Multiscale burst failure of type IV hydrogen storage vessels considering the influence of temperature

-

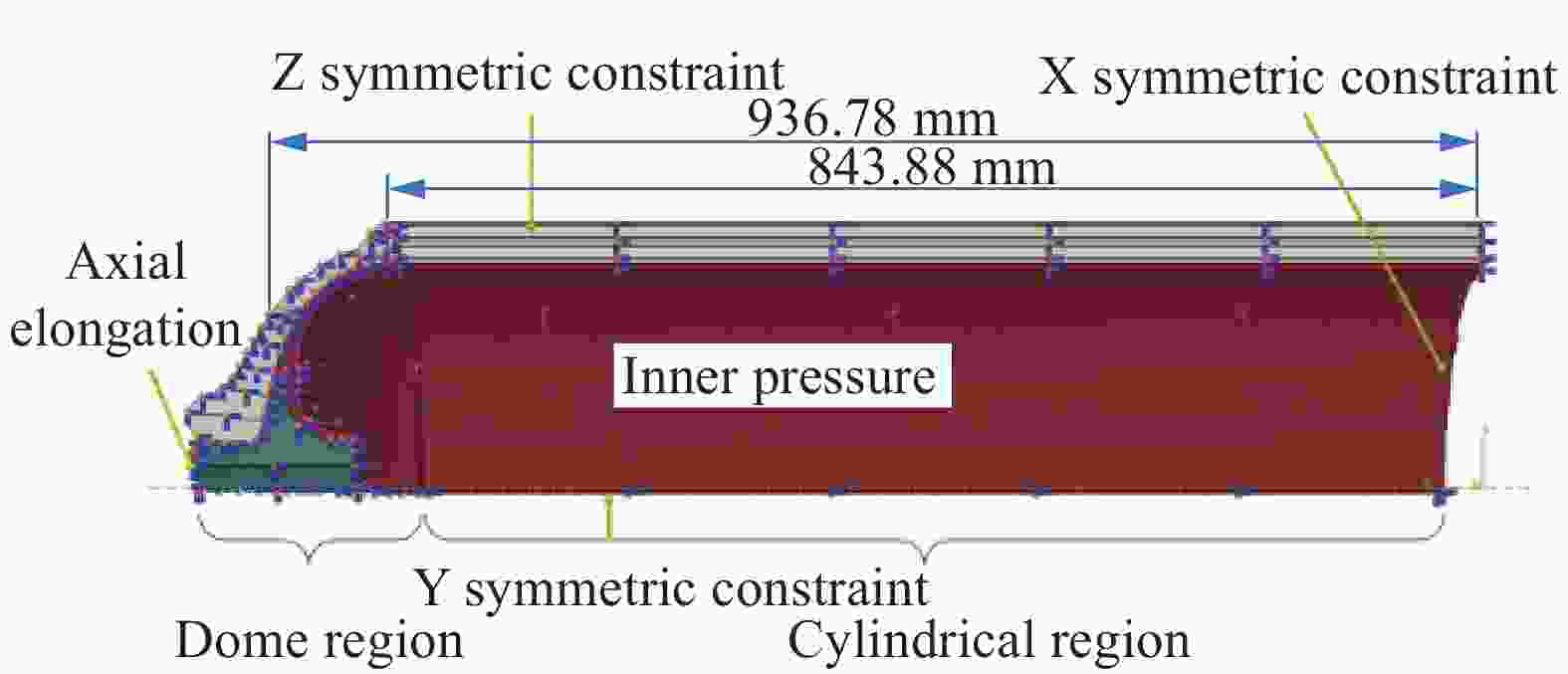

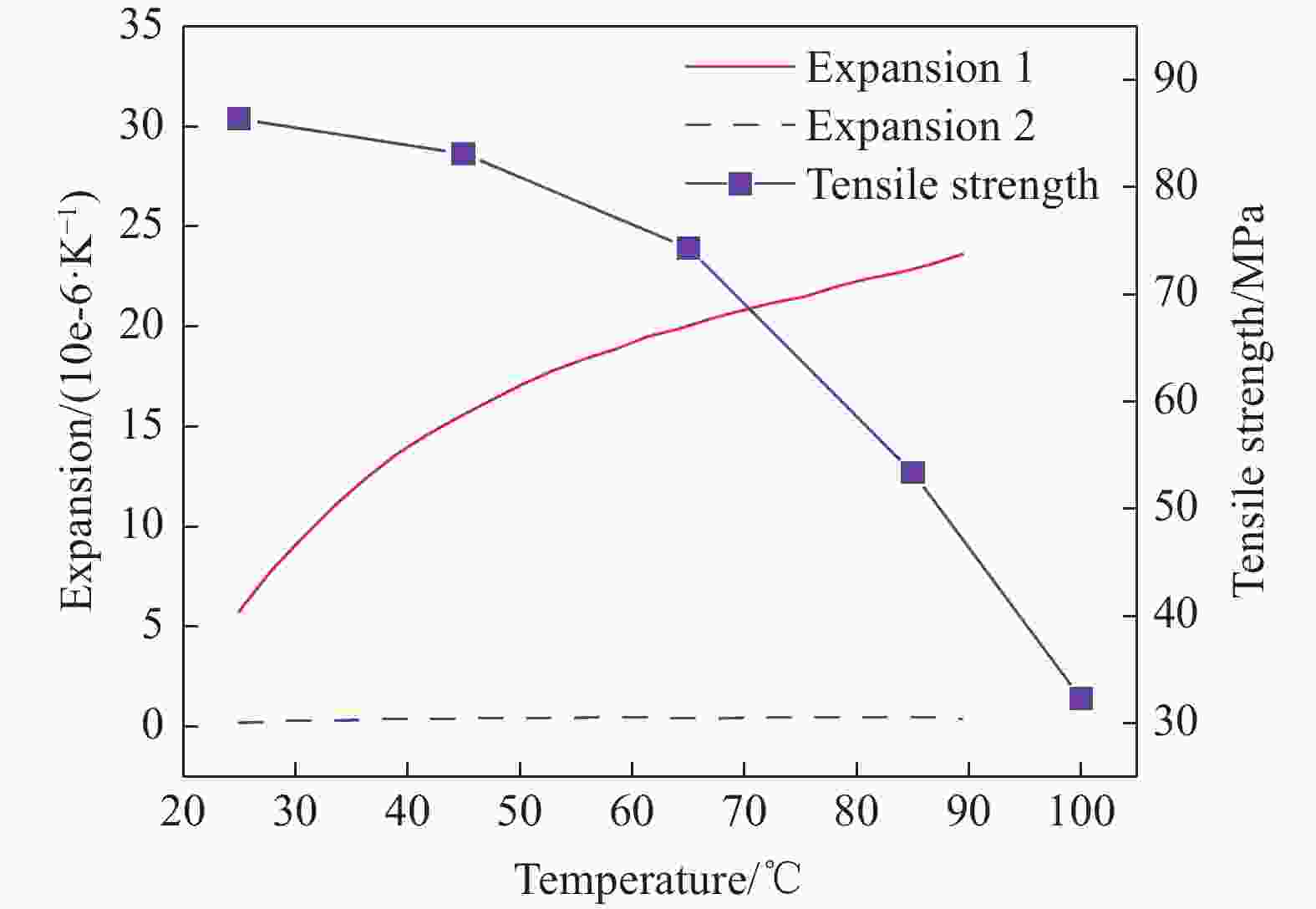

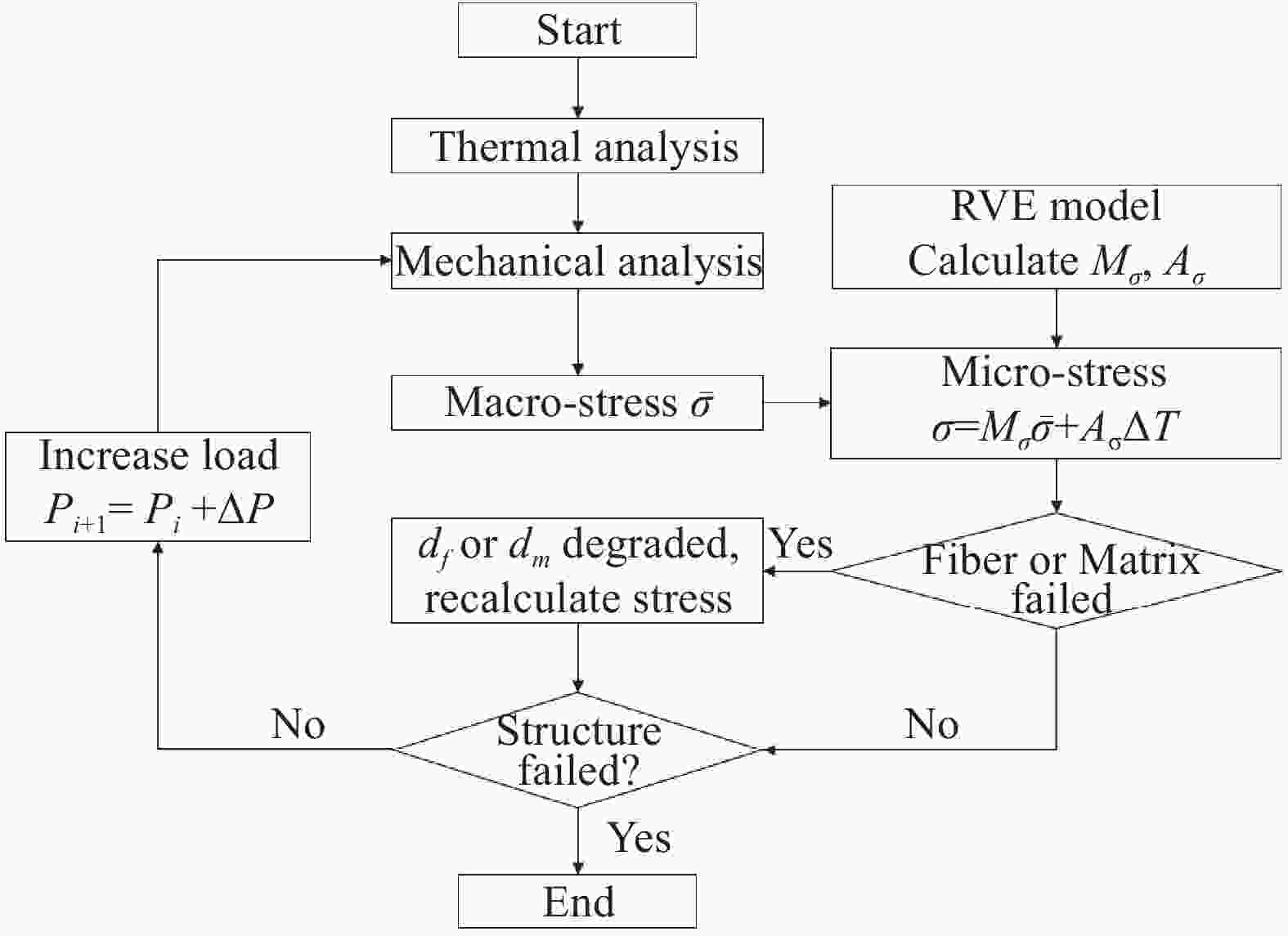

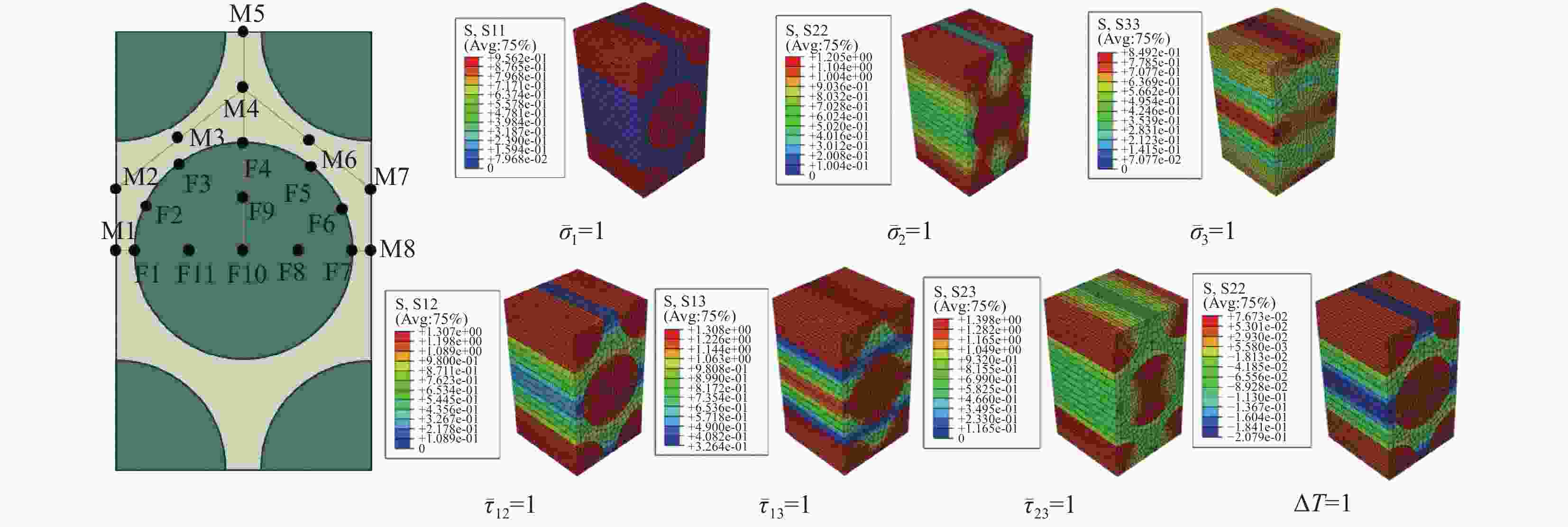

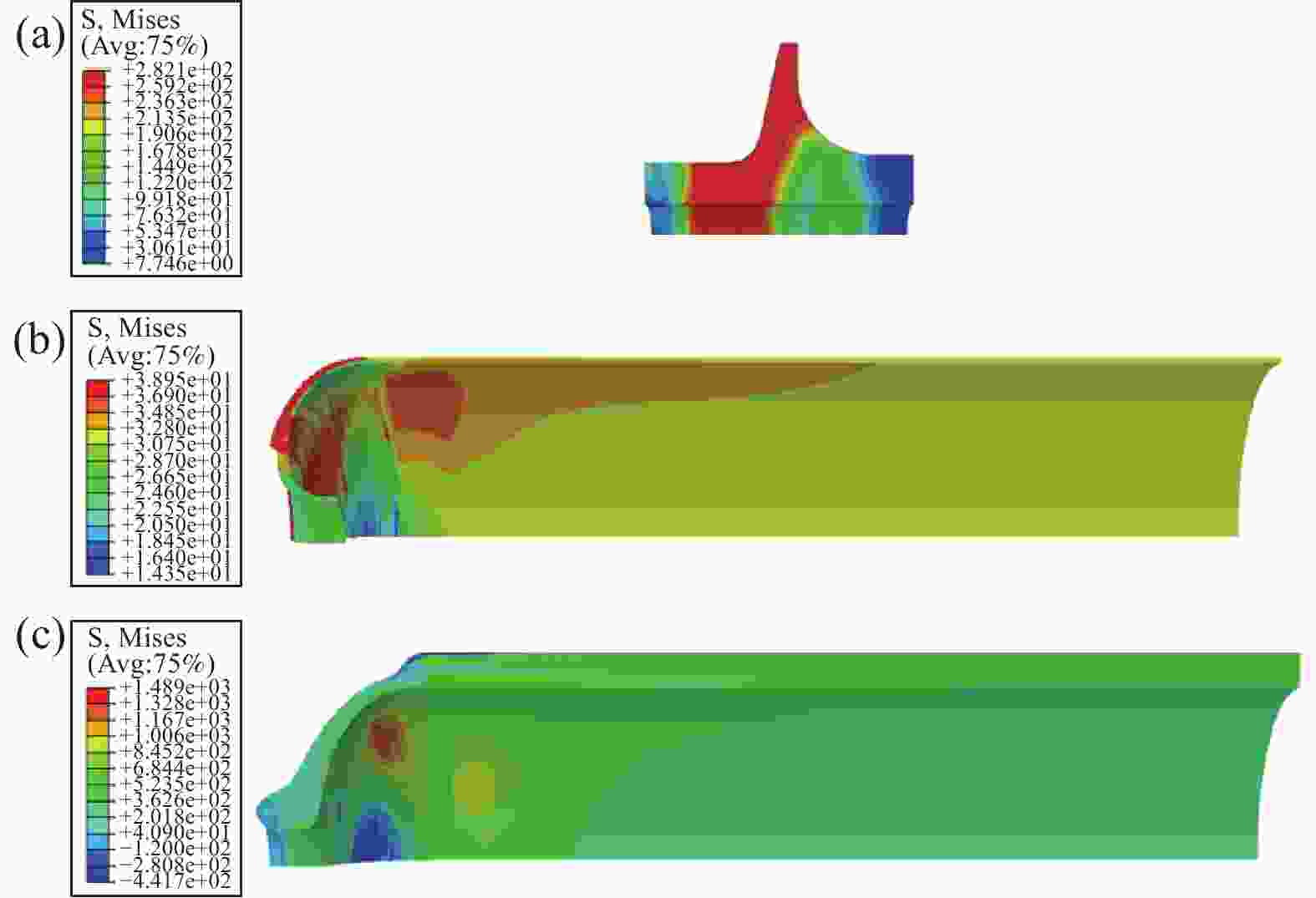

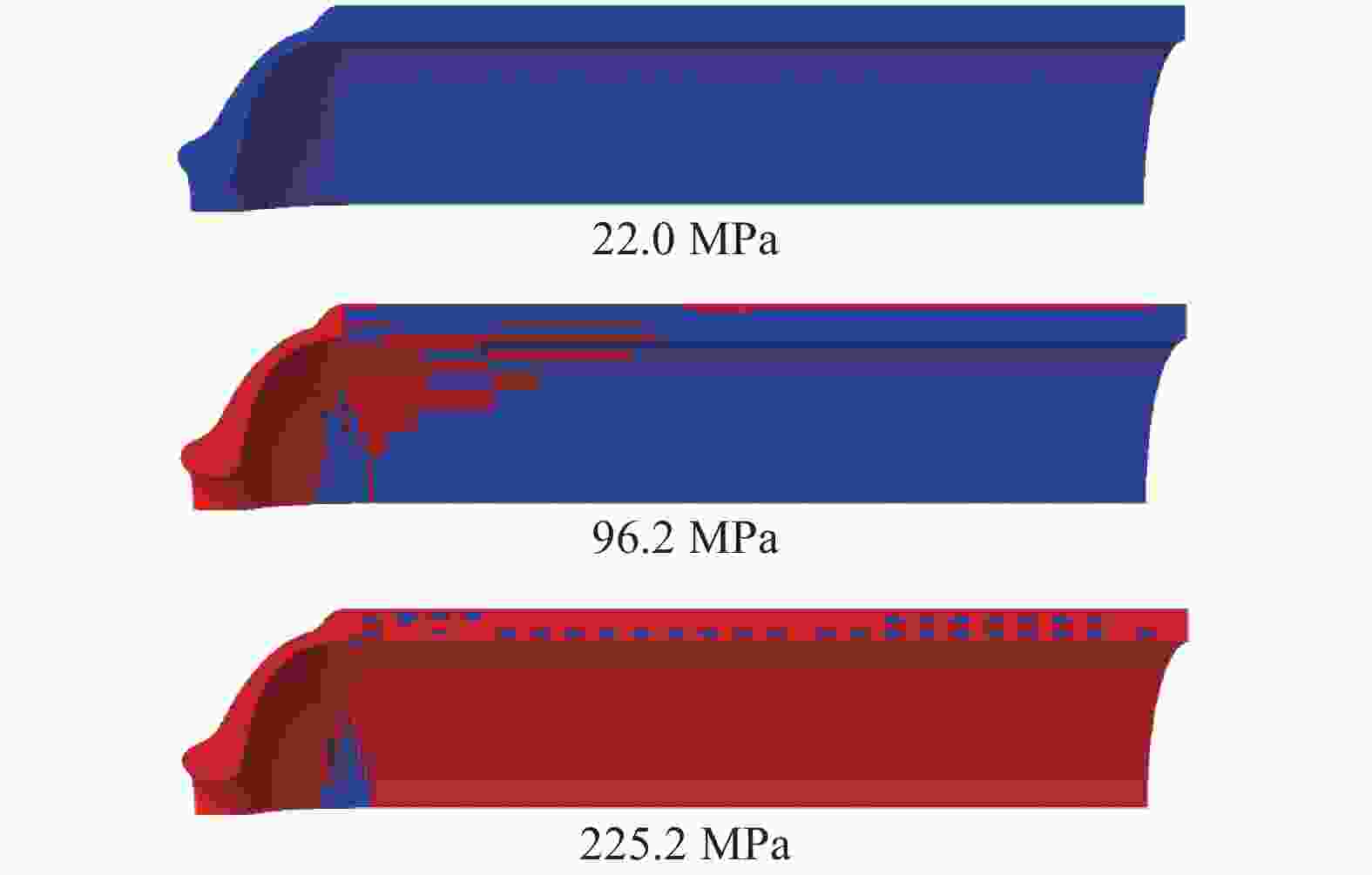

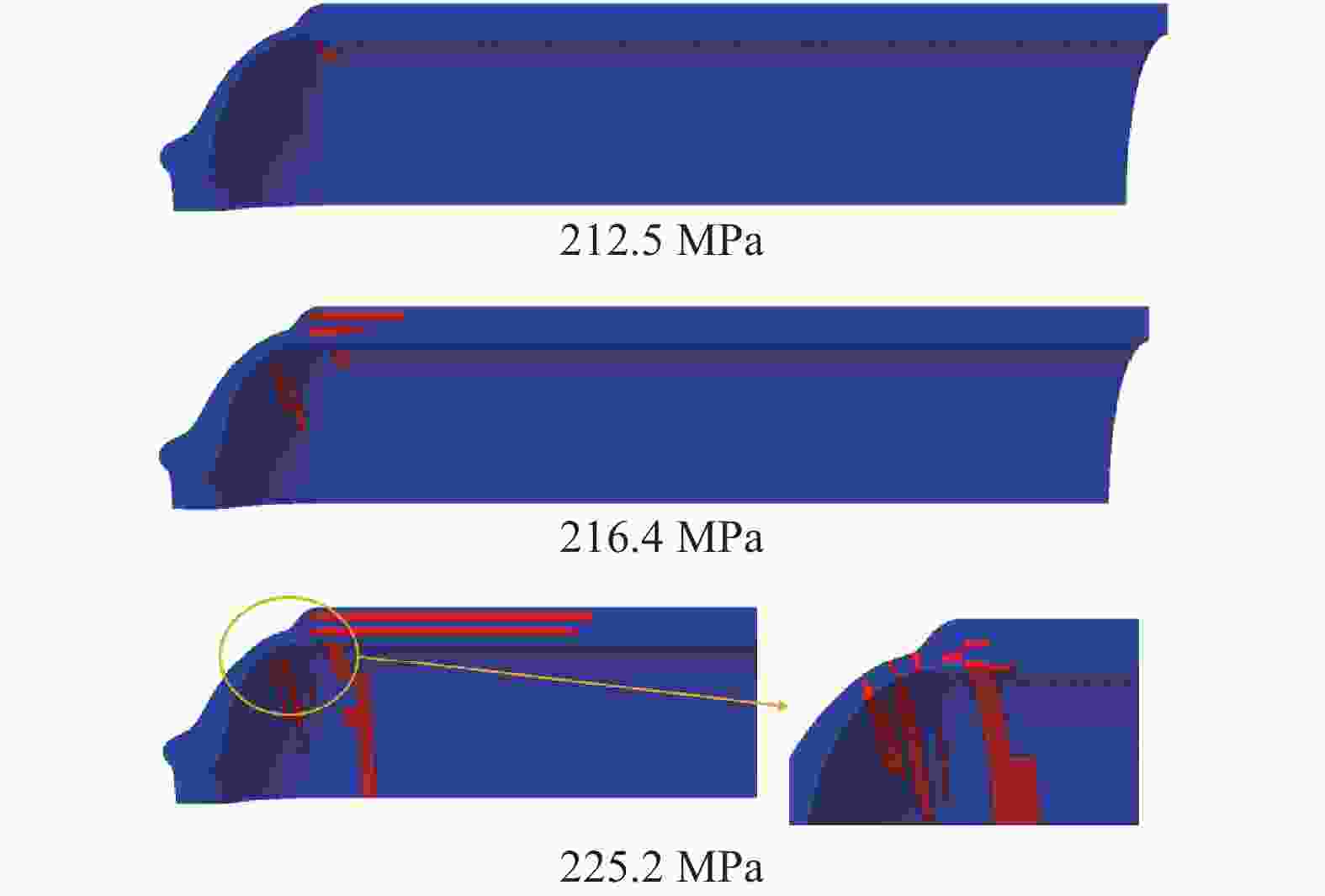

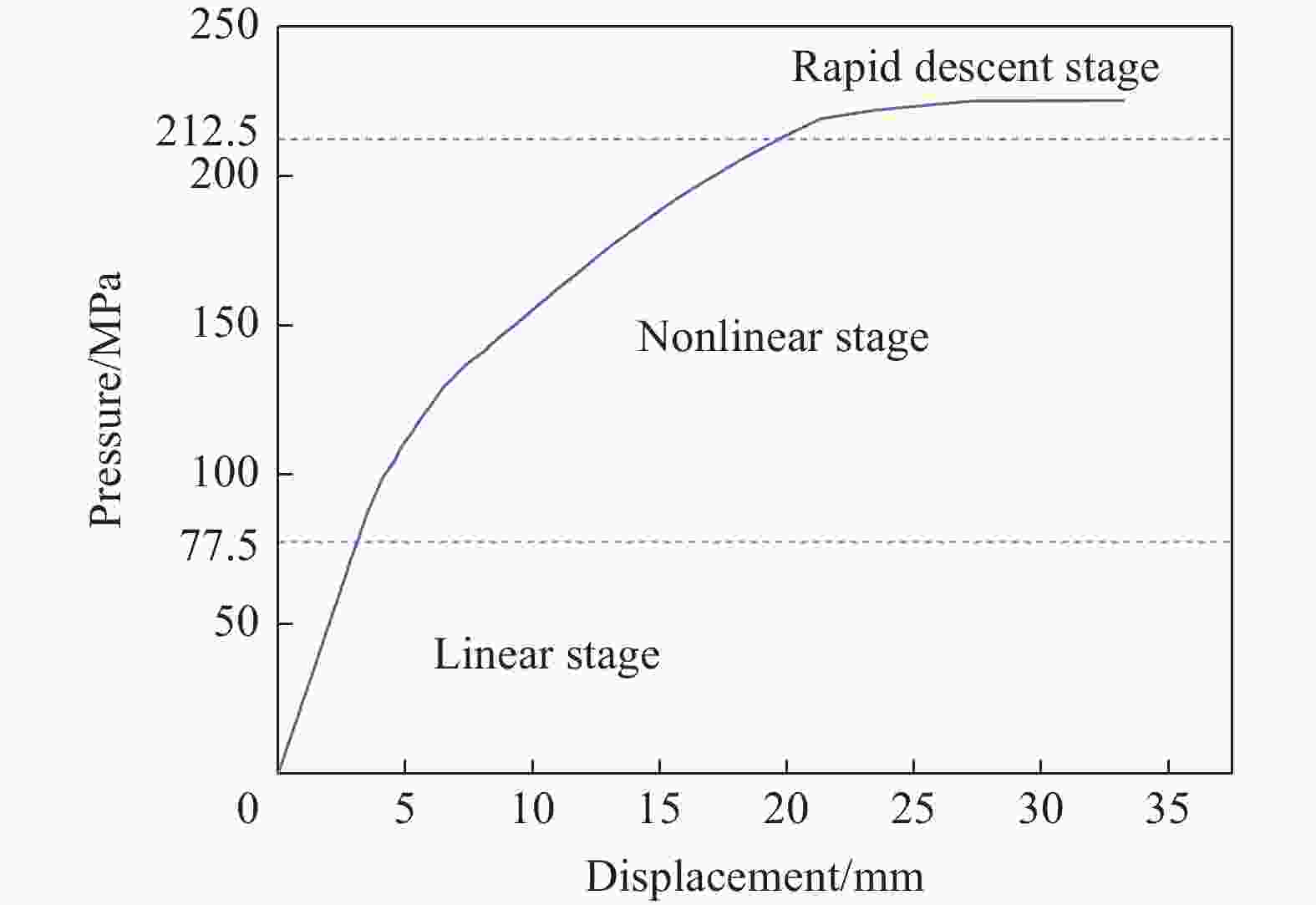

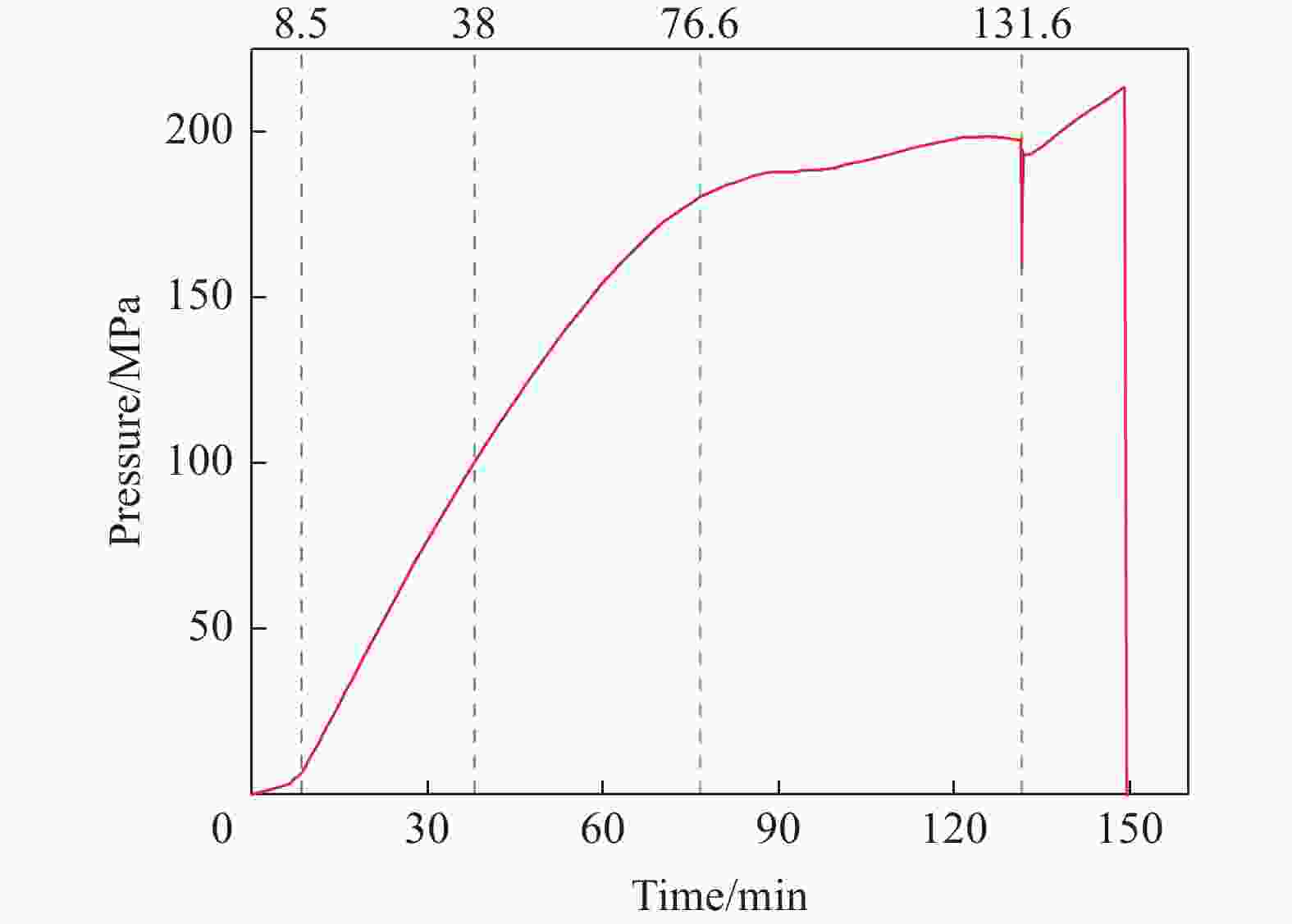

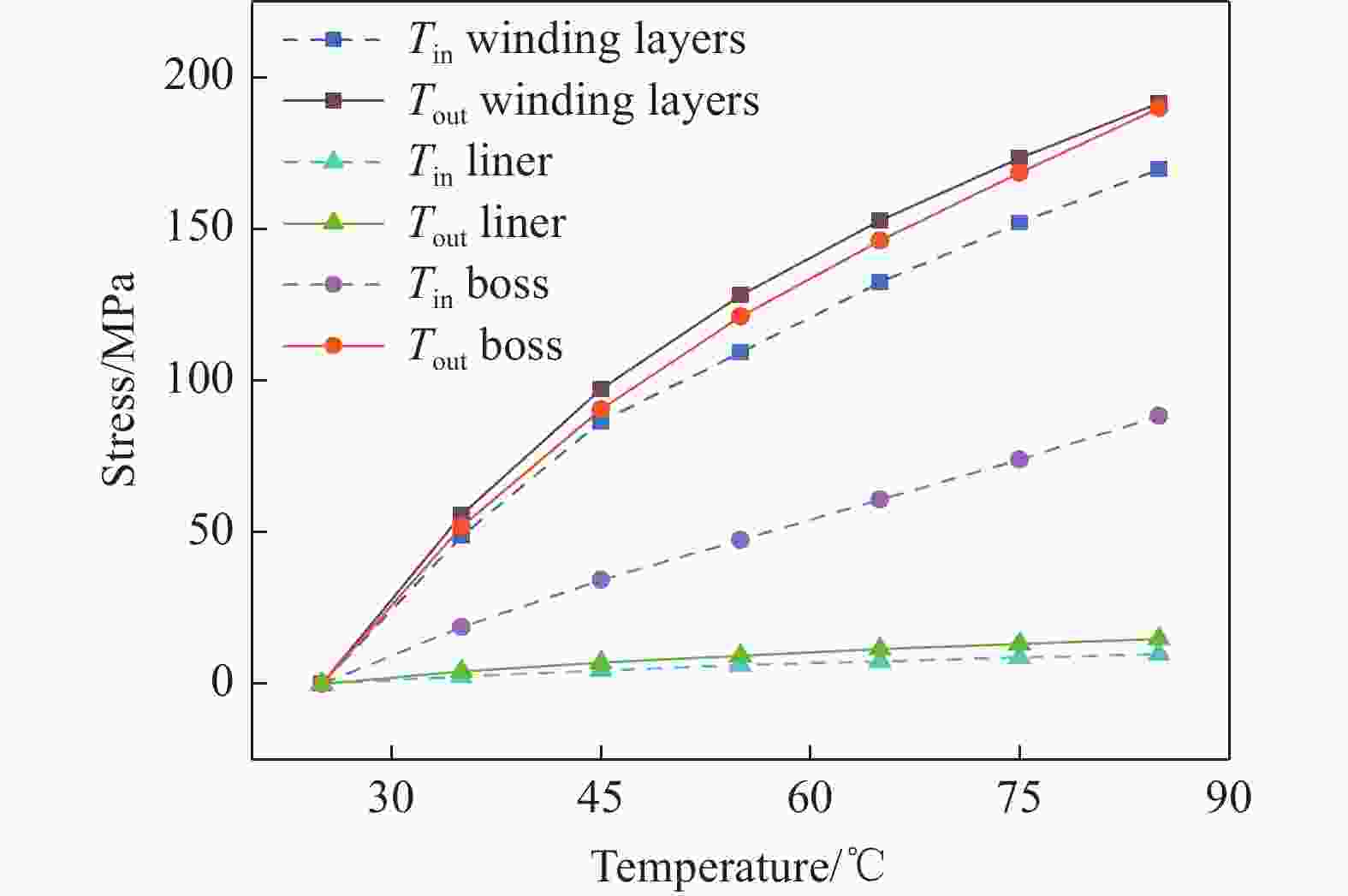

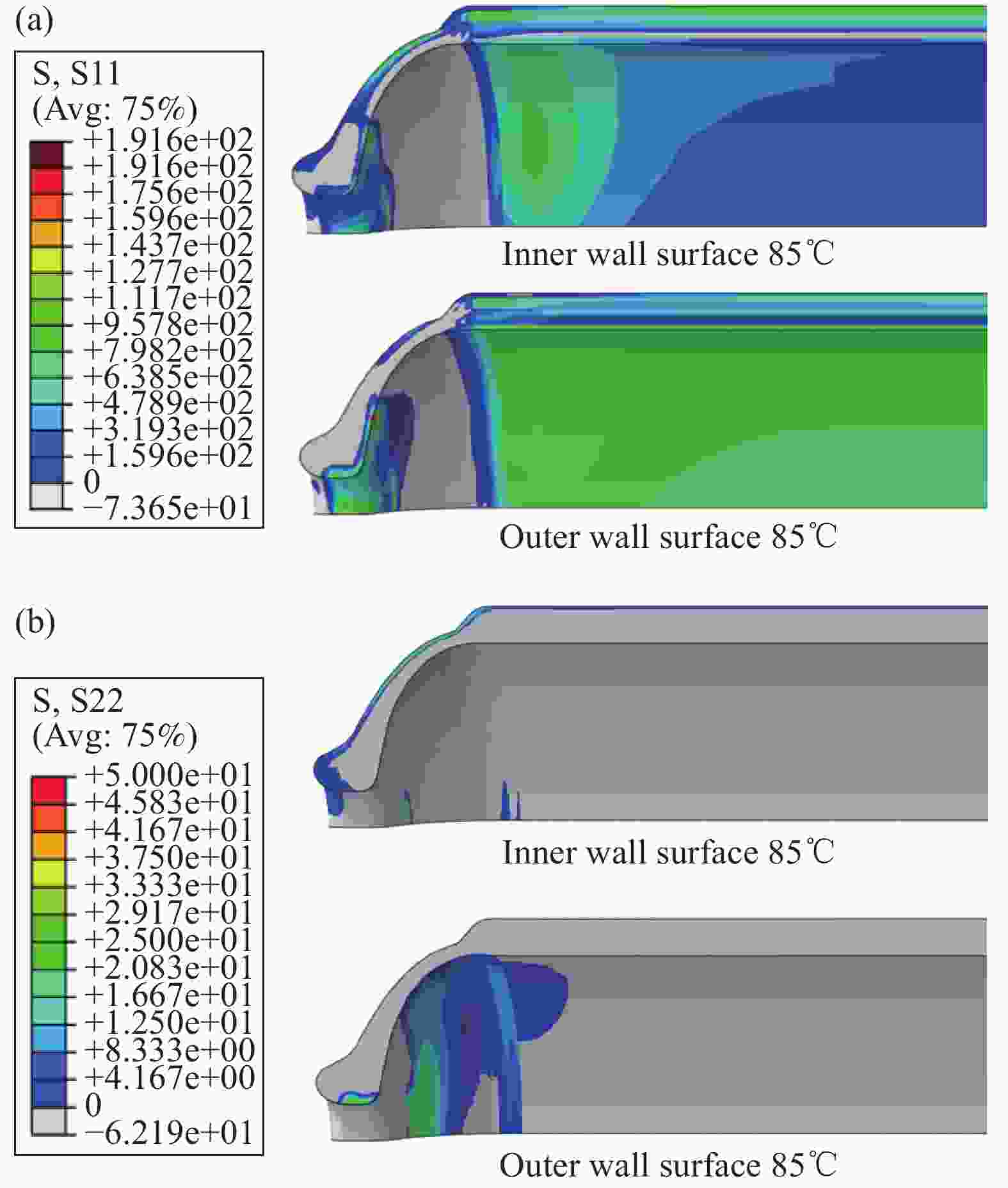

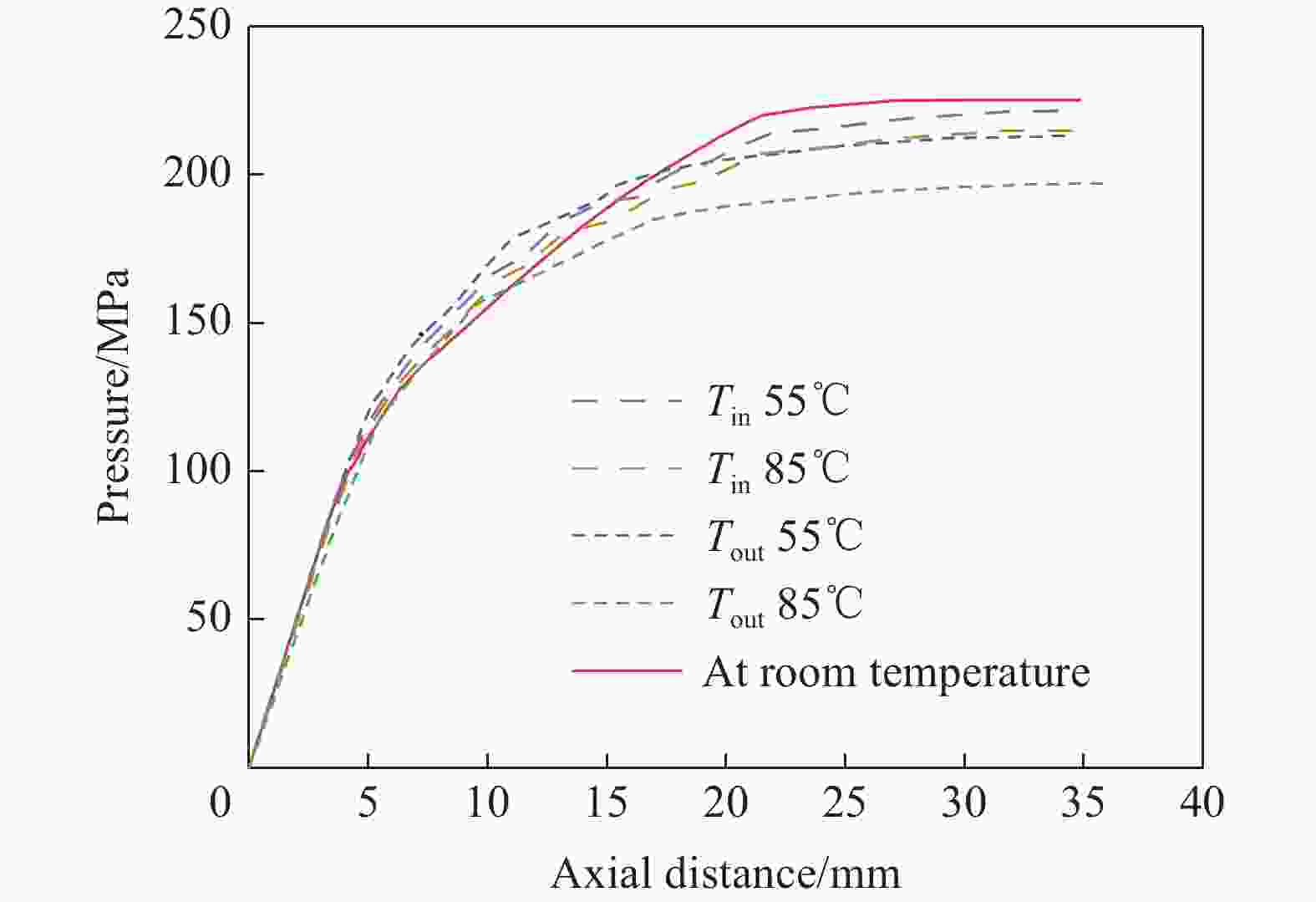

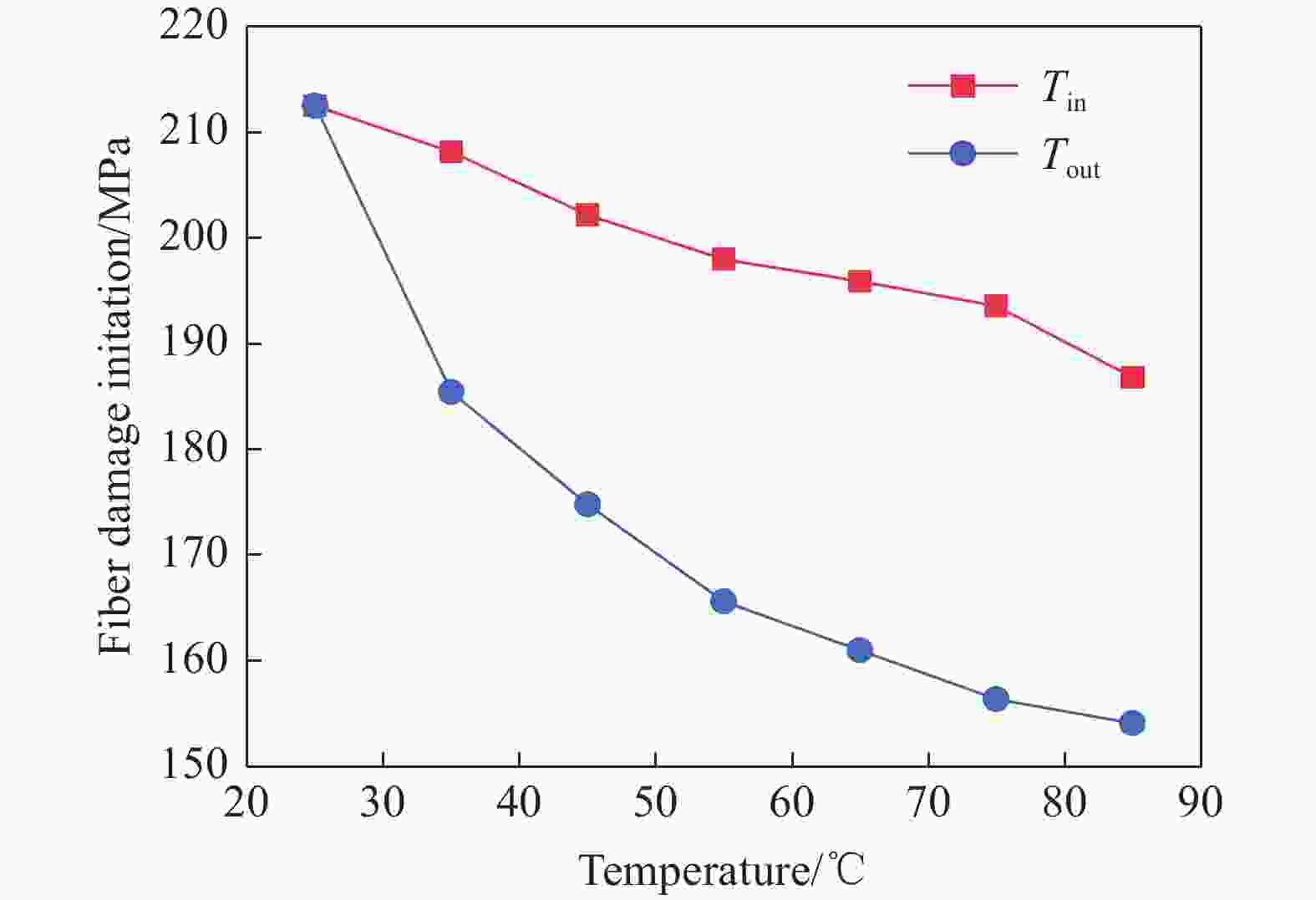

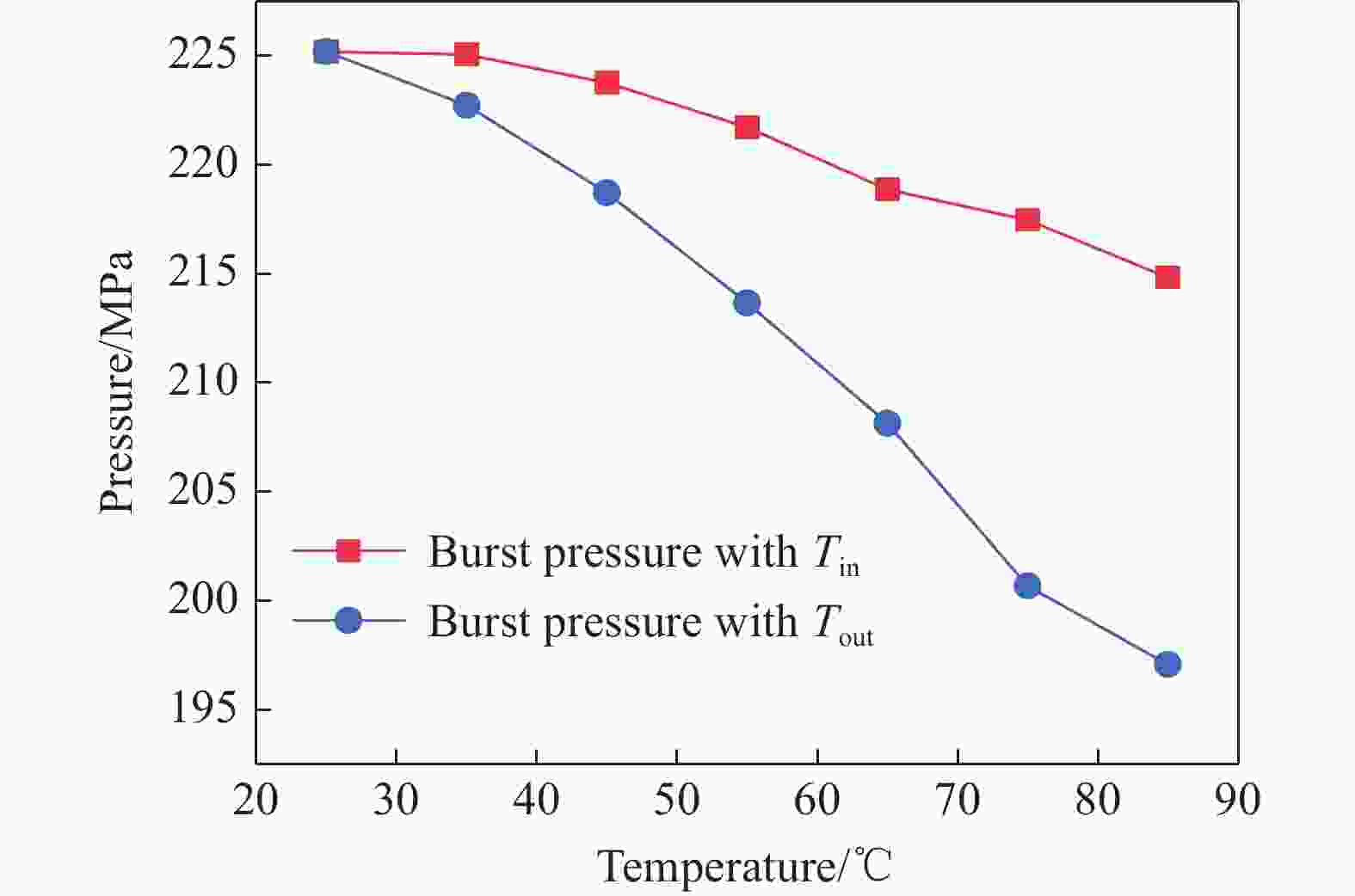

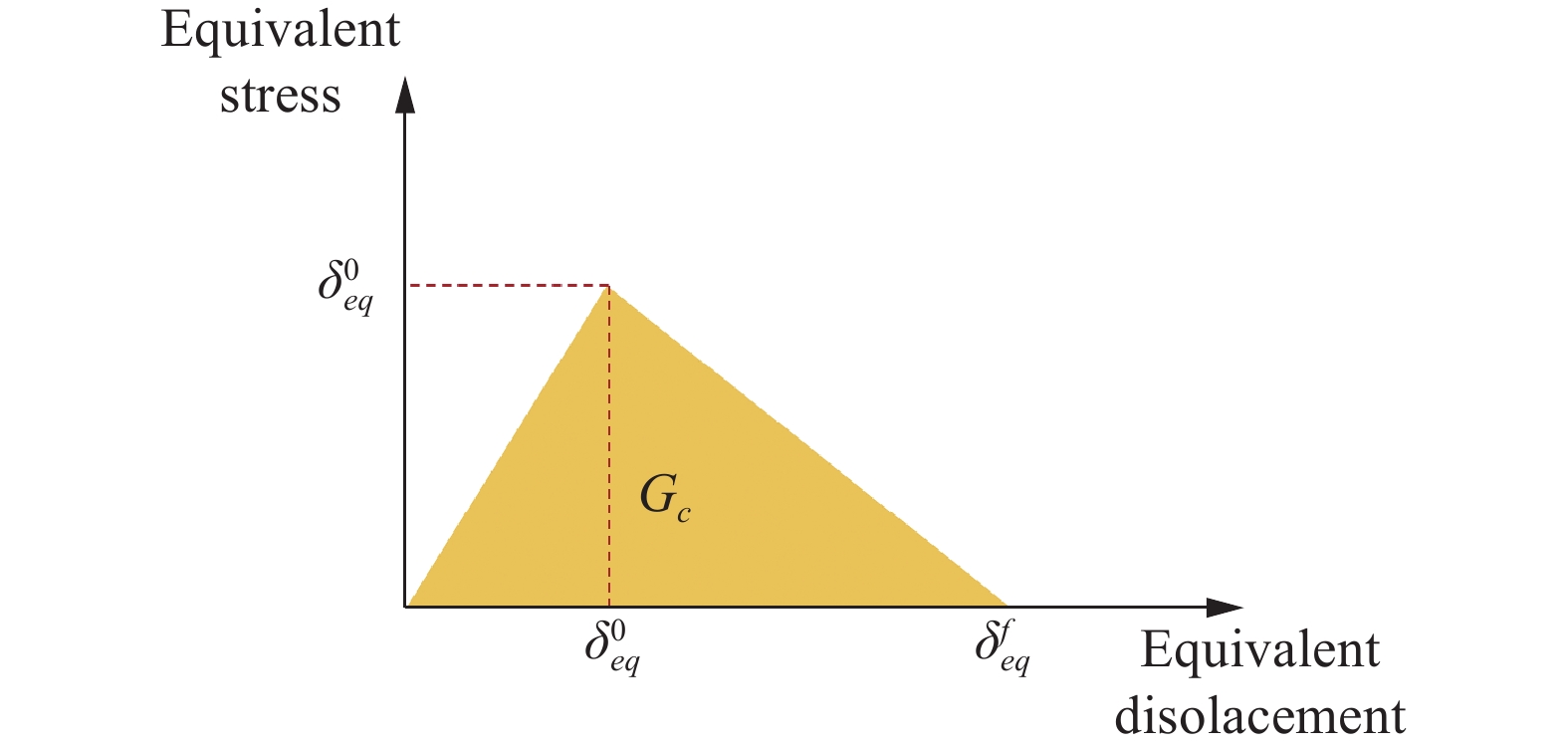

摘要: Ⅳ型储氢瓶已成为最具潜力的车载储能装备之一,在快速充装及服役过程中储氢瓶会产生显著温升效应或面临环境温度变化,深入研究该工况下储氢瓶的爆破失效行为对提高其安全使用具有重要意义。本文基于微观失效理论,建立了稳态传热模型、微观力学模型和热力耦合模型,发展了一种考虑温度影响的多尺度爆破失效仿真分析方法,研究了25~85℃范围内温度上升对Ⅳ型储氢瓶爆破失效行为的影响。结果表明,纤维损伤是导致IV型储氢瓶爆破失效的主要原因,预测得到室温下储氢瓶的爆破压力和爆破失效发生位置与试验结果吻合;随着温度的上升,不均匀的温度分布和热膨胀产生了热压应力,与压力载荷产生的拉应力部分抵消,降低了储氢瓶组分的损伤扩展速度,同时复合材料缠绕层的强度下降,储氢瓶的爆破压力降低。其中,外壁面或内壁面温度从室温上升至85℃时,纤维初始损伤发生时载荷分别下降了27.5%和12.1%,最终爆破压力分别下降了12.5%和4.6%。Abstract: Type IV hydrogen storage vessels have become one of the most promising vehicle energy storage equipment, while during the rapid filling process and service life, the hydrogen storage vessel suffers the significant temperature rise effects or environmental temperature change. To improve the safety and reliability of type IV hydrogen storage vessels, it is of great significance to investigate the burst failure behavior under such operating conditions. In this work, the steady-state heat transfer model, micromechanics model, and thermal-mechanical coupling model were established based on the micromechanics of failure theory. And a multiscale burst failure analytical method was developed to study the influence of temperature at the range of 25℃ to 85℃ on burst failure behavior. The results show that, fiber damage is the main cause of the burst failure of the type IV hydrogen storage vessel, and the predicted burst pressure and failure location agree with the experimental result well. As the temperature rises, thermal compressive stress generated by non-uniform temperature distribution and thermal expansion, partially offsets the tensile stress generated by the pressure, and slows down the development of the constituent damage. And the strength of the composite winding layer decreases, leading to a decrease in the burst pressure of the vessel. When the temperature of the outer or inner wall surface rises from room temperature to 85℃, the pressure of the initial fiber damage decreases by 27.5% and 12.1%, and the burst pressure decreases by 12.5% and 4.6%, respectively.

-

Key words:

- composites /

- type Ⅳ hydrogen storage vessel /

- multiscale /

- temperature /

- progressive damage /

- burst pressure

-

表 1 铝合金6061和PA6材料参数

Table 1. Materials properties of alloy 6061 and PA6

Properties 6061-T6 PA6 Modulus /GPa 68.90 1.88 Poisson’s ratio 0.33 0.38 Yield Strength /MPa 284.89 39.78 Break Elongation /% 20 104 Density /(g·cm−3) 2.75 1.08 Conductivity /(W·(m·K)−1) 180.00 3.01 Specific heat /(J·(kg·K) -1) 896.00 1750.00 Expansion /(10−6·K−1) 23.60 106.00 表 2 常温下T700碳纤维/环氧树脂复合材料参数

Table 2. Materials properties of the T700 carbon fiber/epoxy composite at room temperature

Properties Ply (T700-Epoxy) Fiber

(T700)Matrix

(Epoxy)Longitudinal modulus E1/GPa 142.00 232.00 3.50 Transverse moduli E2=E3/GPa 10.30 18.00 3.50 Shear modulus G12=G13/GPa 7.10 8.70 1.25 Shear modulus G23/GPa 3.80 5.80 1.25 Poisson’s ratio υ12=υ13 0.25 0.20 0.35 Poisson’s ratio υ23 0.42 0.49 0.35 Tensile strength /GPa XT =2.50,

YT =0.06Tf =4.90 Tm =0.11 Compressive strength /GPa XC =1.25,

YC =0.19Cf =2.50 Cm =0.24 Toughness /(N·mm−1) - Gfc =106.00 Gnc =0.28,

Gsc =0.79Density /(g·cm−3) 1.53 2.75 1.17 Conductivity /(W·(m·K)−1) 14.61 180.00 1.84 Specific heat /(J·(kg·K)−1) 972.20 896.00 1330.00 Expansion/(10−6·K−1) $ {\alpha }_{1} $ =5.78,

$ {\alpha }_{2} $ =0.19$ {\alpha }_{1\mathrm{f}} $ =2.50,

$ {\alpha }_{2\mathrm{f}} $ =0.0012.90 Notes: 1−Direction of fiber; 2−In-plane direction of the matrix; 3−Out-plane direction of the matrix. -

[1] AIR A, SHAMSUDDOHA M, GANGADHARA PRUSTY B. A review of type V composite pressure vessels and automated fibre placement based manufacturing[J]. Composites Part B: Engineering, 2023, 253: 1-17. [2] DONG C, LIU Y, LI J, et al. Hydrogen permeability of polyamide 6 used as liner material for type IV on-board hydrogen storage cylinders[J]. Polymers, 2023, 15(18): 1-13. [3] LI J, LIU J, ZHAO B, et al. Research on temperature rise of type IV composite hydrogen storage cylinders in hydrogen fast-filling process[J]. Energies, 2023, 16(6): 1-21. [4] SAPRE S, VYAS M, PAREEK K. Impact of refueling parameters on storage density of compressed hydrogen storage tank[J]. International Journal of Hydrogen Energy, 2021, 46(31): 16685-16692. doi: 10.1016/j.ijhydene.2020.08.136 [5] 刘峻. 结构参数对车载储氢气瓶快充温升的影响规律研究[D]. 杭州: 浙江大学, 2021.LIU Jun. The study on the effects of geometrical parameters on temperature rise in on-board gaseous hydrogen storage cylinder during the fast filling process [D]. Hangzhou: Zhejiang University, 2021 (in Chinese). [6] 邹光雄, 寇文能, 涂成林, 等. 高温环境对汽车制动的影响[J]. 汽车文摘, 2019, (7): 42-45.Zhou Guangxiong, Guan Wenneng, Tu Chenglin, et al. Influence of high temperature environment on automobile braking system[J]. Automotive Digest, 2019, (7): 42-45 (in Chinese). [7] WEI Q, CHEN H, WANG J, et al. Research on temperature rise performance of EV charging coupler[J]. Journal of Physics: Conference Series, 2020, 1626(1): 1-7. [8] LEH D, MAGNEVILLE B, SAFFRÉ P, et al. Optimisation of 700 bar type IV hydrogen pressure vessel considering composite damage and dome multi-sequencing[J]. International Journal of Hydrogen Energy, 2015: 1-16. [9] Chen Y Z, Zhao S L, Ma H J, et al. Analysis of Hydrogen Embrittlement on Aluminum Alloys for Vehicle-Mounted Hydrogen Storage Tanks: A Review[J]. Metals, 2021, 11(8): 1-23. [10] 姚嘉平, 王建, 张谦, 等. Ⅳ型储氢气瓶塑料内胆的失效形式与机理[J]. 塑料, 2023, 52(1): 133-138.YAO Jiaping, WANG Jian, ZHANG Qian, et al. Failure modes and mechanism of plastic liner of type Ⅳ hydrogen storage vessel[J]. Plastics, 2023, 52(1): 133-138 (in Chinese). [11] 白皛, 乔亮, 范峻铭, 等. Ⅳ型储氢气瓶塑料内胆氢渗透特性及失效分析研究进展[J]. 中国塑料, 2024, 38(1): 62-78.BAI Xiao, QIAO Liang, FAN Junming, et al. Research progress in hydrogen permeation characteristics and failure analysis of plastic liner of type IV hydrogen storage vessel[J]. China Plastics, 2024, 38(1): 62-78 (in Chinese). [12] BLANC-VANNET P, PAPIN P, WEBER M, et al. Sample scale testing method to prevent collapse of plastic liners in composite pressure vessels[J]. International Journal of Hydrogen Energy, 2019, 44: 8682-8691. doi: 10.1016/j.ijhydene.2018.10.031 [13] WANG X, TIAN M, CHEN X, et al. Advances on materials design and manufacture technology of plastic liner of type Ⅳ hydrogen storage vessel[J]. International Journal of Hydrogen Energy, 2022, 47(13): 8382-8408. doi: 10.1016/j.ijhydene.2021.12.198 [14] JIN S, CHENG P, BAI Y, et al. Progressive failure analysis and burst mode study of type IV composite vessels[J]. Ships and Offshore Structures, 2022: 1-10. [15] HU Z Y, CHEN M H, ZU L, et al. Investigation on failure behaviors of 70 MPa type IV carbon fiber overwound hydrogen storage vessels[J]. Composite Structure, 2021, 259: 113387-113397. doi: 10.1016/j.compstruct.2020.113387 [16] BOUVIER M, GUIHENEUF V, JEAN-MARIE A. Modeling and simulation of a composite high-pressure vessel made of sustainable and renewable alternative fibers[J]. International Journal of Hydrogen Energy, 2019, 44(23): 11970-11978. doi: 10.1016/j.ijhydene.2019.03.088 [17] MAGNEVILLE B, GENTILLEAU B, VILLALONGA S, et al. Modeling, parameters identification and experimental validation of composite materials behavior law used in 700 bar type IV hydrogen high pressure storage vessel[J]. International Journal of Hydrogen Energy, 2015, 40: 13193-13205. doi: 10.1016/j.ijhydene.2015.06.121 [18] JEBELI M A, HEIDARI-RARANI M. Development of Abaqus WCM plugin for progressive failure analysis of type IV composite pressure vessels based on Puck failure criterion[J]. Engineering Failure Analysis, 2022, 131: 1-15. [19] ALAM S, YANDEK G R, Lee R C, et al. Design and development of a filament wound composite overwrapped pressure vessel[J]. Composites Part C: Open Access, 2020, 2: 1-14. [20] HWANG J S, KO K H, JUNG G S. Proposal of a short-body hydrogen pressure vessel to assess the burst of long-body/large-capacity vessels[J]. International Journal of Precision Engineering and Manufacturing, 2023, 24(3): 471-483. doi: 10.1007/s12541-022-00757-5 [21] 鄢家乐, 陈学东, 范志超, 等. 70MPa车载Ⅳ型储氢气瓶铺层设计与实验验证[J]. 西安交通大学学报, 2022, 56(10): 71-80. doi: 10.7652/xjtuxb202210007YAN Jiale, CHEN Xuedong, FAN Zhichao et al. Layered design and experimental verification of 70MPa vehicle-mounted type Ⅳ hydrogen storage cylinder[J]. Journal of Xi’an Jiaotong University, 2022, 56(10): 71-80 (in Chinese). doi: 10.7652/xjtuxb202210007 [22] LEH D, SAFFRÉ P, FRANCESCATO P, et al. A progressive failure analysis of a 700-bar type IV hydrogen composite pressure vessel[J]. International Journal of Hydrogen Energy, 2015, 40(38): 13206-13214. doi: 10.1016/j.ijhydene.2015.05.061 [23] WU Q, ZU L, WANG P, et al. Design and fabrication of carbon-fiber-wound composite pressure vessel with HDPE liner[J]. International Journal of Pressure Vessels and Piping, 2022, 200: 1-8. [24] LI F, CHEN X, XU P, et al. Optimal design of thin-layered composites for type IV vessels: Finite element analysis enhanced by ANN[J]. Thin-walled Structures, 2023, 187: 1-15. [25] RAFIEE R, TORABI M A. Stochastic prediction of burst pressure in composite pressure vessels[J]. Composite Structures, 2018, 185: 573-583. doi: 10.1016/j.compstruct.2017.11.068 [26] GENTILLEAU B, TOUCHARD F, GRANDIDIER J C. Numerical study of influence of temperature and matrix cracking on type IV hydrogen high pressure storage vessel behavior[J]. Composite Structures, 2014, 111: 98-110. doi: 10.1016/j.compstruct.2013.12.034 [27] 朱国华, 竺森森, 胡珀, 等. CFRP薄壁结构多尺度建模及耐撞性分析[J]. 复合材料学报, 2023, 40(6): 3626-3639.ZHU Guohua, ZHU Sensen, HU Po, et al. Multi-scale modeling and crashworthiness analysis of CFRP thin-walled structures[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3626-3639 (in Chinese). [28] REN M, ZHANG X, HUANG C, et al. An integrated macro/micro-scale approach for in situ evaluation of matrix cracking in the polymer matrix of cryogenic composite tanks[J]. Composite Structures, 2019, 216: 201-212. doi: 10.1016/j.compstruct.2019.02.079 [29] NGUYEN B N, ROH H S, MERKEL D R, et al. A predictive modeling tool for damage analysis and design of hydrogen storage composite pressure vessels[J]. International Journal of Hydrogen Energy, 2021, 46(39): 20573-20585. doi: 10.1016/j.ijhydene.2021.03.139 [30] 刘长喜, 姜旭, 王佳杰, 等. 纤维缠绕复合材料压力容器的多尺度分析与性能预测[J]. 工程塑料应用, 2023, 51(11): 115-122. doi: 10.3969/j.issn.1001-3539.2023.11.019Liu Changxi, Jiang Xu, Wang Jiajie, et al. Multiscale analysis and performance prediction of filament-wound composite pressure vessel[J]. Engineering Plastics Application, 2023, 51(11): 115-122 (in Chinese). doi: 10.3969/j.issn.1001-3539.2023.11.019 [31] ZHANG N, GAO S, SONG M, et al. A multiscale study of CFRP based on asymptotic homogenization with application to mechanical analysis of composite pressure vessels[J]. Polymers, 2022, 14: 1-23. [32] LIN S, YANG L, XU H, et al. Progressive damage analysis for multiscale modelling of composite pressure vessels based on Puck failure criterion[J]. Composite Structures, 2021, 255: 1-12. [33] HA S K, JIN K K, HUANG Y. Micro-mechanics of failure (MMF) for continuous fiber reinforced composites-All Databases[J]. Journal of Composite Materials, 2008, 41(18): 1873-1895. [34] WANG L, ZHENG C, WEI S, et al. Micromechaics-based progressive failure analysis of carbon fiber/epoxy composite vessel under combined internal pressure and thermomechanical loading[J]. Composites Part B: Engineering, 2016, 89: 77-84. doi: 10.1016/j.compositesb.2015.11.018 [35] JIN K K, YUANCHEN H, LEE Y H, et al. Distribution of micro stresses and interfacial tractions in unidirectional composites[J]. Journal of Composite Materials, 2008, 42(18): 1825-1849. doi: 10.1177/0021998308093909 [36] 全国绝热材料标准化技术委员会. 绝热材料稳态热阻及有关特性的测定 防护热板法. GB/T 10294-2008[S]. 北京: 中国标准出版社, 2008.National Technical Committee 191 on Thermal Insulation Materials of Standardization Administration of China. Thermal insulation-Determination of steady-state thermal resistance and related properties-Guarded hot plate apparatus. GB/T 10294-2008[S]. Beijing: Standards Press of China, 2008 (in Chinese). [37] ASTM, Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry, ASTM E1269-11[S]. West Conshohocken, 2018. [38] International Organization for Standardization. Plastics-Thermomechanical analysis (TMA)- Part 2: Determination of coefficient of linear thermal expansion and glass transition temperature: ISO 11359-2[S]. Switzerland, 2005. [39] 全国纤维增强塑料标准化技术委员会. 树脂浇铸体性能试验方法: GB/T 2567-2021[S]. 北京: 中国标准出版社, 2021.National Technical Committee 39 on Fiber Reinforced Plastic of Standardization Administration of China. Test methods for properties of resin casting body: GB/T 2567-2021[S]. Beijing: China Standards Press, 2021 (in Chinese). [40] 全国气瓶标准化技术委员会. 车用压缩氢气纤维全缠绕气瓶定期检验与评定: GB/T 42626-2023[S]. 北京: 中国标准出版社, 2023.National Technical Committee 31 on Cylinder of Standardization Administration of China. Periodic inspection and evaluation of fully wrapped fibre reinforced composite gas cylinders of compressed hydrogen gas for automotive vehicles: GB/T 42626-2023[S]. Beijing: China Standards Press, 2023 (in Chinese). [41] 王亮. 基于微观力学分析的复合材料储氢容器强度与寿命研究[D]. 杭州: 浙江大学, 2016.Wang Liang, Micromechanics-based failure theory for strength and life investigation of carbon fiber-reinforced composite hydrogen storage vessel[D]. Hangzhou: Zhejiang University, 2016 (in Chinese). [42] SIMONOVSKI I, BARALDI D, MELIDEO D, et al. Thermal simulations of a hydrogen storage tank during fast filling[J]. International Journal of Hydrogen Energy, 2015, 40(36): 12560-12571. doi: 10.1016/j.ijhydene.2015.06.114 [43] IMMEL R, MACK-GARDNER A. Development and validation of a numerical thermal simulation model for compressed hydrogen gas storage tanks[J]. SAE International Journal of Engines, 2011, 4(1): 1850-1861. doi: 10.4271/2011-01-1342 [44] 全国气瓶标准化技术委员会. 车用压缩氢气塑料内胆碳纤维全缠绕气瓶: GB/T 42612-2023[S]. 北京: 中国标准出版社, 2023.National Technical Committee 31 on Cylinder of Standardization Administration of China. Fully-wrapped carbon fiber reinforced cylinders with a plastic liner for the on-board storage of compressed hydrogen as a fuel for land vehicles: GB/T 42612-2023[S]. Beijing: China Standards Press, 2023 (in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 64

- HTML全文浏览量: 35

- 被引次数: 0

下载:

下载: