Tensile failure mechanism of carbon fiber/epoxy composite L-joints

-

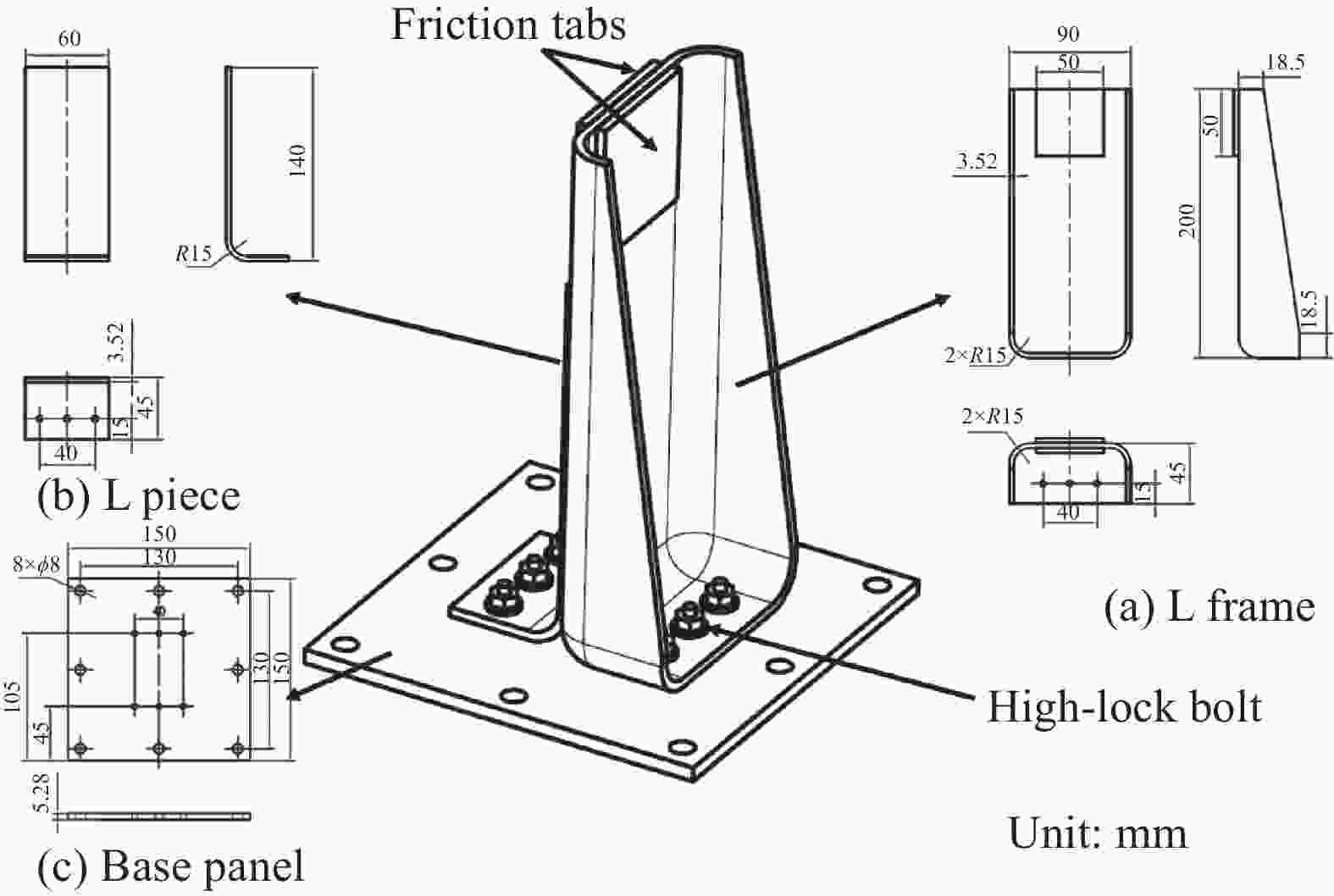

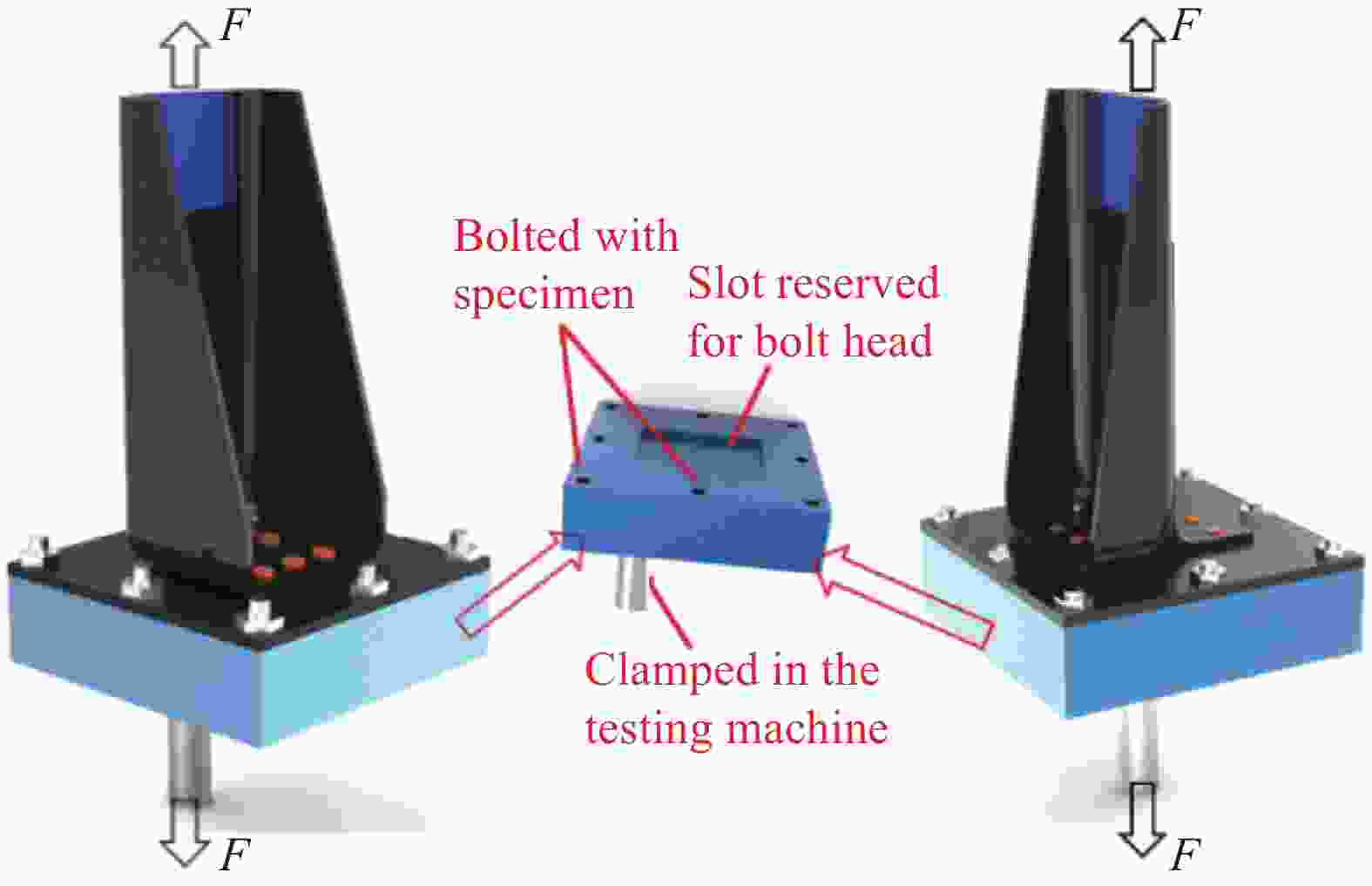

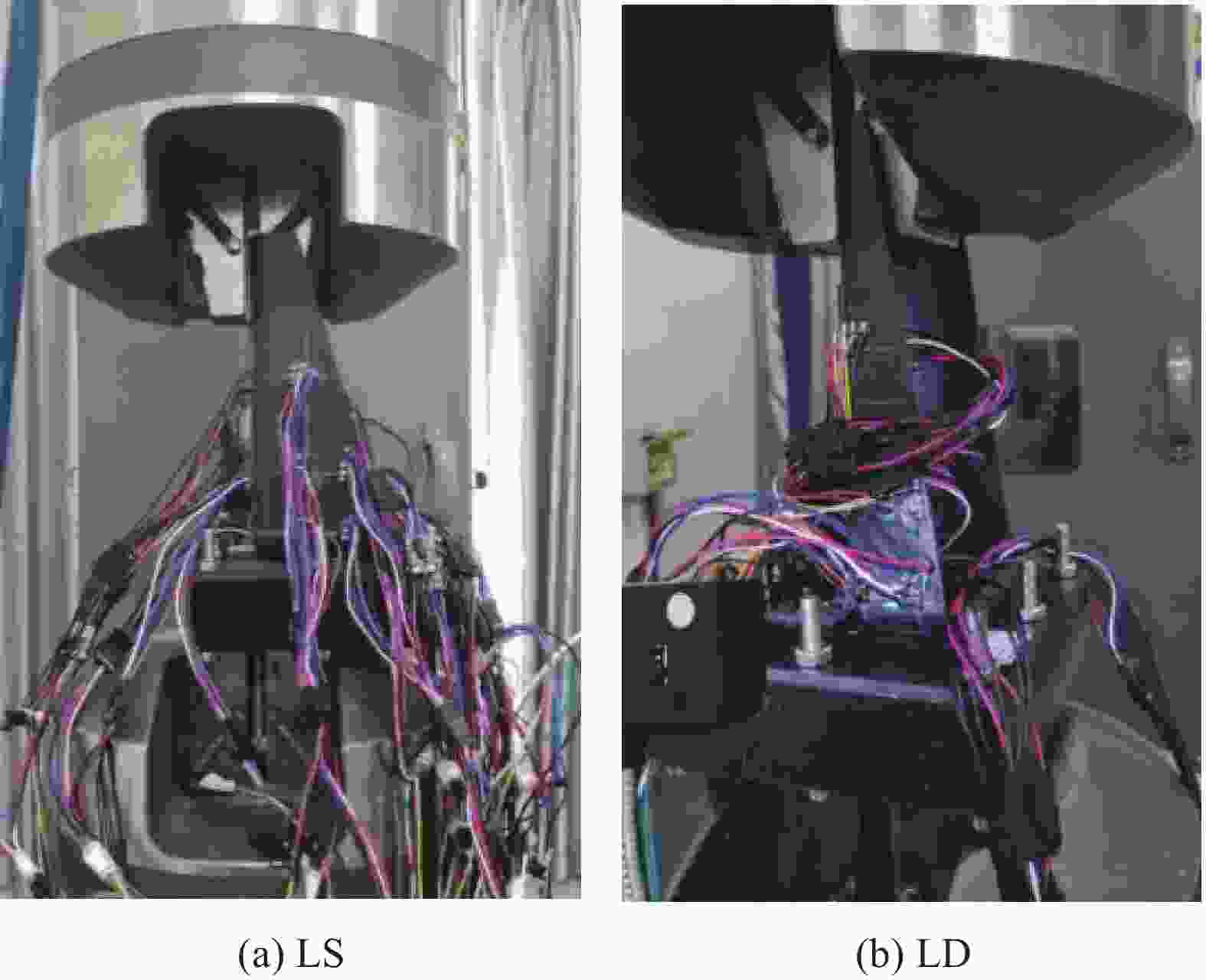

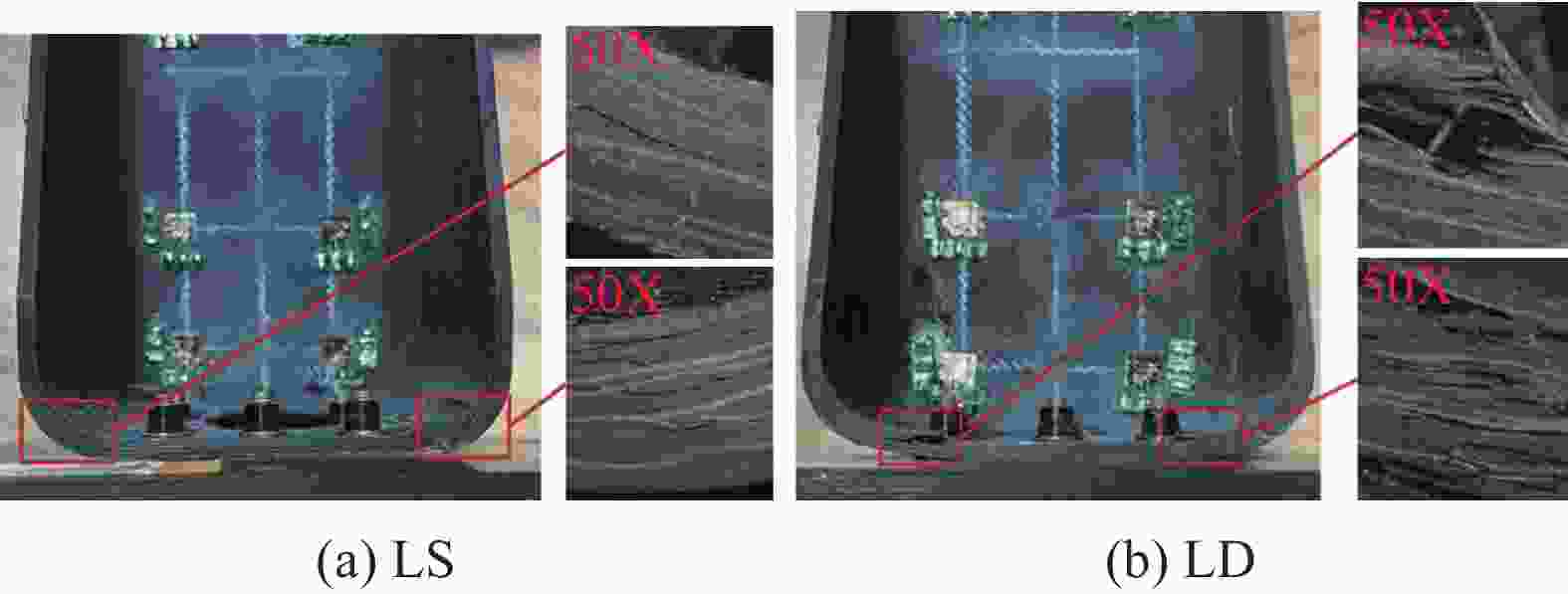

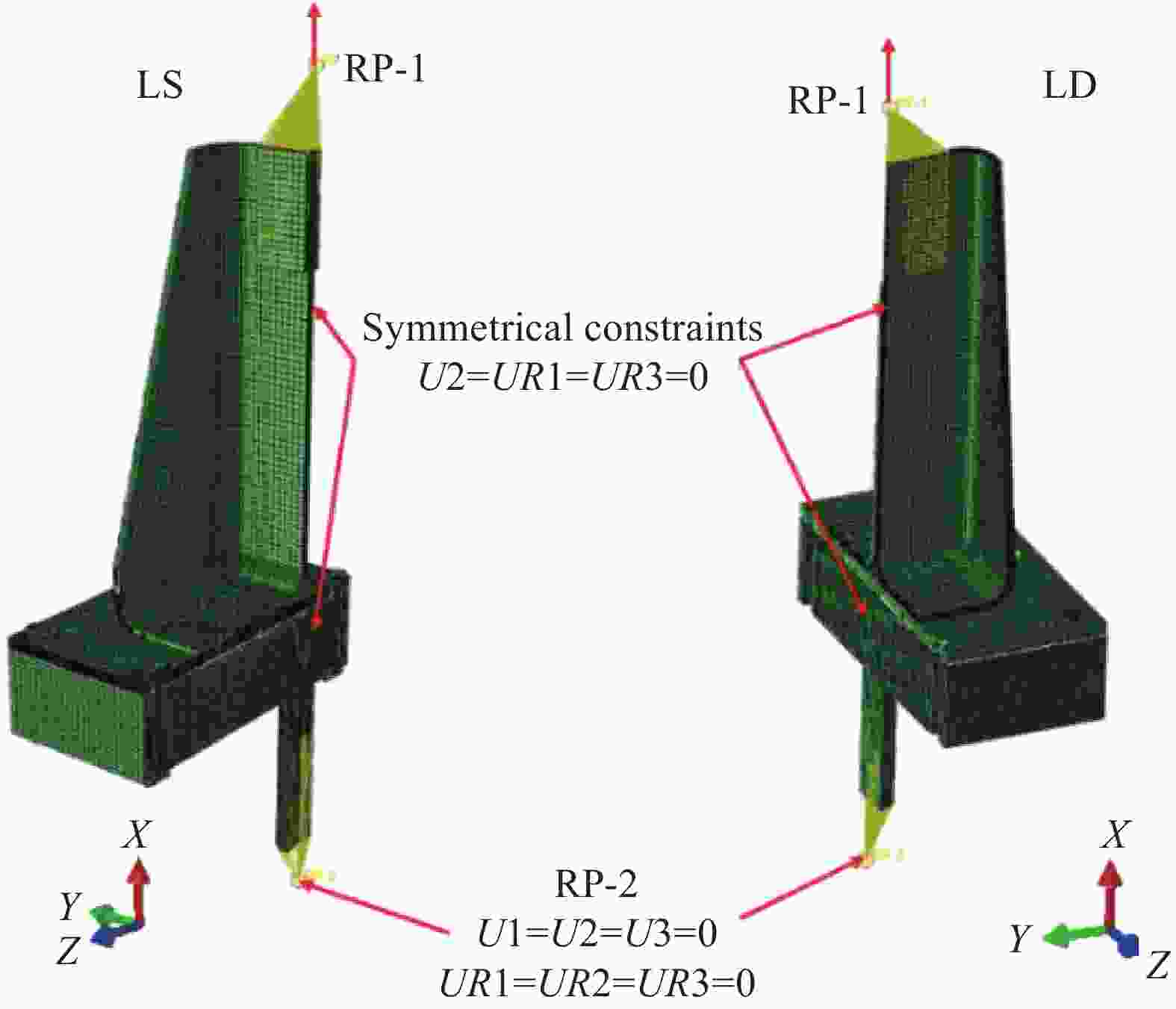

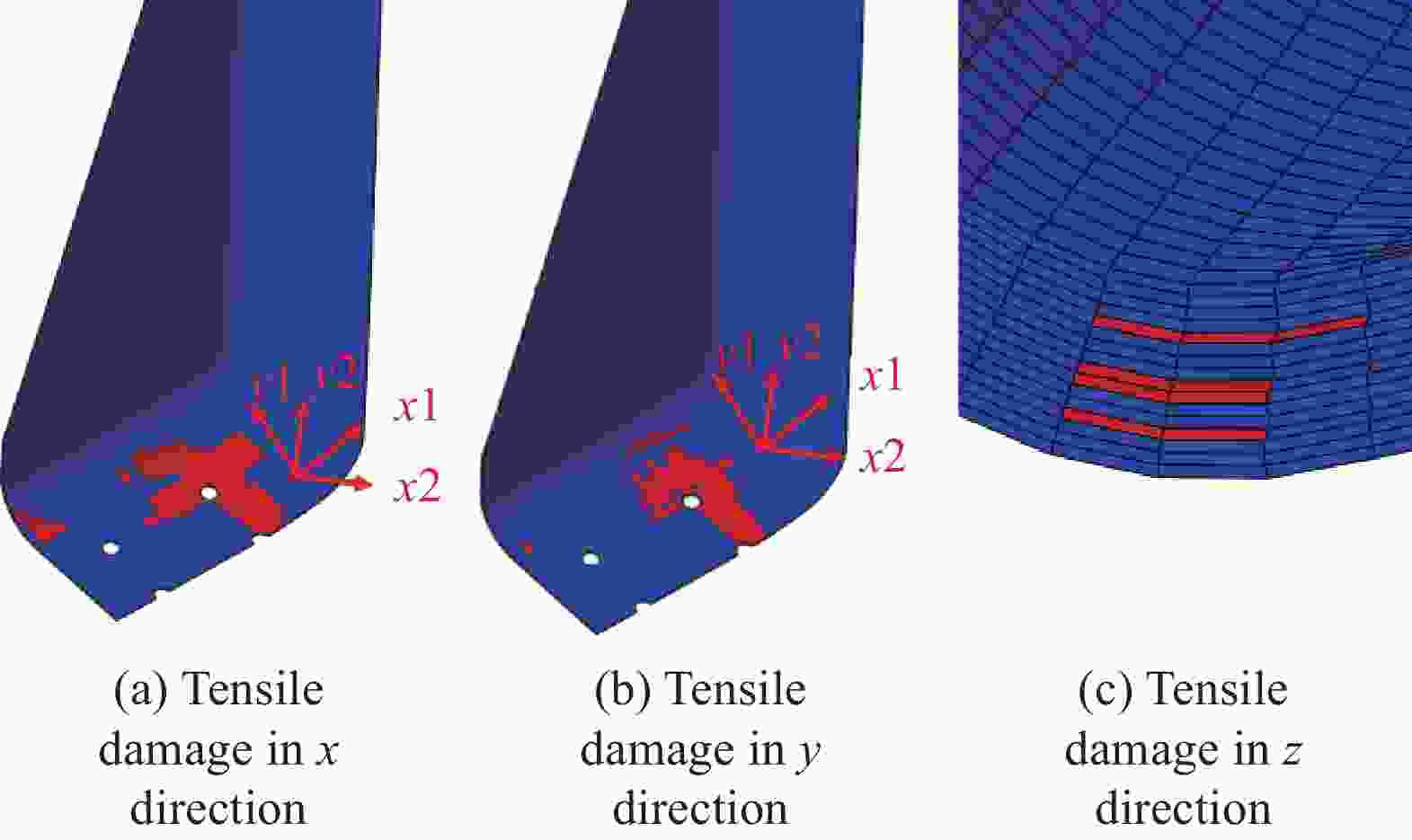

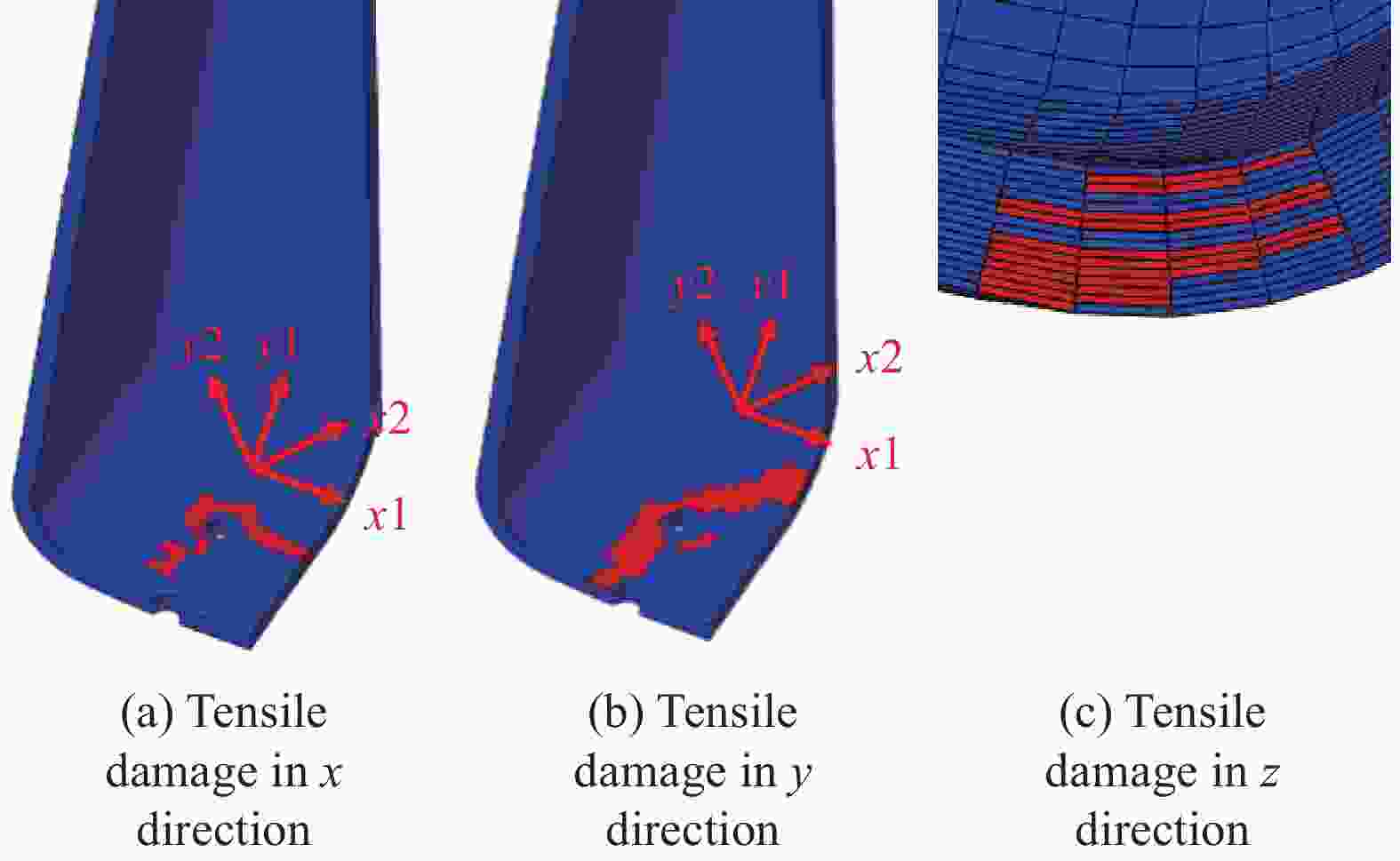

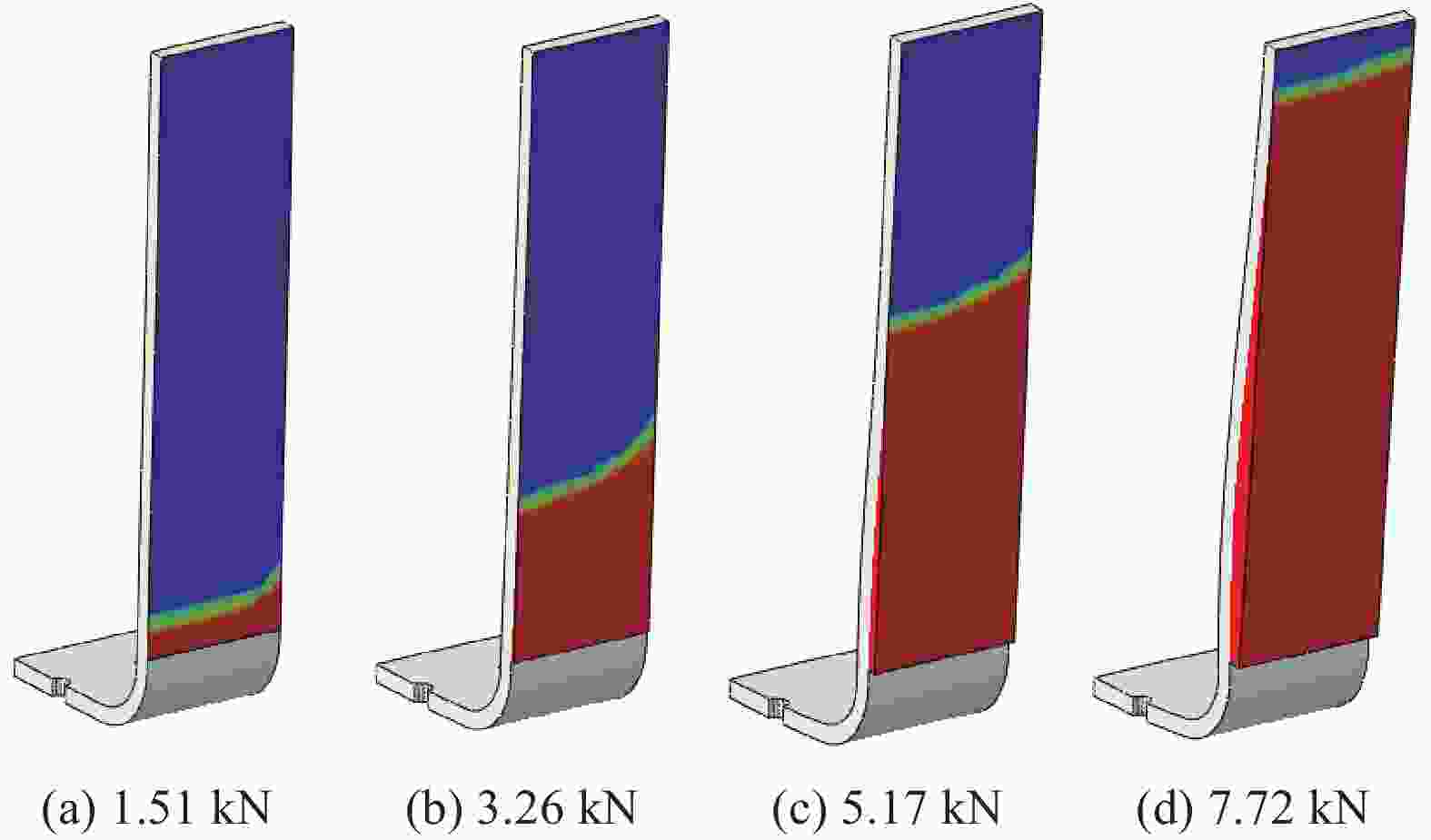

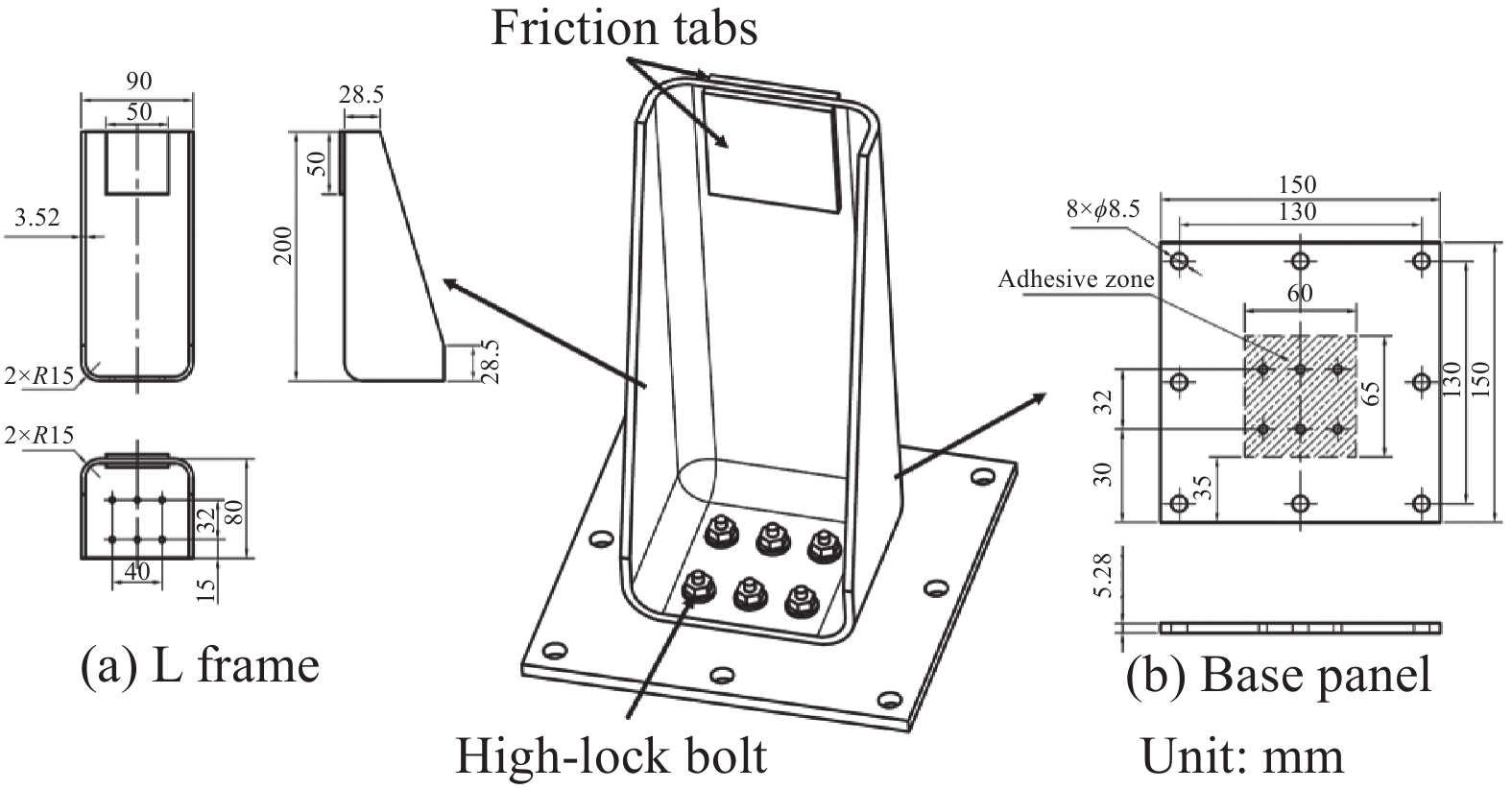

摘要: 设计了单L型(LS)及双L型(LD)两种重量相近的L型接头。采用试验与数值模拟相结合的方式对两种接头的拉伸失效机制进行了研究。通过自行设计的试验夹具在伺服液压试验机上将两种L型接头准静态加载至破坏,分析其破坏机制及应变分布。研究发现,两种L型接头存在不同的失效机制,在破坏阶段单L型接头表现出更好的延展性。单L型接头加载至峰值载荷时,在靠近加载侧的内侧螺栓孔附近首先出现破坏,随后损伤向外侧螺栓孔附近扩展,直至完全失效。双L型接头加载至峰值载荷的50%左右时,L型框体和L型片之间的胶膜首先发生破坏,随后载荷继续增加至峰值载荷时,L型框螺栓孔附近发生破坏,损伤向框体边缘扩展,载荷大幅下降。此外,两种接头的应变随载荷的增加存在不同的变化趋势。采用一种新型复合材料初始失效准则及刚度折减方法,编写用户自定义子程序(UMAT),结合内聚区模型建立复合材料L型接头的渐进损伤模型。基于ABAQUS软件进行计算,得到接头的预测失效载荷及破坏形式。结果表明:有限元分析所得复合材料L型接头的损伤位置及失效模式与试验吻合,预测载荷与试验值相差较小,证明了有限元模型的适用性。Abstract: Single-L and double-L composite joints were designed with similar weights. A combination of experiment and numerical simulation was used to study the tensile failure mechanism of the two joints. Two kinds of L-joints were quasi-statically loaded to failure on the servo hydraulic testing machine through a self-designed test fixture, and the failure mechanism and strain distribution were analyzed. It’s found that the two L-joints have different failure mechanisms, and the single L-joint exhibits better ductility in the failure stage. When the single L-joints are loaded to the peak load, the damage first occurs near the inner bolt hole in the loading side, and then the damage spreads to the outer bolt hole until failing completely. When the double L-joints are loaded to about 50% of the peak load, the adhesive film between the L-shaped frame and the L-shaped sheet is first damaged, and then when the load continues to increase to the peak load, damage occurs near the bolt holes of the L-shaped frame, extending to the edge of the frame, the load drops significantly. In addition, the strains of the two joints have different trends with the increase of load. Based on a new type of composite material initial failure criterion and stiffness reduction method, a user-defined material subroutine (UMAT) was written. Combined with the cohesive zone model, the progressive damage model of the composite material L-joint was established. Based on ABAQUS software for calculation, the predicted failure load and failure mode of composite single L-joint and double L-joint were obtained. The results show that the damage position and failure mode of the composite L-joint obtained by the finite element analysis are consistent with the test, and the predicted load is slightly different from the test value, which proves the applicability of the finite element model.

-

Key words:

- composite /

- L-joint /

- failure mechanism /

- finite element analysis /

- cohesive zone model

-

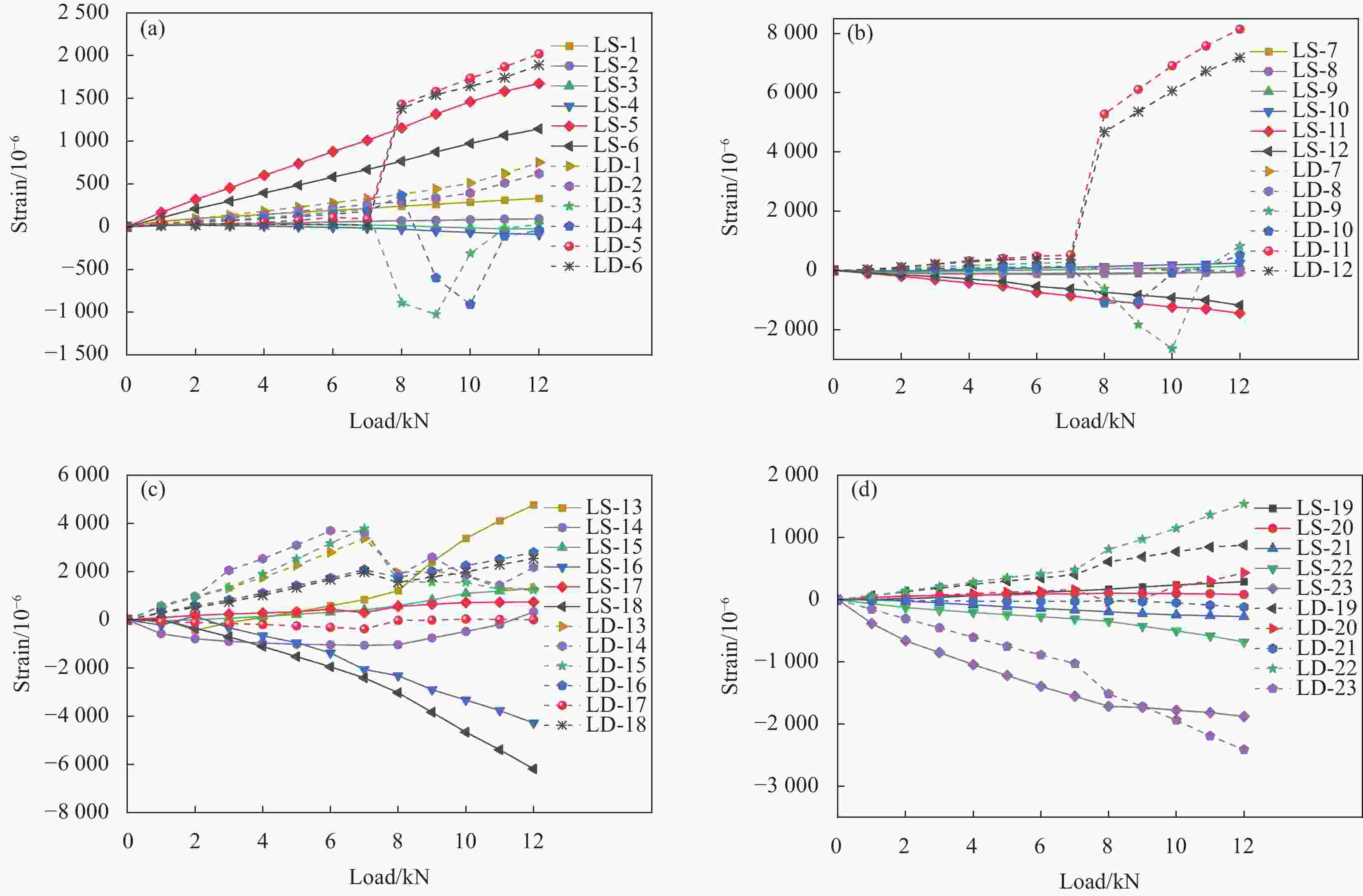

图 9 LS1和LD1的应变-载荷曲线:(a) L型框正面:面A;(b) LS1中L型框背面和LD1中L型片表面:面B;(c) L型框底面:面C;(d) L型框侧面:面D

Figure 9. Strain-load curves of LS1 and LD1: (a) Front of L frame: Surface A; (b) Back of the L frame of LS1 and surface of the L frame of LD1: Surface B; (c) Bottom of the L frame: Surface C; (d) Side of the L frame: Surface D

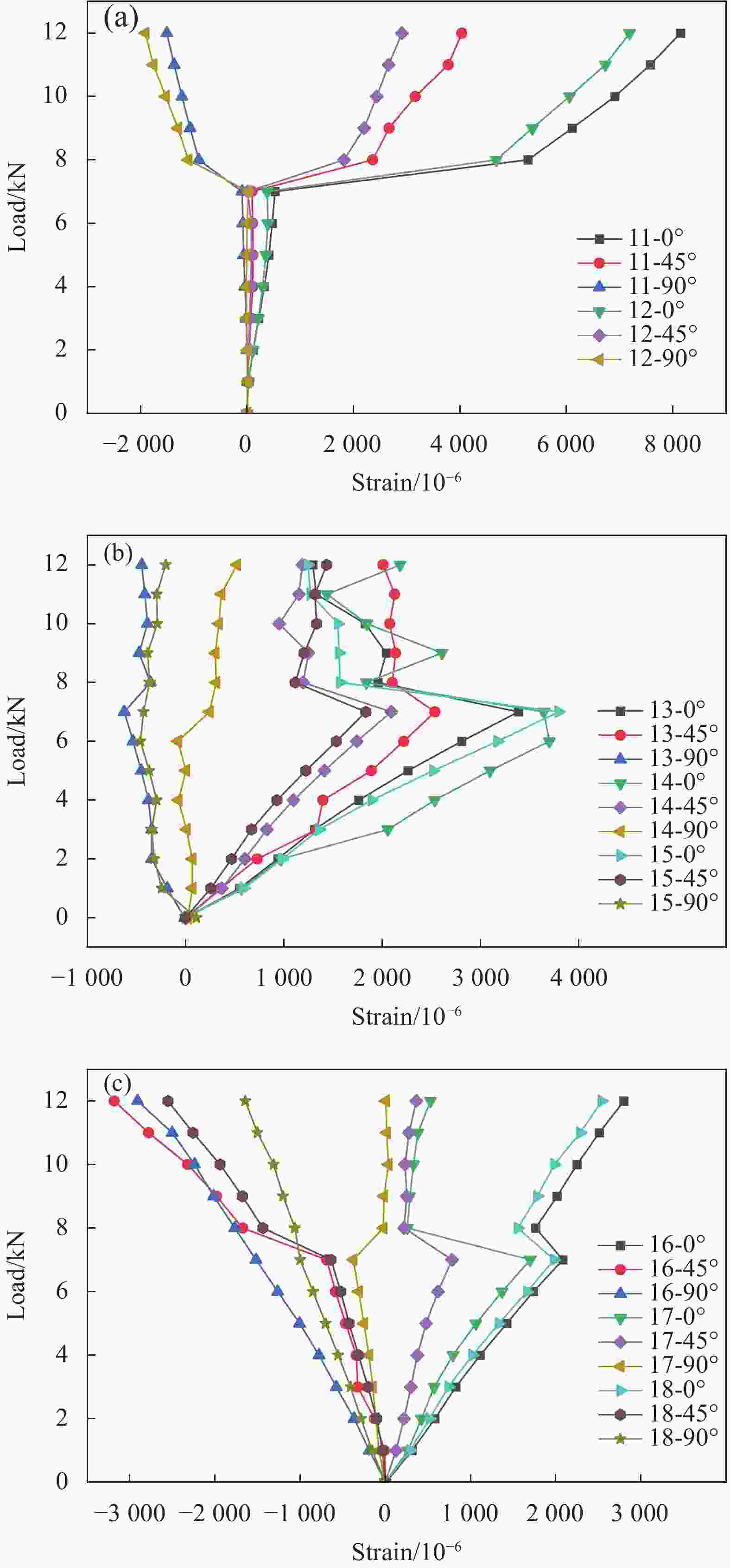

图 10 双L型接头11~18号测点各方向载荷-应变曲线:(a) L型片底部:11号、12号测点;(b) L型片螺栓附近:13号、14号、15号;(c) L型框螺栓附近:16号、17号、18号

Figure 10. Load-strain curves in each direction at measuring points 11-18 for double L-joint: (a) Bottom of L-piece: No.11 and No.12; (b) Near bolts of the L-piece: No.13, No.14 and No.15 ; (C) Near bolts of the L-frame: No.16, No.17 and No.18

表 1 碳纤维/环氧树脂复合材料的性能参数

Table 1. Material properties of carbon fiber/epoxy composite

Parameter Material properties Value Parameters Ex= Ey/GPa 57.7 Ez/GPa 15* υxy 0.07 υxz=υyz 0.27* Gxy/GPa 9.7 Gxz=Gyz/GPa 6* Fracture

parametersXt= Yt/MPa 609.7 Zt/MPa 50* Xc= Yc/MPa 533.6 Zc/MPa 150* Sxy/MPa 141.7 Sxz= Syz/MPa 70* Notes: Ex, Ey, Ez—Elastic modulus in direction of x, y, z; Xt, Yt, Zt—Tensile strength in the three directions above; Xc, Yc, Zc—Compress strength in the three directions above; υij, Gij, Sij (i, j = x, y, z)—Poisson’s ratio, shear modulus and shear strength for x-y, x-z, y-z plane; *Material data were provided by the manufacture, Avic Aviation High-tech CO., LTD.. The rest data were measured by experiment on the laminates. 表 2 碳纤维/环氧树脂复合材料L型接头拉伸试验结果

Table 2. Tensile load test results of carbon fiber/epoxy composite L-joint

Specimen number Failure load/

kNAverage load/

kNCoefficient of variation/% LS1 14.225 14.109 4.296 LS2 13.316 LS3 14.787 LD1 14.305 14.215 1.095 LD2 14.344 LD3 13.996 表 3 碳纤维/环氧树脂复合材料接头性能退化方式

Table 3. Degradation modes of carbon fiber/epoxy composite joint

Direction Criterion Material

constants

to degradeStiffness

degradation

ratiox Eq. (1) $\begin{gathered} {E_x},{\upsilon_{xy}},{\upsilon_{x{\textit{z}}}}, \\ {G_{xy}},{G_{x{\textit{z}}}} \\ \end{gathered} $ 0.4407 Eqs. (2) and (3) 0.001 y Eq. (4) $\begin{gathered} {E_y},{\upsilon _{xy}},{\upsilon _{y{\textit{z}}}}, \\ {G_{xy}},{G_{y{\textit{z}}}} \\ \end{gathered} $ 0.4407 Eqs. (5) and (6) 0.001 z Eqs. (7) and (8) $\begin{gathered} {E_{\textit{z}}},{\upsilon_{x{\textit{z}}}},{\upsilon_{y{\textit{z}}}}, \\ {G_{x{\textit{z}}}},{G_{y{\textit{z}}}} \\ \end{gathered} $ 0.001 Parameter Stiffness Normal strength

$t_{\text{n}}^{\text{o}}$/ MPaShear strength

$t_{\text{s}}^{\text{o}} = t_{\text{t}}^{\text{o}}$/ MPaFracture energy

${G^{\text{C}}}$/${\text{(J}} \cdot {{\text{m}}^{{{ - 2}}}})$$E/{E_{{\text{nn}}}}$/${\text{(MPa}} \cdot {\text{m}}{{\text{m}}^{{{ - 1}}}})$ ${G_1}/{E_{{\text{ss}}}} = {G_2}/{E_{{\text{tt}}}}$/${\text{(MPa}} \cdot {\text{m}}{{\text{m}}^{{{ - 1}}}})$ Value 1000 300 20 30 2 Notes:$E/{E_{{\text{nn}}}}$,${G_1}/{E_{{\text{ss}}}}$,${G_2}/{E_{{\text{tt}}}}$—Interface stiffness for three directions, respectively; $t_{\text{n}}^{\text{o}}$,$t_{\text{s}}^{\text{o}}$,$t_{\text{t}}^{\text{o}}$—Interface strength for three directions, respectively. 表 5 碳纤维/环氧树脂复合材料L型接头部分测点应变仿真值与试验值对比

Table 5. Comparison of simulation and test values of some strain gauges on carbon fiber/epoxy composite L-joint

Strain gauge number Single L-joint strain at 12 kN Double L-joint strain at 6 kN Simulation

value/10−6Test

value/10−6Simulation

value/10−6Test

value/10−65 1321 1675 53 110 6 1321 1143 53 30 11 −1270 −1446 387 476 12 −1270 −1173 387 393 13 3110 4471 2822 2810 14 3915 331 3300 3703 15 3110 1308 2822 3175 -

[1] SHANG X, MARQUES E A S, CARBAS R J C, et al. Fracture mechanism of adhesive single-lap joints with composite adherends under quasi-static tension[J]. Composite Structures,2020,251:112639. doi: 10.1016/j.compstruct.2020.112639 [2] 毛振刚, 侯玉亮, 李成, 等. 搭接长度和铺层方式对CFRP复合材料层合板胶接结构连接性能和损伤行为的影响[J]. 复合材料学报, 2020, 37(1):121-131.MAO Zhengang, HOU Yuliang, LI Cheng, et al. Effect of lap length and stacking sequence on strength and damage behaviors of adhesively bonded cfrp composite laminates[J]. Acta Materiae Compositae Sinica,2020,37(1):121-131(in Chinese). [3] CHENG X, WANG S, ZHANG J, et al. Effect of damage on failure mode of multi-bolt composite joints using failure envelope method[J]. Composite Structures,2017,160:8-15. doi: 10.1016/j.compstruct.2016.10.042 [4] 赵丽滨, 徐吉峰. 先进复合材料连接结构分析方法[M]. 北京: 北京航空航天大学出版社, 2015.ZHAO Libin, XU Jifeng. Advanced composite connection structure analysis method[M]. Beijing: Beihang University Press, 2015(in Chinese). [5] PHILLIPS H J, SHENOI R A. Damage tolerance of laminated tee joints in FRP structures[J]. Composites Part A: Applied Science and Manufacturing,1998,29(4):465-478. doi: 10.1016/S1359-835X(97)00081-X [6] 王国平, 黄领才, 王冠. 复合材料层板多钉连接设计与试验研究[C]//第19届全国直升机年会论文. 哈尔滨: 中国航空学会, 2003: 65-70.WANG Guoping, HUANG Lingcai, WANG Guan. Design and experimental research of composite laminate multi-bolted joint[C]// The 19th National Helicopter Conference. Harbin: Chinese Society of Aeronautics and Astronautics, 2003: 65-70(in Chinese). [7] SHAMAEI-KASHANI A, SHOKRIEH M M. A strain-rate-dependent analytical model for composite bolted joints[J]. Steel and Composite Structures,2021,41:279-292. doi: 10.12989/scs.2021.41.2.279 [8] MONTAGNE B, LACHAUD F, PAROISSIEN E, et al. Failure analysis of single lap composite laminate bolted joints: Comparison of experimental and numerical tests[J]. Composite Structures,2020,238:111949. doi: 10.1016/j.compstruct.2020.111949 [9] 孙旋, 童明波, 陈智, 等. 碳纤维复合材料接头力学性能试验与仿真分析[J]. 复合材料学报, 2016, 33(11):2517-2527.SUN Xuan, TONG Mingbo, CHEN Zhi, et al. Test and simulation analysis of mechanical properties for joint of carbon fiber composites[J]. Acta Materiae Compositae Sinica,2016,33(11):2517-2527(in Chinese). [10] SHENOI R A, HAWKINS G L. Influence of material and geometry variations on the behavior of bonded tee connections in FRP ships[J]. Composites,1992,23(5):335-345. doi: 10.1016/0010-4361(92)90333-P [11] HAWKINS G L, HOLNESS J W, DODKINS A R, et al. The strength of bonded tee joints in FRP ships[J]. Plastics Rubber and Composites Processing and Applications, 1993, 19: 279-284. [12] GUO S, LI W. Numerical analysis and experiment of sandwich T-joint structure reinforced by composite fasteners[J]. Composite Part B: Engineering,2020,199:108288. doi: 10.1016/j.compositesb.2020.108288 [13] 文立伟, 余坤, 宦华松. 缝合复合材料T型接头拉伸载荷下的有限元数值模拟[J]. 航空学报, 2021, 42(2):136-143.WEN Liwei, YU Kun, HUAN Huasong. Finite element numerical simulation of stitched composite T-joint under tensile load[J]. Acta Aeronautica et Aetronautica Sinica,2021,42(2):136-143(in Chinese). [14] FEIH S, SHERCLIFF H R. Composite failure prediction of single-L joint structures under bending[J]. Composites Part A: Applied Science and Manufacturing,2005,36(3):381-395. doi: 10.1016/j.compositesa.2004.06.021 [15] WOOD M D K, TONG L, LUO Q, et al. Failure of stitched composite L-joints under tensile loading - Experiment and simulation[J]. Journal of Reinforced Plastics and Composites, 2009, 28(6): 715-742. [16] QIN K, YAN R, CUI M, et al. Failure mode shift of sandwich composite L-joint for ship structures under tension load[J]. Ocean Engineering, 2020, 214: 107863. [17] 石好男, 王继辉, 张桂明. 复合材料L型接头的损伤与破坏模式研究[J]. 复合材料科学与工程, 2019(3):16-20.SHI Haonan, WANG Jihui, ZHANG Guiming. The research on damage and failure modes of composite L-joint[J]. Composites Science and Engineering,2019(3):16-20(in Chinese). [18] ZHAO L, QIN T, ZHANG J, et al. Modified maximum stress failure criterion for composite π joints[J]. Journal of Composite Materials, 2012, 47(23): 2995-3008. [19] ZHAO L, GONG Y, QIN T, et al. Failure prediction of out-of-plane woven composite joints using cohesive element[J]. Composite Structures, 2013, 106: 407-416. [20] ZHAO L, QIN T, CHEN Y, et al. Three-dimensional progressive damage models for cohesively bonded composite π joint[J]. Journal of Composite Materials, 2014, 48(6): 707-721. [21] 成李南, 迟坚, 屈天骄, 等. 夹芯复合材料π型接头失效实验研究[J]. 机械强度, 2020, 42(4):837-841.CHENG Linan, CHI Jian, QU Tianjiao, et al. Experiment research on failure of composite sandwich π-joint[J]. Journal of Mechanical Strength,2020,42(4):837-841(in Chinese). [22] QIN K, YAN R, SHEN W, et al. Research on the tension damage behavior of sandwich composite L-joints: Experiment and simulation[J]. Composite Structures, 2020, 232: 111566. [23] 陈丁丁, 朱萌, 胡其高, 等. 含拼接铺层碳纤维增强树脂复合材料拉伸破坏机制[J]. 复合材料学报, 2020, 37(6):1312-1320.CHEN Dingding, ZHU Meng, HU Qigao, et al. Tensile failure mechanism of carbon fiber reinforced polymer composites with ply splice[J]. Acta Materiae Compositae Sinica,2020,37(6):1312-1320(in Chinese). [24] BENZEGGAGH M L, KENANE M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus[J]. Composites Science and Technology, 1996, 56(4): 439-449. [25] 郭丽君, 陆方舟, 李想, 等. 碳纤维/环氧树脂复合材料缠绕接头拉伸失效机制[J]. 复合材料学报, 2020, 37(9):2163-2172.GUO Lijun, LU Fangzhou, LI Xiang, et al. Tensile failure mechanism of carbon fiber/epoxy composite winding joint[J]. Acta Materiae Compositae Sinica,2020,37(9):2163-2172(in Chinese). -

下载:

下载: