Fabrication of Magnetic Fe3O4@SiO2@TiO2-Au with Core-shell Structure and Its Photocatalytic Reduction Activity

-

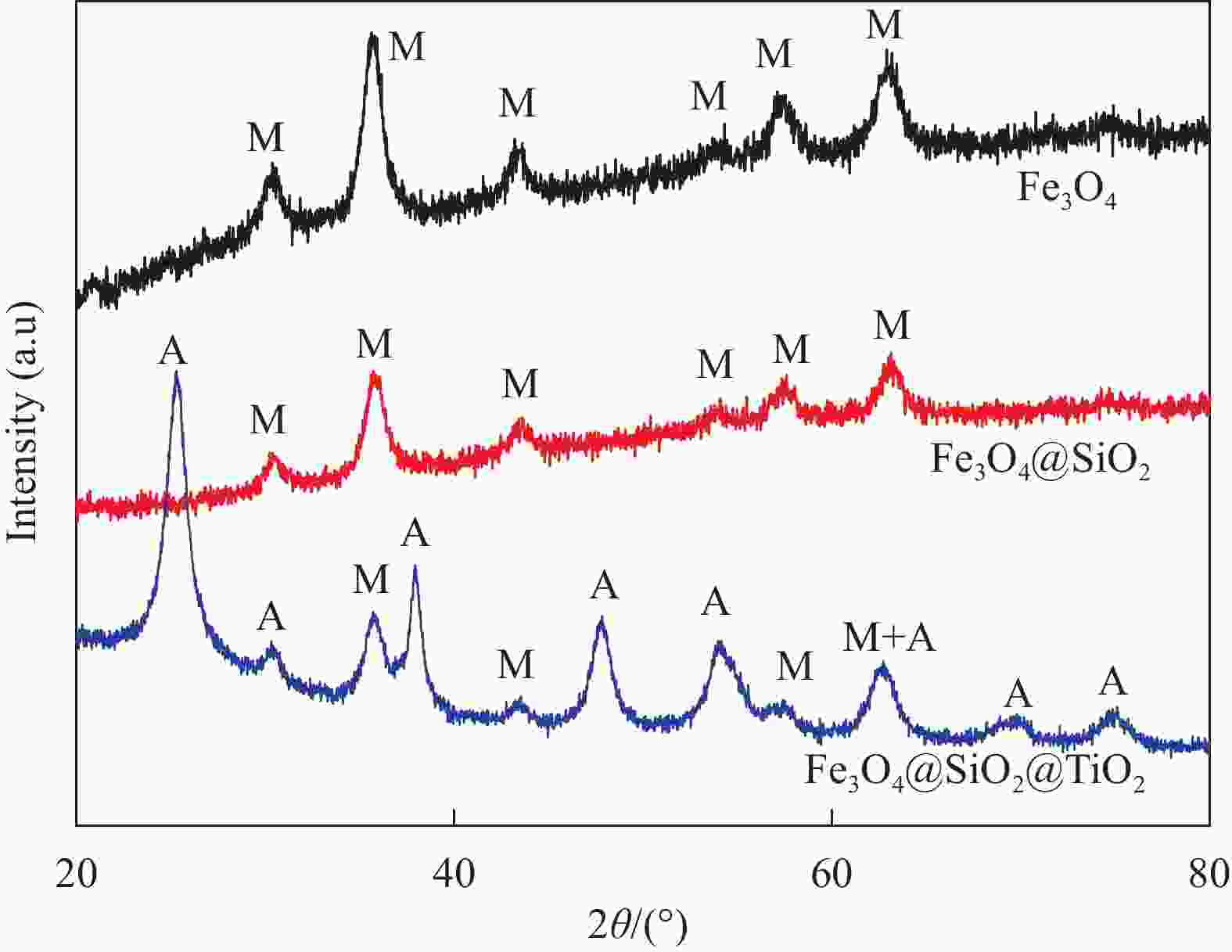

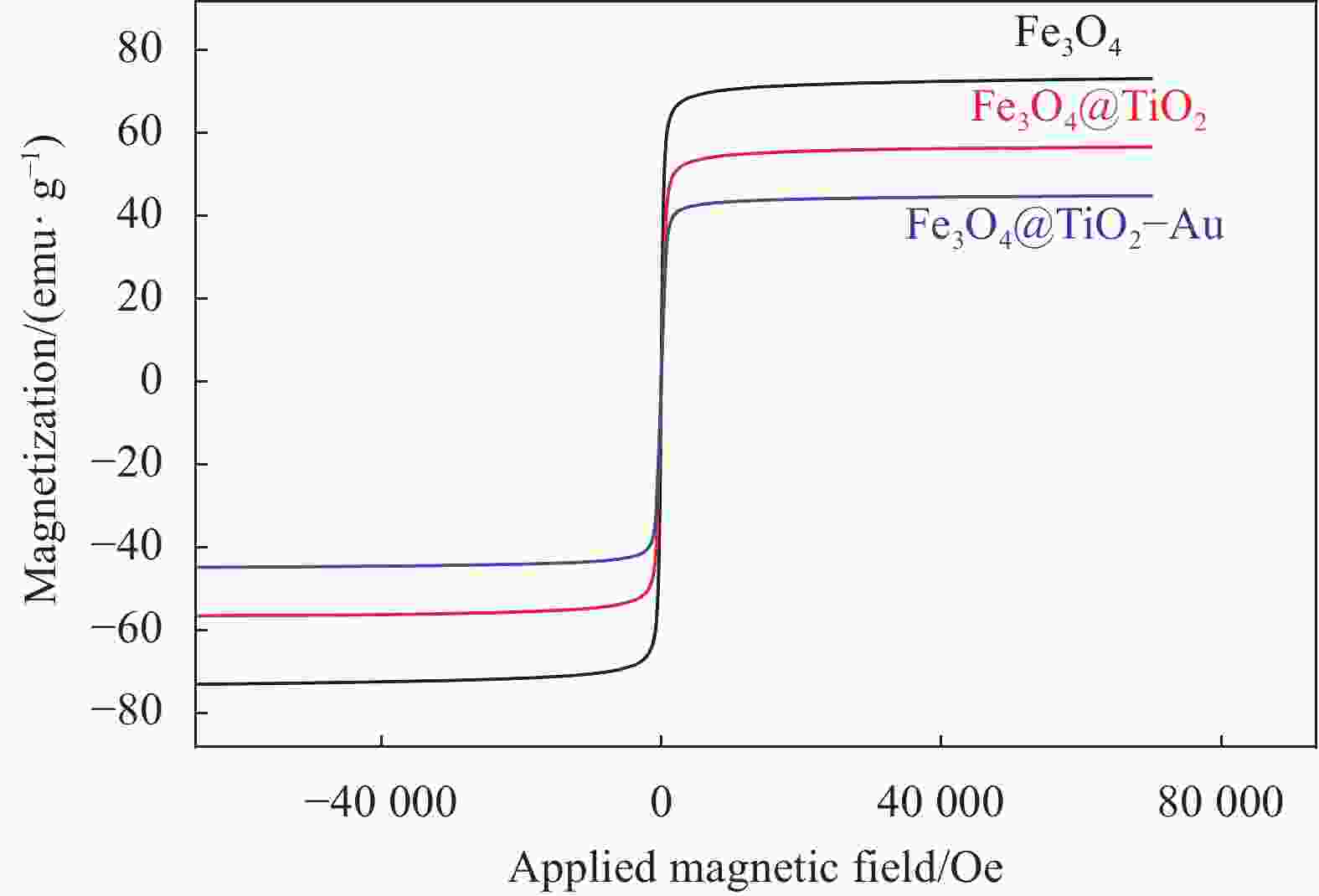

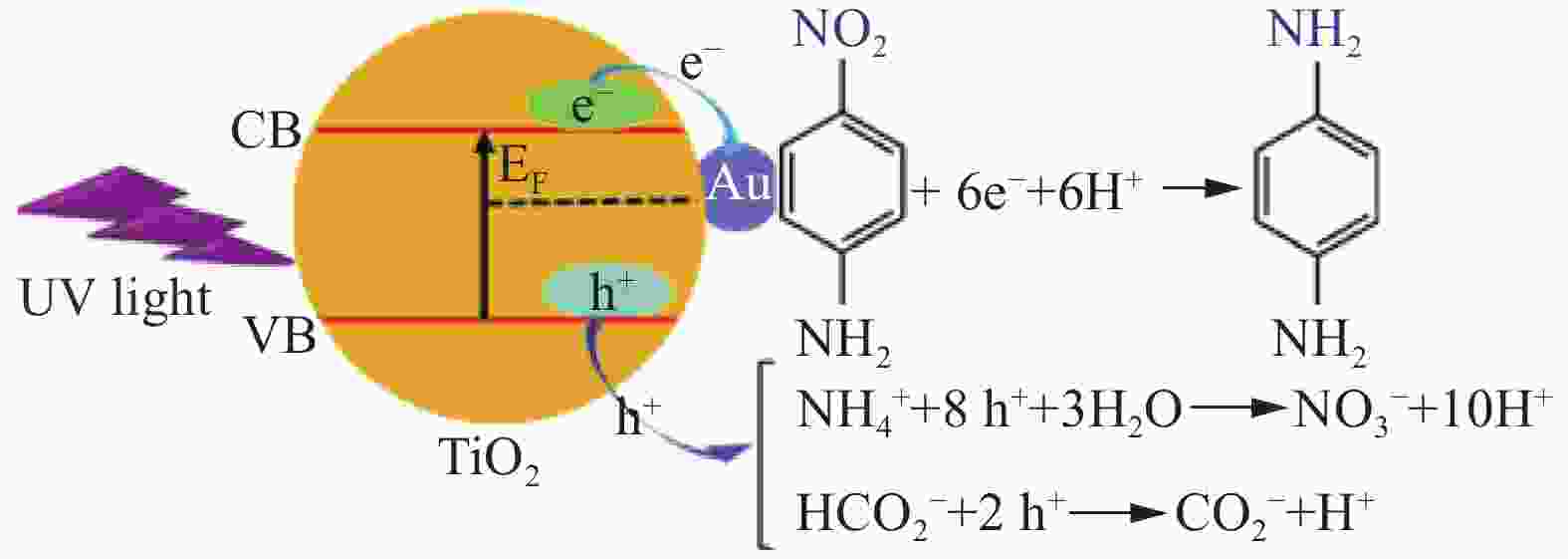

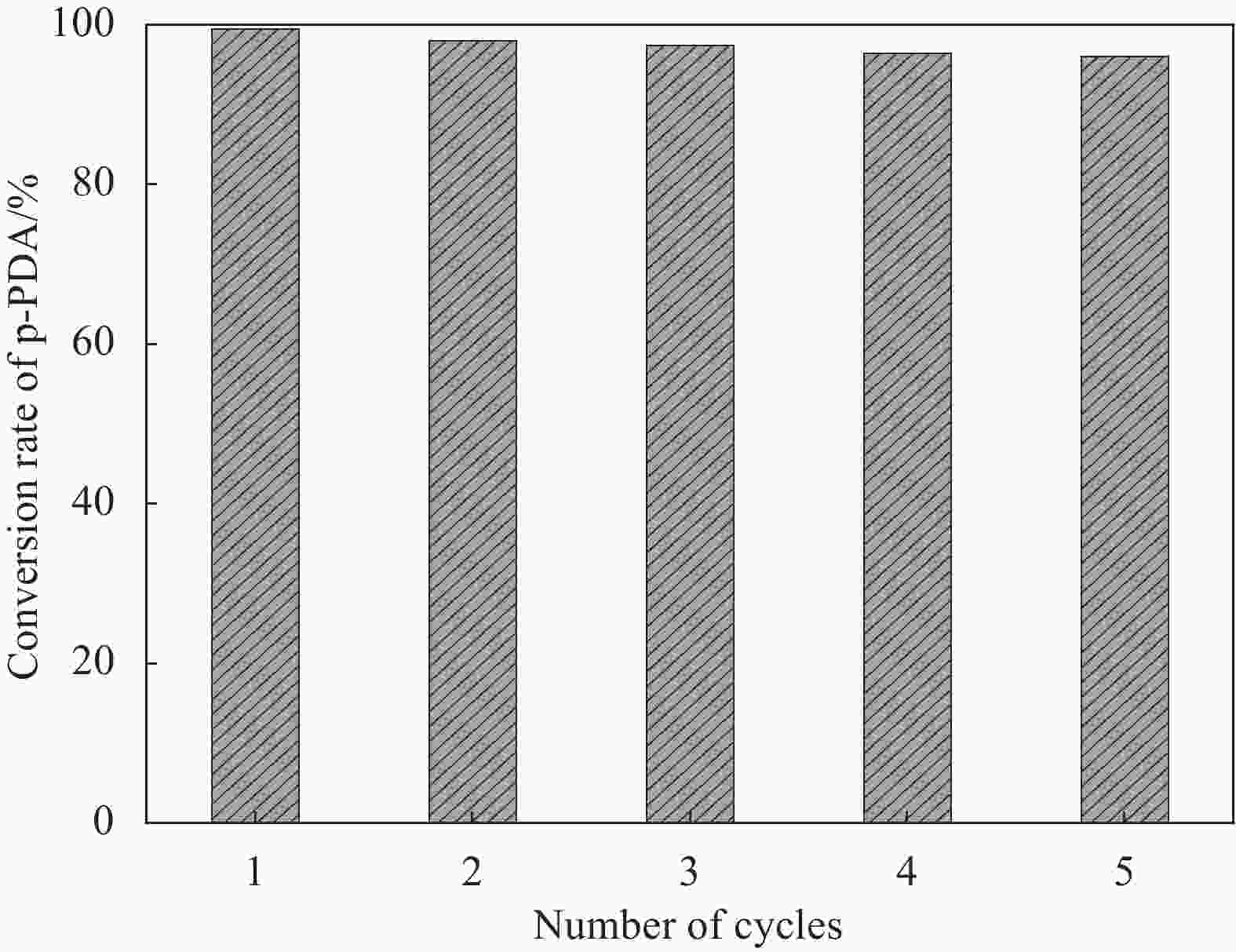

摘要: TiO2基的光催化剂已被广泛用于各种有机物污染物的光氧化和水中六价铬Cr(VI)的光还原。然而,对光催化还原硝基芳香化合物为胺基芳香化合物的研究鲜有报道。本研究采用液相沉积(LPD)法将锐钛矿型TiO2沉积在非晶SiO2包覆的Fe3O4上,制备了核壳结构的Fe3O4@SiO2@TiO2磁性光催化剂。为进一步提高其光催化活性,将均匀分散的Au纳米粒子(Au NPs)修饰在其表面,以获得Fe3O4@SiO2@TiO2-Au纳米复合材料。对这两种TiO2基的磁性复合材料进行表征并将其用作光催化剂。在紫外光照射下,用HCOONH4作为空穴捕集剂和H源,以对硝基苯胺(p-NA)光催化还原至对苯二胺(p-PDA)作为模型反应,评价其光催化还原性能。结果表明,虽然两种光催化剂都能将p-NA完全还原成p-PDA,但Fe3O4@SiO2@TiO2-Au表现出比Fe3O4@SiO2@TiO2更优异的光催化活性。这是因为TiO2表面修饰的Au NPs能有效地促进光激发的电子从TiO2的导带转移到Au,最大限度地减少电子和空穴的复合率,延长光电子的寿命。此外,不可或缺的HCOONH4在p-NA的光催化还原中能有效地捕获光生空穴,及大地提高了其光催化还原效率。Abstract: TiO2-based photocatalysts have been widely used for photoxidation of various organic pollutants and photoreduction of Cr(VI) in aqueous solution. However, less attention has been paid to the photocatalyzed reduction of nitro group to amino group of nitroaromatics. In this study, liquid-phase deposition (LPD) technique was adopted to deposit anatase TiO2 shell on amorphous SiO2-coated Fe3O4 to form core-shell Fe3O4@SiO2@TiO2 magnetic photocatalyst. To further promote its photocatalytic activity, uniformly dispersed Au nanoparticles (NPs) were decorated on its surface to obtain Fe3O4@SiO2@TiO2-Au composite. Both the TiO2-based magnetic composites were characterized and used as photocatalysts. To evaluate their photocatalytic performance, the photocatalyzed reduction of p-nitroaniline (p-NA) to p-phenylenediamine (p-PDA) was chosen as a model reaction under UV irradiation using HCOONH4 as a hole scavenger and H source. Although p-NA can be completely reduced to p-PDA by the two photocatalysts, Fe3O4@SiO2@TiO2-Au exhibits much superior photocatalytic activity to Fe3O4@SiO2@TiO2. The is because Au NPs decorated on the TiO2 can efficiently facilitate the photoexcited electron-transfer from the conduction band of TiO2 to Au, which is favorable for minimizing the recombination rate of electrons and holes and prolong the lifetime of the photoelectrons. In addition, HCOONH4 plays an indispensable role in improving the photocatalytic reduction of p-NA via capturing photo-generated holes.

-

Key words:

- magnetism /

- TiO2 /

- core-shell structure /

- Fe3O4@SiO2@TiO2-Au /

- photocatalytic reduction /

- p-nitroaniline

-

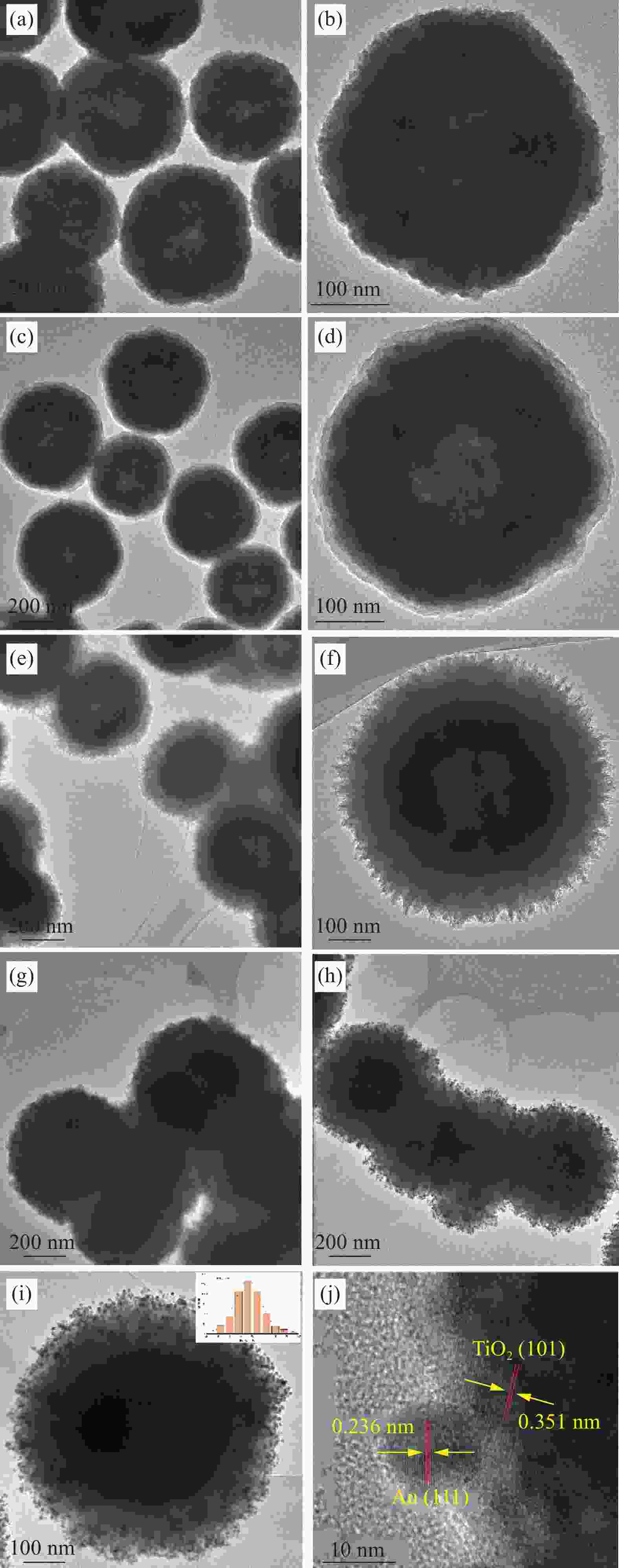

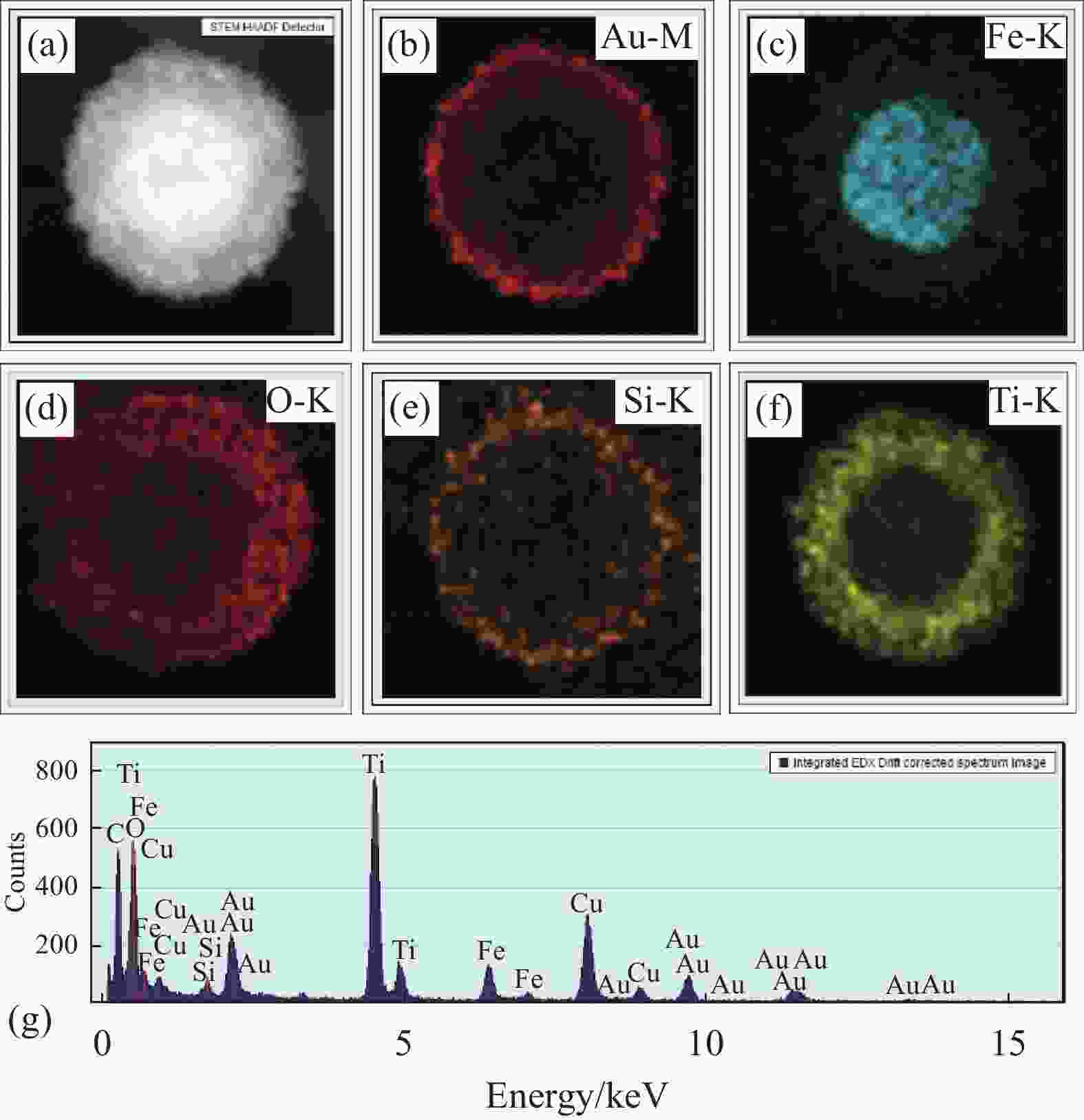

图 2 Fe3O4 (a,b), Fe3O4@SiO2 (c,d), Fe3O4@SiO2@TiO2 (e,f), Au-seed-decorated Fe3O4@SiO2@TiO2 (g) 和 Fe3O4@SiO2@TiO2-Au (h,i)的不同放大倍数的透射电镜照片; the deposited TiO2 and Au NPs on Fe3O4@SiO2 (j)的高分辨透射电镜照片

Figure 2. TEM images with different magnifications: Fe3O4 (a,b), Fe3O4@SiO2 (c,d), Fe3O4@SiO2@TiO2 (e,f), Au-seed-decorated Fe3O4@SiO2@TiO2 (g), Fe3O4@SiO2@TiO2-Au (h,i) and HRTEM of the deposited TiO2 and Au NPs on Fe3O4@SiO2 (j).

图 8 Fe3O4@SiO2@TiO2 和 Fe3O4@SiO2@TiO2-Au分别在有HCOONH4 (a,b)和无HCOONH4 (c,d)条件下光催化还原p-NA的UV-Vis谱图(p-NA: 20 mg·L−1,HCOONH4: 800 mg·L−1,催化剂: 50 mg)

Figure 8. UV-vis absorption spectra of the p-NA aqueous solution under UV irradiation catalyzed by Fe3O4@SiO2@TiO2 (a,c) in both the presence and the absence of HCOONH4 and Fe3O4@SiO2@TiO2-Au (b,d) in both the presence and the absence of HCOONH4, respectively.(p-NA: 20 mg·L−1, HCOONH4: 800 mg·L−1,,catalyst: 50 mg)

-

[1] AHMED A, SANDLER S I. Hydration free energies of multifunctional nitroaromatic compounds[J]. Journal of Chemical Theory and Compution, 2013, 9(6): 2774-2785. doi: 10.1021/ct3011002 [2] ALINA G, SÜHNHOLZ S, GEORGI A, et al. Fe-zeolites for the adsorption and oxidative degradation of nitroaromatic compounds in water[J]. Journal of Hazardous Materials, 2023, 459: 132125. doi: 10.1016/j.jhazmat.2023.132125 [3] BILAL M, BAGHERI A R, BHATT P, et al. En vironmental occurrence, toxicity concerns, and remediation of recalcitrant nitroaromatic compounds[J]. Journal of Environmental Management, 2021, 291: 112685 doi: 10.1016/j.jenvman.2021.112685 [4] HIDALGO A M, LEÓN G, GÓMEEZ M, MURCIA M D, et al. Behaviour of RO90 membrane on the removal of 4-nitrophenol and 4-nitroaniline by low pressure reverse osmosis[J]. Journal of Water Process Engineering, 2015, 7: 169-175. doi: 10.1016/j.jwpe.2015.06.007 [5] ZHU C C, HUANG H N, CHEN Y G. Recent advanc es in biological removal of nitroaromatics from wastewater[J]. Environmental Pollution 2022, 307 : 119570 [6] 殷月月, 杨 勇, 张良柱, 等. 金/钯哑铃状纳米晶的制备及其催化对硝基苯酚还原研究[J]. 无机材料学报, 2018, 33(1): 19-26 doi: 10.15541/jim20170146YIN Y Y, YANG Y, ZHANG L Z, et al. Facile Synthesis of Au/Pd nano-dumbells for catalytic reduction of p-nitrophenol[J]. Journal of Inorganic Materials, 2018, 33(1): 19-26. (in chinese doi: 10.15541/jim20170146 [7] YANG M Q, PAN X Y, ZHANG N, et al. A facile one-step way to anchor noble metal (Au, Ag, Pd) nanoparticles on a reduced graphene oxide mat with catalytic activity for selective reduction of nitroaromatic compounds[J]. CrystEngComm, 2013, 15(34): 6819-6828. doi: 10.1039/c3ce40694f [8] LUO P F, XU K L, ZHANG R, et al. Highly effi cient and selective reduction of nitroarenes with hydrazine over supported rhodium nanoparticles[J]. Catalysis Science & Technology, 2012, 2(2): 301-304. [9] FOUNTOULAKI S, DAIKOPOULOU V, GKIZIS P L, et al. Mechanistic studies of the reduction of nitroarenes by NaBH4 or hydrosilanes catalyzed by supported gold nanoparticles[J]. ACS Catalysis, 2014, 4(10): 3504-3511. doi: 10.1021/cs500379u [10] GONG Y Z, YANG C, JI H W, et al. Aqueous oxidations started by TiO2 photoinduced holes can be a rate-determining step[J]. Chemistry-An Asian Journal, 2017, 12(16): 2048-2051. doi: 10.1002/asia.201700658 [11] PAN D L, HAN Z Y, MIAO Y C, et al. Ther- mally stable TiO2 quantum dots embedded in SiO2 foams: characterization and photocatalytic H2 evolution activity[J]. Applied Catalysis B:Environmental, 2018, 229: 130-138. doi: 10.1016/j.apcatb.2018.02.022 [12] YANG Y, WANG G Z, Deng Q, et al. Micro wave-assisted fabrication of nanoparticulate TiO2 microspheres for synergistic photocatalytic removal of Cr(VI) and methyl orange[J]. ACS Applied Materials & Interfaces, 2014, 6(4): 3008-3015. [13] LI W, WU Z X, WANG J X, et al. A perspective on mesoporous TiO2 materials[J]. Chemistry of Materials, 2014, 26(1): 287-298. doi: 10.1021/cm4014859 [14] LIU Q, QIU W, WU P, et al. Low-temperature ammonia oxidation in a microchannel reactor with wall-loaded X(X = Pt, Pd, Rh, PtPdRh)/TiO2 nanotube catalysts[J]. Industrial & Engineering Chemistry Research, 2019, 58(23): 9819-9828 [15] HUSSAIN M, AHMAD M, NISAR A, et al. Enhanced photocatalytic and electrochemical properties of Au nanoparticles supported TiO2 microspheres, New Journal of Chemistry, 2014, 38 (4): 1424-1432. [16] 龚新怀, 李明春, 杨坤, 等. 纳米Fe3O4@茶渣/海藻酸钙磁性复合材料制备及其对亚甲基蓝的吸附性能与吸附机制[J]. 复合材料学报, 2021, 38(02): 424-438.GONG X H , LI M C, YANG K, et al. Preparation of nano-Fe3O4@tea waste/calcium alginate magnetic composited bead and it’s adsorption characteristics and mechanisms for methylene blue from aqueous solution.[J]. Acta Materiae Compositae Sinica, 2021, 38(02): 424-438 (in Chinese). [17] 梁艳莉, 马剑琪, 郭少波. CoFe2O4@PDA@Pt核壳型磁性复合材料的制备及催化性能. 复合材料学报[J]. 2021, 38(05): 1551-1557.LIANG Y L , MA J Q, GUO S B. Preparation and catalytic properties of CoFe2O4@PDA@Pt magnetic composite with core shell structure[J]. Acta Materiae Compositae Sinica, 2021, 38(05): 424-438 (in Chinese). [18] 方丽, 罗琨. Fe3O4@Ag3PO4光催化剂可见光降解盐酸环丙沙星的研究[J]. 水处理技术, 2022, 48(12): 71-76.FANG L, LUO K. Photocatalytic Degradation of Ciprofloxacin Hydrochloride by Fe3O4@Ag3PO4 under Visible-Light Irradiation[J]. Technology of Water Treatment, 2022, 48(12): 71-76. (in chinese [19] JIN S, PARK E, GUO S, et al. Process monitor- ing of photocatalytic degradation of 2, 4-dinitrotoluene by Au-decorated Fe3O4@TiO2 nanoparticles: surface-enhanced Raman scattering method[J]. Spectrochimica Acta Part A:Molecular and Biomolecular Spectroscopy, 2022, 275: 121155. doi: 10.1016/j.saa.2022.121155 [20] LI C Y, YOUNESI R, CAI Y L, et al. Photo- catalytic and antibacterial properties of Au-decorated Fe3O4@mTiO2 core-shell microspheres[J]. Applied Catalysis B:Environmental, 2014, 156-157: 314-322. doi: 10.1016/j.apcatb.2014.03.031 [21] CHI Y, YUAN Q, Li Y J, et al. Magnetically separable Fe3O4@SiO2@TiO2-Ag microspheres with well-designed nanostructure and enhanced photocatalytic activity[J]. Journal of Hazardous Materials, 2013, 262: 404-411. doi: 10.1016/j.jhazmat.2013.08.077 [22] LI X Y, LIU D P, Song S Y, et al. Fe3O4@SiO2@TiO2@Pt Hierarchical core-shell microspheres: controlled synthesis, enhanced degradation system, and rapid magnetic separation to recycle[J]. Crystal Growth & Design, 2014, 14(11): 5506-5511. [23] MA D W, SCHNEIDER J, LEE W I, et al. Controlla ble synthesis and self-template phase transition of hydrous TiO2 colloidal spheres for photo/electrochemical applications[J]. Advances in Colloid and Interface Science, 2021, 295: 102493. doi: 10.1016/j.cis.2021.102493 [24] BEYDOUM D, AMAL R, LOW G, et al. Oc currence and prevention of photodissolution at the phase junction of magnetite and titanium dioxide[J]. Journal of Molecular Catalysis A:Chemical, 2002, 180(1-2): 193-200. doi: 10.1016/S1381-1169(01)00429-0 [25] KALIDINDI S B, JAGIRDAR B R. Nanocatal- ysis and prospects of green chemistry[J]. ChemSusChem, 2012, 5(1): 65-75. doi: 10.1002/cssc.201100377 [26] CHENG C M, WEN Y H, XU X F, et al. Tuna ble synthesis of carboxyl-functionalized magnetite nanocrystal clusters with uniform size[J]. Journal of Materials Chemistry, 2009, 19(46): 8782-8788. doi: 10.1039/b910832g [27] MA J Q, GUO S B, Guo X H, et al. Liquid-phase deposition of TiO2 nanoparticles on core-shell Fe3O4@SiO2 spheres: preparation, characterization, and photocatalytic activity[J]. Journal of Nanoparticle Research, 2015, 17(7): 307. doi: 10.1007/s11051-015-3107-1 [28] JANA N R, GEARHEART L, MURPHY C J. Seeding growth for size control of 5-40 nm diameter gold nanoparticles[J]. Langmuir, 2001, 17(22): 6782-6786. doi: 10.1021/la0104323 [29] ZHANG Y Y, GUO S B, MA J Q, et al. Prepara tion, characterization, catalytic performance and antibacterial activity of Ag photodeposited on monodisperse ZnO submicron spheres[J]. Journal of Sol-Gel Science and Technology, 2014, 72(1): 171-178. doi: 10.1007/s10971-014-3440-3 [30] LI G, BAI R B, ZHAO X S. Coating of TiO2 thin films on the surface of SiO2 microspheres: toward industrial photocatalysis[J]. Industrial & Engineering Chemistry research, 2008, 47(21): 8228-8232. [31] CHIU C Y, CHUNG P J, Lao K U, et al. Facet-dependent catalytic activity of gold nanocubes, octahedra, and rhombic dodecahedra toward 4-nitroaniline reduction[J]. Journal of Physical Chemistry C, 2012, 116(44): 23757-23763. doi: 10.1021/jp307768h [32] WU W, WEN L, SHEN L, et al. A new insight into the photocatalytic reduction of 4-nitroaniline to p-phenylenediamine in the presence of alcohols[J]. Applied Catalysis B: Environmental, 2013, 130–131: 163-167. [33] YAMAMOTO Y, FUKUI M, TANAKA A, et al. Hydrogen- and noble metal-free conversion of nitro aromatics to amino aromatics having reducible groups over an organically modified TiO2 photocatalyst under visible light irradiation[J]. Catalysis Science & Technology, 2019, 9(4): 966-973. [34] FUKUI M, KOSHIDA W, TANAKA A, et al. Photocatalytic hydrogenation of nitrobenzenes to anilines over noble metal-free TiO2 utilizing methylamine as a hydrogen donor[J]. Applied Catalysis B:Environmental, 2020, 268: 118446. doi: 10.1016/j.apcatb.2019.118446 [35] CHENTHAMARKSHAN C R, RAJESHWAR K, WOLFRUM E R. Heterogeneous photocatalytic reduction of Cr(VI) in UV-irradiated titania suspensions: effect of protons, ammonium ions, and other interfacial aspects[J]. Langmuir, 2000, 16(6): 2715-2721. doi: 10.1021/la9911483 [36] JAKOB M, LEVANON H, KAMAT P V. Charge distribution between UV-irradiated TiO2 and gold nanoparticles: determination of shift in the Fermi level[J]. Nano Letters, 2003, 3(3): 353-358. doi: 10.1021/nl0340071 [37] VANDARKUZHALI S A A, PUGAZHENTHIR- ANN, MANGALARAJA R V, et al. Ultrasmall plasmonic nanoparticles decorated hierarchical mesoporous TiO2 as an efficient photocatalyst for photocatalytic degradation of textile dyes[J]. ACS Omega, 2018, 3(3): 9834-9845. -

点击查看大图

点击查看大图

计量

- 文章访问数: 137

- HTML全文浏览量: 108

- 被引次数: 0

下载:

下载: