与PTFE基体的界面结合性能,使材料在摩擦过程中不易产生大块硬质磨粒,并形成强度与稳定性较高的转移膜;复合材料摩擦学行为受往复频率及载荷影响显著,而且在高往复频率及低载荷下磨损率较低。本研究采用稀土LaCl3表面处理方法合成CF-CNT多尺度增强体并将其用于提高聚四氟乙烯复合材料摩擦学性能,所得结论为高性能树脂基复合材料的设计提供了参考。Abstract: To avoid the fibre damage and serious pollution caused by the traditional chemical methods, this study synthesized the carbon fibre (CF)-carbon nanotube (CNT) micro-nano multiscale reinforcer by rare-earth LaCl3 surface treatment method, and then prepared CF-CNT multiscale reinforced polytetrafluoroethylene (PTFE) composites via sintering process. The morphology and surface microcrystalline structure of the reinforcer, and the hardness, crystal structure and wettability of the composite were characterized, and the influence mechanism of the CF-CNT multiscale reinforcer on the crystallinity and surface energy of the PTFE composite was revealed. The coefficient of friction and wear rate of the composites were tested under different reciprocating tribological test parameters, every stage of the friction process was thoroughly discussed with the proposition of corresponding friction and wear mechanism. These results demonstrate that: the avoidance of fibre damage and toxic raw materials distinguishes the proposed CF-CNT reinforcer synthesis method from the traditional methods. The lower surface energy of CF-CNT reinforced composite decreases its initial friction coefficient. The wear rate of the CF-CNT reinforced composite is reduced by 75.3%, which is superior to the counterpart in similar studies. The multiscale structure and La(III) on CF-CNT improve the interface bonding performance of the CF-CNT reinforced composites, prevent the generation of large and hard wear debris during the surface yielding process as well as promoting the formation of high strength and stable transfer film. The tribological behaviors of the CF-CNT reinforced composites is sensitive to the reciprocating frequency and load, the higher frequency and lower load favour the lower wear rate. This study synthesized CF-CNT multiscale reinforcer via rare-earth LaCl3 surface treatment method to enhance the tribological properties of PTFE composite, the obtained research conclusions are instructive for the design of high-performance polymer composite.

-

Key words:

- LaCl3 /

- carbon fibre /

- carbon nanotube /

- polytetrafluoroethylene /

- reciprocating tribological test

-

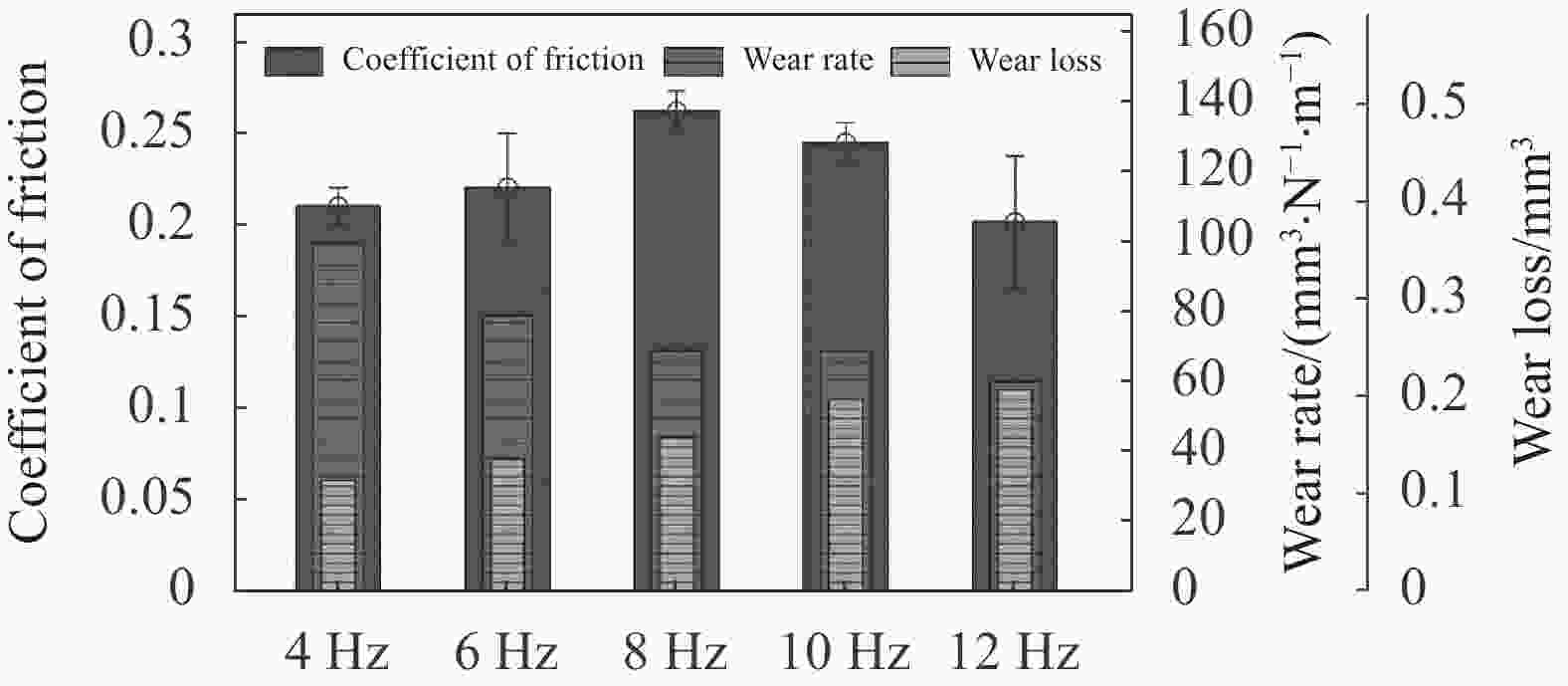

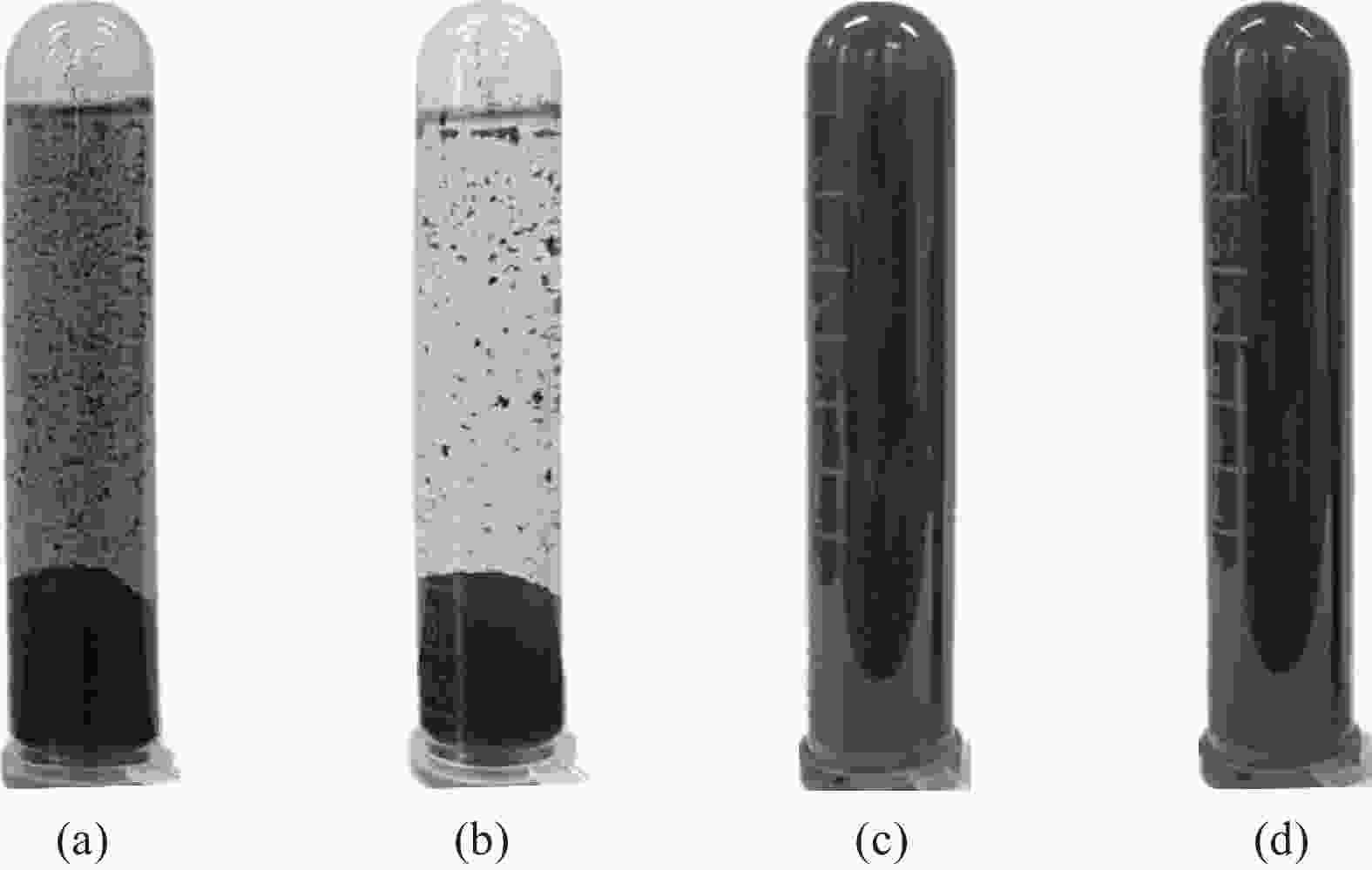

图 1 超声30 min所得浓度为1.0 g/L的分散系静置不同时刻的沉降结果对比图:碳纳米管(CNT)-乙醇分散系静置1 h (a)及24 h (b),RCNT-乙醇分散系静置1 h (c)及24 h (d)

Figure 1. Comparison of the sedimentation results of the dispersion system with a concentration of 1.0 g/L obtained by ultrasonicating for 30 min at different times: Carbon nanotube (CNT)-ethanol dispersion system kept still for 1 h (a) and 24 h (b), RCNT-ethanol dispersion system kept still for 1 h (c) and 24 h (d)

表 1 不同复合材料的硬度

Table 1. Hardness of different composites

Sample Hardness (Shore D) PTFE 57.0±2.9 CF/PTFE 61.7±1.5 RCF/PTFE 62.3±0.6 CF-CNT/PTFE 61.3±1.4 RCF-RCNT/PTFE 62.7±0.2 表 2 不同复合材料的接触角

Table 2. Contact angle of different composites

Sample Contact angle/(°) Water Diiodomethane PTFE 109.0±4.4 78.1±5.9 CF/PTFE 120.8±0.5 76.4±1.8 RCF/PTFE 118.4±2.9 79.0±1.3 CF-CNT/PTFE 119.1±2.5 75.8±2.1 RCF-RCNT/PTFE 110.2±4.4 78.4±0.6 表 3 所用液相的表面能

Table 3. Surface tension of the used test liquid

Wetting

liquidsSurface

tension

$ {\gamma }_{l} $/(mJ·m−2)Dispersion component

$ {\gamma }_{l}^{d} $/(mJ·m−2)Polar

component

$ {\gamma }_{l}^{p} $/(mJ·m−2)Water 72.8 21.8 51.0 Diiodomethane 50.8 48.5 2.3 表 4 相关研究中PTFE基复合材料摩擦学性能对比

Table 4. Tribological performance comparison of PTFE based composites in similar studies

Ref. Composites Type of friction Test conditions Wear rate

/

(×10−6 mm3·N−1·m−1)Decrement of

wear rate/%[41] PTFE Reciprocating sliding Counterface: φ=10 mm steel ball,

load: 10 N, frequency: 10 Hz304.8 −48.1 30vol.% h-BN/AO/PTFE 158.2 [42] PTFE/AP Reciprocating sliding Counterface: φ=9 mm Si3N4 ball,

load: 10 N, frequency: 1 Hz3.2 −44.1 6wt.% modified CF/PTFE/AP 1.79 [43] PTFE Reciprocating sliding Counterface: φ=5 mm Si3N4 ball,

load: 3 N, frequency: 2 Hz2.5 −44.0 5wt.% CF/5wt.%BP/PTFE 1.4 [2] PTFE Continuous sliding Counterface: φ=6 mm steel ball,

load: 10 N,

rotational speed: 200 r/min390 −29.7 20wt.%CF/PTFE 274 [1] PTFE Reciprocating sliding Counterface: 5×5×25 mm steel pin,

load: 50 N, frequency: 2 Hz0.21 — 15wt.% AF/PTFE 0.23 +9.5 15wt.% CF/PTFE 0.24 +14.3 15wt.% GF/PTFE 0.18 −14.3 0.5wt.% BF/PTFE 0.15 −28.6 0.5wt.% BF+

10wt.%MoS2/PTFE0.17 −19.1 [20] PI Reciprocating sliding Counterface: φ=4 mm steel ball,

load: 4.5 N, velocity: 0.083 m/s6.44 −72.2 5wt.% CF-CNT reinforcer/PI 1.79 This study PTFE Reciprocating sliding Counterface: φ=6 mm steel ball, load: 16 N, frequency: 6 Hz 321.6 −75.4 5wt.% RCF-RCNT reinforcer/PTFE 79.0 Notes: h-BN—hexagonal boron nitride; AO—alumina particles; AP—aluminum dihydrogen phosphate; BP—black phosphorus; AF—aramid fiber; GF—glass fiber; BF—basalt fiber; PI—polyimide. -

[1] KUMAR R, MALAVAL B, ANTONOV M, et al. Performance of polyimide and PTFE based composites under sliding, erosive and high stress abrasive conditions[J]. Tribology International,2020,147:106282. doi: 10.1016/j.triboint.2020.106282 [2] WU H, ZHU L, YUE W, et al. Wear-resistant and hydrophobic characteristics of PTFE/CF composite coatings[J]. Progress in Organic Coatings,2019,128:90-98. doi: 10.1016/j.porgcoat.2018.12.013 [3] LIU P, HUANG T, LU R, et al. Tribological properties of modified carbon fabric/polytetrafluoroethylene composites[J]. Wear,2012,289:17-25. doi: 10.1016/j.wear.2012.04.021 [4] ZAKARIA M R, MD AKIL H, ABDUL KUDUS M H, et al. Hybrid carbon fiber-carbon nanotubes reinforced polymer composites: A review[J]. Composites Part B-Engineering,2019,176:107313. doi: 10.1016/j.compositesb.2019.107313 [5] KARGER-KOCSIS J, MAHMOOD H, PEGORETTI A. All-carbon multi-scale and hierarchical fibers and related structural composites: A review[J]. Composites Science and Technology,2020,186:107932. doi: 10.1016/j.compscitech.2019.107932 [6] CHEN Q, PENG Q, ZHAO X, et al. Grafting carbon nanotubes densely on carbon fibers by poly(propylene imine) for interfacial enhancement of carbon fiber composites[J]. Carbon,2020,158:704-710. doi: 10.1016/j.carbon.2019.11.043 [7] ZHANG R L, WANG C G, LIU L, et al. Polyhedral oligomeric silsesquioxanes/carbon nanotube/carbon fiber multiscale composite: Influence of a novel hierarchical reinforcement on the interfacial properties[J]. Applied Surface Science,2015,353:224-231. doi: 10.1016/j.apsusc.2015.06.156 [8] CONTE M, IGARTUA A. Study of PTFE composites tribological behavior[J]. Wear,2012,296(1):568-574. [9] GATEMAN S M, ALIDOKHT S A, MENA-MORCILLO E, et al. Wear resistant solid lubricating coatings via compression molding and thermal spraying technologies[J]. Surface and Coatings Technology,2021,426:127790. doi: 10.1016/j.surfcoat.2021.127790 [10] WANG Y, YAN F. Tribological properties of transfer films of PTFE-based composites[J]. Wear,2006,261(11):1359-1366. [11] JOHANSSON P, MARKLUND P, BJÖRLING M, et al. Effect of humidity and counterface material on the friction and wear of carbon fiber reinforced PTFE composites[J]. Tribology International,2021,157:106869. doi: 10.1016/j.triboint.2021.106869 [12] AMENTA F, BOLELLI G, PEDRAZZI S, et al. Sliding wear behaviour of fibre-reinforced PTFE composites against coated and uncoated steel[J]. Wear,2021,486-487:204097. doi: 10.1016/j.wear.2021.204097 [13] SAWAE Y, MORITA T, TAKEDA K, et al. Friction and wear of PTFE composites with different filler in high purity hydrogen gas[J]. Tribology International,2021,157:106884. doi: 10.1016/j.triboint.2021.106884 [14] TANG H, LI W, ZHOU H, et al. One-pot synthesis of carbon fiber/carbon nanotube hybrid using lanthanum (III) chloride for tensile property enhancement of epoxy composites[J]. Applied Surface Science,2022,571:151319. doi: 10.1016/j.apsusc.2021.151319 [15] JIANG M R, ZHOU H, CHENG X H. Effect of rare earth surface modification of carbon nanotubes on enhancement of interfacial bonding of carbon nanotubes reinforced epoxy matrix composites[J]. Journal of Materials Science,2019,54(14):10235-10248. doi: 10.1007/s10853-019-03631-4 [16] WANG L, LIU R, LI X, et al. Tailoring electrochemically active sites in carbon fiber by edge oxygen functionalized strategy for high performance yarn energy storage[J]. Journal of Power Sources,2021,491:229579. doi: 10.1016/j.jpowsour.2021.229579 [17] JAIN V, BIESINGER M C, LINFORD M R. The Gaussian-Lorentzian Sum, Product, and Convolution (Voigt) functions in the context of peak fitting X-ray photoelectron spectroscopy (XPS) narrow scans[J]. Applied Surface Science,2018,447:548-553. doi: 10.1016/j.apsusc.2018.03.190 [18] FENG P, SONG G, LI X, et al. Effects of different “rigid-flexible” structures of carbon fibers surface on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites[J]. Journal of Colloid and Interface Science,2021,583:13-23. doi: 10.1016/j.jcis.2020.09.005 [19] WEN Z, XU C, QIAN X, et al. A two-step carbon fiber surface treatment and its effect on the interfacial properties of CF/EP composites: The electrochemical oxidation followed by grafting of silane coupling agent[J]. Applied Surface Science,2019,486:546-554. doi: 10.1016/j.apsusc.2019.04.248 [20] CHEN B, LI X, LI X, et al. Friction and wear properties of polyimide-based composites with a multiscale carbon fiber-carbon nanotube hybrid[J]. Tribology Letters,2017,65(3):111. doi: 10.1007/s11249-017-0891-z [21] LU Y, WANG J, WANG L, et al. Construction of 3D carbon fiber/carbon nanotube/silicone rubber nanocomposites for stretchable conductors through interface host-guest dendrimers[J]. Composites Science and Technology,2021,205:108692. doi: 10.1016/j.compscitech.2021.108692 [22] ALROBEI H, PRASHANTH M K, MANJUNATHA C R, et al. Adsorption of anionic dye on eco-friendly synthesised reduced graphene oxide anchored with lanthanum aluminate: Isotherms, kinetics and statistical error analysis[J]. Ceramics International, 2021, 47(7, Part B): 10322-10331. [23] QIN J, WANG C, YAO Z, et al. Mechanical property deterioration and defect repair factors of carbon fibers during the continuous growth of carbon nanotubes by chemical vapor deposition[J]. Ceramics International,2021,47(13):19213-19219. doi: 10.1016/j.ceramint.2021.03.269 [24] ISLAM M S, DENG Y, TONG L, et al. Grafting carbon nanotubes directly onto carbon fibers for superior mechanical stability: Towards next generation aerospace composites and energy storage applications[J]. Carbon,2016,96:701-710. doi: 10.1016/j.carbon.2015.10.002 [25] CHAI L, JIANG H, ZHANG B, et al. Influence of the gamma irradiation dose on tribological property of polytetrafluoroethylene[J]. Tribology International,2020,144:106094. doi: 10.1016/j.triboint.2019.106094 [26] FENG B, FANG X, WANG H, et al. The Effect of Crystallinity on Compressive Properties of Al-PTFE[J]. Polymers,2016,8(10):356. doi: 10.3390/polym8100356 [27] ZHANG Y, KOU K, ZHANG S, et al. Effect of fiber diameter on thermal properties of short-glass-fiber-reinforced PTFE-based composites[J]. Journal of Materials Science-Materials in Electronics,2020,31(13):10715-10723. doi: 10.1007/s10854-020-03621-2 [28] ZHANG X, JIANG X, QIN W, et al. Effect of the lanthanum and cerium phenylphosphonates on the crystallization and mechanical properties of isotactic polypropylene[J]. Journal of Polymer Research,2021,28(4):124. doi: 10.1007/s10965-021-02486-1 [29] MAO X, DENG Y, LIN J, et al. Effects of rare earth samarium oxide on the properties of polypropylene-graft-cardanol grafted by reactive extrusion[J]. Journal of Applied Polymer Science,2014,131(21):41012. [30] SUH J, BAE D. Mechanical properties of polytetrafluoroethylene composites reinforced with graphene nanoplatelets by solid-state processing[J]. Composites Part B-Engineering,2016,95:317-323. doi: 10.1016/j.compositesb.2016.03.082 [31] OWENS D K, WENDT R C. Estimation of the surface free energy of polymers[J]. Journal of Applied Polymer Science,1969,13(8):1741-1747. doi: 10.1002/app.1969.070130815 [32] KAELBLE D H. Dispersion-Polar Surface Tension Properties of Organic Solids[J]. Journal of Adhesion,1970,2(2):66-81. doi: 10.1080/0021846708544582 [33] FOWKES F M. Determination of interfacial tensions, contact angles, and dispersion forces in surfaces by assuming additivity of intermolecular interactions in surfaces[J]. Journal of Physical Chemistry,1962,66(2):382. doi: 10.1021/j100808a524 [34] SHIRAKI Y, YOKOYAMA H. Novel hydrophobic and oleophobic surfaces using polyurethane with hydrogenated polyisoprene soft segment[J]. Materials Today Communications,2020,24:101243. doi: 10.1016/j.mtcomm.2020.101243 [35] UNTERWEGER C, DUCHOSLAV J, STIFTER D, et al. Characterization of carbon fiber surfaces and their impact on the mechanical properties of short carbon fiber reinforced polypropylene composites[J]. Composites Science and Technology,2015,108:41-47. doi: 10.1016/j.compscitech.2015.01.004 [36] WU Q, ZHAO R, XI T, et al. Comparative study on effects of epoxy sizing involving ZrO2 and GO on interfacial shear strength of carbon fiber/epoxy composites through one and two steps dipping routes[J]. Composites Part A-Applied Science and Manufacturing,2020,134:105909. doi: 10.1016/j.compositesa.2020.105909 [37] SINGH N, SINHA S K. Tribological performances of hybrid composites of Epoxy, UHMWPE and MoS2 with in situ liquid lubrication against steel and itself[J]. Wear,2021,486-487:204072. doi: 10.1016/j.wear.2021.204072 [38] MINN M, SINHA S K. The frictional behavior of UHMWPE films with different surface energies at low normal loads[J]. Wear,2010,268(7):1030-1036. [39] BRADLEY R S. LXXIX. The cohesive force between solid surfaces and the surface energy of solids[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science,1932,13(86):853-862. doi: 10.1080/14786449209461990 [40] TABOR D. Surface forces and surface interactions[J]. Journal of Colloid and Interface Science,1977,58(1):2-13. doi: 10.1016/0021-9797(77)90366-6 [41] CHEN H, LI C, YAO Q, et al. Enhanced thermal conductivity and wear resistance of polytetrafluoroethylene via incorporating hexagonal boron nitride and alumina particles[J]. Journal of Applied Polymer Science,2022,139(3):51497. doi: 10.1002/app.51497 [42] 蒋国强, 郭永信, 刘雅玄, 等. 改性碳纤维的制备及其增强PTFE复合涂层摩擦学性能[J]. 中国表面工程, 2020, 33(5):90-98. doi: 10.11933/j.issn.1007-9289.20200718001JIANG G, GUO Y, LIU Y, et al. Preparation of Modified Carbon Fiber and Its Influence on Tribological Properties of PTFE Composite Coating[J]. China Surface Engineering,2020,33(5):90-98(in Chinese). doi: 10.11933/j.issn.1007-9289.20200718001 [43] LV Y, WANG W, XIE G, et al. Self-Lubricating PTFE-Based Composites with Black Phosphorus Nanosheets[J]. Tribology Letters,2018,66(2):61. doi: 10.1007/s11249-018-1010-5 [44] YANG Y, WANG H, REN J, et al. Multi-environment adaptability of self-lubricating core/shell PTFE@PR composite: Tribological characteristics and transfer mechanism[J]. Tribology International,2021,154:106718. doi: 10.1016/j.triboint.2020.106718 [45] CHEN S, WEI L, CHENG B, et al. Dry sliding tribological properties of PI/UHMWPE blends for high speed application[J]. Tribology International,2020,146:106262. doi: 10.1016/j.triboint.2020.106262 [46] WANG H, QI X, ZHANG W, et al. Tribological properties of PTFE/Kevlar fabric composites under heavy loading[J]. Tribology International,2020,151:106507. doi: 10.1016/j.triboint.2020.106507 [47] ZHU M, MA J. Basalt fiber modified with lanthanum-ethylenediaminetetraacetic acid as potential reinforcement of cyanate matrix composites[J]. Applied Surface Science,2019,464:636-643. doi: 10.1016/j.apsusc.2018.09.129 [48] XIE T, SHI Y. Effects of LaF3/CeF3 on the friction transfer of PTFE-based composites[J]. Tribology International,2021,161:107069. doi: 10.1016/j.triboint.2021.107069 [49] ROBSHAW T, TUKRA S, HAMMOND D B, et al. Highly efficient fluoride extraction from simulant leachate of spent potlining via La-loaded chelating resin. An equilibrium study[J]. Journal of Hazardous Materials,2019,361:200-209. doi: 10.1016/j.jhazmat.2018.07.036 [50] MARTINEZ-VARGAS D R, RANGEL-MENDEZ J R, CHAZARO-RUIZ L F. Fluoride electrosorption by hybrid La(III)-activated carbon electrodes under the influence of the La(III) content and the polarization profile[J]. Journal of Environmental Chemical Engineering,2022,10(1):106926. doi: 10.1016/j.jece.2021.106926 [51] POPOV V L. Contact Mechanics and Friction: Physical Principles and Applications[J]. Berlin, Heidelberg:Springer,2017:391. -

点击查看大图

点击查看大图

计量

- 文章访问数: 1023

- HTML全文浏览量: 450

- 被引次数: 0

下载:

下载: