Influence of fused deposition modeling and annealing heat treatment on the fiber orientation of short carbon fiber reinforced nylon 6

-

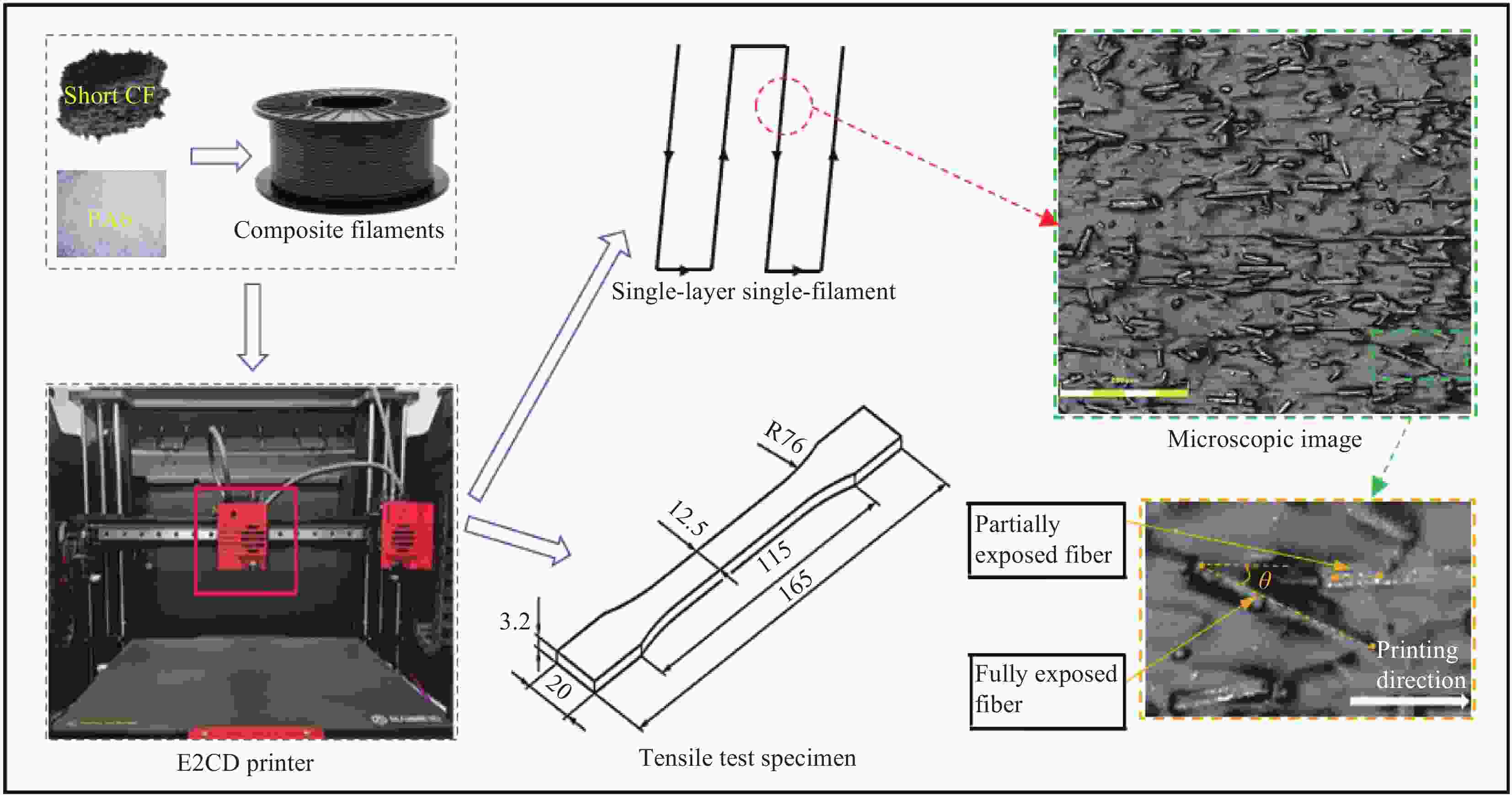

摘要: 探究了熔融沉积成型和退火热处理的工艺参数对于短切碳纤维增强尼龙6微观纤维取向的影响,以及不同碳纤维长径比的该种材料熔融沉积成型后在纤维取向上的差异。通过在单层-单丝试样的顶面进行显微观察,使用Image J软件测量平面纤维取向角,得到不同工艺参数下的平面纤维取向分布直方图,并采用正态曲线拟合以便对比分析。实验结果显示,随着打印速度的提高,取向与打印方向保持一致的纤维数量呈先上升后下降的趋势,在V=40 mm/s时获得峰值,标准差σ为11.14,频率峰值为0.42;同时,拉伸模量也呈此变化趋势,通过Pearson相关系数计算,发现两者呈强相关,增材工艺参数对拉伸模量的影响与纤维取向的变化密切相关。纤维取向一致性并非随着加入碳纤维长径比的增大而提高,而是与制件中的保留长径比相关。不同退火温度下,当退火温度介于玻璃转化温度和结晶温度之间相对于靠近两者,对于纤维取向的影响更为显著,且在150℃下获得标准差为6.39、频率峰值为0.54的最优效果。Abstract: The influence of process parameters in fused deposition modeling and annealing heat treatment on the microfiber orientation of short carbon fiber-reinforced nylon 6 was investigated in the study, as well as the differences in fiber orientation after fused deposition modeling for this material with varying carbon fiber slenderness ratio. Microscopic observations were conducted on single-layer-single-fiber samples, and Image J software was used to measure the planar fiber orientation angles. Histograms of planar fiber orientation under different process parameters were obtained and fitted with normal curves for comparative analysis. The experimental results indicate that with increasing printing speed, the number of fibers oriented in the printing direction first rises and then falls, reaching a peak at V=40 mm/s, with a standard deviation σ of 11.14 and a frequency peak of 0.42. Additionally, the tensile modulus follows a similar trend, and Pearson correlation analysis reveals a strong correlation between the two. Fiber orientation consistency does not improve with an increase in carbon fiber slenderness ratio, but is related to the retained slenderness ratio in the specimen. At different annealing temperatures, the impact on fiber orientation is more pronounced when the annealing temperature is between the glass transition temperature and the crystallization temperature, with the optimal effect achieved at 150℃ with a standard deviation of 6.39 and peak frequency of 0.54.

-

Key words:

- composites /

- additive manufacturing /

- planar fiber orientation /

- elastic modulus /

- process parameters

-

表 1 FDM工艺参数

Table 1. FDM process parameters

Parameters Value Parameters Value Infill Density 100% Layer height 0.2 mm Raster angle 0° Layer width 0.8 mm Nozzle temperature 300℃ Infill speed 20, 30, 40, 50,

60 mm/s表 2 CF270-PA6的DSC实验结果

Table 2. DSC experimental results of CF270-PA6

Materials Tg/℃ Tc/℃ Tm/℃ CF270-PA6 55 190 220 Notes:Tg represents the glass transition temperature; Tc represents the crystallization temperature; Tm represents the melting temperature. 表 3 退火实验布置

Table 3. The annealing experiment setup

Set Material Annealing

temperature/℃Annealing

time/h1,2,3,4,5 CF270-PA6 70,90,120,150,200 7 Re CF270-PA6 no no Notes:Re serves as the room temperature reference group without undergoing annealing treatment. -

[1] 黎宇航, 董齐, 邰清安, 等. 熔融沉积增材制造成形碳纤维复合材料的力学性能[J]. 塑性工程学报, 2017, 24(3): 225-230. doi: 10.3969/j.issn.1007-2012.2017.03.037LI Yuhang, DONG Qi, TAI Qingan, et al. Mechanical properties of carbon fiber composite in fused deposition modeling of additive manufacturing[J]. Journal of Plasticity Engineering, 2017, 24(3): 225-230(in Chinese). doi: 10.3969/j.issn.1007-2012.2017.03.037 [2] ZHANG W, COTTON C, SUN J, et al. Interfa-cial bonding strength of short carbon fi-ber/acrylonitrile-butadiene-styrene composites fabricated by fused deposition modeling[J]. Composites Part B: Engineering, 2018, 137: 51-59. doi: 10.1016/j.compositesb.2017.11.018 [3] NING F, CONG W, QIU J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B: Engineering, 2015, 80: 369-378. doi: 10.1016/j.compositesb.2015.06.013 [4] MAGRI A E, El Mabrouk K, VAUDREUIL S, et al. Mechanical properties of CF-reinforced PLA parts manufactured by fused deposition modeling[J]. Journal of Thermoplastic Composite Materials, 2019, 34(5): 581-595. [5] IVEY M, MELENKA G W, CAREY J P, et al. Characterizing short-fiber-reinforced composites produced using additive manufacturing[J]. Advanced Manufacturing: Polymer & Composites Science. 2017, 3(3): 81-91. [6] FERREIRA R T L, AMATTE I C, DUTRA T A, et al. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers[J]. Composites Part B: Engineering, 2017, 124: 88-100. doi: 10.1016/j.compositesb.2017.05.013 [7] CHACON J M, CAMINERO M Á, NUNEZ P J, et al. Effect of nozzle diameter on mechanical and geometric performance of 3D printed carbon fibre-reinforced compo-sites manufactured by fused filament fabrication[J]. Rapid Prototyping Journal, 2021, 27(4): 769-784. doi: 10.1108/RPJ-10-2020-0250 [8] NARANJO J, AHUETT H, ORTA P, et al. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing[J]. Additive Manufac-turing, 2019, 26: 227-241. doi: 10.1016/j.addma.2018.12.020 [9] NING F, CONG W, HU Y, et al. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties[J]. Journal of Composite Materials, 2017, 51(4): 451-462. doi: 10.1177/0021998316646169 [10] PACE F, STAMOPOULOS A G, ECKL M, et al. Analysis of the Manufacturing Porosity in Fused Filament Fabricated Onyx/Long Fiber Reinforced Composites Using X-Ray Computed Tomography[J]. Journal of Nondestructive Evaluation. 2023, 42(4). [11] FERREIRA I, MELO C, NETO R, et al. Study of the annealing influence on the mechanical performance of PA12 and PA12 fibre reinforced FFF printed specimens[J]. Rapid Prototyping Journal, 2020, 26(10): 1761-1770. doi: 10.1108/RPJ-10-2019-0278 [12] SUN B, MUBARAK S, ZHANG G, et al. Fused-Deposition Modeling 3D Printing of Short-Cut Carbon-Fiber-Reinforced PA6 Composites for Strengthening, Toughening, and Light Weighting[J]. Polymers, 2023, 15(18): 3722 doi: 10.3390/polym15183722 [13] LIAO G, LI Z, CHENG Y, et al. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling[J]. Materials & Design, 2018, 139: 283-292. [14] SPOERK M, SAVANDAIAH C, ARBEITER F, et al. Anisotropic properties of oriented short carbon fibre filled polypropylene parts fabricated by extrusion-based additive manufacturing[J]. Composites Part A: Applied Science and Manufacturing, 2018, 113: 95-104. doi: 10.1016/j.compositesa.2018.06.018 [15] PAPON E A, HAQUE A. Fracture toughness of additively manufactured carbon fiber reinforced compo-sites[J]. Additive Manufacturing, 2019, 26: 41-52. doi: 10.1016/j.addma.2018.12.010 [16] TEKINALP H L, KUNC V, VELEZ-GARCIA G M, et al. Highly oriented carbon fiber–polymer composites via additive manufacturing[J]. Composites Science and Technology. 204, 105: 144-150. [17] 管涛, 李元庆, 郭方亮, 等. 基于纤维取向分布图像处理技术的短纤维增强聚合物基复合材料力学性能预测方法[J]. 复合材料学报, 2024, 41.GUAN Tao, LI Yuanqing, GUO Fangliang, et al. A method for predicting the mechanical properties of short fiber rein-forced polymer composites based on fiber orientation distribution image processing technique[J]. Acta Materiae Compositae Sinica, 2024, 41 (in Chinese). [18] YANG D, ZHANG H, WU J, et al. Fibre flow and void formation in 3D printing of short-fibre reinforced thermoplastic composites: An experimental benchmark exercise[J]. Additive Manufacturing, 2021, 37: 101686. doi: 10.1016/j.addma.2020.101686 [19] YAN J, DEMIRCI E, GANESAN A, et al. Extrusion width critically affects fibre orientation in short fibre reinforced material extrusion additive manufacturing[J]. Additive Manufacturing, 2022, 49: 102496. doi: 10.1016/j.addma.2021.102496 [20] International A. Standard test method for tensile properties of plastics[M]. ASTM international, 2014. [21] HELLER B P, SMITH D E, JACK D A. Effects of extrudate swell and nozzle geometry on fiber orientation in Fused Filament Fabrication nozzle flow[J]. Additive Manufacturing, 2016, 12: 252-264. doi: 10.1016/j.addma.2016.06.005 [22] HELLER B P, SMITH D E, JACK D A. Planar deposition flow modeling of fiber filled composites in large area additive manufacturing[J]. Additive Manufacturing, 2019, 25: 227-238. doi: 10.1016/j.addma.2018.10.031 [23] GENG P, ZHAO J, WU W, et al. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament[J]. Journal of Manufacturing Processes, 2019, 37: 266-273. doi: 10.1016/j.jmapro.2018.11.023 [24] FERREIRA R T L, AMATTE I C, DUTRA T A, et al. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers[J]. Composites Part B: Engineering, 2017, 124: 88-100. doi: 10.1016/j.compositesb.2017.05.013 [25] 熊爱华, 柳和生, 黄兴元, 等. 纤维参数对纤维取向及塑件变形影响模拟研究[J]. 材料科学与工艺, 2012, 20(3): 132-138. doi: 10.11951/j.issn.1005-0299.20120326XIONG Aihua, LIU Hesheng, HUANG Xingyuan, at al. Simulated study on effect of fiber parameters on fiber orientation and injection-molded part's deflection[J]. Materials Science & Technology, 2012, 20(3): 132-138(in Chinese). doi: 10.11951/j.issn.1005-0299.20120326 [26] LIAO G, LI Z, CHENG Y, et al. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling[J]. Materials & Design, 2018, 139: 283-292. [27] El Magri A, El Mabrouk K, VAUDREUIL S, et al. Optimization of printing parameters for improvement of mechanical and thermal performances of 3D printed poly (ether ether ketone) parts[J]. Journal of Applied Polymer Science, 2020, 137(37): 49087. doi: 10.1002/app.49087 [28] WANG X, XU D, LIU H, et al. Effects of thermal residual stress on interfacial properties of polyphenylene sulphide/carbon fibre (PPS/CF) composite by microbond test[J]. Journal of materials science, 2016, 51: 334-343. doi: 10.1007/s10853-015-9251-2 [29] YAN X, IMAI Y, SHIMAMOTO D, et al. Relationship study between crystal structure and thermal/mechanical properties of polyamide 6 reinforced and unreinforced by carbon fiber from macro and local view[J]. Polymer, 2014, 55(23): 6186-6194. doi: 10.1016/j.polymer.2014.09.052 [30] LIU B, WANG X, LONG S, et al. Interfacial micromechanics of carbon fiber-reinforced polyphenylene sulfide composites[J]. Composite interfaces, 2014, 21(4): 359-369. doi: 10.1080/15685543.2014.878875 [31] LI H, WANG Y, ZHANG C, et al. Effects of thermal histories on interfacial properties of carbon fiber/polyamide 6 composites: Thickness, modulus, adhesion and shear strength[J]. Composites Part A: Applied Science and Manufacturing, 2016, 85: 31-39. doi: 10.1016/j.compositesa.2016.03.007 [32] 孙春燕, 畅同晨, 闫盼盼, 等. 残余应力对碳纤维填充聚合物注塑制品电阻率的影响[J]. 机械工程学报, 2014, 50(6): 81-86. doi: 10.3901/JME.2014.06.081SUN Chunyan, CHANG Tongchen, YAN Panpan, at al. The Influence of Residual Stress on the Electrical Resistivity of Carbon Fiber Reinforced Polymer Injection Molded Products[J]. Journal Of Mechanical Engineering, 2014, 50(6): 81-86(in Chinese). doi: 10.3901/JME.2014.06.081 [33] BHANDARI S, LOPEZ-ANIDO R A, GARDNER D J. Enhancing the interlayer tensile strength of 3D printed short car-bon fiber reinforced PETG and PLA composites via annealing[J]. Additive Manufacturing, 2019, 30: 100922. doi: 10.1016/j.addma.2019.100922 -

点击查看大图

点击查看大图

计量

- 文章访问数: 28

- HTML全文浏览量: 25

- 被引次数: 0

下载:

下载: