Piezoresistive effect of carbon fiber 3D angle-interlock woven composites under bending

-

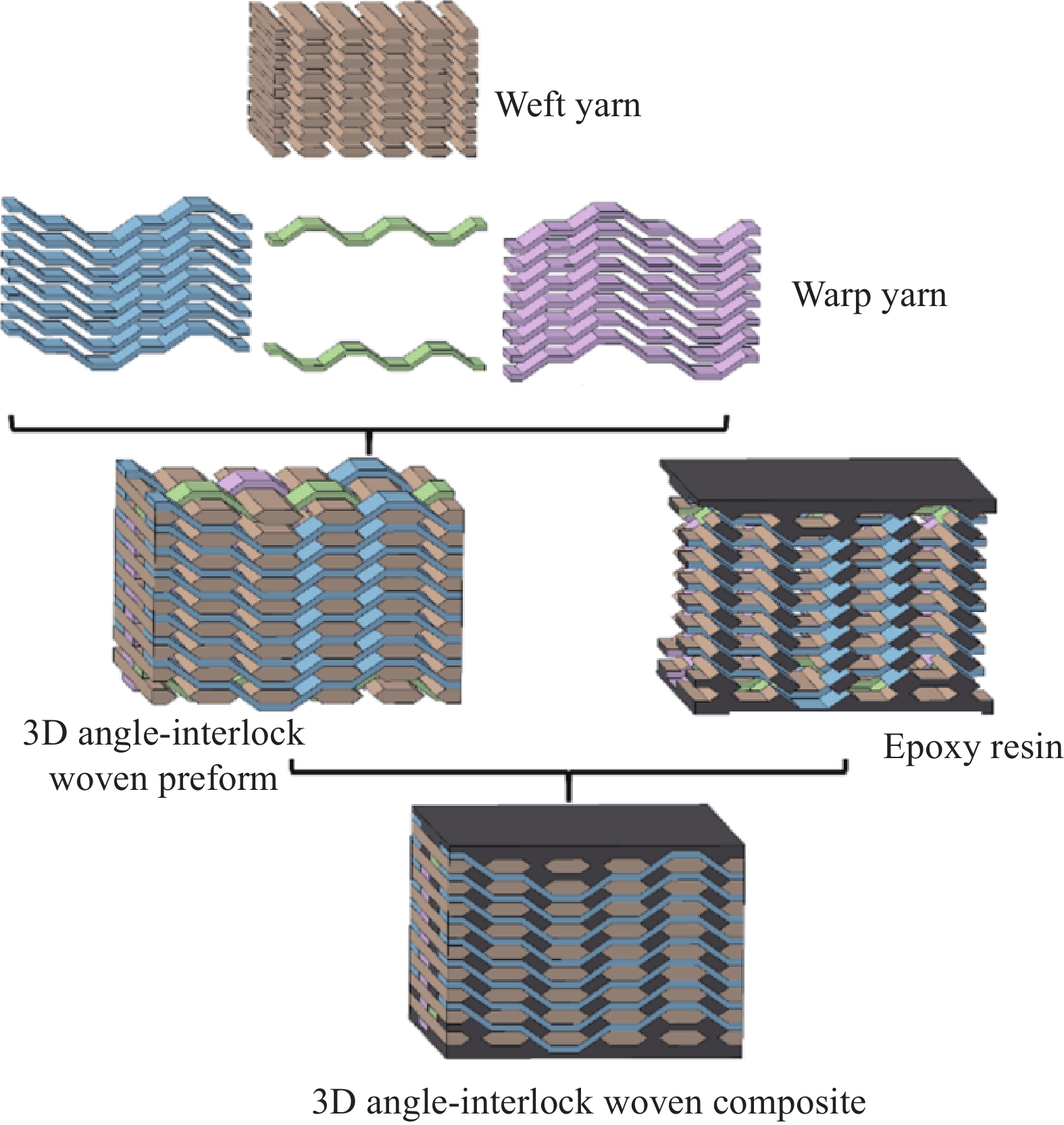

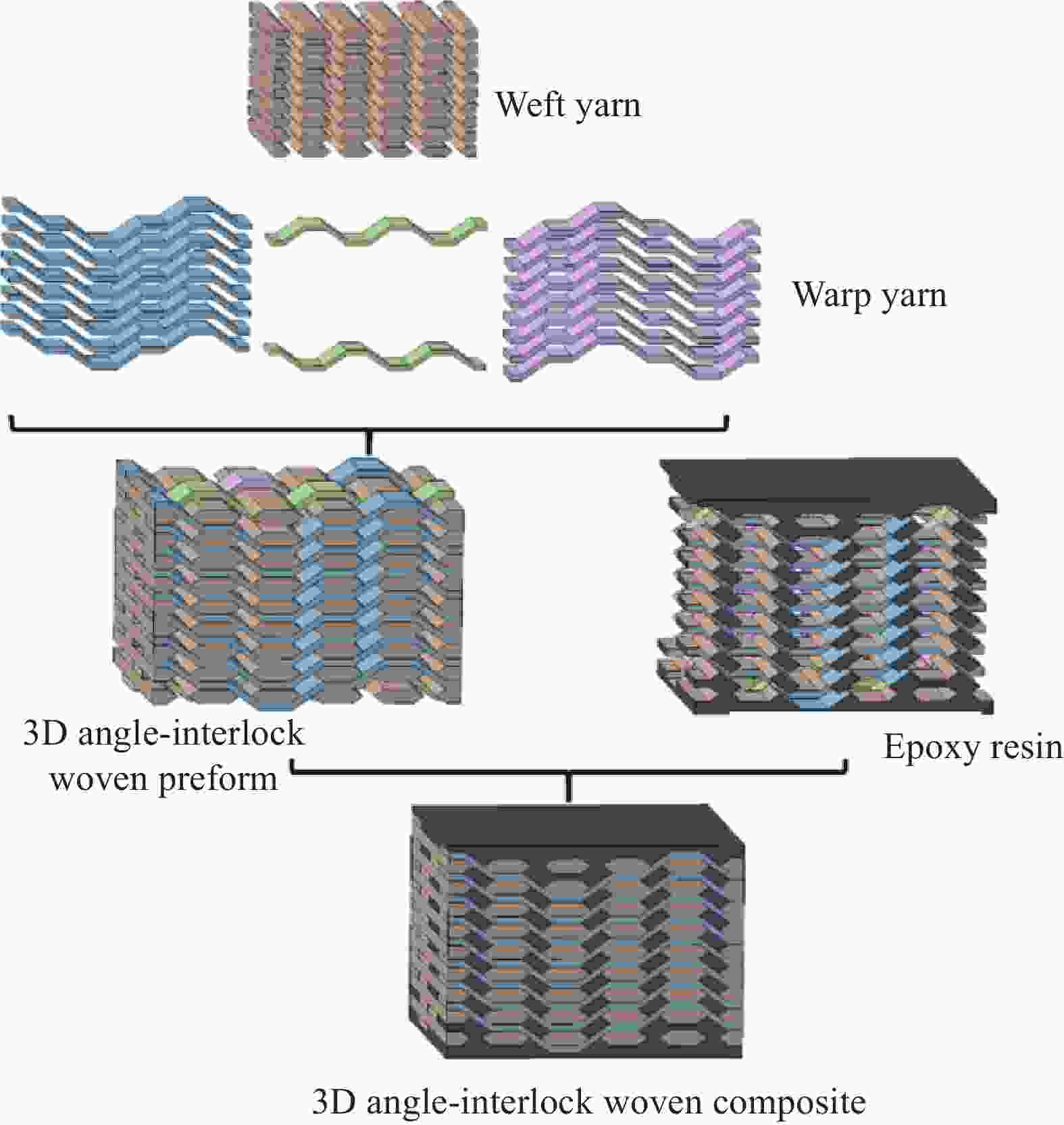

摘要: 电阻法在碳纤维复合材料结构健康监测(SHM)中具有巨大应用前景。本文研究了碳纤维三维角联锁机织复合材料经向和纬向试件在弯曲作用下力-电阻响应,探究电阻变化与复合材料结构损伤的相关性。试验结果表明:经向和纬向试件在弯曲作用下电阻变化与试件主要承载纱线损伤情况具有相关性。准静态三点弯曲加载下,试件电阻变化可以反映试件承载能力变化:在最大载荷点之前,试件电阻基本不变;主要承载纱线发生断裂损伤时,电阻增加。弯曲疲劳加载下,试件电阻变化可以反映试件承载能力退化情况:在弯曲疲劳加载前期,三维角联锁机织复合材料呈现负压阻效应;随着循环次数增加,基体裂纹、界面脱粘等不可逆损伤不断累积,电阻缓慢增大;在弯曲疲劳加载后期,主要承载纱线断裂,电阻显著增加;试件最终疲劳失效时,电阻急剧增加。Abstract: Electrical resistance method has great prospects in structural health monitoring (SHM) of carbon fiber reinforced composites. The piezoresistive effect of carbon fiber 3D angle-interlock woven composites in the warp direction and weft direction under bending was investigated to find the relationship between the resistance variation and structure damage. The experimental results show that the resistance variation of the warp and weft samples under bending corresponded with the damage of the main load-bearing yarns. The resistance variation of the composite reflected the change in the load-bearing ability of the composite under the quasi-static three-point bending test. The electrical resistance did not change before the maxim load, while that increased after the main load-bearing yarns occurred breakage. The resistance variation of the composite reflected the degradation in the load-bearing ability of the composite under the bending fatigue test. In the early stage of the bending fatigue test, the negative piezoresistive effect of the composites was observed. The electrical resistance increased slowly due to the accumulation of the irreversible damage including matrix cracks and interface debonding, while that increased significantly after the main load-bearing yarns were damaged. The electrical resistance increased dramatically when the samples occurred fatigue failure.

-

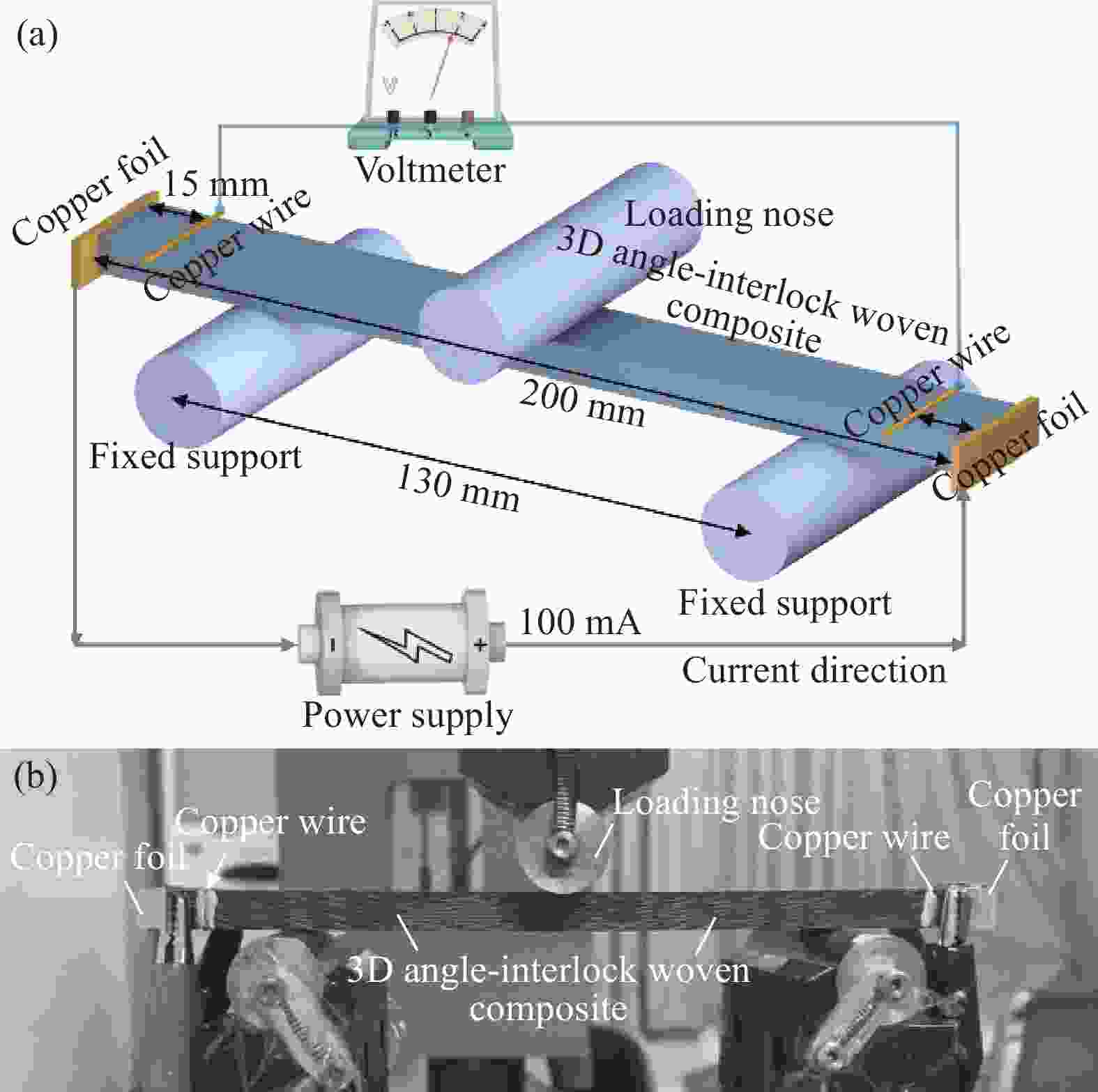

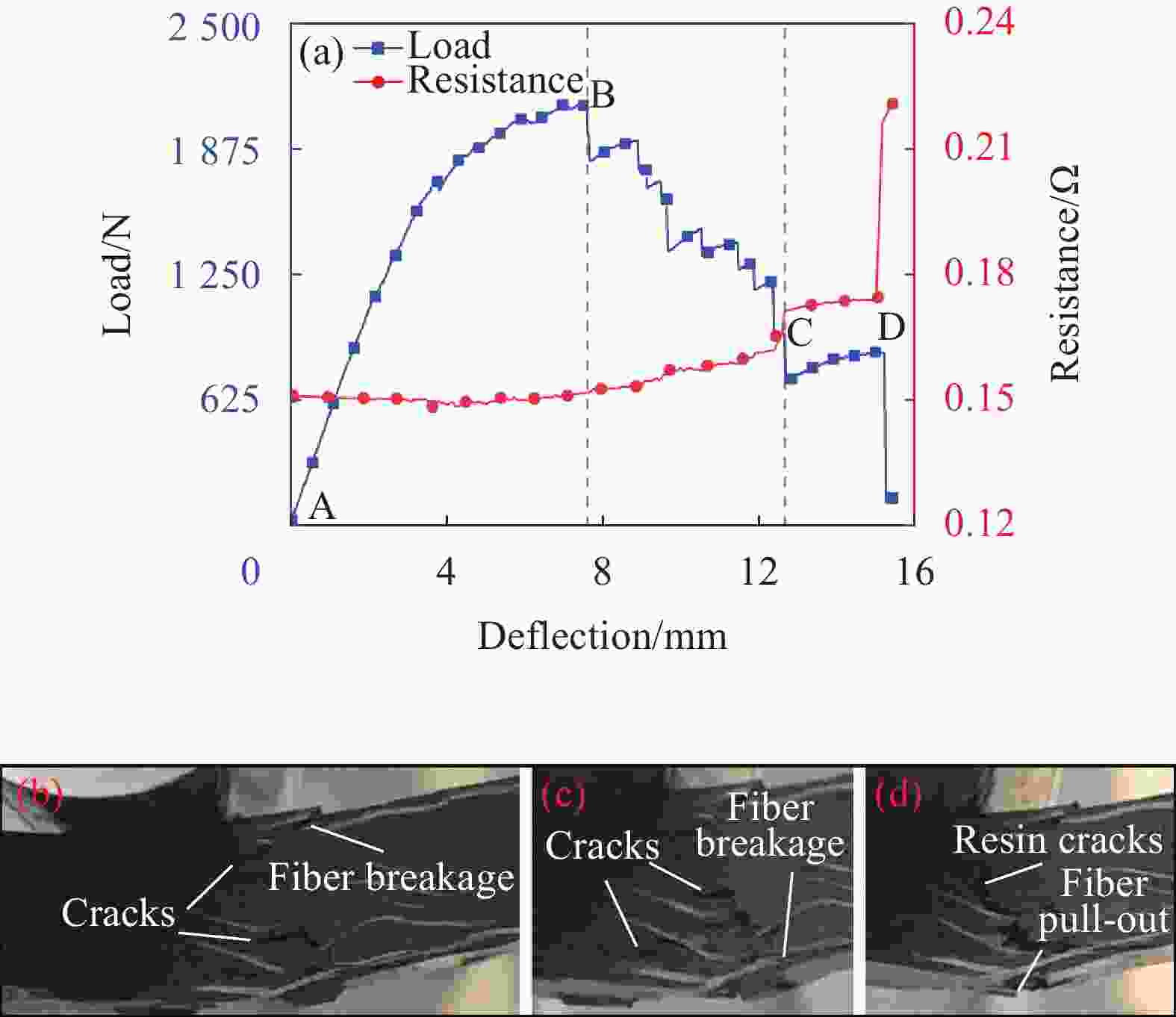

图 3 三维角联锁机织复合材料经向试件在准静态弯曲加载下试验结果:(a) 载荷-挠度曲线和电阻-挠度曲线;(b) B点试件表面破坏形态;(c) C点试件表面破坏形态;(d) D点试件表面破坏形态

Figure 3. Measurement results of warp-direction 3D angle-interlock woven composite specimen during quasi-static bending test: (a) Load-deflection curve and resistance-deflection curve; (b) Surface failure morphology at point B; (c) Surface failure morphology at point C; (d) Surface failure morphology at point D

图 4 三维角联锁机织复合材料纬向试件在准静态弯曲加载下试验结果:(a) 载荷-挠度曲线和电阻-挠度曲线;(b) B点试件表面破坏形态;(c) C点试件表面破坏形态;(d) D点试件表面破坏形态

Figure 4. Measurement results of weft-direction 3D angle-interlock woven composite specimen during quasi-static bending test: (a) Load-deflection curve and resistance-deflection curve; (b) Surface failure morphology at point B; (c) Surface failure morphology at point C; (d) Surface failure morphology at point D

图 5 三维角联锁机织复合材料经向试件在弯曲疲劳加载下试验结果:(a) 载荷-挠度曲线;(b) 挠度-循环次数曲线;(c) 第13900次加载后表面破坏形态;(d) 电阻-循环次数曲线;(e) 第6995次至第7005次加载力阻响应;(f) 第13940次至第13952次加载力阻响应

Figure 5. Measurement results of warp-direction 3D angle-interlock woven composite specimen during bending fatigue test: (a) Load-deflection curves; (b) Deflection-number of loading cycles curve; (c) Surface failure morphology after 13900th load; (d) Resistance-number of loading cycles curve; (e) Piezoresistive response from 6995th to 7005th load; (f) Piezoresistive response from 13940th to 13952nd load

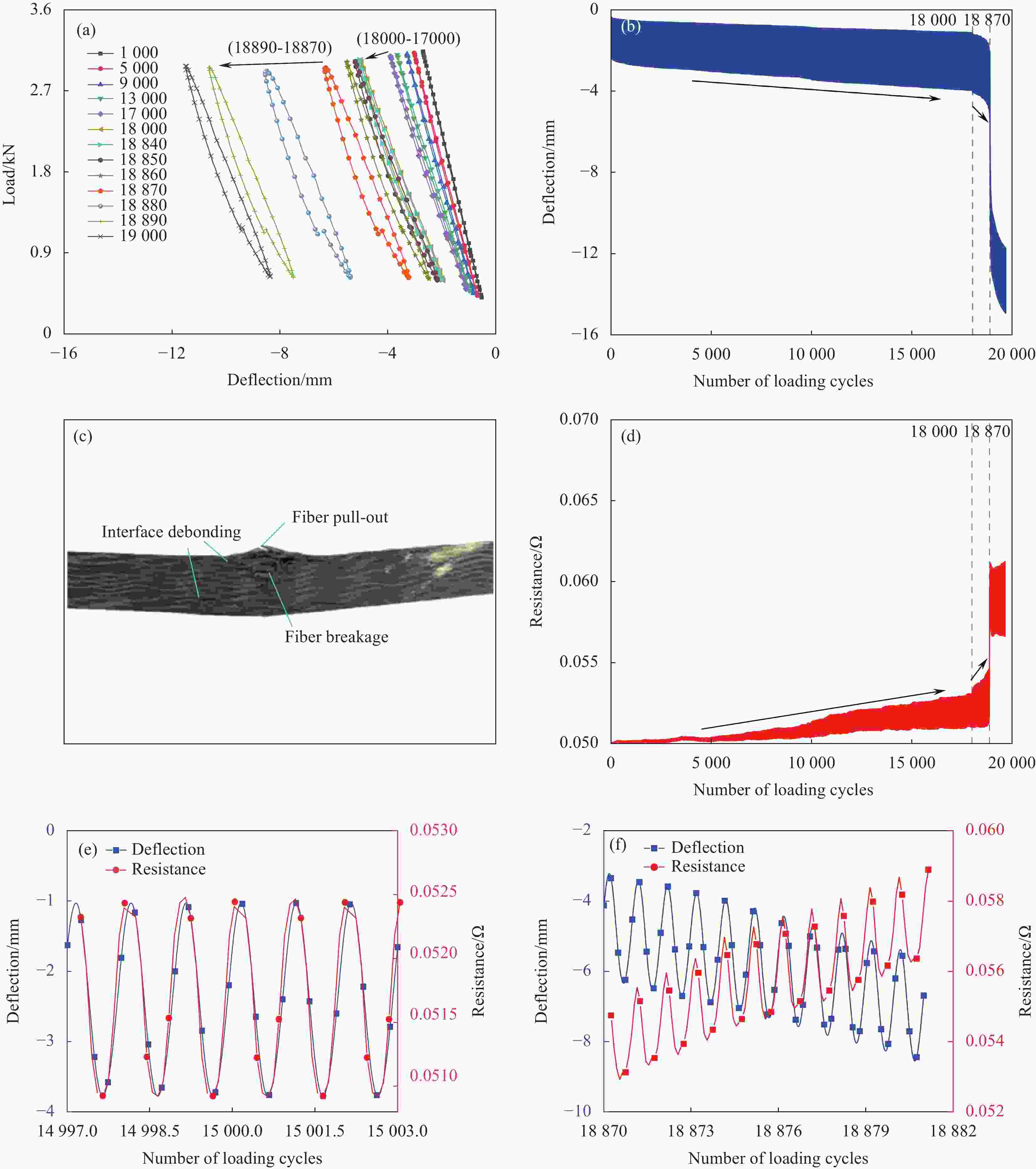

图 6 三维角联锁机织复合材料纬向试件在弯曲疲劳加载下试验结果:(a) 载荷-挠度曲线;(b) 挠度-循环次数曲线;(c) 第18870次加载后表面破坏形态;(d) 电阻-循环次数曲线;(e) 第14997次至第15003次加载力阻响应;(f) 第18870次至第18882次加载力阻响应

Figure 6. Measurement results of weft-direction 3D angle-interlock woven composite specimen during bending fatigue test: (a) Load-deflection curves; (b) Deflection-number of loading cycles curve; (c) Surface failure morphology after 18870th load; (d) Resistance-number of loading cycles curve; (e) Piezoresistive response from 14997th to 15003rd load; (f) Piezoresistive response from 18870th to 18882nd load

-

[1] 姚思远, 陈秀华. 三维机织复合材料在拉压循环载荷下的疲劳性能[J]. 复合材料学报, 2018, 35(10):2706-2714.YAO Siyuan, CHEN Xiuhua. Fatigue behaviors of 3D woven composites under tension-compression cyclic loading[J]. Acta Materiae Compositae Sinica,2018,35(10):2706-2714(in Chinese). [2] LIANG B, BOISSE P. A review of numerical analyses and experimental characterization methods for forming of textile reinforcements[J]. Chinese Journal of Aeronautics,2021,34(8):143-163. doi: 10.1016/j.cja.2020.09.027 [3] WIELHORSKI Y, MENDOZA A, RUBINO M, et al. Numerical modeling of 3D woven composite reinforcements: A review[J]. Composites Part A: Applied Science and Manufacturing,2022,154:106729. doi: 10.1016/j.compositesa.2021.106729 [4] 陈利, 焦伟, 王心淼, 等. 三维机织复合材料力学性能研究进展[J]. 材料工程, 2020, 48(8):62-72.CHEN Li, JIAO Wei, WANG Xinmiao, et al. Research progress on mechanical properties of 3 D woven composites[J]. Journal of Materials Engineering,2020,48(8):62-72(in Chinese). [5] ZHENG T, GUO L, HUANG J, et al. A novel mesoscopic progressive damage model for 3D angle-interlock woven composites[J]. Composites Science and Technology,2020,185:107894. doi: 10.1016/j.compscitech.2019.107894 [6] ROCHA H, SEMPRIMOSCHNIG C, NUNES J P. Sensors for process and structural health monitoring of aerospace composites: A review[J]. Engineering Structures,2021,237:112231. doi: 10.1016/j.engstruct.2021.112231 [7] RAMAKRISHNAN M, RAJAN G, SEMENOVA Y, et al. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials[J]. Sensors (Basel),2016,16(1):99. doi: 10.3390/s16010099 [8] ZHANG Z, HE M, LIU A, et al. Vibration-based assessment of delaminations in FRP composite plates[J]. Composites Part B: Engineering,2018,144:254-266. doi: 10.1016/j.compositesb.2018.03.003 [9] SZEBÉNYI G, BLÖSSL Y, HEGEDÜS G, et al. Fatigue monitoring of flax fibre reinforced epoxy composites using integrated fibre-optical FBG sensors[J]. Composites Science and Technology,2020,199:108317. doi: 10.1016/j.compscitech.2020.108317 [10] KAPPEL E, PRUSSAK R, WIEDEMANN J. On a simultaneous use of fiber-Bragg-gratings and strain-gages to determine the stress-free temperature Tsf during GLARE manufacturing[J]. Composite Structures,2019,227:111279. doi: 10.1016/j.compstruct.2019.111279 [11] 郑华升, 朱四荣, 李卓球. 碳纤维增强塑料(CFRP)力阻效应的研究评述[J]. 材料科学与工程学报, 2017, 35(6):1009-1013, 1021.ZHENG Huasheng, ZHU Sirong, LI Zhuoqiu. Research state of piezoresistivity of CFRP[J]. Journal of Materials Science and Engineering,2017,35(6):1009-1013, 1021(in Chinese). [12] FORINTOS N, SARKADI T, CZIGANY T. Electric resistance measurement–based structural health monitoring with multifunctional carbon fibers: Predicting, sensing, and measuring overload[J]. Composites Communications,2021,28:100913. doi: 10.1016/j.coco.2021.100913 [13] THOMAS A J, KIM J J, TALLMAN T N, et al. Damage detection in self-sensing composite tubes via electrical impedance tomography[J]. Composites Part B: Engineering,2019,177:107276. doi: 10.1016/j.compositesb.2019.107276 [14] SANNAMANI M, GAO J, CHEN W W, et al. Damage detection in non-planar carbon fiber-reinforced polymer laminates via electrical impedance tomography with surface-mounted electrodes and directional sensitivity matrices[J]. Composites Science and Technology,2022,224:109429. doi: 10.1016/j.compscitech.2022.109429 [15] OGI K, TAKAO Y. Characterization of piezoresistance behavior in a CFRP unidirectional laminate[J]. Composites Science and Technology,2005,65(2):231-239. doi: 10.1016/j.compscitech.2004.07.005 [16] TODOROKI A, OMAGARI K, SHIMAMURA Y, et al. Matrix crack detection of CFRP using electrical resistance change with integrated surface probes[J]. Composites Science and Technology,2006,66(11):1539-1545. [17] TODOROKI A, TANAKA M, SHIMAMURA Y. Measurement of orthotropic electric conductance of CFRP laminates and analysis of the effect on delamination monitoring with an electric resistance change method[J]. Composites Science and Technology,2002,62(5):619-628. doi: 10.1016/S0266-3538(02)00019-2 [18] SEVKAT E, LI J, LIAW B, et al. A statistical model of electrical resistance of carbon fiber reinforced composites under tensile loading[J]. Composites Science and Technology,2008,68(10):2214-2219. [19] 黄俊捷, 刘荣桂, 许兆辉, 等. 基于碳纤维材料力阻效应的传感器工程应用初探[J]. 玻璃钢/复合材料, 2017(9):46-51.HUANG Junjie, LIU Ronggui, XU Zhaohui, et al. Study on the engineering application of the sensor based on the piezo-resistance effect of CFRP[J]. Composites Science and Engineering,2017(9):46-51(in Chinese). [20] CHUNG D D L. A critical review of piezoresistivity and its application in electrical-resistance-based strain sensing[J]. Journal of Materials Science,2020,55(32):15367-15396. doi: 10.1007/s10853-020-05099-z [21] ABRY J C, BOCHARD S, CHATEAUMINOIS A, et al. In situ detection of damage in CFRP laminates by electrical resistance measurements[J]. Composites Science and Technology,1999,59(6):925-935. doi: 10.1016/S0266-3538(98)00132-8 [22] WEBER I, SCHWARTZ P. Monitoring bending fatigue in carbon-fibre/epoxy composite strands: A comparison between mechanical and resistance techniques[J]. Composites Science and Technology,2001,61(6):849-853. doi: 10.1016/S0266-3538(01)00028-8 [23] CHO J W, CHOI J S, YOON Y S. Electromechanical behavior of hybrid carbon/glass fiber composites with tension and bending[J]. Journal of Applied Polymer Science,2002,83(11):2447-2453. doi: 10.1002/app.10226 [24] XUE L Z, LI K Z, JIA Y, et al. Flexural fatigue behavior of 2D cross-ply carbon/carbon composites at room tempera-ture[J]. Materials Science and Engineering: A,2015,634:209-214. doi: 10.1016/j.msea.2015.03.029 [25] GADOMSKI J, PYRZANOWSKI P. Experimental investigation of fatigue destruction of CFRP using the electrical re-sistance change method[J]. Measurement,2016,87:236-245. doi: 10.1016/j.measurement.2016.03.036 [26] ROH H D, LEE S Y, JO E, et al. Deformation and interlaminar crack propagation sensing in carbon fiber composites using electrical resistance measurement[J]. Composite Structures,2019,216:142-150. doi: 10.1016/j.compstruct.2019.02.100 [27] ZHANG R, ZHANG L, FANG H, et al. Electromechanical-mode coupling model and failure prediction of CFRP under three-point bending[J]. Electronics, 2021, 10(16): 2007. [28] SALEH M N, YUDHANTO A, LUBINEAU G, et al. The effect of z-binding yarns on the electrical properties of 3D woven composites[J]. Composite Structures,2017,182:606-616. doi: 10.1016/j.compstruct.2017.09.081 [29] CHENG X, ZHOU H, WU Z, et al. Detection of bending direction and amplitude by electrical resistance measurement of axial carbon fibers in braided composite tube[J]. Textile Research Journal,2018,89(12):2500-2508. [30] CHENG X, ZHOU H, WU Z, et al. An investigation into self-sensing property of hat-shaped 3D orthogonal woven composite under bending test[J]. Journal of Reinforced Plastics and Composites,2018,38:149-166. [31] HAN C, HUANG S, SUN B, et al. Electrical resistance changes of 3D carbon fiber/epoxy woven composites under short beam shear loading along different orientations[J]. Composite Structures,2021,276:114549. doi: 10.1016/j.compstruct.2021.114549 [32] 国家市场监督管理总局. 聚合物基复合材料疲劳性能测试方法 第5部分: 弯曲疲劳: GB/T 35465.5—2020[S]. 北京: 中国标准出版社, 2020.State Administration for Market Regulation. Test methods for fatigue properties of polymer matrix composites materials—Part 5: Flexural fatigue: GB/T 35465.5—2020[S]. Beijing: China Press Standards, 2020(in Chinese). -

下载:

下载: